Method for preparing alloy flat-sheet membrane by using low-temperature thermal induced phase separation method

A phase separation method and flat membrane technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of poor membrane pressure resistance, fewer flat membranes, and excessively large pore diameters, etc., and achieve long-term use. Effects of lifetime, small membrane pore size, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

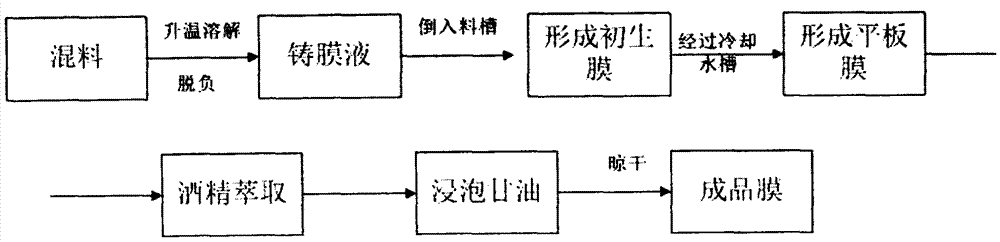

Method used

Image

Examples

Embodiment 1

[0038] Mix polyvinylidene fluoride resin with a weight average molecular weight of 250,000 and polysulfone with a weight average molecular weight of 50,000, add a normal temperature solvent N,N-dimethylformamide and a high temperature solvent dibutyl phthalate as solvents, and then add a molecular weight of 10,000 polyethylene glycol and 50,000 molecular weight polyvinylpyrrolidone as additives, including polyvinylidene fluoride 12wt%, polysulfone 3wt%, polyethylene glycol 8wt%, polyvinylpyrrolidone 5wt%, dibutyl phthalate 42 wt% of ester, 30 wt% of N,N-dimethylformamide. Raise the temperature of the feed liquid to 70°C and stir to dissolve it. After unloading, put it into the trough of the film scraping equipment. The trough, scraper, and roller keep the temperature at 75-80°C, the winding speed is 8m / min, and the gas path is 5 ~10cm, the material liquid is coated on the non-woven fabric by a scraper, and enters the pure water gel bath at 15°C to solidify into a film after pa...

Embodiment 2

[0040] Mix polyvinylidene fluoride resin with a weight average molecular weight of 350,000 and polysulfone with a weight average molecular weight of 60,000, use normal temperature solvent N,N-dimethylformamide and high temperature solvent dibutyl phthalate as solvents, and additives with a molecular weight of 2,000 polyethylene glycol and polyvinylpyrrolidone with a molecular weight of 100,000. Its content is polyvinylidene fluoride 8.4wt%, polysulfone 3.6wt%, polyethylene glycol 8wt%, polyvinylpyrrolidone 2wt%, dibutyl phthalate 62.4wt%, N,N-dimethylformaldehyde Amide 15.6 wt%. Raise the temperature of the feed liquid to 110°C and stir to dissolve it. After unloading, put it into the trough of the film scraping equipment. The trough, scraper, and roller keep the temperature at 115-120°C. ~10cm, the material liquid is coated on the non-woven fabric by a doctor blade, and then enters the pure water gel bath at 25°C to solidify into a film after passing through the air process....

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com