Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about How to "Improve the dilution effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

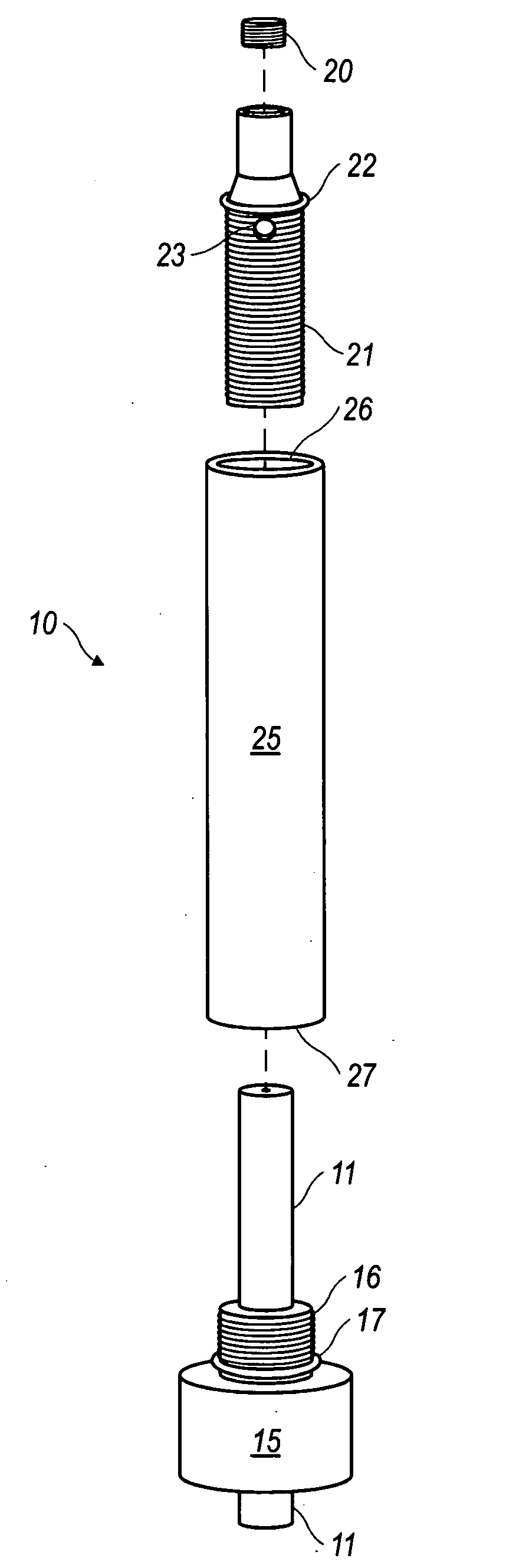

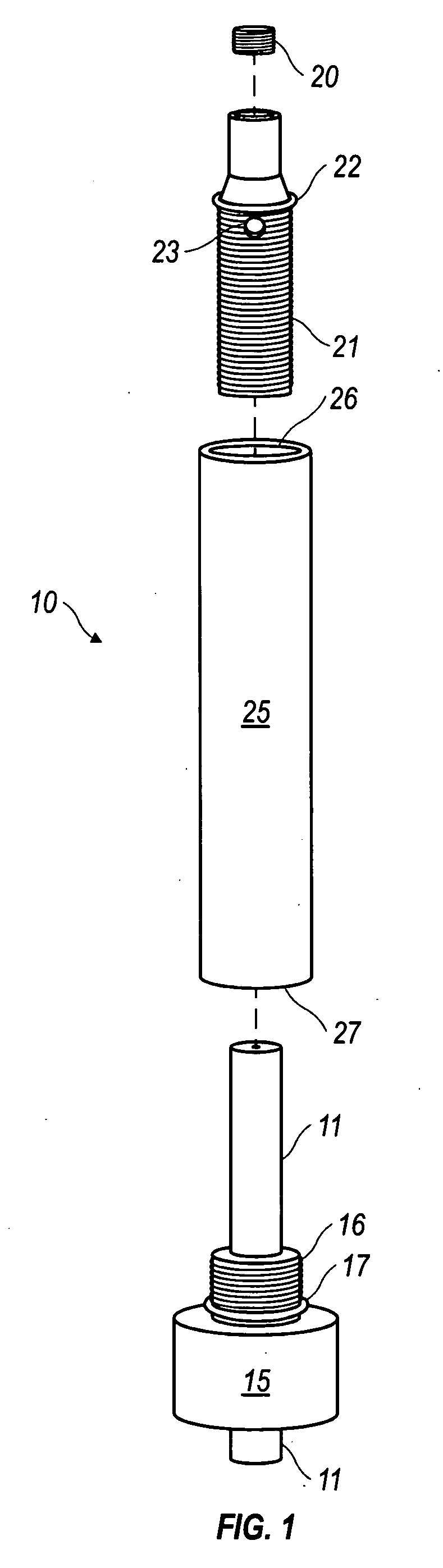

Enhanced reliability sealing system

InactiveUS20060249914A1Provides redundancyImprove the dilution effectEngine sealsDependabilityLubricant

An enhanced reliability sealing system is disclosed herein. The sealing system has multiple sealing elements for entrapping a lubricating agent capable of reducing or eliminating properties of a processing medium that could damage or compromise operation of the sealing system.

Owner:DULIN ROBERT D

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

The invention discloses a multiple crosslink ultraviolet solidification aqueous polyurethane disperser, a relative preparation method and an application. The preparation method comprises synthesizing polyurethane initial polymerized compound I, synthesizing polyurethane prepolymer II, synthesizing polyurethane prepolymer III, synthesizing polyurethane acrylate oligomer and synthesizing ultraviolet solidification aqueous polyurethane disperser. The invention mainly utilizes aromatic diisocyanate, diatomic alcohol prepolymer, polyhydroxy carboxylic acid, epoxy resin and hydroxyl acrylate as raw materials, with better water dispersity and storage stability, which leads in light inducer, levelling agent, defoaming agent and thickener to prepare ultraviolet solidification aqueous wood paint better than solvent ultraviolet solidification photosensitive resin, with stable storage, low fineness, high rigidity, high brightness, better flow leveling property, better water resistance, better solvent resistance, excellent abrasion resistance, environment protection, easy process and fire hazard resistance.

Owner:SOUTH CHINA UNIV OF TECH

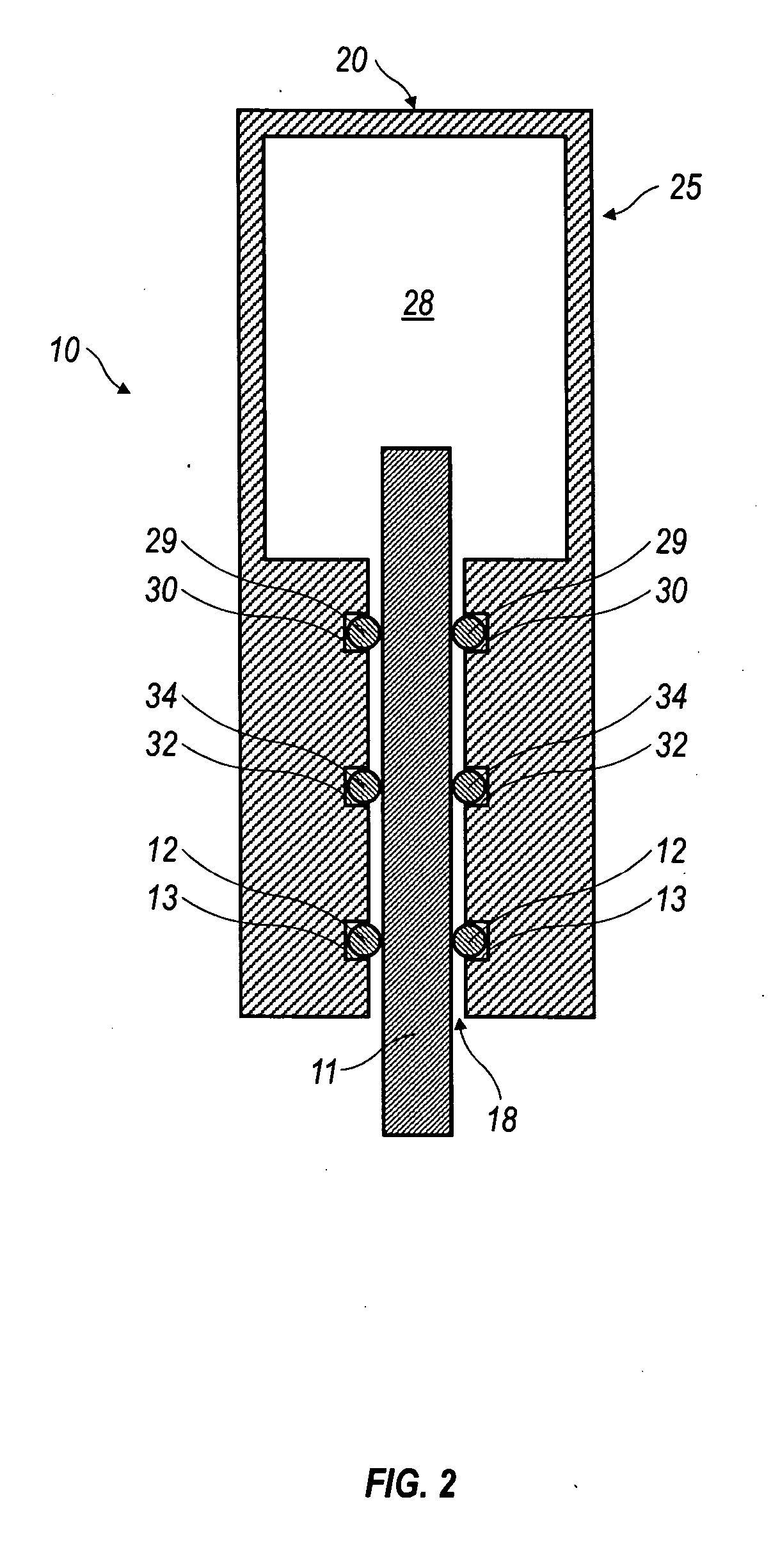

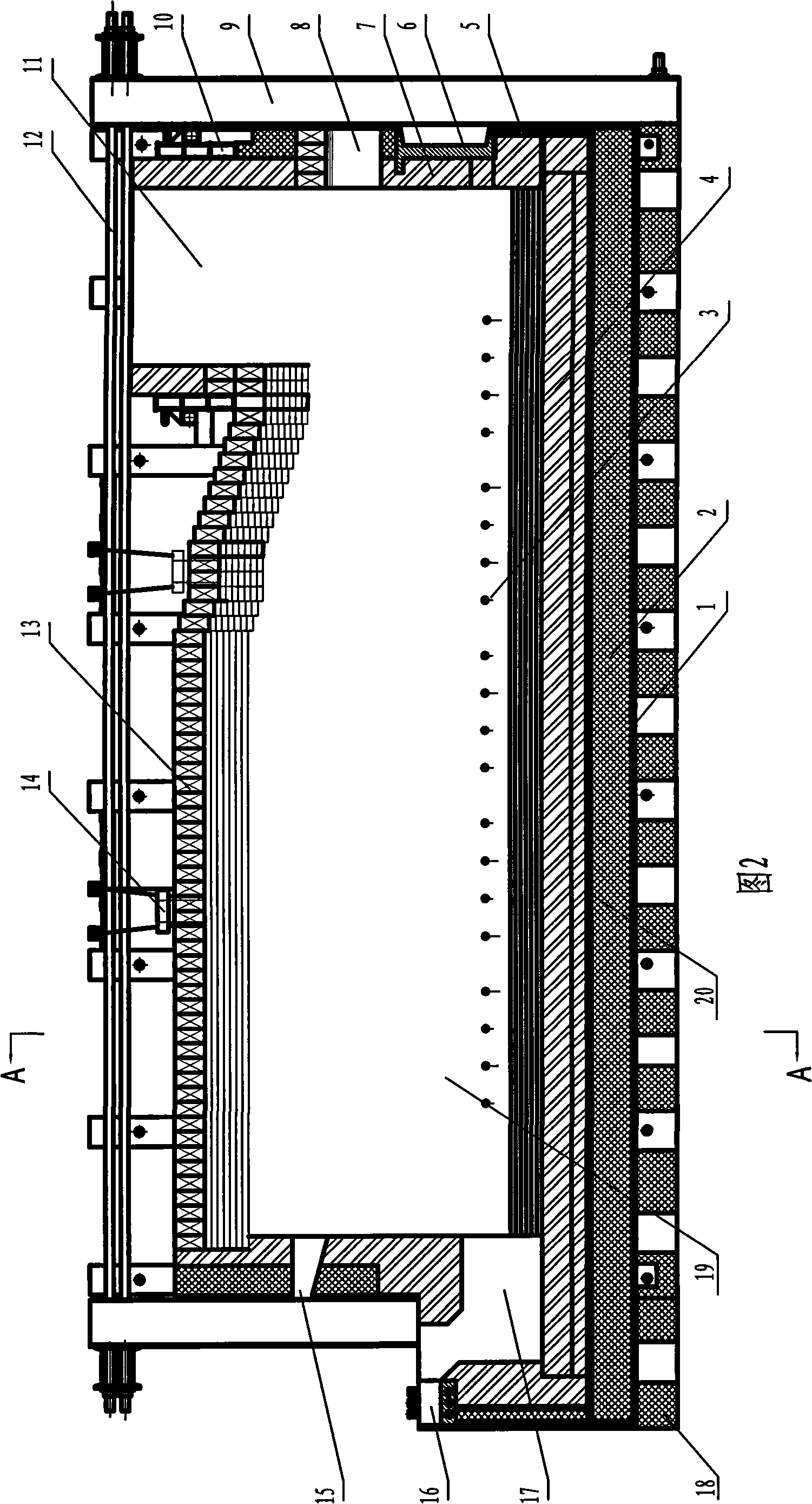

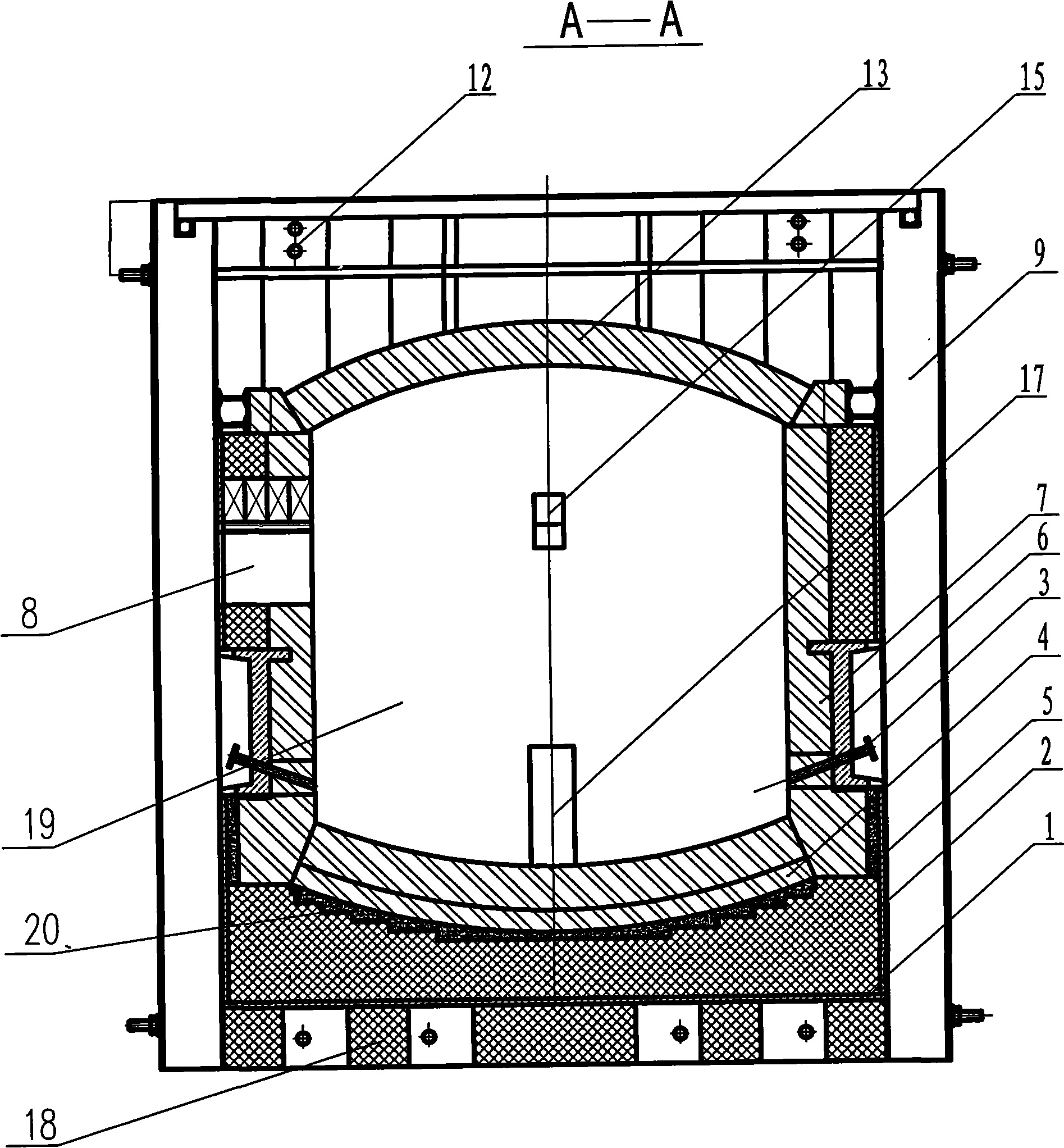

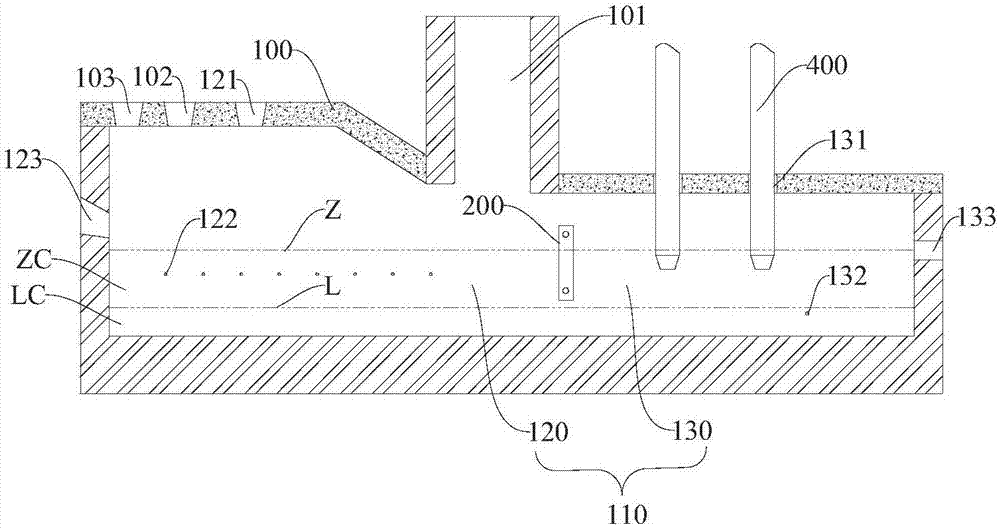

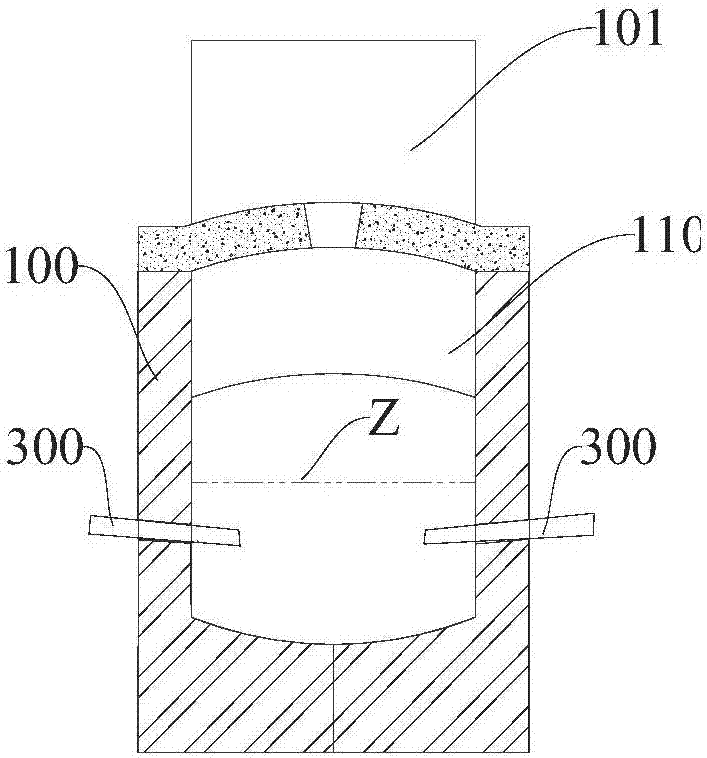

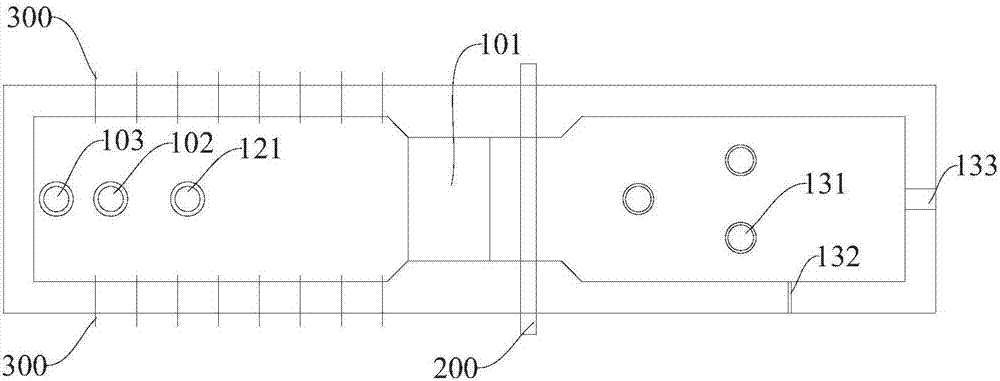

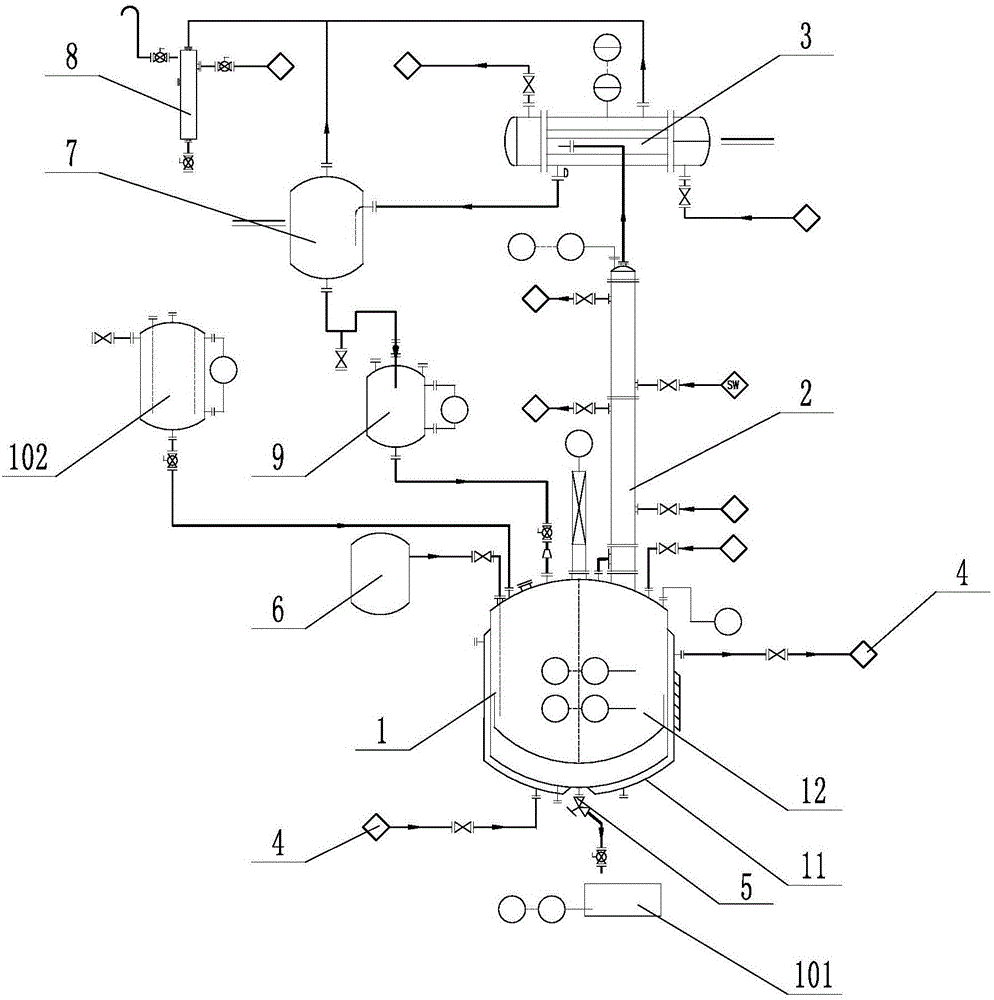

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185ALess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure oxygen

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the high pressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnace through a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

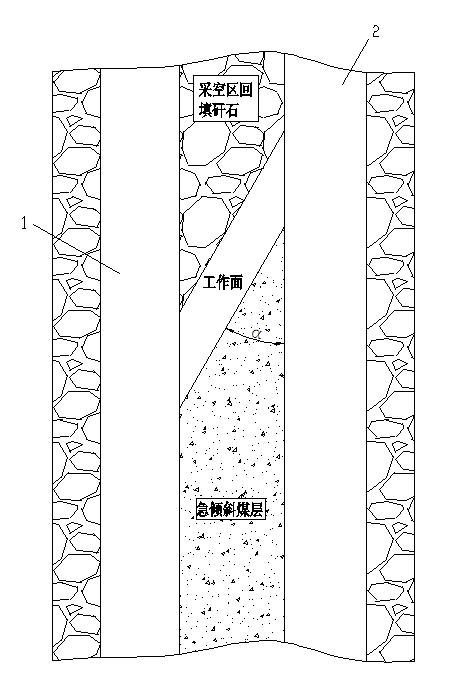

Steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method

InactiveCN102587913ADecrease the inclinationReduce coal lossUnderground miningSurface miningSupporting systemResource utilization

The invention discloses a steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method. The method comprises the following steps: preparation: digging a first laneway and a second laneway at the upper end and the lower end of the steeply inclined seam respectively; forming an initial mining working surface with the pitching oblique mining angle alpha of 25 to 35 degrees between the two laneways; arranging a coal mining machine, a scraper plate conveying machine, and a plurality of hydraulic brackets which are parallelogram-shaped in the overhead view and form a supporting system on the initial mining working surface; arranging the machine head of the scraper plate conveying machine behind relative to the machine tail while the hydraulic brackets in the propelling direction are sequentially behind a certain distance from the machine tail of the scraper plate conveying machine; arranging a reversed loader on the second laneway; coal mining: cutting coal up and low by using the coal-mining head of a coal-mining machine; moving the brackets: moving the hydraulic brackets sequentially from bottom to top; pushing and sliding: pushing and sliding by using a scraper trough conveyor of the scraper plate conveying machine in strokes to finish one time pushing and sliding quantity; and transporting coal: transporting coal to the outside by using the reversed loader. According to the method, the steeply inclined seam comprehensive mining operation is realized conveniently, and recovery ratio and resource utilization ratio are increased.

Owner:重庆市能源投资集团科技有限责任公司 +1

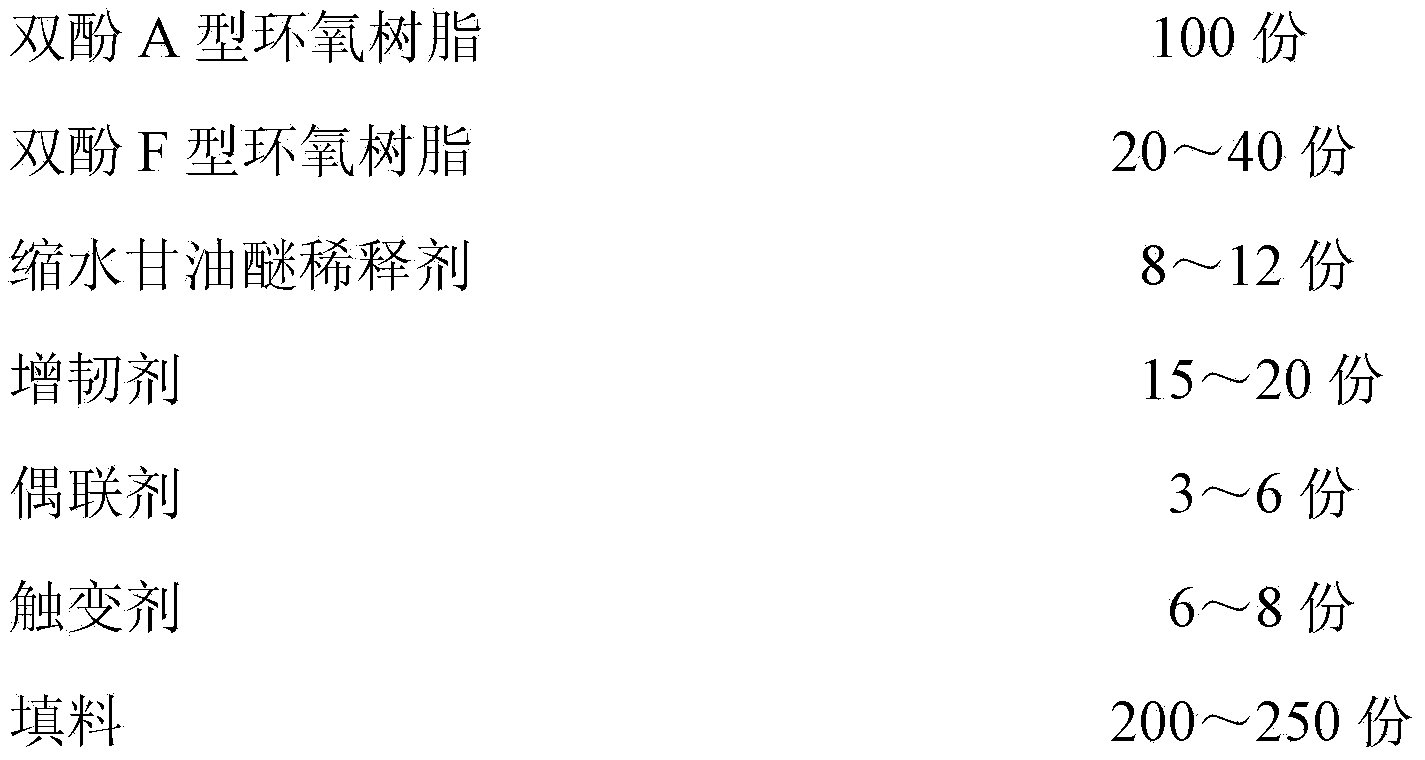

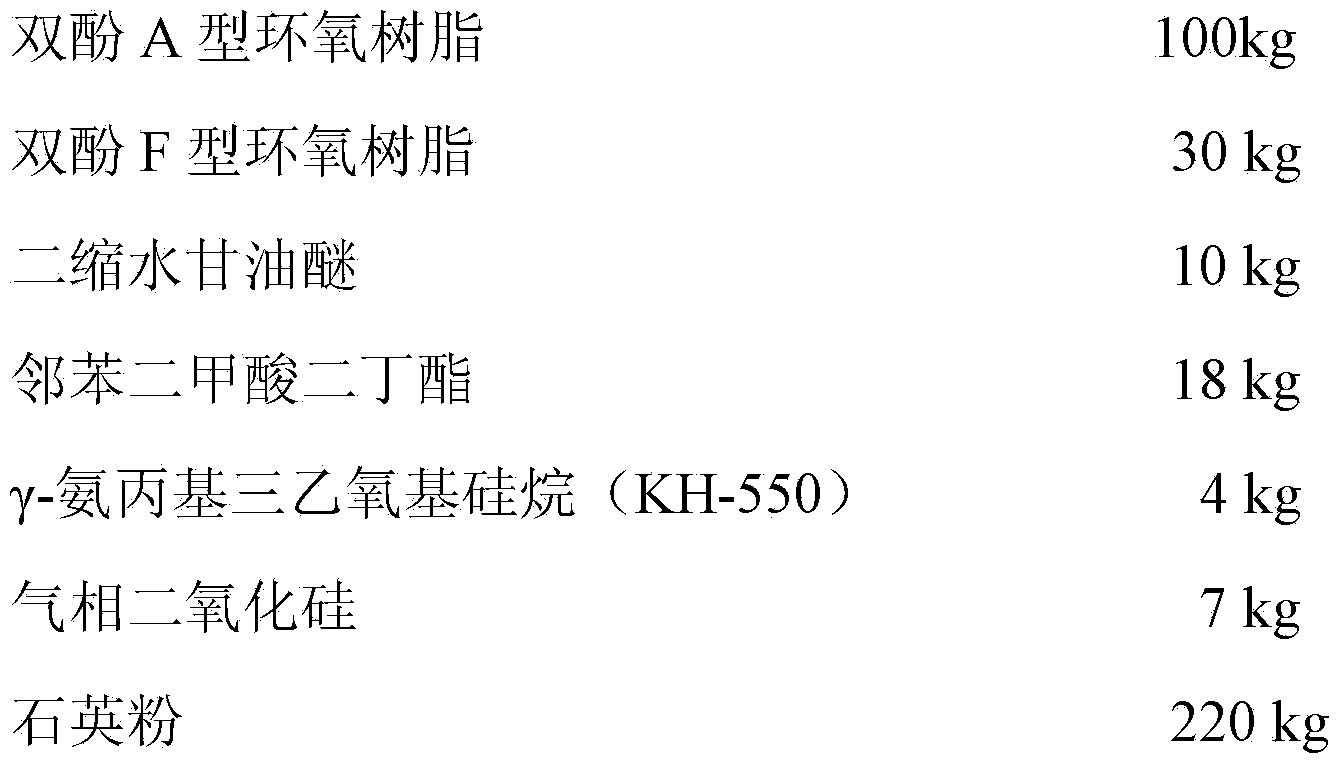

Low-temperature anti-crystalized structural adhesive and preparation method thereof

InactiveCN104371627ALow viscositySmall shrinkageNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryAdhesive

The invention relates to a low-temperature anti-crystalized structural adhesive and a preparation method thereof. The structural adhesive is prepared by mixing an A component and a B component according to the weight ratio of 2 to 1, wherein the A component consists of bisphenol A epoxy resin, bisphenol F epoxy resin, a glycidyl ether diluent, a flexibilizer, a coupling agent, a fumed silica thixotropic agent and fillers; the B component comprises an alicyclic amine curing agent, an accelerant, a fumed silica thixotropic agent and fillers. According to the low-temperature anti-crystalized structural adhesive, the bisphenol A epoxy resin and bisphenol F epoxy resin are compounded for use, and the diluent containing polyfunctional groups is adopted, so that not only can a good dilution effect be achieved, but also the usage amount of the bisphenol F epoxy resin can be reduced so as to prevent the crystallization of the epoxy resin; the viscosity and shrinkage can be reduced, and therefore the production cost is lowered; the preparation method is simple and feasible, no volatile substances are generated during production, and the low-temperature anti-crystalized structural adhesive is a green and environment-friendly building material and has no harm to the health of production personnel and users.

Owner:CARBON COMPOSITESTIANJIN CO LTD

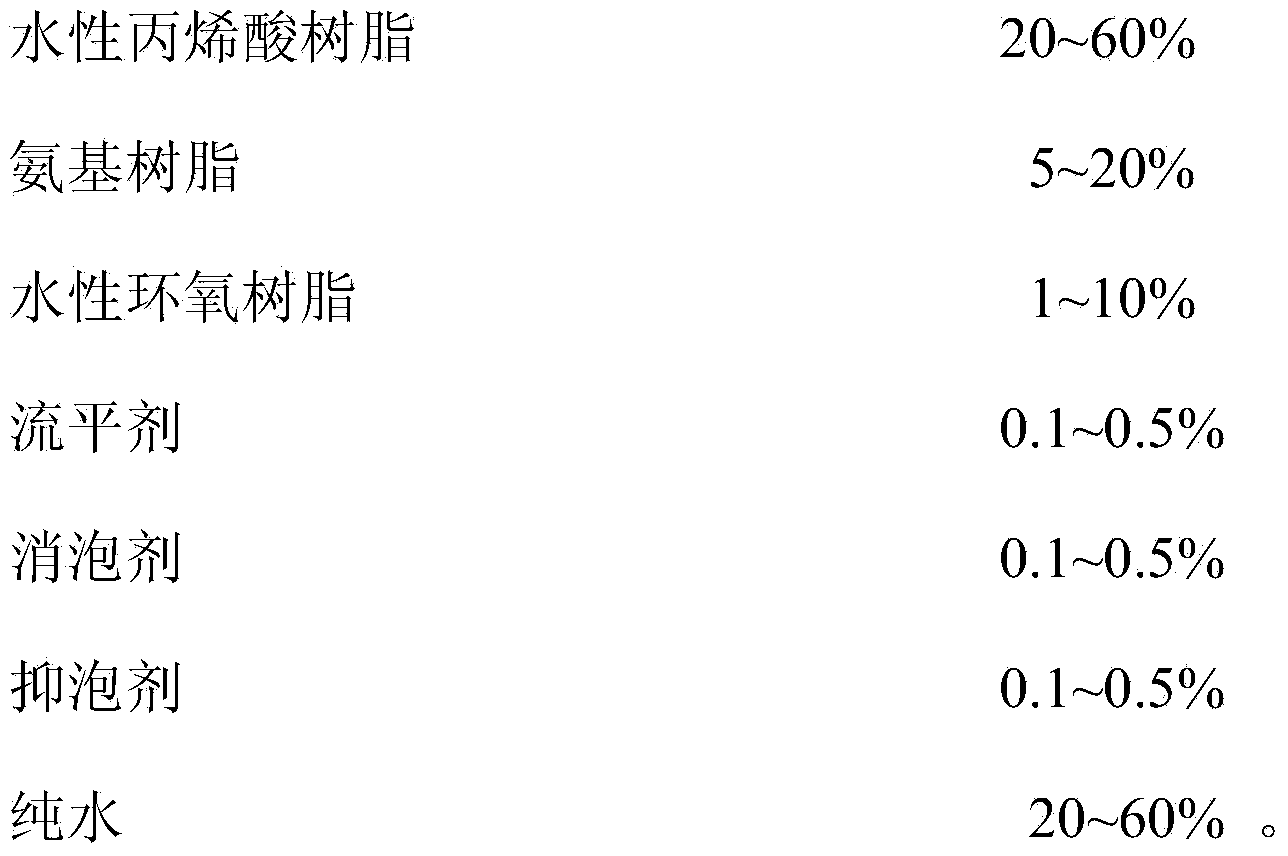

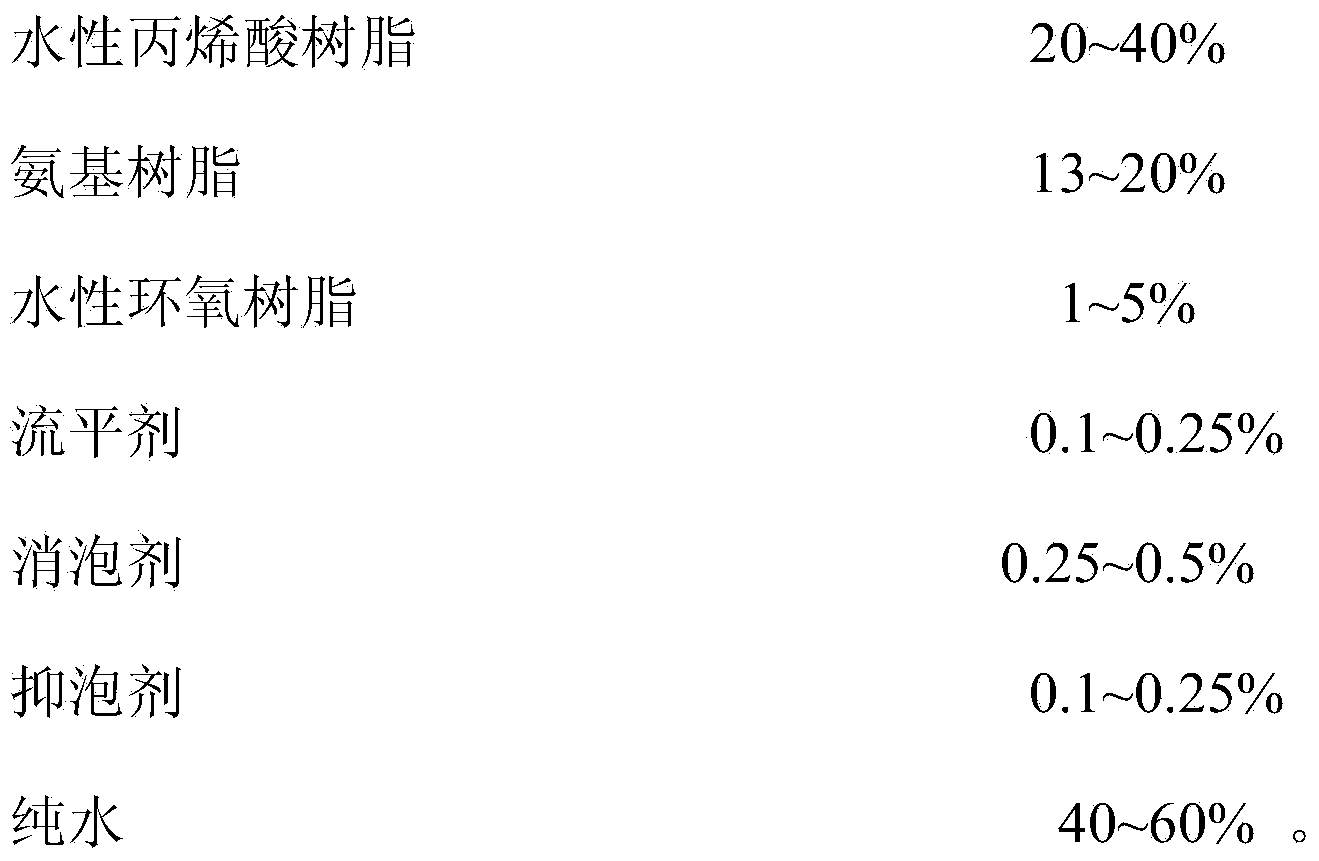

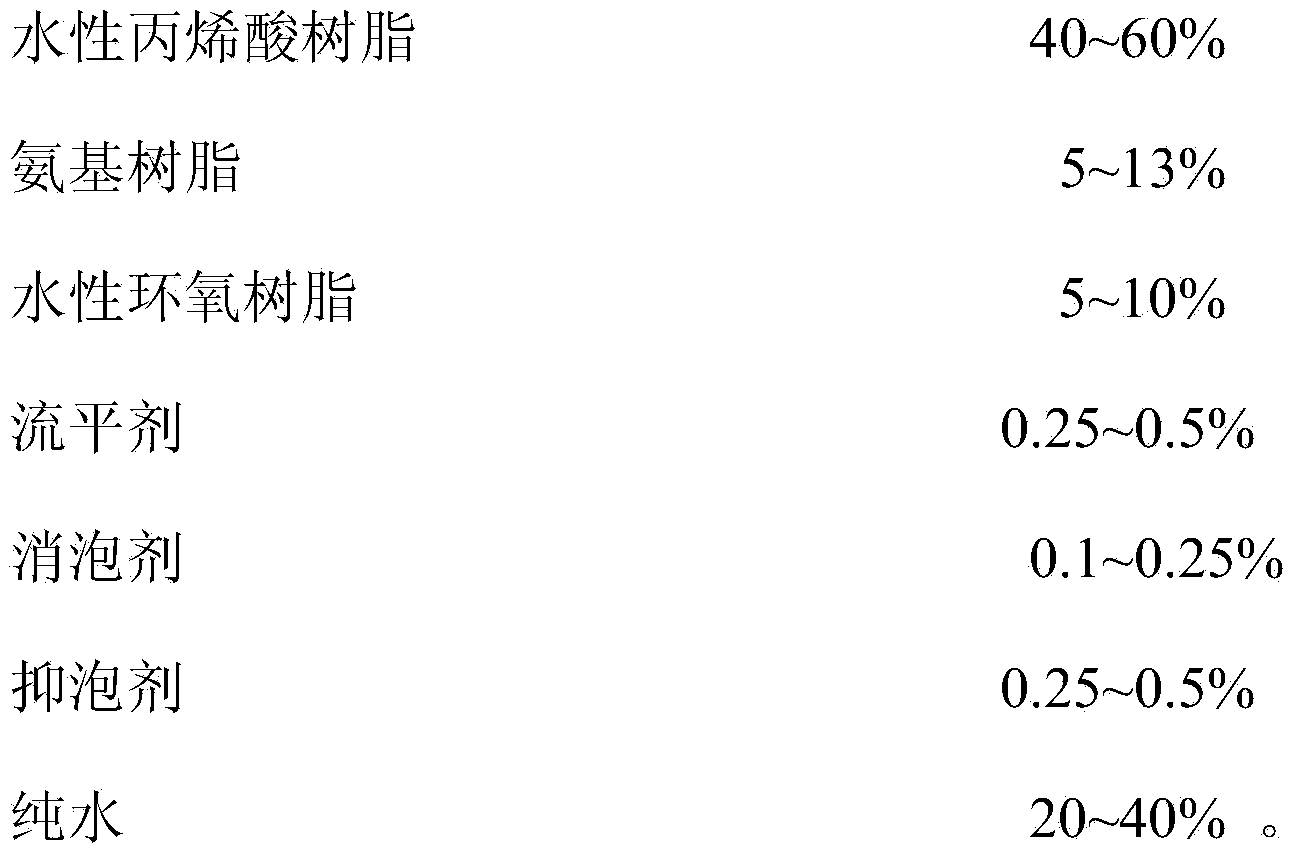

High-brightness high-hardness water-based acrylic baking varnish and preparation method thereof

InactiveCN104371471AIncrease brightnessHigh brightness and high hardnessEpoxy resin coatingsWater basedEpoxy

The invention relates to a high-brightness high-hardness water-based acrylic baking varnish which comprises the following raw materials in percentage by mass: 20-60% of water-based acrylic resin, 5-20% of amino resin, 1-10% of water-based epoxy resin, 0.1-0.5% of leveling agent, 0.1-0.5% of defoaming agent, 0.1-0.5% of foam inhibitor and 20-60% of pure water. The paint film, which is formed by coating the acrylic baking varnish on the metal surface, has the advantages of high hardness, favorable resistance to acid, alkali and salt, environmental protection and high safety. The preparation method of the high-brightness high-hardness water-based acrylic baking varnish comprises the following steps: weighing the materials according to the formula; adding the water-based acrylic resin, amino resin and water-based epoxy resin into a material cylinder, and stirring at 750-850 rpm for 5-15 minutes; shutting off the stirrer, adding the pure water into the material cylinder, and stirring for 5-15 minutes; slowly adding the leveling agent, defoaming agent and foam inhibitor into the material cylinder; and stirring for 5-15 minutes to obtain the finished product. The preparation method has the advantages of simple technique, high yield and high production efficiency, and is easy to operate.

Owner:GUANGZHOU FUCHENGMEI CHEM

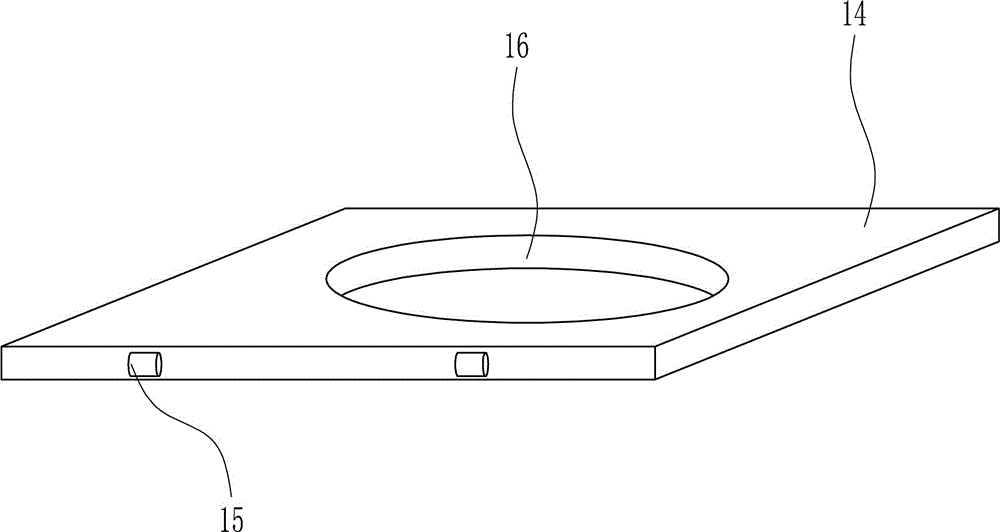

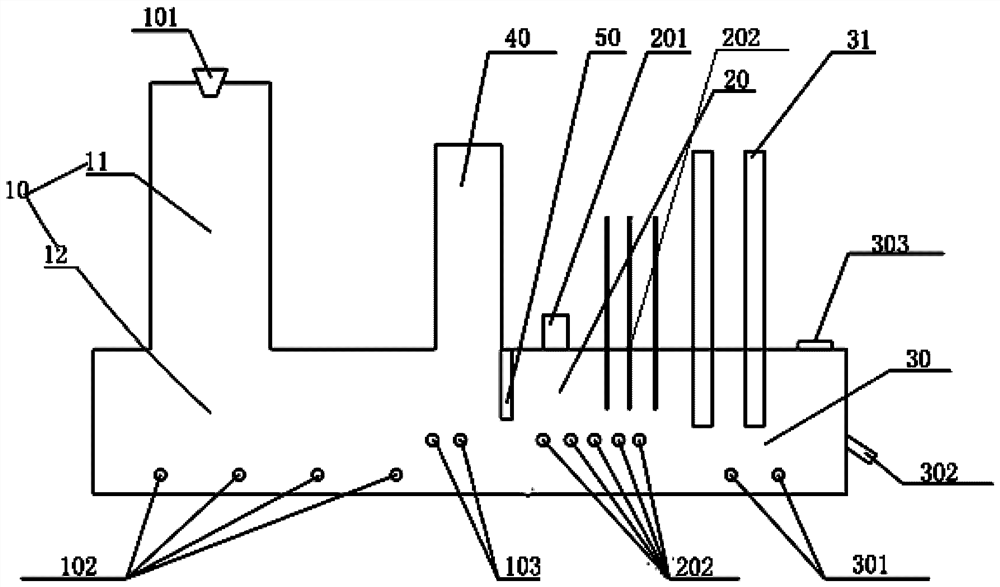

Electric heating dilution furnace

PendingCN107036443ALess investmentSmall footprintCrucible furnacesProcess efficiency improvementSlagElectrode insertion

The invention discloses an electric heating dilution furnace. The electric heating dilution furnace comprises a furnace body, a separation wall, a spraying gun and an electrode, wherein a furnace cavity is defined in the furnace body; the furnace body is provided with a smoke outlet; the separation wall is arranged in the furnace cavity for dividing the furnace cavity into a blowing area and a settling area for communicating up and down; the blowing area is provided with a charging port and a spraying gun insertion hole; the settling area is provided with an electrode insertion hole, a sulfonium outlet and a slag outlet; the spraying gun is inserted in the spraying gun insertion hole for blowing oxygen-enriched gas and a reducing agent into a slag layer in the blowing area; and the electrode is inserted in an electrode insertion hole, and extends into a slag layer in the settling area. The electric heating dilution furnace has the advantages of a side blowing furnace and the electric heating dilution furnace, and is excellent in dilution effect, high in metal recovery rate, low in investment and small in floor area.

Owner:CHINA ENFI ENGINEERING CORPORATION

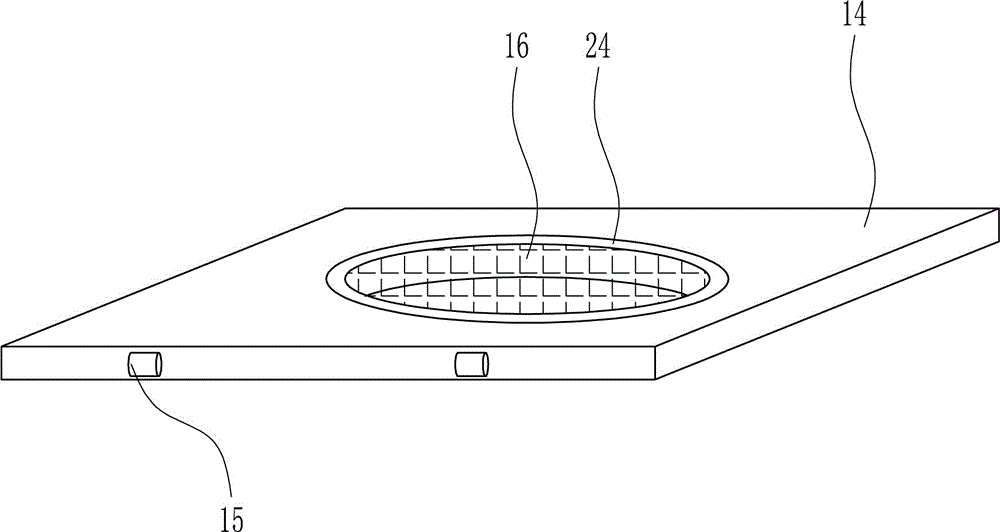

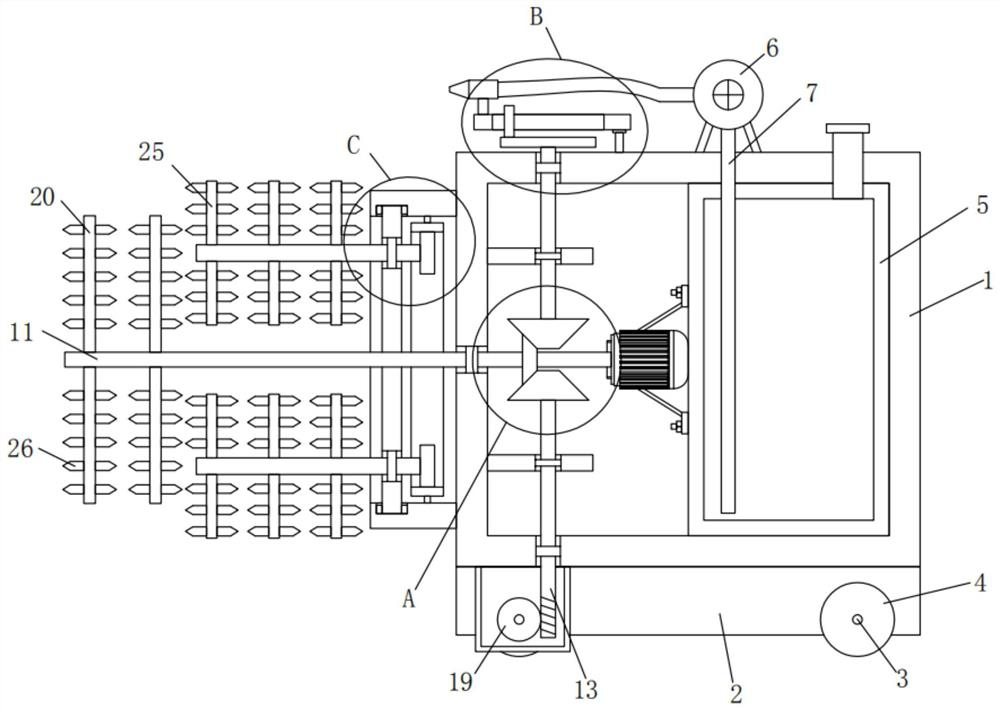

Diluting device for electronic component dispensing glue

InactiveCN106732100ANot easy to splashAvoid wastingShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringElectronic component

The invention belongs to the technical field of electronic component processing equipment, and particularly relates to a diluting device for electronic component dispensing glue. The invention provides the diluting device for electronic component dispensing glue, wherein a barrel body can be fixed in a glue dilution process, the glue is not easy to splash, waste is avoided, the cost is reduced, the dilution effect is good and the device is simple to operate. The diluting device for the electronic component dispensing glue comprises a bottom plate, a side plate, an up-down moving mechanism, a moving plate, a rotating mechanism, a cover plate, a bearing block, a rotating shaft, stirring blades, a first fixing block, a second fixing block, a placing plate, a pulley and the barrel body, wherein the side plate is vertically welded on the left side of the top of the bottom plate, a mounting groove is vertically formed in the side plate, and the up-down moving mechanism is arranged in the mounting groove. According to the invention, a clamping device is adopted for fixing the barrel body in the glue dilution process, the cover plate is matched with the barrel body, so that the glue is not easy to splash during dilution, waste is avoided, and the cost is reduced.

Owner:南昌叁润科技有限公司

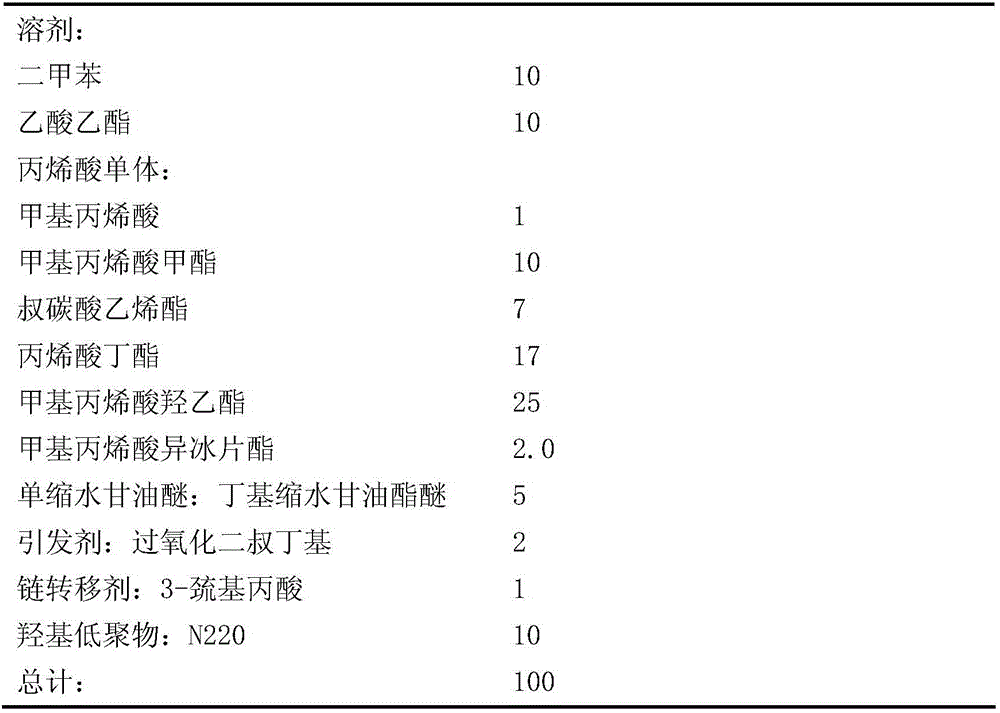

High-solid low-viscosity hydroxy acrylic resin as well as preparation method and application thereof

ActiveCN106009454ALow viscosityHigh cost performancePolyurea/polyurethane coatingsPolymer scienceOligomer

The invention discloses high-solid low-viscosity hydroxy acrylic resin as well as a preparation method and application thereof. During preparation, a first part of solvent and mono-glycidyl ether are added into a reaction kettle, stirred and heated to 140-180 DEG C; a first part of initiator and a chain transfer agent are added into an acrylic monomer mixture, the obtained mixture is dropwise added into a reaction kettle within 3-6 h, and the temperature is kept for 0.5-1h after dropwise addition; the residual initiator and the residual solvent are mixed uniformly and added into the reaction kettle within 20-40 min, the temperature is kept for 1-2 h after the addition is completed, a hydroxyl oligomer is added, stirring is performed for 30-60 min, the temperature is lowered for material discharge, and the high-solid low-viscosity hydroxy acrylic resin is obtained. The resin solid accounts for 70% or higher, the viscosity is as low as 300mPa*s. The technology for preparing the hydroxy acrylic resin is simple, the cost is low, and a bi-component polyurethane coating film has excellent water resistance, acid and alkali resistance and mechanical properties.

Owner:英德市佐桐化学品有限公司

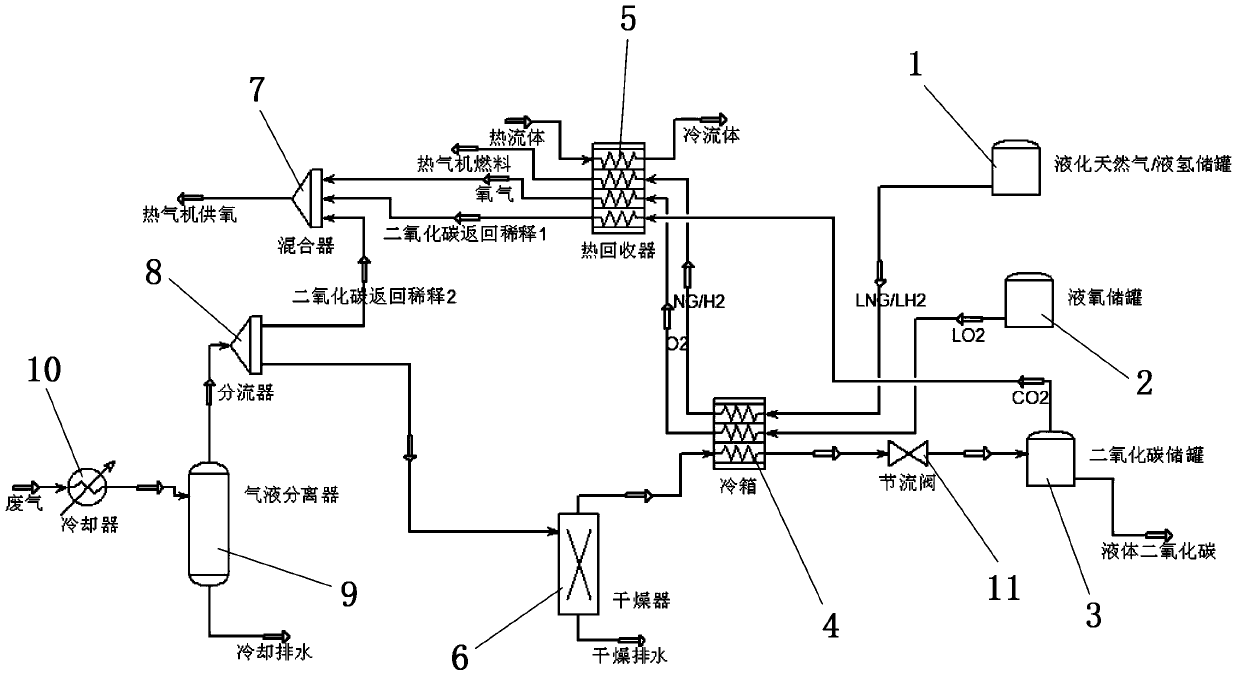

Use and storage device and method of waste gas of underwater vehicle

InactiveCN109838684AImprove the dilution effectLeave no trackDispersed particle separationPipeline systemsLiquid hydrogenEngineering

The invention discloses a use and storage device and method of waste gas of an underwater vehicle. The use and storage device comprises a liquefied natural gas / liquid hydrogen storage tank pump, a liquid oxygen storage tank, a carbon dioxide storage tank, a cold box, a heat recovery device, a dryer, a mixer, a distributor, a gas-liquid separator, a cooler and a throttle valve; and the liquefied natural gas / liquid hydrogen storage tank pump and the liquid oxygen storage tank are connected with the cold box and the heat recovery device correspondingly, the carbon dioxide storage tank is connected with the mixer through the heat recovery device, the mixer is externally connected with a hot-gas engine, waste gas of the hot-gas engine is connected with the gas-liquid separator through the cooler, the gas-liquid separator is connected with the dryer and the mixer through the distributor correspondingly, the dryer is connected with the cold box, and the cold box is connected with the carbon dioxide storage tank. According to the use and storage device and method of the waste gas of the underwater vehicle, due to the fact that liquefied natural gas / liquid hydrogen and liquid oxygen capableof being stored are used as double energy sources, the cold energy is sufficient, the waste gas discharged by the hot-gas engine is liquefied and stored while fuel and oxygen are supplied for the hot-gas engine, tracks and chemical thermal signals are not left behind, and the engine is not limited and influenced by seawater backpressure.

Owner:JIMEI UNIV

High-solid-content finishing oil-based acrylic resin for automobiles and preparation method thereof

The invention discloses a high-solid-content finishing oil-based acrylic resin for automobiles and a preparation method thereof, which belong to the field of automobile paints and solve the problems of low solid content, high viscosity, poor solubility and the like in the existing acrylic resin paint. The resin contains acrylic acid, styrene, butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, methacrylic acid, butyl methacrylate, 2-ethylhexyl acrylate, n-dodecyl mercaptan, lauryl methacrylate, isoborneol methacrylate, 2-hydroxyethyl acrylate, 2-hydroxypropyl acrylate, 100# solvent oil, di-tert-pentyl peroxide, glycidol tert-carboxylate and a resin reactive diluent. The solid content can reach 90%. The acrylic resin has the advantages of favorable dilution property and low viscosity. The self-made reactive diluent can greatly enhance the water resistance and acid resistance of the paint. The construction solid content of the resin is nearly 70%. The acrylic resin greatly lowers the discharge of VOC (volatile organic compound), and is environment-friendly and practical.

Owner:安徽优科新材料科技有限公司

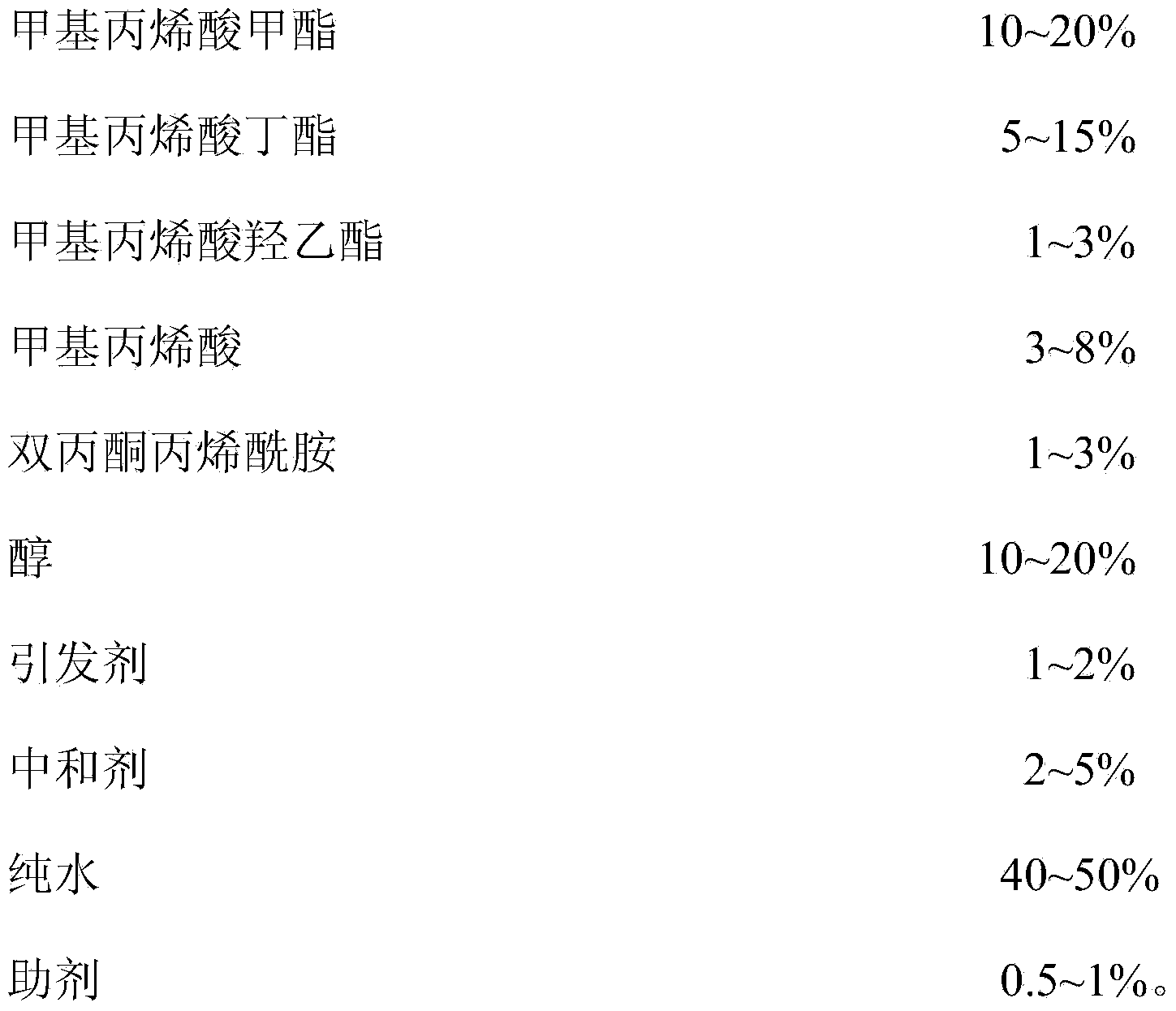

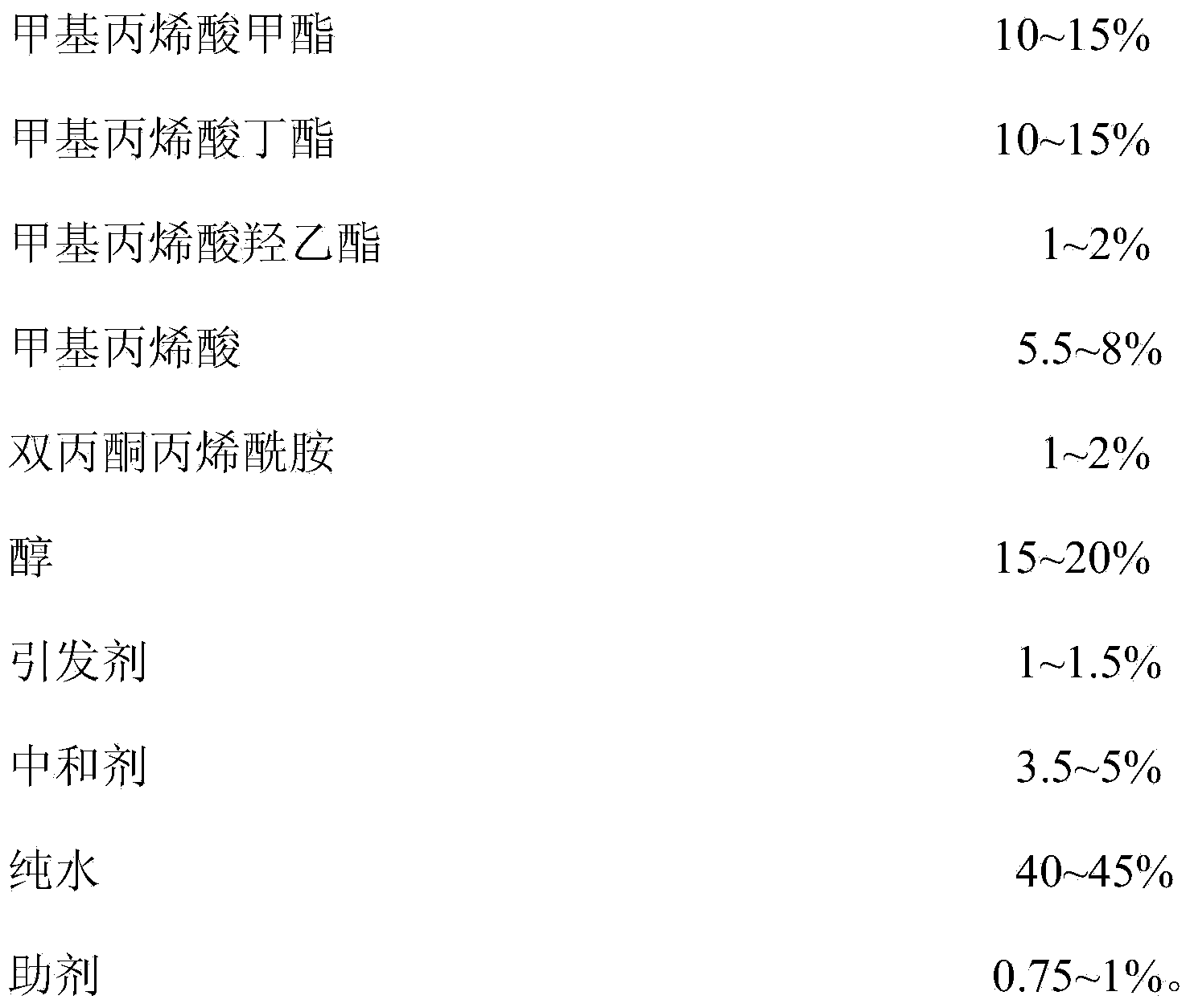

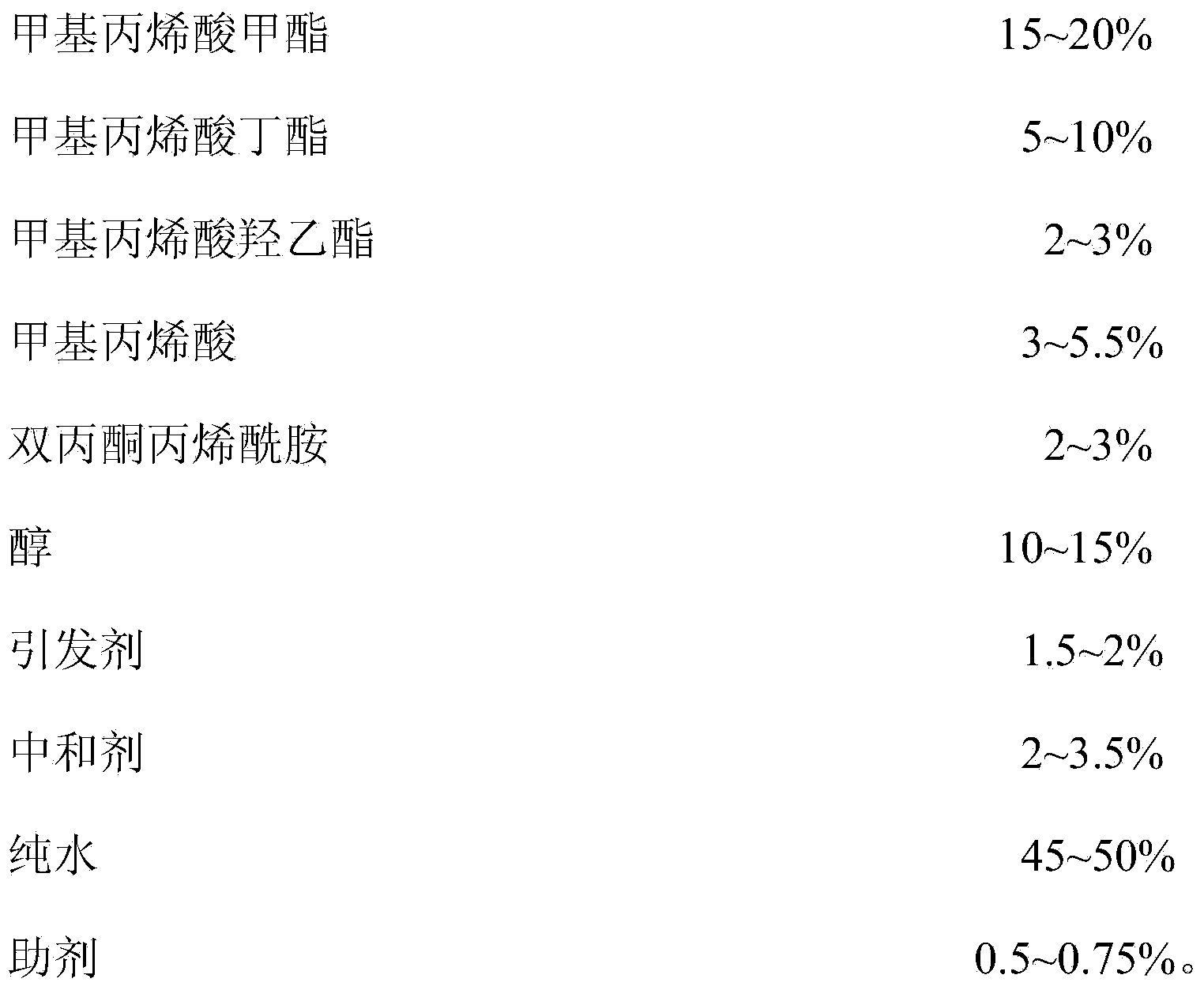

Self-crosslinked water-based acrylic air-drying paint and preparation method thereof

The invention relates to a self-crosslinked water-based acrylic air-drying paint which comprises the following raw materials in percentage by mass: 10-20% of methyl methacrylate, 5-15% of butyl methacrylate, 1-3% of hydroxyethyl methacrylate, 3-8% of methacrylic acid, 1-3% of diacetone acrylamide, 10-20% of alcohol, 1-2% of initiator, 2-5% of neutralizer, 40-50% of pure water and 0.5-1% of assistant. The paint film formed by the paint has the advantages of favorable closeness, favorable oxidation resistance, favorable hand perspiration resistance and favorable salt spray resistance. The preparation method of the paint comprises the following steps: weighing the raw materials; mixing the methyl methacrylate, butyl methacrylate, hydroxyethyl methacrylate, methacrylic acid, diacetone acrylamide and 75-85% of initiator to obtain a mixed solution; adding the alcohol into a reaction kettle, introducing nitrogen and heating; adding the mixed solution into the reaction kettle, adding the rest of initiator into the reaction kettle, removing the solvent, and cooling; adding the neutralizer into the reaction kettle; and adding the pure water into the reaction kettle, and adding the assistant into the reaction kettle to obtain the finished product. The method has the advantages of simple technique and high production efficiency.

Owner:GUANGZHOU FUCHENGMEI CHEM

Cationic emulsified wax and its prepn

InactiveCN1388222AImprove adsorption capacityUniform film formationWax physical treatmentParaffin waxAntistatic agent

The cationic emulsifier wax includes paraffin, cationic surfactant, coemulsifier and water. It is prepared through the process including smelting and mixing paraffin and coemulsifier in the container with stirrer and heating to emulsifying temperature; heating to dissolve cationic surfactant in water inside one other container and heating to emulsifying temperature to prepare water solution of surfactant; adding the water solution of surfactant slowly into reactor while stirring for some period; cooling while stirring to room temperature and packing the product. The product may be stored stably for at least 60 days. It may be used as antistatic agent and softening agent for fabric.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of drilling fluid diluent compound methyl silicate

ActiveCN103059821AEnhanced inhibitory effectLow viscosityDrilling compositionPtru catalystSilicic acid

The invention relates to a preparation method of a drilling fluid diluent compound methyl silicate. The method comprises the following steps: (1) preparing methyl silicate: adding water in a reactor, then adding alkali, heating to 70-90 DEG C after the alkali is dissolved, adding methyl silicic acid, continuing heating to 90-110 DEG C, and reacting to generate methyl silicate, wherein the weight ratio of water to methyl silicic acid to alkali is 1: 0.1-0.3: 0.2-0.6; and (2) preparing compound methyl silicate: adding sodium silicate and low molecular weight polyacrylate in generated methyl silicate, uniformly stirring sufficiently, adding an organic tin catalyst, and reacting for 3-5 hours at 90-120 DEG C to obtain a liquid diluent product compound methyl silicate with effective substance content of 25-40%. The drilling fluid diluent methyl silicate has the advantages of good diluting effect, low cost, wide application range, and long stabilization time, and can resist high temperature of more than 150 DEG C.

Owner:DAQING HEZHENG CHEM

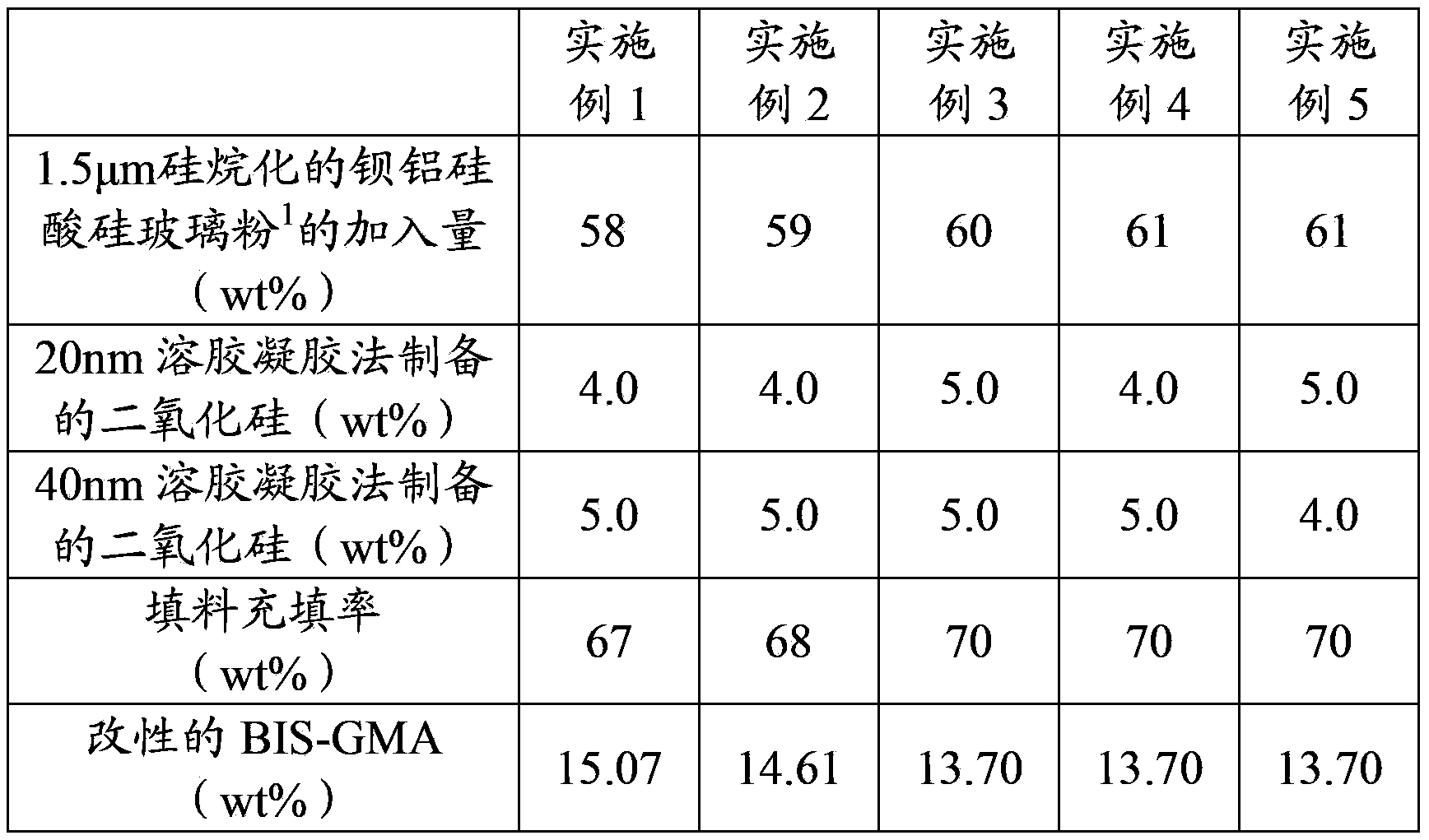

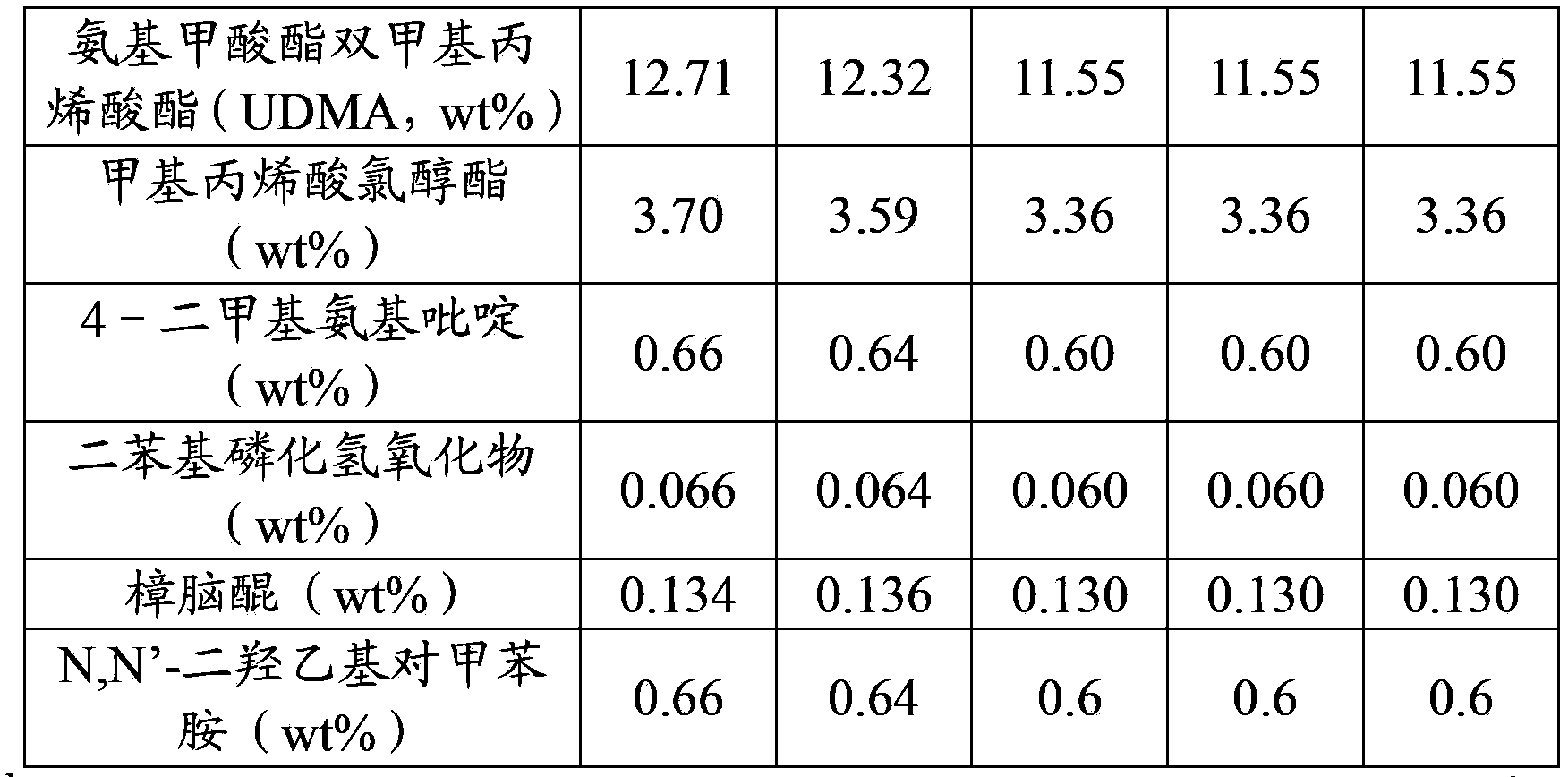

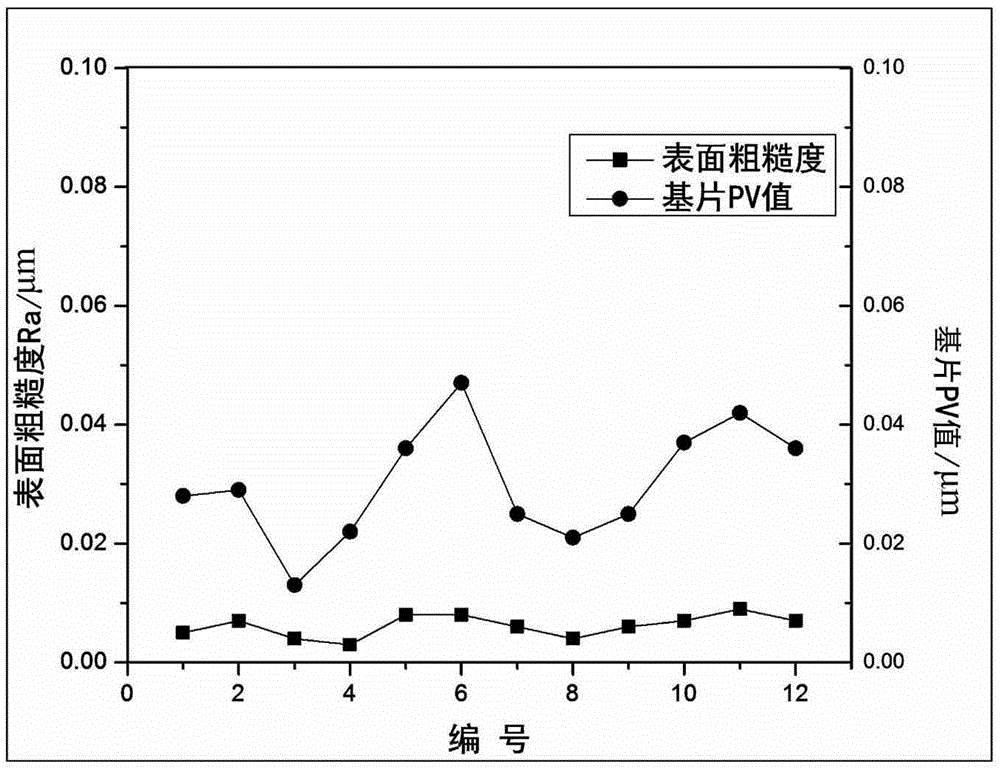

Dual curing crown nuclear resin for dentistry and preparation method thereof

InactiveCN103356391AMake up for the defect of poor infiltrationLow hydroxyl contentImpression capsDentistry preparationsFilling rateDual curing

The invention relates to dual curing crown nuclear resin for dentistry and a preparation method thereof. The dual curing crown nuclear resin comprises the following components in percentage by weight: 50-80 wt% of structured packing, 4.0-5.0 wt% of chemical curing initiator, 0.5-1.0 wt% of photocuring initiator, and the balance of two or more polymerizable acrylic monomers, wherein the mean grain size of the structured packing is 0.02-10 microns; and the structured packing contains the particles of which the volume fraction is less than 50% and the mean grain size is greater than 1.5 microns. The resin displays low cure volume shrinkage, high packing filling rate and high strength, so that the performance of the resin is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Manufacturing method for super-hard resin grinding wheel

ActiveCN105290996AImprove the dilution effectControl porosityGrinding devicesFirming agentGrinding wheel

The invention discloses a manufacturing method for a super-hard resin grinding wheel. The manufacturing method includes the following steps that firstly, hollow spheres are dried for 0.5-4 h in a drying oven at the temperature of 80-100 DEG C and evenly mixed with diamond and then pass a screen with 100-200 meshes; secondly, epoxy resin liquid is stirred in a water bath with the temperature of 70-80 DEG C for 2-5 minutes, then diluent and a coupling agent are added, after stirring heating is conducted continuously for 5-10 minutes, the obtained mixture of the hollow spheres and the diamond in the first step is added, and stirring heating is conducted continuously for 5-10 minutes; thirdly, the temperature of the water bath in the second step is reduced to 55-60 DEG C, the diluent and a curing agent are evenly mixed and then added to sizing obtained in the second step, the obtained mixture is poured into a mold after even mixing is conducted and hardened for 3-8 h under the temperature of 80-90 DEG C, and then curing is conducted; and fourthly, the material cured in the third step is cooled to the room temperature to be demolded, a grinding wheel ring is obtained, machining is conducted, and the super-hard resin grinding wheel is obtained.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Nickel smelting device and nickel smelting method

The invention provides a nickel smelting device and a nickel smelting method. The nickel smelting device is integrated equipment and comprises a smelting area, a dilution area and a settling area which horizontally and sequentially communicate with one another, wherein the smelting area comprises a flash smelting reaction tower and a settling pond which is located below the flash smelting reactiontower and directly communicates with the flash smelting reaction tower; the flash smelting reaction tower is used for carrying out flash smelting on a nickel smelting raw material under the action offirst oxygen-enriched air to produce nickel matte containing 20-75wt% of nickel, smelting slag and smelting smoke; and the dilution area communicates with the settling pond, is provided with a plurality of first spray holes and is further provided with a plurality of first spray guns corresponding to the first spray holes one to one. The nickel smelting device can simultaneously have the excellent properties in the aspects of being short in process, good in dilution effect, low in energy consumption, free of adding of a large number of vulcanizing agents and the like in the nickel smelting process.

Owner:CHINA ENFI ENGINEERING CORPORATION

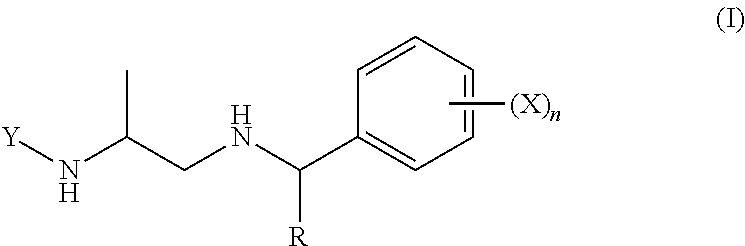

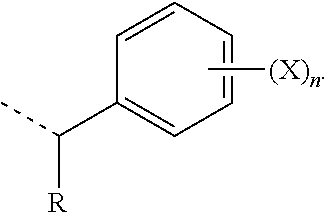

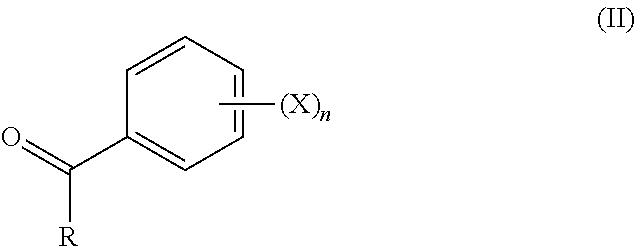

Amine for low-emission epoxy resin compositions

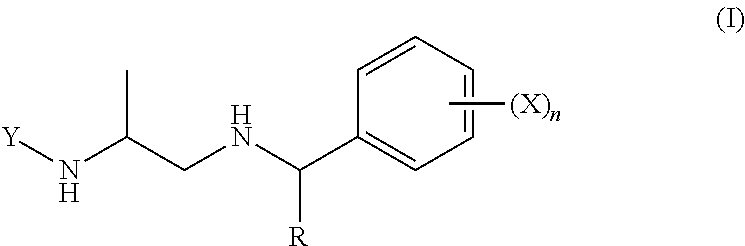

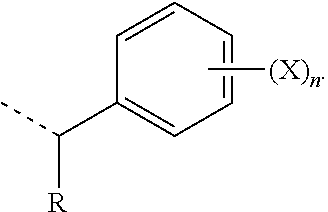

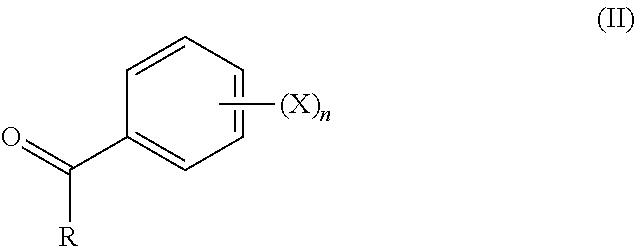

ActiveUS20170218114A1High hardnessImprove surface qualityOrganic chemistryEpoxy resin coatingsEpoxyPolymer science

An amine of the formula (I) for use as hardener for epoxy resins, hardeners for epoxy resins containing the amine of the formula (I) and resultant epoxy resin compositions which more particularly can be used as low-emission room-temperature-curing epoxy-resin coatings with high hardness and surface quality. The amine of the formula (I) has little odour and is a very successful diluent for epoxy resin compositions. It is more particularly obtained by reductive alkylation from 1,2-propylenediamine and an aldehyde or ketone.

Owner:SIKA TECH AG

Floor white-mark resistant UV paint

InactiveCN104403551AGood flexibilityGood strengthPolyurea/polyurethane coatingsEpoxy resin coatingsDefoaming AgentsChemistry

The floor white-mark resistant UV paint is composed of a prime paint and a surface paint. The prime paint is composed of polyurethane acrylate (PUA) resin, epoxy acrylate resin, light-cured monomers, and a photosensitizer and is prepared by evenly mixing all the components mentioned above. The surface paint is composed of polyurethane acrylate (PUA) resin, light-cured monomers, a matting agent, a photosensitizer, a dispersant, and a defoaming agent, and is prepared by the following steps: adding PUA resin, 20 to 30% of light-cured monomers, a dispersant, and a defoaming agent into a reactor at first, dispersing for 0.5 hour, then adding a matting agent into the reactor, dispersing for 2 hours, finally adding the residual light-cured monomers and a photosensitizer into the reactor, dispersing for 0.5 hour, and evenly mixing so as to obtain the surface paint. The prime paint and the surface paint are used as a combination, the paint is not easily scratched by hard objects, the paint color will not fade, the scratches formed by sharp things can be wiped off, and the paint also has the advantages of durability and beautiful and elegant appearance.

Owner:HUNAN BANFERT NEW MATERIALS TECH

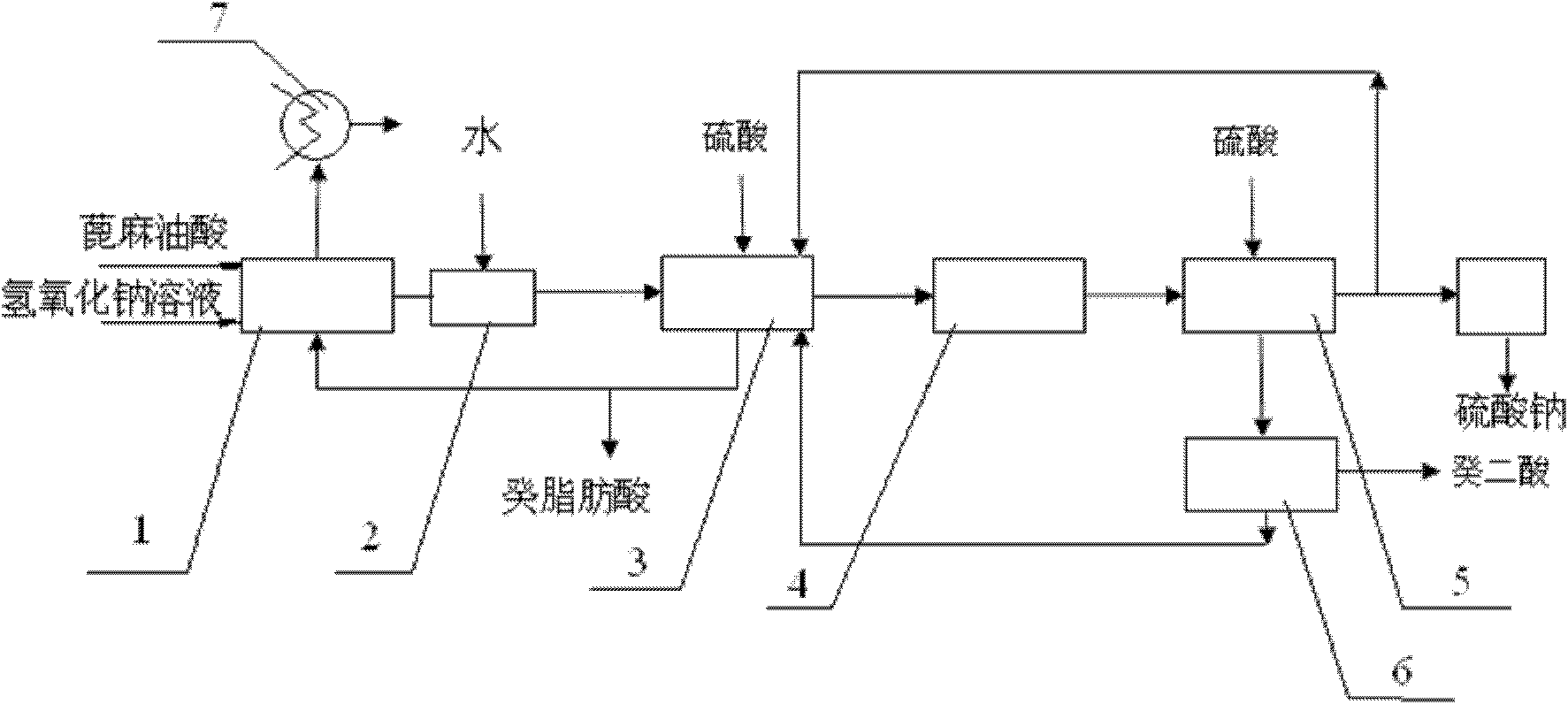

Preparation method for sebacic acid

ActiveCN102351682AEliminate pollutionSimple recycling processOrganic compound preparationCarboxylic compound preparationOctanolSebacic acid

The invention provides a preparation method for sebacic acid, which comprises the following steps: (1) adding ricinoleic acid, a diluent decanoic fatty acid and a sodium hydroxide solution in a reaction vessel for heating reaction, generating sebacic acid disodium salt, octanol, hydrogen and decanoic fatty acid sodium, (2) mixing and dissolving sebacic acid disodium salt, decanoic fatty acid, decanoic fatty acid sodium and water, placing into a neutralizing tank for neutralizing by sulfuric acid to obtain water phase of sebacic acid monosodium salt, then adding sulfuric acid into water phase, reacting and collecting the target product sebacic acid. The method of the invention reduces the difficulty of waste water treatment and the production cost which has the advantages of energy saving and consumption reduction, decanoic fatty acid is a by-product of sebacic acid production as well as a diluent which has the advantages of repeated usage and convenient recovery, no extra impurity is introduced in the production process, the product has good quality, and the major product sebacic acid, co-product octanol and by-product decanoic fatty acid have good quality.

Owner:上海华谊工程有限公司

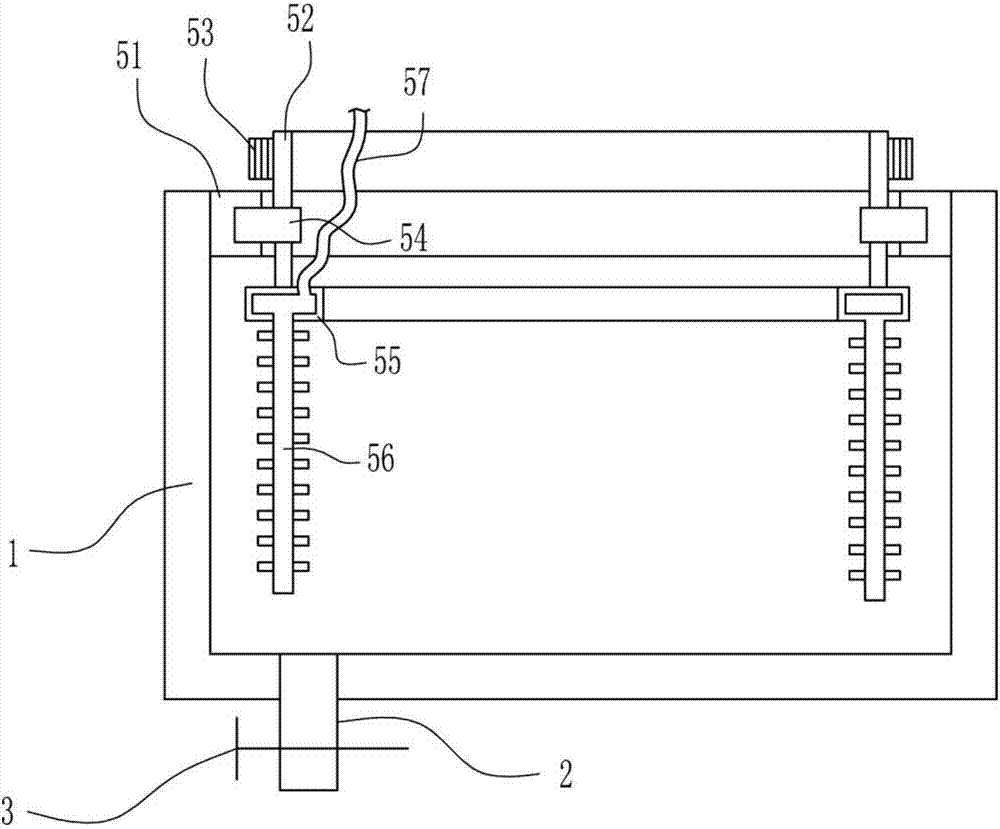

Uniform papermaking additive dilution device used for papermaking

The invention relates to a dilution device, in particular to a uniform papermaking additive dilution device used for papermaking. In order to achieve the technical purpose that by means of the uniform papermaking additive dilution device used for papermaking, water can be uniformly injected into a papermaking additive so that the papermaking additive can meet dilution requirements, the uniform papermaking additive dilution device comprises a dilution tank and the like. A material outlet pipe is connected with the left side on the bottom of the dilution tank, a valve is arranged on the material outlet pipe, a driving mechanism is connected with the upper portion of the left wall of the dilution tank, a material feeding mechanism is connected with the inner wall of the dilution tank, and the material feeding mechanism is connected with the driving mechanism. By means of the uniform papermaking additive dilution device, the dilution speed of the papermaking additive is increased, the clear water can be uniformly injected into the papermaking additive, the papermaking additive dissolution or dilution effect is improved, convenience is brought to work, moreover, tools and parts are not affected with damp, dust prevention is achieved, and the effect that the papermaking additive is uniformly and effectively diluted or dissolved is achieved.

Owner:于都县正亿纸品纸业有限公司

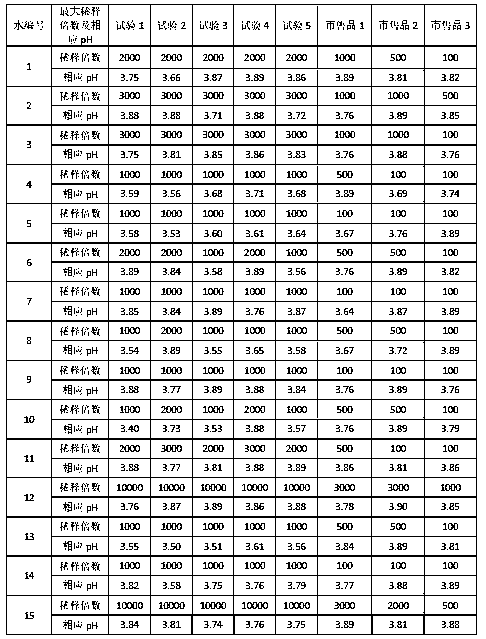

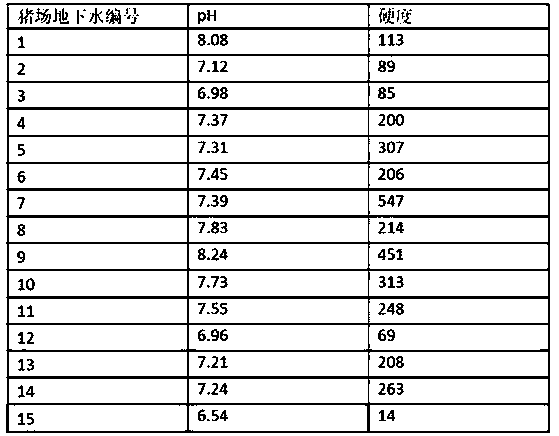

Composite acidifying agent, preparation method and applications thereof

The invention provides a composite acidifying agent, which comprises, by weight, 36-45 parts of formic acid, 8-10 parts of citric acid, 0.5-1.5 parts of acetic acid, 0.5-1.5 parts of propionic acid, 0.2-1 part of succinic acid, 0.05-0.1 part of ethylenediamine tetraacetic acid disodium salt, 2-10 parts of an organic acid salt, 0.2-1 part of a surfactant, 0.2-0.5 part of a correction agent and 35-46 parts of water. The invention also provides a preparation method and an application method of the acidifying agent. According to the invention, the acidifying agent is especially suitable for pig farm waterline disinfection, drinking water disinfection and pigsty flushing disinfection, has characteristics of high efficiency and low toxicity, can reduce the pH value of the digestive tract of animals, effectively control the diarrhea of weaned nursery piglets and improve the growth performance of animals, has good dilution effect and good buffer effect on different water qualities, and particularly has significant buffer effect compared with the similar products when the water quality hardness is relatively high.

Owner:HUNAN AGRI UNIV ANIMAL PHARMA

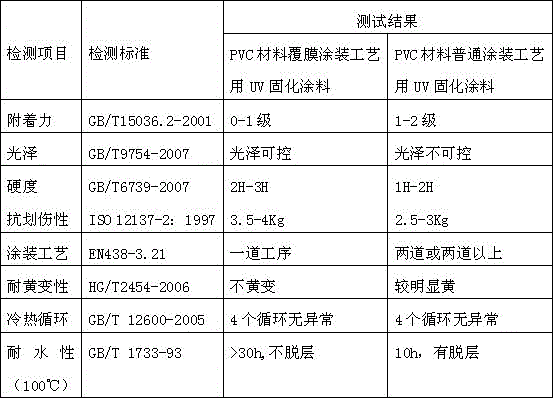

UV curing coating for PVC material coating process and preparation method for UV curing material

InactiveCN105820720AImprove adhesionImprove the dilution effectPolyurea/polyurethane coatingsEpoxy resin coatingsPhotoinitiatorChemistry

The invention discloses an ultraviolet (UV) curing coating for a PVC material coating process and a preparation method for the UV curing material. The UV curing coating for the PVC material coating process is composed of the following raw materials in percentage by mass: 20-30% of modified epoxy acrylate, 35-40% of special functional group acrylate, 8-15% of aliphatic polyurethane acrylate, 20-30% of a reactive diluent, 6-10% of a photoinitiator and 0.3-1% of an additive. The UV curing coating for the PVC material coating process finishes coating only by one coating process and is quickly cured to form a film under UV-irradiation; the coating forming the film is good in adhesion, high in hardness, controllable in luster, good in scratch resistance, excellent in yellowing resistance and excellent in water resistance; and compared with a conventional process, the process has the advantages that the efficiency is high, intermittent production can be realized, the finished product defect rate is low and the like.

Owner:HUNAN JINHAI SCI & TECH

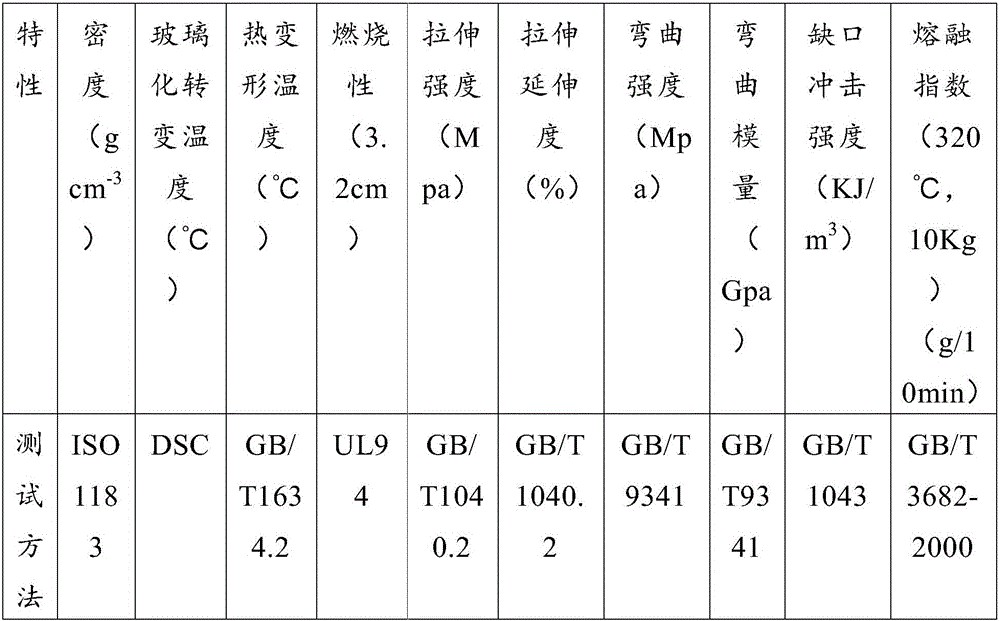

Industrial polysulfone resin production process

The invention relates to the technical field of high polymer material preparation, in particular to an industrial polysulfone resin production process. The industrial polysulfone resin production process comprises the following steps that step one, polymerization reaction pretreatment is performed; step two, polymerization reaction is performed; step three, polymerization reaction is completed. The problem of large polymeric hydrocarbon molecular weight distribution span of a polysulfone high polymer material is solved by adopting the industrial polysulfone resin production process. The improved industrial polysulfone resin production process makes the produced polysulfone high polymer material high in purity, concentrated in molecular weight distribution, higher in production efficiency and more stable in quality.

Owner:任进军

Municipal pipeline dredging device and use method thereof

The invention relates to the technical field of pipeline dredging, and discloses a municipal pipeline dredging device and a use method thereof. The municipal pipeline dredging device comprises a box body, wherein two first rotating shafts are rotatably installed at the bottom of the box body, two rolling wheels are fixedly installed on the outer sides of the two first rotating shafts, a water tank is fixedly installed in the box body, a water pump is fixedly installed on the top of the box body, one end of a water pipe and one end of a hose are fixedly installed at the bottom and on one side of the water pump respectively, the other end of the water pipe extends into the water tank, the other end of the hose fixedly communicates with a spray head, a motor is fixedly installed on one side of the water tank, and one end of a second rotating shaft is fixedly connected to an output shaft of the motor. The municipal pipeline dredging device has the advantages of reasonable and clever structural design and convenience in use, and sludge in a municipal pipeline can be effectively diluted, so that the sludge can automatically circulate, and the dredging efficiency is improved.

Owner:陈丽阳

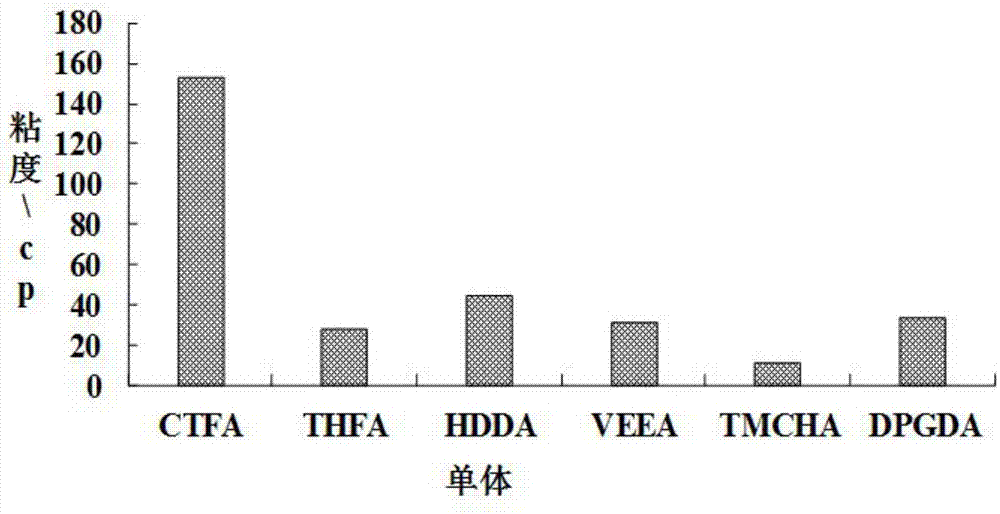

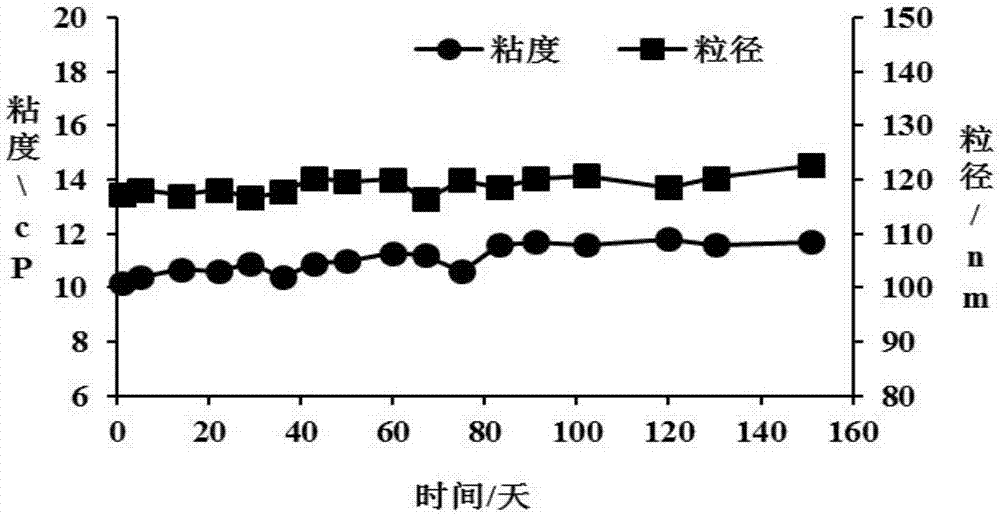

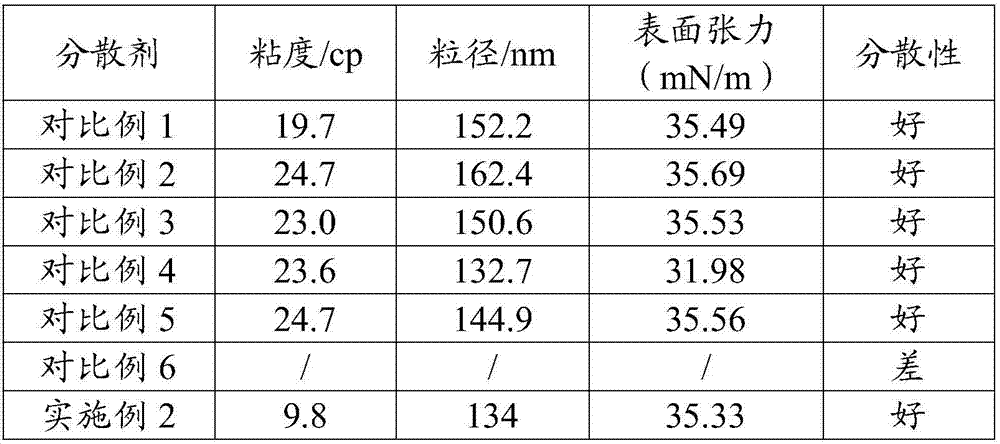

UV inkjet color paste and preparation method and application thereof

The invention provides a UV inkjet color paste which is prepared from the following components in parts by weight: 40-60 parts of UV monomer, 2-4 parts of hyperdispersant and 5-15 parts of carbon black, wherein the particle size of the UV inkjet color paste is less than 1mu m; the carbon black is easily dispersed; a molecular structure of the hyperdispersant is divided into two parts, one part is an anchoring group, and the other part is a solvation chain; through adsorption of the carbon black by the anchoring group and extension of the solvation chain in the monomer, the carbon black is fully dispersed in the UV monomer. According to the UV inkjet color paste provided by the invention, the components generate a synergistic effect; the provided UV inkjet color paste is of a uniform hue; after the UV inkjet color paste is placed in a gradual aging test environment for a long time, the viscosity and the particle size are not changed obviously; the dispersity and the dilutability are high; the properties such as color paste viscosity and surface tension are good; the data of an embodiment indicates that minimum viscosity of the UV inkjet color paste is 5-6cp, the surface tension is 35.2-38.9mN / m, and the average particle size is 123-146nm.

Owner:杭华油墨股份有限公司

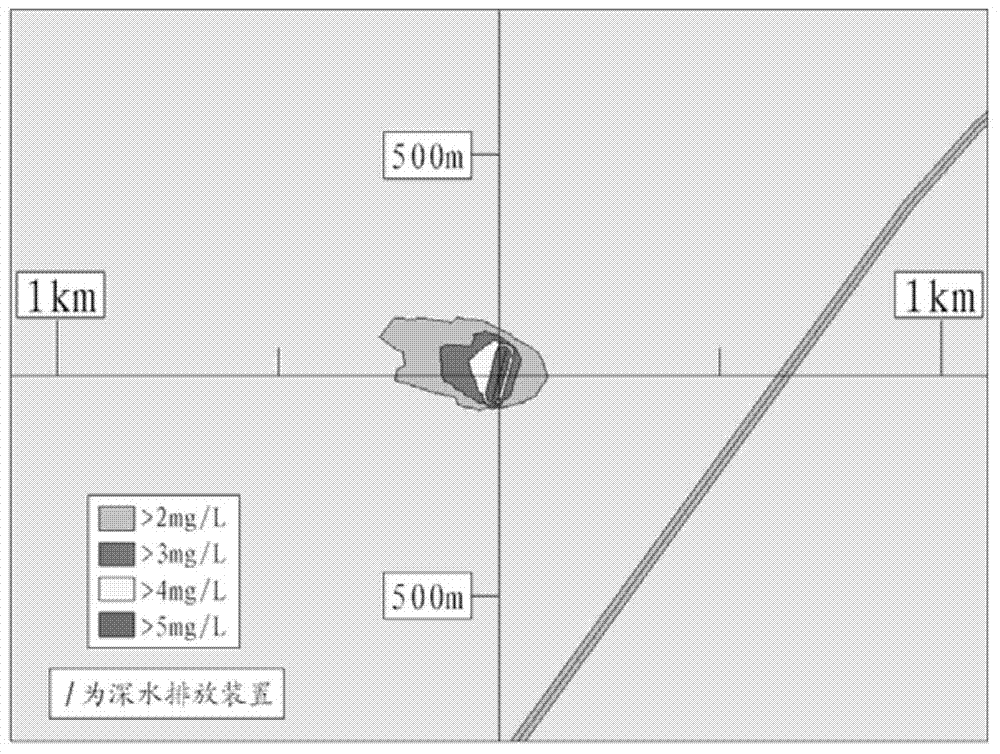

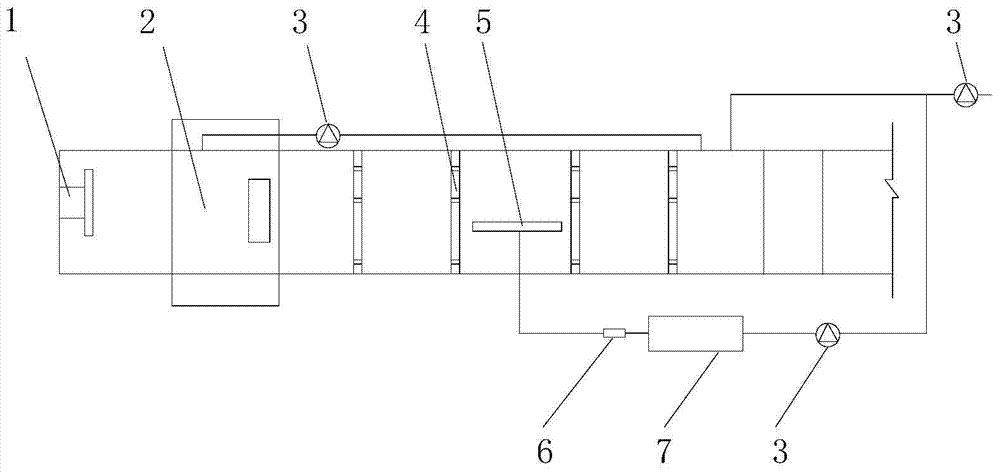

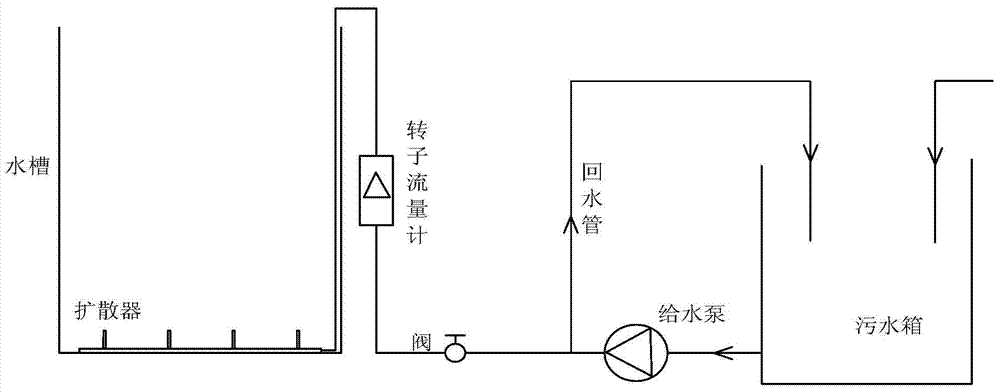

Method for determining length of sewage diffuser based on cooperation of physical model test and numerical simulation

InactiveCN103577645AGuaranteed dilution and diffusion effectRealize normal outflowSpecial data processing applicationsPhysical modelEconomic benefits

The invention discloses a method for determining the length of a sewage diffuser based on the cooperation of a physical model test and numerical simulation. The method includes the following steps that the length of the diffuser is preliminarily estimated, the number of ascending tubes contained in the diffuser is determined, the sewage diffusion effect is analyzed by the utilization of numerical simulation, the sewage diffusion effect in a near region is simulated by the utilization of a physical model, hydraulic power numerical simulation of the diffuser is conducted, the hydraulic power physical model test of the diffuser is conducted, and the length with the good hydraulic power feature is the finally-determined length. According to the method, sewage diffusion and hydraulic power outflow are analyzed, and the defects that a traditional method is too single and a computed result cannot be verified are overcome; through the length of the diffuser determined through the method, the sewage dilution diffusion effect can be guaranteed, sewage normal outflow can be also achieved, and a sewage discharge project can be efficiently operated; cost can be saved for a construction unit through the result, and good economic benefits are possessed.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +1

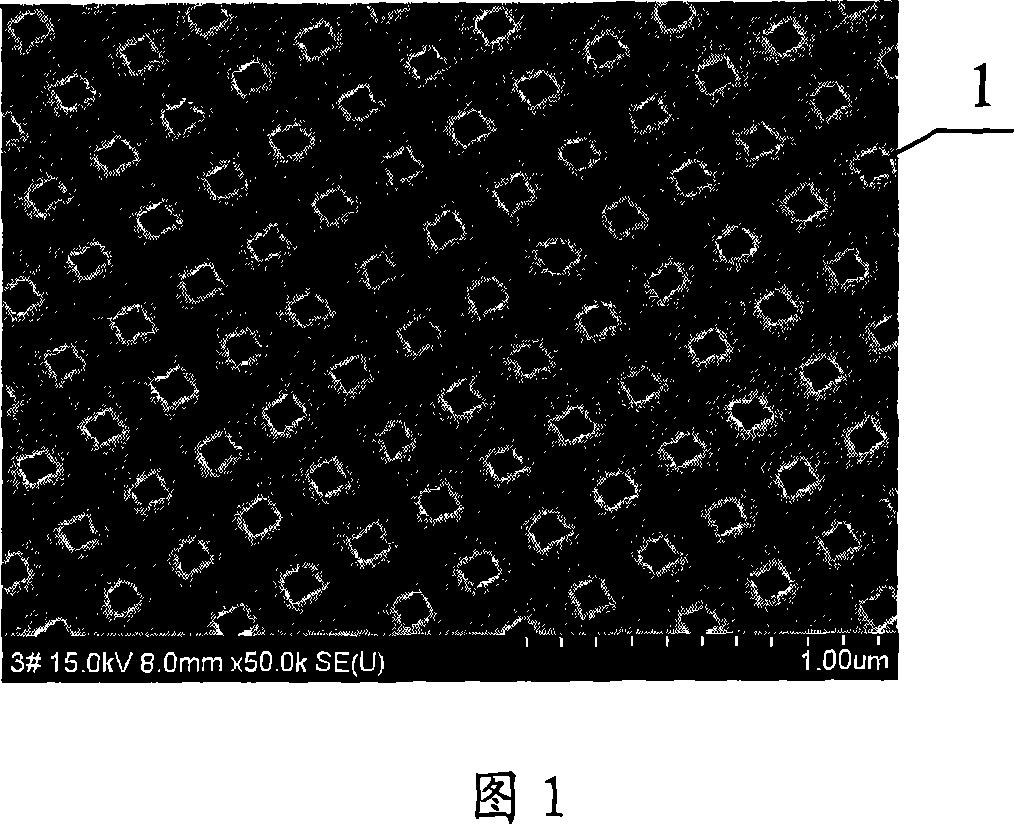

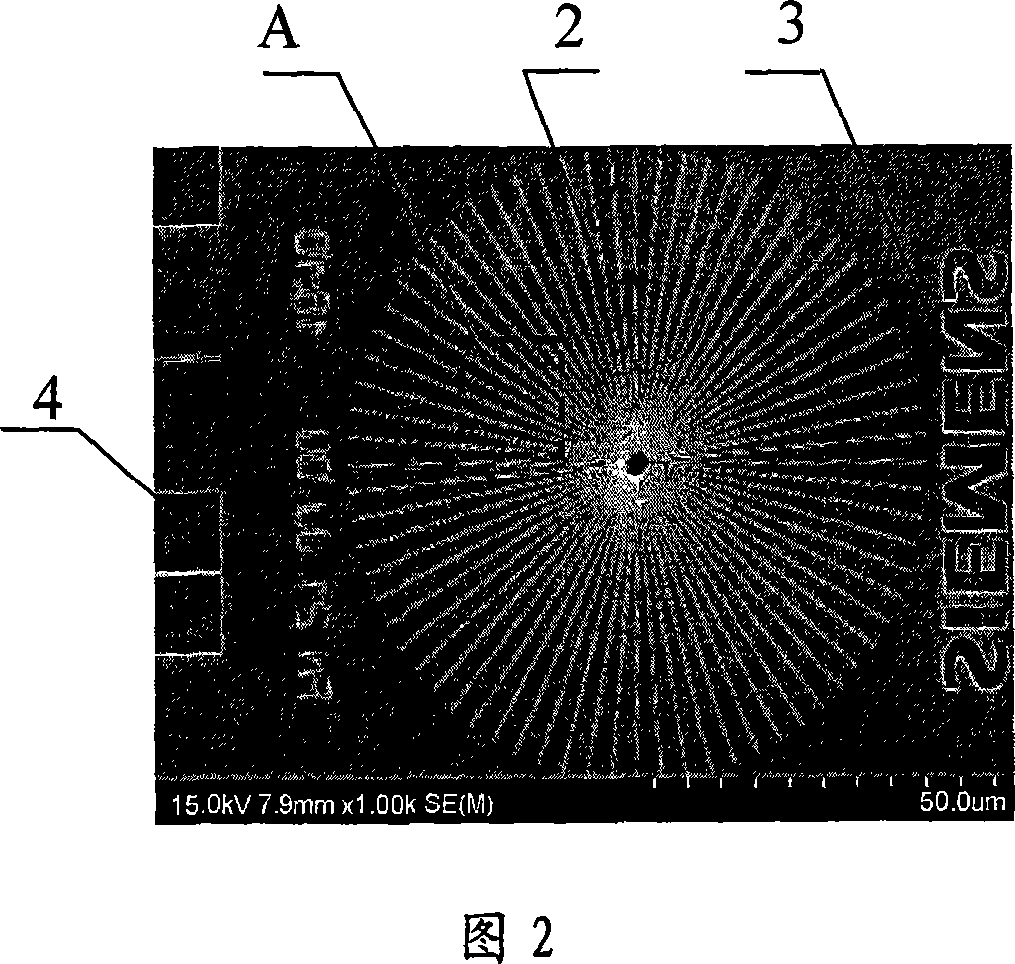

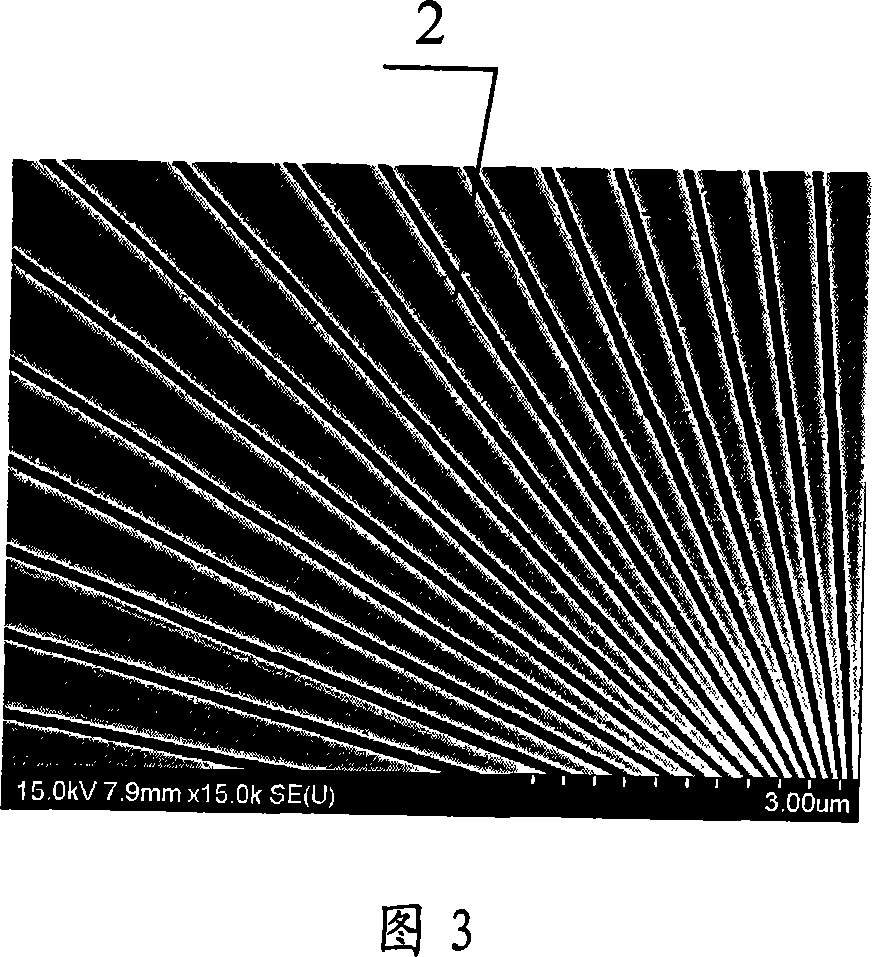

Ultraviolet photo-cured radical type etching glue for micro nano structure imprinting and copying

InactiveCN101055419AIncreasing the thicknessGood chemical resistancePhotomechanical apparatusMicro nanoTripropylene glycol

The invention relates to a micro-nano structural imprint-copy-used ultraviolet light curing free radical type etching gum which has the composing of: a curing body 1 is bisphenol A-epoxy acrylic ester or phenolic epoxy acrylic ester which is 24 to 48% by weight, a curing body 2 also a thinner is tripropylene glycol genus acrylic ester which is 20 to 46% by weight, a curing auxiliaries is dipentaerythritol-6-acrylic ester or GP-537 or GP-71-SS which is 5 to 16% by weight, a photo-initiation is 2,4,6-methylbenzene formyl radicel diphenyl phosphine oxide which is 5 to 16% by weight, the sum of each weight of the component is 100%. In addition, in order to regulate the viscosity of the solution, the thinner 1,6hexandiol twain acrylic ester is added until the viscosity of the solution is satisfied. Compared with the other gum, the gum of the invention has the advantages of: high curing speed, small constringency, low viscosity, high adhesive force, strong against corrosion, simple confect art and convenient application.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

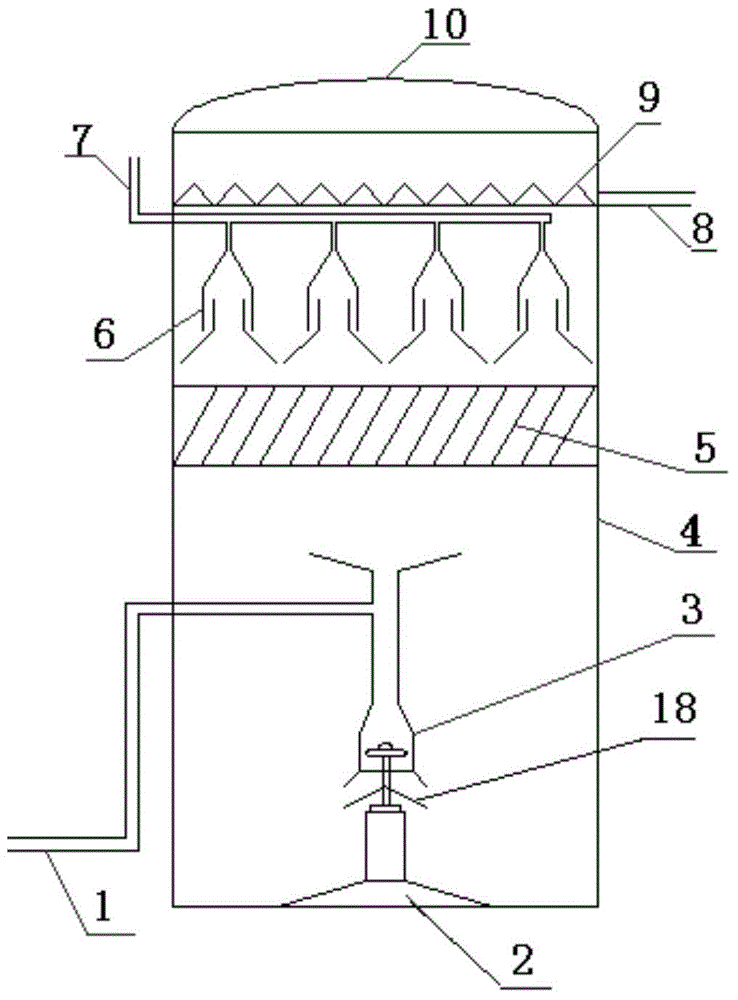

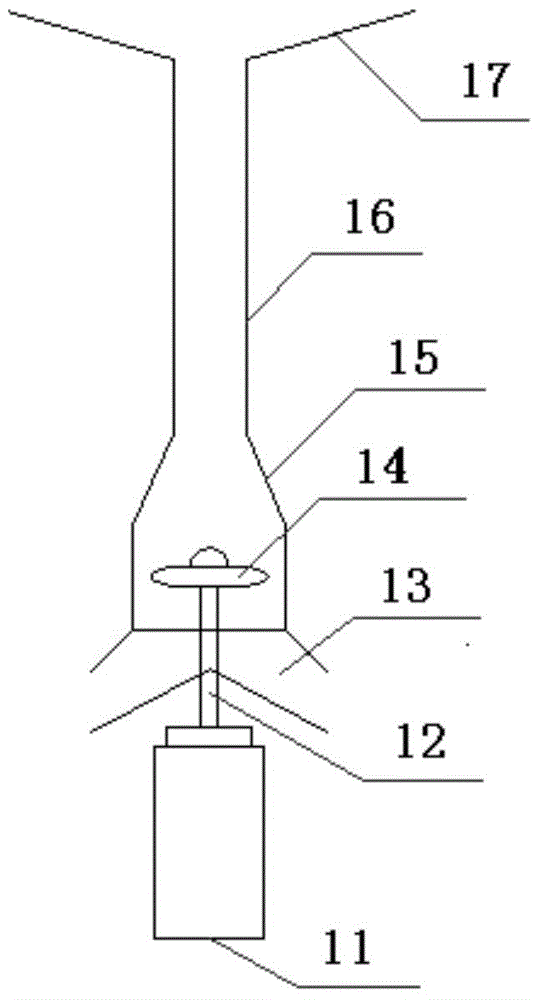

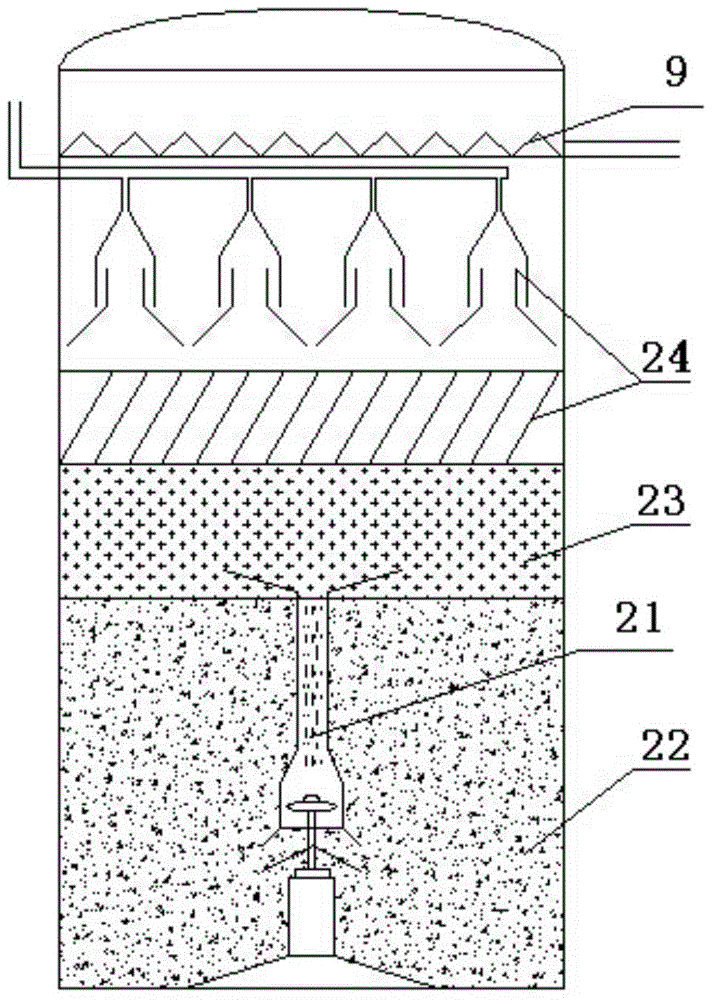

Mechanical internal circulation jet-flow anaerobic reactor and wastewater treatment method thereof

ActiveCN104445605AChange cloth waterChange the way of beingTreatment with anaerobic digestion processesHigh concentrationFluidized bed

The invention discloses a mechanical internal circulation jet-flow anaerobic reactor and a wastewater treatment method thereof, and belongs to the technical field of biological sewage treatment. The mechanical internal circulation jet-flow anaerobic reactor comprises a reactor tank body, a multi-phase separator, a water outlet weir and an internal circulation jet-flow device, wherein the internal circulation jet-flow device comprises an upper part and a lower part; the upper part comprises a jet-flow hole, a diffusion hole, a flow guide pipe and a flow stabilization hole; the lower part comprises a motor, a rotary shaft and high-speed blades. The wastewater treatment method comprises the following steps: forming a fluidized bed layer, forming a suspended bed layer, separating a separation region and discharging water from the water outlet weir. Due to the use of the internal circulation jet-flow device, the difficult problems of low treatment load, instable effect and relatively narrow application range in the treatment process of an existing conventional anaerobic reactor are solved; the mechanical internal circulation jet-flow anaerobic reactor has the advantages of high treatment load, good water impact resistance, high concentration of biological toxicity resistance matters, quick starting and the like.

Owner:NANJING UNIV

Amine for low-emission epoxy resin compositions

ActiveUS10301423B2High hardnessImprove processing qualityOrganic chemistryEpoxy resin coatingsEpoxyAlkyl transfer

An amine of the formula (I) for use as hardener for epoxy resins, hardeners for epoxy resins containing the amine of the formula (I) and resultant epoxy resin compositions which more particularly can be used as low-emission room-temperature-curing epoxy-resin coatings with high hardness and surface quality. The amine of the formula (I) has little odor and is a very successful diluent for epoxy resin compositions. It is more particularly obtained by reductive alkylation from 1,2-propylenediamine and an aldehyde or ketone.

Owner:SIKA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com