Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Control aperture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asymmetrically-structural ceramic ultrafiltration membrane and preparation method thereof

ActiveCN101791524AHigh porosityUniform pore sizeSemi-permeable membranesUltrafiltrationDefoaming Agents

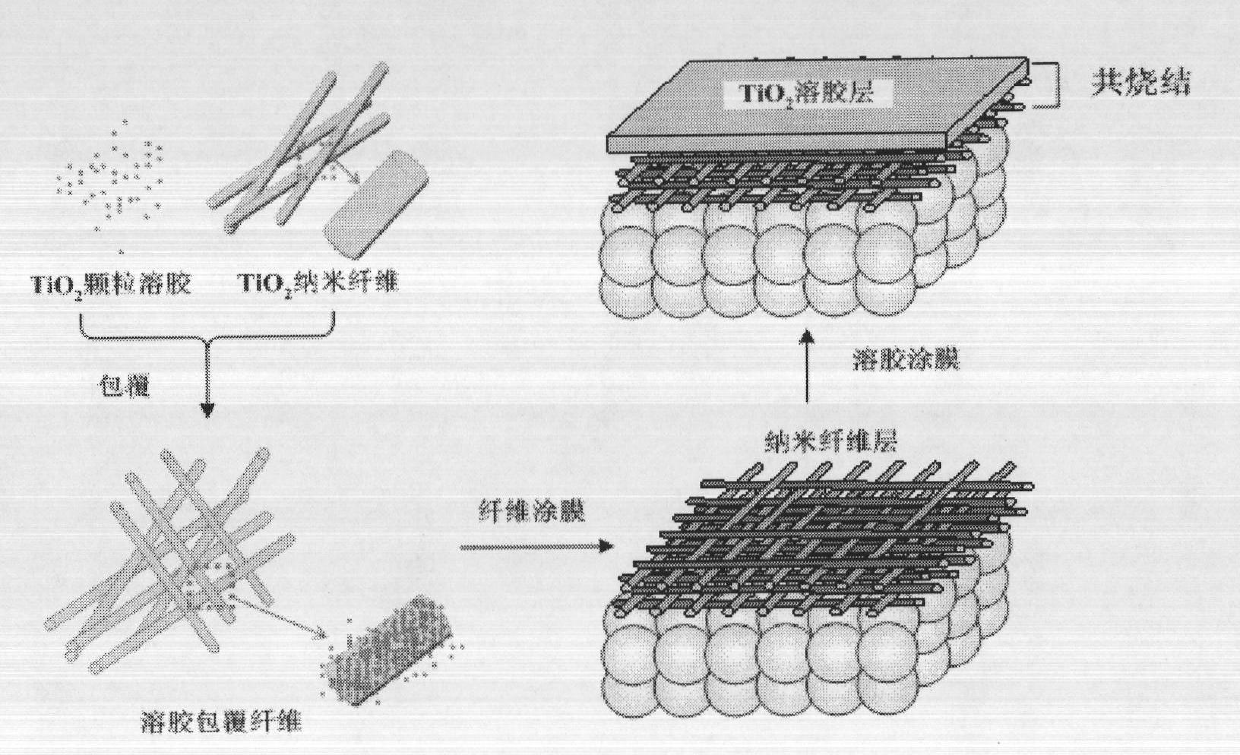

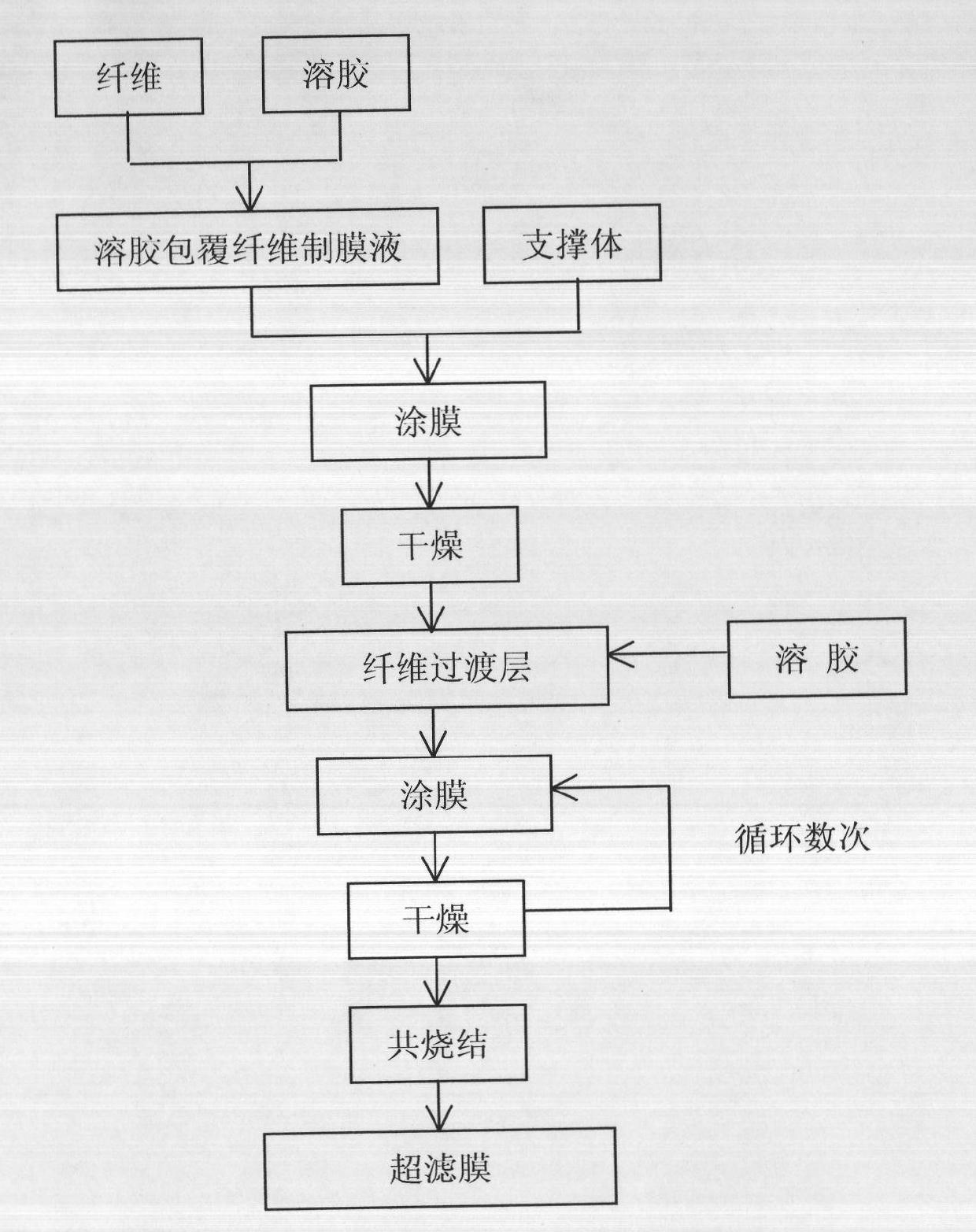

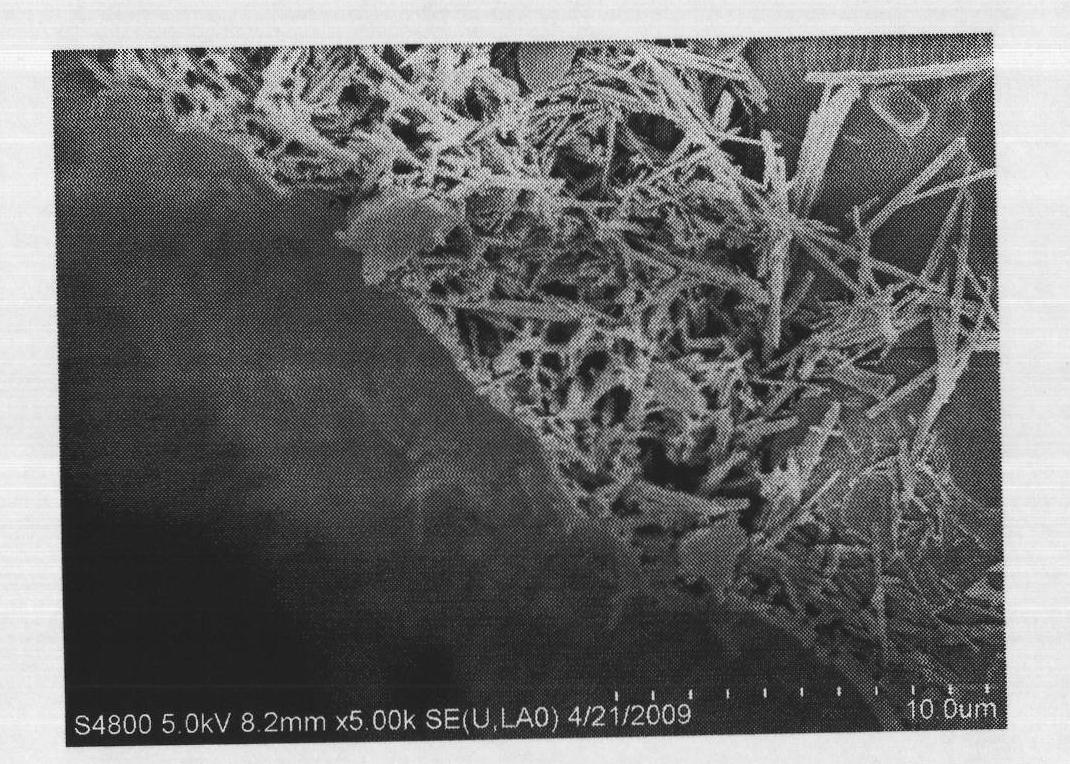

The invention relates to an asymmetrically-structural ceramic ultrafiltration membrane and a preparation method thereof, wherein the preparation method thereof comprises the steps: dispersing one-dimensional fibrous material in sol and sufficiently mixing the material with the gel; by adding deionized water, controlling the weight ratio of gel particle to fiber in membrane preparing solution in a range from 0.01 to 0.4, adjusting pH value of the solution, adding dispersing agent, thickening agent and defoaming agent to formulate the membrane preparing solution, coating membrane on a porous support body and drying the porous support body to form a transition layer; coating the gel-containing membrane preparing solution on the surface of the transition layer, air-drying, oven-drying and roasting the wet membrane, and naturally cooling the membrane to result in the asymmetrically-structural ceramic ultrafiltration membrane. Since the transition layer is composed of fiber and sintering is promoted through the gel, resistance of the transition layer is advantageously lessened and interior combination strength of the transition layer is enhanced; the fiber-constructed transition layer divides large pores into small pores to provide larger total porosity and flowing pore channel, thus high permeation flux is maintained while high selectivity is obtained.

Owner:NANJING UNIV OF TECH

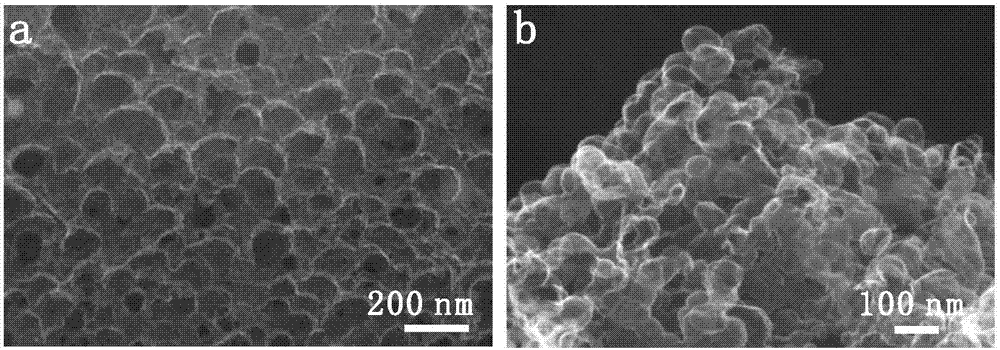

Uniform fluorescent microball and preparation method

ActiveCN102492428ASmall sizeControl apertureLuminescent compositionsMicroballoon preparationMicrosphereFluorescence

The invention discloses a uniform fluorescent microball and a preparation method. The preparation method includes the following steps: (1) preparing porous polymer microballs with uniform particle diameter and hole diameter in advance; (2) compounding quantum dots in the polymer microballs prepared in the step (1) so as to obtain quantum-dot polymer composite microballs; and (3) dispersing the quantum-dot polymer composite microballs prepared in the step (2) into ethanol / water mixed solution and adding ethyl silicate to prepare the fluorescent microball with the surface covered by silicon dioxide. The particle diameter of the fluorescent microball prepared by the above preparation method ranges from 500nm to 100 mu m and is uniform and controllable, and the fluorescent microball is high in fluorescent efficiency and stable in chemical property and has potential application value in the bioinstrumentation and medical fields.

Owner:WUXI ZODOLABS BIOTECH

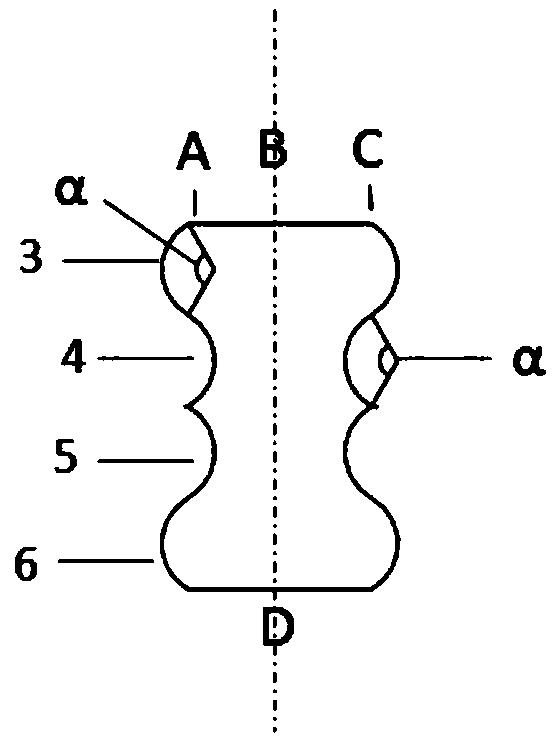

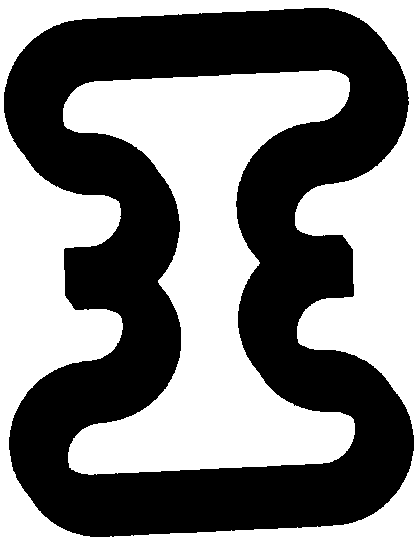

4D-printing shape-memory-polymer-composite-material tracheal stent and preparing method thereof

The invention discloses a 4D-printing shape-memory-polymer-composite-material tracheal stent and a preparing method thereof, and belongs to the technical field of 4D printing. As for the problem thata traditional tracheal stent is difficult to implant, and the secondary stricture problem caused by the overlarge hole diameter of the tracheal stent, and the problem that as the hole diameter of thetracheal stent is over small, swinging of airway cilia is blocked, a compound of a shape memory polymer and nanometer iron oxide serves as a material, a curve-edge rectangle serves as a basic unit, and a tracheal-stent three dimensional structure model is designed; the tracheal-stent three dimensional structure is printed and formed with the fused deposition or direct writing printing method, is subjected to electrostatic spinning medicine carrying covering, and then is subjected to in-vitro remote excitation so that the shape of the stent is recovered, and a formed tracheal stent is obtained.The 4D-printing shape-memory-polymer-composite-material tracheal stent and the preparing method thereof are suitable for production of the tracheal stent.

Owner:HARBIN INST OF TECH

Preparation method of ceramic microfiltration membrane by using attapulgite nano fibers as separating layer

ActiveCN102179184ALarge total porosityHigh selectivitySemi-permeable membranesFully developedNanofiber

The invention discloses a preparation method of a ceramic microfiltration membrane by using attapulgite nano fibers as a separating layer, which is characterized by comprising the steps of: A, dispersing the attapulgite nano fibers in deionized water, adding a dispersing agent, a thickening agent and a defoaming agent to prepare a membrane solution; B, coating a membrane on a porous support body,and airing the wet membrane and drying; and C, roasting at a temperature of 400-800 DEG C for 1-6h, and naturally cooling to obtain a dual-layer ceramic microfiltration membrane. A separation layer of the ceramic microfiltration membrane consists of the attapulgite nano fibers. When a sieve mesh structure is formed, in the attapulgite nano fibers, macropores are separated into micropores to form communicated pore canals, thus the special nano fiber structure of the attapulgite is fully developed, larger total porosity and circulating pores are provided, and high penetration flux is maintainedwhile high selectivity is obtained.

Owner:HUAIYIN TEACHERS COLLEGE

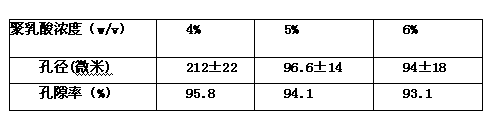

Method for preparing polylactic acid porous support material

The present invention discloses a method for preparing polylactic acid porous support material. By changing the conditions in the preparation process, such as ratio of dioxane and water, concentration of a polylactic acid solution, coarsening temperature, coarsening time, and the number of the coarsenings, the micromorphological structure of a porous support such as pore size, pore morphology and porosity can be effectively controlled. The pore size of 5-400 microns is controllable, breaking material pore size ceiling of 200 microns by the conventional thermally induced phase separation. The method has a very important significance for the preparation of porous tissue engineering materials.

Owner:XIAN REJE BIOLOGICAL TECH

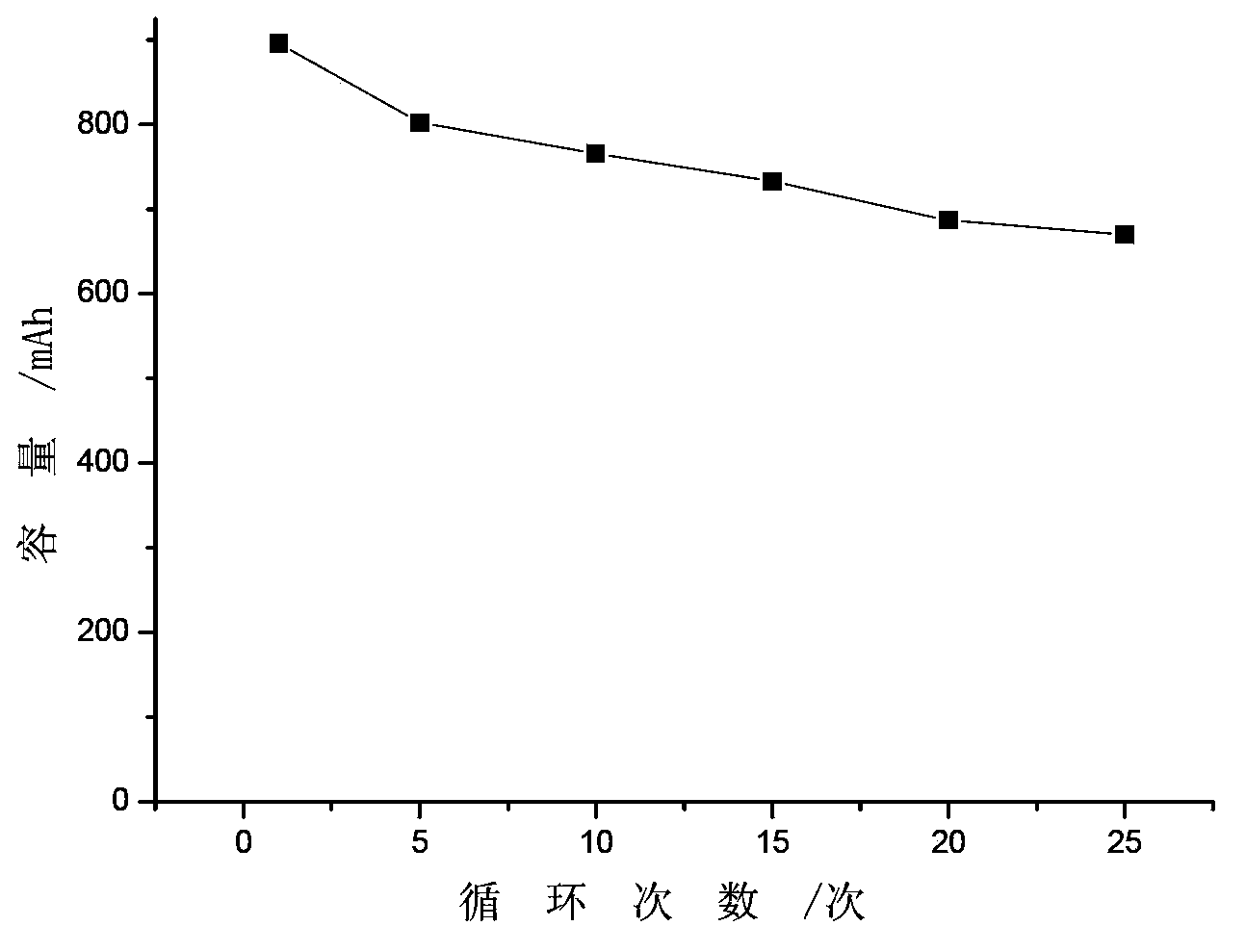

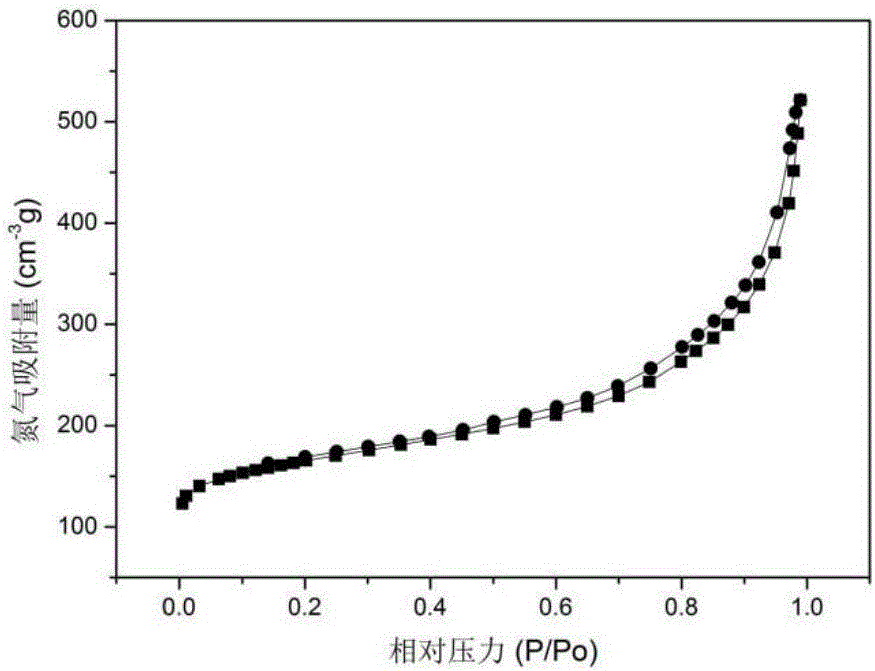

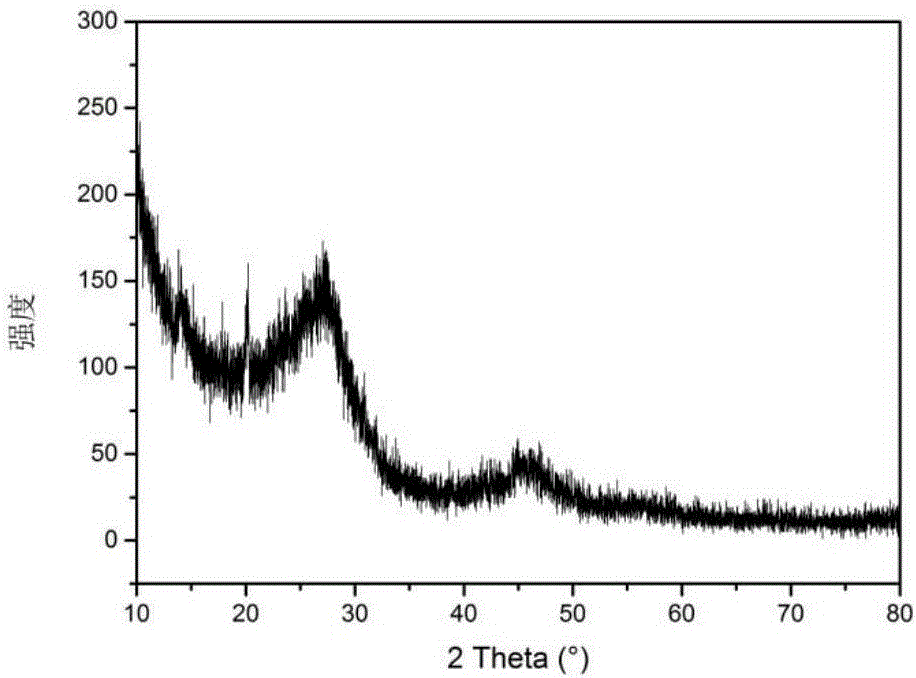

Silicon-carbon composite nano-tube preparation method

ActiveCN104979539AThe removal process is simple and thoroughGood lookingMaterial nanotechnologyCell electrodesCarbon compositesSolvent

The present invention discloses a silicon-carbon composite nano-tube preparation method, which comprises: dissolving zinc oxide nano-rods in a solvent, adjusting to achieve an alkaline state, mixing with tetraethyl orthosilicate, reacting, carrying out centrifugation drying to obtain a silicon dioxide coated core-shell structure material, recording as ZnO@SiO2, adding the ZnO@SiO2 to a reactor, heating in the presence of an inert gas, introducing acetylene gas, reacting, depositing a carbon coating layer on the silicon dioxide coated core-shell structure material surface, recording as ZnO@SiO2@C, carrying out a magnesium thermal reduction reaction on the ZnO@SiO2@C, removing the zinc oxide nano-rod template, and carrying out a post-treatment to obtain the silicon-carbon composite nano-tubes. According to the present invention, the zinc oxide nano-rods are adopted as the template to prepare the silicon-carbon composite nano-tubes, the preparation process is simple, the template removing is convenient and complete, the large-scale industrial production is easily achieved, and the new approach for synthesizing other types of the nano-tubes is provided.

Owner:浙江锂宸新材料科技有限公司

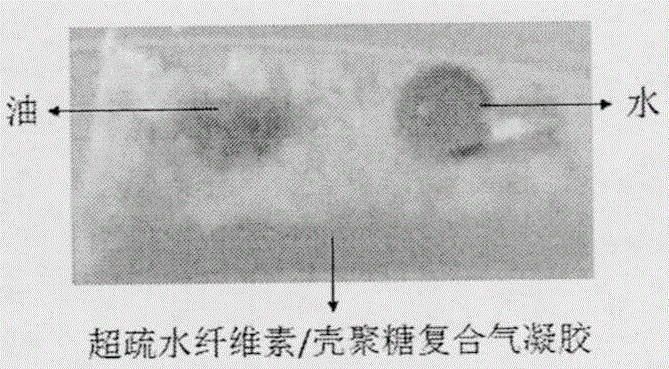

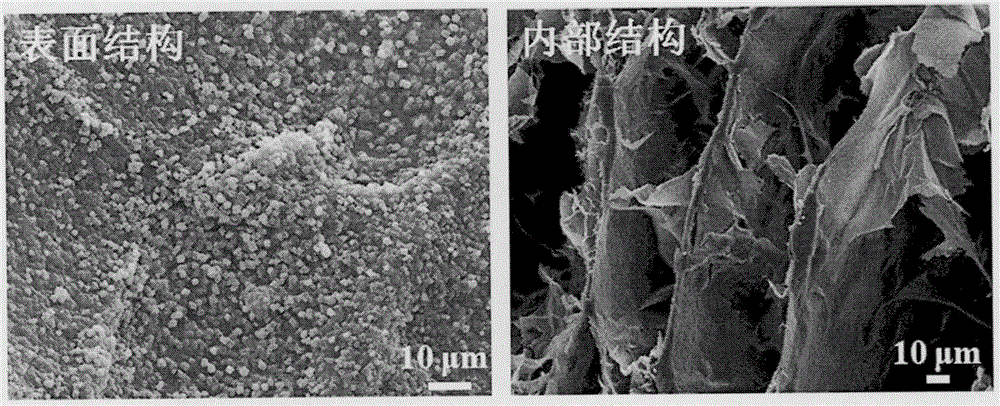

Preparation method of super-hydrophobic cellulose/chitosan compound aerogel oil-water separation material

ActiveCN105709695AControl apertureControl porosity sizeOther chemical processesAlkali metal oxides/hydroxidesPorosityCellulose

The invention relates to a preparation method of a super-hydrophobic cellulose / chitosan compound aerogel oil-water separation material. The method includes the first step of cellulose / chitosan compound solution preparation, the second step of cellulose / chitosan compound aerogel preparation, and the third step of super-hydrophobic cellulose / chitosan compound aerogel preparation. Prepared cellulose / chitosan compound aerogel has a high pore rate, the surface of the cellulose / chitosan compound aerogel has high roughness, the preparation process is simple, and raw materials are wide in source, low in cost, green and environmentally friendly. By means of the related hydrophobic modification method, super-hydrophobic fruit can be rapidly and effectively obtained in an energy-saving mode, and greasy dirt collection, oil-water separation and the like can be economically and rapidly achieved.

Owner:刘 志勇 +3

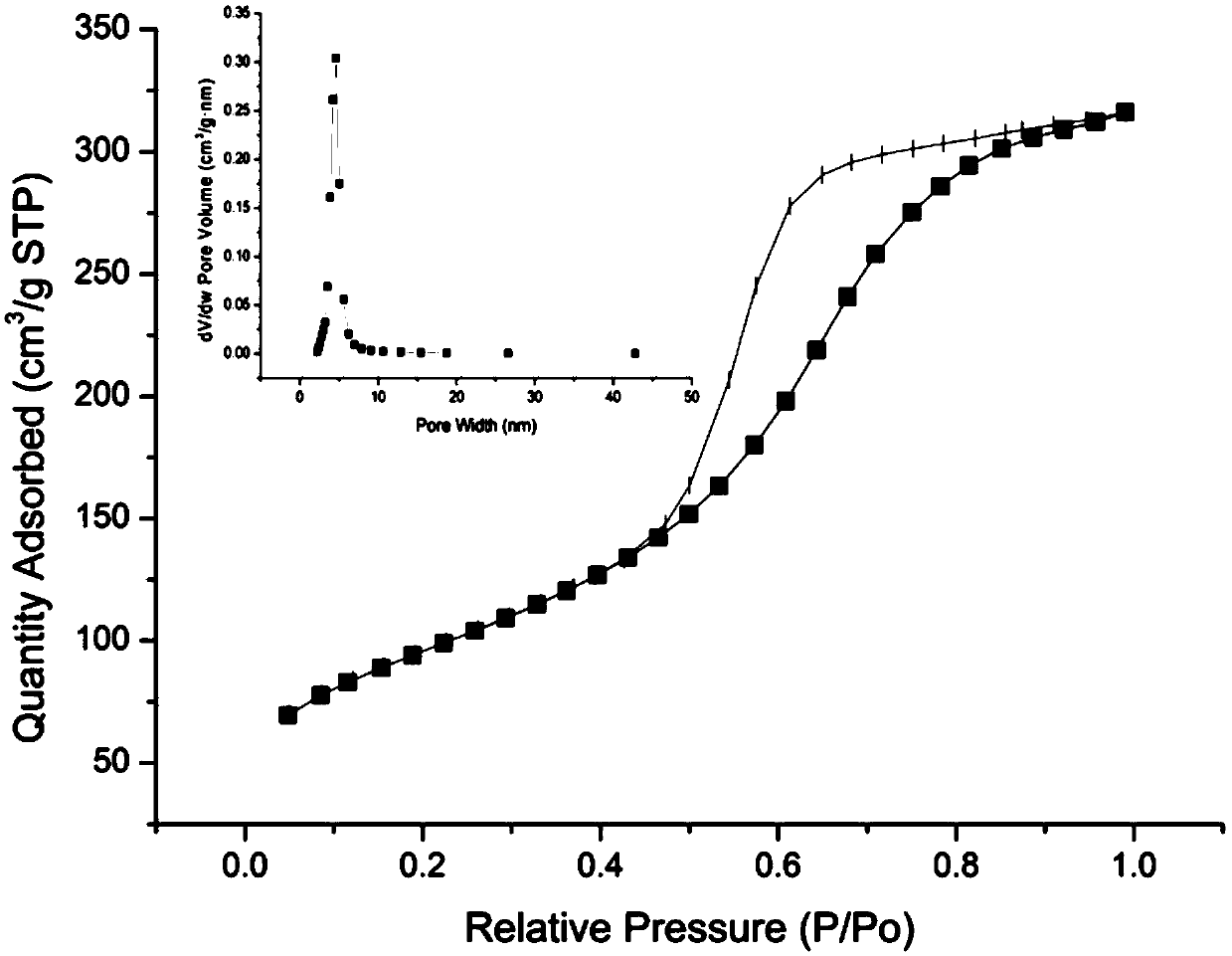

Attapulgite-graphite-like carbon nitride composite ceramic microfiltration membrane with photocatalytic performance and preparation method and application thereof

ActiveCN107008152AHas photocatalytic propertiesHigh selectivityMembranesUltrafiltrationPorosityChemical Linkage

The invention relates to an attapulgite-graphite-like carbon nitride composite ceramic microfiltration membrane with photocatalytic performance and a preparation method thereof and belongs to the field of ceramic membranes. The method comprises the steps of preparing casting solution slurry from titanate coupling agent modified attapulgite and melamine; and preparing a wet membrane of the ceramic microfiltration membrane through a dip-coating method, airing at a room temperature and roasting to prepare the attapulgite-graphite-like carbon nitride composite ceramic microfiltration membrane. A separation layer of the ceramic microfiltration membrane is prepared from attapulgite fibers and graphite-like carbon nitride and the attapulgite fibers are disorderly stacked into the separation layer, so that relatively large total porosity and superficial area are provided for the separation layer; coupling of photocatalysis and separation processes can be achieved by using the photocatalytic performance of the graphite-like carbon nitride, and self-cleaning of the membrane is achieved; and the graphite-like carbon nitride is uniformly and dispersedly immobilized on the surface of attapulgite of the membrane through the chemical bonding effect, so that the disadvantages that granular graphite-like carbon nitride is easy to aggregate, difficult to separate and difficult to reuse in the using process are effectively avoided.

Owner:HUAIYIN TEACHERS COLLEGE

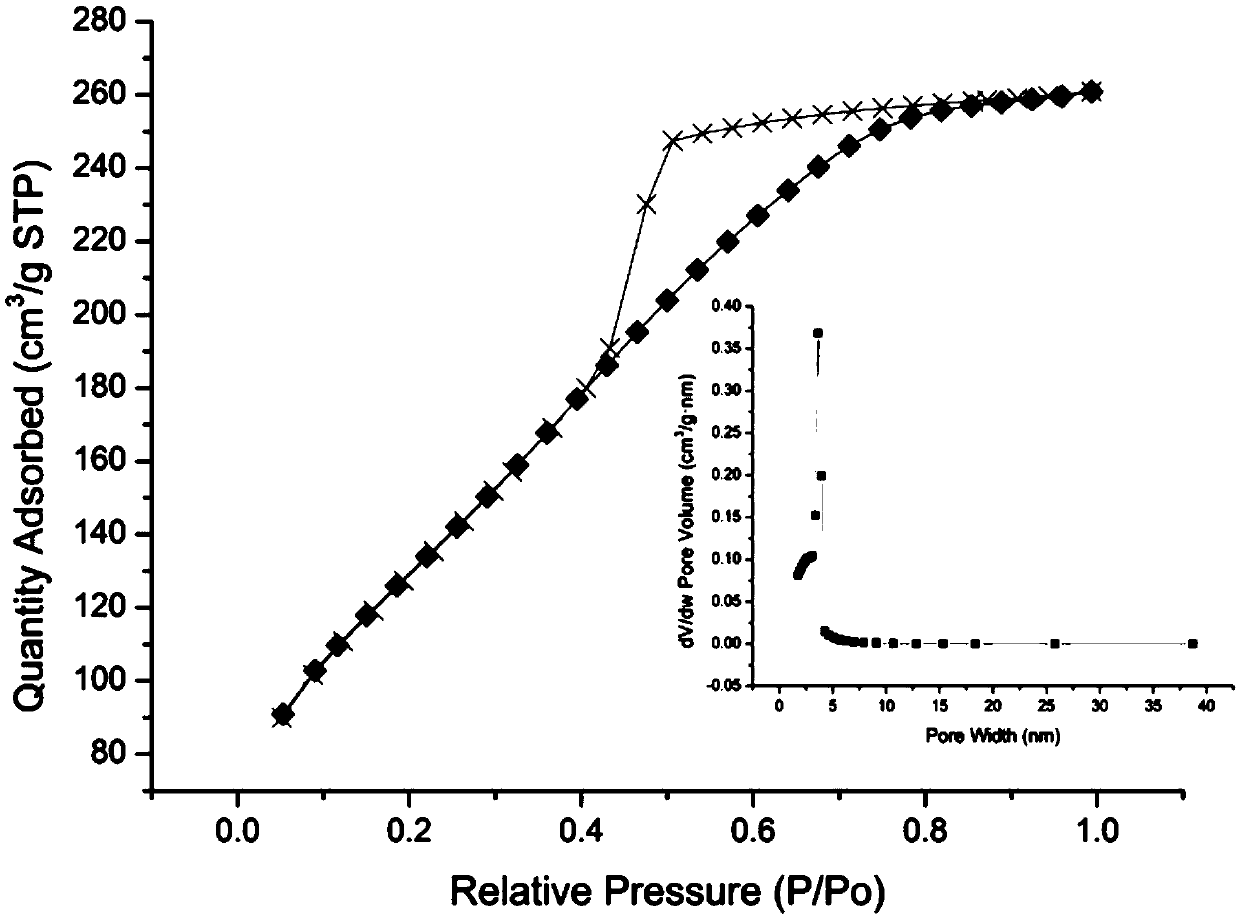

Small-sized metallic oxide nano-cluster/mesoporous SiO2 nanocomposite and preparation method thereof

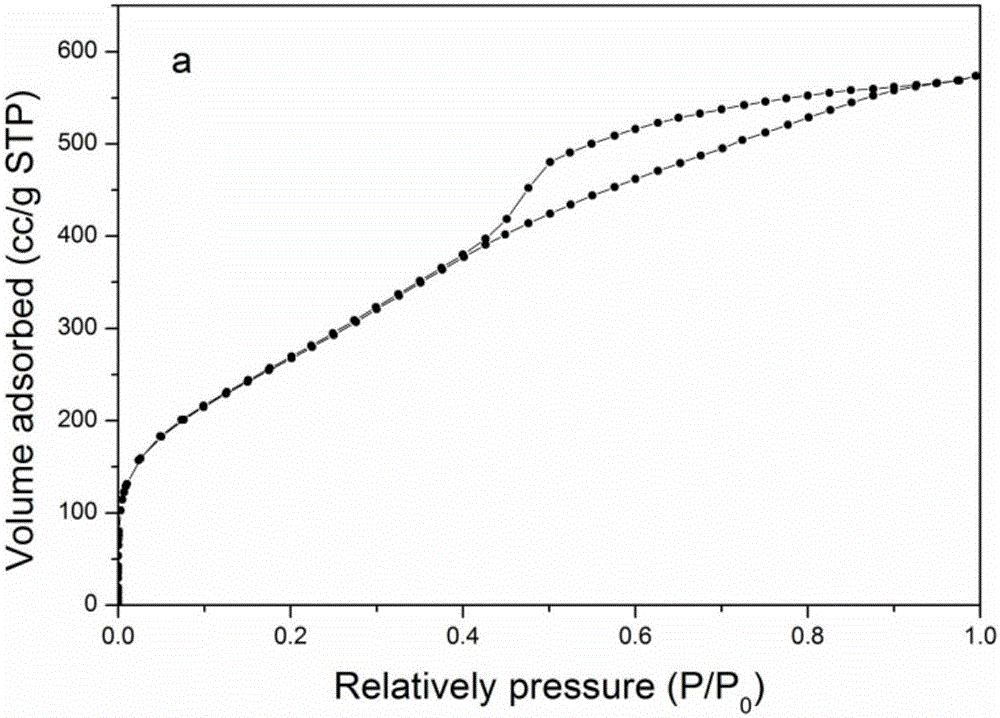

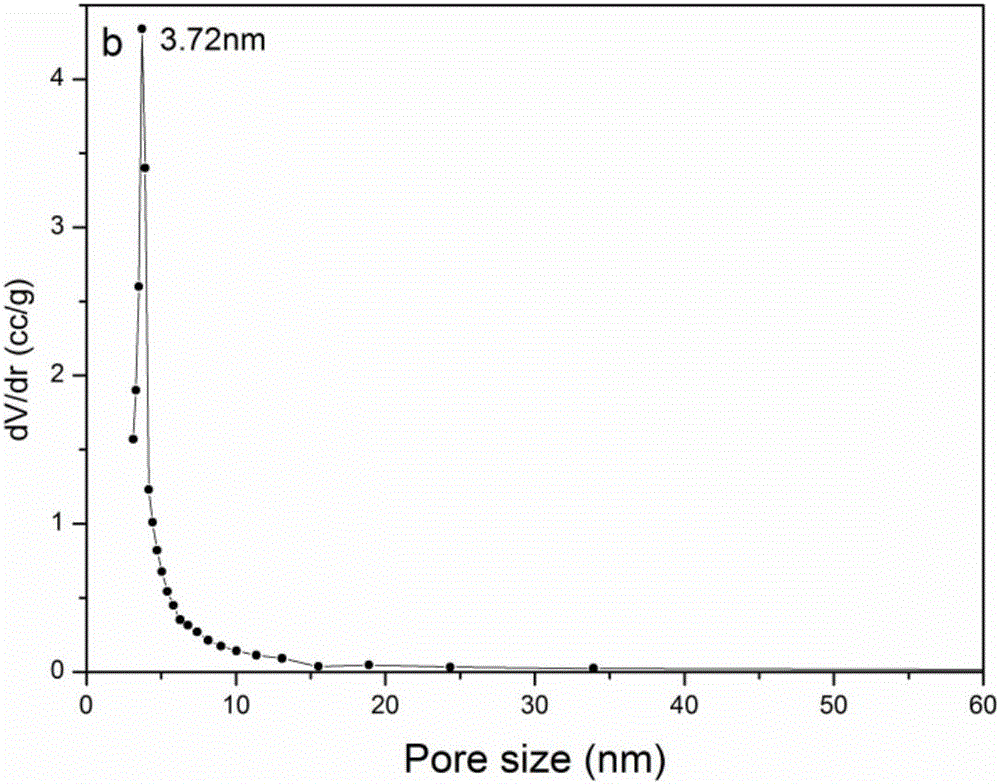

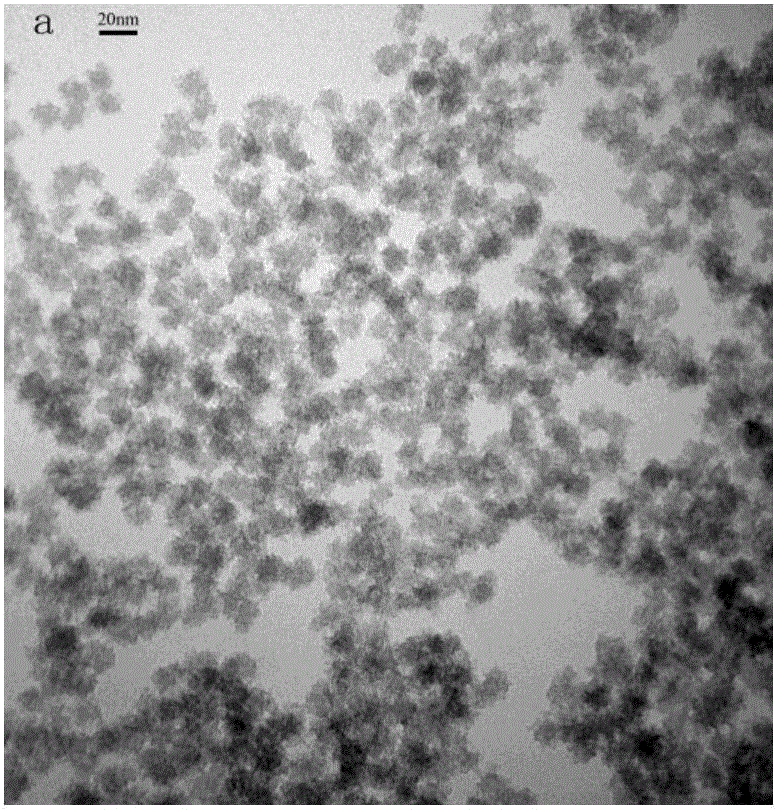

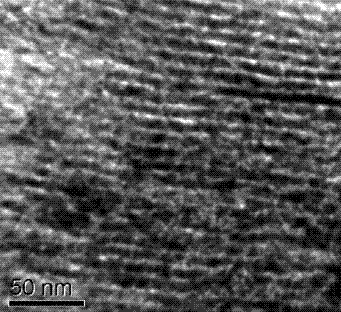

ActiveCN106000391ASimple processSmall sizeMaterial nanotechnologyHydrocarbon oils refiningNano clustersPore diameter

The invention belongs to the field of nanometer material preparation and particularly relates to a small-sized metallic oxide nano-cluster / mesoporous SiO2 nanocomposite and a preparation method thereof. The particle size and the pore diameter of every mesoporous SiO2 nanosphere carrier are 5-30 nm and 2-5 nm respectively; every metallic oxide nano-cluster refers to MoO3 or WO3 and 0.1-2 nm in particle size. A reversed-phase microemulsion method is adopted for synthesis. The preparation method of the small-sized metallic oxide nano-cluster / mesoporous SiO2 nanocomposite is simple in technology, economic and safe; the metallic oxide nano-clusters are highly dispersed on the mesoporous SiO2 carrier, the metallic oxide nano-clusters and the mesoporous SiO2 carrier are controllable in both size and shape, and accordingly the small-sized metallic oxide nano-cluster / mesoporous SiO2 nanocomposite is excellent in catalytic performance.

Owner:DALIAN UNIV OF TECH

Preparation method of order meso porous manganese dioxide/ conductive polyaniline composite material

The invention relates to a preparation method of order meso porous manganese dioxide / conductive polyaniline composite material, which includes the following steps: enabling meso porous silicon oxide as a hard template, combining high order meso porous manganese oxide through a water hot method, mixing the order meso porous manganese oxide and aniline monomer in acid solution, enabling the two to react under the condition of oxidant to obtain the high order meso porous manganese dioxide / conductive polyaniline composite material. The preparation method is simple and easy to implement, regulation and control of specific surface area of the order meso porous manganese dioxide / conductive polyaniline composite material by adjusting combining method of the hard template.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

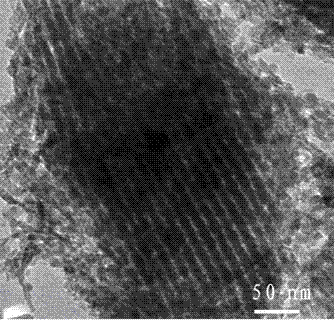

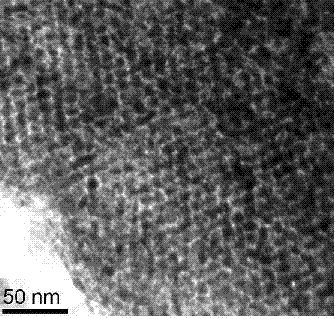

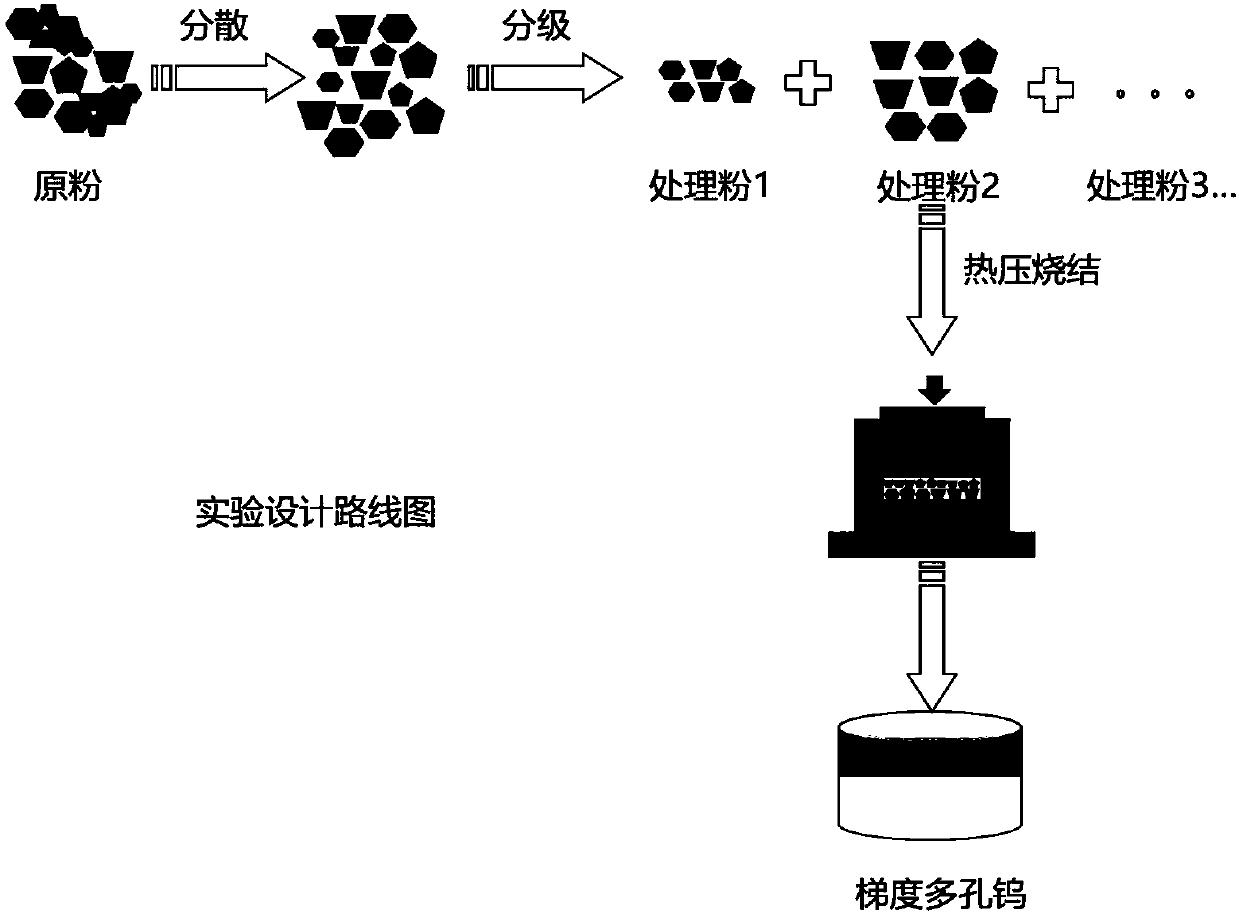

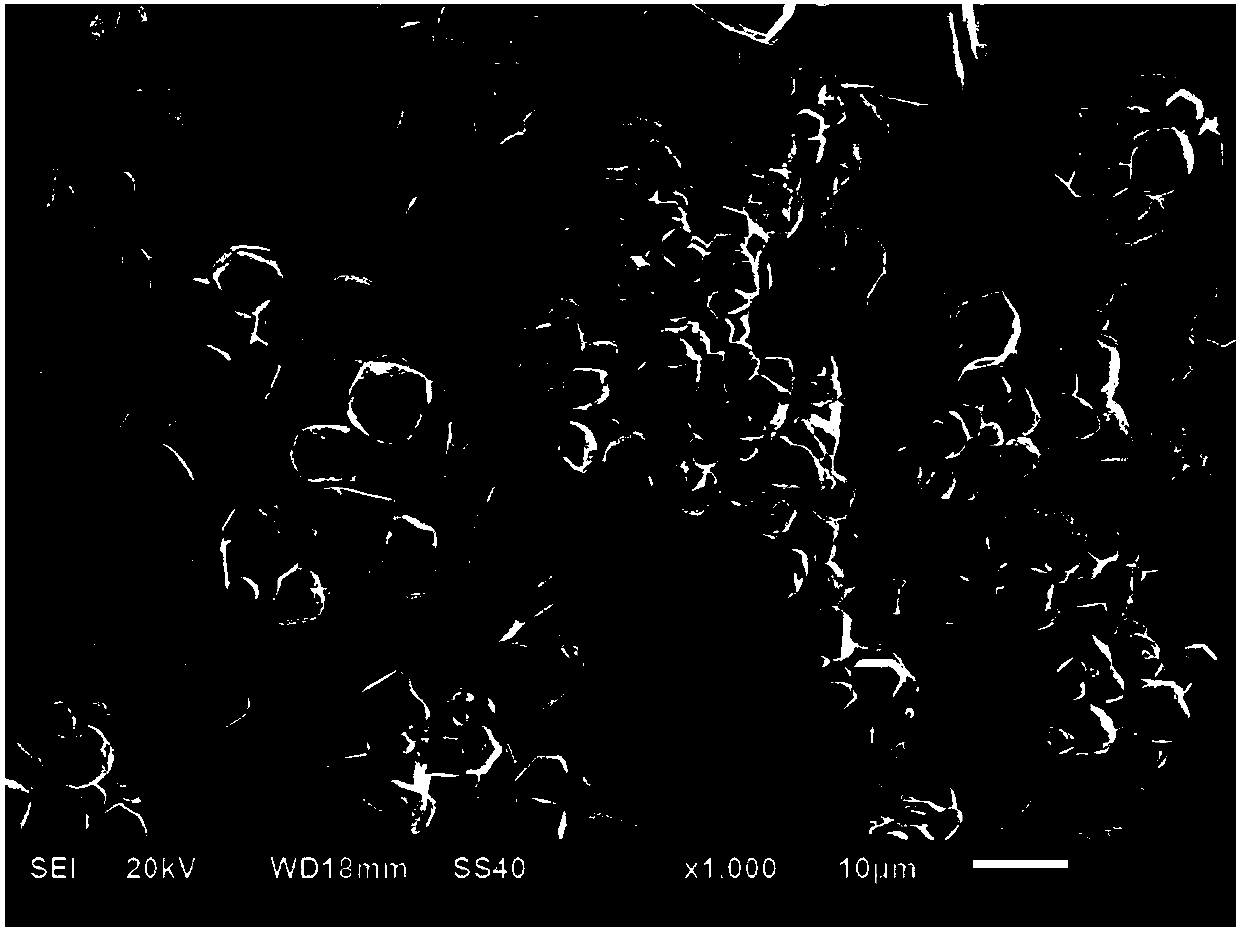

Method for preparing gradient porous tungsten

The invention provides a method for preparing gradient porous tungsten, and belongs to the technical field of porous material preparation. After high-purity tungsten powder is subjected to dispersiontreatment through air flow grinding, aggregates of original tungsten powder can be opened, and completely-dispersed tungsten powder is obtained; and after classification treatment, narrow-size-distribution tungsten powder of different particle sizes can be obtained; and the tungsten powder of different particle sizes is matched after selection treatment, and the gradient porous tungsten can be prepared through powder paving-pressing-sintering or laminating powder paving-hot press sintering. The gradient porous tungsten prepared through the method is controllable in pore property, uniform in size and distribution of pore diameters of various layers and good in pore connectivity. Two or more kinds of powder of different particle sizes are selected to be matched, and the number of layers of afinal gradient porous tungsten product and the pore properties of the layers can be flexibly controlled.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of NiO porous membrane

ActiveCN102251267AMild preparation conditionsReduce manufacturing costAnodisationMuffle furnaceElectrolyte

The invention discloses a preparation method of NiO porous membrane. According to the invention, first, an Ni substrate is pretreated; the pretreated Ni substrate is adopted as an anode, a Pt sheet is adopted as a cathode, a nitric acid solution is adopted as an electrolyte, and an anodic oxidation treatment is carried out for 5min to 30min with an applied voltage of 5V to 25V while the electrolyte is stirred; the Ni substrate processed from the anodic oxidation treatment is washed with deionized water, and is naturally dried in air, such that an Ni substrate with an amorphous NiO porous membrane is obtained; the Ni substrate with the amorphous NiO porous membrane is baked in a muffle furnace, such that an Ni-based crystalline cubic phase NiO porous membrane is obtained. According to the invention, no obvious boundary is between the NiO porous membrane and the substrate material which is the Ni substrate; and bonding strength between the two is high. NiO porous membranes produced withother methods have problems of deformation, efflorescence and peeling during long-term use. With the method provided by the invention, the problems are solved, and the cycling stability of the product is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

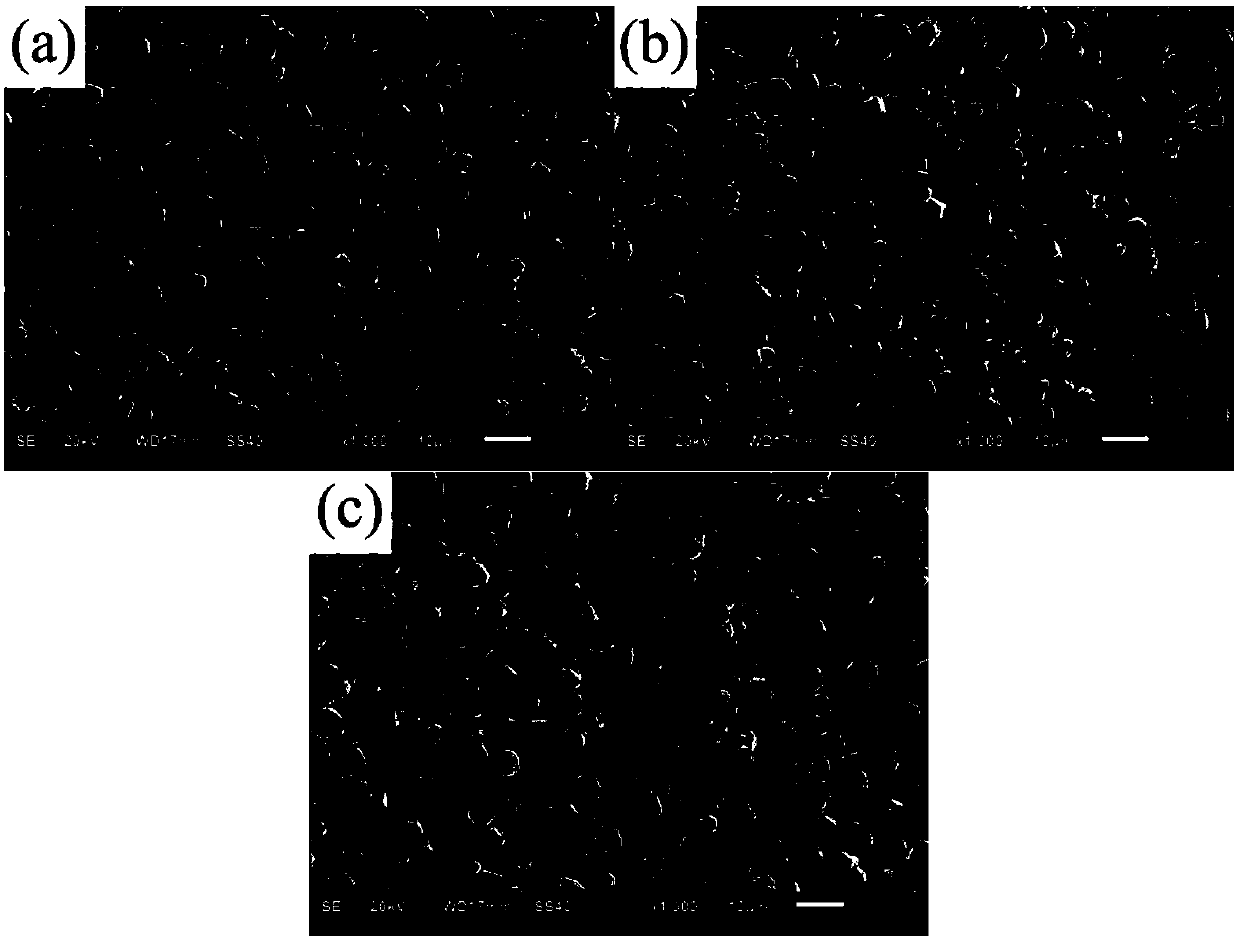

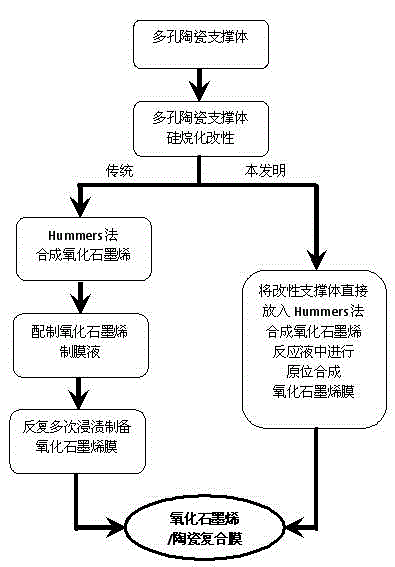

In situ synthesis graphene oxide/porous ceramic composite membrane preparation method

InactiveCN104857860ASolving Dispersion ProblemsInhibition dispersionSemi-permeable membranesOrganic solventSilanes

An in situ synthesis graphene oxide / porous ceramic composite membrane preparation method comprises the following steps: (1) a silane coupling agent is added into an organic solvent for the preparation of a silane modified solution, and the volume ratio of silane coupling agent to organic solvent is 2-5:30-50; (2) a porous ceramic support is put into the silane modified solution for standing for 2-10 hours, under the condition of the temperature of 30-85 DEG C, the porous ceramic support is taken out from the silane modified solution to obtain a silane modified porous ceramic support; (3) the silane modified porous ceramic support is put into a reaction liquid for Hummers method preparation of graphene oxide, a graphene oxide / porous ceramic composite membrane with the thickness value of 80-300 nm is prepared by controlling of the reaction temperature and reaction time, and the graphene oxide / porous ceramic composite membrane is taken out from the reaction liquid, and is died by standing at room temperature to obtain an in situ synthesis graphene oxide / porous ceramic composite membrane.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Preparation method of cheap ultra-filtration membrane for treating oil producing wastewater

ActiveCN104258742ANo post-processingSimple processSemi-permeable membranesWater bathsFiltration membrane

The invention provides a preparation method of a cheap ultra-filtration membrane for treating oil producing wastewater. The preparation method comprises the following steps: dissolving nano silicon dioxide into a polyvinyl chloride dissolving solvent under ultrasonic condition to prepare a suspension solution of nano particles; then sequentially and slowly adding a pore-forming agent, a de-foaming agent and polyvinyl chloride into the suspension solution; continuously and mechanically agitating in a water bath of 30-40 DEG C for more than 24 hours until a homogeneous membrane casting solution is formed; sufficiently de-foaming the membrane casting solution in a vacuum drying box and scraping a membrane by using a membrane scraping machine; after volatilizing the scraped new membrane in the air for 15-60 seconds, slowly putting the scraped new membrane into a coagulating bath for coagulation; and after separating the membrane from a glass plate, sufficiently immersing the membrane in pure water for 48 hours to obtain a nano silicon dioxide modified polyvinyl chloride flat plate membrane. The preparation method of the cheap ultra-filtration membrane can be used for nano silicon dioxide polyvinyl chloride hollow fiber type ultra-filtration membranes and micro-filtration membranes, reverse osmosis membranes, nano-filtration membranes, pipe type membranes, capillary tube membranes or spiral-wound membranes.

Owner:HARBIN ENG UNIV

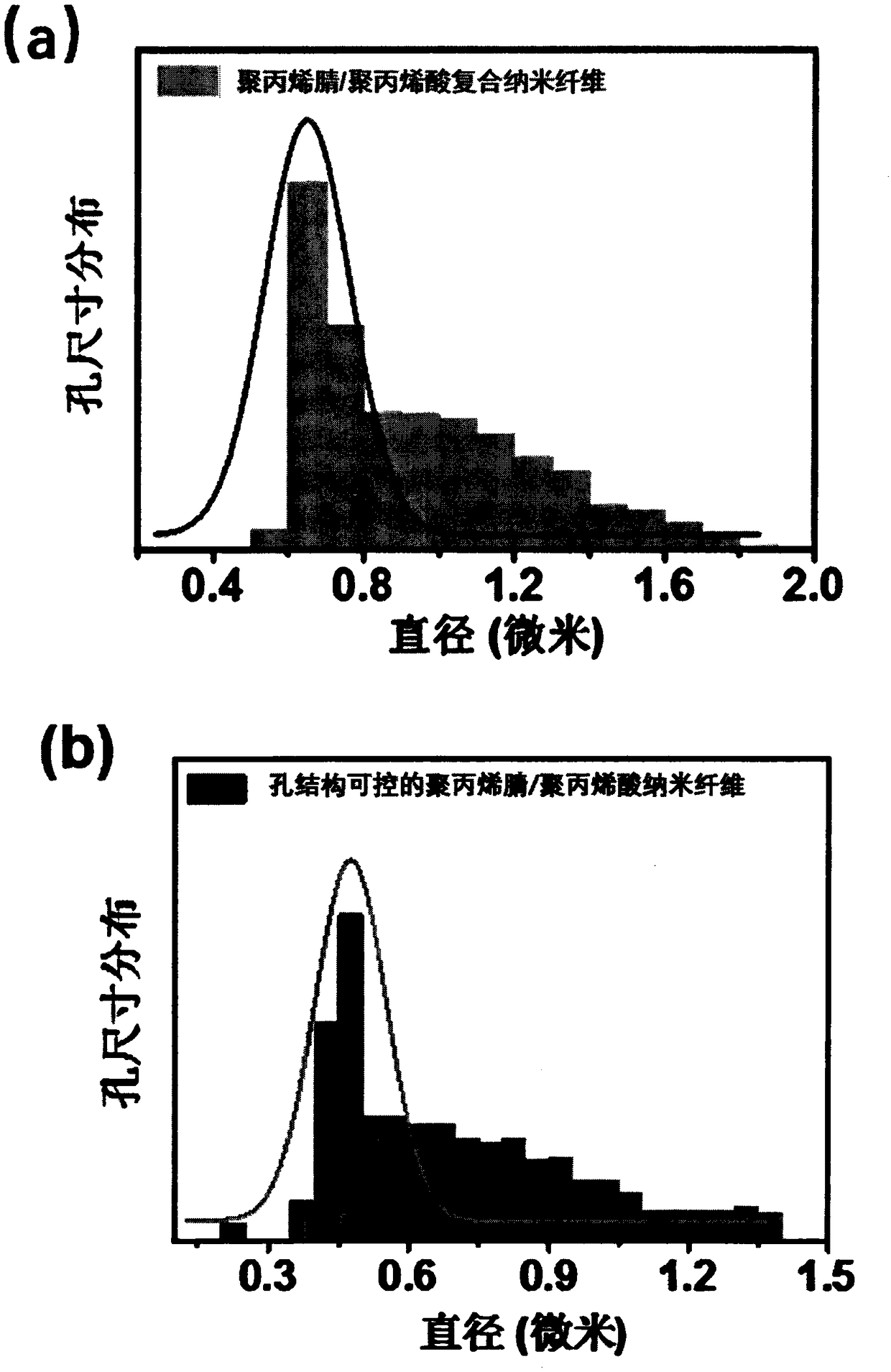

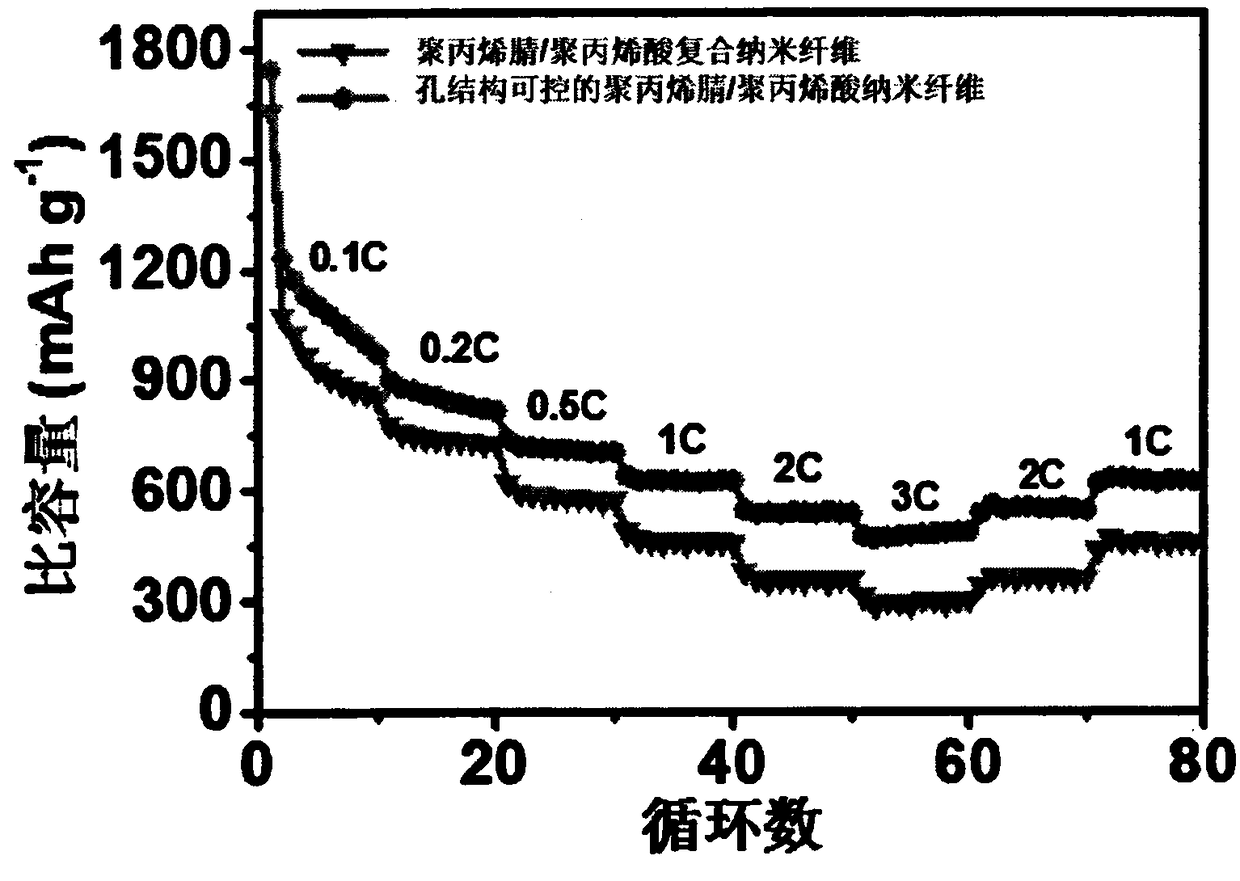

Polyacrylonitrile/polyacrylic acid nanofiber lithium sulfur battery diaphragm with controllable pore structure

InactiveCN108589034AUniform shapeControllable pore structureFibre typesElectro-spinningChemistryNanofiber

The invention provides a polyacrylonitrile / polyacrylic acid nanofiber lithium sulfur battery diaphragm with a controllable pore structure. A preparation method of the polyacrylonitrile / polyacrylic acid nanofiber lithium sulfur battery diaphragm with the controllable pore structure is characterized by comprising the following steps: preparing polyacrylonitrile / polyacrylic acid composite nanofibersby electrospinning; performing ethanol vapor treatment to obtain the polyacrylonitrile / polyacrylic acid composite nanofibers with the controllable pore structure. The prepared composite material has the characteristics of complete fiber morphology, uniform pore size distribution and the like. Polyacrylonitrile can act as a composite nanofiber framework while polyacrylic acid is used as a structurecontrol material of the composite nanofibers. The composite nanofiber diaphragm has the advantages of environmental friendliness, high efficiency, precise regulation of pore size and porosity, stablephysical and chemical properties and the like.

Owner:DONGHUA UNIV

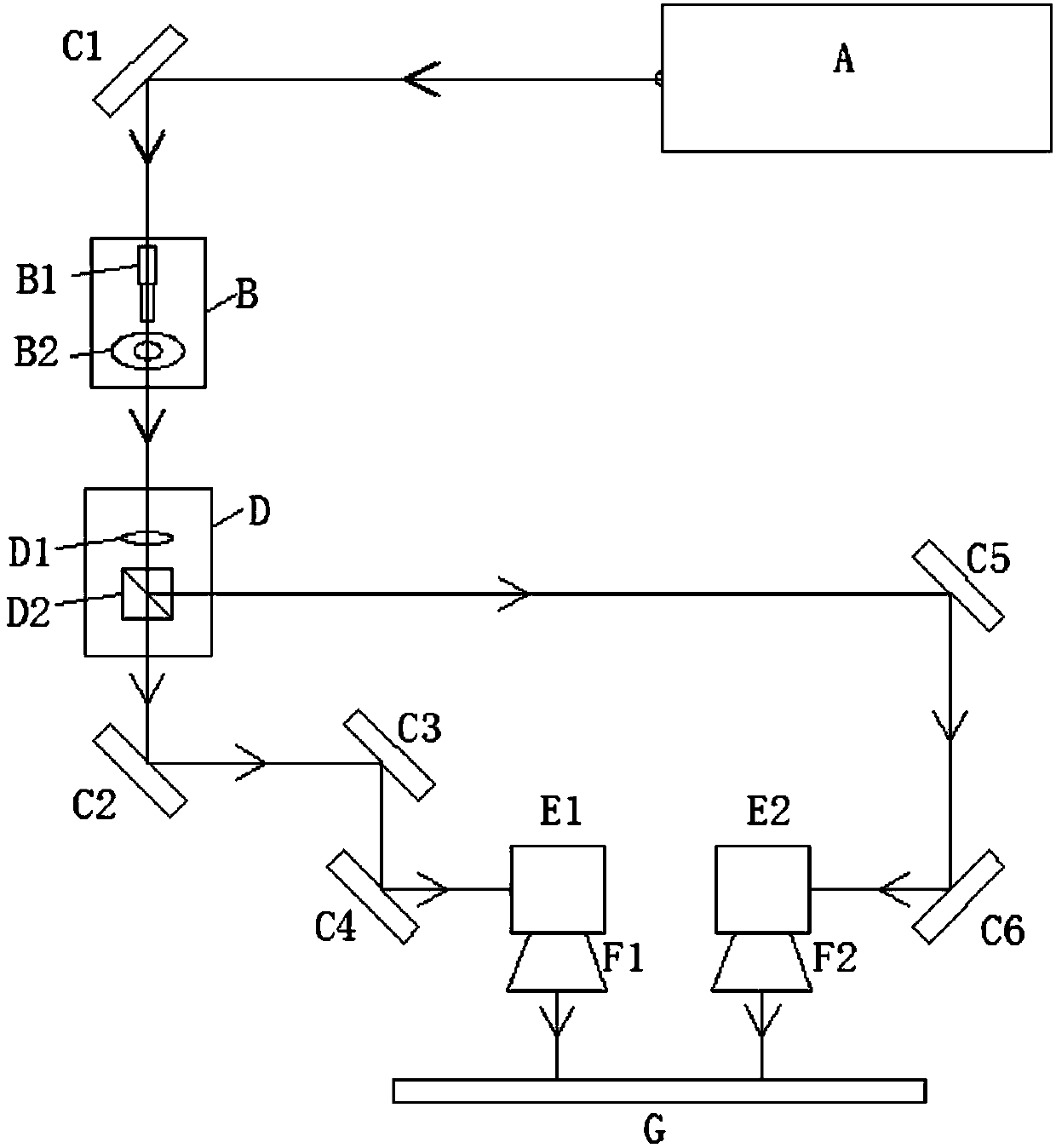

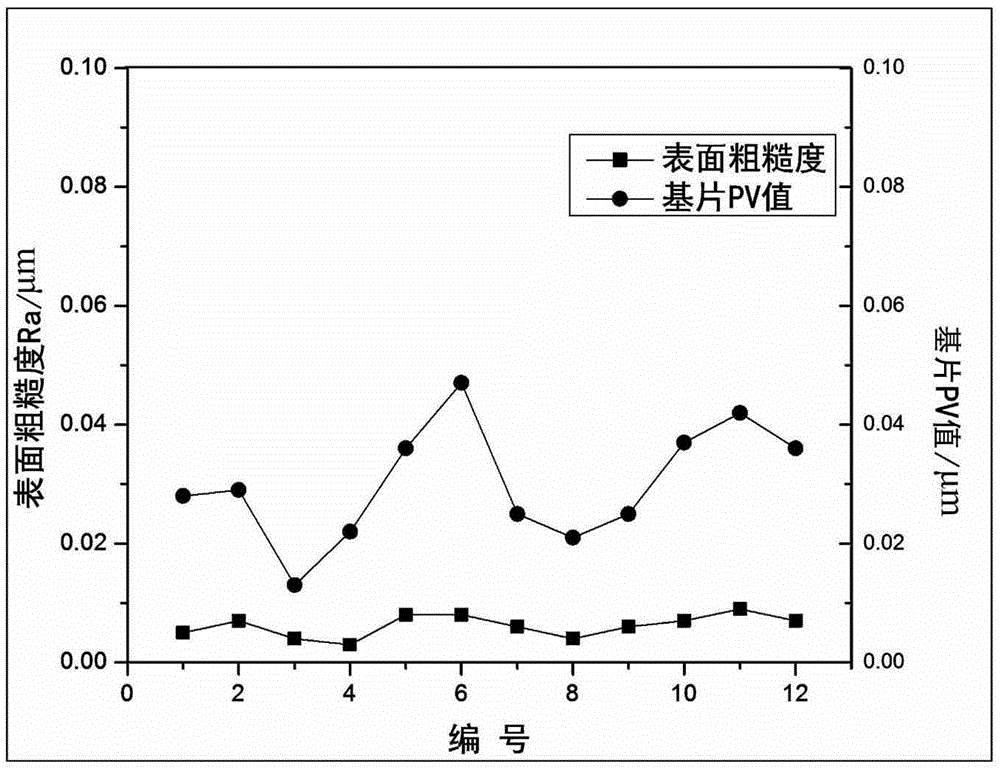

LTCC ultrafast machining system and method thereof

PendingCN108031992ASmall diameterGuaranteed roundnessLaser beam welding apparatusUltrasound attenuationLight beam

The invention relates to a LTCC ultrafast machining system and a method thereof. The system is provided with a laser, a first reflecting unit, a light beam shaping module, an attenuation module, a second reflecting unit, a first scanning unit, a third reflecting unit and a second scanning unit in a light path direction; the laser outputs light beams; the first reflecting unit emits the light beams, output from the laser, into the light beam shaping module; the light beam shaping module expands and filters the light beams; the attenuation module divides incident light into two light beams in aparallel direction and a perpendicular direction; the second reflecting unit emits P polarized light, divided in the horizontal direction, to the first scanning unit; the first scanning unit focuses the light beams reflected by the second reflecting unit, and a field lens is focused on machined objects; the third reflecting unit emits S polarized light, divided in the vertical direction, to the second scanning unit; and the second scanning unit focuses the light beams reflected by the third reflecting unit, and a field lens is focused on the machined objects. A ultrafast green-light picosecondlaser and a matched high-speed galvanometer and optical device are adopted; the diameters of micro through holes on a LTCC substrate are reduced below 50 microns; the roundness of the micro through holes reaches above 95%; and the taper is within 3 microns.

Owner:SUZHOU DELPHI LASER +1

Manufacturing method for super-hard resin grinding wheel

ActiveCN105290996AImprove the dilution effectControl porosityGrinding devicesFirming agentGrinding wheel

The invention discloses a manufacturing method for a super-hard resin grinding wheel. The manufacturing method includes the following steps that firstly, hollow spheres are dried for 0.5-4 h in a drying oven at the temperature of 80-100 DEG C and evenly mixed with diamond and then pass a screen with 100-200 meshes; secondly, epoxy resin liquid is stirred in a water bath with the temperature of 70-80 DEG C for 2-5 minutes, then diluent and a coupling agent are added, after stirring heating is conducted continuously for 5-10 minutes, the obtained mixture of the hollow spheres and the diamond in the first step is added, and stirring heating is conducted continuously for 5-10 minutes; thirdly, the temperature of the water bath in the second step is reduced to 55-60 DEG C, the diluent and a curing agent are evenly mixed and then added to sizing obtained in the second step, the obtained mixture is poured into a mold after even mixing is conducted and hardened for 3-8 h under the temperature of 80-90 DEG C, and then curing is conducted; and fourthly, the material cured in the third step is cooled to the room temperature to be demolded, a grinding wheel ring is obtained, machining is conducted, and the super-hard resin grinding wheel is obtained.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

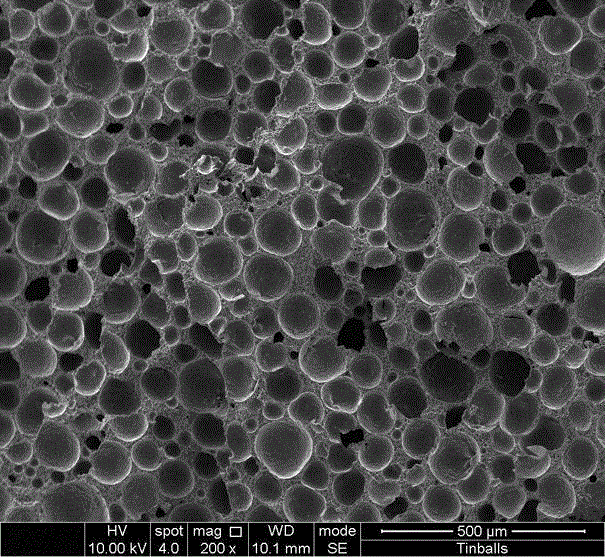

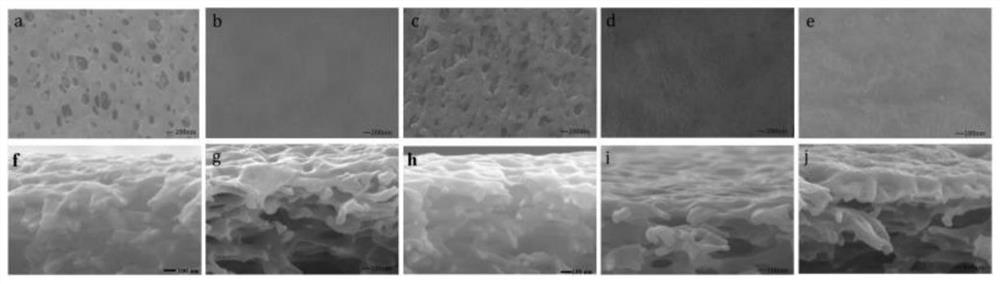

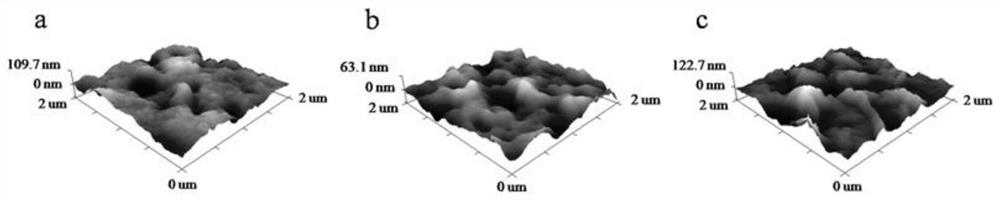

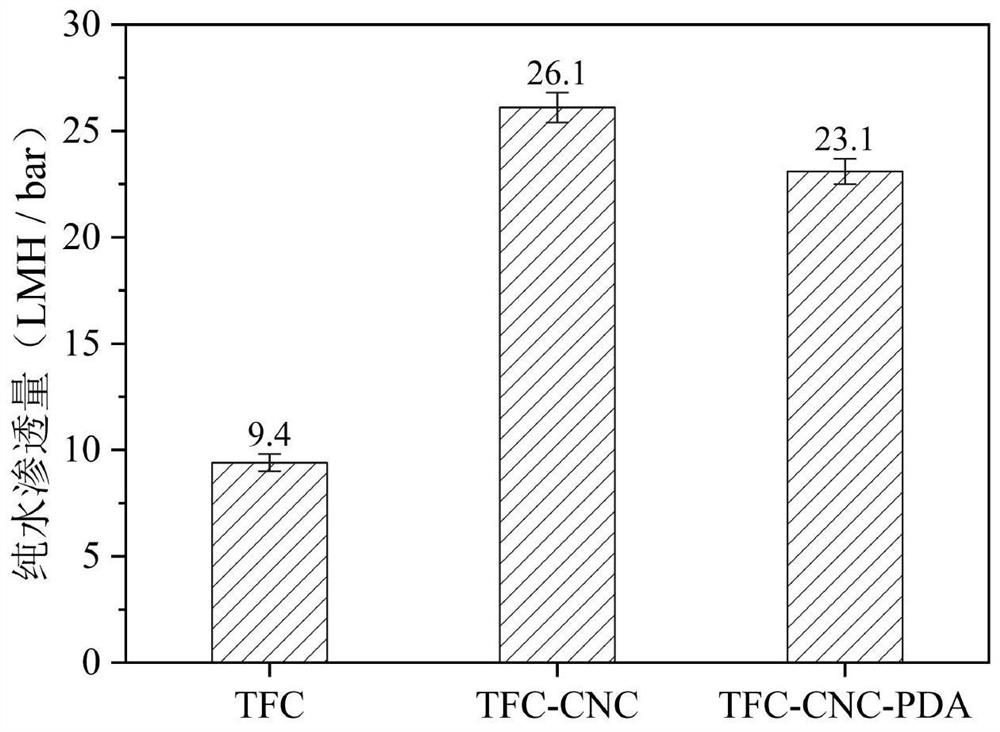

Two-step modified composite nanofiltration membrane containing cellulose nanocrystal intermediate layer and dopamine in-situ modified layer and preparation method thereof

PendingCN112452164AImprove permeabilityHigh retention performanceSemi-permeable membranesPolyamideNanofiltration

The invention discloses a two-step modified composite nanofiltration membrane containing a cellulose nanocrystal intermediate layer and a dopamine in-situ modified layer and a preparation method thereof. The invention belongs to the field of membrane materials and preparation thereof. The invention aims to solve the technical problem that the permeability and interception performance of the existing nanofiltration membrane are mutually balanced. The two-step modified composite nanofiltration membrane containing the cellulose nanocrystal middle layer and the dopamine in-situ modified layer is of a four-layer structure and sequentially comprises a microfiltration membrane bottom layer, a cellulose nanocrystal middle layer, a polyamide separation layer and a dopamine modified layer from bottom to top. The method comprises the following steps: carrying out suction filtration on a cellulose nanocrystal dispersion liquid to the surface of the bottom layer of the microfiltration membrane, then sequentially soaking in a piperazine solution and a trimesoyl chloride solution, taking out, carrying out heat treatment, and finally soaking in a dopamine mixed solution to obtain the composite nanofiltration membrane. According to the method, the permeability of the nanofiltration membrane is greatly improved, and meanwhile, the interception performance of the nanofiltration membrane can be improved to a certain extent.

Owner:HARBIN INST OF TECH

Electrochemical power supply diaphragm, manufacturing method thereof, electrochemical battery or capacitor

InactiveCN103903871AHigh tensile strengthImprove the safety of useHybrid capacitor separatorsCell component detailsEmulsionHexafluoropropylene

The invention provides an electrochemical power supply diaphragm and a manufacturing method thereof. The method includes the steps that polyvinylidene fluoride-hexafluoropropylene is dissolved in acetone to prepare a polyvinylidene fluoride-hexafluoropropylene acetone solution with the mass concentration of 5-20%, then deionized water is added into the solution, and the mixture is uniformly stirred to obtain emulsion; the mass content of the deionized water in the emulsion is 1-10%; organic short fibers are added into the emulsion, and the mixture is uniformly mixed to obtain mixed emulsion; the obtained mixed emulsion is coated on a clean glass substrate, the glass substrate is removed after the mixed emulsion is dried, and accordingly the electrochemical power supply diaphragm is obtained. The organic short fibers are one or more of PET fibers, PAN fibers and aramid fibers. The electrochemical power supply diaphragm is proper in aperture and good in heat resistance and safety, and safety of an electrochemical battery or a capacitor can be effectively improved. The invention further provides the electrochemical battery or the capacitor using the diaphragm.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method of preparing nano-crystalline powdered alloy powder

The invention provides a method of preparing nano-crystalline powdered alloy powder, and belongs to the field of a powder metallurgy preparation technology. The method comprises the steps: preparing an oxide precursor by adopting a solution method; carrying out reductive sintering on the precursor powder in hydrogen; and obtaining pure nickel-tungsten alloy powder with fine crystal particles. According to the method provided by the invention, all raw materials are mixed by using a liquid phase, reactants can be uniformly mixed on an atom level, and the problem that the alloy powder is difficult to mix can be solved; meanwhile, the method has the characteristics of low cost and high use ratio of raw material powder; in addition, because the nano-crystalline powdered alloy powder is plied as nano-crystalline powder, and the method is higher in rigidity, wearability, corrosion resistance, resistance to high temperature oxidation and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of non-metal-doped titanium dioxide porous film with ordered pores

The invention relates to a preparation method of a non-metal-doped titanium dioxide porous film with ordered pores. The preparation method comprises the following steps of: uniformly dispersing a reagent which is completely decomposed into gaseous substances NH3 and(or) CO and CO2 and titanium dioxide nano-particles or titanium dioxide soil into water or alcohol to prepare a dispersion system; preparing titanium dioxide slices by the prepared dispersion system through methods such as spin-coating, lifting, scraping or tabletting, and drying under a certain temperature; and thermally treating the dried titanium dioxide slices in a certain vacuum degree to control heat-up velocity to prepare the non-metal-doped titanium dioxide porous film with ordered pores. According to the preparation method disclosed by the invention, effective control of order and pore diameter of pores of the titanium dioxide porous film as well as effective doping of non-metal materials (N and C) is realized at the same time by controlling the amount of the reagent, the vacuum degree and the heat-up velocity during thermal treatment.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

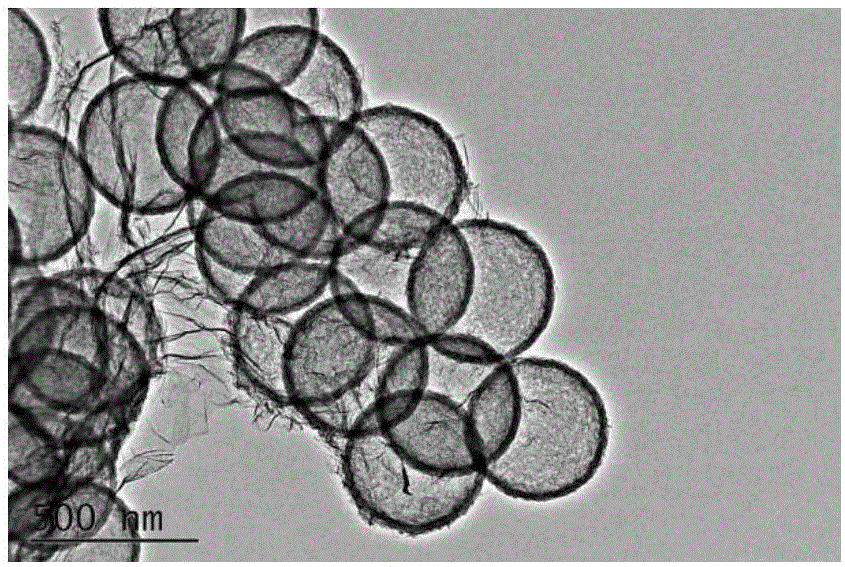

Graphene loaded with hollow carbon spheres composite material preparation method

InactiveCN106848248AGood spherical structureEvenly dispersedCell electrodesSecondary cellsMaterials preparationSupercapacitor

The invention provides a graphene loaded with hollow carbon spheres composite material preparation method, and belongs to the technical field of graphene composite material preparation method. The method comprises the steps of S1, pre-oxidizing graphite oxide; S2, preparing graphite oxide; S3, preparing a resorcin / formaldehyde@Sio2 precursor; S4, preparing graphene-resorcin / formaldehyde@Sio2 composite material; S5, preparing graphene-hollow carbon sphere; S6, preparing working electrodes. The carbon spheres produced by using the method present an excellent spherical structure, and are evenly distributed on the surface of the graphene. According to the hollow carbon spheres produced by using the method, the pH value and ethanol consumption can be used for effectively controlling the bore diameters of the hollow carbon spheres, have a big specific area and a good repeatability, and therefore the method is beneficial to the assembly of super conductors with a high performance.

Owner:HARBIN INST OF TECH

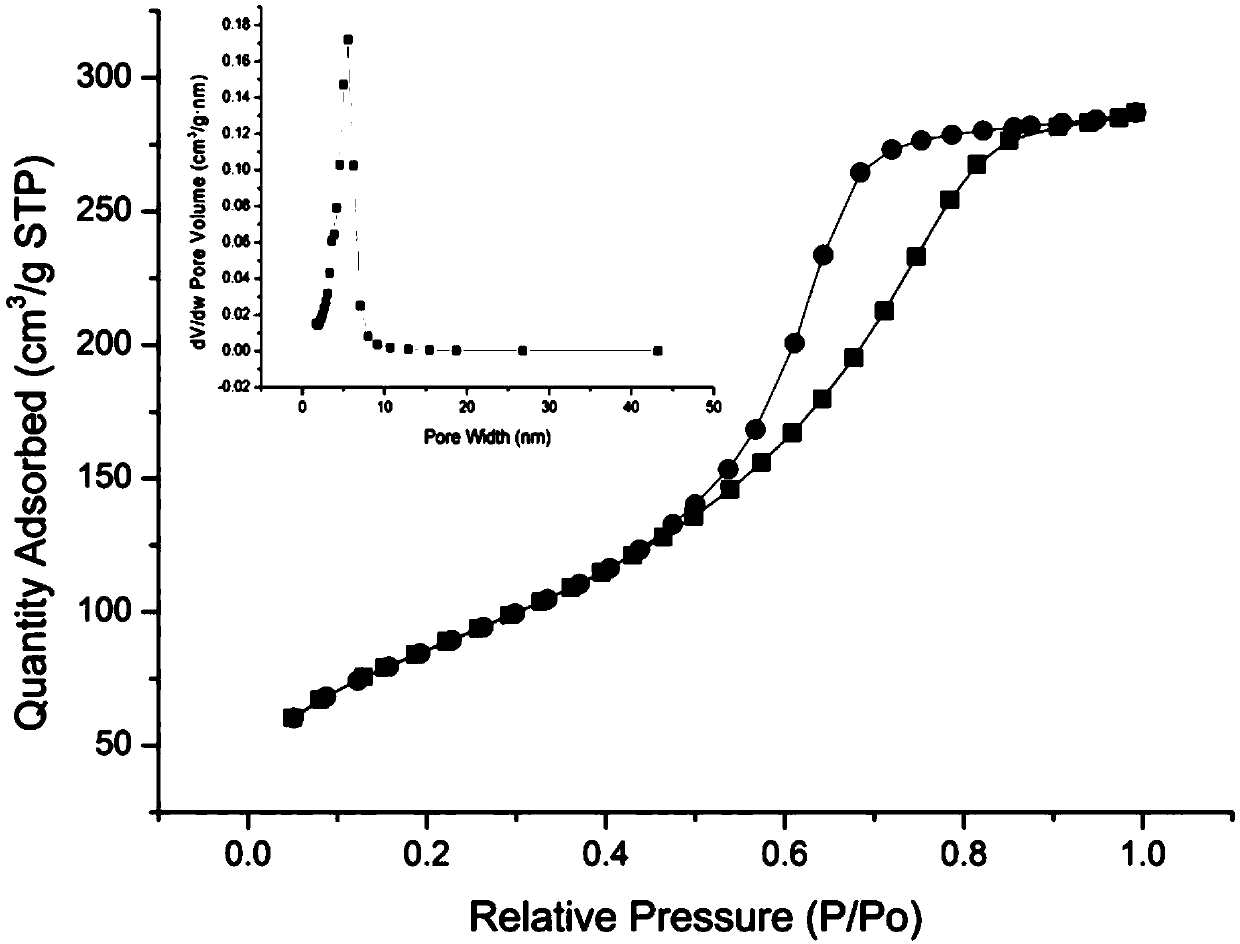

Method for preparing mesoporous silica material by hydroxyethyl cellulose serving as template

ActiveCN109574021APromote polycondensation reactionControl apertureSilicaBiocompatibility TestingMesoporous silica

The invention relates to a method for preparing a mesoporous silica material by hydroxyethyl cellulose serving as a template. The method particularly includes the steps: 1) adding hydroxyethyl cellulose into water, heating, stirring and dissolving to obtain hydroxyethyl cellulose water solution, slowly adding alkali metal silicate water solution into the hydroxyethyl cellulose water solution to uniformly mixing mixture, sufficiently stirring the mixture until clear and bright solution is acquired, adjusting a pH (potential of hydrogen) of a reaction system to reach 5-6 by acid solution, and standing for 1-24 hours to obtain reaction liquid; 2) centrifuging the reaction liquid, drying and collecting to obtain a solid matter, and calcining the solid matter to obtain the mesoporous silica material. According to the method, a non-ionic surface active agent serves as a hydroxyethyl cellulose template agent to assemble mesoporous silica, unformed mesoporous silica material is synthesized byan unconventional acid hydrolysis process, and the raw materials are rich, renewable and good in biocompatibility, and the method is simple in synthetic process, mild and controllable in preparation condition and simple, efficient and nontoxic in preparation process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Composite super capacitor diaphragm material with good isolation performance

InactiveCN106128793AHigh tensile strengthGood chemical stabilityHybrid capacitor separatorsHybrid/EDL manufacturePolyesterPolyvinyl alcohol

The invention discloses a composite super capacitor diaphragm material with good isolation performance. The composite super capacitor diaphragm material is prepared from the following raw materials in parts by weight: 35-40 parts of polyvinyl alcohol fibers, 33-35 parts of polypropylene fibers, 10-13 parts of polyacrylonitrile powder, 30-32 parts of acetone, 72-75 parts of N,N-dimethyl formamide, 8-10 parts of water-soluble PVA fibers at 70 DEG C, 4-5 parts of cationic starch, 4-5 parts of glass wool, 2-3 parts of liquid paraffin, 1.5-2 parts of dimethylsiloxane, 9-11 parts of clay, 2-3 parts of palmitic acid and 3-4 parts of polyester adhesive powder. The ingredients of the glass wool, the clay and the like are also added to preparation of a product through a series of modified additives, so that the breathability is good; the mechanical strength of the product is improved; the high-temperature tolerance is improved; the super capacitor material can also keep a good isolating state at a high temperature; and the service lifetime of a super capacitor is prolonged.

Owner:ANHUI JIANGWEI PRECISION IND

Supercapacitor composite separator material of high mechanical strength

InactiveCN105990036AHigh tensile strengthGood chemical stabilityHybrid capacitor separatorsNon-woven fabricsPolyvinyl alcoholSlurry

The invention discloses a supercapacitor composite separator material of high mechanical strength. The supercapacitor composite separator material is prepared by the raw material of the following parts by weight: 35-40 parts of polyvinyl alcohol fiber, 33-35 parts of mekralon, 10-13 parts of polyacrylonitrile powder, 30-32 parts of acetone, 72-75 parts of N,N-dimethyl formamide, 8-10 parts of water soluble PVA fiber of 70 DEG C, a moderate amount of water, 13-15 parts of calcium carbonate, 5-7 parts of glass fiber, 7-9 parts of mica powder, 2-3 parts of oxidized polyethylene wax, 1-1.2 parts of sodium dodecyl benzene sulfonate, 2-3 parts of waterborne polyurethane emulsion, 3-4 parts of animal glue and 1-1.5 parts of polydimethylsiloxane. The processed calcium carbonate, the glass fiber and the mica powder are added in the preparation process of nonwoven fabric and evenly dispersed in slurry so that the mechanical strength of the prepared product can be further enhanced, the product is enabled to be anti-tensile and is not liable to fracture, and thus the supercapacitor composite separator material of high mechanical strength is the supercapacitor used composite separator material of excellent performance.

Owner:ANHUI SUREPHON CAPACITOR CO LTD

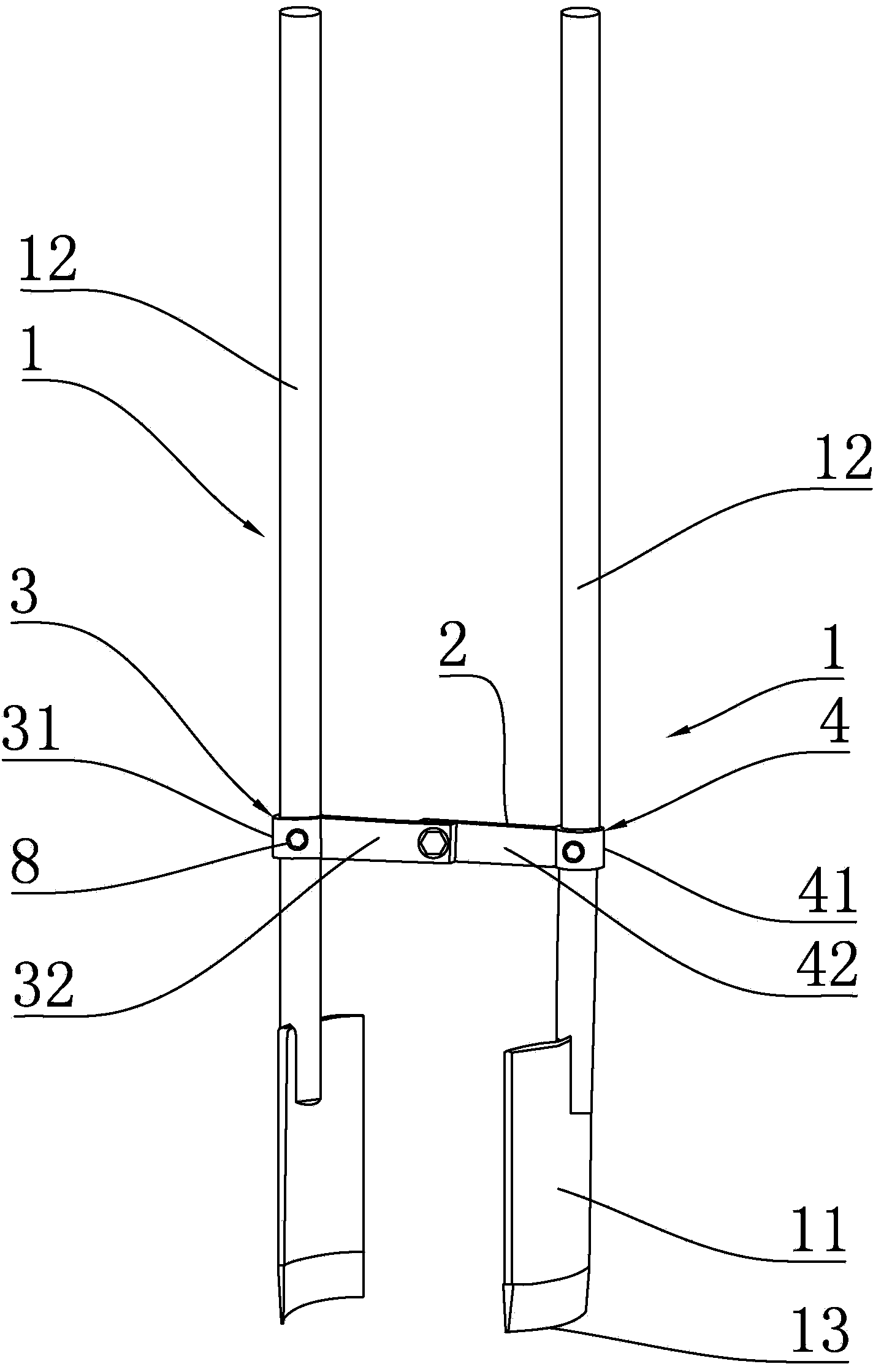

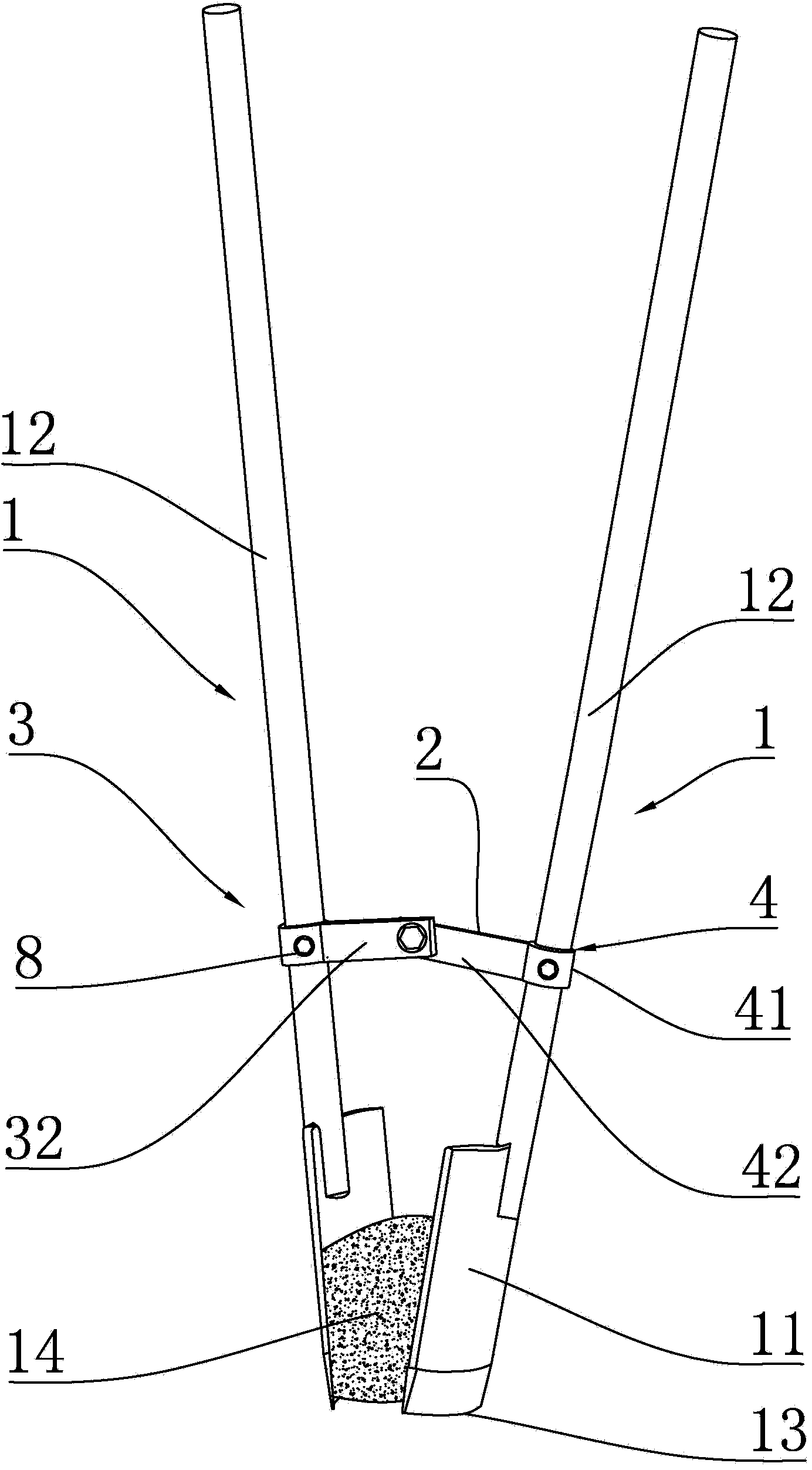

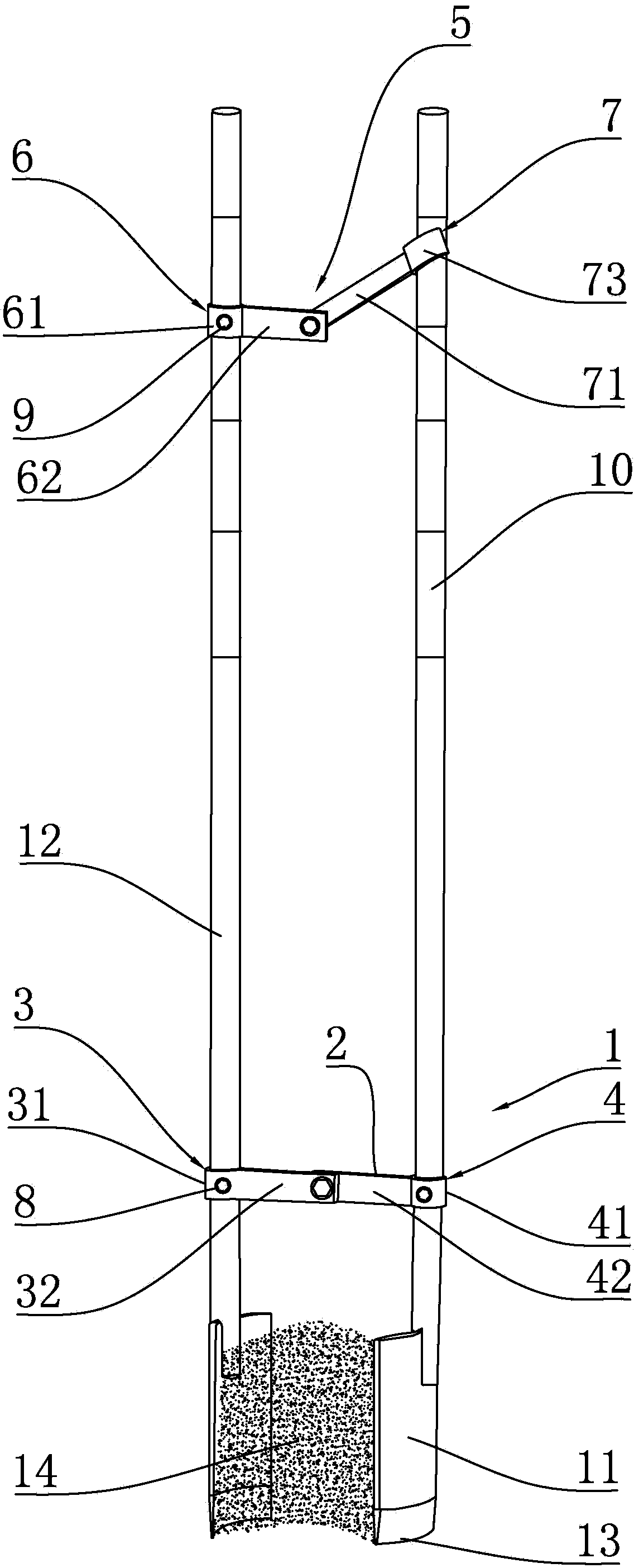

Hole digging and soil picking up device

ActiveCN104032778ABalanced and stable forceWon't breakHand-operated machines/dredgersEngineeringPore diameter

The invention provides a hole digging and soil picking up device which comprises two hole digging pieces and a connecting device through which the two hole digging pieces are connected. Each hole digging piece comprises a shovel piece and a handle connected with the shovel piece. The connecting device comprises a first connecting piece and a second connecting piece which are hinged together, wherein the first connecting piece is fixedly connected with the handle in one hole digging piece, and the second connecting piece is fixedly connected with handle in the other hole digging piece. The hole digging and soil picking up device further comprises a locking device, wherein the locking device comprises a third connecting piece and a fourth connecting piece which are hinged together. By means of the device, deep holes can be dug precisely and soil can be picked up without damaging the pore diameter and the structure of surrounding earth blocks, the device meets the requirement for digging underground holes with various pore diameters and various depths, tools do not need to be frequently replaced when deep holes are dug or soil is picked up, and efficiency of hole digging work is improved.

Owner:湖南终南山科技发展有限公司

Three-dimensional hollow carbon foam electrode materials, preparation method of three-dimensional hollow carbon foam electrode materials and application of three-dimensional hollow carbon foam electrode materials

InactiveCN107275098AStrong structural controllabilityLow costHybrid capacitor electrodesHybrid/EDL manufactureDissolutionZinc nitrate

The present invention discloses a three-dimensional hollow carbon foam electrode materials, a preparation method of the three-dimensional hollow carbon foam electrode materials and an application of the three-dimensional hollow carbon foam electrode materials. The method concretely comprises the following steps: mixing zinc nitrate, fuel and deionized water to perform full stirring and dissolution, putting the mixed solution on an electric furnace for heating until viscidity cementing products are obtained, the products are arranged in a muffle furnace for annealing to obtain zinc oxide template materials with multi-stage holes, and preparing charcoal electrode materials with multistage apertures through adoption of a template method. Compared to the prior art, the reaction materials are wide in source, low in cost and environmentally friendly, the synthesis steps are simple, the raw materials is nontoxic and safe and mild in reaction condition, and the method for removal of temperature materials is unique so as to fit large-size production and commercialization application. The prepared multi-stage hole carbon materials have multistage aperture structures having micropores, mesoporouses and macroporouses, large in specific surface area, have excellent charge and discharge multiplying power characteristics and cycle stability in an application and can satisfy the application requirement of an electrochemistry power storage device.

Owner:HUNAN UNIV

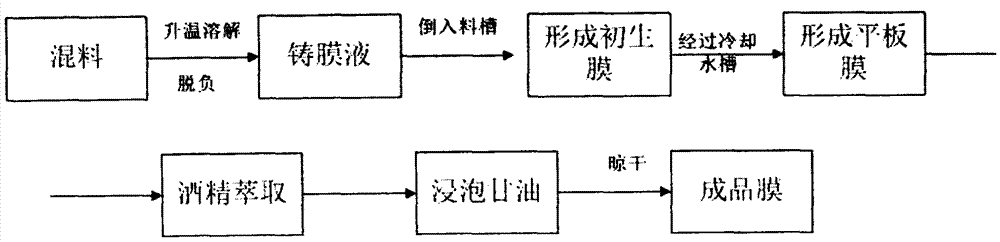

Method for preparing alloy flat-sheet membrane by using low-temperature thermal induced phase separation method

InactiveCN104324618AHigh crystallinityLower melting temperatureSemi-permeable membranesPolyethylene glycolAlloy

The invention discloses a method for preparing an alloy flat-sheet membrane by using a low-temperature thermal induced phase separation method. The method comprises the steps of blending polyvinylidene fluoride and polysulfone; mixing under stirring at a temperature of 60-150 DEG C, by using polyethylene glycol and polyvinyl pyrrolidone as additives and a normal temperature solvent of N,N-dimethyl formamide and a high temperature solvent of dibutyl phthalate as diluents; then desorbing to obtain a membrane-casting solution; and then scraping the membrane-casting solution on a non-woven fabric with a flat-sheet membrane scraper to obtain the alloy flat-sheet membrane.

Owner:唐山海清源科技股份有限公司

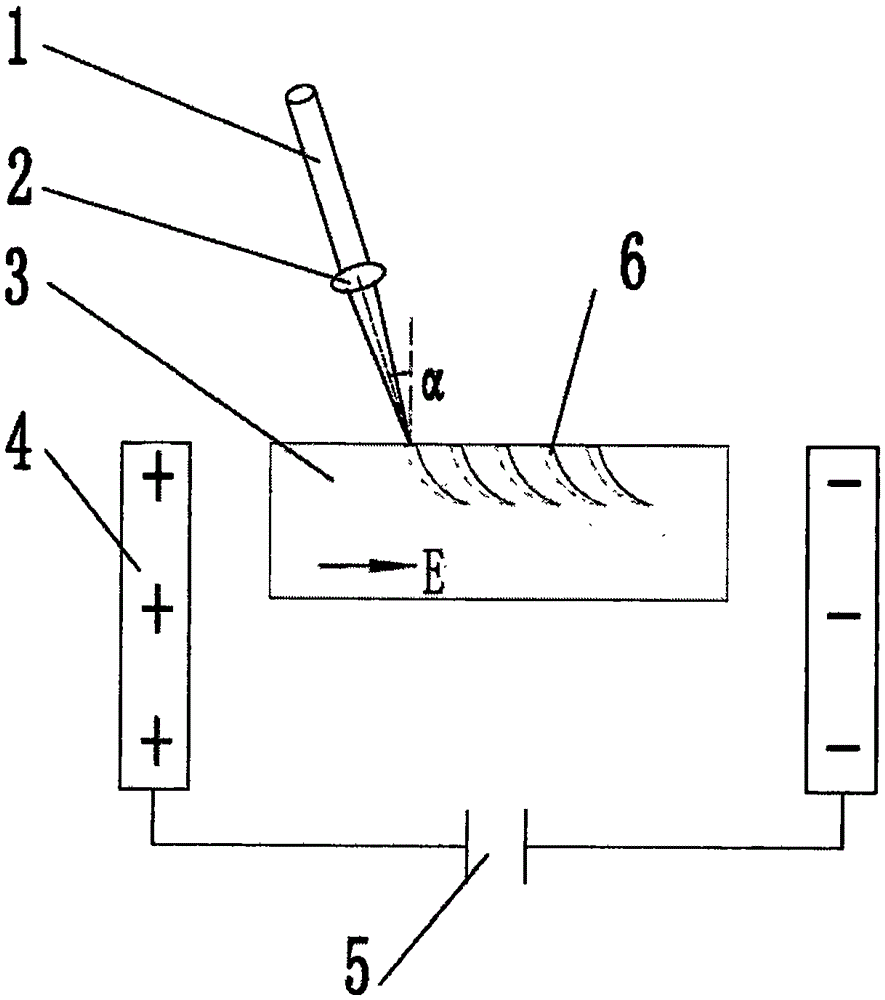

Method for making controllable curved holes through femtosecond lasers with assistance of electric field

InactiveCN105537782AControl spacingLow priceWelding/soldering/cutting articlesLaser beam welding apparatusDiameter ratioEngineering

The invention provides a method for making controllable curved holes through femtosecond lasers with the assistance of an electric field. Devices needed in the method comprise a femtosecond laser generator, the electric field with adjustable intensity and a six-dimensional mobile platform. The method comprises the steps that an aluminum oxide material is ultrasonically cleaned in acetone, absolute ethyl alcohol and deionized water for 5 min separately; the treated aluminum oxide material is fixed on the six-dimensional mobile platform, the femtosecond lasers generated by the femtosecond laser generator are gathered on the aluminum oxide material through a 5X objective lens, and the light path formed by the femtosecond lasers and the platform form an alpha angle; parameters such as energy, repetition frequency and the number of pulses of the femtosecond lasers are adjusted to control the depth-diameter ratio of micro holes, and meanwhile the intensity of the electric field is adjusted to control the curved directions and radians of the micro holes; the machined aluminum oxide material is taken down from the six-dimensional mobile platform and ultrasonically cleaned in acetone, absolute ethyl alcohol and deionized water for 5 min separately. By means of the method for making the controllable curved holes through the femtosecond lasers with the assistance of the electric field, control over the curved hole directions and the radians of the curved holes can be achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

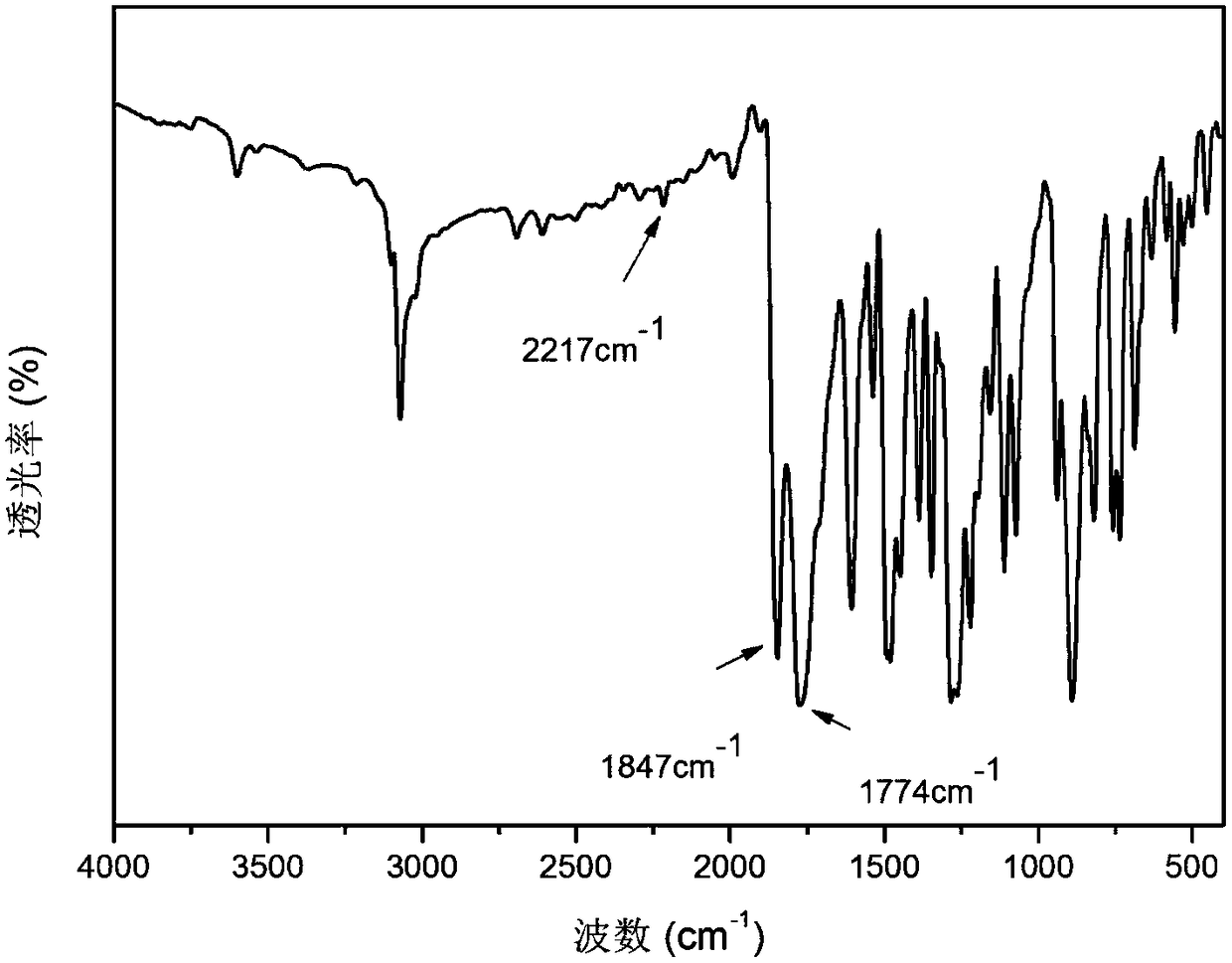

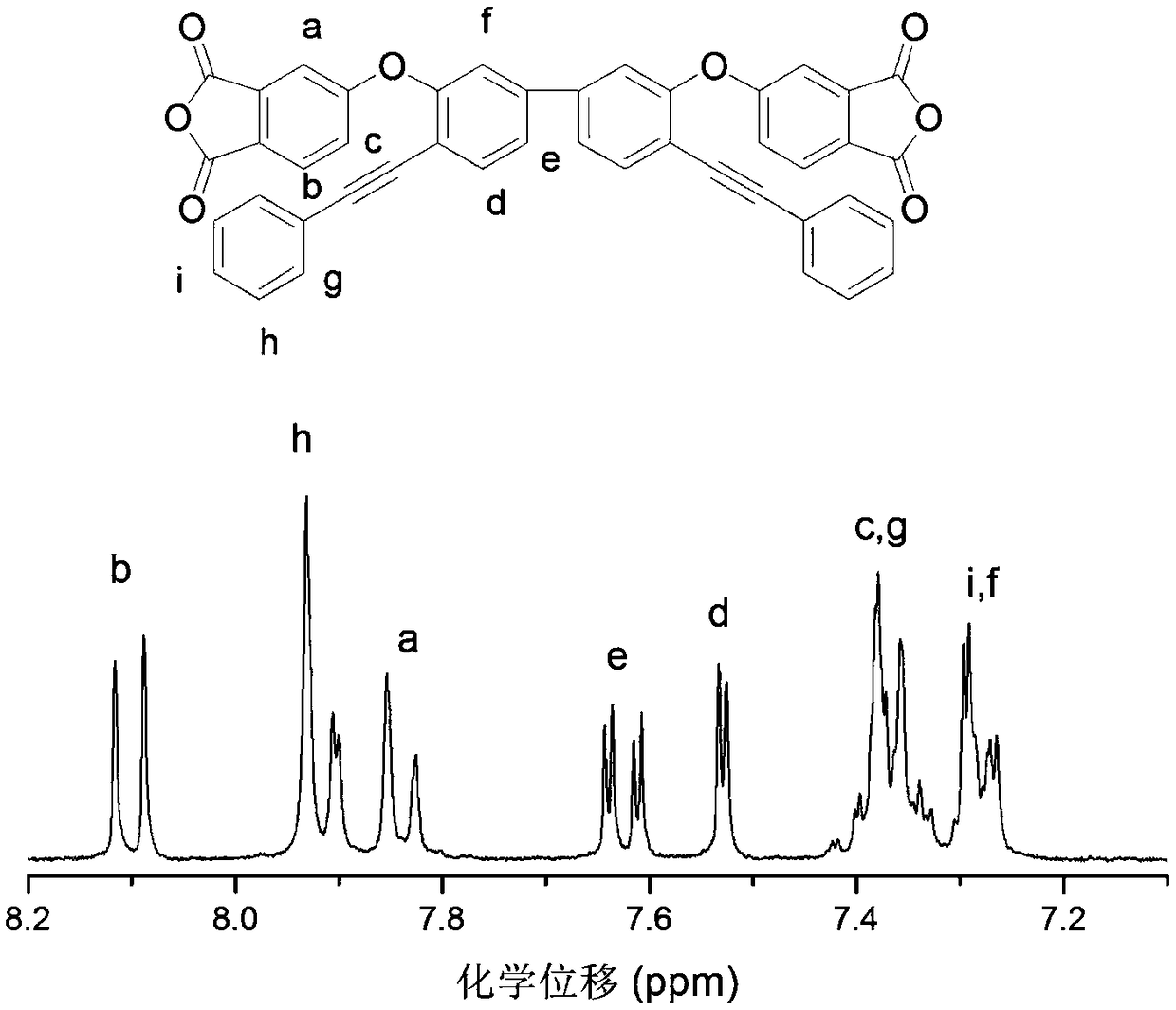

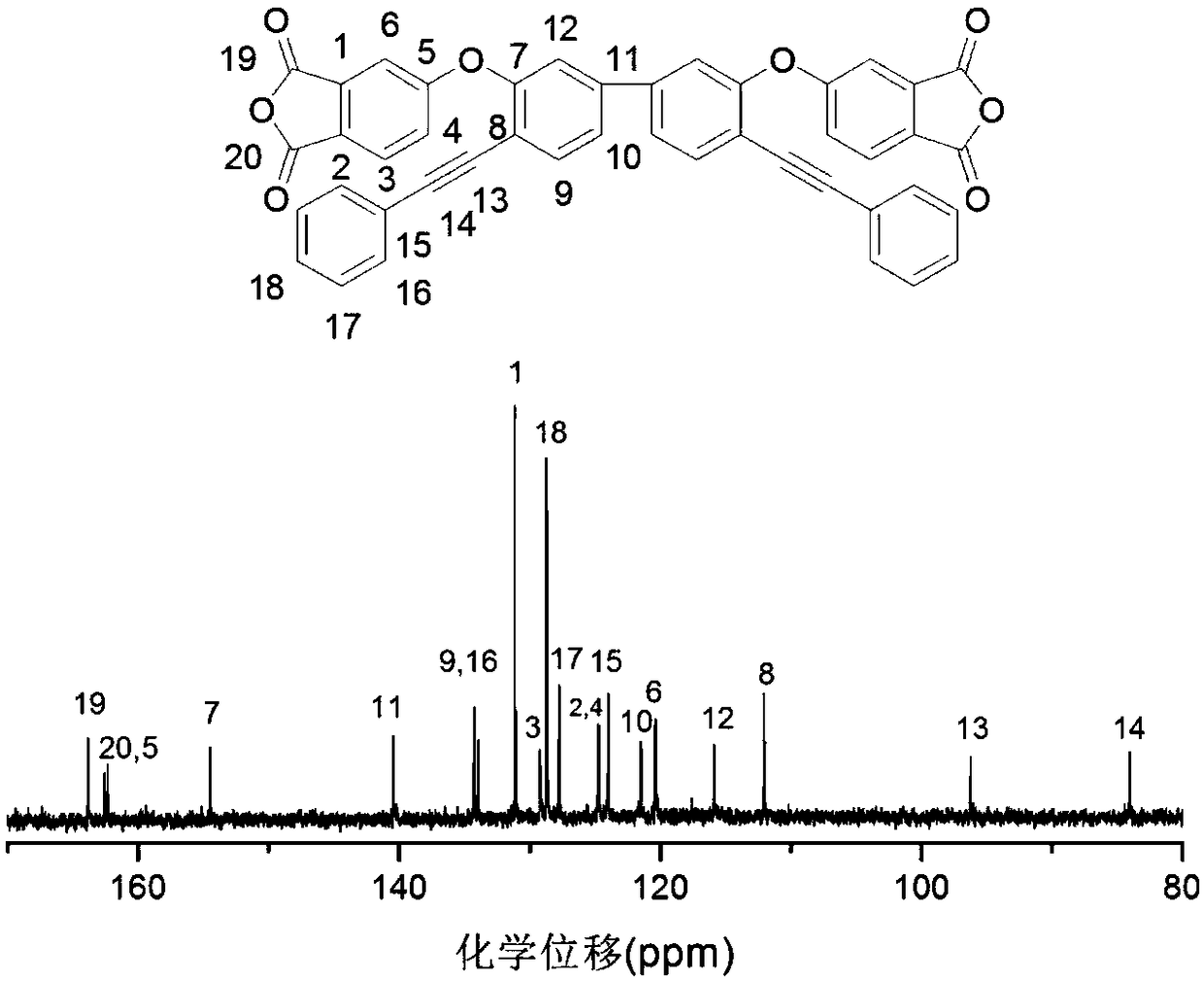

Dianhydride monomer with side chains containing phenylacetylene and synthesis method and application of dianhydride monomer

ActiveCN108586403ALarge specific surface areaControl apertureOrganic chemistryOther chemical processesCross-linkBenzene

The invention discloses a dianhydride monomer with side chains containing phenylacetylene and a synthesis method and application of the dianhydride monomer, and belongs to the technical field of synthesis and preparation of polyimide. The dianhydride monomer is called 3,3'-bi(3,4-dicarboxyphenoxy)-4,4'-diphenylethynylbiphenyl dianhydride, and the dianhydride monomer with the side chains containingphenylacetylene is based on a biphenyl structure, contains cross-linkable groups containing phenylacetylene, and can be applied to synthesis of linear and hyperbranched polyimide; and a polyimide material with better properties is prepared through post-crosslinking treatment, the structure of the material is regulated by controlling the content of cross-linking groups, so that the performance ofthe polyimide material is improved; the material has potential application in gas adsorbing materials.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com