A kind of production method and device of nylon 66 saline solution

A technology of brine solution and production equipment, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as disadvantages that cannot be ignored, achieve convenient polycondensation reaction, improve storage stability, and simplify production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

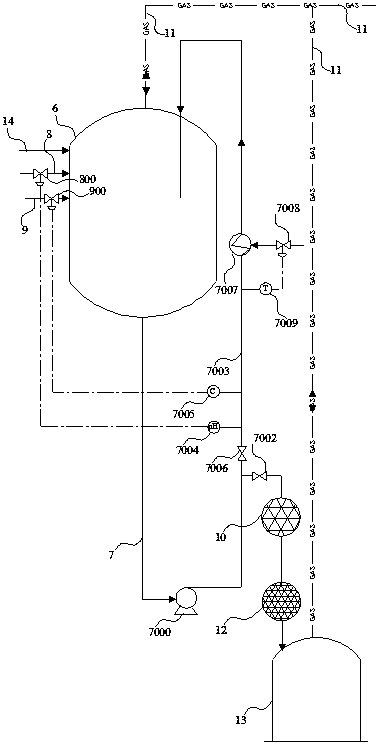

[0032] Such as figure 1 Shown, a kind of production system of nylon 66 brine solution comprises a refining reaction unit and aging tank 13, and described refining reaction unit comprises refining reactor 6, and the bottom of described refining reactor 6 is provided with second discharge pipeline 7 And through the second discharge pipe 7, it is connected with the aging tank 13, the tops of the refining reactor 6 and the aging tank 13 are connected to the nitrogen blanketing device 11, and the upper part of the refining reactor 6 is respectively provided with a second upper-level material inlet. material pipeline 14, the second hexamethylenediamine feed pipeline 8 and the second water inlet pipeline 9; the refining reactor 6 is provided with a second circulation pipeline 7003, and the second circulation pipeline 7003 communicates with the second outlet in a branched manner. On the feed pipeline 7, the second circulation pipeline 7003 connects the bottom and the top of the refini...

Embodiment 2

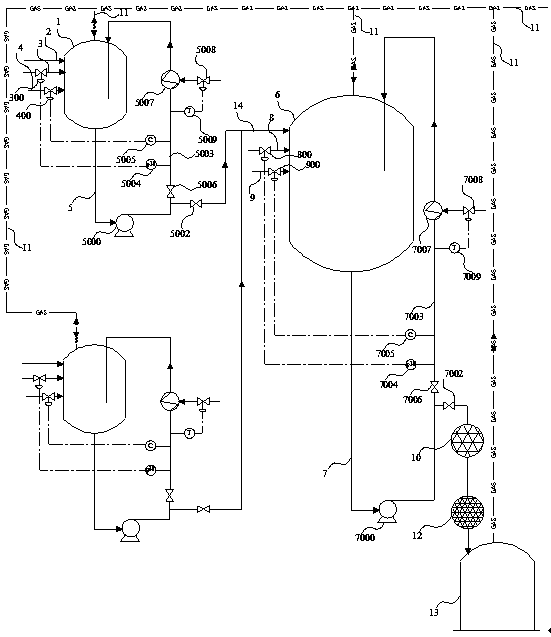

[0038] Such as figure 2 As shown, the difference between embodiment two and embodiment one is: on the basis of embodiment one, embodiment two is provided with two crude reaction units after the refining reaction unit, and the two crude reaction units are connected in parallel and each The first discharge pipeline 5 of the crude reactor 1 is all connected to the second upper material feed pipeline 14 of the refining reactor 6 of the refining reaction unit; the top of the crude reactor 1, the refining reactor 6 and the aging tank 13 Both are connected to the nitrogen blanketing device 11;

[0039] The structural description of the crude reaction unit is as follows:

[0040] Described crude reaction unit comprises crude reactor 1, and the bottom of described crude reactor 1 is provided with the first discharge pipe 5, and the top of crude reactor 1 is respectively provided with the first superior material feed pipe 2, The first hexamethylenediamine feed pipeline 3 and the firs...

Embodiment 3

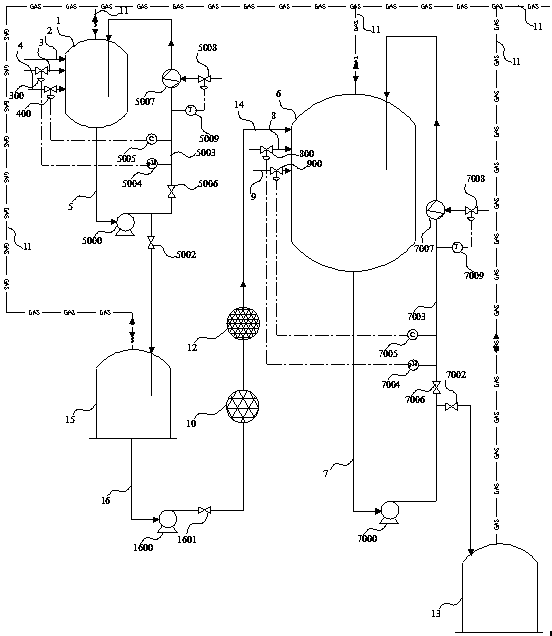

[0046] Such as image 3 As shown, the difference between Embodiment 3 and Embodiment 2 lies in the following points: (1) only one crude reaction unit is provided; (2) an intermediate storage tank 15 is provided between the crude reaction unit and the refined reaction unit, The discharge pipeline 5 of the crude reactor 1 is connected to the intermediate storage tank 15, and the bottom of the intermediate storage tank 15 is provided with a feed pipeline 16, and the feed pipeline 16 is connected to the second upper material feed pipeline of the refining reactor 6 14, and the delivery pipeline 16 is provided with 3# pump 1600, 5# shut-off valve 1601, 1# filter 10 and 2# filter 12 from back to front, and the aperture of the 1# filter 10 is greater than 2# The pore size of the filter 12, the pore size of the 1# filter 10 is preferably 75-250 μm, and the pore size of the 2# filter 12 is preferably 1-20 μm; (3) There is no filter on the discharge pipe 7 of the refining reaction unit r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com