Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Improve charge and discharge rate performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microporous membrane and its uses thereof

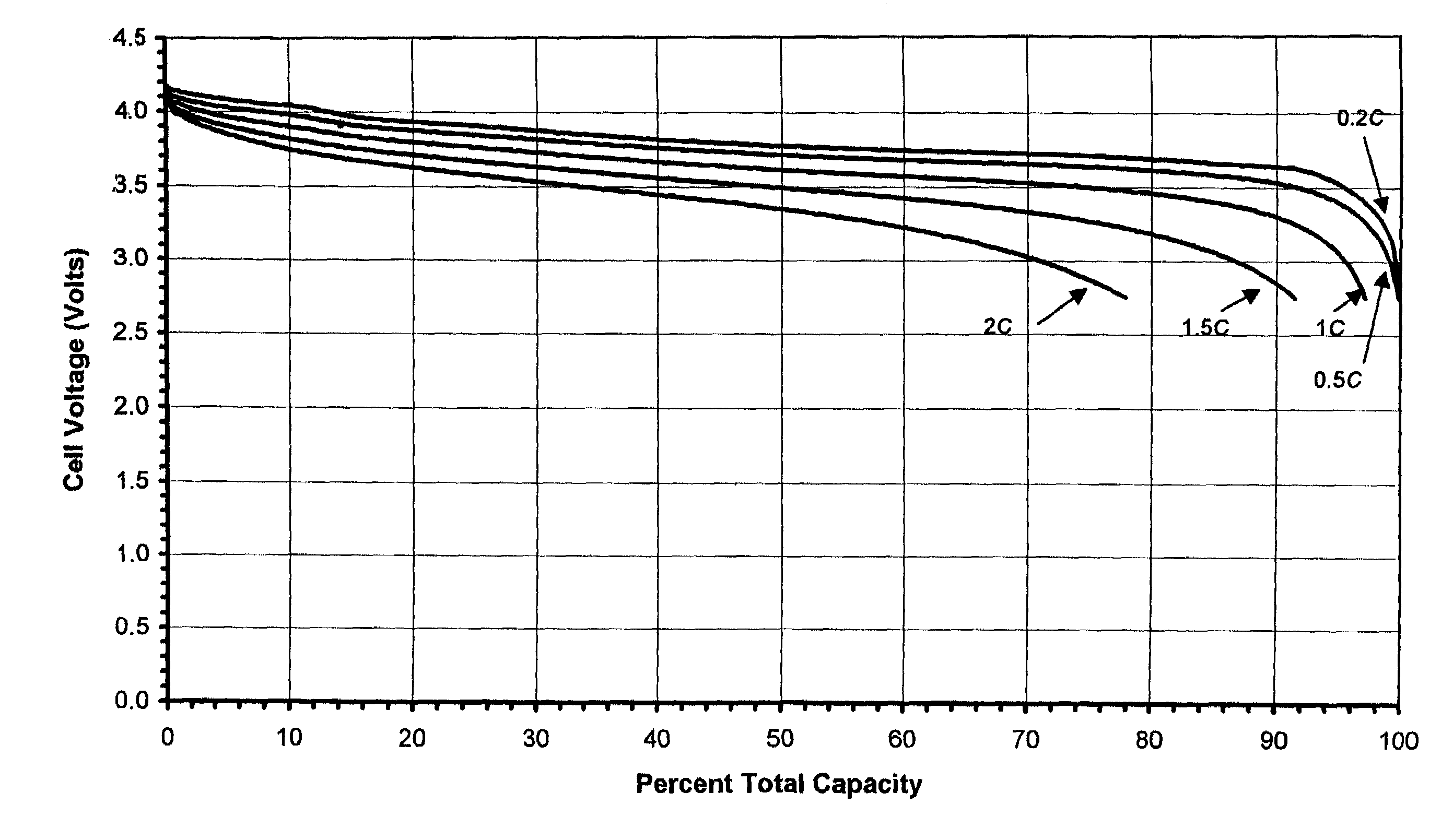

InactiveUS6998193B2Improve charge and discharge rate performanceHigh porositySemi-permeable membranesMembranesFuel cellsSupercapacitor

A novel microporous membrane comprising a hot-melt adhesive and an engineering plastics, the methods of preparing such microporous membrane and the uses of the microporous membrane in, e.g., batteries, super capacitors, fuel cells, sensors, electrochromic devices or the like.

Owner:POLICELL TECH

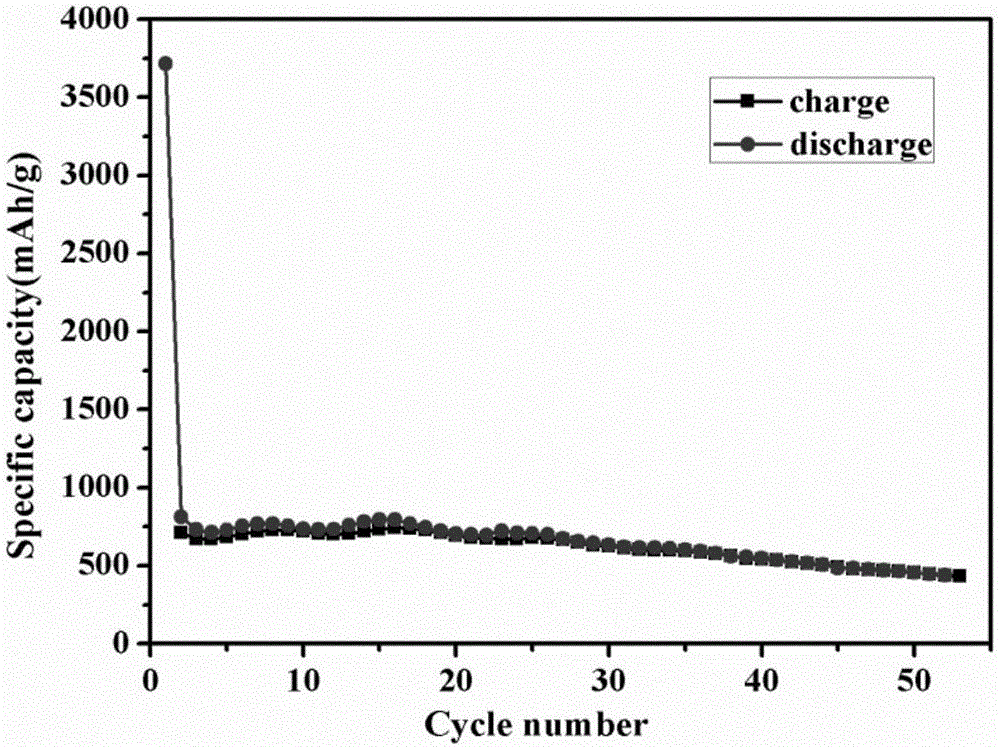

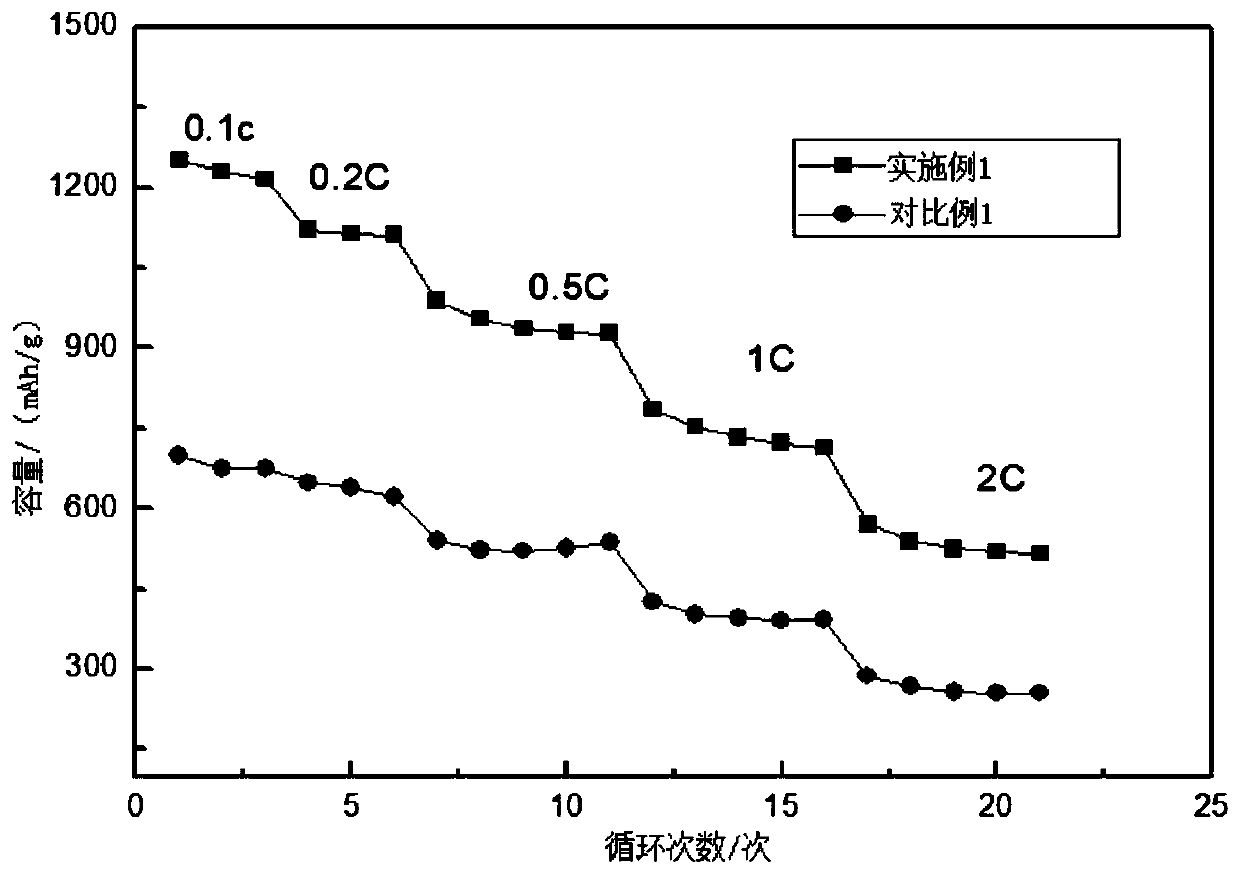

Preparation method for nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability

InactiveCN105098181AReduce manufacturing costImprove charge and discharge performanceNegative electrodesSodium-ion batteryChemistry

The invention discloses a preparation method for a nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability, comprises: 1) preparing an Sn source solution A with the concentration of 0.5-1.2 mol / L, regulating the pH of the solution A to be 1-9; and preparing an S source solution B with the concentration of 0.1-2.4 mol / L; 2) mixing the solution A and the solution B at an element molar ratio of nSn: nS being equal to (1.0-2.5): (2.0-4.3), and uniformly stirring to form a solution D; 3) putting the solution D into a homogenous phase hydrothermal reaction kettle for performing a homogenous phase hydrothermal reaction; and 4), cooling the reaction kettle, then centrifuging, washing, separating and drying to obtain the nano-flake SnS2 sodium-ion battery negative electrode material, wherein under 100 mA / g current density, the initial discharge capacity of the negative electrode material reaches 745 mAh / g; and after circulating for 100 times, the capacity is kept at 560 mAh / g.

Owner:SHAANXI UNIV OF SCI & TECH

Lithium iron phosphate composite material, its preparation method and application

ActiveCN102437311AImprove conductivityFast charge and dischargeNon-aqueous electrolyte accumulator electrodesChemical compositionLithium iron phosphate

The invention is suitable for the technical field of batteries, and provides a lithium iron phosphate composite material, its preparation method and an application. The lithium iron phosphate composite material has a nanoparticle structure with lithium iron phosphate nanocrystals as the core. The external surface of the nanoparticle structure is covered with a nano-carbon particle coating, the external surface of which is covered with grapheme. The chemical composition of the lithium iron phosphate nanocrystals is LiFe1-xMxPO4, wherein M is metal ions and x is being less than 1 and greater than or equal to 0.001. By cladding the nano-carbon particles with the lithium iron phosphate crystals, adding grapheme and adding metal ions in the lithium iron phosphate crystals, conductivity of the lithium iron phosphate composite material in the embodiment of the invention is greatly improved. Simultaneously, the nano particle size of the lithium iron phosphate crystals guarantees rapid charge and discharge of the lithium iron phosphate crystals in the embodiment of the invention.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

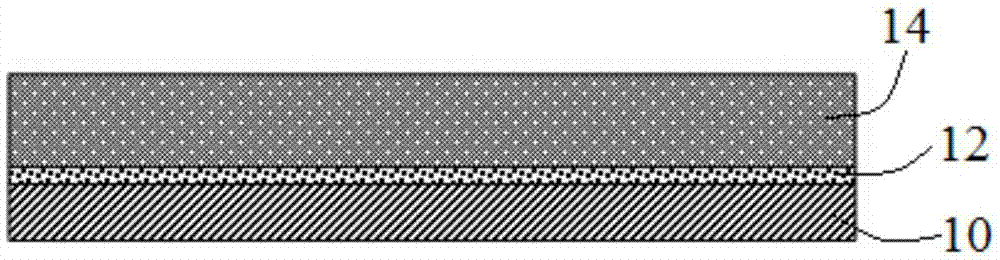

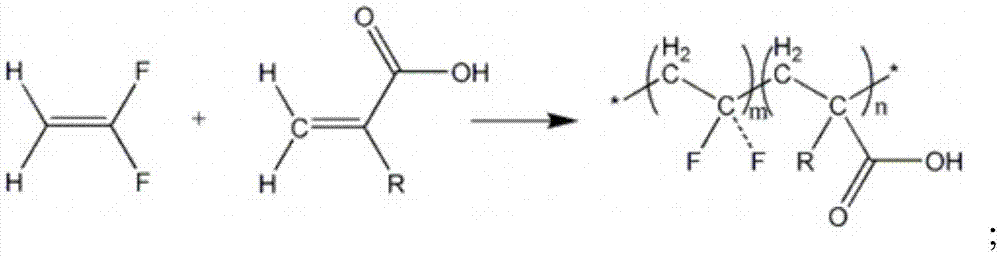

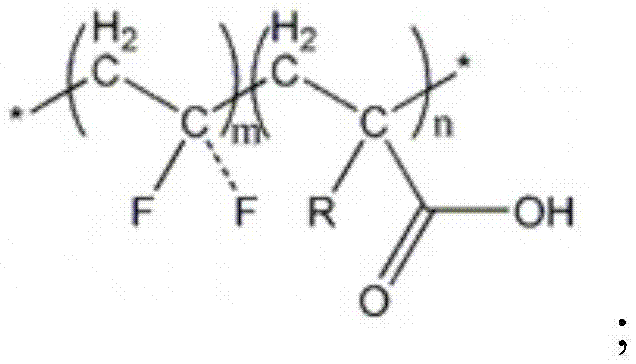

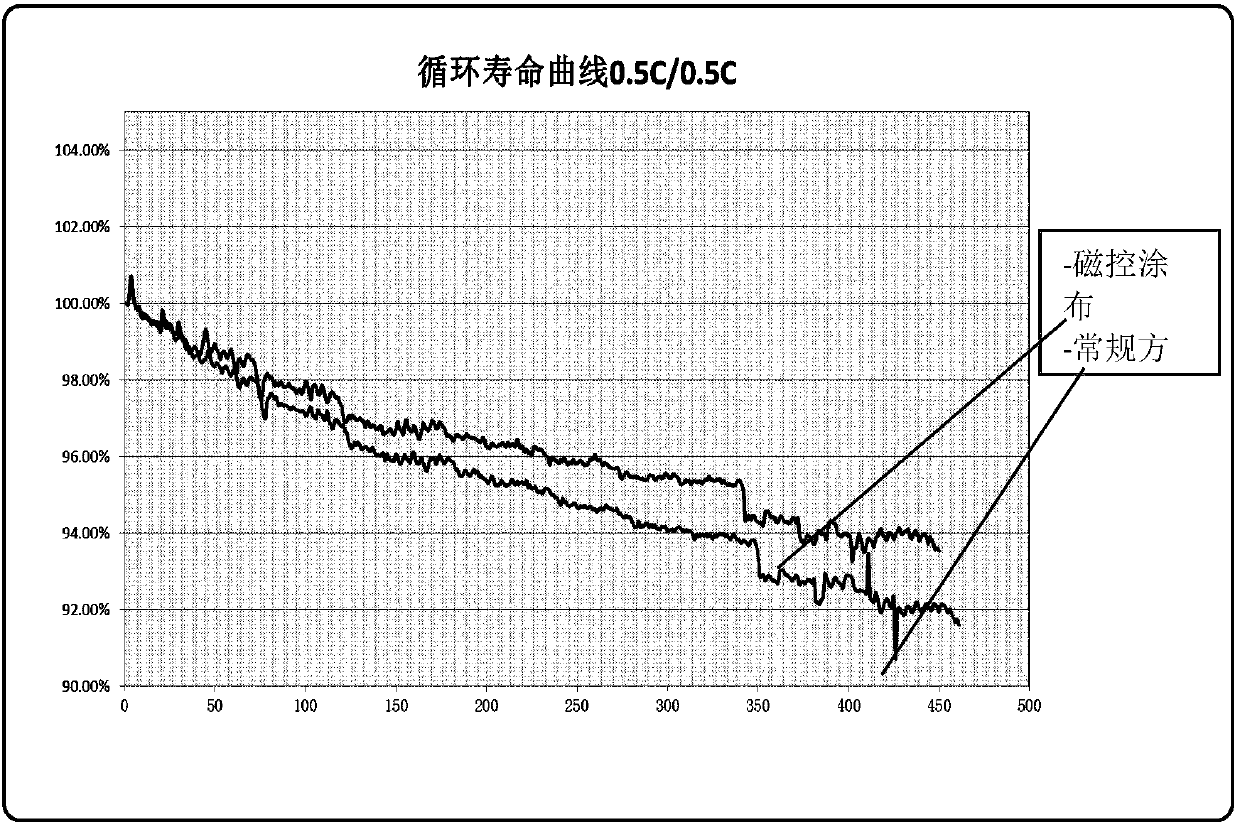

Lithium ion battery and positive electrode piece thereof

InactiveCN106941149AImprove charge and discharge rate performanceLong cycle lifeElectrode carriers/collectorsSecondary cellsEngineeringEthylene Homopolymers

The invention discloses a lithium ion battery and a positive electrode piece thereof. The positive electrode piece comprises a positive electrode current collector, a priming coat coated on the positive electrode current collector and a positive electrode diaphragm coated on the priming coat, the positive electrode current collector is aluminum foil, and the positive electrode diaphragm contains a positive electrode active material and a PVDF homopolymer binder; and the priming coat comprises a conductive agent and acrylic acid modified polyvinylidene fluoride copolymer (Ac-PVDF) used as a binder. The priming coat is introduced to the positive pole electrode piece of the lithium ion battery, the priming coat mainly contains the acrylic acid modified polyvinylidene fluoride copolymer and the conductive agent, the Ac-PVDF can significantly increase the adhesion between the positive electrode diaphragm and the positive current collector, and the conductive agent can reduce the interface resistance, so the charge and discharge performance of the battery is improved, and the cycle life of the battery is prolonged.

Owner:NINGDE AMPEREX TECH

High-energy density lithium ion battery cell and preparation method thereof

ActiveCN103094619AReduce interface resistanceIncrease energy densityFinal product manufactureCell component detailsFiberCarbon fibers

The invention discloses a high-energy density lithium ion battery cell and a preparation method thereof. The cell comprises a matrix layer, a composite positive electrode layer, a composite diaphragm layer, a composite negative electrode layer, an isolation layer and an positive electrode / negative electrode collector region, wherein a fast lithium ion conductor is doped in the composite diaphragm layer, so that the ion conductivity of the cell is improved, better thermal stability and puncture-resistant strength can be achieved, and the security of a battery can be improved; and the composite positive electrode / negative electrode layers adopt a three-layer sandwich structure of an positive electrode / negative electrode activity layer, a conductive layer and an positive electrode / negative electrode activity layer in sequence, the conductive layer is formed by alternatively arranging conductive fiber of carbon fiber, carbon nanotubes and the like, so that not only can the coating strength be enhanced so as to prevent the breakage of the coating, but also the conductivity of the coating can be increased. According to high-energy density lithium ion battery cell and the preparation method thereof, the spraying technology, novel afflux technology and fast lithium ion conductor materials are simultaneously used and organically combined, so that the energy density and the charging and discharging rate of the cell can be greatly improved, the preparation cost can be greatly lowered, and the technique is simple and easy for industrialized production.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

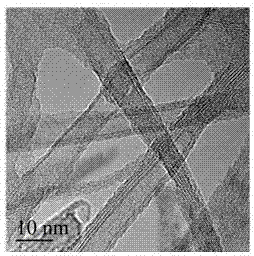

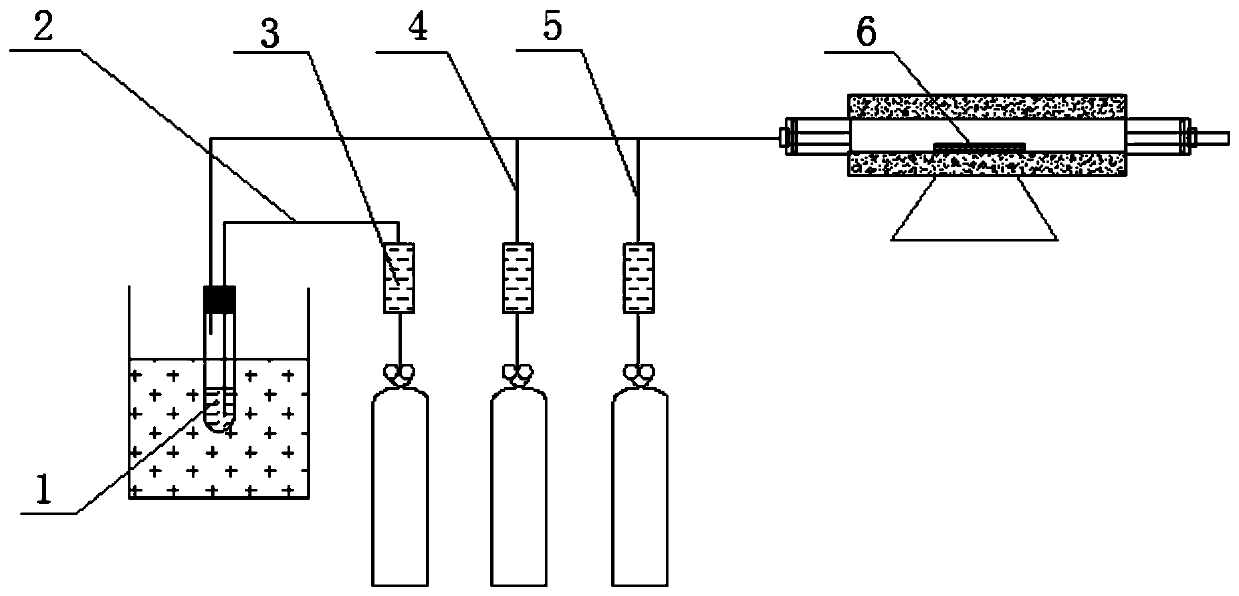

Electrospinning preparation method for cobaltosic oxide carbon nanometer fibers for sodium-n battery

InactiveCN106784745AShorten the diffusion pathEasy to embedMaterial nanotechnologyCell electrodesAir atmosphereFiber

The invention discloses an electrospinning preparation method for cobaltosic oxide carbon nanometer fibers for a sodium-ion battery. An electrospinning precursor liquid is prepared from Co2+ salts, polyvinylpyrrolidone and an organic solvent, a Co2+ salt / PVP composite fiber membrane by adopting an electrospinning method, then preparing Co3O4 carbon nanometer fibers through an air atmosphere calcination technology, and prepared Co3O4 crystals have a regular hexagonal nano-sheet structure and are uniformly inlaid in the carbon nanometer fibers to enable a material to have larger specific surface area. According to the electrospinning preparation method, with unique carbon nanometer fiber porous structure and ultrathin nano-sheet crosslinking structure, permeation of electrolyte and electron / ion transfer are effectively promoted, the diffusion path of sodium ions in the material is shortened, embedding and disembedding of the sodium ions are facilitated, the capacitance is higher, the cycling stability is better, and the dynamics performance of the material is greatly improved. The electrospinning preparation method is simple in technology and low in cost.

Owner:XIJING UNIV

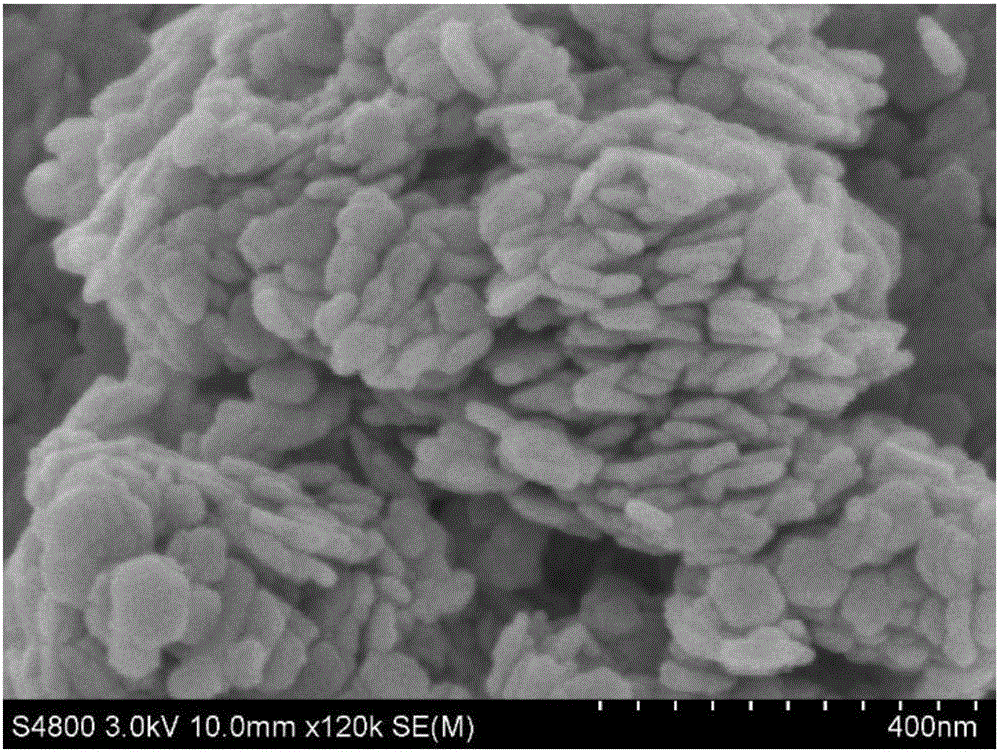

Graphene carbon-coated sodium vanadium phosphate material, preparation method thereof and application method of sodium vanadium phosphate material used as sodium ion battery positive electrode material

InactiveCN108172831AIncrease contact areaIncreased diffusion rateCell electrodesCarbon layerHydrocarbon mixtures

The invention discloses a graphene carbon-coated sodium vanadium phosphate material, a preparation method thereof and an application method of the sodium vanadium phosphate material used as a sodium ion battery positive electrode material. The graphene carbon-coated sodium vanadium phosphate material is formed by uniformly coating a two-dimensional nanometer sheet-shaped sodium vanadium phosphatecrystal with a graphene carbon layer. The preparation method of the graphene carbon-coated sodium vanadium phosphate material comprises the steps of sequentially ball-grinding and mixing an anionic surfactant, a phosphorus source, a hydrocarbon mixture, a vanadium source and a sodium source to obtain a sodium vanadium phosphate precursor; and placing the sodium vanadium phosphate precursor in a protection atmosphere for calcination, thereby obtaining the graphene carbon-coated sodium vanadium phosphate material having good crystallinity, uniform nanometer size and excellent electrochemical performance and completely coated with graphene carbon. When the graphene carbon-coated sodium vanadium phosphate material is used as a sodium ion positive electrode material, the sodium ion battery shows excellent cycle property and rate performance; and the preparation process of the graphene carbon-coated sodium vanadium phosphate material is simple and is low in cost, and mass production is easyto amplify.

Owner:CENT SOUTH UNIV

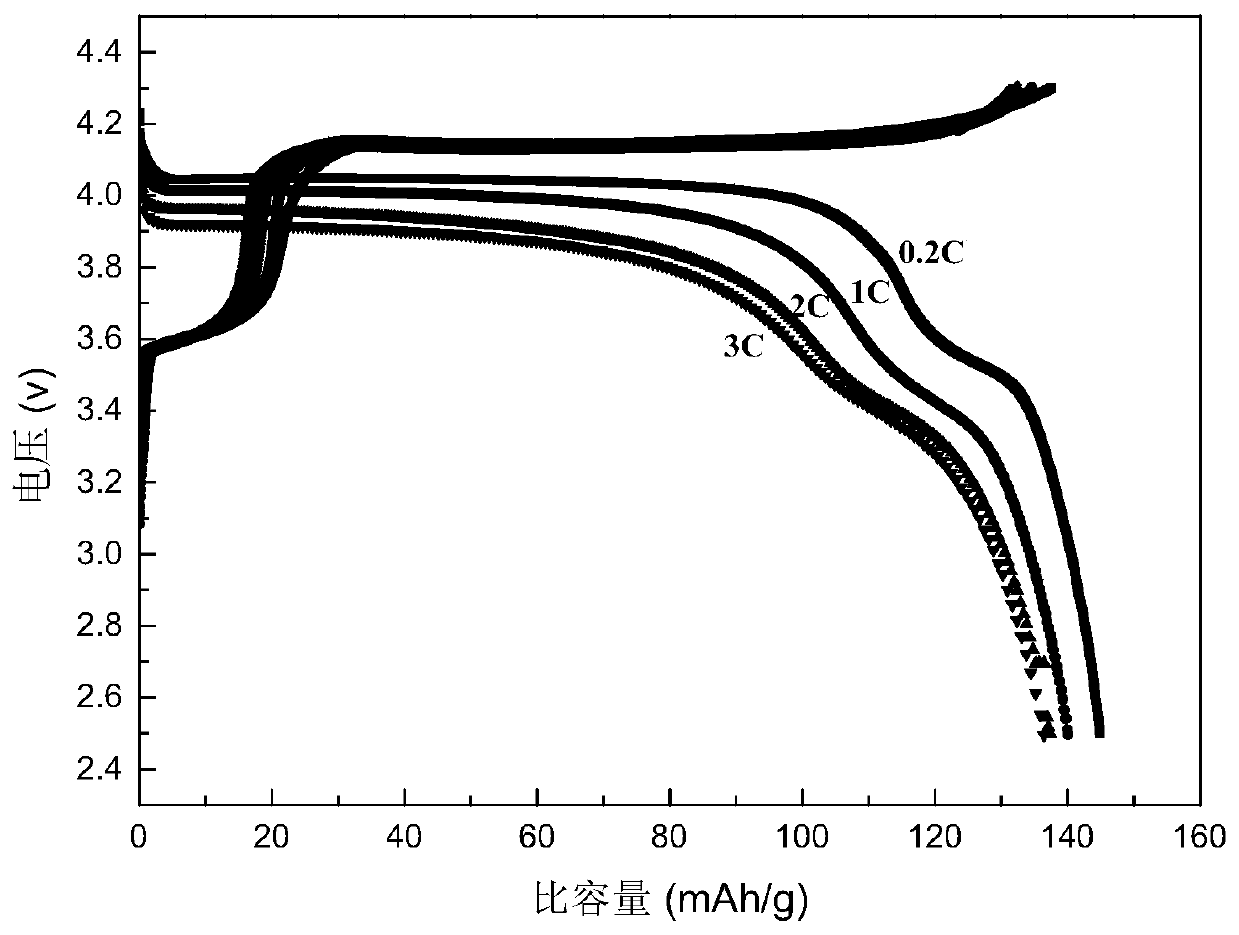

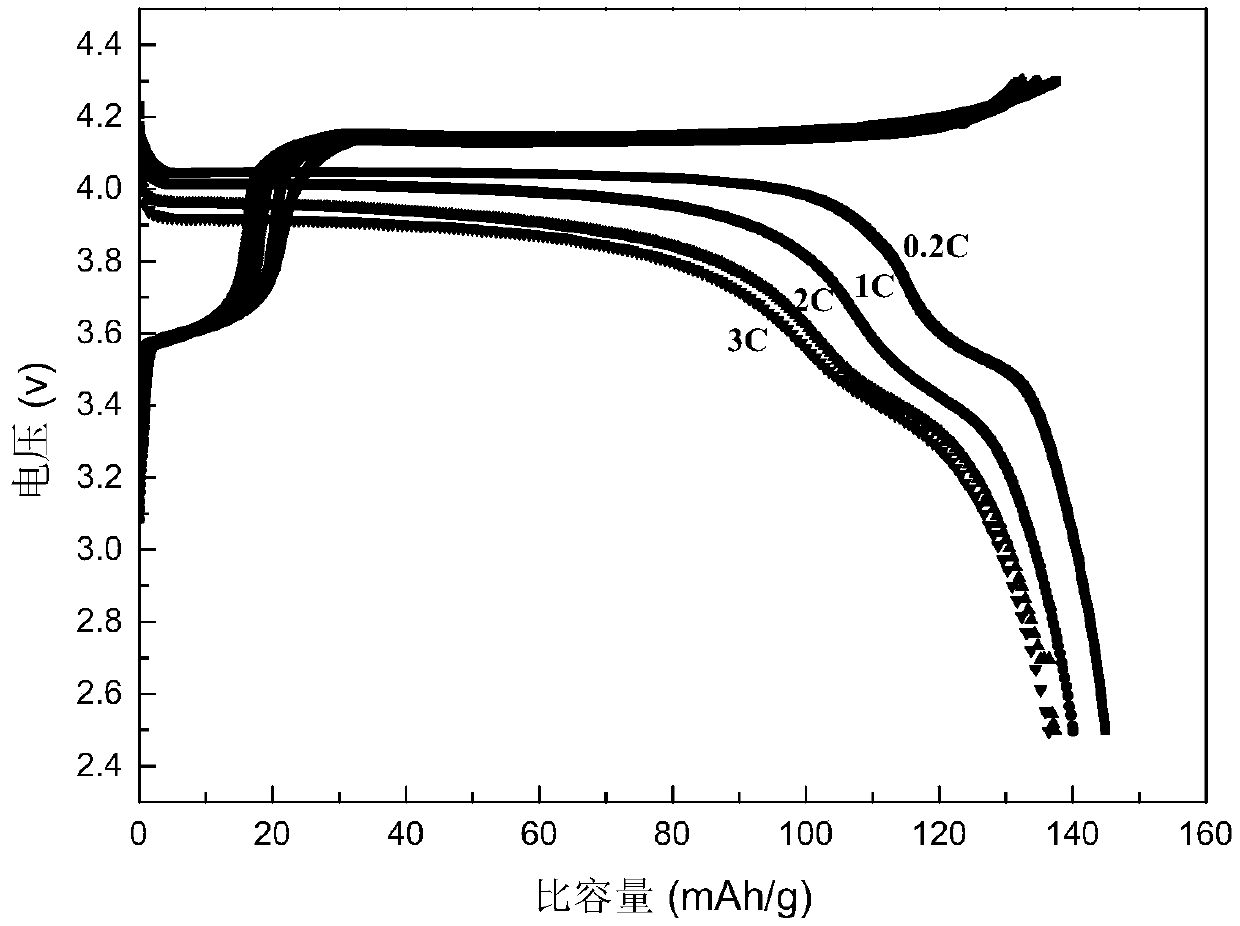

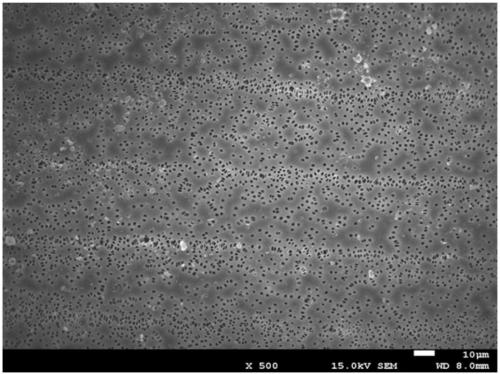

Lithium iron phosphate composite positive electrode material and preparation method and application thereof

ActiveCN110085839AThe crystal phases are closely arrangedImprove diffusion abilityMaterial nanotechnologySecondary cellsCarbon coatingConcentration polarization

The invention provides a lithium iron phosphate composite positive electrode material, which comprises lithium iron phosphate composite nanoparticles and a carbon coating coated on the surfaces of thelithium iron phosphate composite nanoparticles, wherein doping metal elements are evenly distributed in the lithium iron phosphate composite nanoparticles, and the doping metal elements include one or more of aluminum, magnesium, chromium, zirconium, vanadium and cobalt. In the lithium iron phosphate composite positive electrode material, the mass percentage content of the carbon element is 0.5%-4.0%, and the particle size of the lithium iron phosphate composite positive electrode material is 50nm-120nm. The lithium iron phosphate composite positive electrode material can greatly improve thediffusion ability of lithium ions, reduce the concentration polarization of the lithium ions during the charging and discharging process and has outstanding rate performance. The invention further provides a preparation method and an application of the lithium iron phosphate composite positive electrode material.

Owner:FOSHAN DYNANONIC

Anode material, preparation method thereof, anode, lithium ion total battery and manufacturing method

InactiveCN107256963ALow priceImproved magnification performanceMaterial nanotechnologyFinal product manufactureLithiumSynthesis methods

The invention belongs to the technical field of battery materials, and particularly relates to an anode material, a preparation method of the anode material, an anode, a lithium ion total battery, and a manufacturing method of the total battery. The anode material provided by the invention comprises a Na2Ti3O7 nano-tube material; a synthesis method of the nano-tube material comprises the following steps: mixing TiO2 nano-powder and alkali solution, conducting a heating reaction under high pressure, and then, washing a precipitate, generated after a reaction, with water, drying and annealing at 300 to 500 DEG C. According to the anode material provided by the invention, the synthetic raw materials are wide in source and easy to obtain; the cost is low; the charge-discharge rate performance is ultrahigh; the reversible discharge capacity of the anode material reaches 350 mAh / g; and the lithium ion total battery through combination of the anode material has the energy density at a battery level and the power density similar to a capacitor.

Owner:SHANDONG BAOLI BIOMASS ENERGY

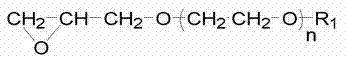

Adhesive for negative pole material of lithium ion battery and preparation method of electrode containing adhesive

The invention belongs to the technical field of lithium ion batteries and particularly relates to an adhesive for a negative pole material of a lithium ion battery. The adhesive is a polyacrylic acid type polymer, and the polyacrylic acid type polymer is formed by condensation of polyacrylic acid and a polyether type high molecular polymer, wherein the polyacrylic acid accounts for 10-30% by weight of the total weight of the polyacrylic acid type polymer. The adhesive disclosed by the invention adopts the water-soluble polyether type polymer with high lithium ion conductivity to modify carboxylic acid groups in the polyacrylic acid. Therefore, the obtained novel polyacrylic acid type polymer after modification can be used as the adhesive for the negative pole material of the lithium ion battery, the first charge-discharge efficiency of the battery can be effectively improved, and the high-temperature circulation performance, high-temperature storage performance, charge-discharge rate and low-temperature rate performance of the battery are also greatly improved. In addition, the invention further discloses a preparation method of a lithium ion electrode.

Owner:DONGGUAN AMPEREX TECH

Three-dimensional hollow carbon foam electrode materials, preparation method of three-dimensional hollow carbon foam electrode materials and application of three-dimensional hollow carbon foam electrode materials

InactiveCN107275098AStrong structural controllabilityLow costHybrid capacitor electrodesHybrid/EDL manufactureDissolutionZinc nitrate

The present invention discloses a three-dimensional hollow carbon foam electrode materials, a preparation method of the three-dimensional hollow carbon foam electrode materials and an application of the three-dimensional hollow carbon foam electrode materials. The method concretely comprises the following steps: mixing zinc nitrate, fuel and deionized water to perform full stirring and dissolution, putting the mixed solution on an electric furnace for heating until viscidity cementing products are obtained, the products are arranged in a muffle furnace for annealing to obtain zinc oxide template materials with multi-stage holes, and preparing charcoal electrode materials with multistage apertures through adoption of a template method. Compared to the prior art, the reaction materials are wide in source, low in cost and environmentally friendly, the synthesis steps are simple, the raw materials is nontoxic and safe and mild in reaction condition, and the method for removal of temperature materials is unique so as to fit large-size production and commercialization application. The prepared multi-stage hole carbon materials have multistage aperture structures having micropores, mesoporouses and macroporouses, large in specific surface area, have excellent charge and discharge multiplying power characteristics and cycle stability in an application and can satisfy the application requirement of an electrochemistry power storage device.

Owner:HUNAN UNIV

Power battery oil-based negative electrode slurry and preparation method thereof

InactiveCN109888210ALower internal resistanceImprove charge and discharge rate performanceCell electrodesSecondary cellsPower batteryPolyvinylidene difluoride

The invention belongs to the technical field of batteries, and particularly relates to power battery oil-based negative electrode slurry. The slurry comprises the following components in parts by mass: 93 to 96.5 parts of a negative active substance, 1.5 to 4.5 parts of a binder, 1 to 2 parts of a conductive agent, 0.05 to 1 part of a defoaming agent and 70 to 100 parts of a solvent, wherein the binder is polyvinylidene fluoride, and the solvent is N-methyl pyrrolidone. Compared with the prior art, the scheme of the invention solves the problem that in the preparation of the existing slurry, alarge amount of bubbles are generated when the viscous slurry is stirred at high speed after an oily bonding system is added, the large amount of bubbles are difficult to be removed, the decrease inthe quality of electrode sheets is further caused, and the electrochemical performance is affected. In addition, the invention also provides a preparation method of the power battery oil-based negative electrode slurry, which reduces the batching time, improves the stirring process, increases the production efficiency, and reduces the energy consumption.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

Modified zinc oxide and preparation method and application thereof

The invention relates to modified zinc oxide and a preparation method and application thereof, in particular to a zinc negative electrode material for an alkaline zinc-air secondary battery, and belongs to the field of an air battery. The modified zinc oxide comprises a zinc oxide inner core, a first coating layer and a second coating layer, wherein the first coating layer is coated on the zinc oxide inner core, the second coating layer is coated on the first coating layer, the material of the first coating layer is C, and the material of the second coating layer is a titanium sub-oxide. The preparation method of the modified zinc oxide comprises the steps of growing a layer of phenolic resin on a surface of zinc oxide in an in-situ way; coating a layer of titanium-based organic-inorganicmixed gel; and performing reaction at 760-880 DEG C to obtain the product with the designed structure. When the product is used as a zinc negative active material of the alkaline zinc-air secondary battery, the product shows excellent electrochemical performance. The material is reasonable in structural design, the preparation process is simple, the obtained product has favorable performance, andindustrial application on a large scale is convenient.

Owner:CENT SOUTH UNIV

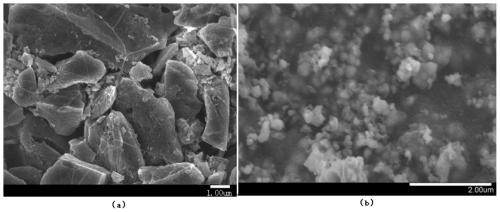

Preparation method of hexagonal lamellar SnS2 sodium-ion battery anode material

InactiveCN106784814AReduce manufacturing costEasy to operateCell electrodesFreeze-dryingSodium-ion battery

The invention discloses a preparation method of a hexagonal lamellar SnS2 sodium-ion battery anode material. The preparation method comprises the following steps: 1) dissolving thioacetamide into deionized water to obtain a solution A; 2) adding hexadecamethyl trimethyl ammonium bromide in the solution A to obtain a transparent clear solution C; 3) dissolving stannic chloride pentahydrate into the transparent clear solution C according to the element molar ratio of nSn to nS being 1.0 to (1.2 to 2.4), and uniformly mixing a mixture to obtain a mixed solution D; 4) regulating a pH value of the mixed solution D to be 1 to 9 so as to form a solution E; 5) carrying out microwave hydrothermal reaction on the obtained solution E; and 6) washing and freeze drying a product to obtain the hexagonal lamellar SnS2 sodium-ion battery anode material. The preparation method has the characteristics of low preparation cost, simpleness in operation and short preparation cycle. A prepared product has the lamination thickness reaching several to several tens nanometers, is high in purity, strong in crystallinity and uniform in morphology and has excellent charge-discharge rate performance by being applied to a sodium-ion battery anode.

Owner:SHAANXI UNIV OF SCI & TECH

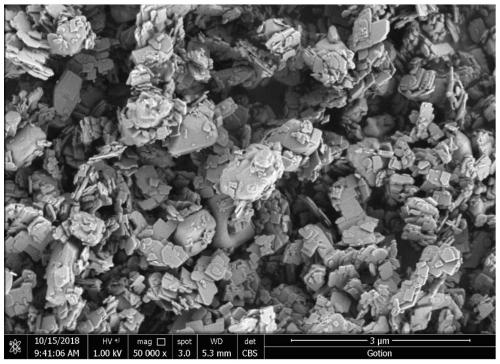

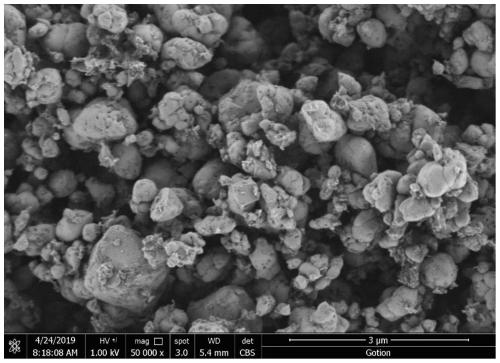

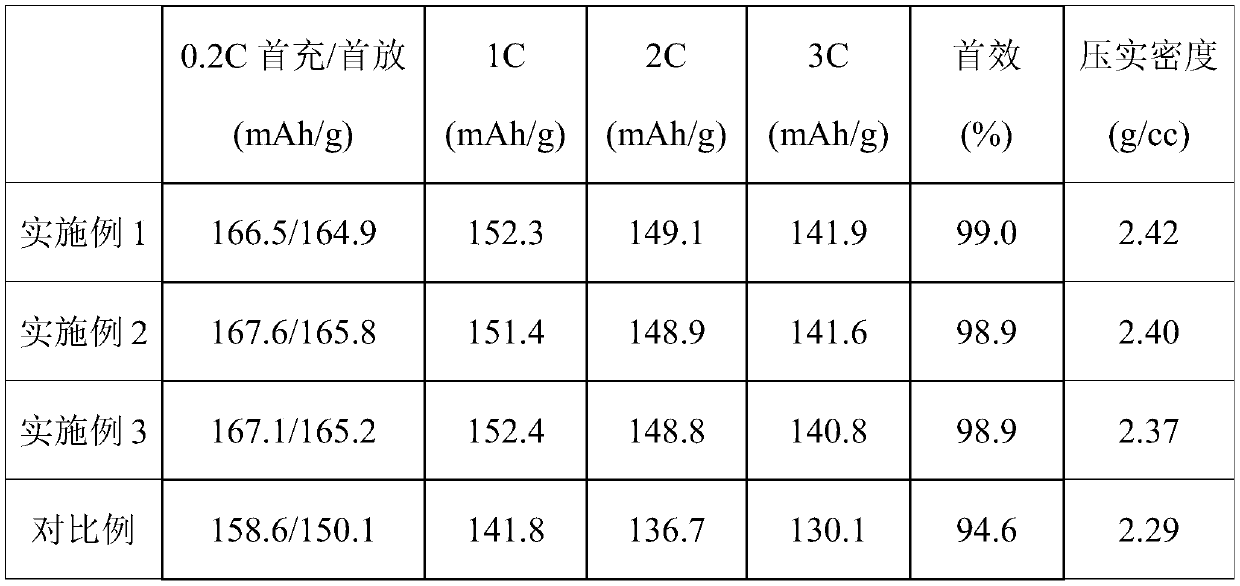

Method for preparing lithium iron phosphate cathode material with high-compaction and high-rate performance

ActiveCN110429277AImprove compactnessImprove compactionPhosphatesCell electrodesHigh rateCharge discharge

The invention discloses a method for preparing a lithium iron phosphate cathode material with high-compaction and high-rate performance, and relates to the technical field of lithium ion battery cathode materials. The method comprises the following steps of: according to a mass ratio of 100:4.5:(0.5-4), adding and dispersing a layered mesoporous graphite phase carbon nitride powder g-C3N4, PVP anda carbohydrate to deionized water to obtain a dispersion A; weighing FePO4 according to a mass ratio of FePO4:g-C3N4=50:(0.8~1.5), and adding and dispersing the FePO4 to the dispersion A to obtain adispersion B; weighing a lithium source according to a stoichiometric ratio of Fe:Li=1:1, and adding and dispersing the lithium source to the dispersion B to obtain a dispersion C; ultrafine grindingthe dispersion C, spray-drying the dispersion C, and then presintering and sintering the dispersion C under a protective atmosphere, naturally cooling a product so as to obtain the lithium iron phosphate cathode material. The method uses the g-C3N4 as a layered template and a main carbon source, and uses the excellent dispersing property of the PVP for shape control and modification in the processof lithium iron phosphate, thereby greatly improving the compaction and charge-discharge rate performance of the lithium iron phosphate cathode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Adhesive for negative materials for lithium-ion battery and method for preparing electrode containing adhesive

InactiveCN103400989AGood lithium ion conduction performanceImprove adhesion strengthCell electrodesMetal foilAdhesive

The invention discloses an adhesive for negative materials for a lithium-ion battery and a method for preparing an electrode containing the adhesive. The adhesive is a polyether high-molecular polymer, and the method for preparing the electrode containing the adhesive takes the polyether high-molecular polymer as an adhesive precursor, and comprises the following steps of: mixing 1.5-5.5 weight percent of polyether high-molecular polymer, 94-97 weight percent of electrode active material, 0.1-2.5 weight percent of reaction auxiliaries and 0.4-4 weight percent of a conductive agent with deionized water, stirring the mixture for 1-3 hours, enabling the polyether high-molecular polymer to generate cross-linking reaction to prepare electrode slurry, then coating the electrode slurry on the surface of a metal foil and finally drying for 2-4 hours at 120-140 DEG C to obtain the electrode. In an electrode preparation process, the polyether high-molecular polymer can generate cross-linking reaction in the role of the reaction auxiliaries, and therefore the bonding strength and the elastic force of the polyether high-molecular polymer are adjusted. Thus, the battery using the adhesive has good charge and discharge rate performance and cycle performance.

Owner:DONGGUAN AMPEREX TECH

Silicon-carbon negative electrode material and preparation method and application thereof

ActiveCN111106333AImprove charge and discharge performanceImprove cycle performanceCell electrodesSecondary cellsSolid carbonLiquid carbon

The invention discloses a silicon-carbon negative electrode material and a preparation method and application thereof. The method comprises the steps of adding silicon powder and a solid carbon sourceinto a V-shaped mixer for mixing; adding a liquid carbon source into the V-shaped mixer in a spraying form, and further mixing to obtain a mixture; sending the mixture to a high-speed crusher, drawing a liquid carbon source into a film to coat the surface of the mixture of the silicon powder and the solid carbon source, and obtaining a mixture containing a coating layer ; and roasting the mixturecontaining the coating layer in an inert atmosphere to obtain the silicon-carbon negative electrode material. By adopting the method, the silicon-carbon negative electrode material with uniformly dispersed silicon and carbon and stable compounding can be prepared, and the expansion of silicon during charging and discharging processes can be suppressed. Compared with a silicon-carbon negative electrode material prepared by adopting an existing preparation process, the silicon-carbon negative electrode material prepared by adopting the preparation process has better charge-discharge performance, cycle performance and charge-discharge rate performance. The preparation method is simple to operate. A drying process of a traditional preparation process is abandoned. Industrial production is facilitated, and the production cost is reduced.

Owner:内蒙古信敏惠纳米科技有限公司

Method for manufacturing fast-charging long-circulating graphite negative pole piece

ActiveCN109935778AImprove rheologyReduce surface tensionMaterial nanotechnologyElectrode manufacturing processesMagnetizationMagnetite Nanoparticles

The invention discloses a method for manufacturing a fast-charging long-circulating graphite negative pole piece, which comprises the steps of 1) crushing petroleum coke, 2) mixing petroleum coke particles, a high-temperature asphalt binder and stearic acid, 3) carrying out multi-stage temperature coating and bonding, 4) cooling to the room temperature, 5) adding Fe3O3 for graphitization treatment, 6) coating a nano Fe3O4 ionic liquid and carrying out magnetization treatment; and 7) drying to obtain the finished product. The method not only can improve the graphitization degree, greatly reducethe graphitization temperature of various amorphous carbons and improve the first charge-discharge efficiency and circulation stabilization of a graphite negative pole material, but also coats magnetic nanoparticle Fe3O4 on the surface, carries out the magnetization treatment and greatly reduces the OI value of the pole piece.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

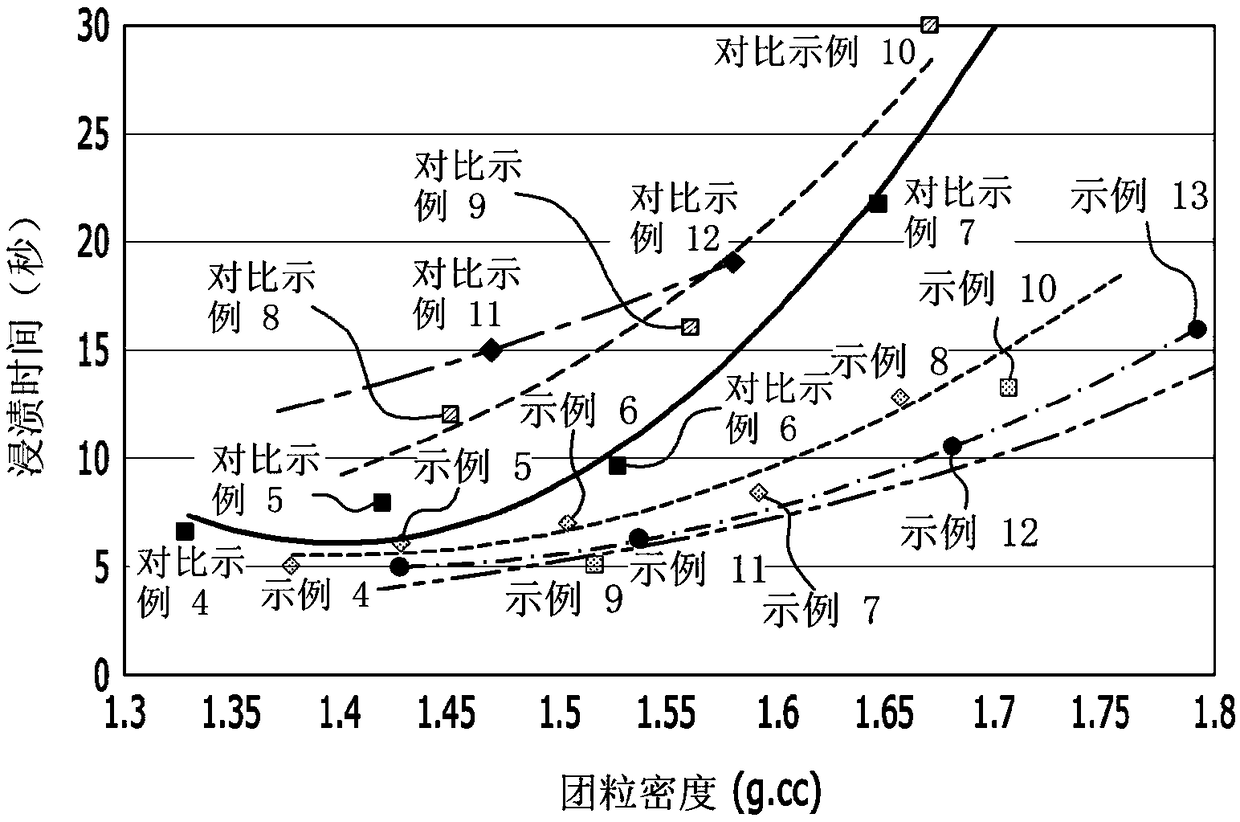

Negative active material for rechargeable lithium battery and rechargeable lithium battery including same

InactiveCN109478647AExcellent electrolyte impregnationImprove charge and discharge rate performanceNegative electrodesLi-accumulatorsPhysical chemistryLithium battery

A negative active material for a rechargeable lithium battery and a rechargeable lithium battery including the same are disclosed, and the negative active material includes a primary particle of a crystalline carbon-based material and secondary particle that is an assembly of the primary particles, wherein a ratio of an average particle diameter (D50) of the secondary particle relative to an average particle diameter (D50) of the primary particle (average particle diameter (D50) of the secondary particle / average particle diameter (D50) of the primary particle) ranges from about 1.5 to about 5and an aspect ratio of the primary particle ranges from about 1 to about 7.

Owner:SAMSUNG SDI CO LTD

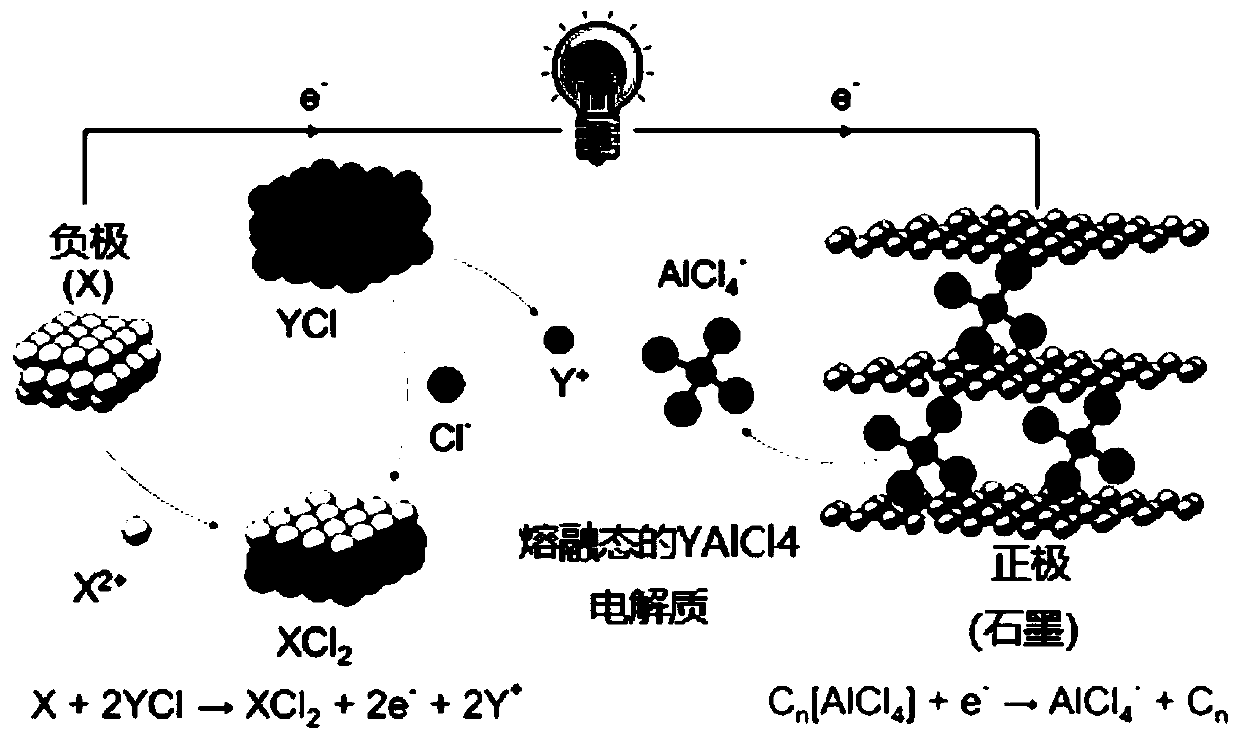

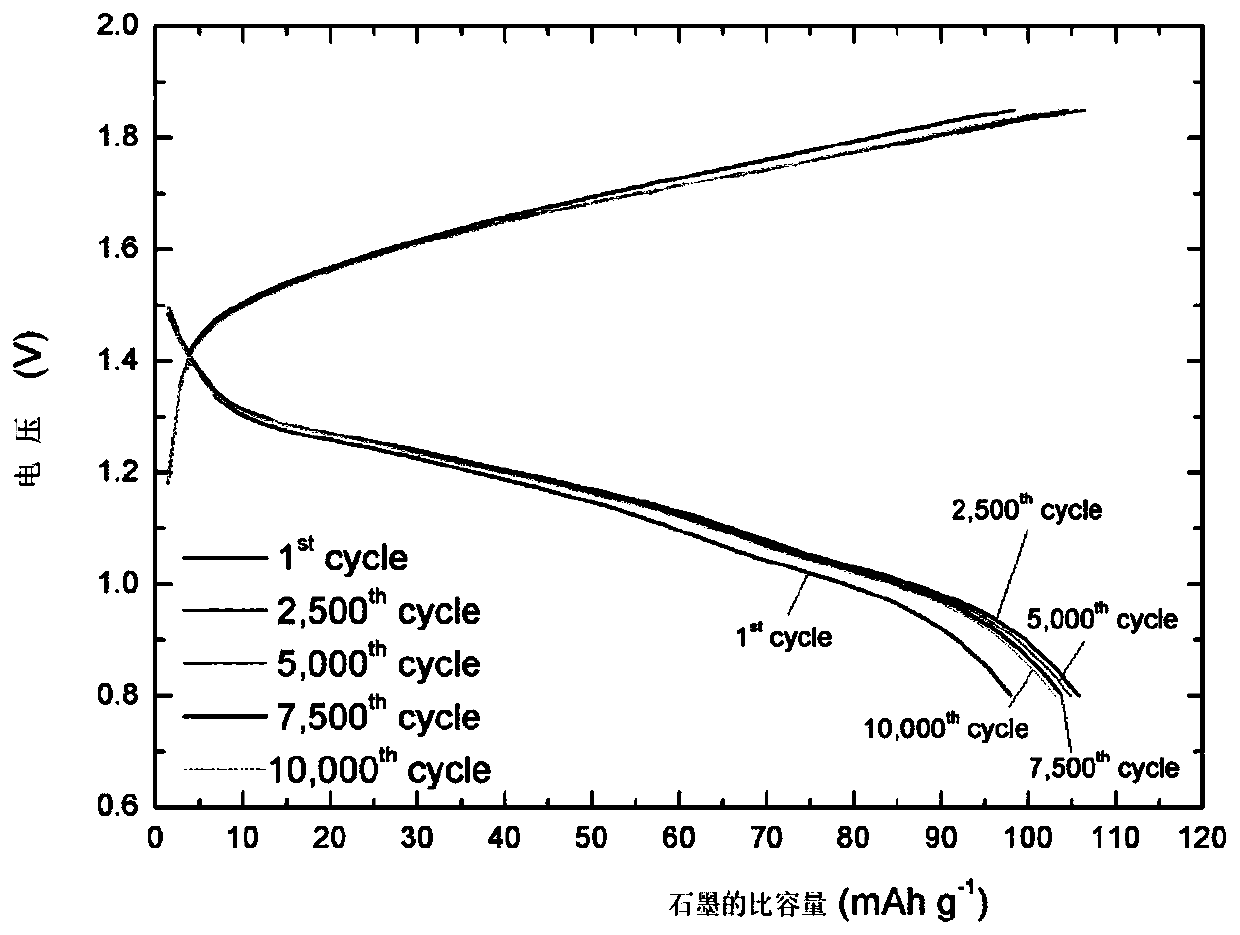

Metal-graphite medium-temperature energy storage battery and preparation method thereof

ActiveCN109950640ALow cost of energy storage throughout the life cycleLow cost of single-cycle energy storage in the whole life cycleFinal product manufactureSecondary cellsComposite electrodeGraphite

The invention discloses a metal-graphite medium-temperature energy storage battery and a preparation method thereof, and the metal-graphite medium-temperature energy storage battery is characterized in that the metal-graphite medium-temperature energy storage battery comprises a positive electrode, a negative electrode and an electrolyte; a gasket is arranged between the positive electrode and thenegative electrode; the electrolyte is arranged in the gasket, and the positive electrode is a graphite material; the electrolyte is YAlCl4 of saturated YCl, wherein Y is Li, Na or K; the negative electrode is an X|XCl2 solid-phase composite electrode, wherein X is a metal with the electronegativity being higher than the electronegativity of Al. The operation temperature of the battery is 100-200DEG C, the cycle life exceeds 10000 times, and the balance voltage is about 1-1.7 V.

Owner:XI AN JIAOTONG UNIV

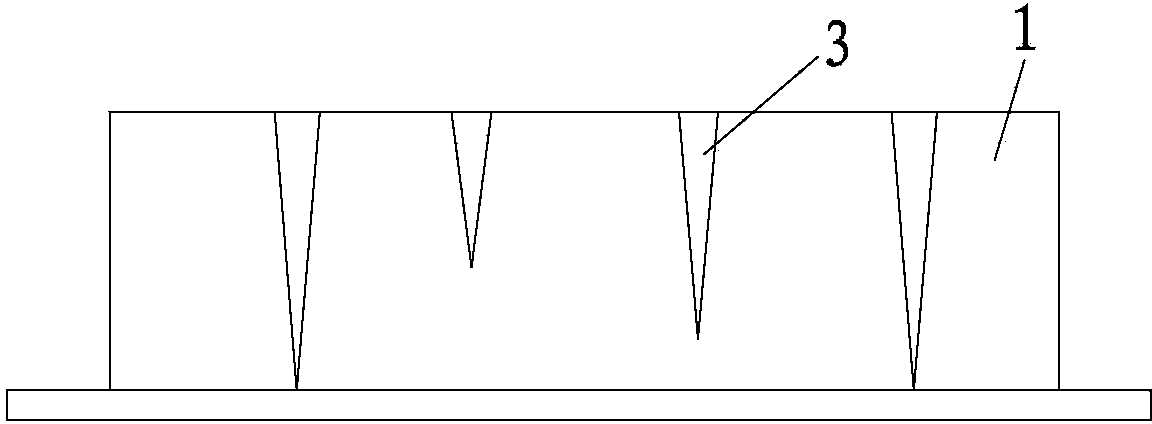

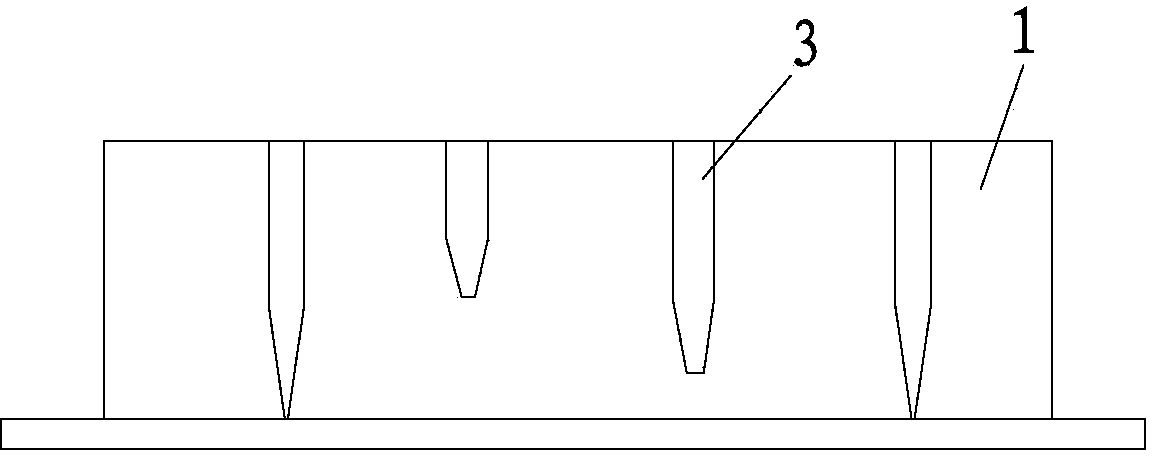

Lithium ion battery positive electrode sheet and battery comprising positive electrode sheet

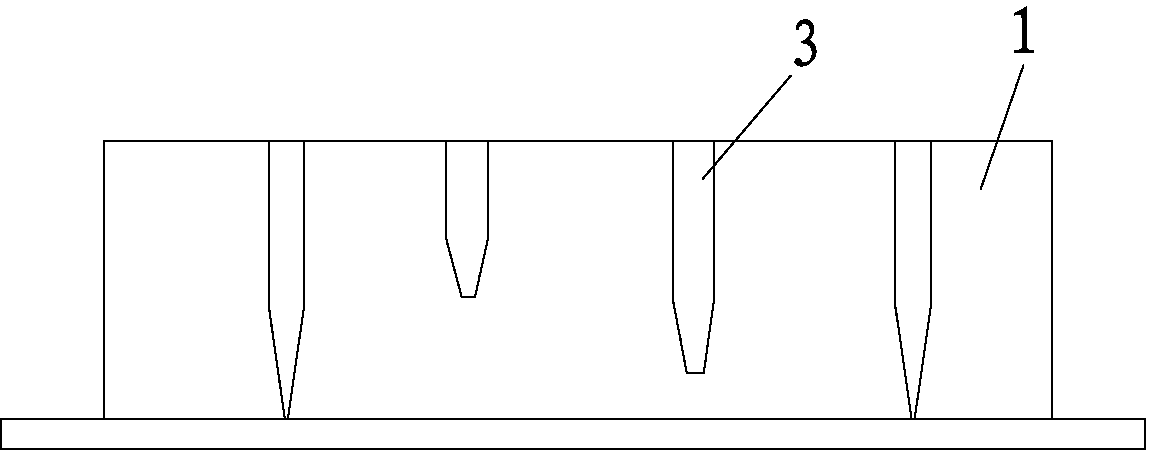

ActiveCN103367701AImprove charge and discharge rate performanceImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesPhysicsChemistry

The invention belongs to the technical field of lithium ion battery, and especially relates to a positive electrode sheet of a lithium ion battery. The positive electrode sheet is provided with a crack structure, wherein the opening of the crack structure is provided on the surface layer of the electrode sheet. With the crack structure, absorption rate of the electrode sheet upon electrolyte can be greatly improved, and standing time after liquid injection of the lithium ion battery can be reduced. In a lithium ion battery with the crack structure, with the existence of the crack, a highway is provided for rapid transmission of the electrolyte in the electrode sheet, and battery charge / discharge rate capability is greatly improved. Also, the invention discloses a lithium ion battery.

Owner:DONGGUAN AMPEREX TECH

Silicon/activated charcoal composite cathode material and preparation method thereof

InactiveCN106784759ARich pore structureAlleviate volume expansionMaterial nanotechnologyNegative electrodesAnilineChemistry

The invention discloses a silicon / activated charcoal composite cathode material and a preparation method thereof. The preparation method comprises the following steps: 1) dispersing nanosilicon spheres in a hydrochloric acid solution to obtain a turbid liquid, the concentration of which is 3-11g / L; 2) adding a dispersant into the turbid liquid obtained in the step 1) to obtain a mixture A; 3) adding a phenylamine monomer into the mixture A obtained in the step 2) to obtain a mixture B; 4) in a stirring state, dropwise adding ammonium persulfate into the mixture B to perform a polymerization reaction for 8-24h to obtain a silicon / polyaniline compound; 5) transferring the silicon / polyaniline compound obtained in the step 4) to a tubular furnace to be carbonized under inert gas shielding; and 6) heating the tubular furnace to the activating temperature under inert gas shielding, then introducing activating gas to activate for 0.5-3h, converting the gas in the tubular furnace into inert gas, and cooling the tubular furnace to room temperature to obtain the silicon / activated charcoal compound.

Owner:CHONGQING UNIV

A preparation method of titanium nitride and carbon double-coated lithium manganese iron phosphate composite material

ActiveCN106058220BEasy to useImprove uniformityCell electrodesSecondary cellsGas phaseTitanium nitride

The invention discloses a preparation method for a lithium manganese iron phosphate composite coated by both titanium nitride and carbon. The preparation method comprises the following steps: adding a certain amount of a carbon source during synthesis of a precursor; and then during sintering, introducing NH3 in a protective atmosphere, introducing TiCl4 with N2 as carrying gas and uniformly depositing a layer of a titanium nitride coating on the surface of lithium manganese iron phosphate by using a chemical vapor deposition method so as to prepare the lithium manganese iron phosphate composite uniformly coated by both titanium nitride and carbon. According to the invention, through adjustment of a carbon source addition amount during synthesis and the flow and deposition time of the three gases during vapor deposition, the granularity, thickness and bulk density of the coating can be adjusted, and the lithium manganese iron phosphate composite uniformly coated by both titanium nitride and carbon can be obtained. The coating has good uniformity and consistency; the composite has high tap density and good conductivity; a lithium ion positive electrode material using the composite has good charge and discharge rate and cycle stability; and the preparation method is simple, controllable and easy for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

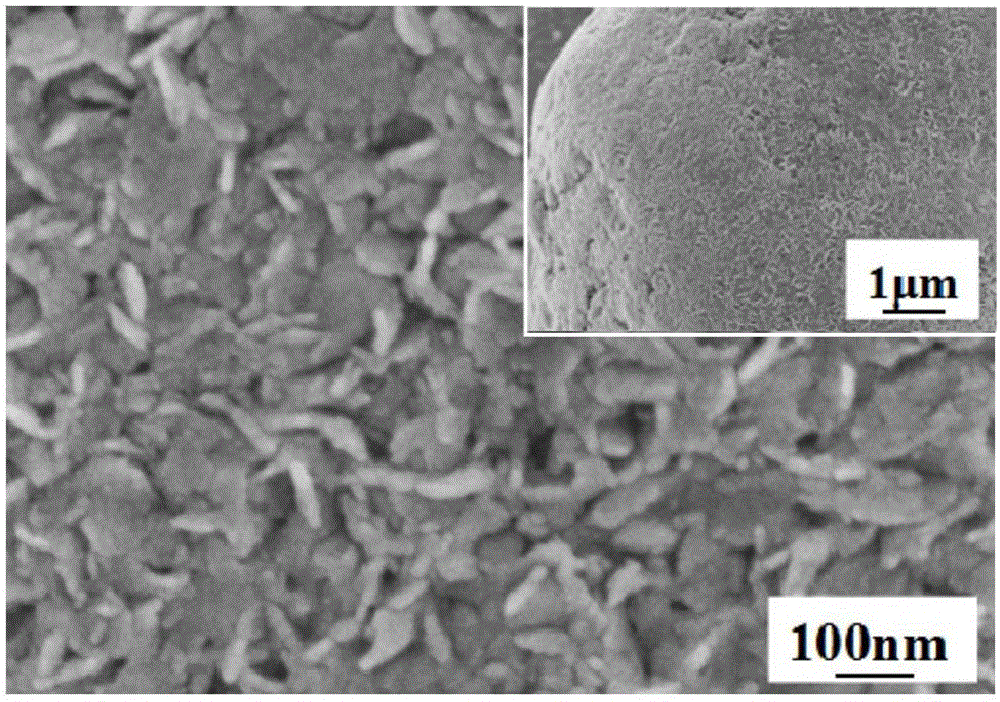

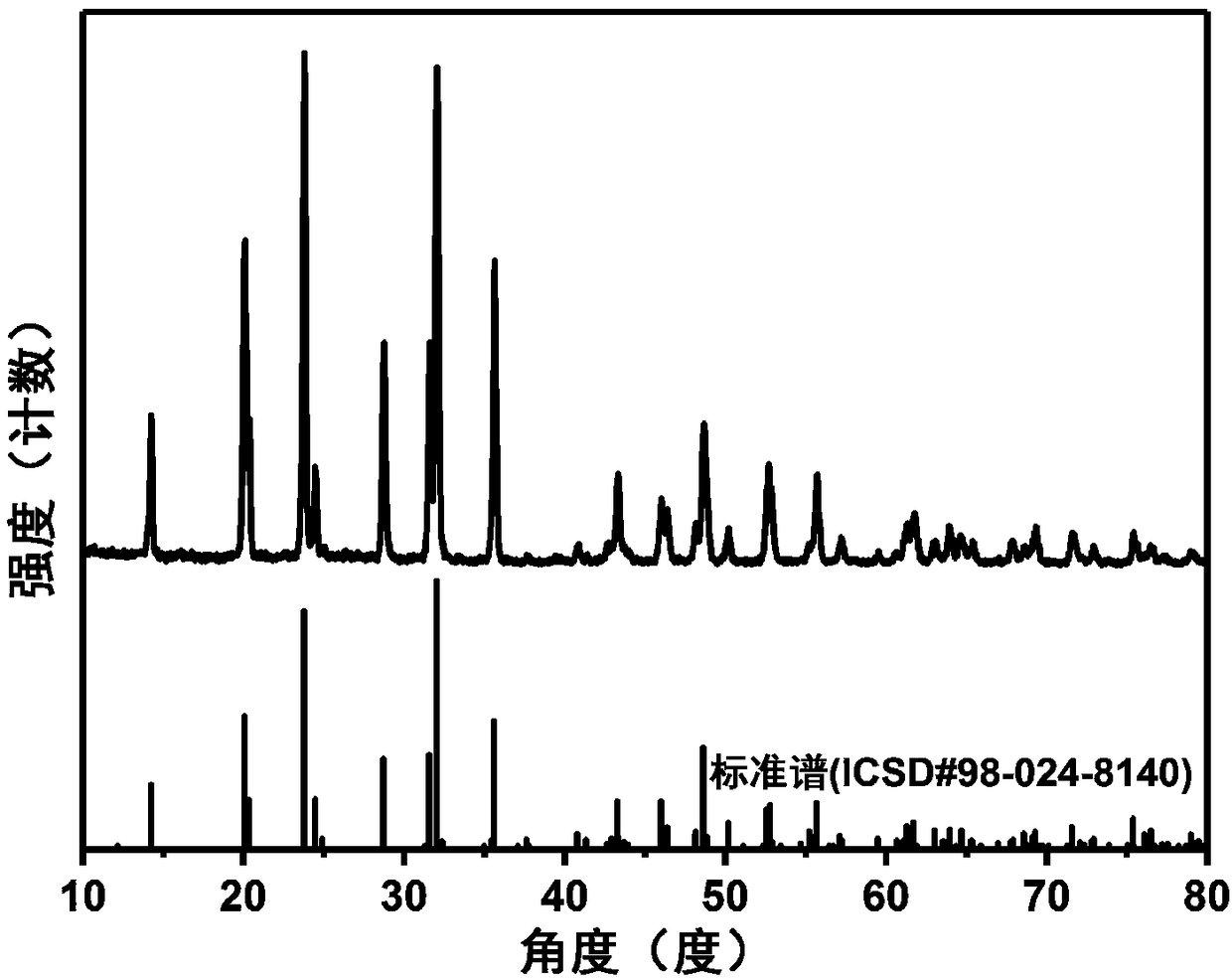

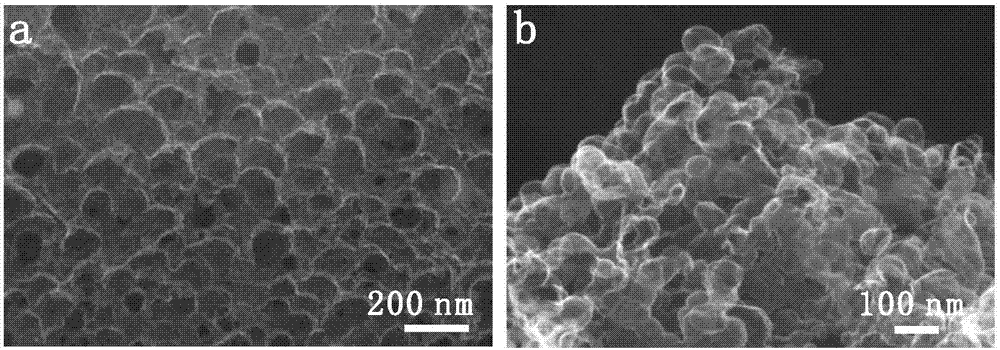

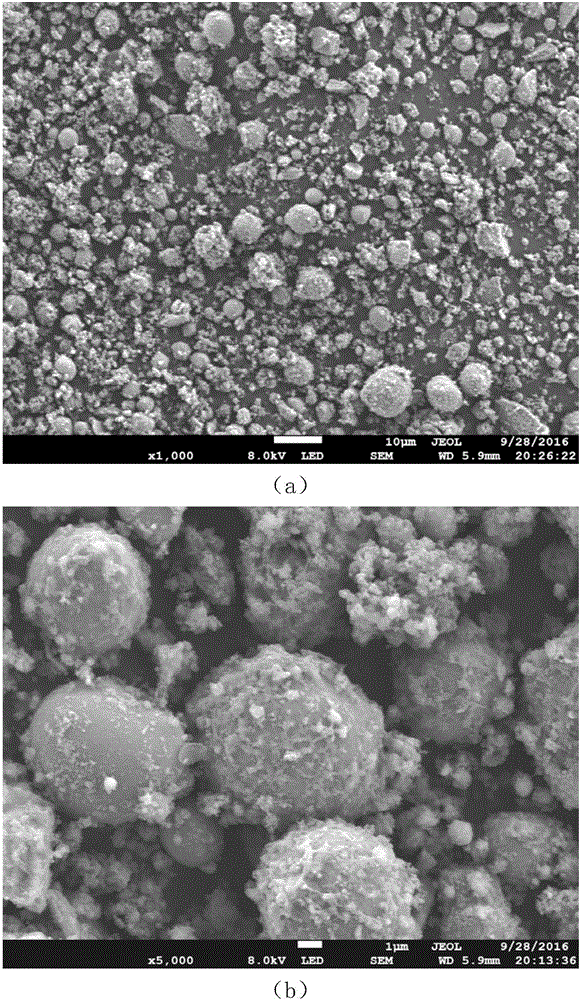

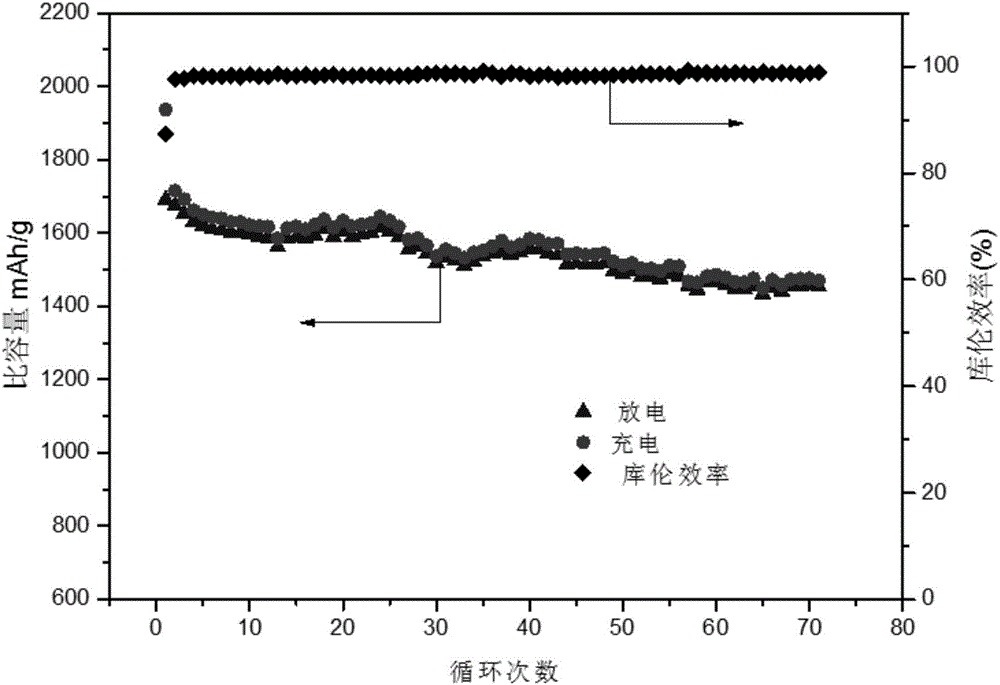

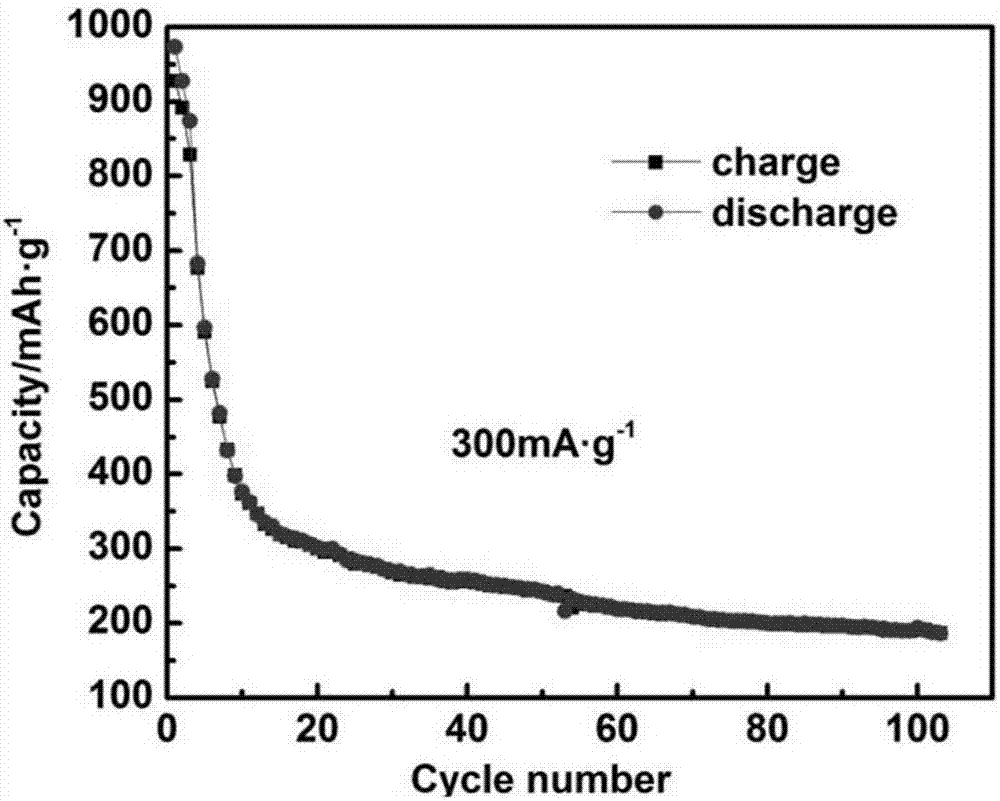

Sodium-ion battery negative electrode material with Ce doped with SnS2 and preparation method of sodium-ion battery negative electrode material

ActiveCN105514393AImprove charge and discharge rate performanceHigh purityCell electrodesSecondary cellsFreeze dryHydrothermal reaction

The invention discloses a sodium-ion battery negative electrode material with Ce doped with SnS2 and a preparation method of the sodium-ion battery negative electrode material. The preparation method comprises the following steps: 1, preparing a SnCl4.5H2O solution, a Ce(NO)3 solution and a NaS.9H2O solution; 2, uniforming the solutions obtained in step 1 according to the mole ratio of Sn to S to Ce, namely nSn: nS: nCe= (1.0-2.5): (2.0-4.3): (0.005-0.01), so that a mixed solution D is obtained; 3, placing the mixed solution D in a hydro-thermo-electric deposition reaction still for conducting an arc discharge hydrothermal reaction; 4, conducting filtration, separation and washing, so that a precursor is obtained, and conducting freeze-drying on the precursor, so that the sodium-ion battery negative electrode material with Ce doped with SnS2 is obtained. A product prepared through the preparation method is of a flowerlike structure assembled by nanosheets, the slice layer shape thickness reaches 10-20 nm, the ball-flower shape diameter is about 300-400 nm, under the current density of 100 mA / g, the initial discharge capacity can reach 1493 mAh / g, and after 50 cycles are ended, the capacity is maintained to be 460 mAh / g.

Owner:SHAANXI UNIV OF SCI & TECH

Porous diaphragm, preparation method thereof and lithium ion battery

ActiveCN111106293AImprove high temperature stabilityImproved magnification performanceSecondary cellsCell component detailsElectrical batteryPhysical chemistry

The invention relates to the field of lithium ion batteries, in particular to a porous diaphragm, a preparation method thereof and a lithium ion battery. The pore size of the porous diaphragm is 0.03-10 [mu]m, the air permeability is 20-500 sec / 100 ml, and the tensile strength is 30-200 MPa; and the porous diaphragm contains crystalline polyimide. The porous diaphragm provided by the invention hasthe properties of good air permeability and tensile strength, excellent thermal stability, high conductivity and the like, and the lithium ion battery prepared from the diaphragm has good charge-discharge rate performance and safety performance.

Owner:HUIZHOU BYD BATTERY

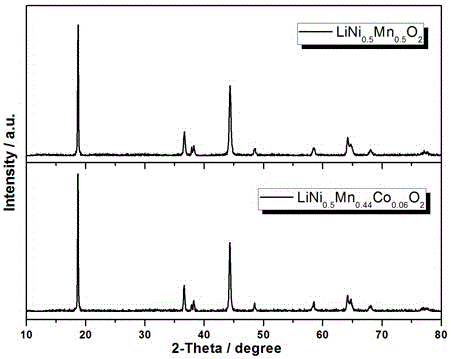

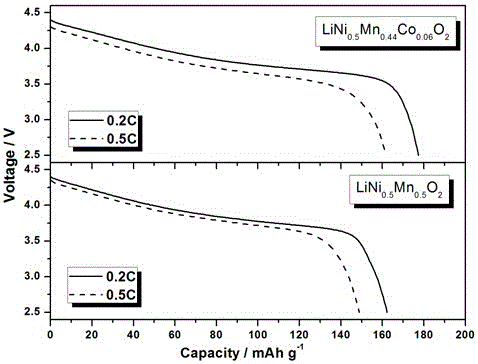

Positive electrode material for lithium-ion battery and preparation method of positive electrode material

ActiveCN105870408AImprove orderImprove charge and discharge rate performanceCell electrodesSecondary cellsLithium-ion batteryMetal

The invention relates to a positive electrode material for a lithium-ion battery and a preparation method of the positive electrode material, and belongs to the technical field of materials for lithium-ion batteries. A chemical general formula of the positive electrode material for the lithium-ion battery is LiNi<0.5>Mn<0.5-x-y>M<x>M'<y>, wherein x is greater than or equal to 0; y is greater than or equal to 0; and x+y is smaller than 0.1 and greater than 0. According to the method provided by the invention, by introducing low-valence metal cations, the valences of M and M' are lower than tetravalence; the material of which the chemical formula is LiNi<0.5>Mn<0.5-x-y>M<x>M'<y>O<2> is synthesized; the valence of Ni<2+> in the material rises due to a charge balance to generate a part of Ni<3+>; and the Ni<3+> and the Li<+> are not easily replaced with each other, so that mixed arrangement of Li / Ni is reduced; and the electrochemical properties of the material are improved.

Owner:KUNMING UNIV OF SCI & TECH

Lithium ion battery negative electrode sheet and battery comprising electrode sheet

InactiveCN103367703AImprove charge and discharge rate performanceImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesPhysicsChemistry

The invention belongs to the technical field of lithium ion battery, and especially relates to a lithium ion battery negative electrode sheet. The negative electrode sheet is provided with a crack structure with an opening arranged on the surface layer of the electrode sheet. With the crack structure, the absorption speed of the electrode sheet upon electrolyte can be greatly improved, and lithium ion battery settlement time can be reduced after injection. In a lithium ion battery with the crack structure, with the crack, a highway is provided for fast transmission of the electrolyte in the electrode sheet, such that battery charge / discharge rate performance can be greatly improved. The invention also discloses a lithium ion battery.

Owner:DONGGUAN AMPEREX TECH

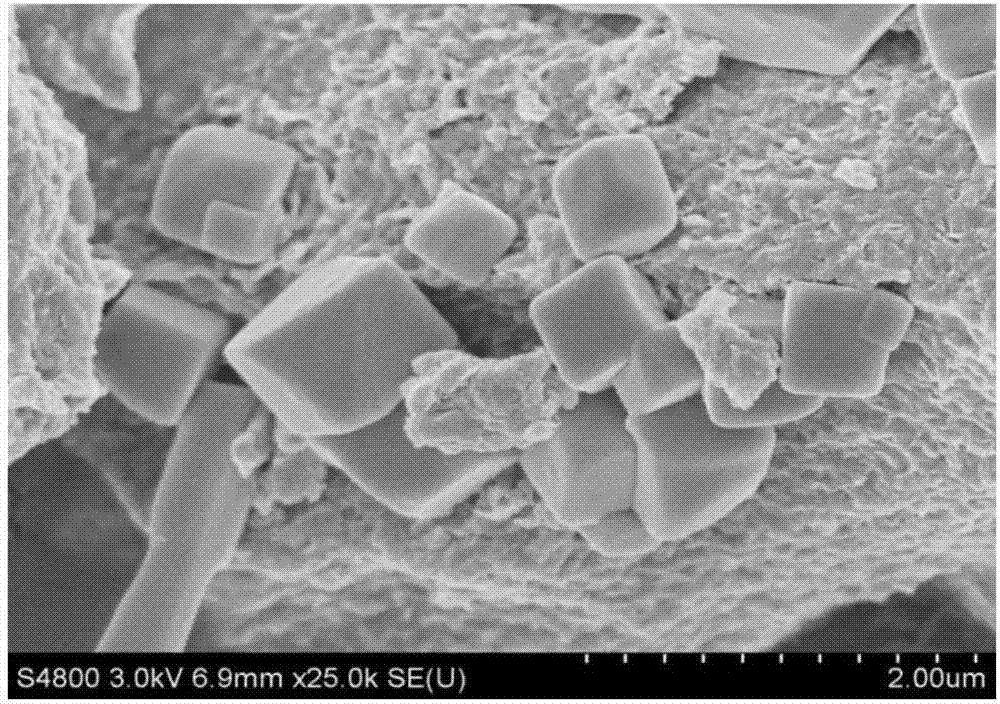

Preparation method of SnS2 sodium-ion battery anode material with cubic structure

ActiveCN107032390AEvenly dispersedHigh crystallinityMaterial nanotechnologyTin compoundsFreeze-dryingSodium-ion battery

The invention discloses a preparation method of a SnS2 sodium-ion battery anode material with a cubic structure. The preparation method comprises steps as follows: 1), sodium thiosulfate is dissolved in deionized water, a solution A is prepared, stannic chloride pentahydrate is dissolved in the equal amount of deionized water, and a solution B is prepared; 2), the solution B is dropwise added to the solution A, a solution C is obtained, hexadecyl trimethyl ammonium chloride is gradually added to the solution C, and a solution D is obtained; 3), the solution D is subjected to ultrasonic oscillation in an ultrasonic generator; 4), pH of the mixed solution D after ultrasonic oscillation treatment is regulated, and a solution E is prepared; 5), the solution E is subjected to a hydrothermal reaction; 6), after the reaction, a precursor is taken out, centrifugally washed with ionized water and anhydrous ethanol and then subjected to freeze drying, and the SnS2 sodium-ion battery anode material with the cubic structure is obtained. The preparation method is low in preparation cost, simple to operate and short in preparation cycle, and the prepared SnS2 sodium-ion battery anode material with the cubic structure has excellent charge-discharge rate performance.

Owner:SHAANXI UNIV OF SCI & TECH

Active material, electrode, secondary battery, battery pack, and vehicle

ActiveCN108630907AIncrease energy densityExcellent charge and discharge rate performanceAlkaline earth titanatesAlkali titanatesHigh energyCrystal structure

The embodiment of the invention relates to an active material, an electrode, a secondary battery, a battery pack, and a vehicle. The invention provides the active material of the secondary battery which can achieve both high energy density and excellent charge-discharge rate performance, the electrode including the active material, the secondary battery including the electrode, the battery pack equipped with the secondary battery, and the vehicle equipped with the battery pack. According to one approach, an active material including a composite oxide is provided. The composite oxide has a monoclinic crystal structure and is represented by the general formula LiwM12-xTi8-yM2zO17+delta , wherein: M1 is at least one selected from the group consisting of Cs, K, and Na; M2 is at least one selected from the group consisting of Zr, Sn, V, Nb, Ta, Mo, W, Fe, Co, Mn, and Al; 0 <=w <=10; 0 < x < 2; 0 < y < 8; 0 < z < 8; and -0.5 <=delta <=0.5.

Owner:KK TOSHIBA

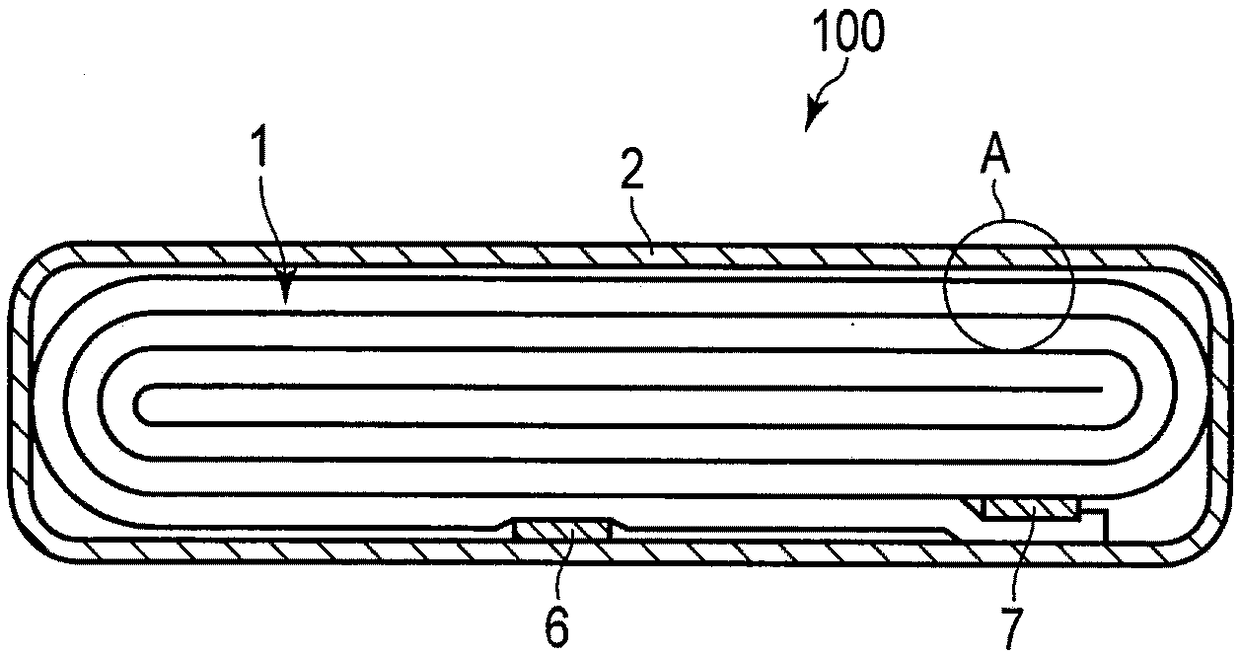

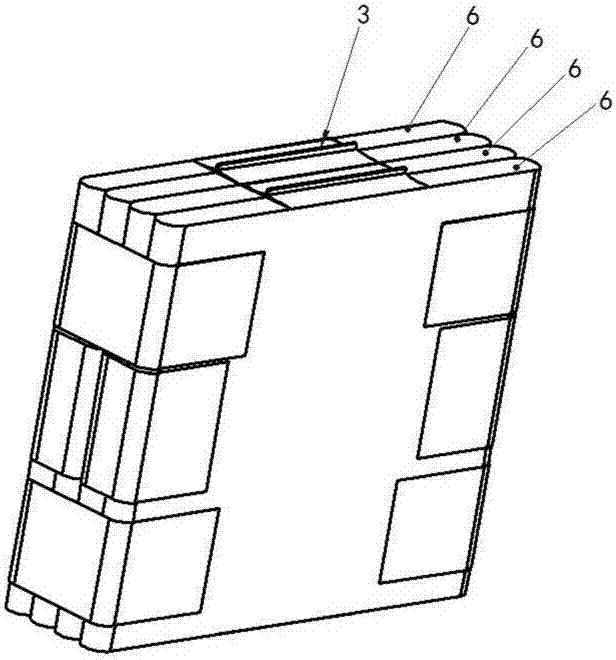

Lithium ion battery with positive electrode and negative electrode in same-side arrangement and manufacturing method thereof

PendingCN107195957ASolve Welding ProblemsHigh capacity densityFinal product manufactureElectrolyte accumulators manufactureEngineeringLithium-ion battery

The application discloses a lithium ion battery with a positive electrode and a negative electrode arranged at the same side and a manufacturing method thereof. The lithium ion battery comprises a shell with an opening structure at an upper end, a naked cell held in the shell and provided with lugs at the left side and the right side, and a shell cover arranged at the upper opening of the shell and provided with poles at the left side and the right side; one end of the pole extends into the shell, and a lug connecting seam corresponding to the lug is formed on the pole extending into the shell; the lug extends into the lug connecting seam on the pole, and the lug is connected with the pole through the friction-stir welding process; the shell cover and the shell are connected together through the friction-stir welding process. By using the lithium ion battery disclosed by the application, the battery production efficiency and yield are improved, the battery capacity and the energy density are improved, the welding quality and the battery rate discharge performance are promoted, and the equipment input cost in the battery production process is lowered.

Owner:GEESUN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com