Manufacturing method for super-hard resin grinding wheel

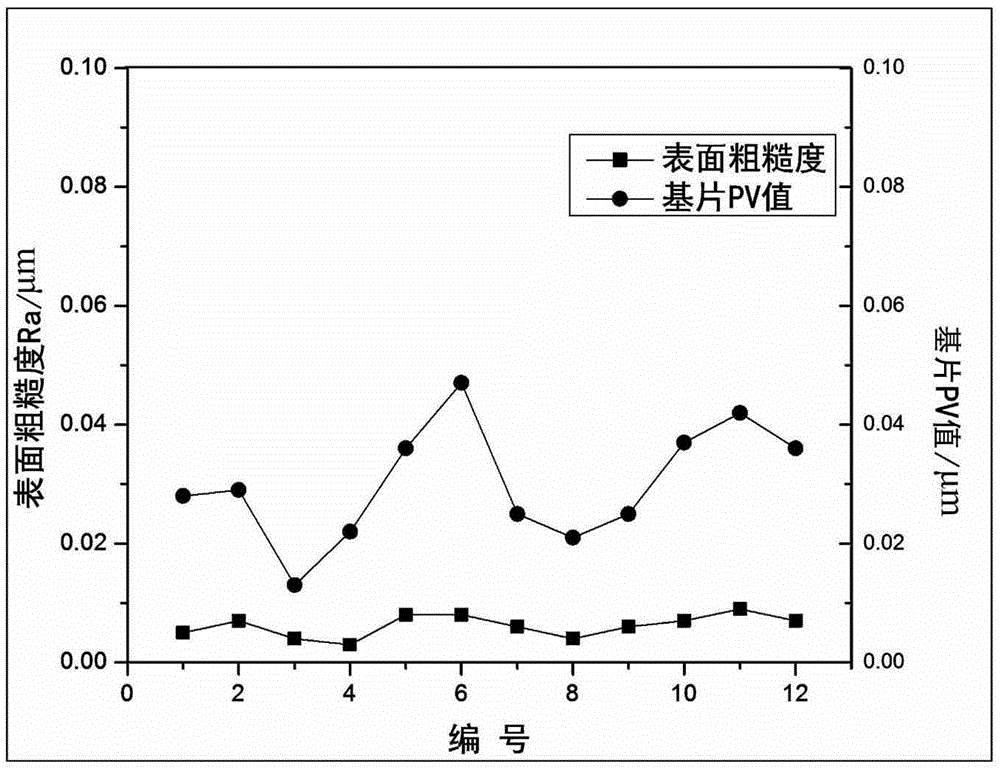

A resin grinding wheel, superhard technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the upper limit of porosity of resin grinding wheel, uneven distribution of pores of resin grinding wheel, difficulty in uniform mixing of molding materials, etc. problems, to achieve the effects of reduced processing costs, high uniformity of structure, and good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A superhard resin grinding wheel, made of the following raw materials in parts by mass: 18 parts of epoxy resin liquid, 18 parts of thinner, 0.7 parts of coupling agent, 0.8 parts of hollow balls, 55 parts of diamond, and 13 parts of curing agent; The diluent is n-butanol, the diamond is nickel-plated diamond, and the particle size of the diamond is 5 μm.

[0024] The preparation method of described superhard resin emery wheel, comprises the following steps:

[0025] ①Dry the hollow ball in an oven at 80°C for 4 hours, mix it with diamond evenly, and pass it through a 100-mesh sieve;

[0026] ②Stir and heat the epoxy resin solution in a water bath at 70°C for 5 minutes, add a diluent and a coupling agent with a total amount of 30% of the diluent, continue stirring and heating for 6 minutes, and then add the hollow spheres and diamonds obtained in step ①. Mixture, continue stirring and heating for 7 minutes;

[0027] ③Reduce the temperature of the water bath in step ② ...

Embodiment 2

[0032] A superhard resin grinding wheel, made of the following raw materials in parts by mass: 15 parts of epoxy resin liquid, 20 parts of diluent, 0.5 parts of coupling agent, 0.5 parts of hollow balls, 40 parts of diamond, and 10 parts of curing agent; The diluent is n-butanol, the diamond is nickel-plated diamond, and the particle size of the diamond is 4 μm.

[0033] The preparation method of described superhard resin emery wheel, comprises the following steps:

[0034] ①Dry the hollow ball in an oven at 90°C for 2 hours, mix it with diamond evenly, and pass it through a 120-mesh sieve;

[0035] ② Stir and heat the epoxy resin solution in a water bath at 80°C for 2 minutes, add 40% of the total amount of diluent and coupling agent, continue stirring and heating for 10 minutes, then add the hollow spheres and diamonds obtained in step ① The mixture was stirred and heated for 5 minutes;

[0036] ③Reduce the temperature of the water bath in step ② to 60°C, mix the remaining...

Embodiment 3

[0041] A superhard resin grinding wheel, made of the following raw materials in parts by mass: 25 parts of epoxy resin solution, 15 parts of diluent, 1 part of coupling agent, 1 part of hollow ball, 60 parts of diamond, and 15 parts of curing agent; The diluent is n-butanol, the diamond is nickel-plated diamond, and the particle size of the diamond is 8 μm.

[0042] The preparation method of described superhard resin emery wheel, comprises the following steps:

[0043] ①Dry the hollow ball in an oven at 100°C for 0.5h, mix it with diamond evenly and pass it through a 100-mesh sieve;

[0044] ②Stir and heat the epoxy resin solution in a water bath at 75°C for 3 minutes, then add a diluent and a coupling agent with a total amount of 35% of the diluent, continue stirring and heating for 5 minutes, then add the hollow spheres and diamonds obtained in step ①. Mixture, continue stirring and heating for 10 minutes;

[0045]③Reduce the temperature of the water bath in step ② to 56°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com