Method for preparing mesoporous silica material by hydroxyethyl cellulose serving as template

A technology of hydroxyethyl cellulose and mesoporous silica, applied in the direction of silica, silicon oxide, etc., can solve the problem of increasing production costs, energy consumption and pollutant discharge, limiting the application of mesoporous silica materials, increasing Difficulty in the post-processing process, etc., to achieve the effects of high efficiency and non-toxicity in the preparation process, mild and controllable preparation conditions, and concentrated pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

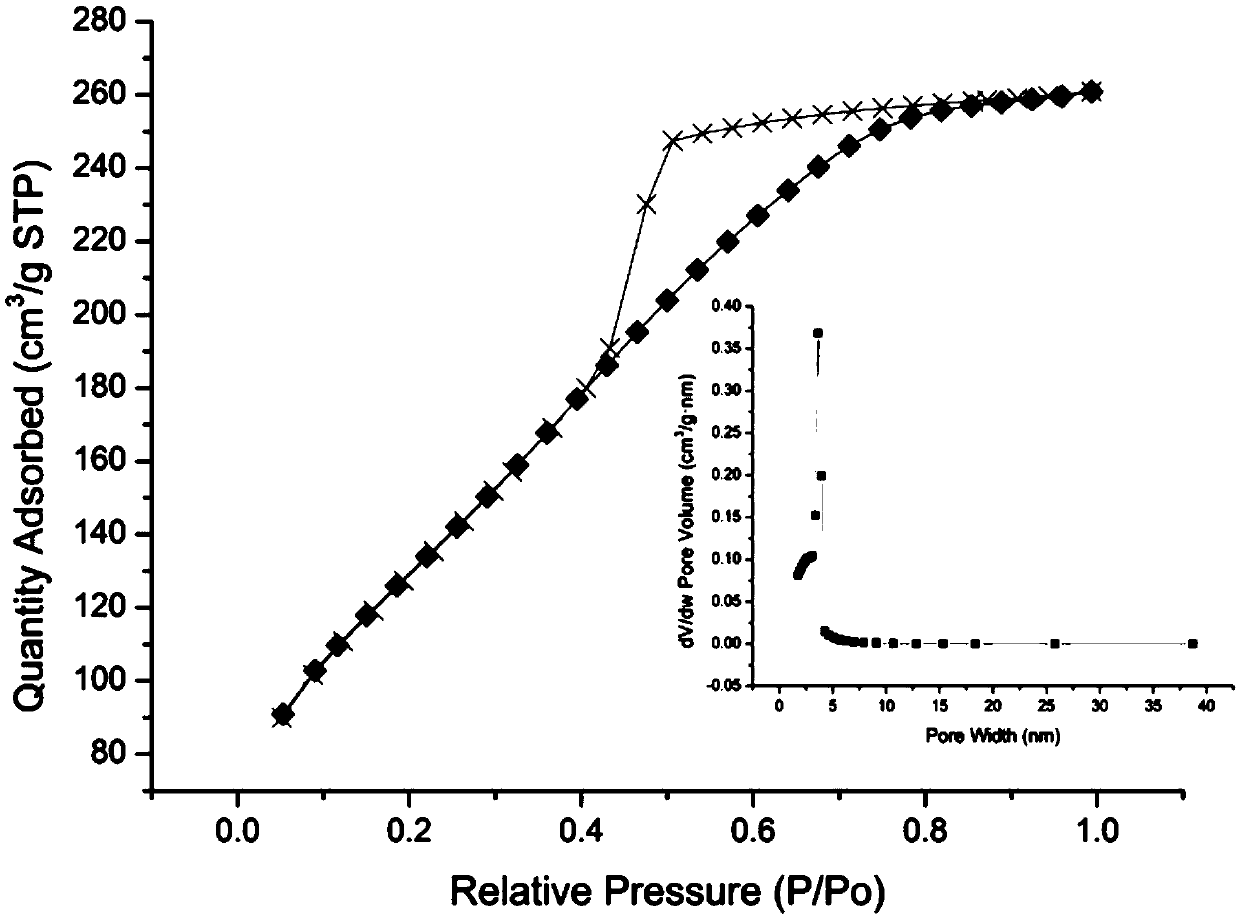

Embodiment 1

[0027] A method for preparing a mesoporous silica material using hydroxyethyl cellulose as a template, specifically comprising the following steps:

[0028] 1) 10g (0.035mol) Na 2 SiO 3 9H 2 O was dissolved in 50mL of water, and stirred to make it reach a dissolution equilibrium to obtain an aqueous alkali metal silicate solution;

[0029] 2) Add 2g of hydroxyethyl cellulose (DS=3, MS=6, molar mass: 736.7g / mol) with a viscosity of 5000-6400mpa·s into 300mL of water, heat in an oil bath at 80°C and fully stir to dissolve to obtain hydroxyethyl cellulose Cellulose aqueous solution;

[0030] 3) Slowly add the aqueous alkali metal silicate solution obtained in the above step 1) into the reaction flask containing the aqueous solution of hydroxyethyl cellulose obtained in step 2), stir well until a clear and translucent solution is obtained, and use 15-20% H 2 SO 4 Adjust the pH value of the reaction system to 6 with the solution, let it stand for 24 hours to obtain the reactio...

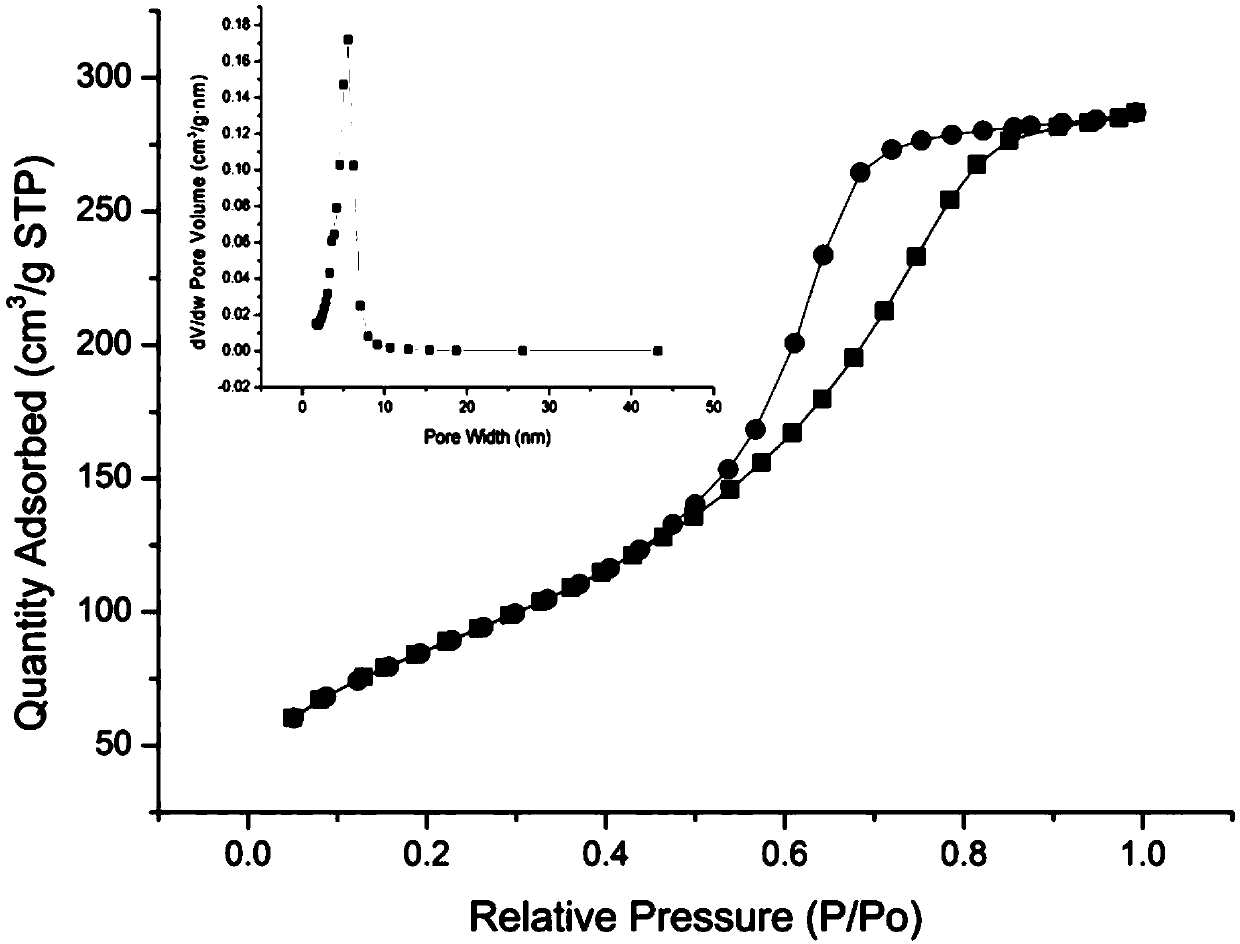

Embodiment 2

[0034] A method for preparing a mesoporous silica material using hydroxyethyl cellulose as a template, specifically comprising the following steps:

[0035] 1) Add 5g Na 2 SiO 3 9H 2 O (0.018mol) was dissolved in 30mL of water, stirred to make it reach a dissolution equilibrium to obtain an aqueous alkali metal silicate solution;

[0036] 2) Add 1.5 g of hydroxyethyl cellulose with a viscosity of 3400 to 5000 mpa·s into 220 mL of water, heat in an oil bath at 80°C, stir and dissolve to obtain an aqueous solution of hydroxyethyl cellulose;

[0037]3) Slowly add the alkali metal silicate aqueous solution obtained above into the reaction flask equipped with the aqueous hydroxyethyl cellulose solution obtained in step 2), stir fully until a clear and translucent solution is obtained, and adjust the reaction system with 2mol / L HCl solution When the pH value reaches 6, let it stand still for 24 hours to obtain the reaction solution. Centrifuge the reaction solution after standing...

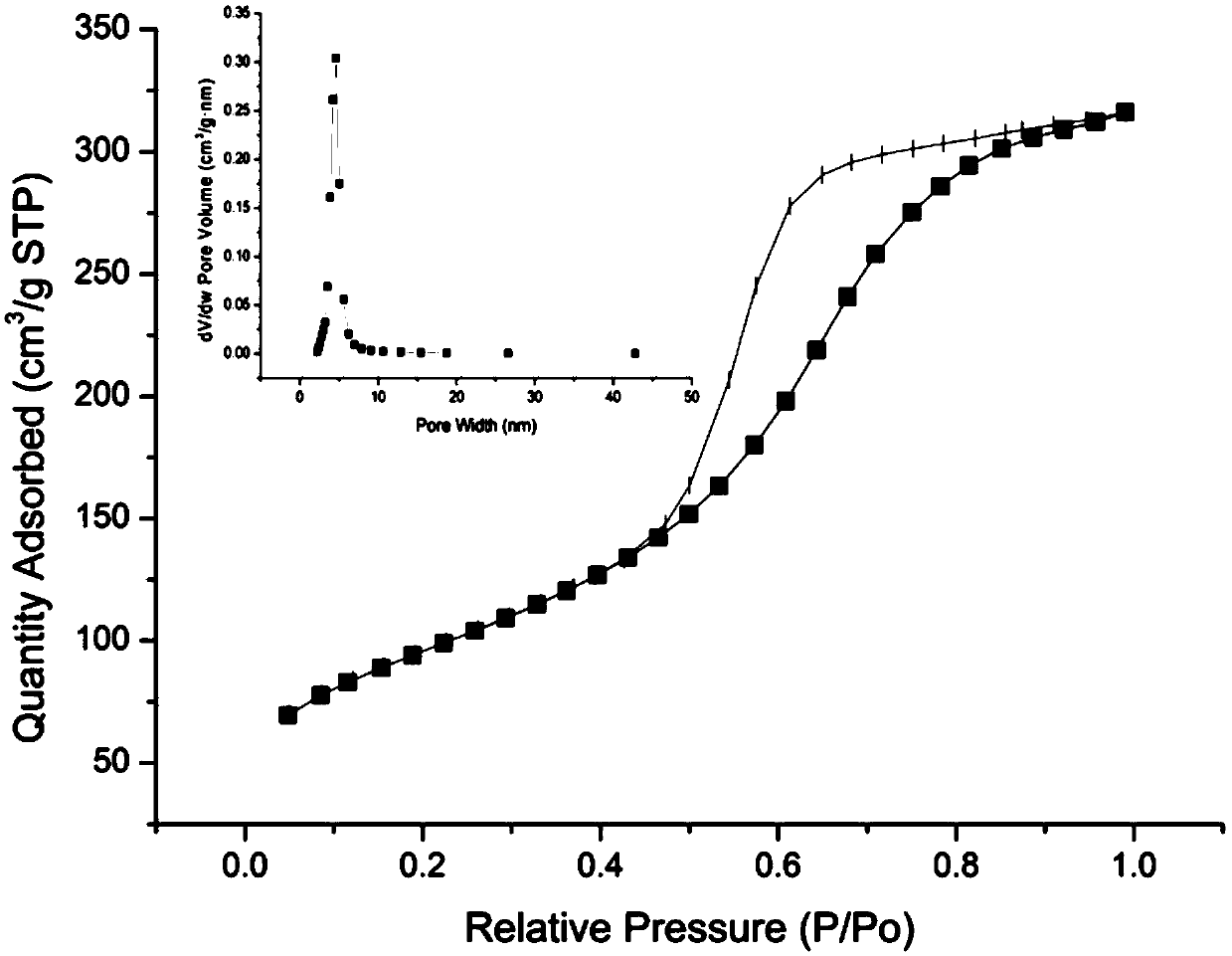

Embodiment 3

[0040] A method for preparing a mesoporous silica material using hydroxyethyl cellulose as a template, specifically comprising the following steps:

[0041] 1) Add 5g Na 2 SiO 3 9H 2 O (0.018mol) was dissolved in 30mL of water, stirred to make it reach a dissolution equilibrium to obtain an aqueous alkali metal silicate solution;

[0042] 2) Add 1.5 g of hydroxyethyl cellulose with a viscosity of 2600 to 3300 mpa s into 165 mL of water, heat in an oil bath at 80°C, stir and dissolve to obtain an aqueous solution of hydroxyethyl cellulose;

[0043] 3) Slowly add the aqueous alkali metal silicate solution obtained in the above step 1) into the reaction flask containing the aqueous solution of hydroxyethyl cellulose obtained in step 2), stir well until a clear and translucent solution is obtained, and use 15-20% H 2 SO 4 Adjust the pH value of the reaction system to 5 with the solution, let it stand for 24 hours to obtain the reaction solution, centrifuge the reaction solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com