Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

975results about How to "Solving Dispersion Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal powder for 3D printer and preparing method thereof

ActiveCN103785860AHigh sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingDispersityMetal particle

Owner:JIANGSU BOQIAN NEW MATERIALS CO LTD

Parallel structure and control method for photovoltaic power generation grid-connected inverter

ActiveCN102185513ASolving Dispersion ProblemsAvoid it happening againAc-dc conversionSingle network parallel feeding arrangementsClosed loopPwm inverter

The invention discloses a parallel structure and a control method for a photovoltaic power generation grid-connected inverter and belongs to the technical field of renewable energy sources. A topological circuit structure of the photovoltaic power generation grid-connected inverter is divided into a parallel structure of single-phase voltage type pulse-width modulation (PWM) inverters and a parallel structure of three-phase voltage type PWM inverters; and in the control method, an outer ring regulator of a control circuit of the parallel voltage type PWM inverters is independent based on a power grid voltage-oriented vector control technology in a control mode of voltage outer ring and current inner ring so as to form a common unified outer ring regulator; control strategies of various inverters are simplified into single closed loop current control so as to achieve the consistency of energy flow directions of the parallel voltage type PWM inverters and avoid ring current; and the parallel current sharing of the voltage type PWM inverters is realized. Therefore, multiple modules of the voltage type PWM inverters are connected in parallel to realize high-power modularized large-scale application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Polymer/graphene anti-static coating, preparation method and application thereof

InactiveCN104449010AEasy reunionSolving Dispersion ProblemsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsStatic performanceCompound system

The invention discloses a polymer / graphene anti-static coating, a preparation method and application thereof. The coating comprises the following constituents by weight percent: 0.01 portions to 0.5 portions of graphene; 0 portion to 10 portions of conductive additive; 90 portions to 100 portions of polymer; and solvent; the preparation method thereof comprises the following steps: completely and uniformly mixing graphene and conductive additive in advance by various manners; preparing a graphene-conductive additive compound system; using the compound system as a base, adding in conductive additive and polymer along with the solvent, completely and uniformly mixing to obtain the coating. Additionally, an anti-static film can be prepared by using different film forming technologies. The polymer / graphene anti-static coating, the preparation method and application thereof effectively solve the problems that graphene in polymer is easy to agglomerate and difficult to be uniformly dispersed in the preparation process of anti-static coating and film; the anti-static performance and mechanical performance of the coating and the film are greatly increased; meanwhile, the preparation technology is easy to be operated; the production is continuous, and the coating and film are suitable for industrial production.

Owner:苏州格瑞丰纳米科技有限公司

Graphene/carbon black thermoplastic resin master batch with high dispersibility and preparation method thereof

The invention discloses a graphene / carbon black thermoplastic resin master batch with high dispersibility and a preparation method thereof. The graphene / carbon black compound in the master batch is formed in an electrostatic self-assembly manner, and comprises 10-50% of graphene, 5-20% of carbon black, 0.5-10% of surfactant, 10-65% of carrier resin and 2-10% of assistant. The preparation method comprises the following steps: (1) compounding and dispersing graphene by adopting the surfactant to control the positive electricity of the graphene surface; (2) forming a stable graphene / carbon black compound from the modified graphene and carbon black with positive electricity through electrostatic incorporation in a self-assembly manner; (3) preparing the graphene / carbon black thermoplastic resin master batch with high dispersibility by matching with a solution blended process, a melt-blending method and an in-situ polymerization method; (4) adding the assistant to extrude and pelletize, so as to prepare the graphene / carbon black / thermoplastic resin master batch particles after processing the master batch. By adopting the obtained master batch, the problems of difficult charging of graphene powder, uneven dispersion, dust pollution, unstable product performance and the like are solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

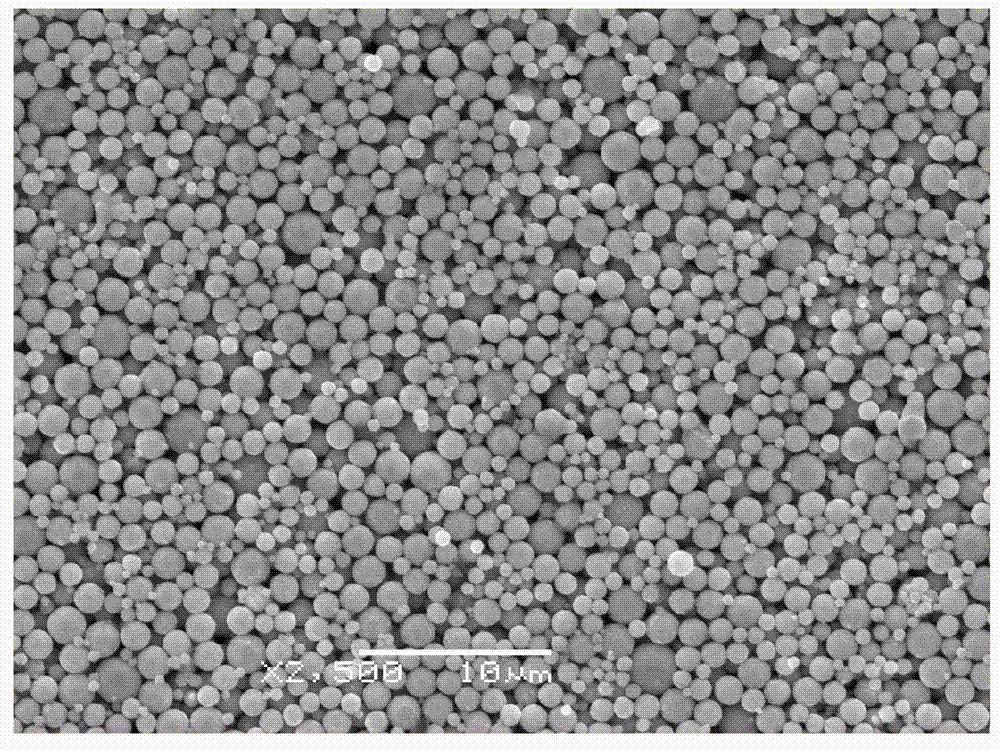

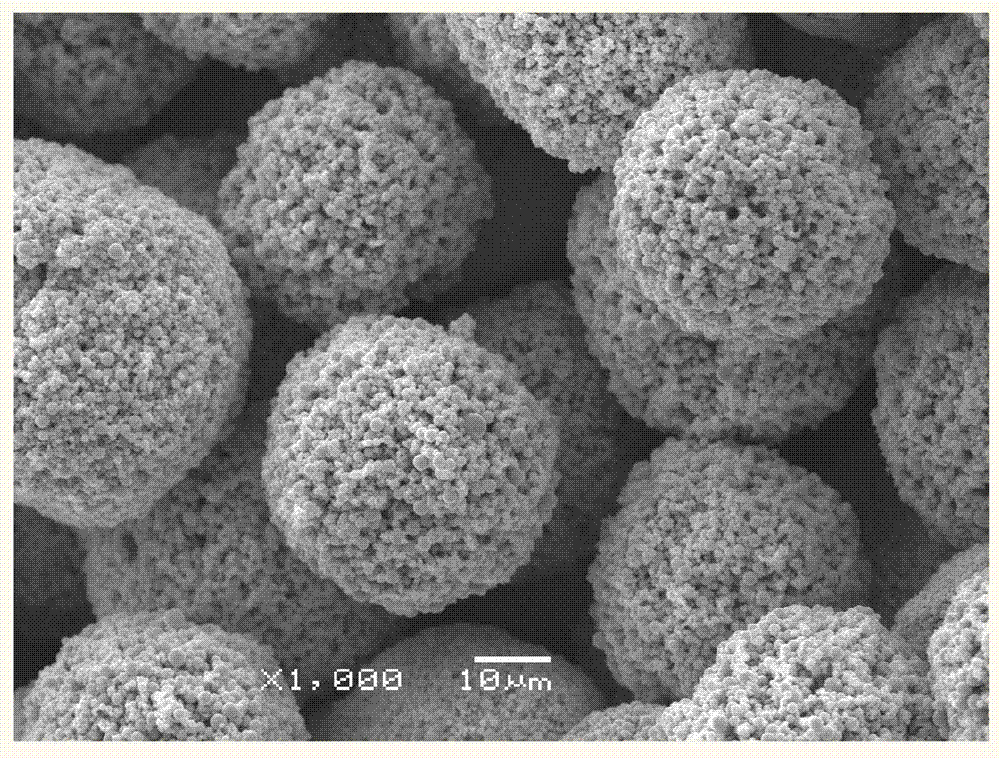

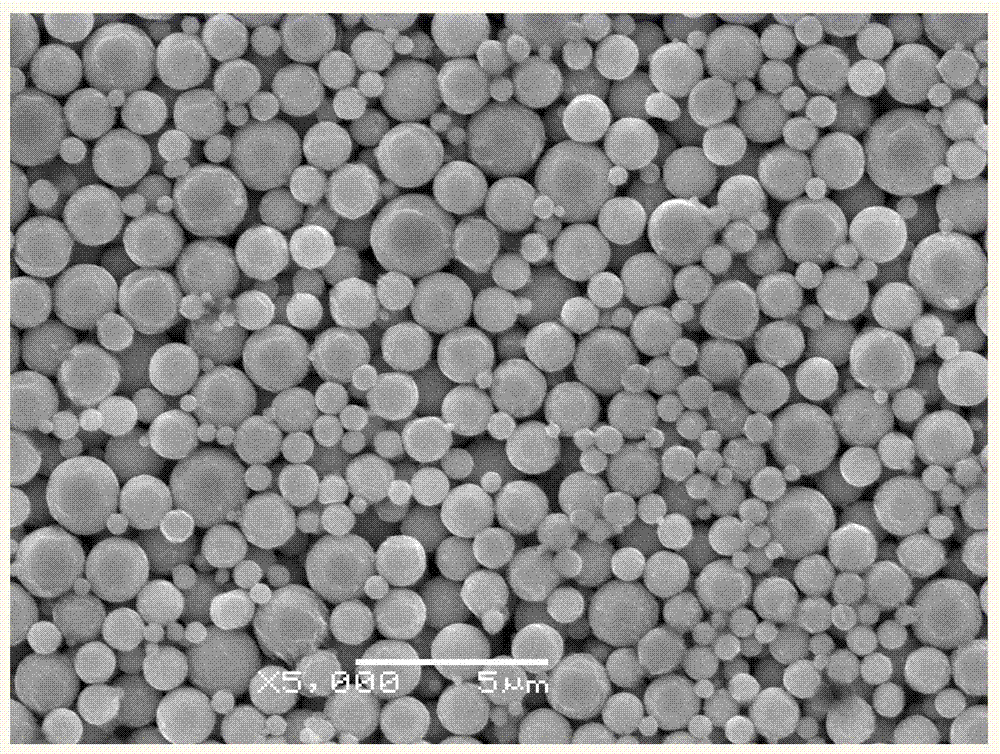

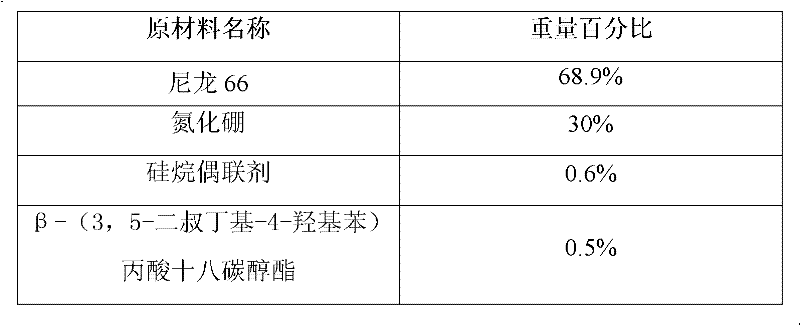

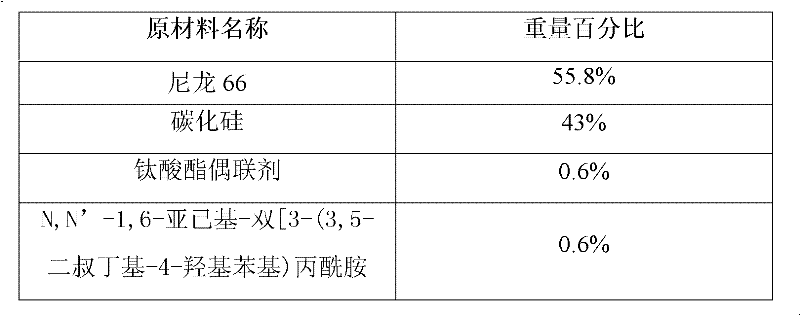

Nylon 66 composite material with high heat conductivity and preparation method thereof

ActiveCN102408710AGood dispersionEvenly dispersedHeat-exchange elementsStrength of materialsNylon 66

The invention discloses a nylon 66 composite material with high heat conductivity, comprising the following substances based on weight percentages: 70-42% of nylon 66, 27-55% of heat conduction filler, 0.5-1.5% of coupling agent and 0.5-1.5% of anti-oxidant. In addition, the invention also discloses a preparation method for the nylon 66 composite material with high heat conductivity, wherein the method adds a processing step on the heat conduction filler based on the conventional method. The nylon 66 composite materials with high heat conductivity prepared by the invention can better keep themechanical property of the nylon 66 composite material and largely raise the heat conductivity at the same time. In comparison with the heat conductivity of the nylon 66 composite material prepared from the heat conduction filler without processing, the heat conductivity of the nylon 66 composite material prepared from the processed heat conduction filler is raised by about 30-50%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

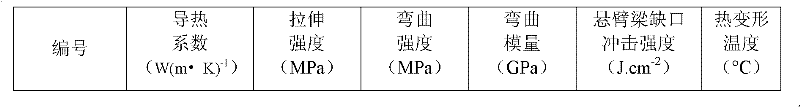

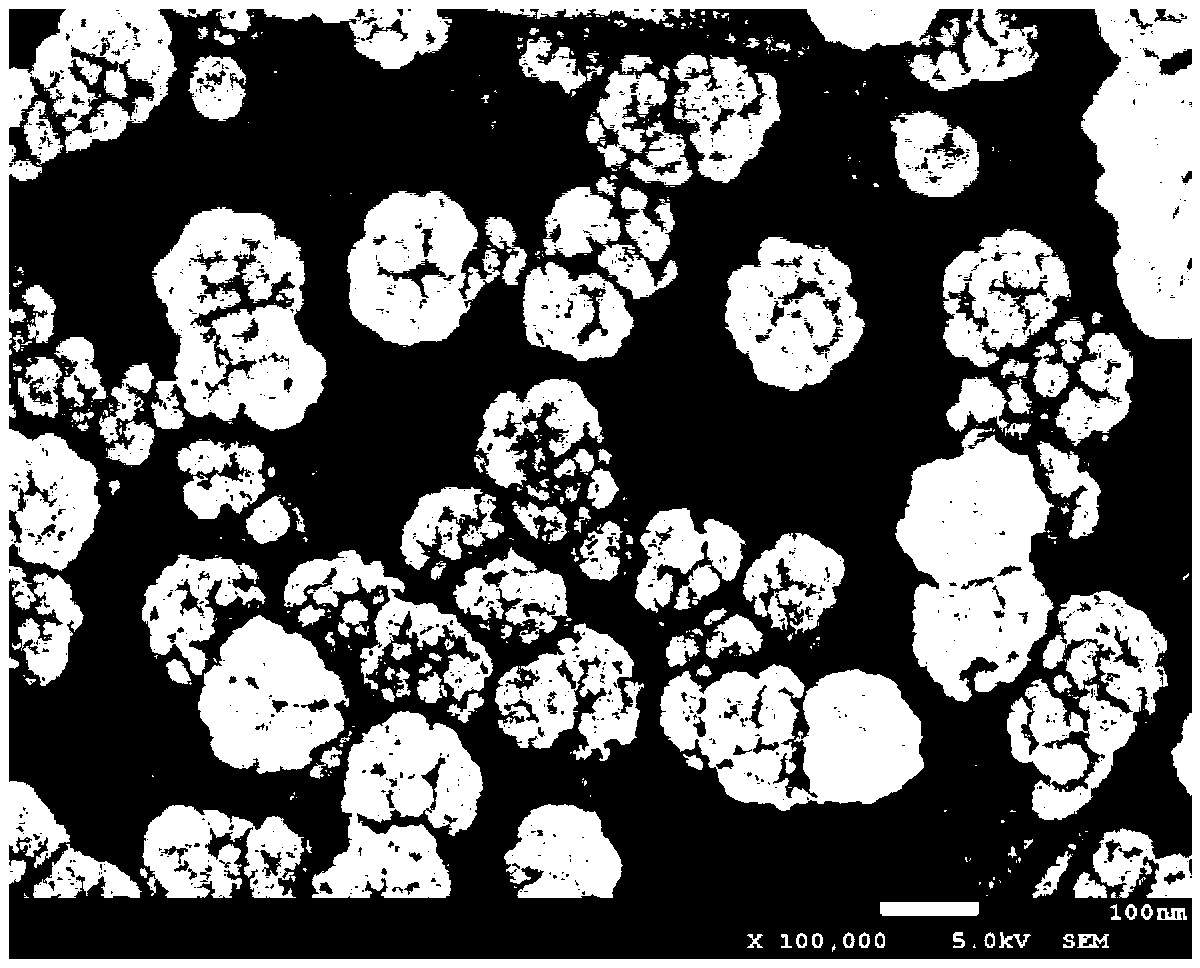

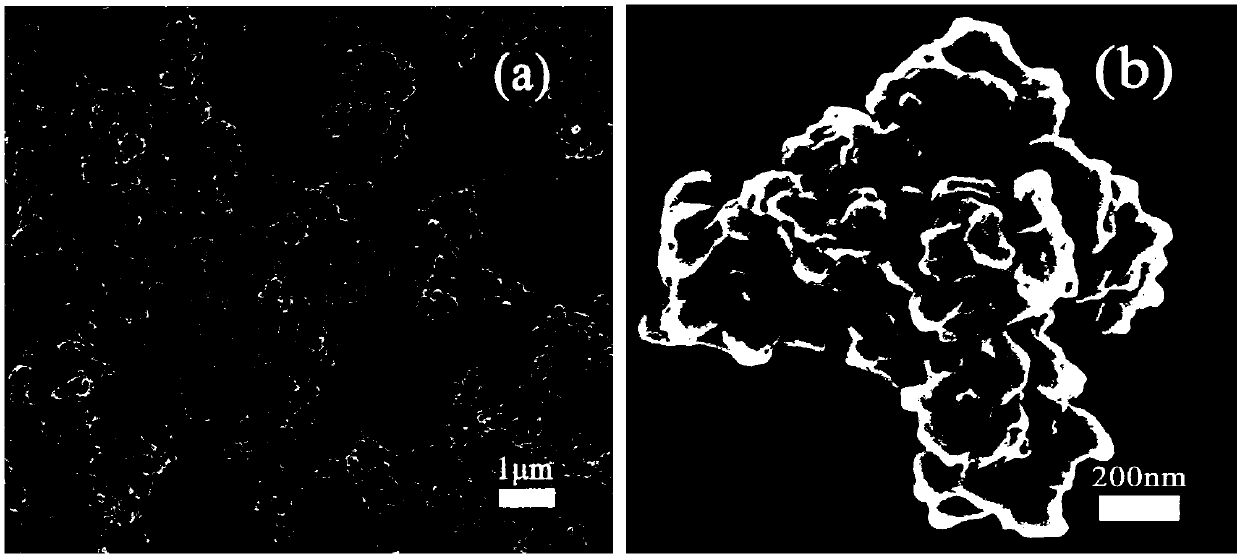

Preparation method of grapheme and ferriferrous oxide composite nanometer material

InactiveCN103274396ASolve the lack of interface binding forceResolving Particle MorphologyMaterial nanotechnologyGrapheneMicrosphereSolvent

A preparation method of a grapheme and ferriferrous oxide composite nanometer material belongs to the technical field of functional materials. The preparation method comprises the following steps: at first, oxidized grapheme is prepared by an improved chemical method; and then oxidized grapheme and ferric ions are adopted as raw materials, and are compounded through adopting a solvothermal technology to carry out one-step in-situ reduction to obtain the grapheme and ferriferrous oxide composite nanometer material. The preparation method solves the problems in the prior art that the interface binding force of grapheme and a magnetic material is insufficient, the appearances, the sizes and the magnetism of magnetic material particles are uncontrollable, and the magnetic material particles cannot be dispersed in water; the prepared composite nanometer material shows a microspheric appearance, has a loose surface and is high in specific surface area; through the change of the ratio of grapheme to the ferric ions, final magnetic property and electrical property of the composite material can be adjusted; and the controllable growth of the grapheme and ferriferrous oxide composite material is realized. The prepared grapheme and ferriferrous oxide nanometer microsheric material with magnetic and electric properties can be used in fields such as biological medicine, energy, invisibility and electronic materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

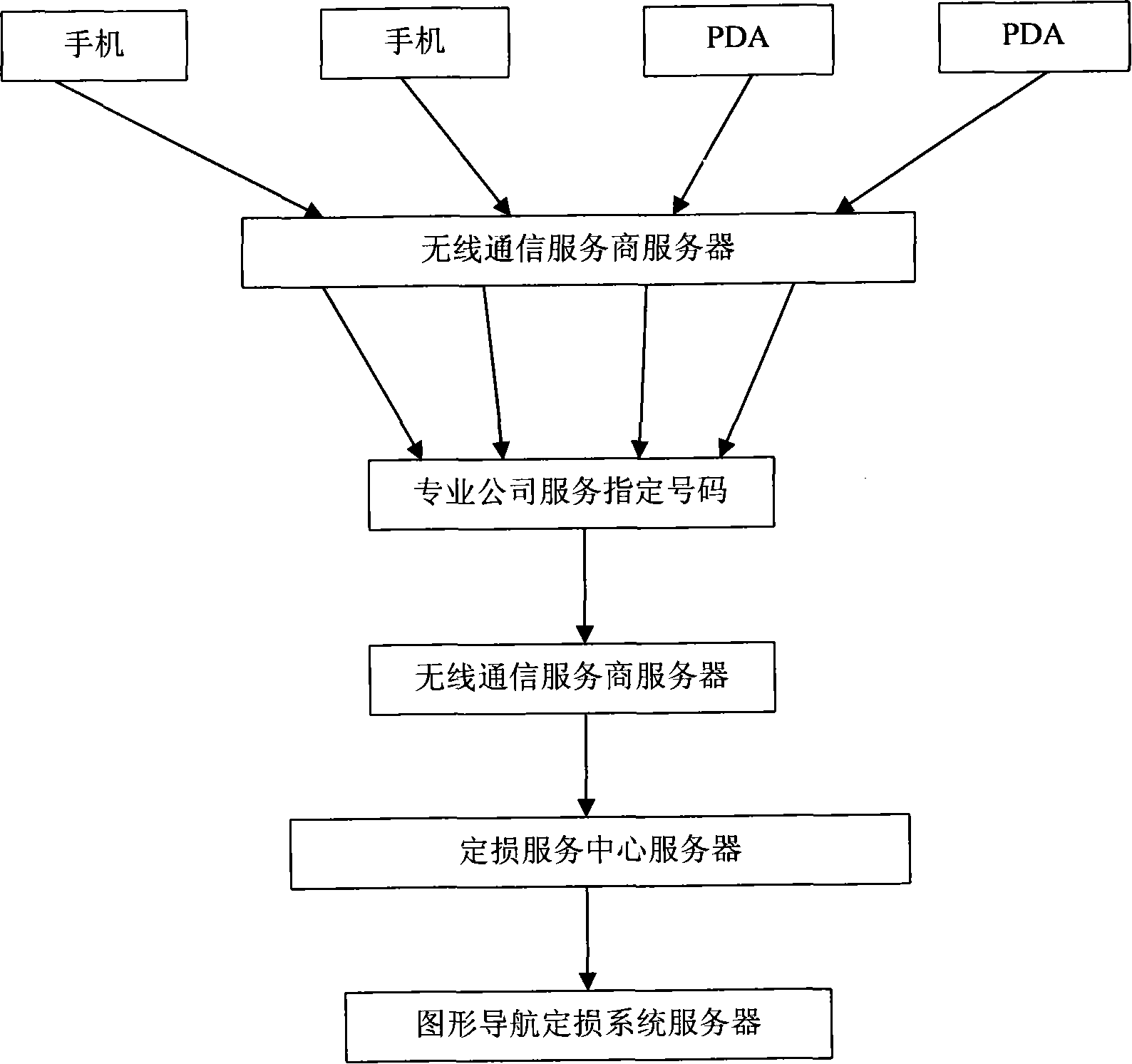

Car damage identification method based on mobile communication terminal or network terminal

InactiveCN101242379ASolve the road occupation problemRealization of fixed lossData processing applicationsData switching networksNetwork terminationRelevant information

The invention discloses a vehicle loss determination method based on mobile communication terminal or network terminal, comprising the steps that: after a traffic accident, a party transmits an image of the damaged part and related information of a vehicle to a loss determination service center by wireless communication network; the loss determination center analyzes the image of the damaged part and related information of the vehicle, determinates the loss by a loss determination system; and the loss determination service center submits the loss determination result to the party by wireless commutation network. The party transmits the image of the damaged part and related information of the vehicle to the loss determination service center by wireless communication network, the loss determination service center determinates the loss by the loss determination system, and submits the result to the party by wireless communication network, therefore the invention is capable of assuring instantaneity, reasonability and precision of loss determination.

Owner:BEIJING AUTOMOTIVE INFORMATION TECH

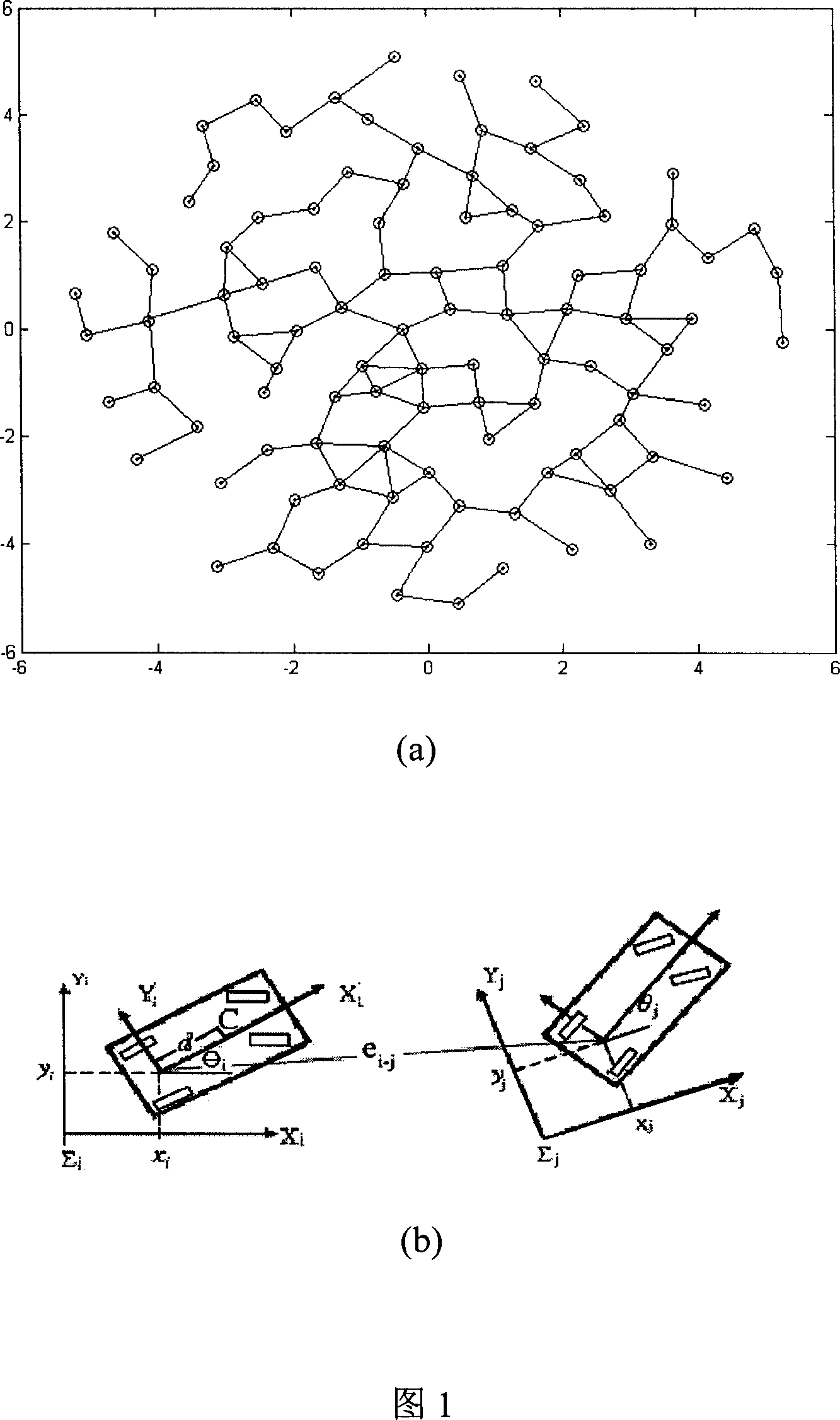

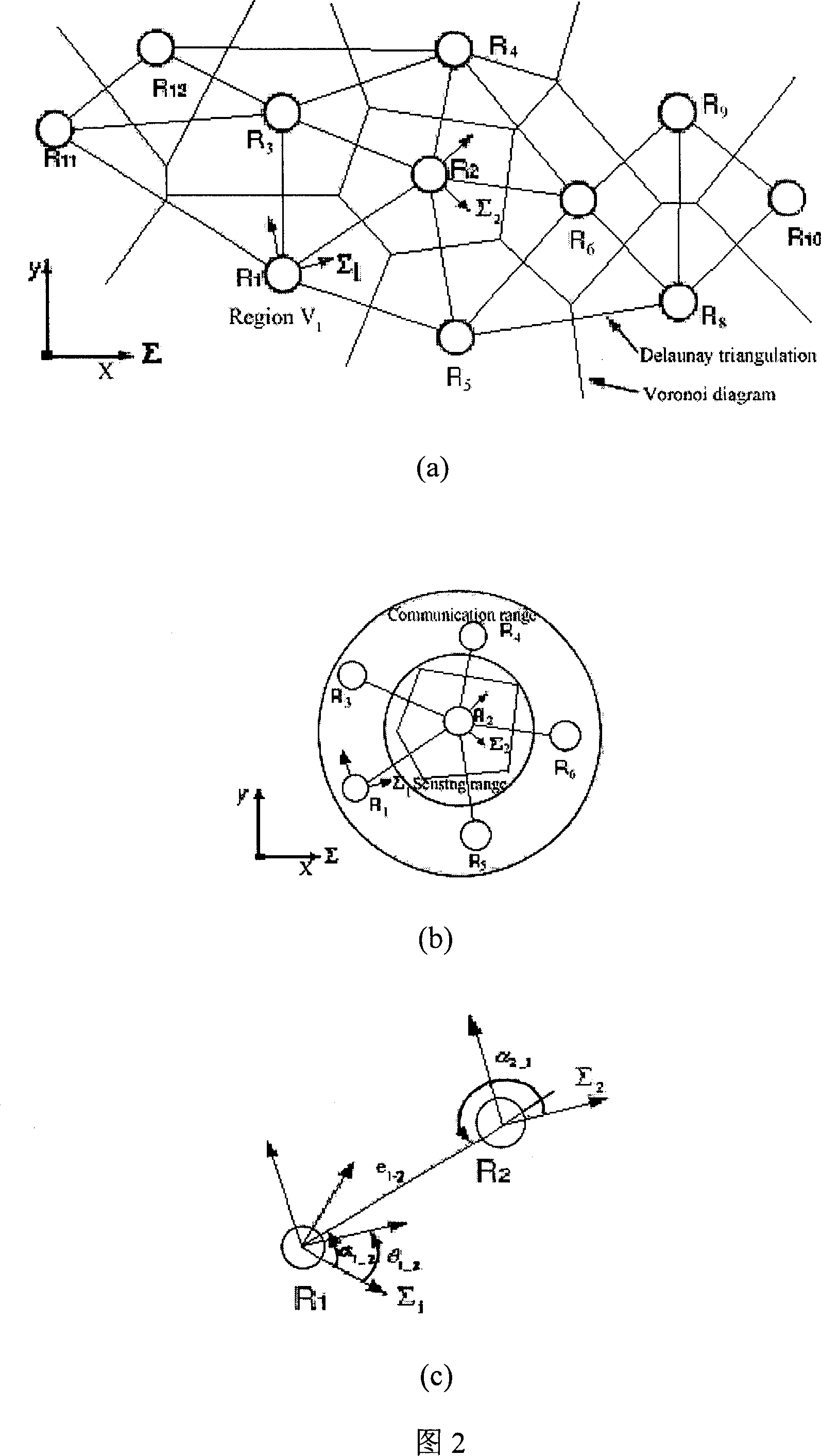

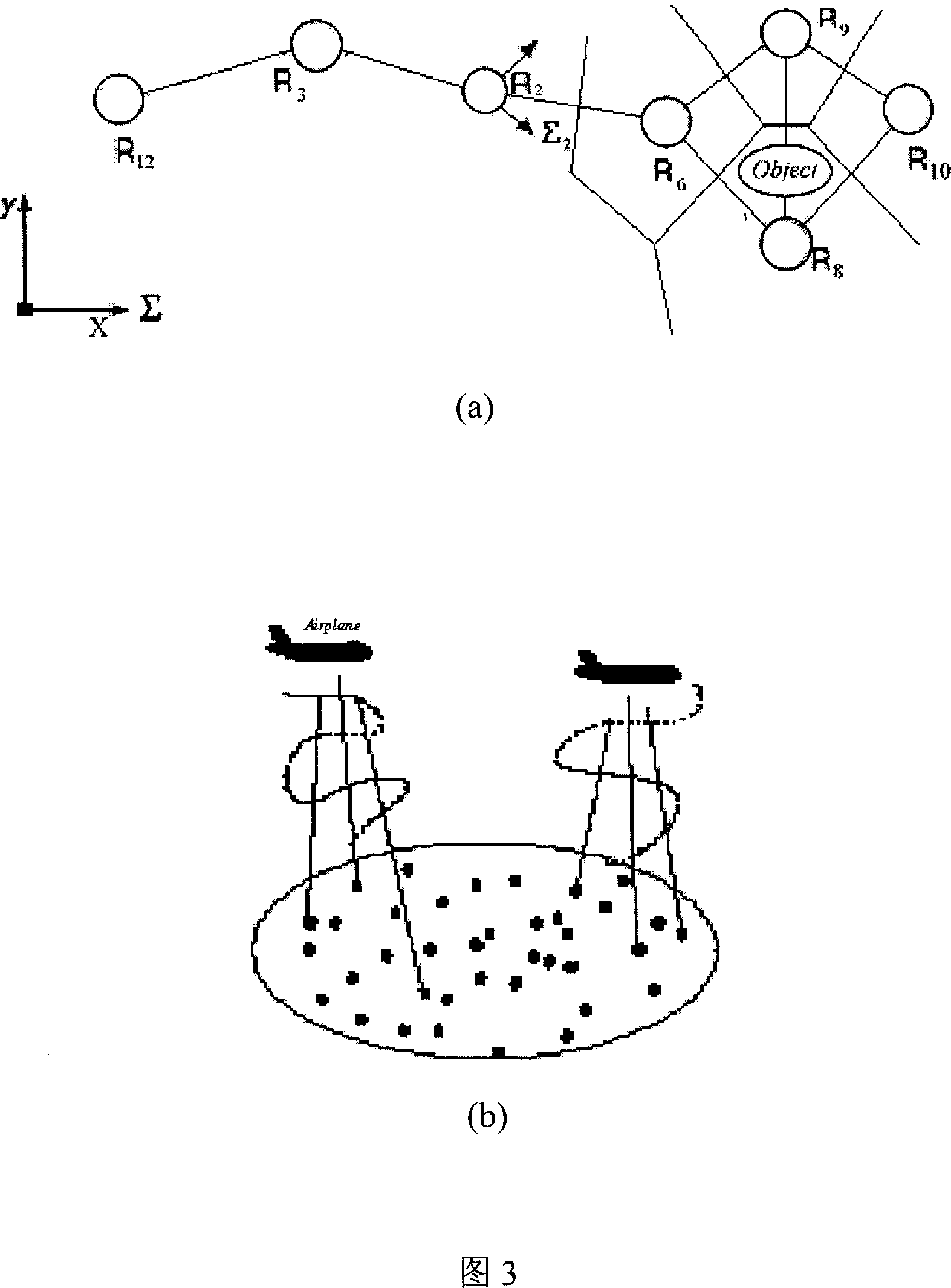

Dynamic modeling and control technology for independent mobile sensor network

InactiveCN101127657ASolving Dispersion ProblemsTroubleshoot Tracking Control IssuesEnergy efficient ICTData switching by path configurationSimulationSensor node

The utility model relates to a dynamic modeling and control technique of a self-moving sensor network and belongs to the sensor network technology. According to the technical proposal provided by the utility model, the dynamic modeling and controlling technology of a self-moving sensor network comprises the steps: the step I: build a distributed moving sensor network model based on the local Delaunay triangulation and other applicable diagram; the step II: use two methods to perform the distributed self-arrangement and the self-organization in the network for the sensor controlling node of each region in the distributed moving sensor network model; the step III: use the formation algorithm to control the network node formation and the node cooperation to achieve the purpose of fully energy-saving; the step IV: build the ad-hoc route data transmission protocol of the self-organization network of the distributed mobile robots to realize the stable work of the entire self-moving sensor network. The utility model can provide an algorithm for the repeatable configuration, cooperation, route development and verification of the sensor network with a plurality of moving sensor nodes.

Owner:无锡青起长升智能科技有限公司

Composite material fiber based on carbon nano-tube and its preparation method

InactiveCN1618850AEvenly dispersedSolving Dispersion ProblemsMonocomponent synthetic polymer artificial filamentFiberBreaking strength

A composite fibre based on carbon nanotubes is prepared through modifying the surface of carbon nanotube, polymerizing them with polymer monomer, trigger and assistant to obtain dope, and spinning. It has 3-20 CN / dtex break strength and 10 to the power (2-8) ohm.cm resistivity.

Owner:DONGHUA UNIV

Controllable oxidative-biological degradation plastic master batch and preparation method thereof

The invention relates to a controllable oxidative-biological degradation plastic master batch, comprising an inorganic filling material, a carrier, an oxidative degradation promoter, a biodegradation promoter and a degradation control agent, wherein the degradation control agent is an anti-oxidant. According to the plastic master batch provided by the invention, a bivariate control system of oxidative degradation and biodegradation can be optimized and linked according to an actual environment so as to allow the plastic master batch to have environment targeting performance and degradation controllability. A preparation method for the plastic master batch is simple, is easy and convenient to operate, improves mixing and dispersing capability of the plastic master batch and provides an effective solution to overcome the problems of organic-inorganic interfacial compatibility and uniform dispersibility.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

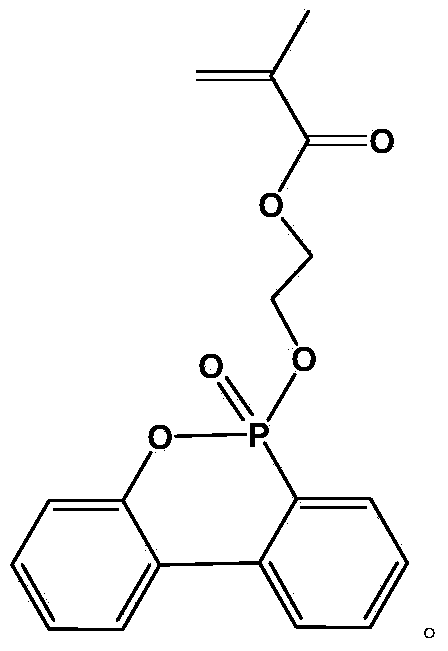

Flame-retardant monomer containing DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) groups and preparation method and application of flame-retardant monomer

InactiveCN103755742AMild reaction conditionsHigh yieldGroup 5/15 element organic compoundsChemistryFire retardant

The invention discloses a flame-retardant monomer containing DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) groups, and a preparation method and an application of the flame-retardant monomer, and relates to a compound. The method comprises the steps of sequentially adding an organic solvent, carbon tetrachloride and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a reaction flask, putting in an ice water bath, adding hydroxyethyl methylacrylate and an acid-binding agent while stirring, after temperature rise reaction, decompressing, and performing suction filtration to remove acid-binding agent salt, purifying a crude product through spin steaming, washing and dryness, and obtaining a product, namely the flame-retardant monomer containing the DOPO groups. The flame-retardant monomer containing the DOPO groups can be applied in preparing a flame-retardant high molecular material. A reaction condition is mild, the productivity is high, the product purification and separation are simple, and the extended production is easy. The monomer is introduced into a polymer matrix such as polystyrene and polymethyl methacrylate by a free radical copolymerization manner, an intrinsic flame-retardant polymer material is prepared, and the defects of poor compatibility of an additive flame retardant and the matrix, high loss possibility during use, poor water resistance and the like are overcome.

Owner:XIAMEN UNIV

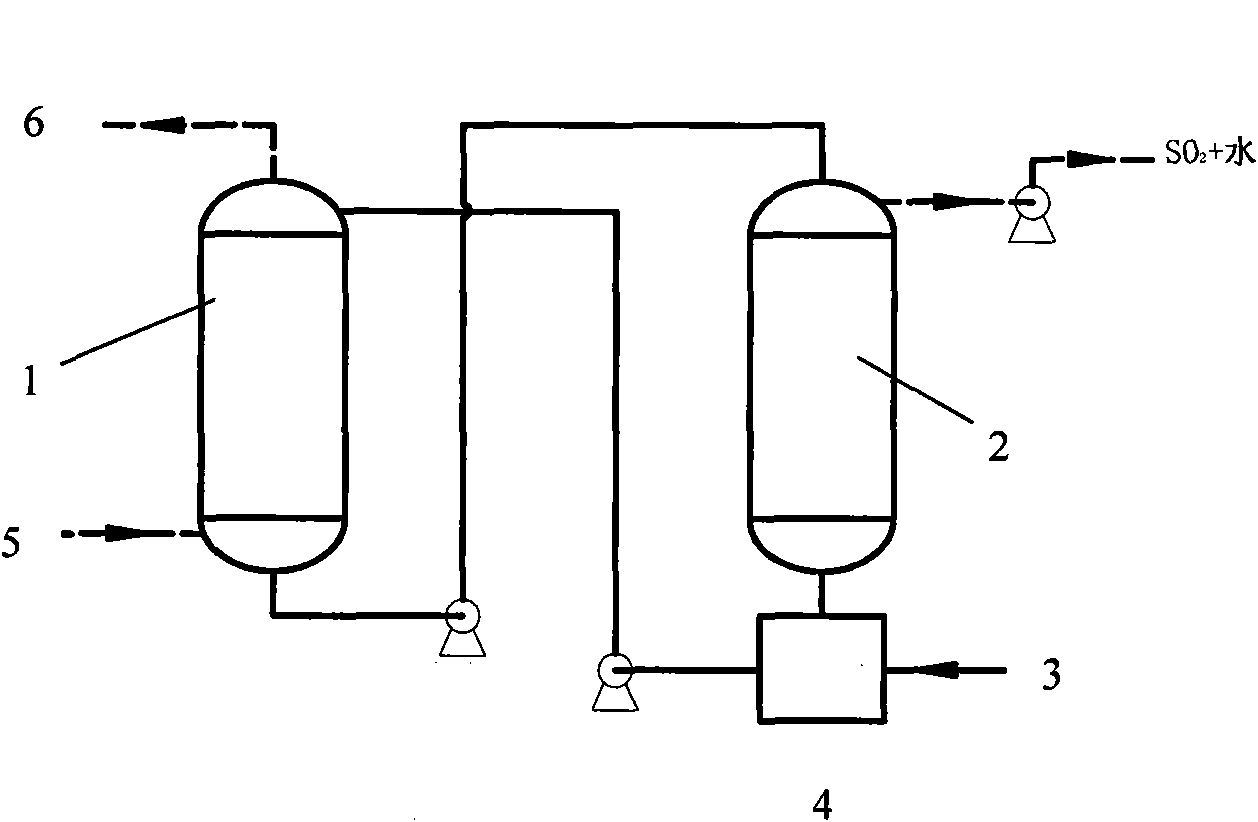

Flue gas desulfurization process

InactiveCN102068876AEasy to recycle and reuseRealize resourcesDispersed particle separationFlue gasTower

The invention provides a flue gas desulfurization process employing an ionic liquid. In the process, the ionic liquid is used as an absorbent, different types of absorption towers are adopted to absorb SO2 in the flue gas at the temperature of 0-200 DEG C under the pressure of 0.09-5.0 MPa, wherein gas-liquid countercurrent contact is adopted, various types of towers are adopted to improve a mass transfer effect so as to realize the emission of flue gas reaching the standard. The ionic liquid after absorbing the SO2 is pumped into a desorber through a pump and is subjected to deabsorption by adopting a heating and / or decompressing method, and SO2 is recovered. The desorbed ionic liquid enters the absorption towers to be reused. The process provided by the invention can be used for effectively removing the SO2 in the flue gas and recovering the SO2.

Owner:BEIJING UNIV OF CHEM TECH

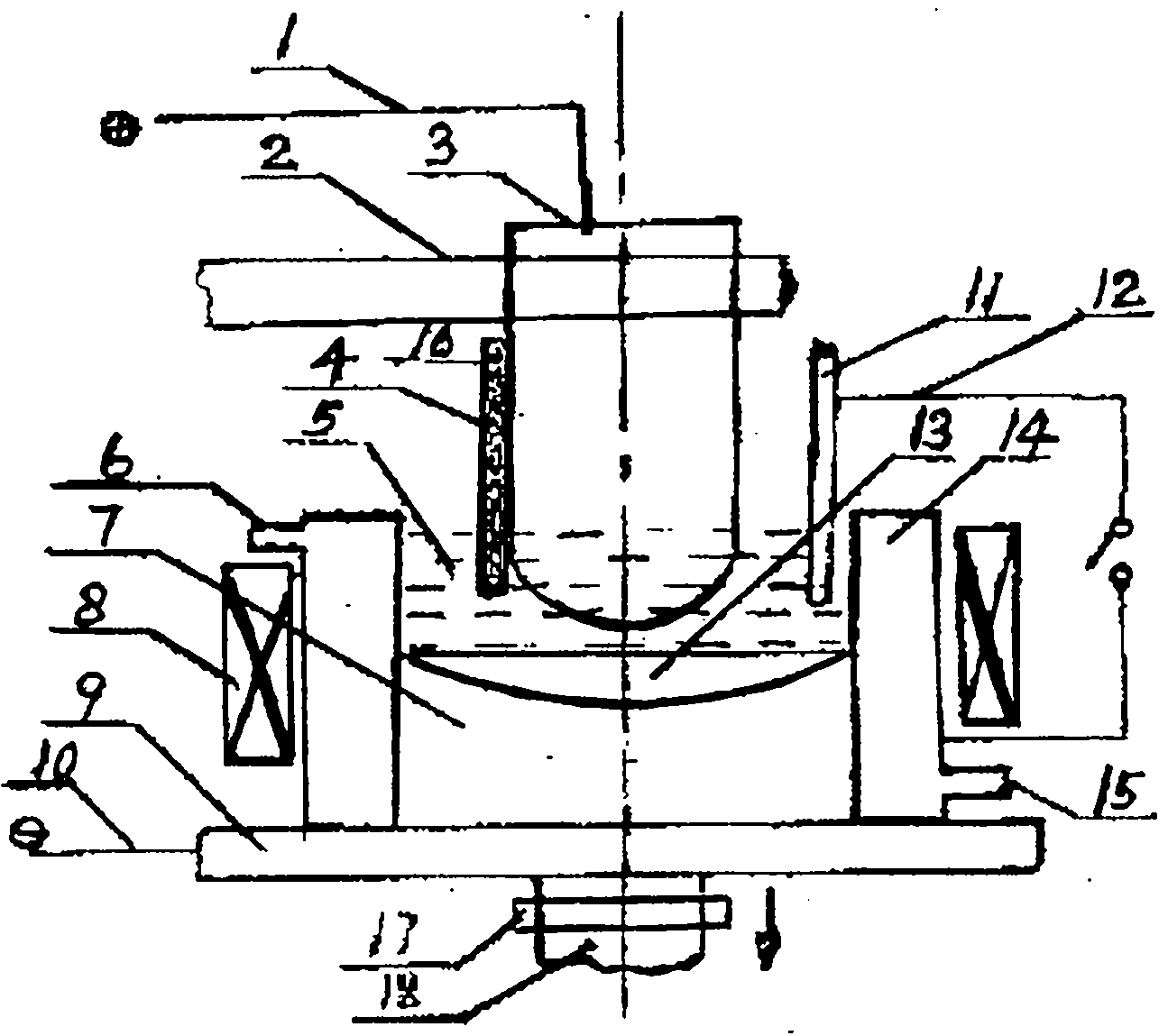

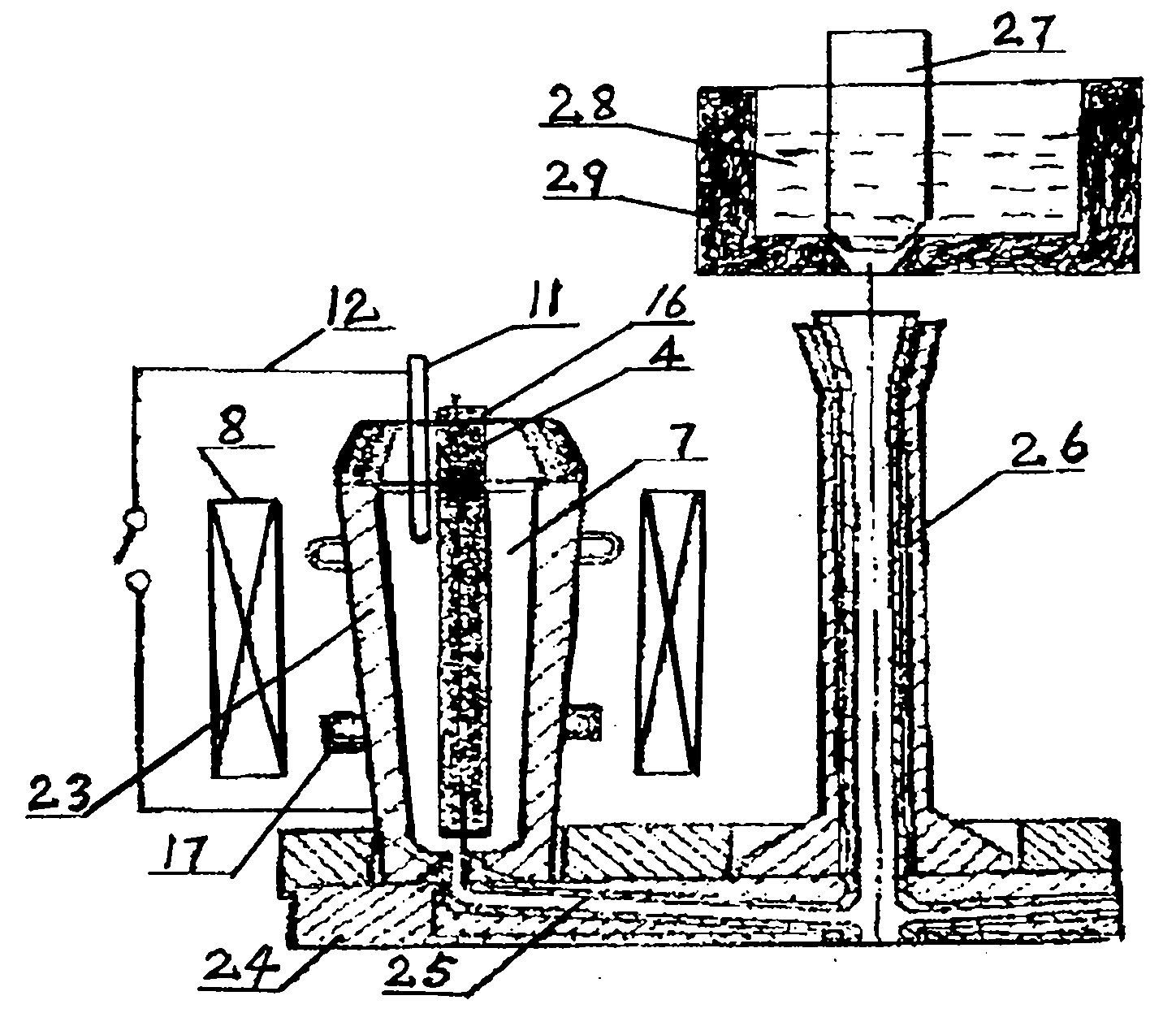

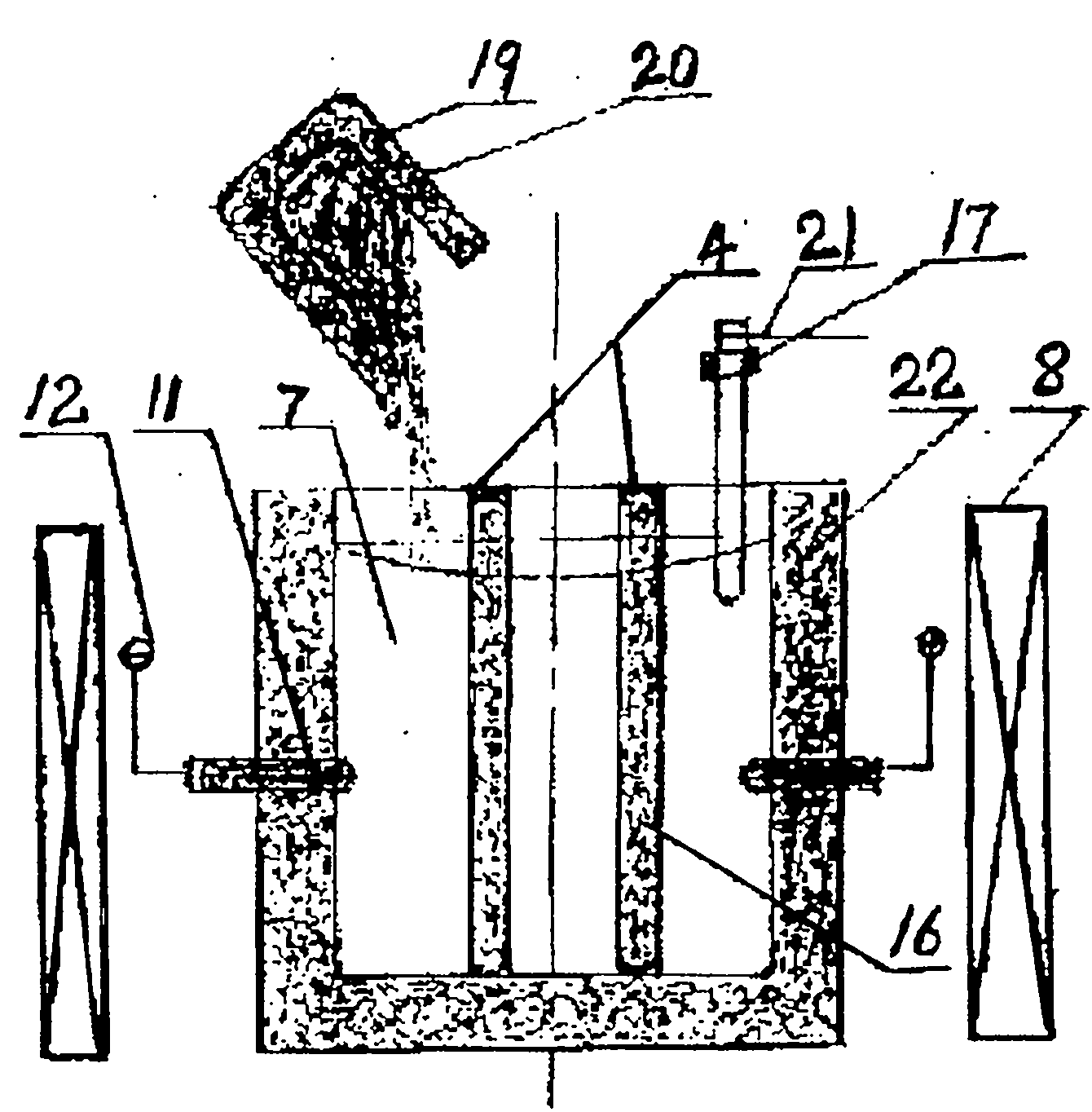

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

Graphene-based enhanced high-solid epoxy anticorrosive coating and method for preparing same

InactiveCN105733405AImprove adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsDiluentGraphene

The present invention involves the field of anticorrosive coatings, which provides a graphene -based high -solid high -solid -based epoxy anticorrosive coating and its production method to solve the poor anticorrosive coating performance of existing technologies, not environmental protection, and graphene difficult to stabilize the stability in the coatings.The problem is composed of the main paint and curing agent mixed. The main paint consists of the following weights of the following weights: epoxy resin 18‑25 weight, dilute agent 10‑15 weight, auxiliary 0.2‑3 weight portion, Graphene 0.1量2 weight, pigment 10‑15 weight, filler 35‑45 weight, tactile 0.5‑5 weight; the curing agent consists of the following weights of each raw material: amine resin 75‑‑‑85 weights, dilute agents 5‑15 weights, and additives 3‑8 weights.

Owner:XINHE NEW MATERIALS CO LTD

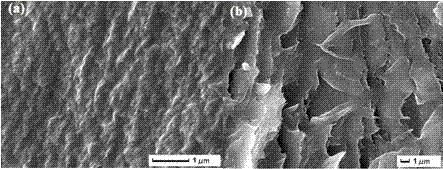

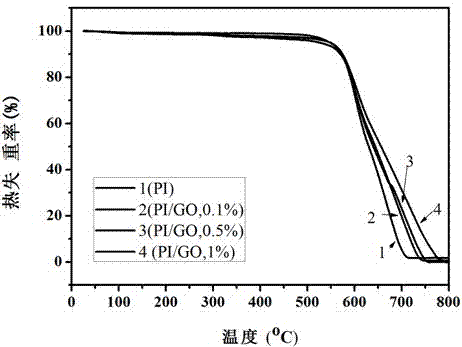

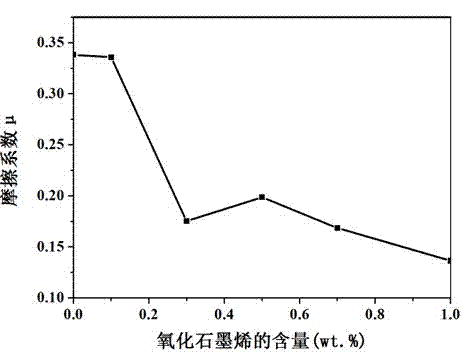

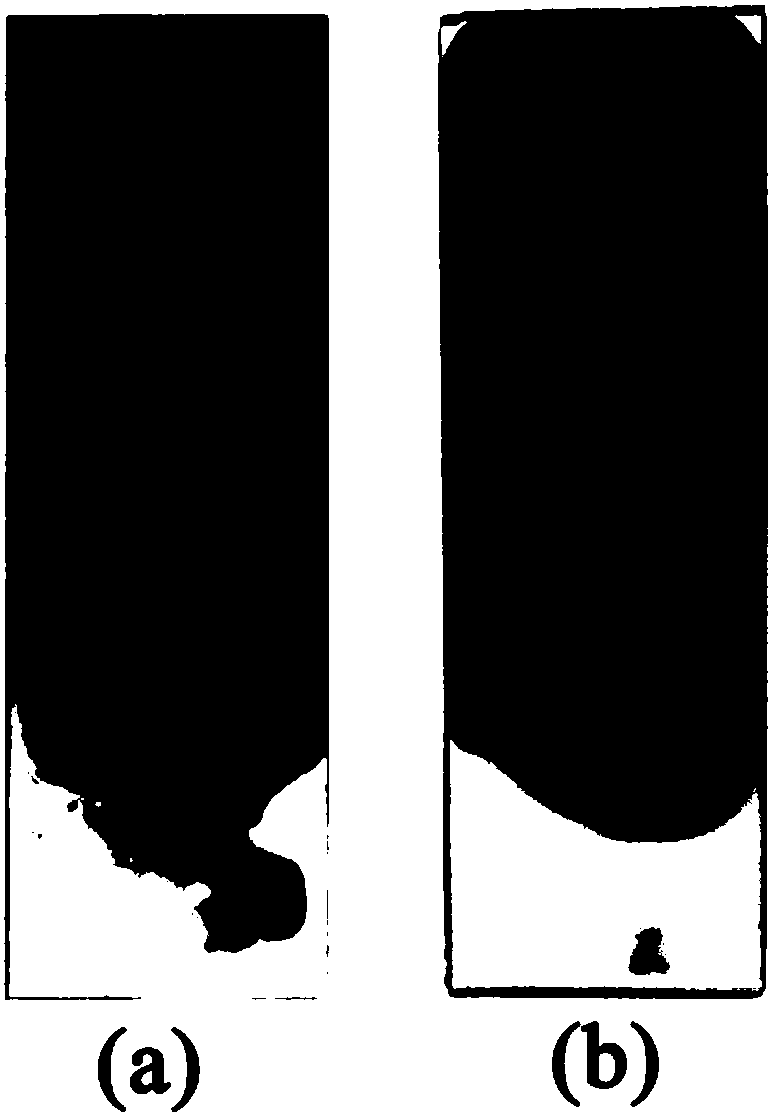

Preparation method for polyimide/oxidized graphene nanocomposite film

InactiveCN103589152ASolve the shortcomings of poor wear resistanceSolving Dispersion ProblemsPolyamideDissolution

The invention relates to a preparation method for a polyimide / oxidized graphene nanocomposite film, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: performing ultrasonic even dispersion on the oxidized graphene in an organic solvent to obtain an oxidized graphene sheet suspension, wherein per ml of the oxidized graphene sheet suspension contains 1.3*10<-5>-1.3*10<-4>g oxidized graphene sheets; introducing nitrogen for carrying out deoxidization protection, adding diamine monomers into the suspension, mechanically stirring until full dissolution is achieved, adding dianhydride monomers, the moles of which are equal to that of the diamine monomers, in batches, and mixing for one to six hours under the ice bath conditions, so as to obtain polyamide acid / oxidized graphene composite solution; pouring the polyamide acid / oxidized graphene composite solution onto a die, removing the organic solvent, performing gradient temperature rise within 100-300DEG C, and carrying out thermal imidization to obtain the polyimide / oxidized graphene nanocomposite film.

Owner:JIANGSU UNIV

Preparation of nano graphite carbon colloidal SOL by pulse electrode process

InactiveCN1579932ASimple processReduce manufacturing costElectrolysis componentsVolumetric Mass DensityPulse period

The invention discloses a method to produce nanometer graphite sol. It supplies a system which includes highly pure graphite as anode, inert materials as cathode and electrolytical aqueous solution. There is an impulsing power source to connect the anode and cathode. The pulse period of the power source is 0.05-0.5 second, effective voltage 2-10V (3-5V is prelatered) and effective amphere density 15-75A (25-35 is prelatered). The efficiency of this invention is higher than common direct-current electrode method. The produced nanometer graphite sol is stable and disperses so it can produce nanometer graphite powder whose diameter is under 15nm.

Owner:华农纳米科技(天津)有限公司

Conductive composite waterborne adhesive as well as one-pot preparation method and application thereof

ActiveCN107663428AGood dispersionGood film formingCell electrodesMacromolecular adhesive additivesPolymer scienceConductive polymer

The invention discloses a conductive composite waterborne adhesive as well as a one-pot preparation method and application thereof. A conductive composite waterborne adhesive material is prepared by adopting a one-pot method by simultaneously initiating grafting polymerization between double bond-containing grafting monomers and hydroxyl-containing waterborne polymers and chemical oxidative polymerization of conductive polymer monomers by adopting the same polymerization initiator, wherein the double bond-containing grafting monomers and the hydroxyl-containing waterborne polymers perform grafting polymerization reaction, and simultaneously, the conductive polymer monomers perform chemical oxidative polymerization; the conductive composite waterborne adhesive prepared by the invention hasgood dispersity, film forming property and chemical stability, can be dispersed in an aqueous solution for a long time in the form of colloid, does not settle, exists stably, has excellent electronicconductivity, solves the problem about dispersity of an adhesive and conductive particles in an electrode slurry preparation process, realizes uniform distribution of various components in an electrode, and ensures high-efficiency electron and ion transportation in the electrode.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

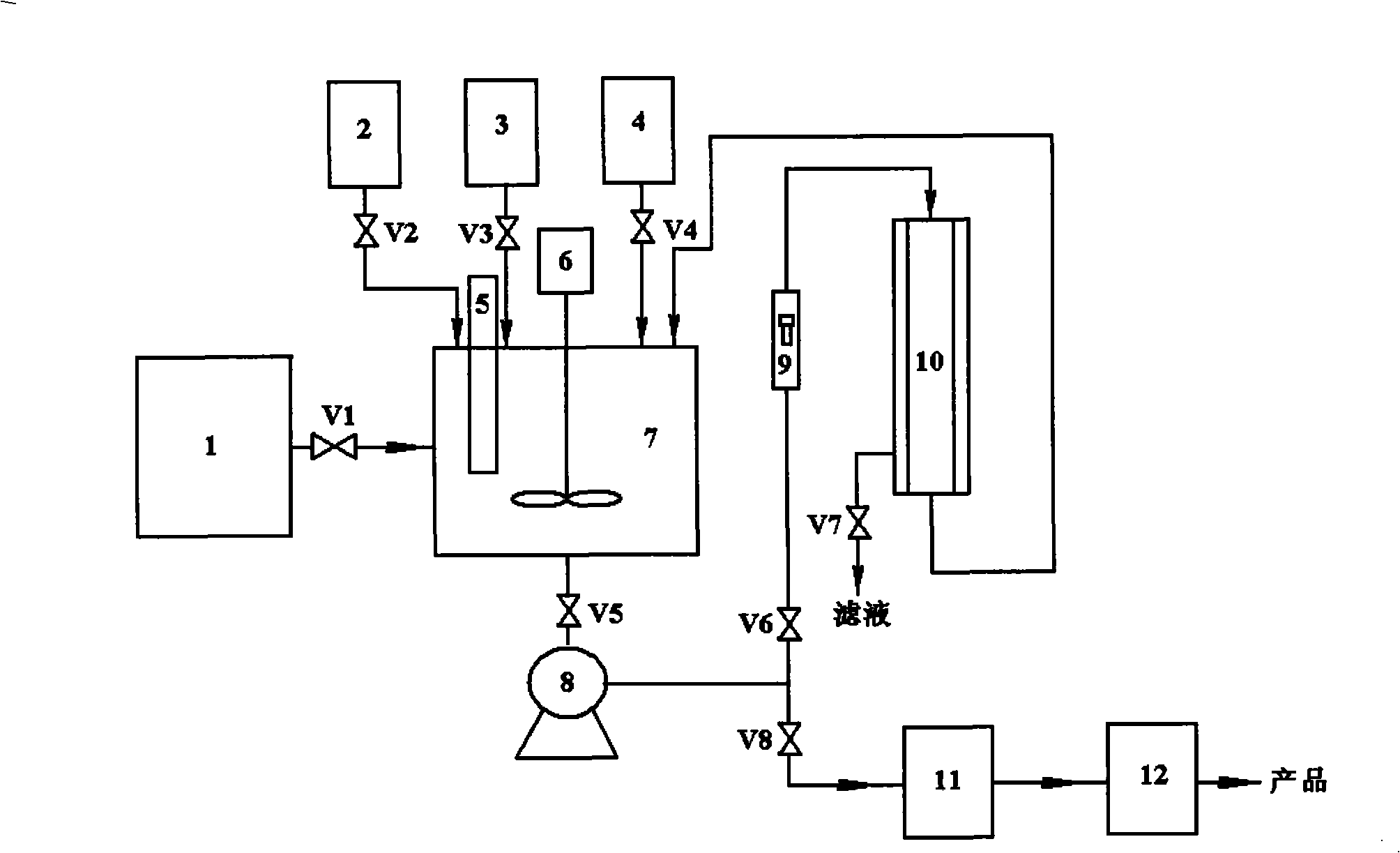

Nano titanium oxide inorganic surface treatment method

ActiveCN101255288AAvoid flocculationReduce clumpingInorganic pigment treatmentNanometreTitanium dioxide

The invention discloses a nm titanium dioxide inorganic surface treating method. The inorganic surface treating is performed when the nm titanium dioxide is in good dispersed state and the inorganic surface treatment effect is increased using the said method. The invention solves the flocculation and dispersion problem of nm titanium dioxide using ultrasonic field, mechanical agitation and film separation and phase integrating. During the process of treating the inorganic surface, on the one hand the nm titanium dioxide dispersion liquid is always under the action of mechanical agitation and ultrasonic, on the other hand, the impurity ions are continuously removed using membrane separation device, so as to make sure the inorganic surface coating reaction under the full dispersed state of the nm titanium dioxide.

Owner:江苏河海纳米科技股份有限公司 +1

Preparation method of polyimide/graphene nanocomposite material

The invention discloses a preparation method for a polyimide / graphene nanocomposite material. The method is characterized by: adopting graphite as a raw material; adopting a modified Hummers method for synthesis of a graphene oxide; adopting an organic molecule containing isocyanic acid radical to modify the graphene oxide; uniformly dispersing the surface modified graphene oxide in an organic solvent system, adding equivalent dianhydride monomer and equivalent diamine monomer at a temperature of 0-25 DEG C after uniformly dispersing; continuously carrying out the reaction for 6-24 hours, followed by carrying out heat treatment for the resulting solution to prepare the high-performance polyimide / graphene nanocomposite material. With the prepared polyimide / graphene nanocomposite material through an in situ polymerization method, dispersing problems and compatibility problems of the graphene in the polyimide matrix are solved, the polyimide nanocomposite material with good dispersity isobtained. In addition, the prepared material provided by the present invention has potential application values in the fields of heat resistant materials, structural materials, conductive materials, adhesives, and the like.

Owner:YANGZHONG HUAXIN FUSHU ELECTRICAL EQUIP

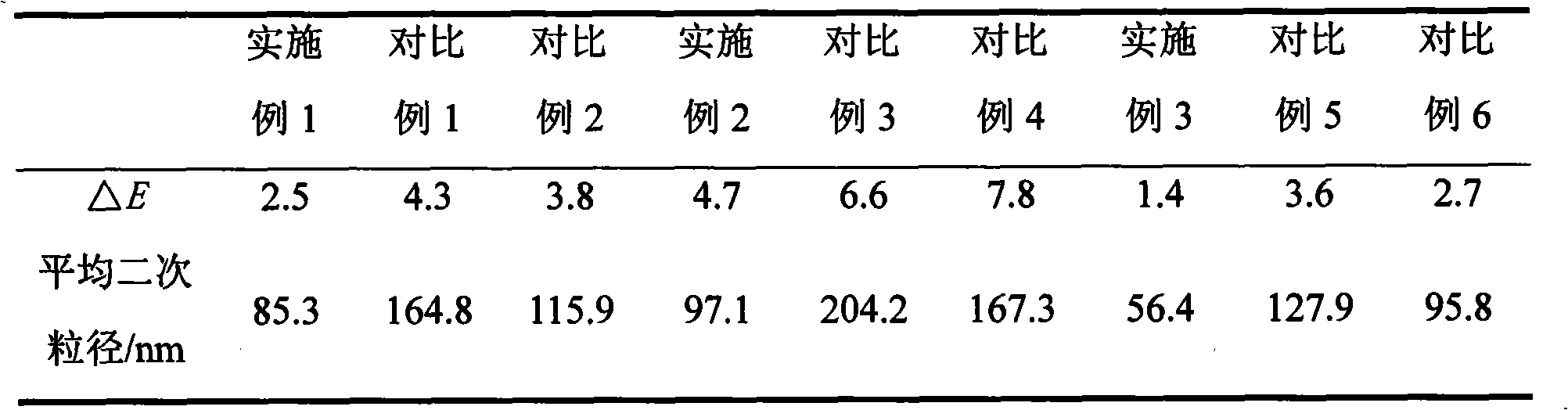

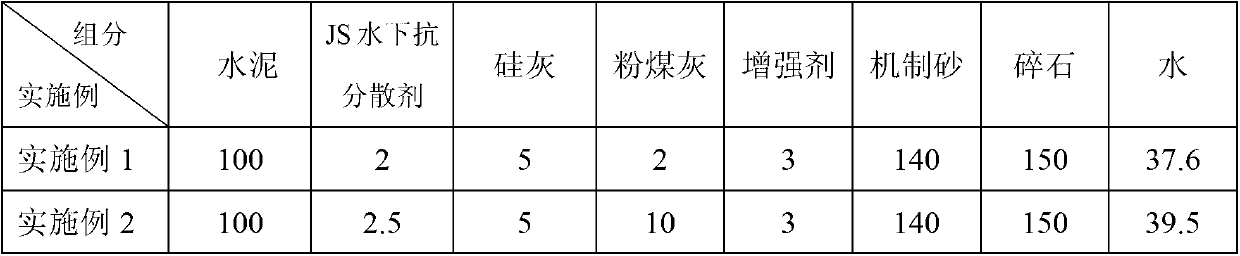

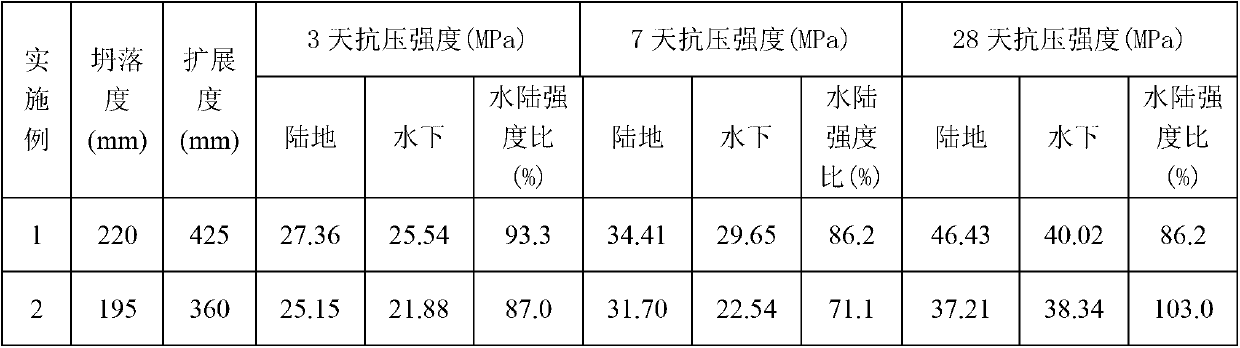

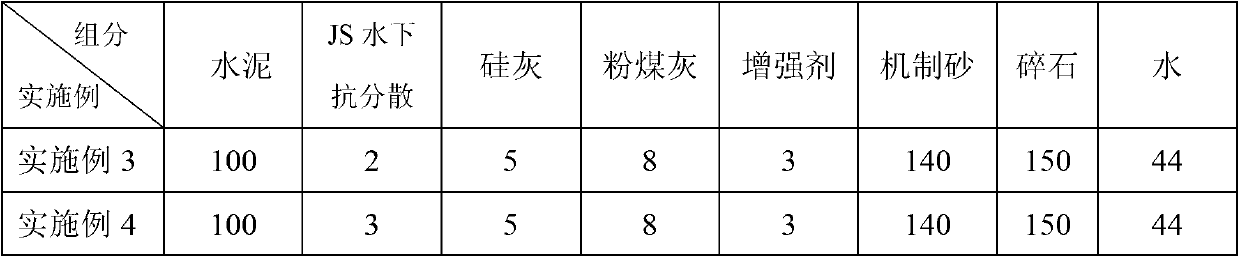

Manufactured sand underwater dispersion resistant concrete and preparation method thereof

The invention relates to a manufactured sand underwater dispersion resistant concrete, which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of underwater dispersion resistant additive, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of an enhancer, 140-200 parts of manufactured sand, 140-200 parts of macadam, and 30-50 parts of water. The preparation method comprises the following steps of firstly putting the manufactured sand, the macadam aggregate, the cement, the enhancer, the coal ash and the silica fume into an agitator, blending through dry mixing, then adding the underwater dispersion resistant additive to further blend through dry mixing, adding water into the material blended through dry mixing previously, stirring for 5-8 minutes, then preparing the manufactured sand underwater dispersion resistant concrete. The manufactured sand underwater dispersion resistant concrete has strong construction mobility, so that the problem of contradiction of mobility and dispersion resistance of the underwater dispersion resistant concrete is better solved, and therefore, the manufactured sand underwater dispersion resistant concrete not only has good dispersion resistance, but also has self-leveling and self-compaction construction mobility.

Owner:江西万年青水泥股份有限公司

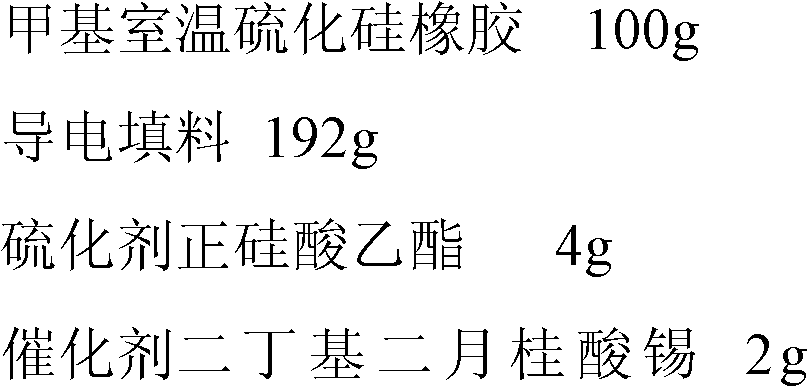

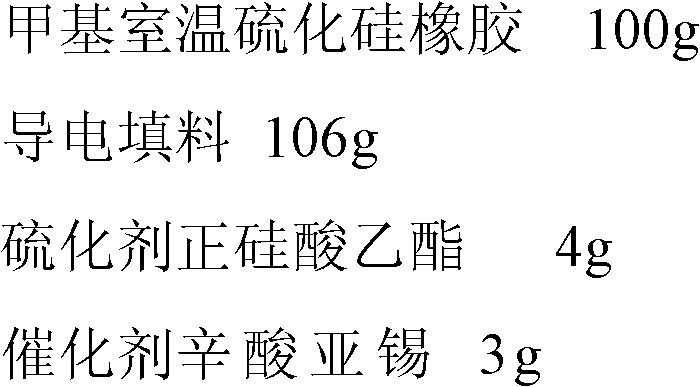

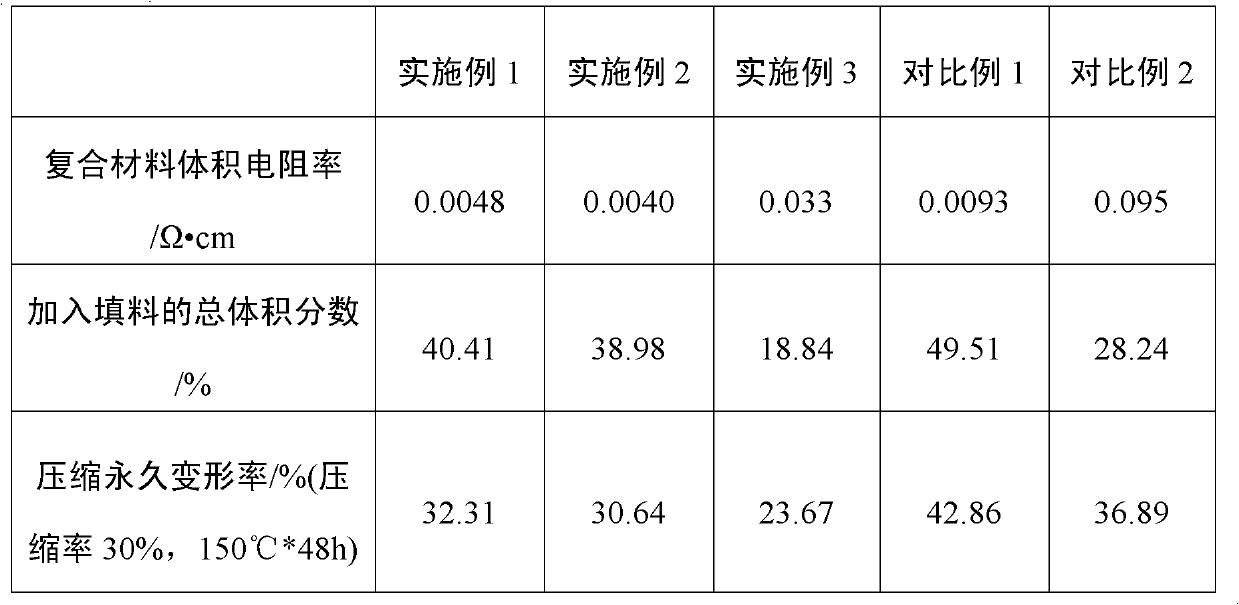

Low-compressive-deformation and high-conductivity rubber composite material and preparation method thereof

The invention relates to a low-compressive-deformation and high-conductivity rubber composite material and a preparation method thereof. The low-compressive-deformation and high-conductivity rubber composite material is prepared by the following steps of: taking silicon rubber as a base body and utilizing modified grain-shaped and fiber-shaped metal-plating conductive fillers containing a reactive double-bond silane coupling agent under a CO2 supercritical state to prepare low-compressive-deformation and high-conductivity rubber composite material. Under the condition of guaranteeing the high conductivity, the use amount of the conductive fillers is reduced and the composite material has low compressive deformation and high conductive property.

Owner:BEIJING UNIV OF CHEM TECH +1

Pitch modified from waste tire rubber powder and preparation method thereof

InactiveCN101831184ATake advantage ofSolve the problem of swellingPlastic recyclingBuilding insulationsMicrowaveCost savings

The invention provides pitch modified from waste tire rubber powder and a preparation method thereof. The preparation method comprises the following steps of: heating 2-14 parts by weight of heavy fraction oil to 90-130 DEG C; adding 84-97.8 parts by weight of waste tire rubber powder and 0.2-2 parts by weight of additives to evenly mix; radiating the mixture by a microwave for 3-10 min; adding 60-85 parts by weight of pitch to 15-40 parts by weight of modified waste tire rubber powder at 160-200 DEG C to mix evenly; and shearing the mixture at a high speed to obtain a mixture, i.e. the modified pitch of the invention. By selecting waste tires as raw materials, the invention has simple and easily obtained raw material, cost saving, environmental protection and pitch performance improvement. The waste tire rubber powder is decarbolized under the microwave radiation to improve the storage stability of the modified pitch. Meanwhile, the waste tires are utilized. The invention has simple modified pitch preparation process and strong practicability.

Owner:JIANGHAN UNIVERSITY

Service system united safe platform

InactiveCN101257399AReduce redundant workSolving Dispersion ProblemsData switching networksSecurity analyticsComputer science

The invention discloses a unified satety platform of an operation system, characterized in that the platform comprises: an intrusion detection module for a access layer network of the operation system; a flow statistic module for the access layer network of the operation system; a vulnerability scanning module for the operation system host device; a server monitoring module for the operation system server; a log audit module for the operation system environment and the system per se; an event inquiring module for collecting the log and auditing the event information; and a strategy audit module for auditing event statistic of the event information and collecting the log. The invention can carry out comprehensive unified satety analysis for the operation system, solve the prior dispersive and complex problem of the safty analysis, lower the cost and reduce active redundancy of satety mamager.

Owner:CHINA MOBILE GROUP SICHUAN

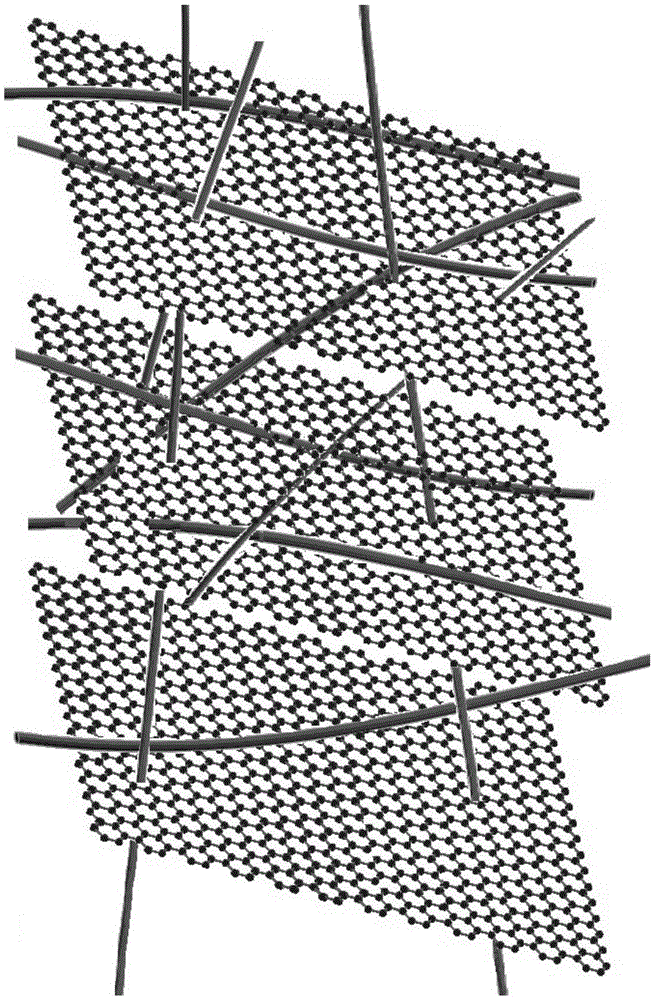

Polyamide6-graphene quantum dot/carbon nanotube anti-static fiber and preparation

InactiveCN105463613AHigh transparencyImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentElectronic transmissionPolyamide

The invention provides polyamide6-graphene quantum dot / carbon nanotube anti-static fiber and preparation. According to the method, the molecular template effect of graphene quantum dots is utilized for being compounded with a carbon nanotube to form a self-assembled three-dimensional network structure first and then combined with a PA6 knitting state structure to form a dislocation effect to construct a conductive path, conductivity is improved on the condition of not losing a mechanical property of PA6 fiber, and meanwhile conductivity and the mechanical property of the PA fiber are promoted. Moreover, by means of compounding of the graphene quantum dots and the carbon nano tube and the self-assembled three-dimensional network structure, electronic transmission efficiency in the carbon nano tube is improved, a small quantity of GQD / CNT is added, conductivity of the fiber can be improved, and transparency is improved at the same time, which is beneficial for treatment technologies like dyeing in the fiber preparing process. By means of the traditional mature PA6 melt spinning technology, the high-strength and high-conductivity PA6-GQD / CNT composite fiber with tensile strength being 0.52-0.81 GPa and line resistance being magnitude 106 is prepared and can be applied to anti-static clothes, needle-punched carpet, filter felt, industrial non-woven fabric, medical supplies and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

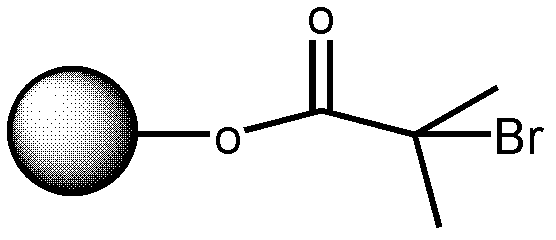

High-dispersivity super-amphiphobic microsphere and self-cleaning epoxy resin paint prepared from same

InactiveCN102585245ASolving Dispersion ProblemsAvoid problems with toxic fluorinated solventsEpoxy resin coatingsEpoxyCompound a

The invention discloses a high-dispersivity super-amphiphobic microsphere and self-cleaning epoxy resin paint prepared from the same. The high-dispersivity super-amphiphobic microsphere is prepared by the following methods that: microspheres, alkali amine catalysts, alpha-halogen acyl bromide or alpha-halogen acyl chloride are mixed for reaction, and microspheres with the surfaces grafted with atom transfer radical polymerization (ATRP) initiators are obtained; the microspheres with the surfaces grafted with the atom transfer radical polymerization (ATRP) initiators are subjected to ATRP random copolymerization or block polymerization reaction with fluorine-containing solvents, and microspheres with the surfaces grafted with monomers F and monomers D capable of taking D-A reaction are obtained; and the microspheres and high-dispersivity substances with compounds A as end bases are enabled to take reaction to obtain the high-dispersivity super-amphiphobic microsphere. According to the high-dispersivity super-amphiphobic microsphere and the self-cleaning epoxy resin paint, polymers capable of being dispersed into the epoxy resin paint are introduced on the super-amphiphobic microsphere interface, so the high-dispersivity super-amphiphobic microsphere can be directly dispersed into the epoxy resin paint, the problems of difficult dispersing and poor bonding force in the use process of the existing uper-amphiphobic microsphere are solved, and the poisonous fluorine-containing solvent adoption is also avoided.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

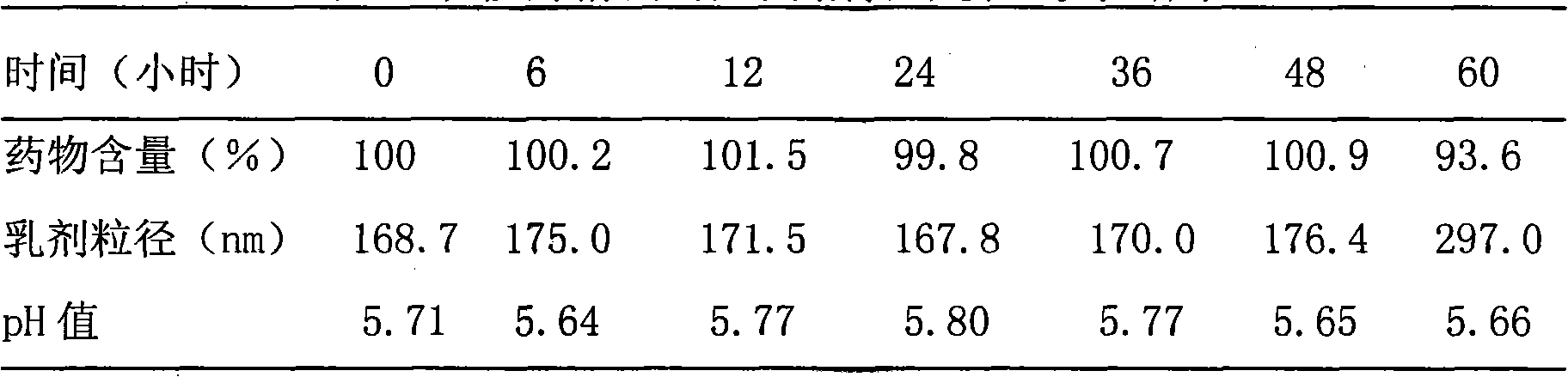

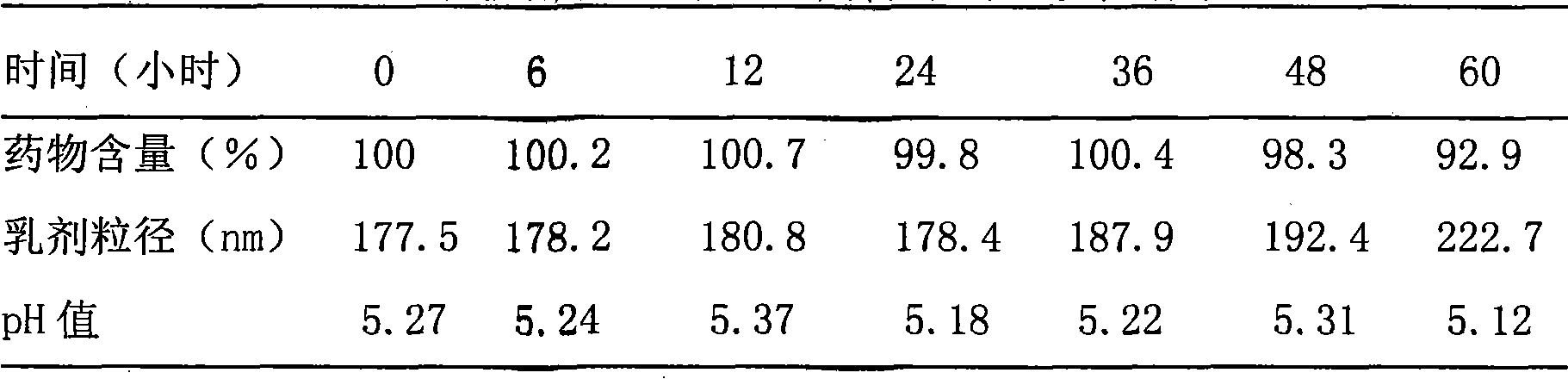

Taxanes medicine preparation for intravenous injection and preparation method thereof

ActiveCN101288642AGood biocompatibilityHigh tolerance in vivoOrganic active ingredientsSolution deliveryDrugs solutionDocetaxel

The invention relates to the technical field of medicine, which is a preparation of a taxane drug for intravenous drug delivery, consisting of two parts of drug solution and an emulsion. The drug solution is composed of paclitaxel or docetaxel, a pH regulator and a solvent for injection, wherein, the solvent for injection is an organic solvent; the emulsion comprises a fat emulsion and is composed of oil for injection, an emulsifier, an antioxidant, an isotonic regulator, a stabilizer, a pH regulator and water for injection. When in use, the drug solution can be added and evenly mixed in the emulsion for direct intravenous drip according to the clinical drug dosage and can also be firstly added in the emulsion with the volume that is not less than 5 times of the volume of the drug solution according to the clinical drug dosage and then added with a certain amount of physiological saline or glucose injection for intravenous drip. The preparation of the invention does not contain solubilizer and has the advantages of little toxicity, safety, effectivity, stability and economy. The fat emulsion can also be taken as a nutrition replenisher for a patient, thus achieving better treatment effects. The physiological saline or the glucose injection can also replace a certain amount of the emulsion, so the storage and the transportation are convenient, and the preparation is more economical.

Owner:JIANGSU TASLY DIYI PHARMA CO LTD

Amylum category complete biodegradable material and preparation method thereof

The invention discloses an amylum category complete biodegradable material and a preparation method thereof. The amylum category complete biodegradable material comprises, by weight, the long-chain branch aliphatic polyester or long-chain branch aliphatic series- aromatic copolyesters 50-70%, the starch 20-30%, the chain extender 0.1-3% and the balance chain extender 9-17%. The preparation method comprises the steps of enabling all components to be mixed in a high speed mixer, feeding in a twin-screw extruder after accurate measurement by means of a measurement scale, and extruding and prilling by adjusting a built-up sequence of a screw and designing different exhaust ports. The amylum category complete biodegradable material and the preparation method of the amylum category complete biodegradable material solve the problems of dispersing, plasticizing and exhausting of starch filler in the twin-screw extruder, and obtained amylum complete biodegradation material not only has complete biodegradation performance, but also has excellent mechanical property and good extrusion molding working quality.

Owner:KINGFA SCI & TECH CO LTD +2

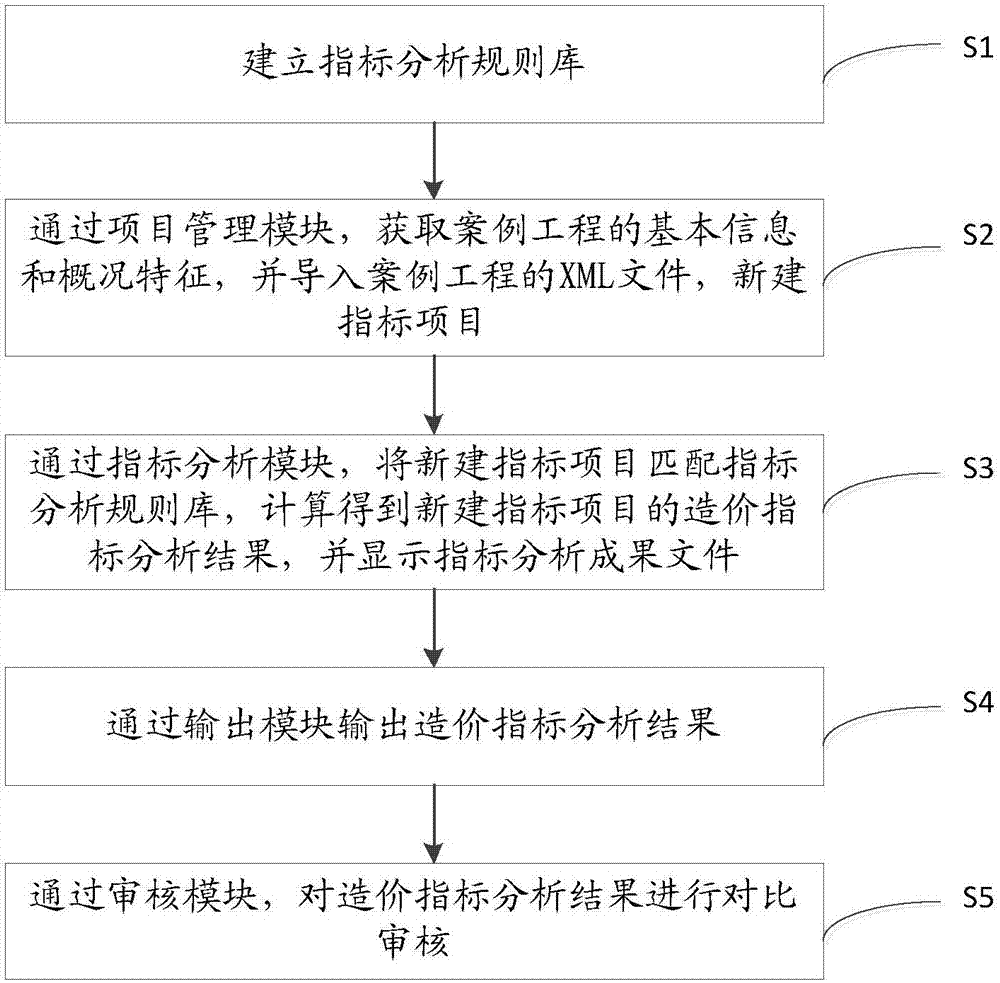

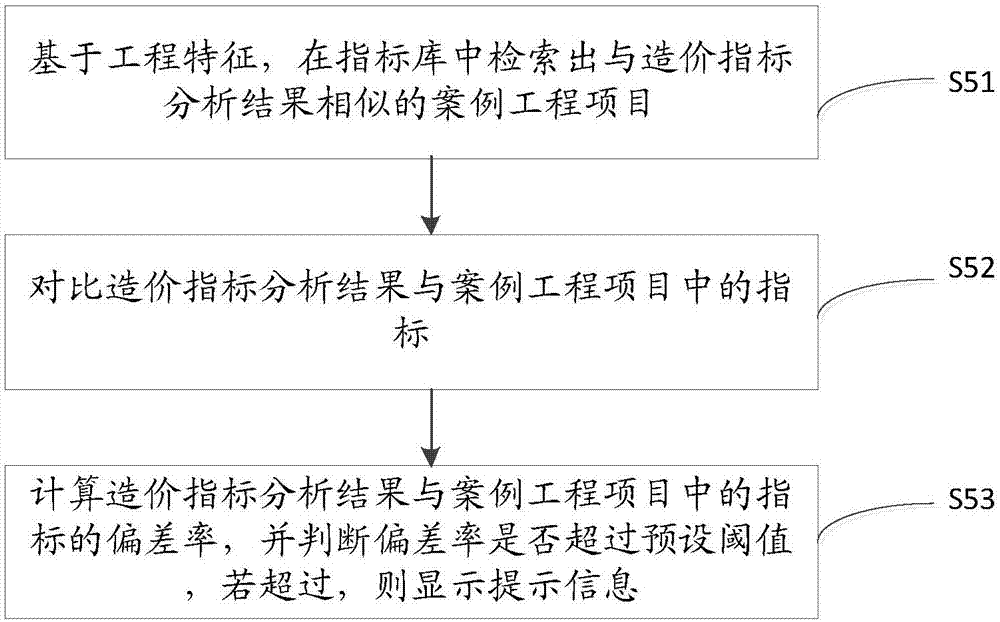

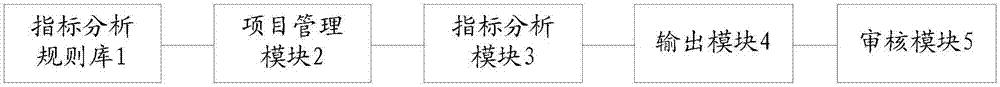

Cost index analysis method and system

InactiveCN106910011AImprove efficiencyRealize data sharingOffice automationResourcesCost indexProject management

The invention discloses a cost index analysis method, comprising the following steps: S1, establishing an index analysis rule base; S2: obtaining basic information and the general characteristics of a case project by a project management module and introducing an XML document of the case project; S3: with an index analysis module, matching a newly-built index project with the index analysis rule base, carrying out calculation to obtain a cost index analysis result of the a newly-built index project, and displaying an index analysis result file; and S4, outputting the cost index analysis result by an output module. In addition, the invention also discloses a cost index analysis system. With the system and the method, the efficiency of analyzing an index by the cost staff can be improved and index data sharing can be realized.

Owner:广东华联软件科技有限公司

6000 mesh inorganic powder filling-modified pe agglomerate and its preparation method

The invention discloses a 6000-order inorganic powder fill modified PE mother particle and preparing method, which comprises the following parts: PE, surface disposer, polyethylene wax, paraffine, 6000-order inorganic material powder, manufacturing adjuvant. The preparing method comprises the following steps: placing 6000-order inorganic material powder in the high-blender to stir and dehumidify; adding surface disposer in the cooling machine to cool; placing PE, polyethylene wax, paraffine and manufacturing adjuvant in the high-blender with modified 6000-order inorganic powder to cool; discharging; graining through squeezer.

Owner:TIANJIN DEHAO NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com