Manufactured sand underwater dispersion resistant concrete and preparation method thereof

An anti-dispersion, machine-made sand technology, applied in the field of building materials, can solve the problems of low strength and poor dispersion resistance, and achieve the effects of improved anti-dispersion performance, self-compacting construction fluidity, and obvious anti-dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

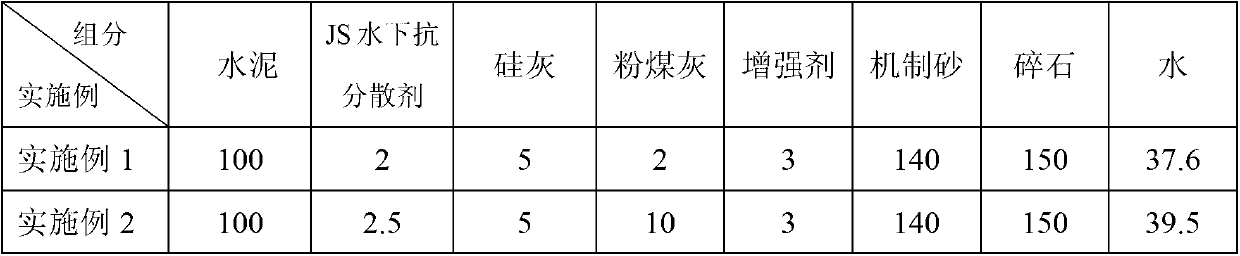

Embodiment 1-2

[0050] Ingredients:

[0051] Cement: Ordinary Portland cement, strength grade 42.5, produced by Chongqing Kehua Cement Factory;

[0052] Fly ash: High-calcium type first-class fly ash, produced by Guizhou Zunyi Power Plant;

[0053] Manufactured sand: fineness modulus not greater than 4, stone powder content less than 10wt%, mud content less than 0.5wt%, produced locally in Guizhou;

[0054] Crushed stone: the maximum particle size is 25mm, the needle flake stone content in the crushed stone is less than 5%, the mud content is less than 1%, 5-25mm continuous gradation, local production in Guizhou;

[0055] Underwater anti-dispersion agent: JS underwater anti-dispersion additive (powder), composed of Wenlun rubber (viscosity-increasing component): polycarboxylate water reducer (water reducer): polyether modified polysiloxane Defoamer (reinforcing component) = 7:20:2, produced by Shanghai Tongyou Building Materials Technology Co., Ltd.;

[0056] Enhancer: calcium formate;

...

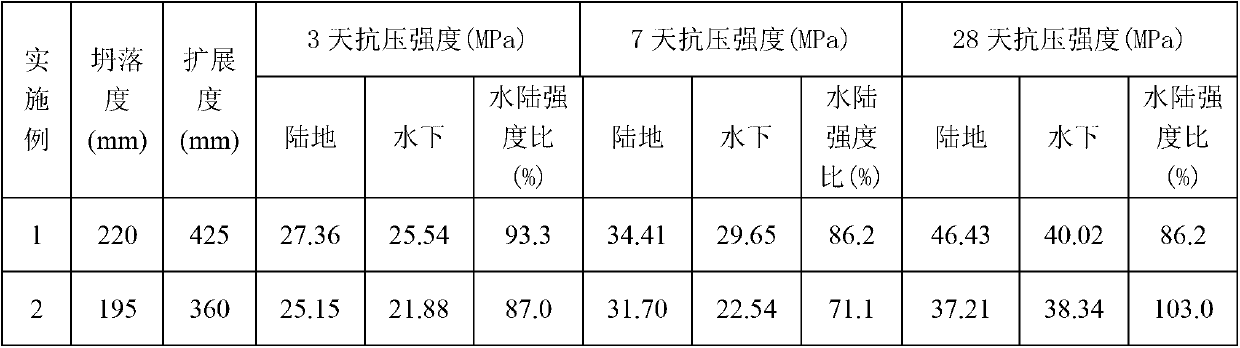

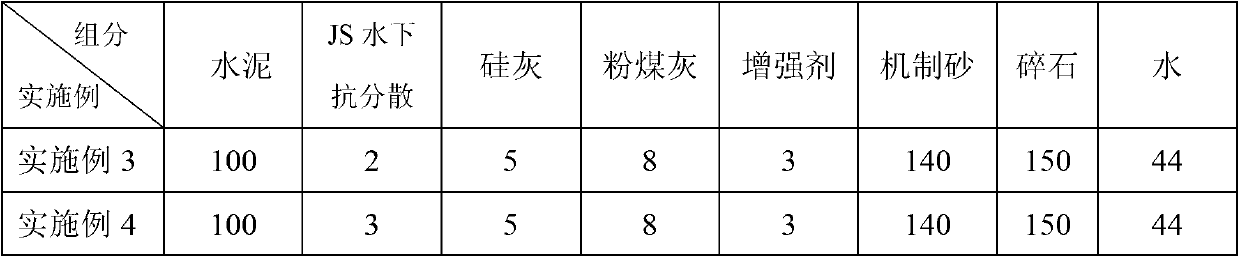

Embodiment 3-4

[0071] Ingredients:

[0072] Cement: Portland cement, strength grade 42.5, produced by Shanghai Conch Cement Factory;

[0073] Underwater anti-dispersion additive: cellulose ether (viscosity-increasing component): sulfamate-based water reducer (water reducer): polyether modified poly

[0074] Silicone defoamer (reinforcing component) = 8:25:2.

[0075] Other batching parameters are with embodiment 1-2;

[0076] The preparation process is the same as in Example 1-2;

[0077] Example 3-4 The composition of the machine-made sand underwater anti-dispersion concrete ingredients is shown in Table 3:

[0078] Table 3 Example 3-4 The composition of the ingredients of the machine-made sand underwater anti-dispersion concrete (by weight)

[0079]

[0080] The working performance and mechanical properties of the machine-made sand underwater anti-dispersion concrete are shown in Table 4:

[0081] Table 4 Performance of underwater anti-dispersion concrete with different underwater ...

Embodiment 5

[0086] Ingredients:

[0087] Cement: Portland cement, strength grade 42.5, provided by the construction unit of Huayudong Bridge Karst Cave Project on Guihuang Highway;

[0088] Fly ash: common type primary fly ash, Shanghai Shiyuan fly ash production plant;

[0089] Enhancer: sodium sulfate;

[0090] Other batching: with embodiment 1-2;

[0091] The preparation process is the same as in Example 1-2;

[0092] Example 5 The amount of each component of the machine-made sand underwater anti-dispersion concrete batching is shown in Table 5:

[0093] Table 5 Example 5 Machine-made sand underwater anti-dispersion concrete ingredients

[0094]

[0095] The working performance and mechanical properties of the machine-made sand underwater anti-dispersion concrete are shown in Table 6:

[0096] Table 6 Performance of machine-made sand underwater anti-dispersion concrete

[0097]

[0098] A large number of trial mix tests were carried out through the optimization of the basic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com