Nylon 66 composite material with high heat conductivity and preparation method thereof

A composite material and high thermal conductivity technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

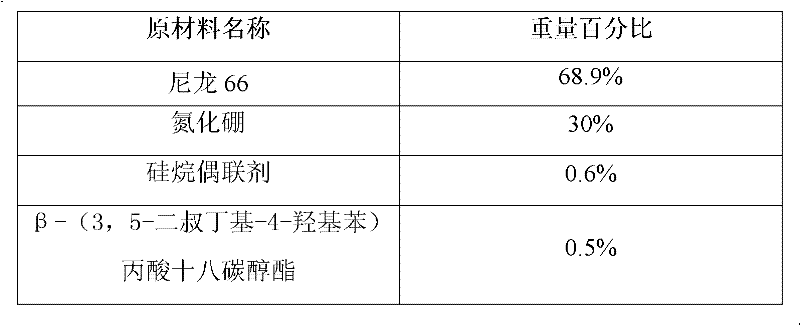

[0018] Raw materials are prepared according to the following weight percentages of raw materials:

[0019]

[0020] Its preparation steps are as follows:

[0021] 1) Thermally conductive filler treatment

[0022] Dissolve nylon 66 in 85% formic acid aqueous solution and bake in an oven at 80°C for 2 to 3 hours. The purpose is to increase the solubility of nylon 66 and completely dissolve nylon 66. After the solvent completely dissolves the nylon 66, add the thermally conductive filler boron nitride into the nylon 66 solution, let the thermally conductive filler and the nylon 66 solution mix fully, then put it in an oven at 80°C for 6 to 8 hours, the purpose is to remove the dissolved Solvent for Nylon 66. After it is dried to constant weight, it is taken out and crushed into a fine powder of 100-500 mesh. Then wash the residual solvent in the fine powder with absolute ethanol. After cleaning the residual solvent, put it into an oven at 80°C for 4-6 hours, the purpose is...

Embodiment 2

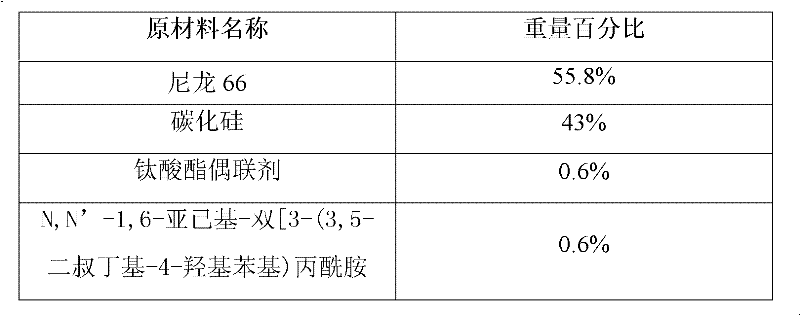

[0026] Raw materials are prepared according to the following weight percentages of raw materials:

[0027]

[0028] Its preparation steps are as follows:

[0029] 1) Thermally conductive filler treatment

[0030] Dissolve nylon 66 in 20% calcium chloride aqueous solution and bake in an oven at 80°C for 2 to 3 hours. The purpose is to increase the solubility of nylon 66 and completely dissolve nylon 66. After the nylon 66 is completely dissolved by the solvent, add the thermally conductive filler silicon carbide into the nylon 66 solution, let the thermally conductive filler and the nylon 66 dissolved mixture be fully mixed, and then put it in an oven at 80°C for 6 to 8 hours. The purpose is to remove the dissolved nylon. 66 solvent. After it is dried to constant weight, it is taken out and crushed into a fine powder of 100-500 mesh. Then wash the residual solvent in the fine powder with absolute ethanol. After cleaning the residual solvent, put it into an oven at 80°C f...

Embodiment 3

[0034] Raw materials are prepared according to the following weight percentages of raw materials:

[0035] its system The preparation steps are as follows:

[0036] 1) Thermally conductive filler treatment

[0037] Dissolve nylon 66 in dimethylformamide and bake in an oven at 80°C for 2 to 3 hours. The purpose is to increase the solubility of nylon 66 and completely dissolve nylon 66. After the solvent completely dissolves the nylon 66, add the thermally conductive filler composed of aluminum nitride and aluminum oxide each accounting for 50% by weight to the nylon 66 solution, let the thermally conductive filler and the nylon 66 dissolved mixture be fully mixed, and then put Bake in an oven at 80°C for 6 to 8 hours, the purpose of which is to remove the solvent that dissolves nylon 66. After it is dried to constant weight, it is taken out and crushed into a fine powder of 100-500 mesh. Then wash the residual solvent in the fine powder with absolute ethanol. After cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com