Self-crosslinked water-based acrylic air-drying paint and preparation method thereof

A water-based acrylic and self-drying paint technology, applied in the coating and other directions, can solve the problems of difficult adjustment of construction, high volatile organic content, water-based acrylic self-drying paint can not meet the electrostatic spraying construction and other problems, to achieve the effect of maintaining mirror gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

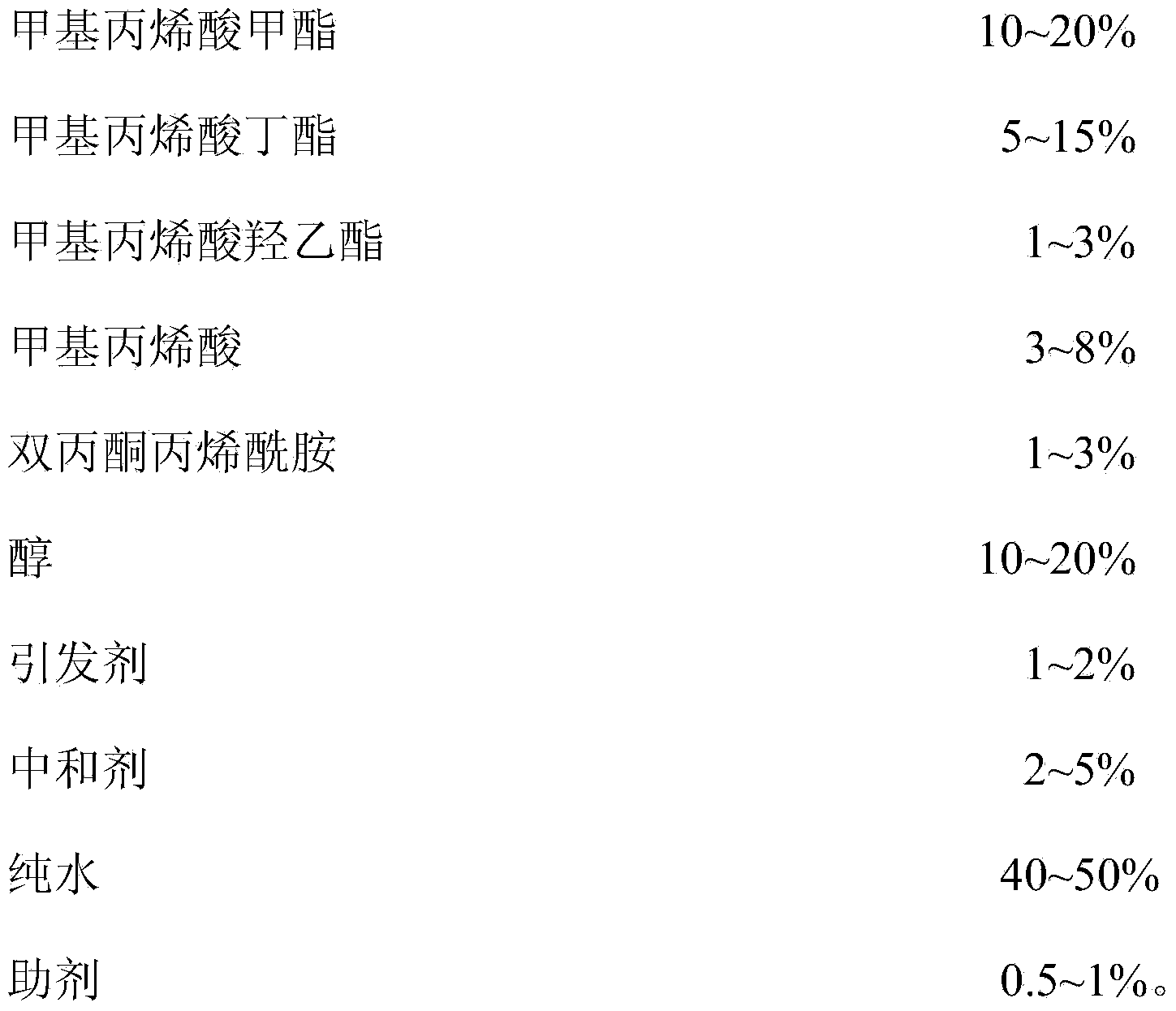

[0066] A kind of self-crosslinking waterborne acrylic acid self-drying paint of the present invention comprises the raw material of following mass percentage:

[0067]

[0068] The alcohol in this embodiment is a monohydric alcohol.

[0069] The monohydric alcohol in this embodiment is n-butanol.

[0070] The initiator of this embodiment is BPO.

[0071] The auxiliary agent in this embodiment is a silane coupling agent.

[0072] The neutralizing agent of the present embodiment is ammonia water.

[0073] A preparation method for self-crosslinking water-based acrylic acid self-drying coating, comprising the following processing steps:

[0074] Step A, weighing the materials of the formula amount, respectively placing them in different containers for use;

[0075] Step B, add methyl methacrylate, butyl methacrylate, hydroxyethyl methacrylate, methacrylic acid, diacetone acrylamide and 80% initiator into a mixing tank and mix evenly to form a mixed solution, ready to use ; ...

Embodiment 2

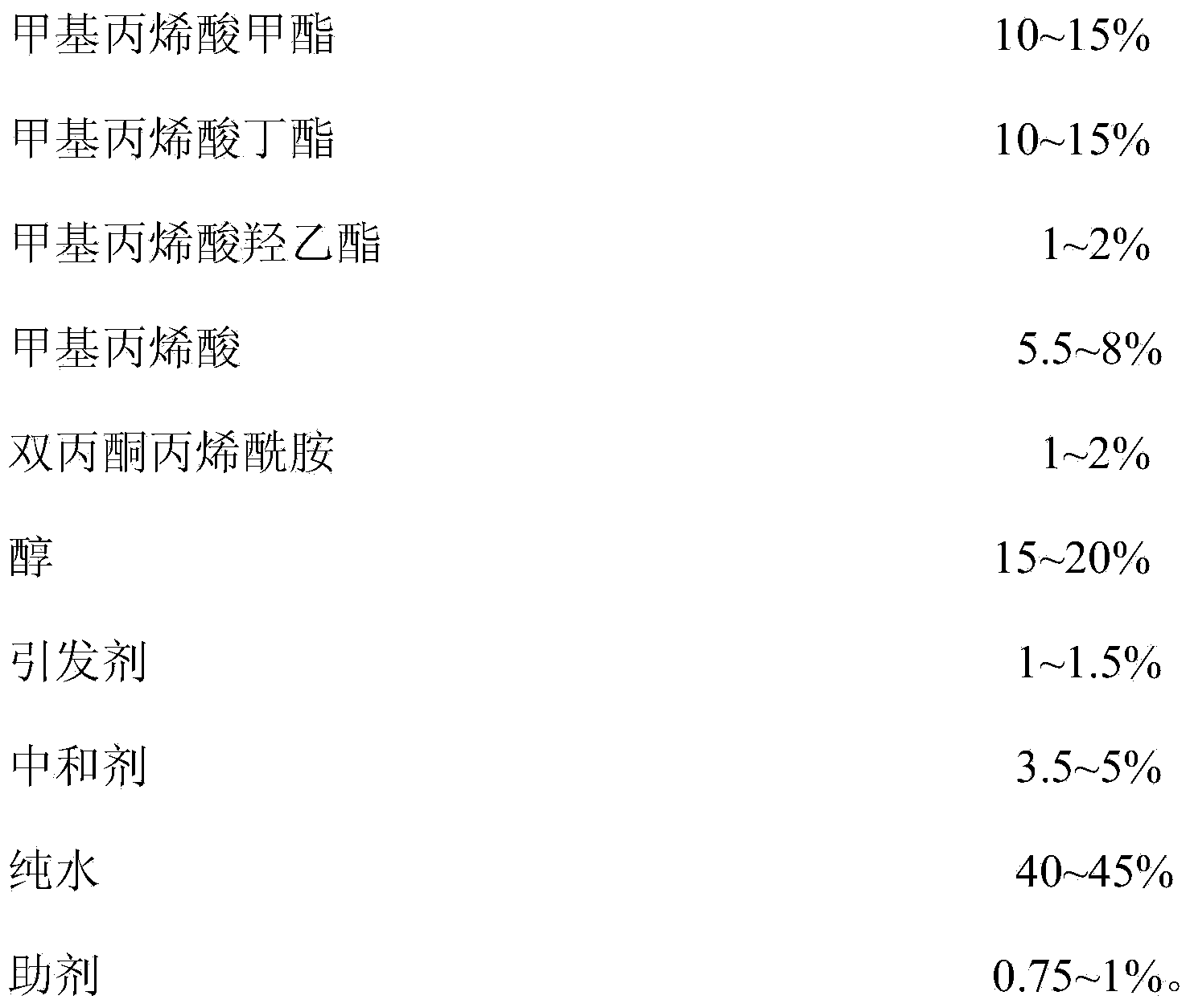

[0081] A kind of self-crosslinking waterborne acrylic acid self-drying paint of the present invention comprises the raw material of following mass percentage:

[0082]

[0083]

[0084] The alcohol in this embodiment is dihydric alcohol.

[0085] The dihydric alcohol of this embodiment is propylene glycol.

[0086] The initiator of the present embodiment is potassium persulfate.

[0087] The auxiliary agent in this embodiment is a titanate coupling agent.

[0088] The neutralizing agent of the present embodiment is triethylamine.

[0089] A preparation method for self-crosslinking water-based acrylic acid self-drying coating, comprising the following processing steps:

[0090] Step A, weighing the materials of the formula amount, respectively placing them in different containers for use;

[0091] Step B, add methyl methacrylate, butyl methacrylate, hydroxyethyl methacrylate, methacrylic acid, diacetone acrylamide and 75% initiator into a mixing tank and mix evenly to...

Embodiment 3

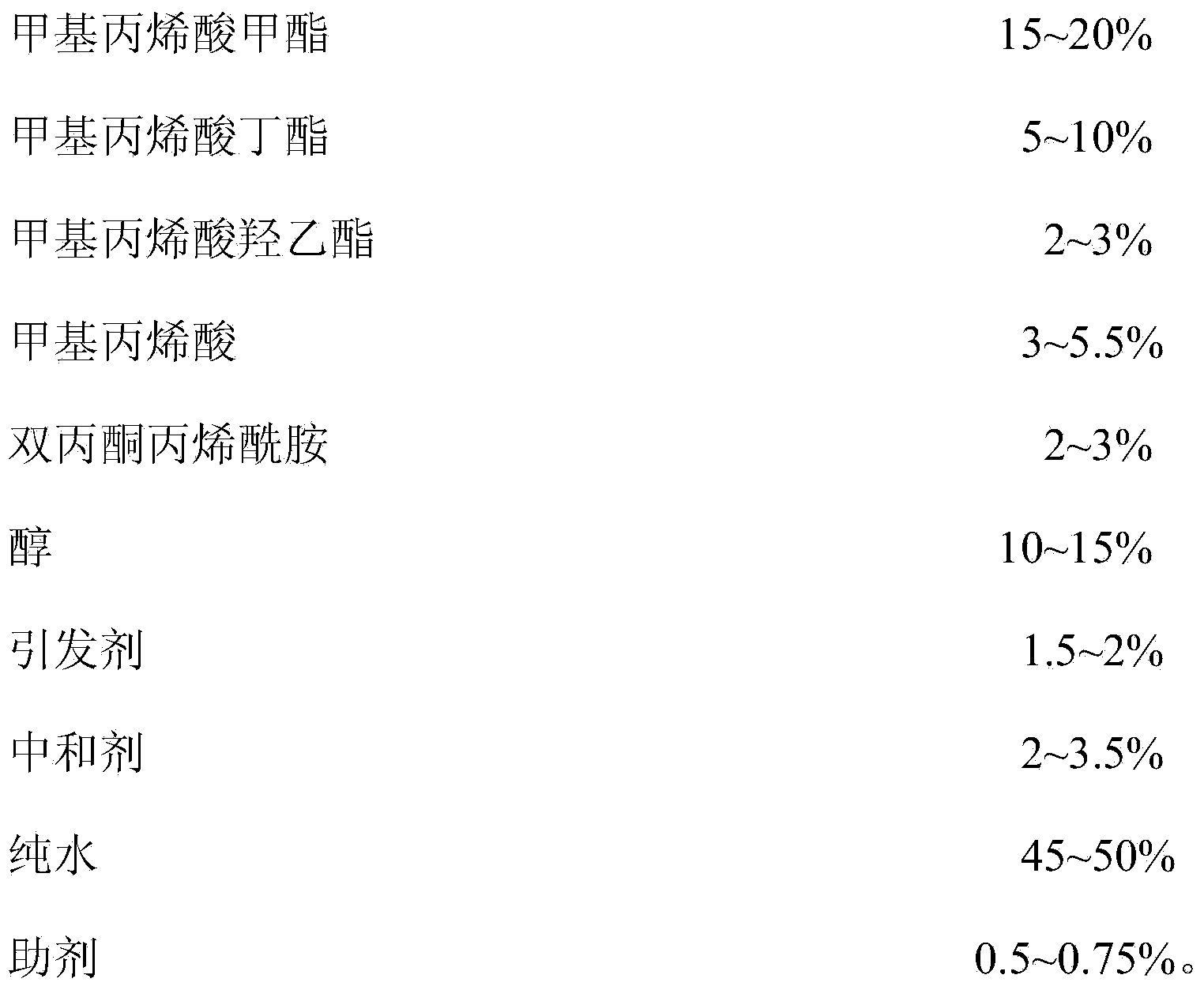

[0098] A kind of self-crosslinking waterborne acrylic acid self-drying paint of the present invention comprises the raw material of following mass percentage:

[0099]

[0100] The alcohol in this embodiment is a polyhydric alcohol.

[0101] The polyhydric alcohol of this embodiment is glycerin.

[0102] The initiator of this embodiment is azobisisobutyronitrile.

[0103] The auxiliary agent in this embodiment is a silane coupling agent.

[0104] The neutralizing agent of the present embodiment is sodium bicarbonate.

[0105] A preparation method for self-crosslinking water-based acrylic acid self-drying coating, comprising the following processing steps:

[0106] Step A, weighing the materials of the formula amount, respectively placing them in different containers for use;

[0107] Step B, add methyl methacrylate, butyl methacrylate, hydroxyethyl methacrylate, methacrylic acid, diacetone acrylamide and 85% initiator into the mixing tank and mix evenly to form a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com