Magnetic component assembly

A technology of magnetic components and components, applied in the direction of inorganic material magnetism, transformer/inductor components, electrical components, etc., can solve the problems of increasing the cost of electronic components and expensive manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

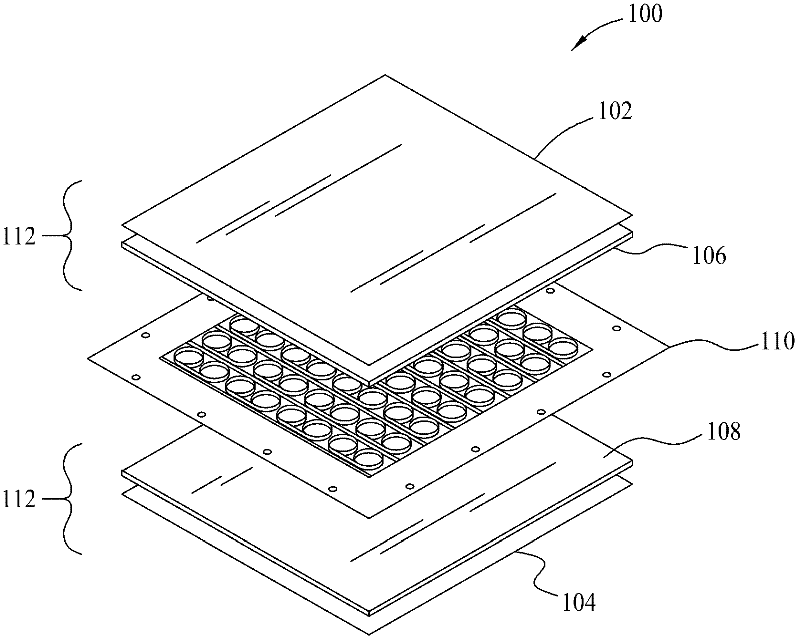

[0027] Example embodiments of inventive electronic component designs are described herein that overcome various challenges in the art. For the most complete understanding of the present invention, the following disclosure has various sections or sections, with Section I discussing specific issues and challenges, and Section II describing example component configurations and assemblies for overcoming these issues.

[0028] I. Introduction to the Invention

[0029] Conventional magnetic components, such as inductors, used in circuit board applications typically include a magnetic core and a conductive winding (sometimes called a coil) within the magnetic core. The core may be made of discrete core parts made of magnetic material with the windings placed between the core parts. Various shapes and types of core components and assemblies are known to those skilled in the art, including but not necessarily limited to U-core and I-core assemblies, ER-core and I-core assemblies, ER-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com