Three-dimensional hollow carbon foam electrode materials, preparation method of three-dimensional hollow carbon foam electrode materials and application of three-dimensional hollow carbon foam electrode materials

A three-dimensional hollow electrode material technology, applied in the field of electrochemical energy storage, can solve the problems of small specific surface area and pore volume, cumbersome synthesis steps, uneven pore size distribution, etc., and meet the requirements of mild reaction conditions, high specific surface area, and high-efficiency reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

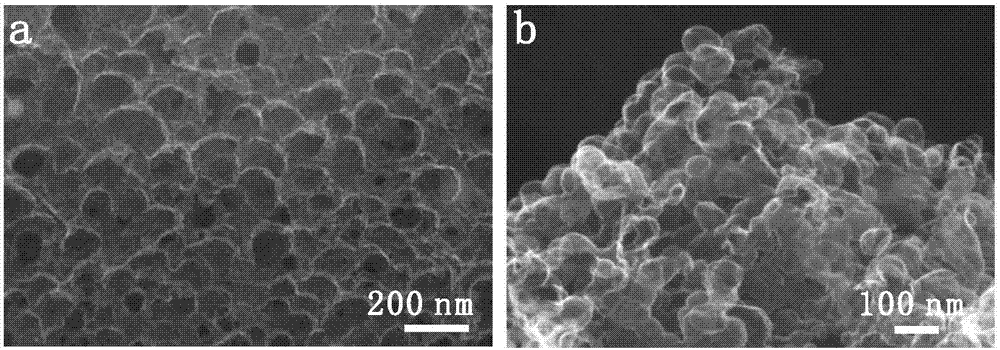

[0043] Such as figure 1 As shown, a preparation method of a three-dimensional hollow carbon foam electrode material with a multi-scale pore structure, the preparation process includes the following steps:

[0044] 1) Preparation of the reactant: mix 11.8996 g of zinc nitrate and 12.6084 g of citric acid (molar ratio of 1:1.5), add deionized water, stir well to make it completely dissolved.

[0045] 2) Place the solution obtained in step 1) on an electric furnace, and heat until the solution boils until a yellow viscous gel-like product is obtained.

[0046] 3) The viscous gel-like product obtained in step 2) is placed in a muffle furnace and annealed at 400° C. The annealing time lasts for 2 hours to obtain an off-white solid product with a multi-scale pore structure.

[0047] 4) Place the product obtained in step 3) in a tube furnace, and use nitrogen as a carrier gas to load ethanol into the tube furnace at a uniform speed. The furnace temperature is maintained at 500°C to carry out ...

Embodiment 2

[0051] A preparation method of a three-dimensional hollow carbon foam electrode material with a multi-scale pore structure. The preparation process includes the following steps:

[0052] 1) Preparation of reactant: mix zinc nitrate and citric acid in a molar ratio of 1:2, add deionized water, and stir thoroughly to make it completely dissolved.

[0053] 2) Place the solution obtained in step 1) on an electric furnace, and heat until the solution boils until a yellow viscous gel-like product is obtained.

[0054] 3) The viscous gel-like product obtained in step 2) is placed in a muffle furnace and annealed at 400° C. The annealing time lasts for 2 hours to obtain an off-white solid product with a multi-scale pore structure.

[0055] 4) Place the product obtained in step 3) in a tube furnace, and use nitrogen as a carrier gas to load ethanol into the tube furnace at a uniform speed. The furnace temperature is maintained at 500°C to carry out the ethanol catalytic decomposition reaction. ...

Embodiment 3

[0061] A preparation method of a three-dimensional hollow carbon foam electrode material with a multi-scale pore structure. The preparation process includes the following steps:

[0062] 1) Preparation of reactant: mix zinc nitrate and sucrose in a molar ratio of 1:1.5, add deionized water, and stir thoroughly to make it completely dissolved.

[0063] 2) Place the solution obtained in step 1) on an electric furnace, and heat until the solution boils until a yellow viscous gel-like product is obtained.

[0064] 3) The viscous gel-like product obtained in step 2) is placed in a muffle furnace and annealed at 400° C. The annealing time lasts for 2 hours to obtain an off-white solid product with a multi-scale pore structure.

[0065] 4) Place the product obtained in step 3) in a tube furnace, and use nitrogen as a carrier gas to load ethanol into the tube furnace at a constant rate. The furnace temperature is maintained at 500 to carry out the ethanol catalytic decomposition reaction. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com