UV inkjet color paste and preparation method and application thereof

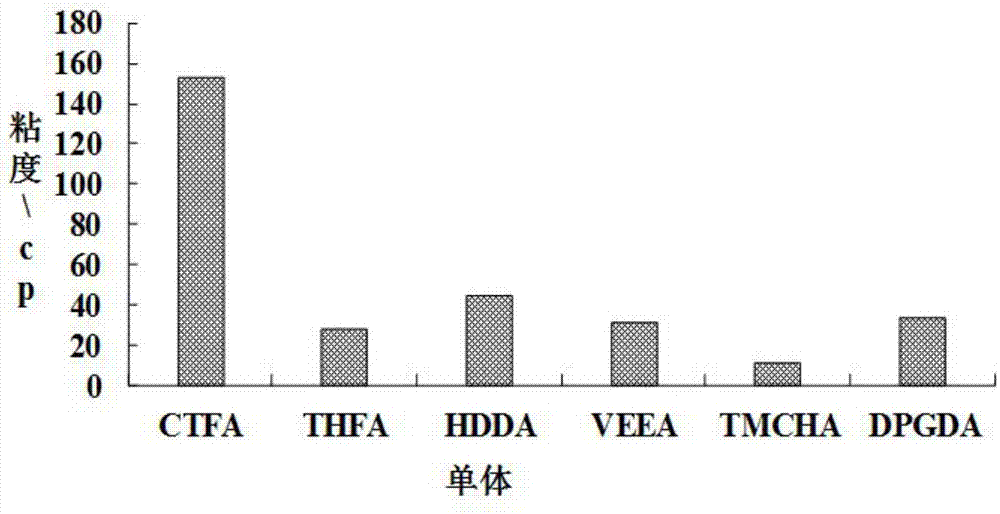

A colorant and inkjet technology, applied in the field of UV inkjet colorant preparation, can solve the problems of poor long-term stability and high viscosity of UV inkjet colorant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method for the UV inkjet color paste described in the above technical solution, comprising the following steps:

[0035] (1) Grinding after mixing UV monomer, hyperdispersant, carbon black and zirconium beads to obtain a mixed material;

[0036] (2) Filter the mixed material obtained in the step (1) through a filter element to obtain UV inkjet color paste.

[0037] In the present invention, the UV monomer, hyperdispersant, carbon black and zirconium beads are mixed and then ground to obtain a mixed material; the present invention does not have any special restrictions on the order of adding the UV monomer, hyperdispersant, carbon black and zirconium beads , the order of adding the mixture well known to those skilled in the art can be adopted; in the embodiment of the present invention, it is preferred to mix the UV monomer, hyperdispersant and carbon black first, and then add the zirconium beads.

[0038] In the present...

Embodiment 1

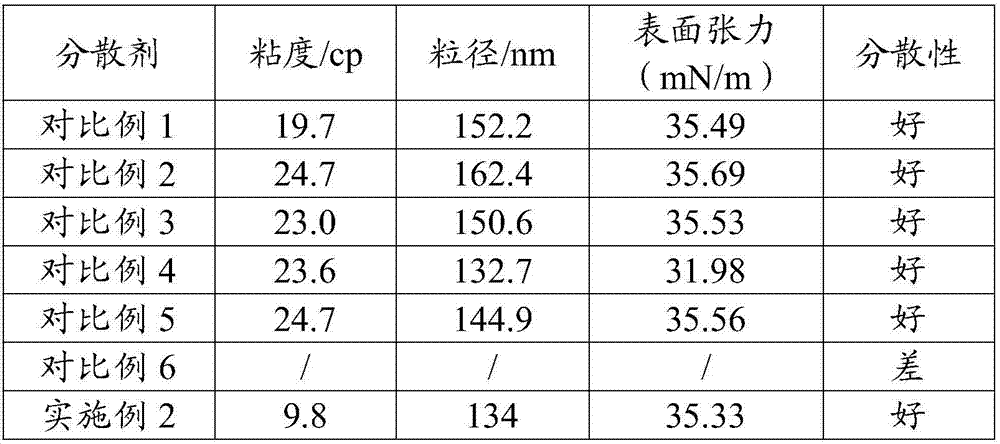

[0051] Put UV monomer tetrahydrofuran acrylate: 40 parts, PRINTEX45: 9 parts, TILO-7000: 2 parts, TILO-5007: 1 part in a glass bottle, add zirconium beads with a particle size of 0.1 mm and disperse it quickly for 0.5 hours. UV inkjet color paste. After inspection: the prepared UV inkjet color paste has good dispersibility and dilution, and has stable performance through the aging test. The viscosity of the color paste is 9.4cp, the surface tension is 35.2mN / m, and the average particle size is 135nm.

Embodiment 2

[0053] Put UV monomer tetrahydrofuran acrylate: 40 parts, PRINTEX45: 9 parts, TILO-7000: 2 parts, TILO-5007: 1 part in a glass bottle, add zirconium beads with a particle size of 0.3mm and disperse it quickly for 1 hour. UV inkjet color paste. After inspection: the prepared UV inkjet color paste has good dispersibility and dilution, and has stable performance through the aging test. The viscosity of the color paste is 9.6cp, the surface tension is 35.5mN / m, and the average particle size is 138nm.

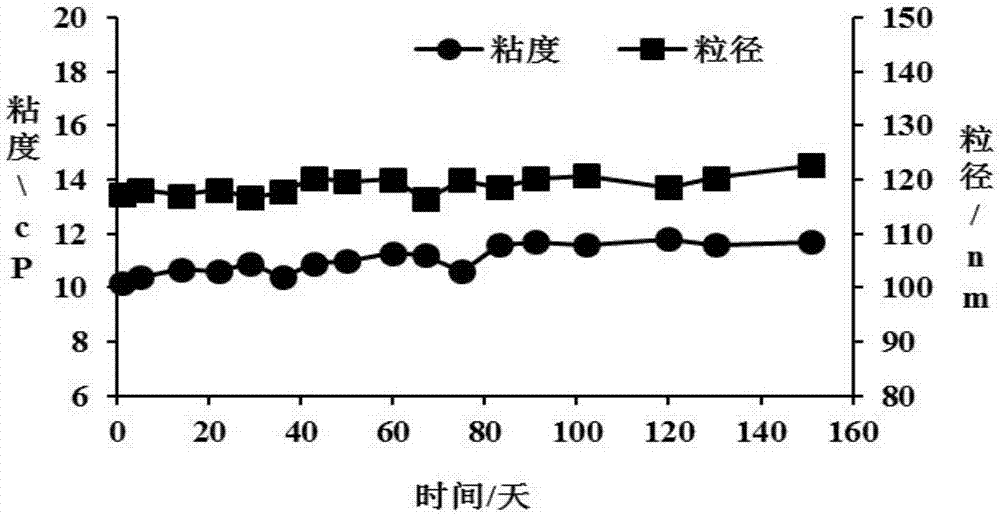

[0054] The UV ink-jet color paste that embodiment 2 makes carries out aging time-lapse follow-up test, and the result is as follows: figure 2 As shown, it shows that the UV inkjet color paste prepared in Example 2 is stable through the aging test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com