Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

599results about How to "Guaranteed roundness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

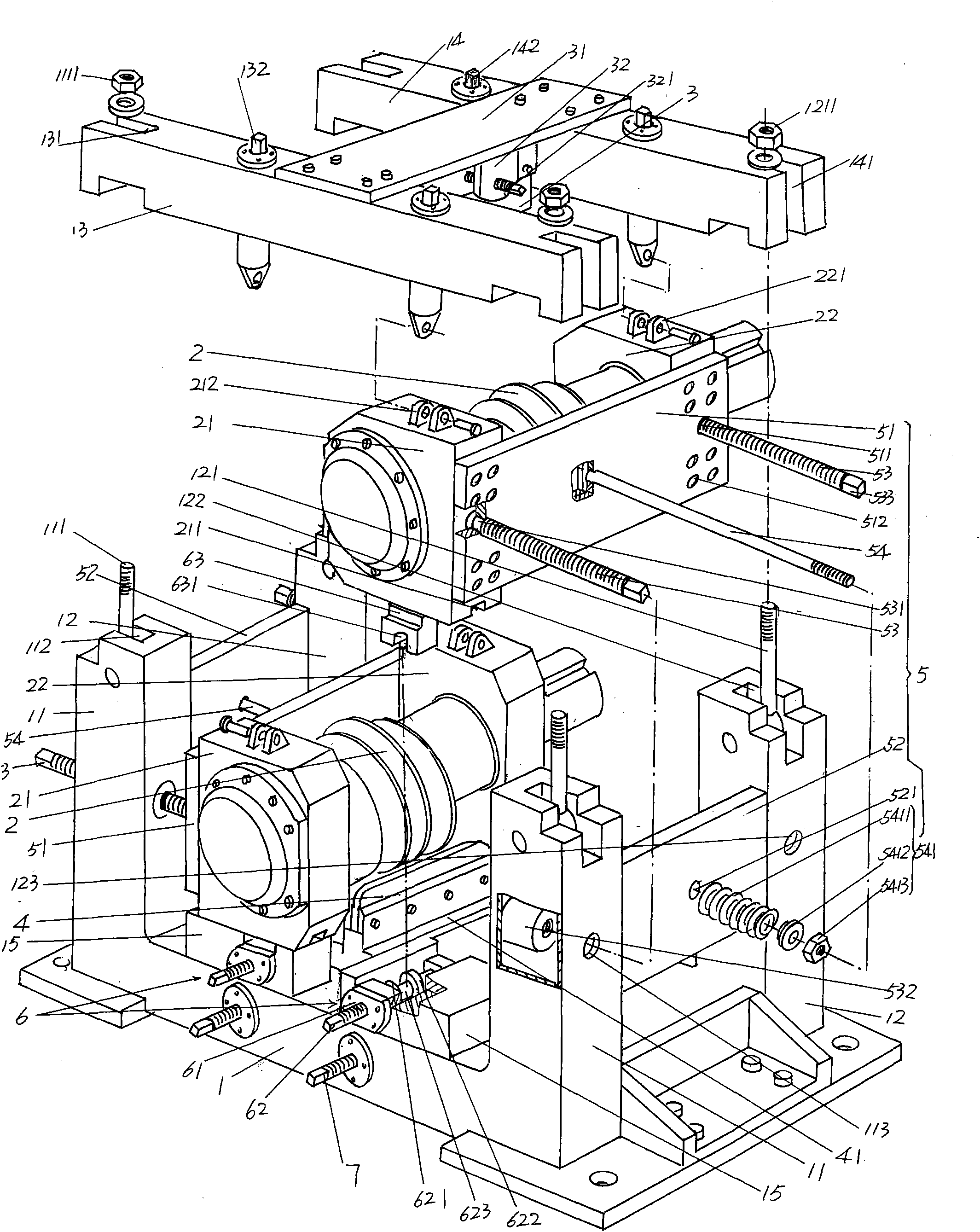

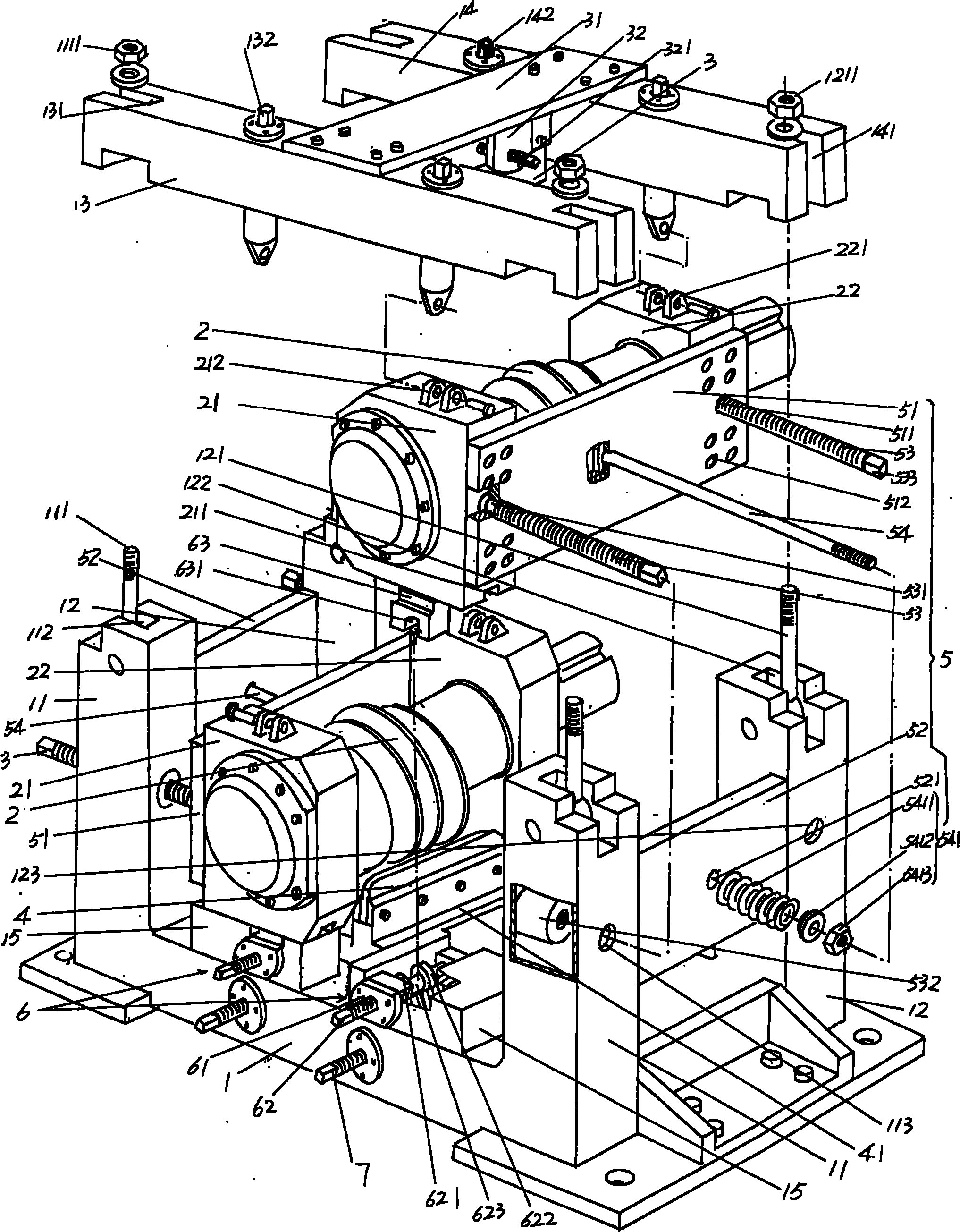

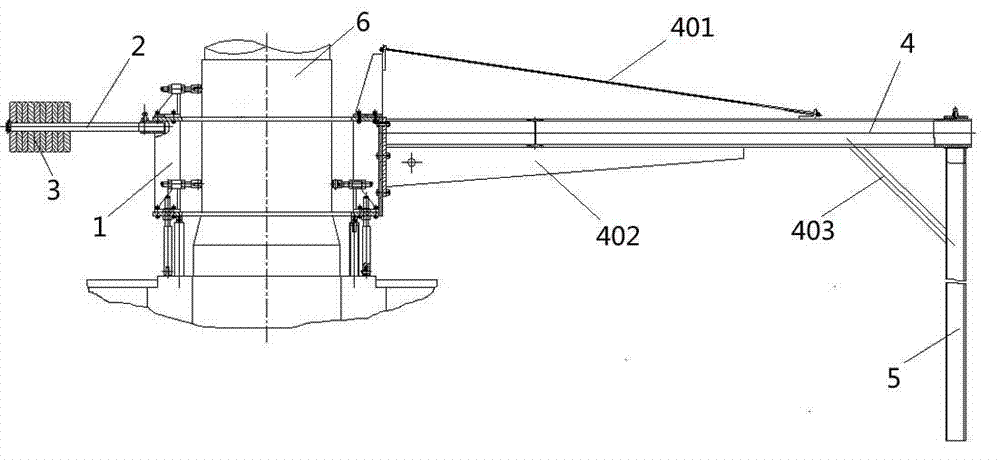

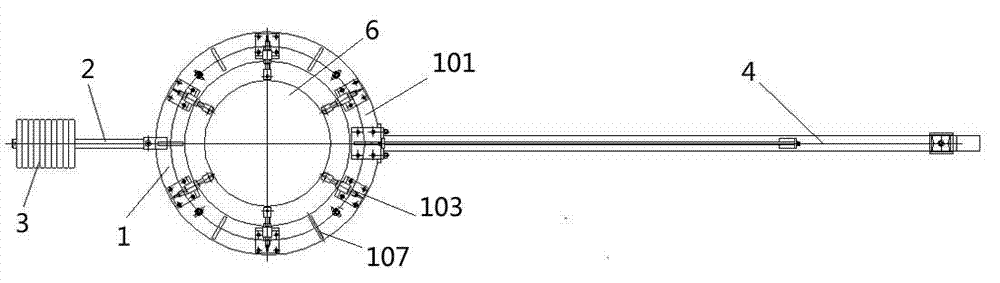

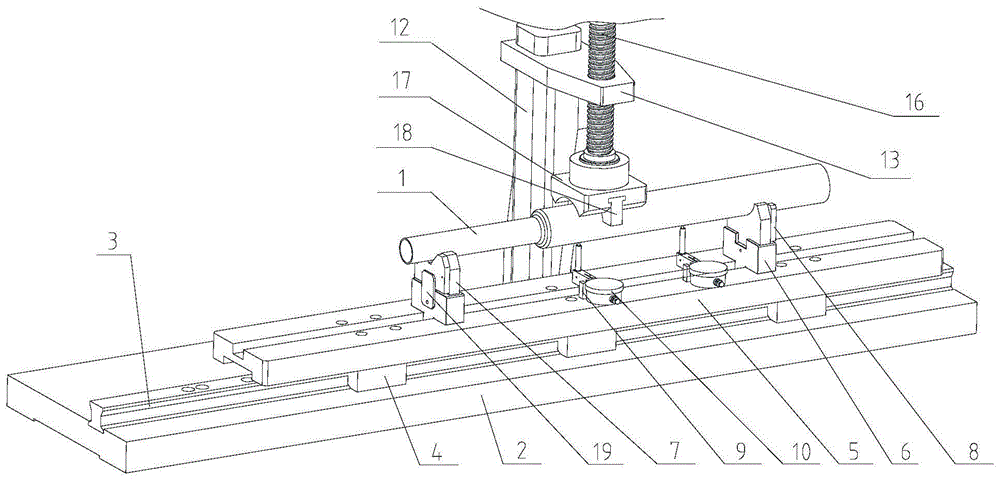

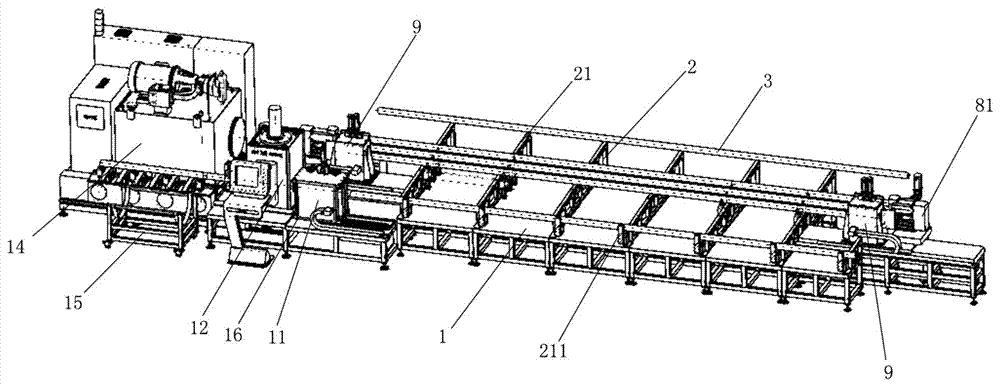

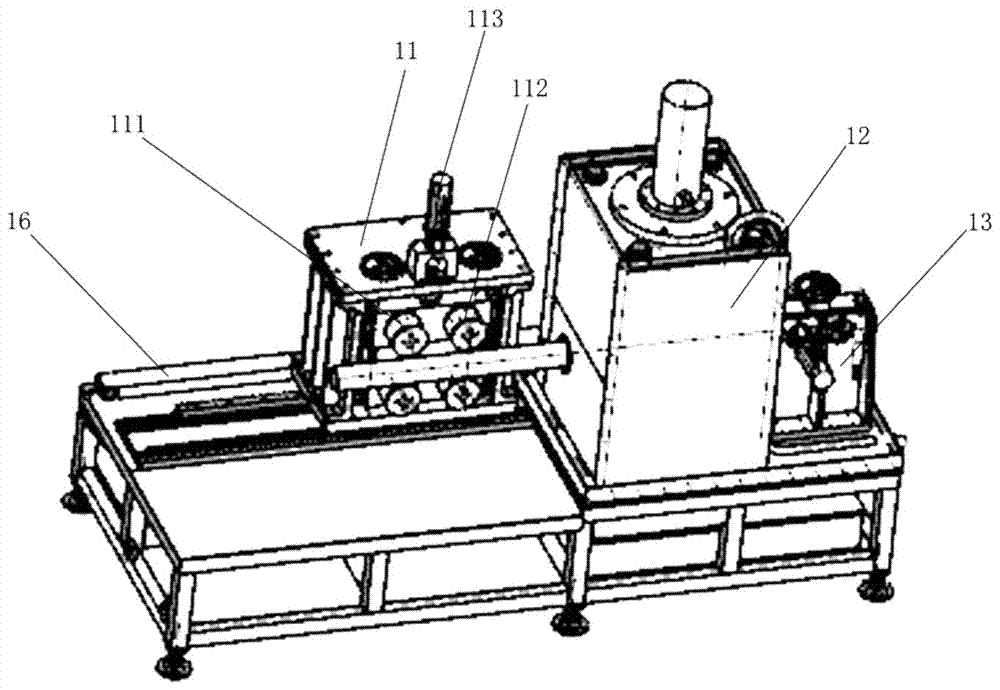

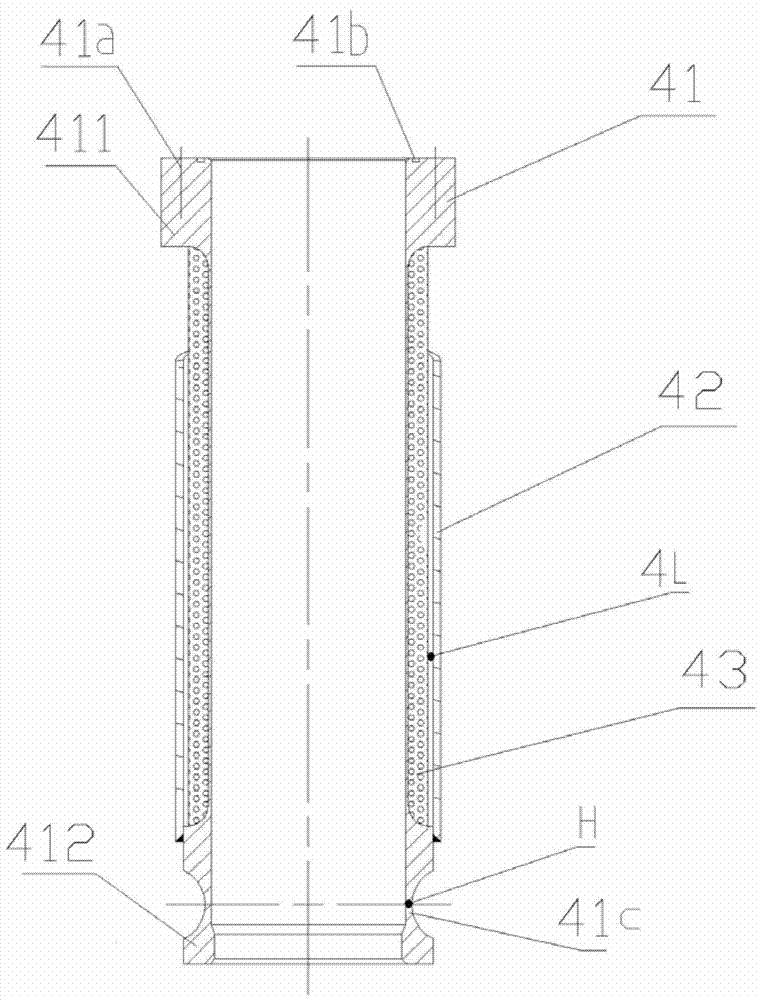

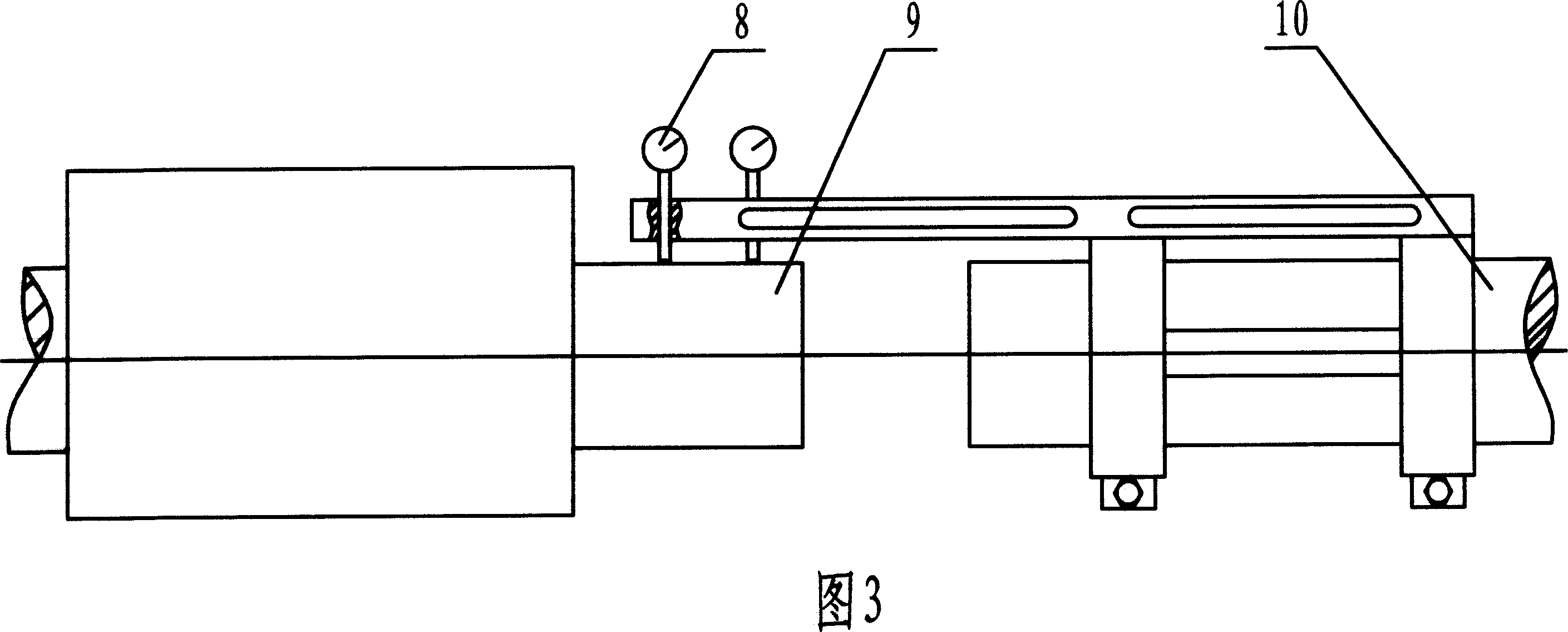

Pipe cutting system

ActiveCN102689046AGuaranteed roundnessReduced chipping timeTube shearing machinesShearing machine accessoriesElectrical controlSteel tube

The invention discloses a system for cutting off a steel pipe or a tubular object. The system mainly comprises an automatic storage loading cabin, a steel pipe conveying device, a multi-specification caliber pipe cutting device and an electrical control system, and is mainly characterized in that the automatic storage loading cabin is connected to the steel pipe conveying device and then is connected to the multi-specification caliber pipe cutting device, and the whole machining process is fully automatically performed under the control action of the electrical control system. Four cutting tools are arranged on unfolding and folding nuts of a screw rod respectively, and the screw rod is driven to rotate through a friction wheel in the process of rotating a rotary cutter plate rack so as to feed the cutting tools. The four cutting tools are used for circumferentially cutting the steel pipe in a laminated mode, so that the roundness of the steel pipe is ensured, and the cutting efficiency is improved.

Owner:SHENZHEN CEMCN

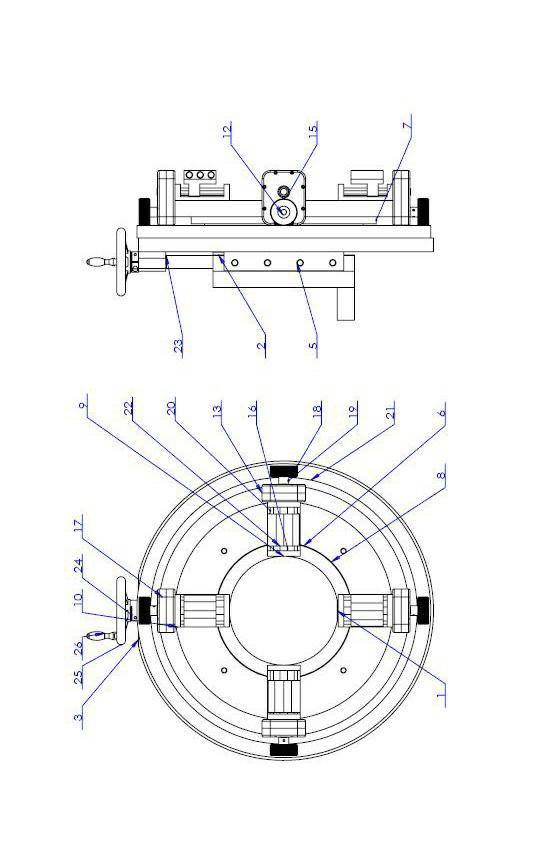

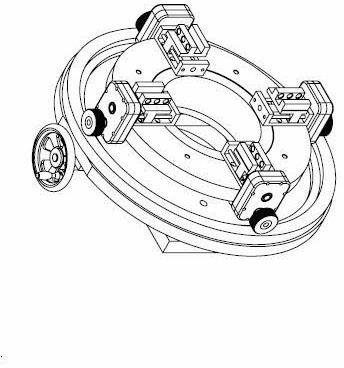

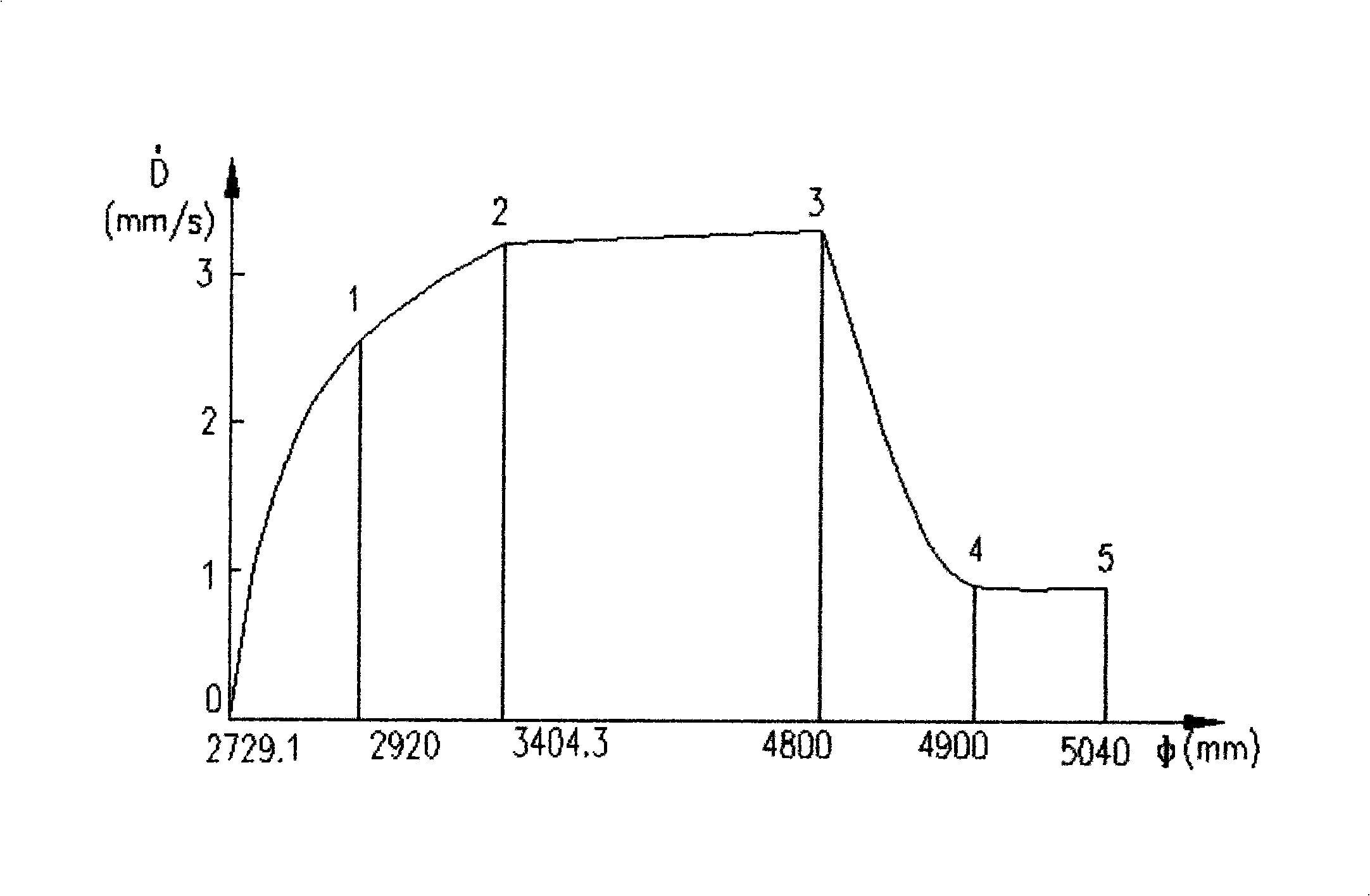

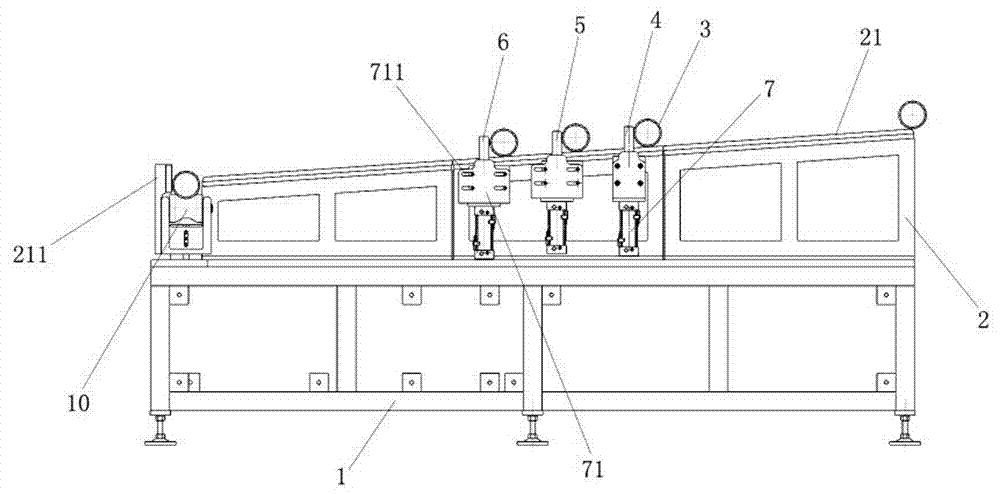

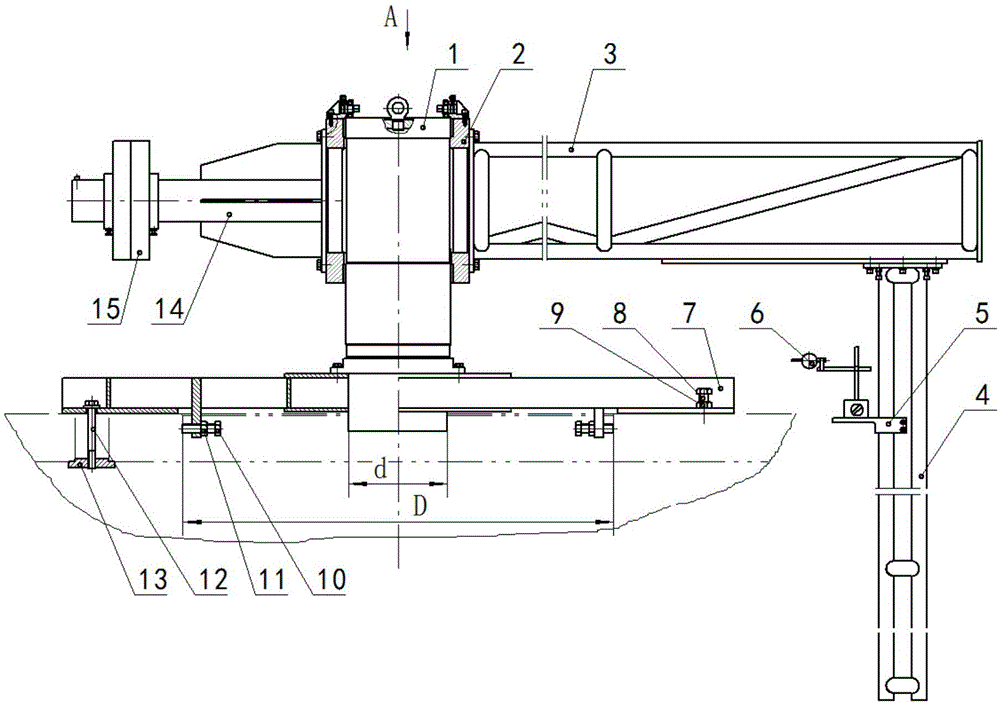

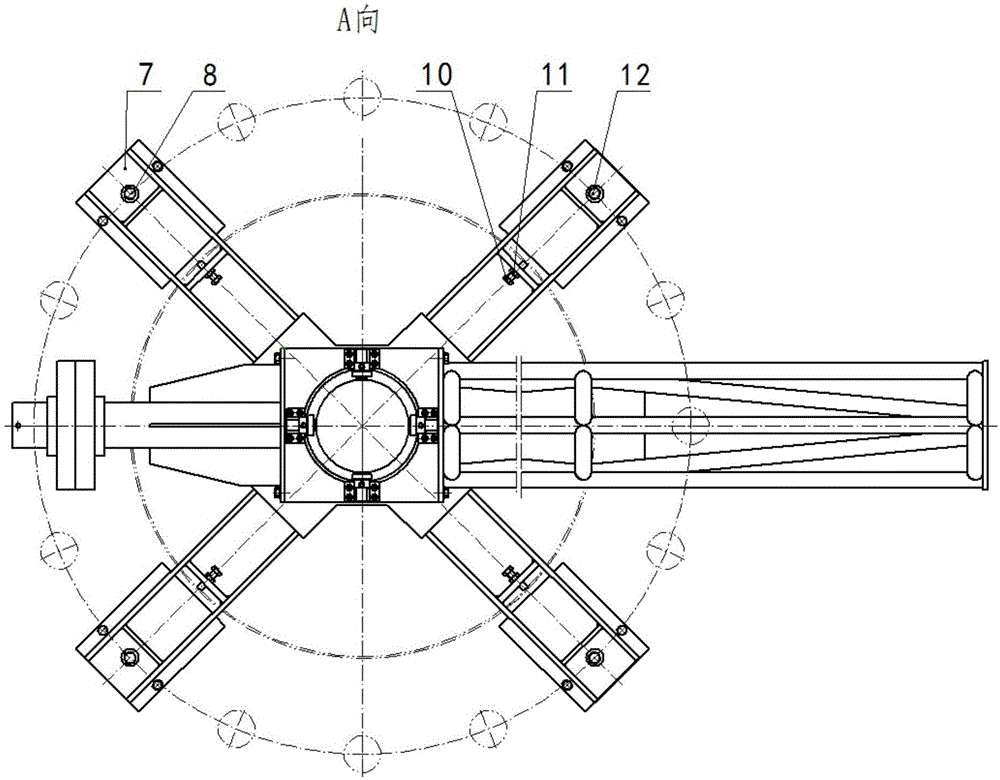

Aluminum alloy ring piece rolling technique and device

InactiveCN101337256AStepless adjustable speedMeet speed requirementsRoll mill control devicesRolling mill drivesNumerical controlMaterials processing

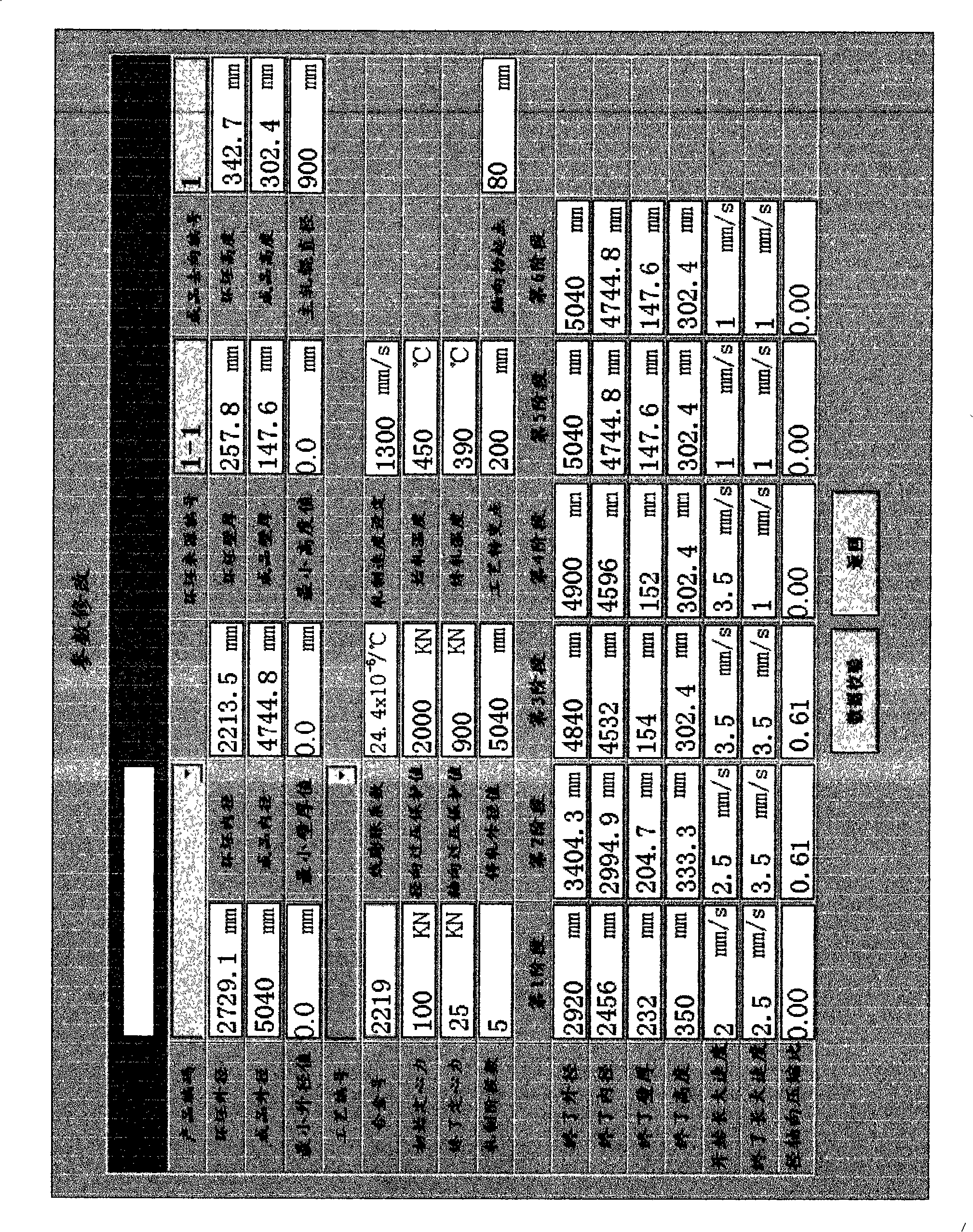

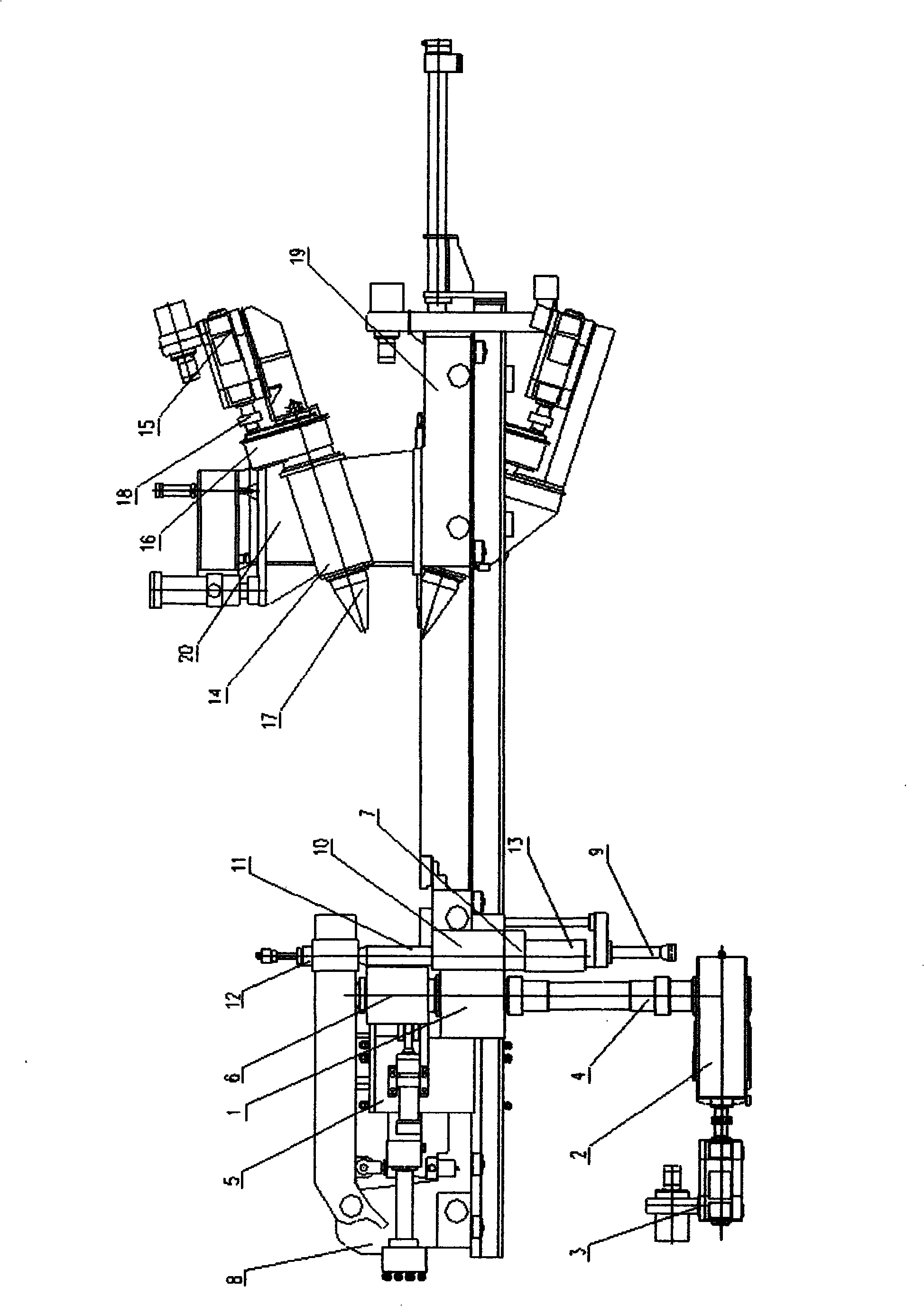

The invention relates to a method and equipment for processing metal material, particularly to a technology and equipment for rolling superlarge-diameter aluminium alloy ring pieces. The method and the equipment are characterized in that the rolling technology comprises the following steps: A. calculating parameters: calculating technical control parameters including the dimensions of a roughcast, the rolling linear speed, the radial-axial rolling force during various stages, the enlargement rate of the ring pieces, the radial-axial feed speed, the external diameter of the ring pieces, the height of the ring pieces and the wall thickness of the ring pieces according to the dimensions of a product ring; B. inputting parameters: inputting the various technical control parameters into a numerical control ring rolling mill computer according to the calculation results; C. numerically controlled rolling: fully automatic control is adopted during the rolling process. A radial rolling mechanism and an axial rolling mechanism are connected on the chassis of the equipment; and the radial rolling mechanism is connected with a king roller drive mechanism (1) and a core roller mechanism (7). The axial rolling mechanism is connected with an axial roller drive mechanism (14). The technology and the equipment for rolling superlarge-diameter aluminium alloy ring pieces lead to smooth rolling process and high-precision of the dimensions of product rings.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Manufacturing method of hub type electroplated ultrathin diamond abrasive cutting wheel

ActiveCN106637359AReduce stressStress reliever for low micro stressElectrolytic coatingsChemical platingGrinding wheel

The invention discloses a manufacturing method of a hub type electroplated ultrathin diamond abrasive cutting wheel. The method comprises the steps that a high-precision aluminum alloy matrix is subjected to chemical plating treatment and placed into an electroplating solution containing diamond abrasive materials, the evenly-suspended diamond abrasive materials are wrapped by a plating layer during reduction of a cathode of anode nickel ions under the effect of a direct current electric field, and a composite plating layer with the needed thickness is formed after uniform codeposition is kept for a certain period of time; and the hub type electroplated ultrathin diamond abrasive cutting wheel with the blade thickness of 0.010-0.150 mm is manufactured through the plating layer surface precise grinding, external circle grinding and blade reverse face microcorrosion treating processes. By the adoption of the phosphorous nickel aminosulfonate electroplating solution, by means of the hardness increasing effect of a hardening agent and the microstress effect of a stress removing agent, a low-stress high-hardness novel nickel-based binding agent is obtained, a blade of a cuter of the hub type electroplated ultrathin diamond abrasive cutting wheel has extremely low stress and high strength, and the problem that the cutter of the abrasive wheel is broken due to stress deformation or too low strength in practical application is avoided.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

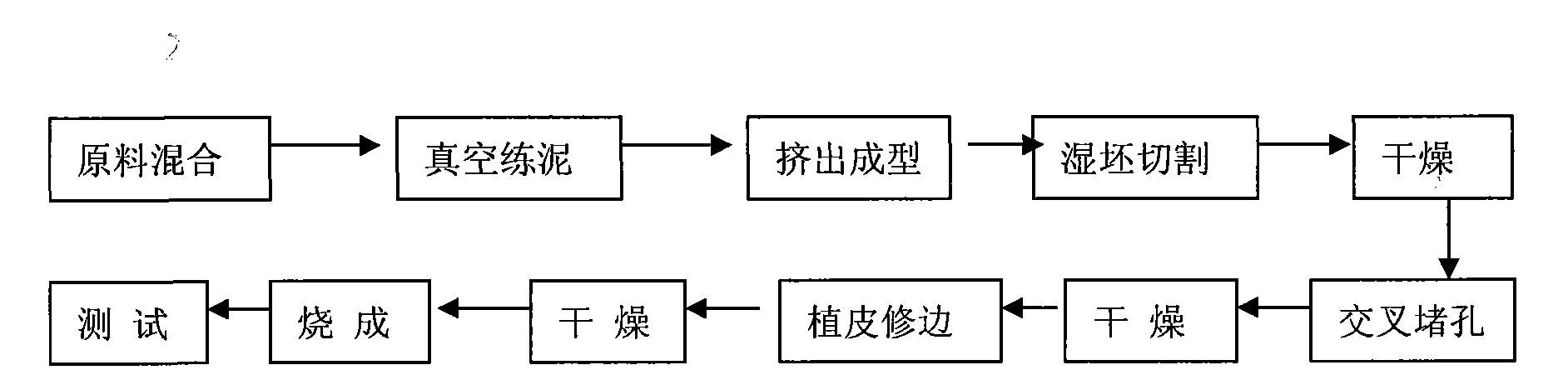

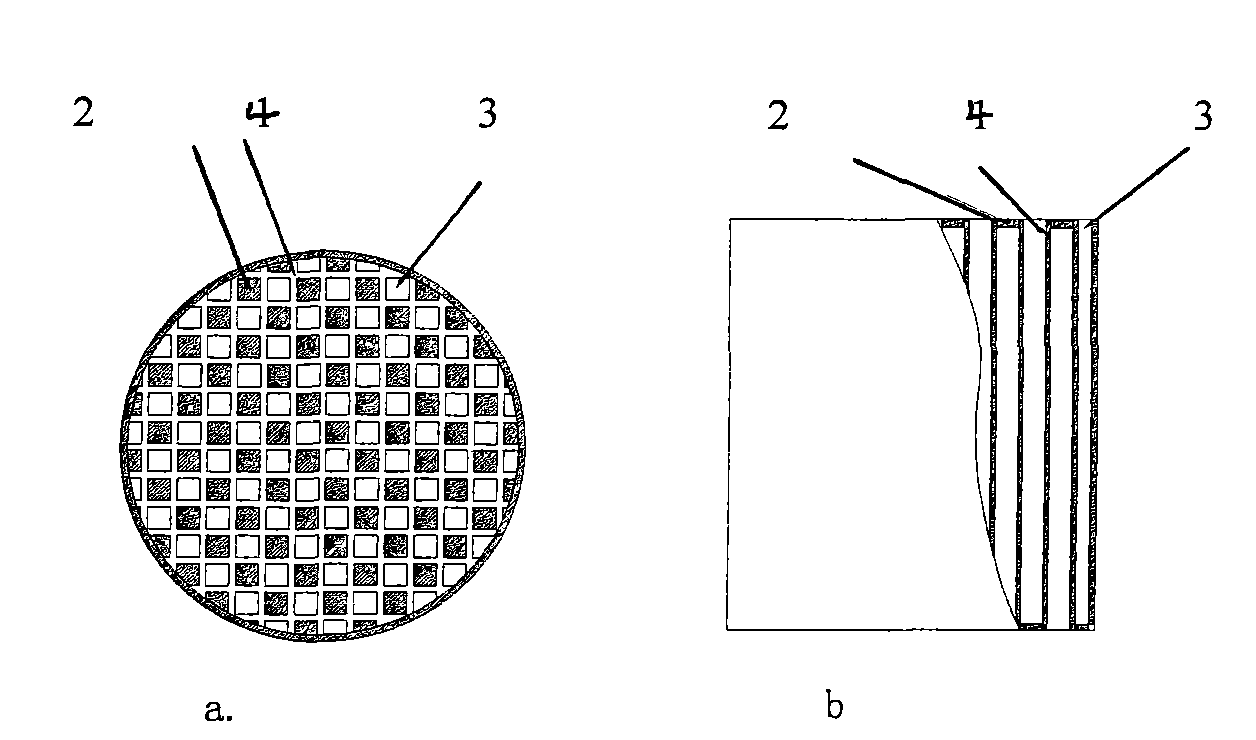

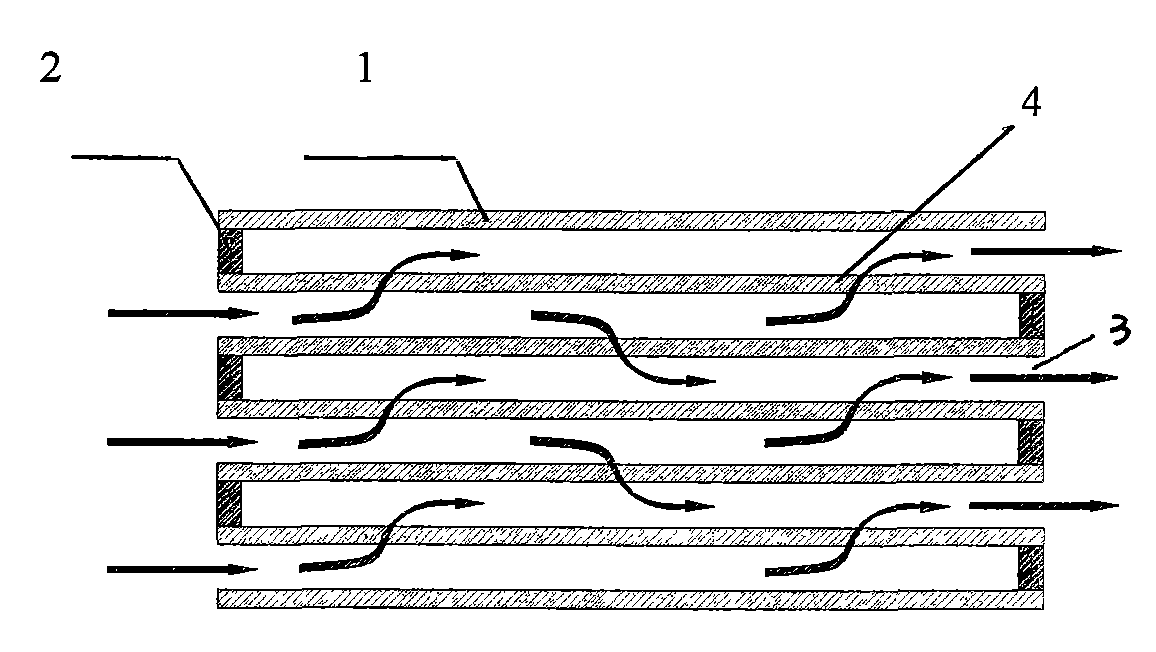

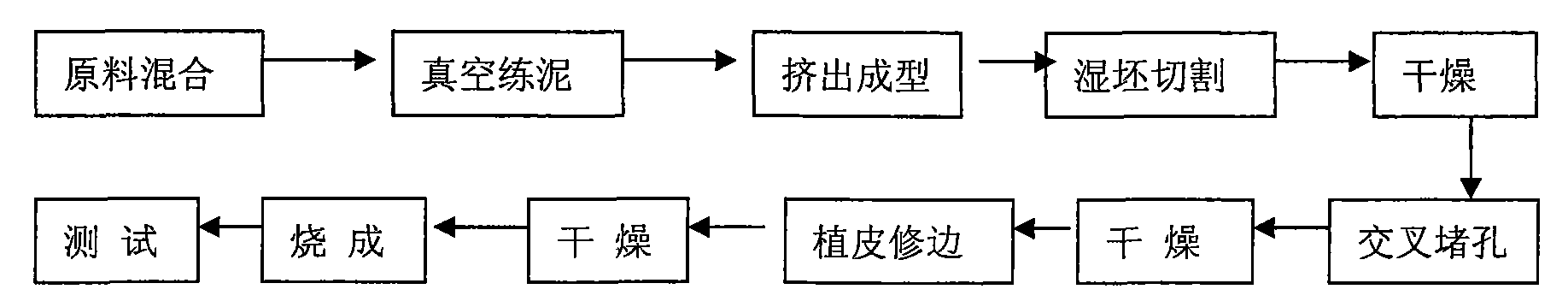

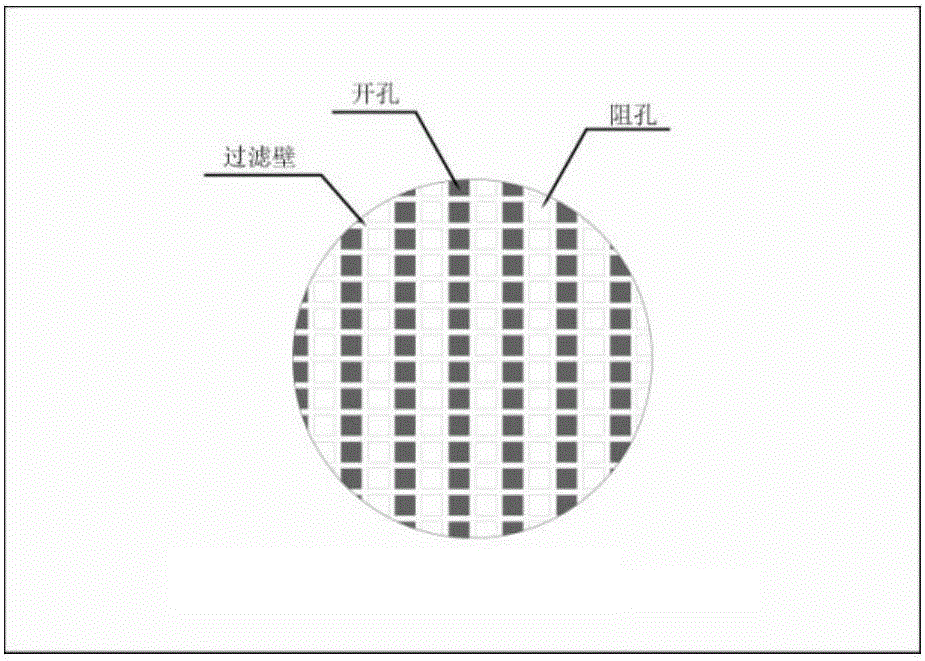

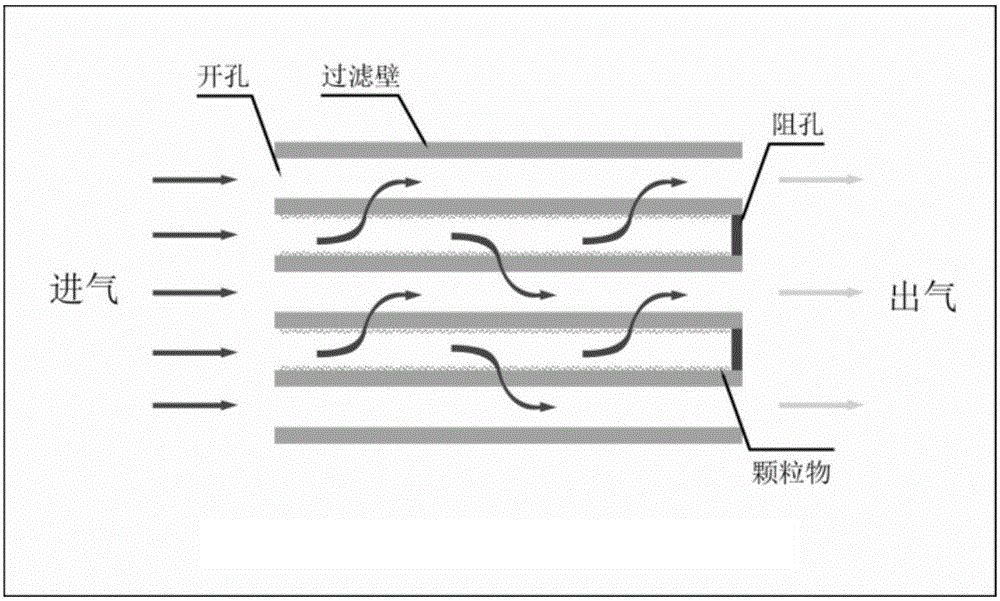

Method for preparing wall-flow honeycomb ceramic filter

InactiveCN101612499ALarge apertureEffective in filtering black smokeExhaust apparatusSilencing apparatusSkin graftingMicrowave

The invention relates to a method for preparing a wall-flow honeycomb ceramic filter, which combines a cordierite honeycomb ceramics material and a special pore-forming agent. Raw materials comprise the following components, mass portions and grain diameters: kaolin is 35 to 45 portions, and the average grain diameter is less than or equal to 5 mu m; talcum is 20 to 30 portions, and the average grain diameter is 15 mu m; alpha-alumina is 4 to 9 portions, and the average grain diameter is less than or equal to 2 mu m; the pore-forming agent consisting of carbon granules or / and organic polymeric particles is 5 to 15 portions, and the average grain diameter is 10 to 20 mu m; and a bonding agent is 3 to 7 portions. The method comprises the following steps: evenly mixing the components and 20 to 30 portions of water to prepare a blank; completing the conversion from the blank to plastic mud after performing vacuum degassing for 2 to 3 times; staling the plastic mud for 24+ / -8 hours, and squeezing out the plastic mud through a mould of an extruder; performing microwave drying on the plastic mud to obtain a dry blank; and performing cross hole blocking, drying, skin grafting and trimming on the dry blank, and finally performing a sintering working procedure to manufacture a product.

Owner:JIANGSU GAOCHUN CERAMICS +1

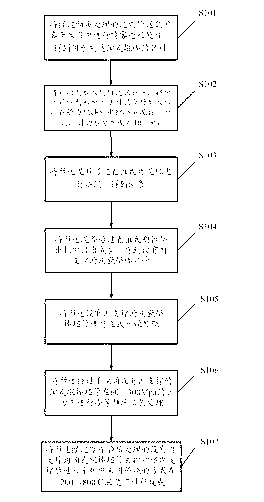

Preparation process of ceramic roller rod

The invention discloses a preparation process of a ceramic roller rod. The preparation process comprises the following steps of: atomizing and prilling on primarily-treated slurry; adding a binder, mixing, then adding water, and mixing in a into pug into a powerful mixer, wherein the water content of the pug is 10-18%; refining the pug through a direct pushing-type pug refining machine, and obtaining pug stripes; enabling the pug stripes to conduct extrusion molding through a direct pushing-type plastic extruder, and obtaining ceramic roller rod blank tubes provided with inner supports; conducting vertical type drying treatment on the ceramic roller rod blank tubes; conducting isostatic cool pressing process treatment on the ceramic roller rod blank tubes at the pressure of 60-300Mpa; and removing the inner supports of the ceramic roller rod blank tubes, putting the ceramic roller rod blank tubes into a kiln, and burning by a hanging and burning mode at the temperature of 1200-1800 DEG C. By means of preparation process, the prepared ceramic roller rod is high in density, high in flexure strength, big in load capacity and good in appearance regulation degree.

Owner:广东金刚新材料有限公司 +1

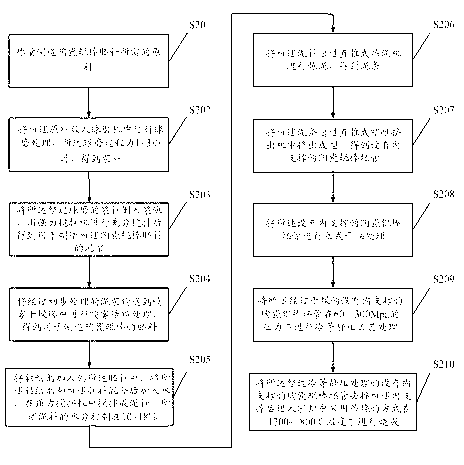

Preparation method for cold rolls of super hardness wide width light gauge aluminum foils

ActiveCN103100829AExcellent hardening performanceExcellent hardenabilityFurnace typesHeat treatment furnacesNumerical controlTemperature control

The invention relates to the technical field of cold rolls, in particular to a preparation method for cold rolls of super hardness wide width double-zero aluminum foils. The method particularly comprises the following steps: firstly, carrying out anneal process on a blank roll which is made of high chromium alloy materials in a forged mode, then carrying out rough turning process, thermal refining, semi fine turning process and heat treatment, and finally carrying out fine turning process on the blank roll to repair a die until a finished product is obtained. According to the preparation method for the cold rolls of the super hardness wide width double-zero aluminum foils, the high chromium alloy materials and a four-pillar sunken downwards type double-power-frequency heat treatment technology are adopted, the cold rolls are manufactured through full numerical control four-area temperature-controlled liquid nitrogen processing cryogenic treatment, the hardness of roll bodies of the cold rolls can reach 102-104 HSD, the depth of a hardening layer is larger than or equal to 25mm, uniformity of the hardness is within HSD+ / -0.5, length of roll faces exceeds 2300mm, high-grade wide width aluminum foils with width of the finished aluminum foils reaching 2300mm and thickness of 0.0065mm or below 0.0065mm can be rolled, and the preparation method is widely applied to industries such as cigarettes, food, medicine, electrons, photographic apparatuses and chemicals for daily use.

Owner:CHANGZHOU ECCO ROLLER

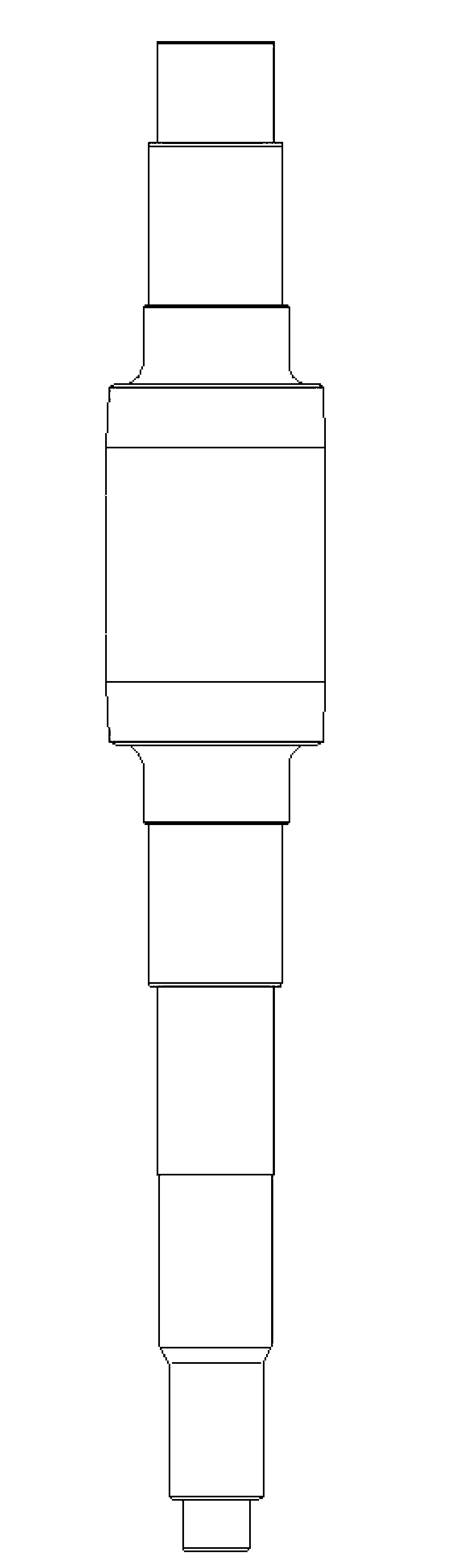

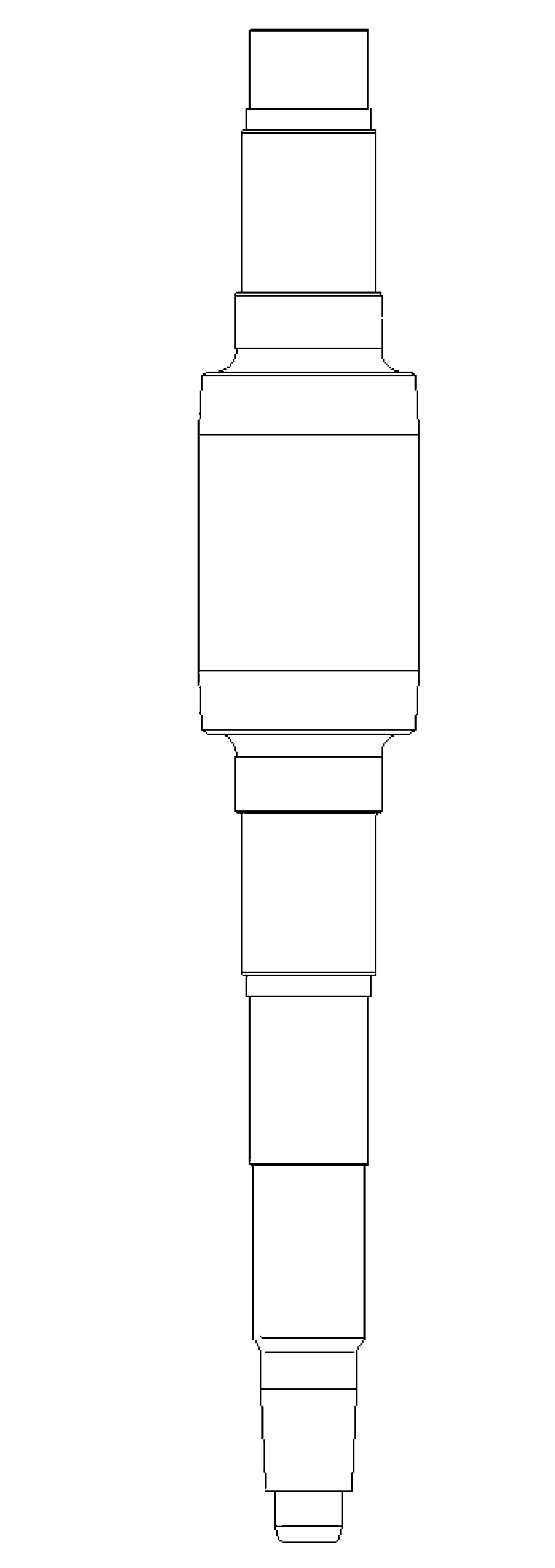

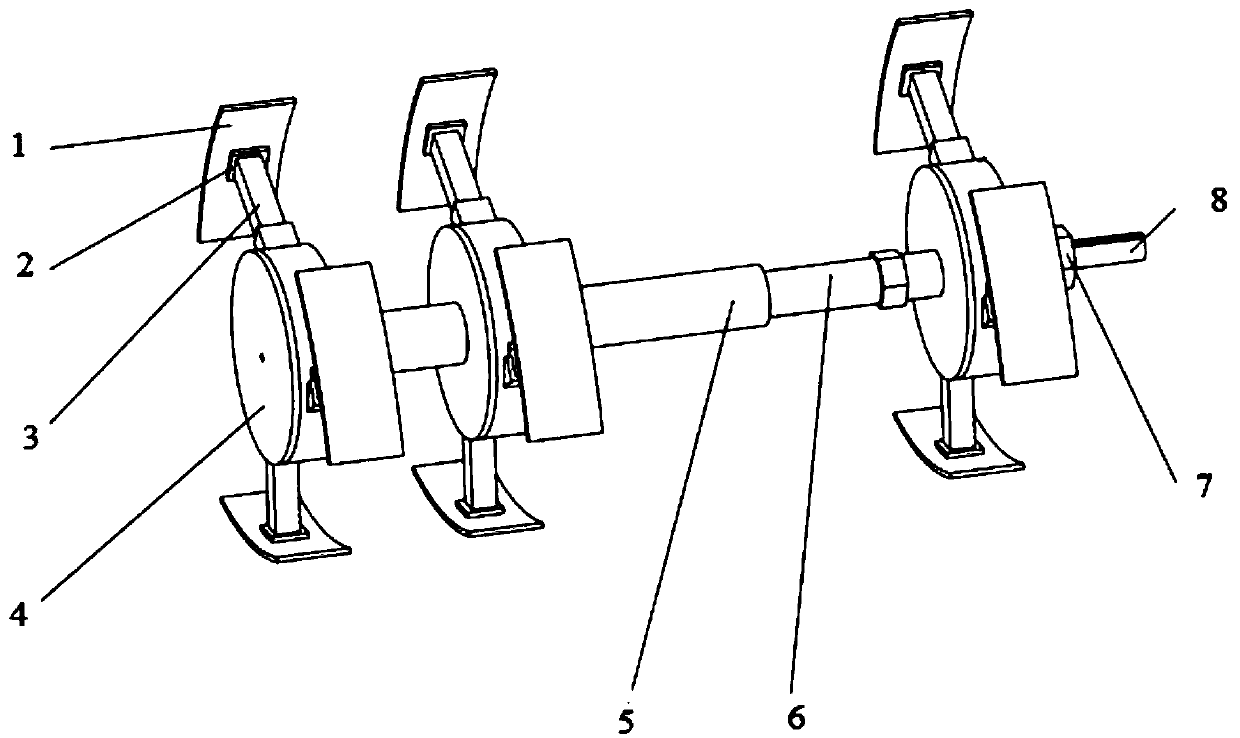

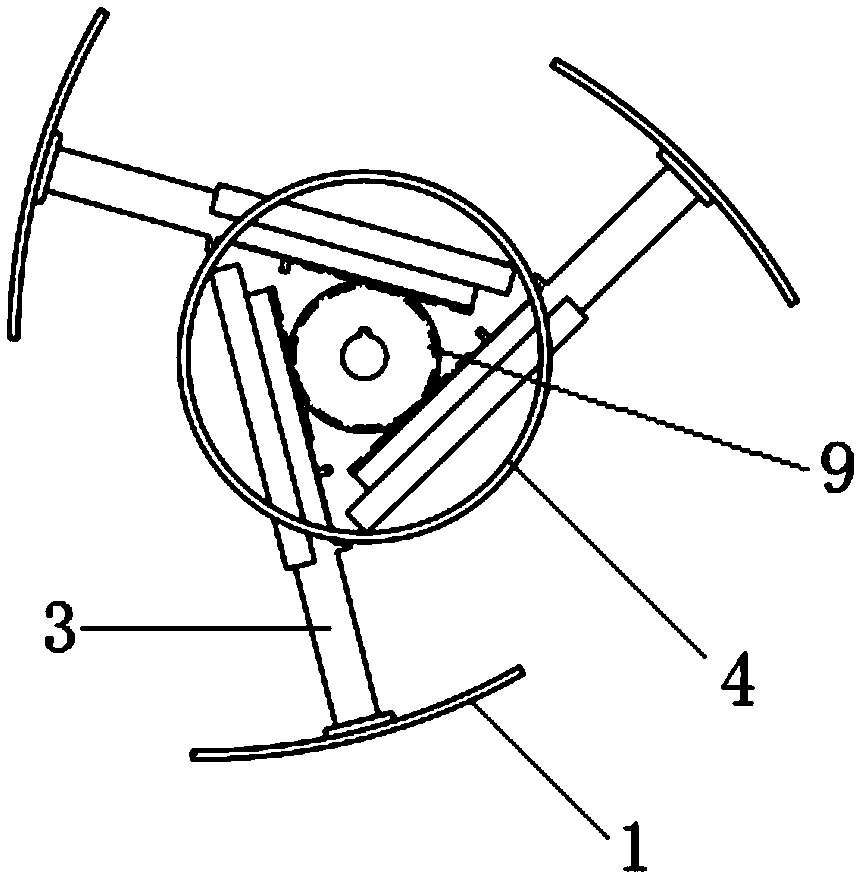

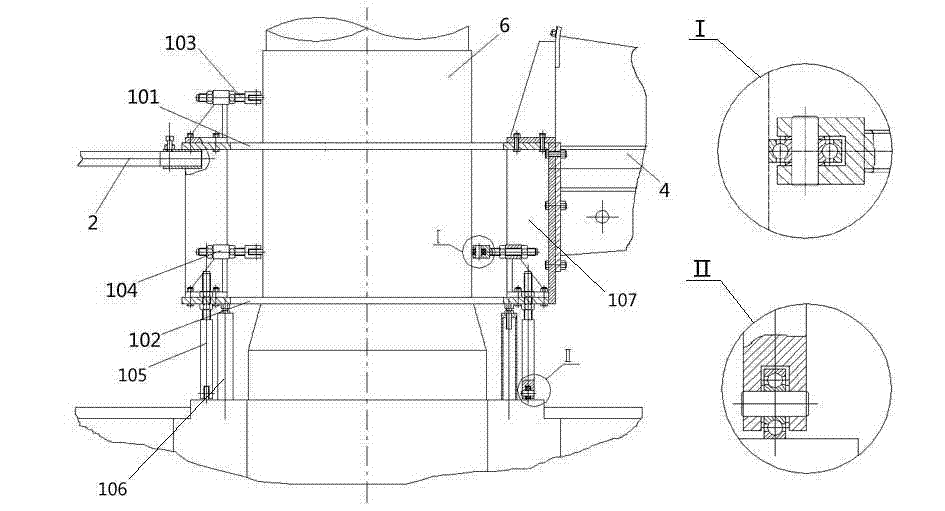

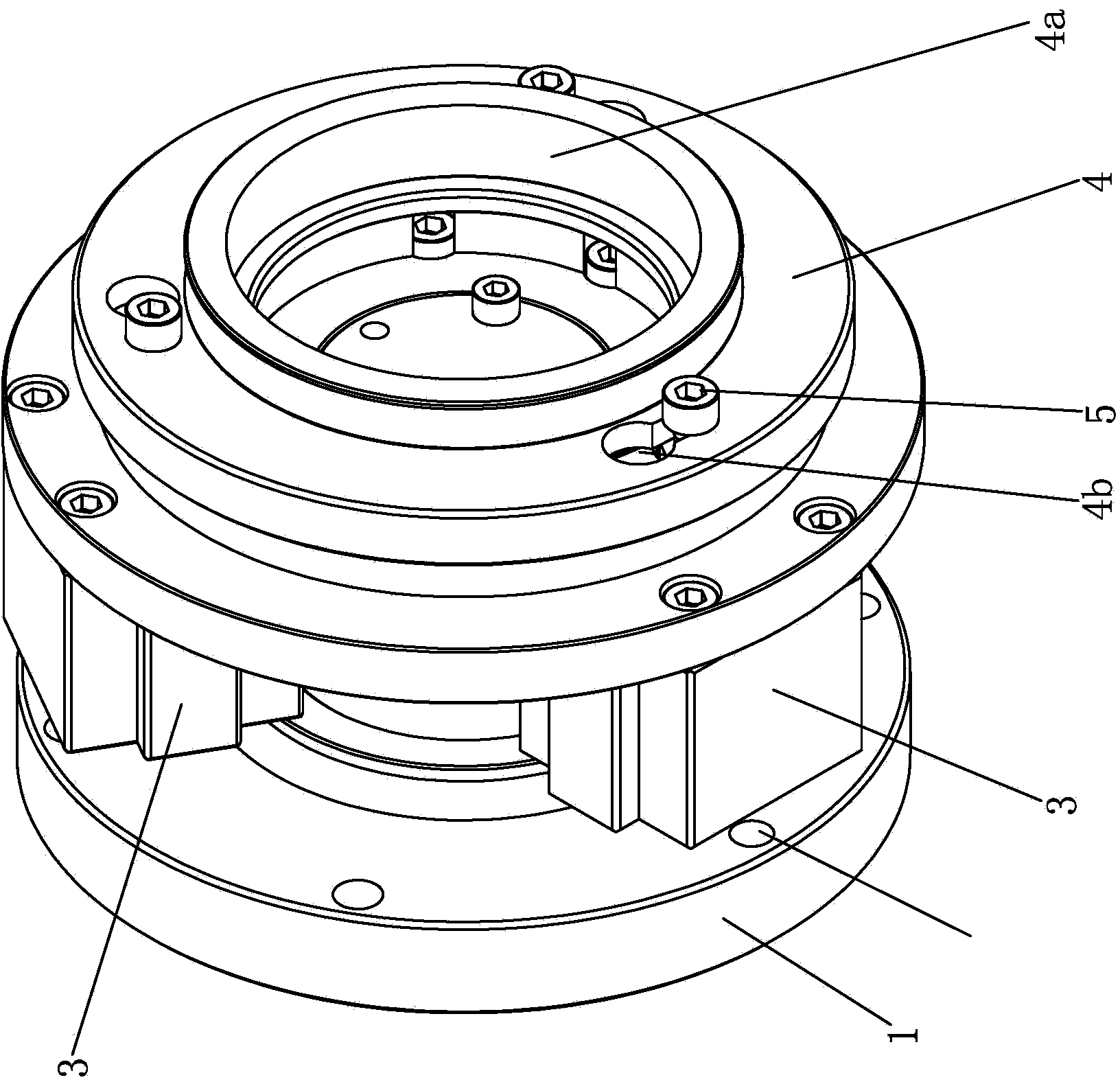

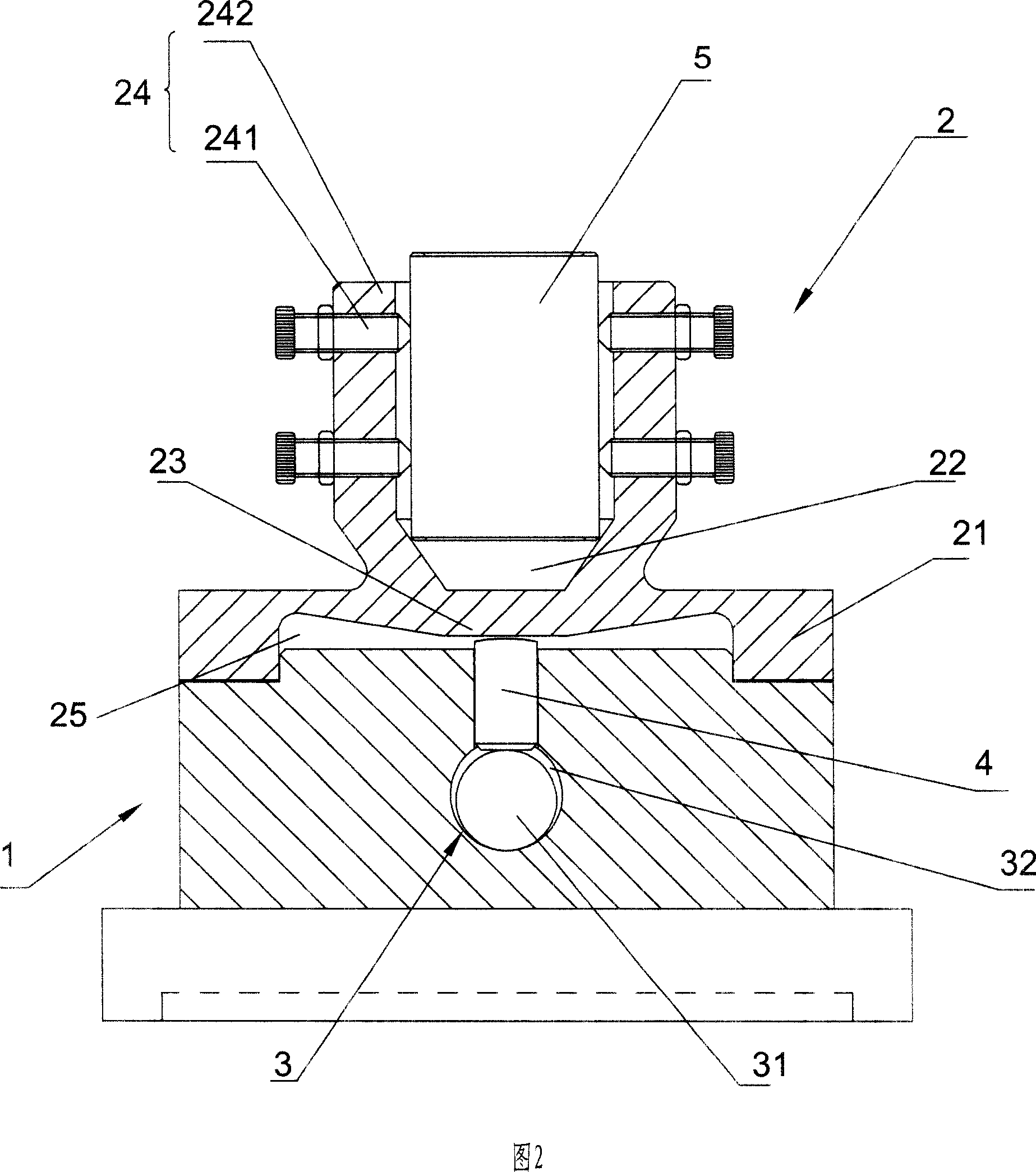

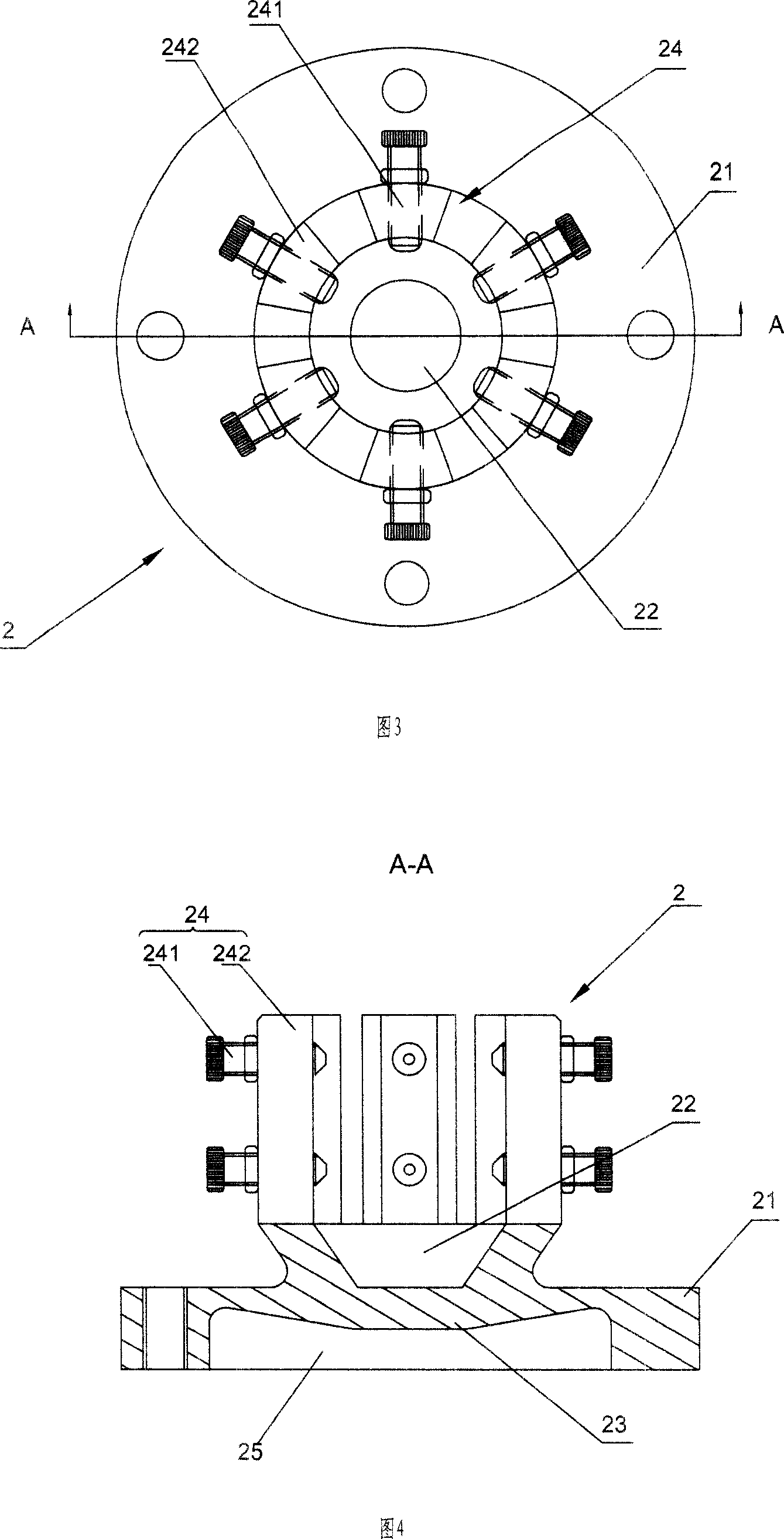

Internal supporting type fixture for turning external circles of thin-wall parts and application of fixture

InactiveCN109604659AGuaranteed straightnessGuaranteed roundnessExpansion mandrelsPipe fittingEngineering

The invention relates to an internal supporting type fixture for turning external circles of thin-wall parts and an application of the fixture. The fixture comprises multiple supporting device units;the supporting device units are connected through telescopic axial connecting components; each supporting device unit comprises a supporting device mounting disk, multiple supporting disks and radialtelescopic arms; a gear is arranged inside each supporting device mounting disk; a rack is arranged at one end of each radial telescopic arm; one end of each radial telescopic arm is inserted in the circumferential side surface of the corresponding supporting device mounting disk to mesh with the corresponding internal gear, and the other end of each radial telescopic arm is fixedly connected withthe corresponding supporting disk; the length of the radial telescopic arms is adjusted by the aid of a rocker arm inserted in the supporting device mounting disks, so that the supporting disks are controlled to support the inner walls of the thin-wall parts. Compared with the prior art, the fixture has the advantages that the roundness and the straightness of the parts can be well guaranteed, and machining of the external circles of different series of thin-wall pipe fittings can be met.

Owner:SHANGHAI UNIV OF ENG SCI

Balling mechanism of steel ball rolling machine

ActiveCN101934334AConsistent parallel distanceSimple structureBearing componentsSteel ballEngineering

The invention relates to a balling mechanism of a steel ball rolling machine, belonging to steel ball processing machinery. The balling mechanism comprises a pair of first support columns, a pair of second support columns, a support of a first upper beam, a support of a second upper beam, a pair of balling rollers, an upper ball barrier plate, a lower ball barrier plate and a pair of balling roller parallel distance adjusting devices. The balling roller parallel distance adjusting devices comprise a connecting plate, an elastic device seat plate, a pair of adjusting screw rods and a pull rod, wherein one end of the connecting plate is fixed with a first shaft seat, and the other end is fixed with a second shaft seat; one end of the elastic device seat plate is fixed with the first support columns, and the other end is fixed with the second support columns; one end of one adjusting screw rod is connected with one end of the connecting plate, the other end is connected with the first support columns, one end of the other adjusting screw rod is connected with the other end of the connecting plate, and the other end is connected with the second support columns; and one end of the pull rod is fixed with the middle part of the connecting plate, the other end penetrates through the elastic device seat plate, and the rod body of the pull rod stretching out of the elastic device seat plate is provided with an elastic device. The roundness of rolled steel balls is ensured, and the technological requirement for rolling large-diameter steel balls is satisfied.

Owner:CHANGSHU FEIFAN METALWORK

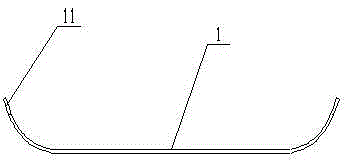

Building technology for pile leg of self-elevating wind power vessel

The invention relates to a building technology for a pile leg of a self-elevating wind power vessel. The building technology mainly comprises the following steps that cylinders are rolled, wherein rolling is carried out on the two ends, the middle part is rolled after the two ends are rolled in place, rolling is carried out in place again, longitudinal seam welding is carried out after positioned welding, and final roundness restoration is carried out; the cylinders are welded, wherein the cylinders are matched, an assembling machine is used for assembling, positioning welding is carried out, and finally welding is carried out; pre-assembling is carried out in a workshop, wherein the overall linearity of a reference section, the gap and the alignment tolerance are adjusted, technological flanges are assembled and welded in place, and the cross central line, the height reference line and the central line of a bolt hole are marked out on the reference section; bolt holes are cut, wherein an upper section and a lower section are rotated to the position of a saddle-shaped cutting machine, the central line of the pile leg is adjusted to be parallel to a track of the saddle-shaped cutting machine, and cutting is carried out according to the marked lines. The building technology has the advantages that various building requirements of the pile leg can be ensured, meanwhile, the building efficiency can be improved, and the building cost can be reduced.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

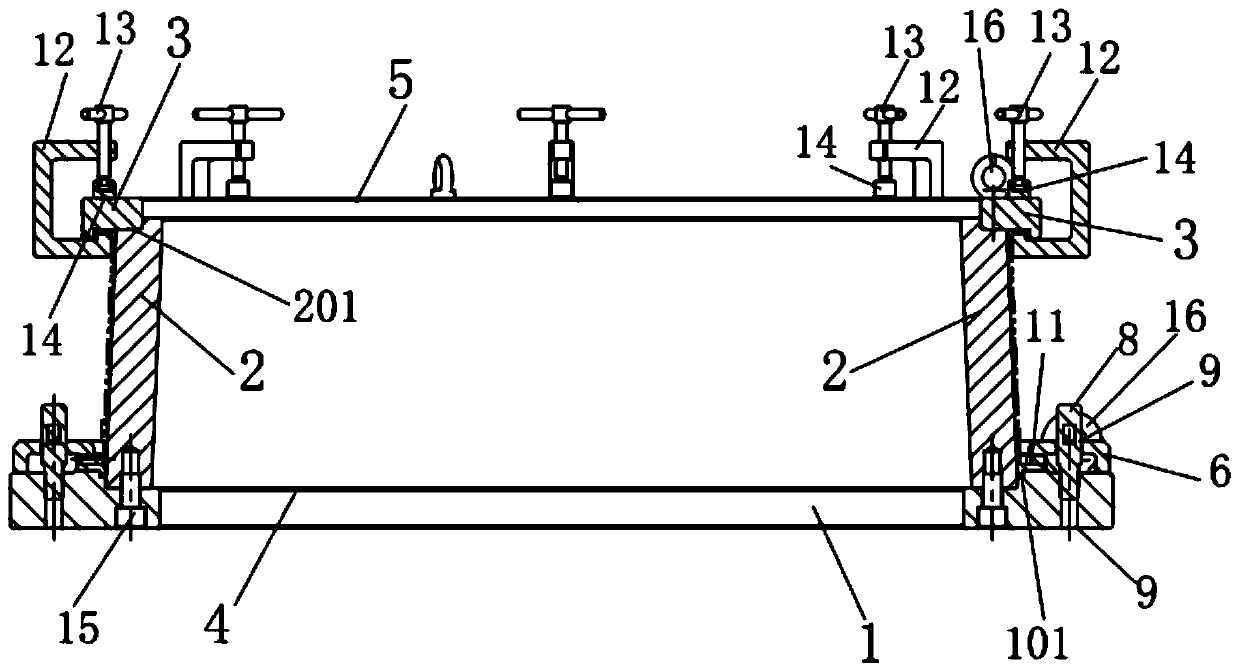

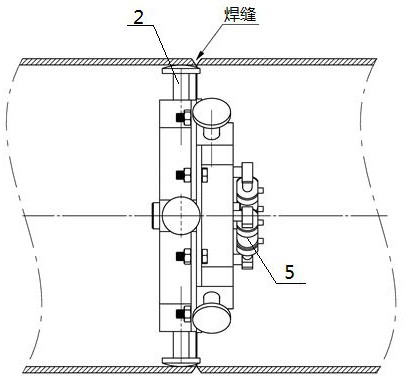

Extensible and retractable inner supporting tool

ActiveCN109366052ALarge stretchEasy accessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

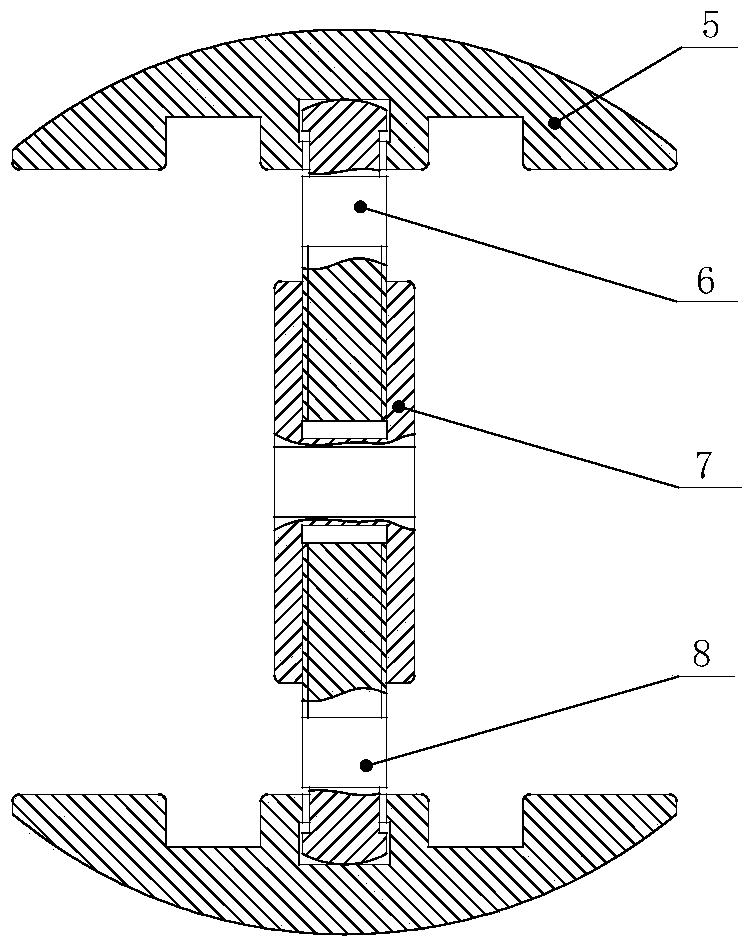

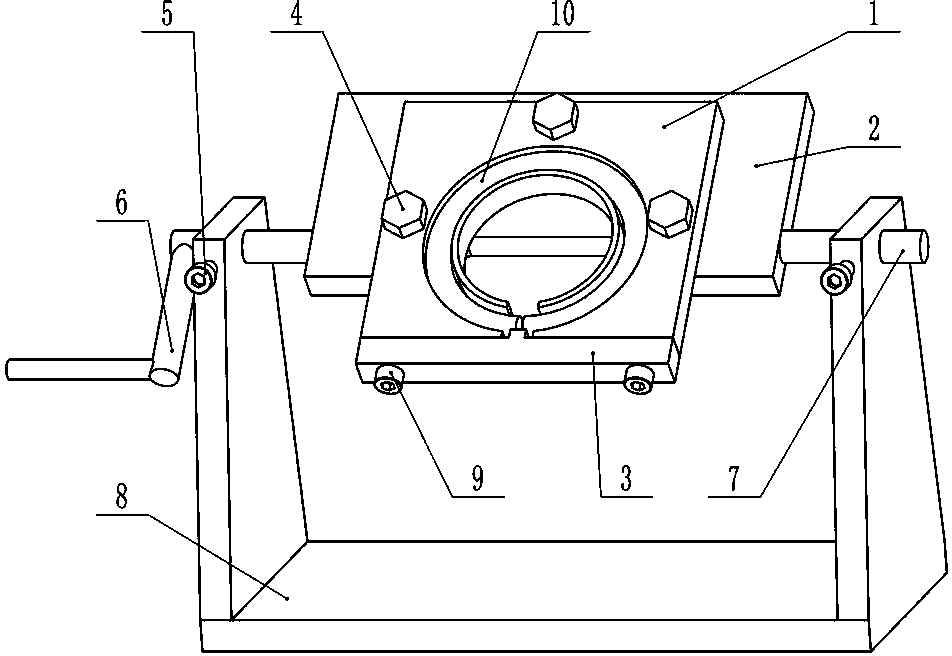

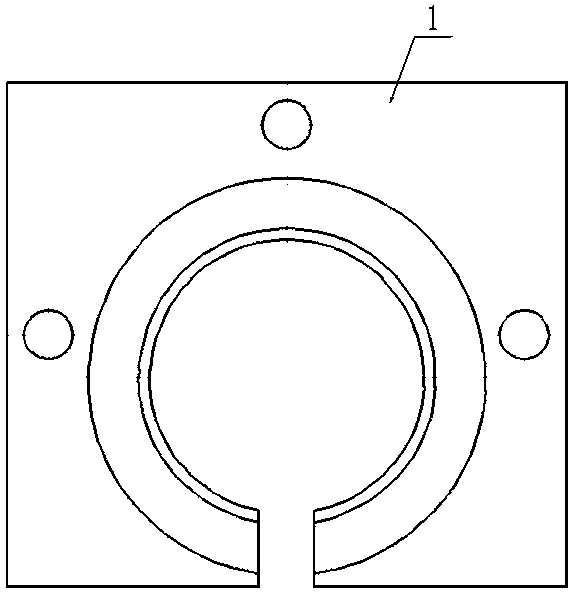

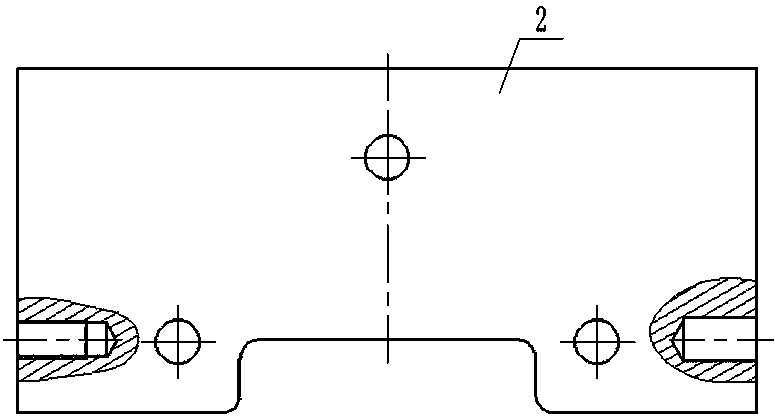

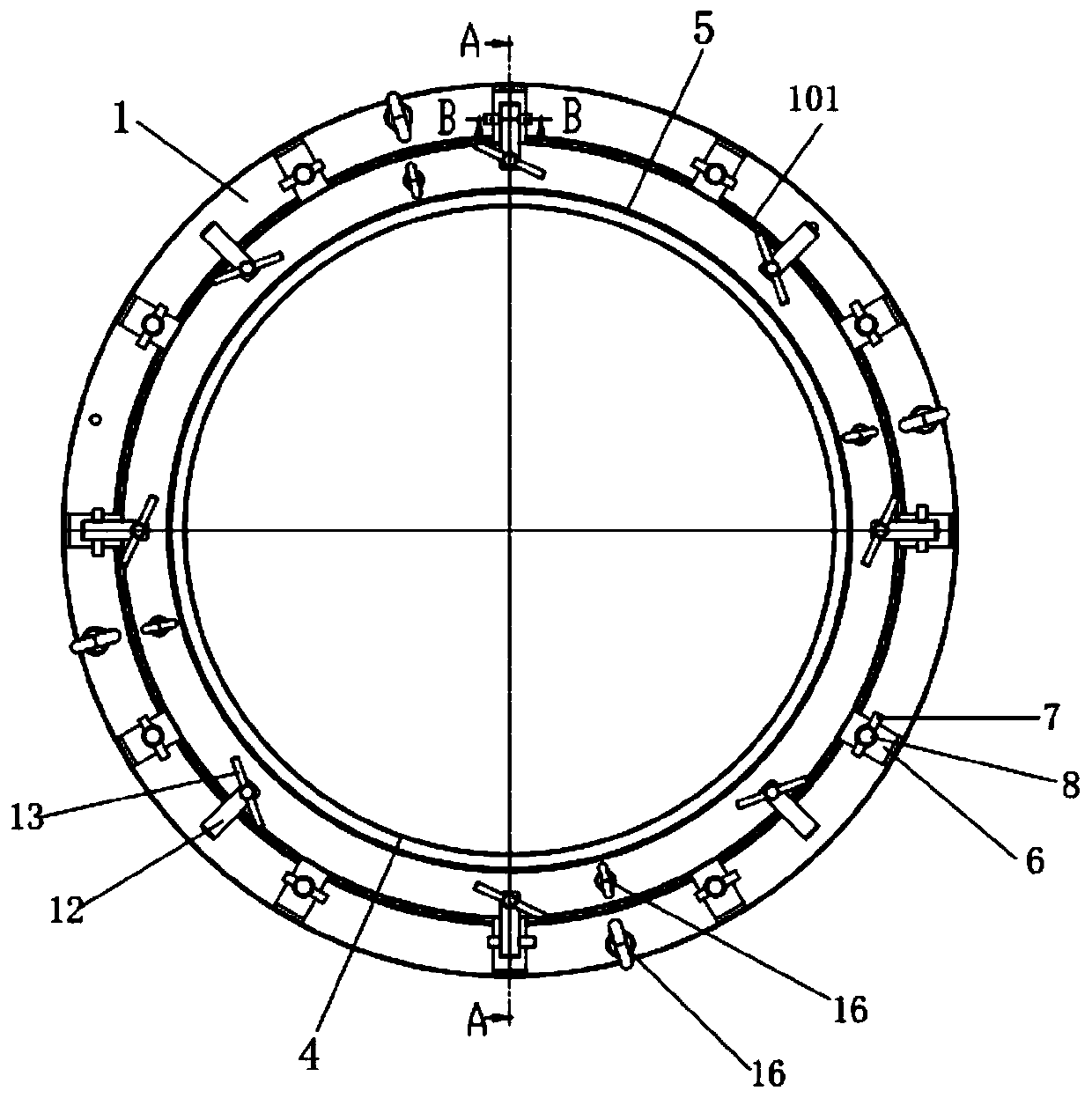

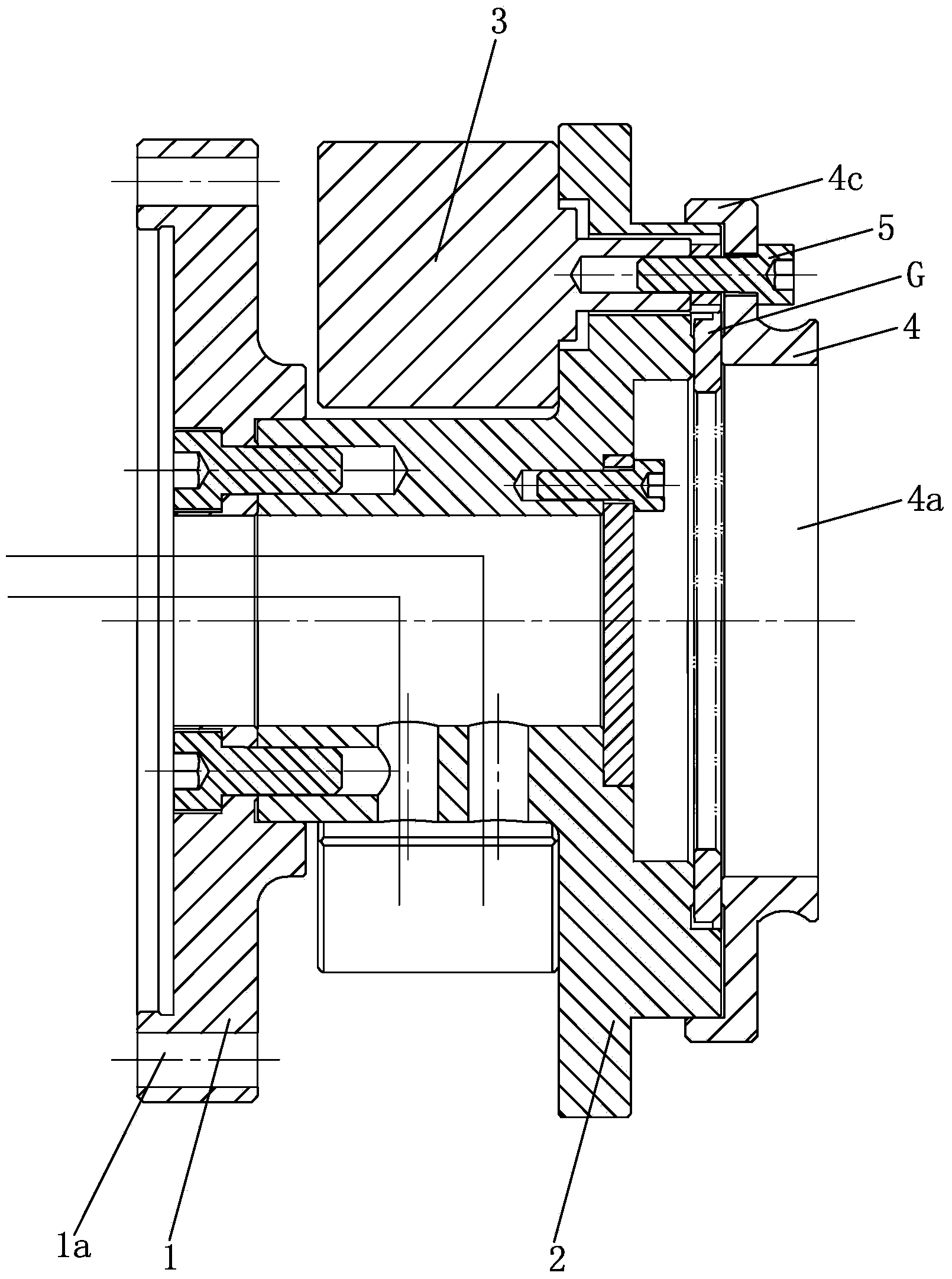

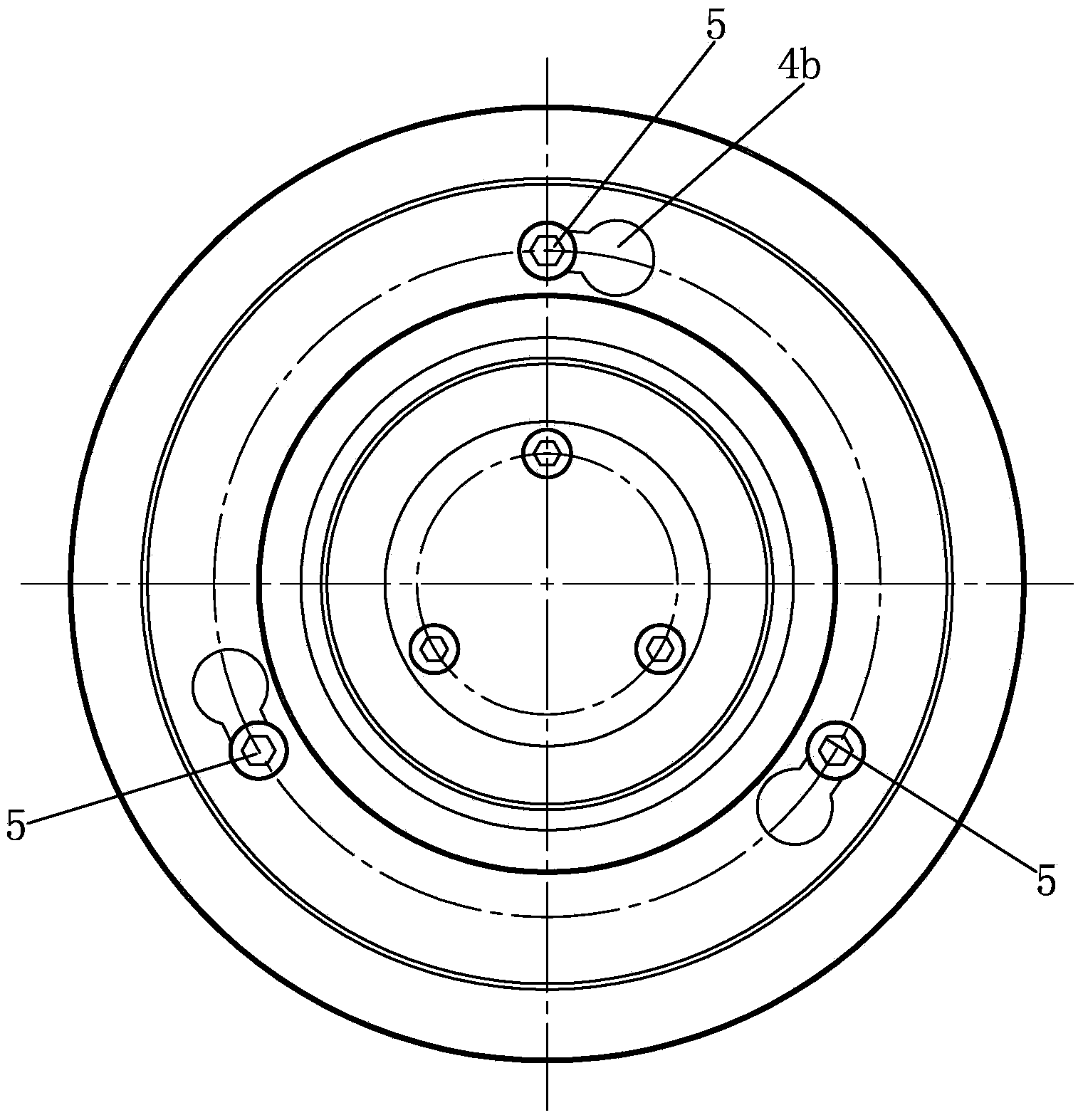

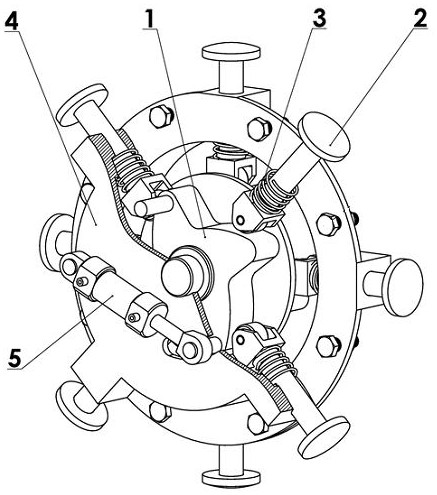

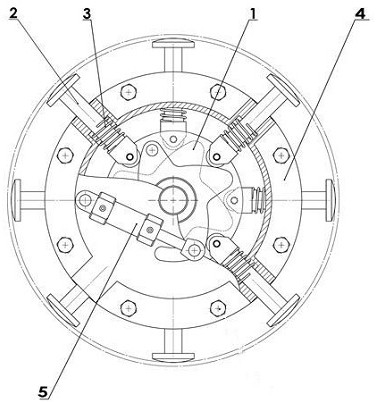

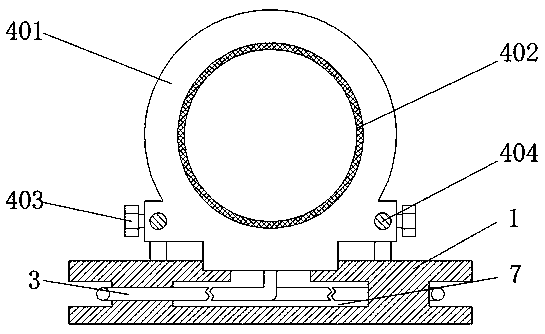

All-position welding fixture for steel wire rope ring

InactiveCN103909375AGuaranteed roundnessHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringUltimate tensile strength

The invention discloses an all-position welding fixture for a steel wire rope ring. The all-position welding fixture comprises a pedestal, an upright plate is mounted at each of two ends of the pedestal, a handle is mounted on one upright plate and is firmly connected with one end of a connecting block through a handle rotating shaft, the other upright plate is provided with a support shaft, and the other end of the connecting block is supported through the support shaft; the connecting block is connected with at least one slot block through bolts, a through hole is formed in the center of the slot block, an annular groove surrounds the through hole in the slot block, and the axial line of the through hole is overlapped with the axial line of the annular groove; a through slot is formed in one end of the slot block, and a propping block is mounted at the position corresponding to the through slot. The 360 degrees all-position welding for the steel wire rope ring joint is realized through rotating the handle, the welding quality is improved, and the operation is facilitated and simplified; the slot block is matched with the propping block, the welding roundness of the steel wire rope ring is guaranteed, and accordingly the welding intensity is improved; the all-position welding fixture is capable of processing different types of steel wire rope rings through changing the slot block and the propping block, and the universality is strong.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

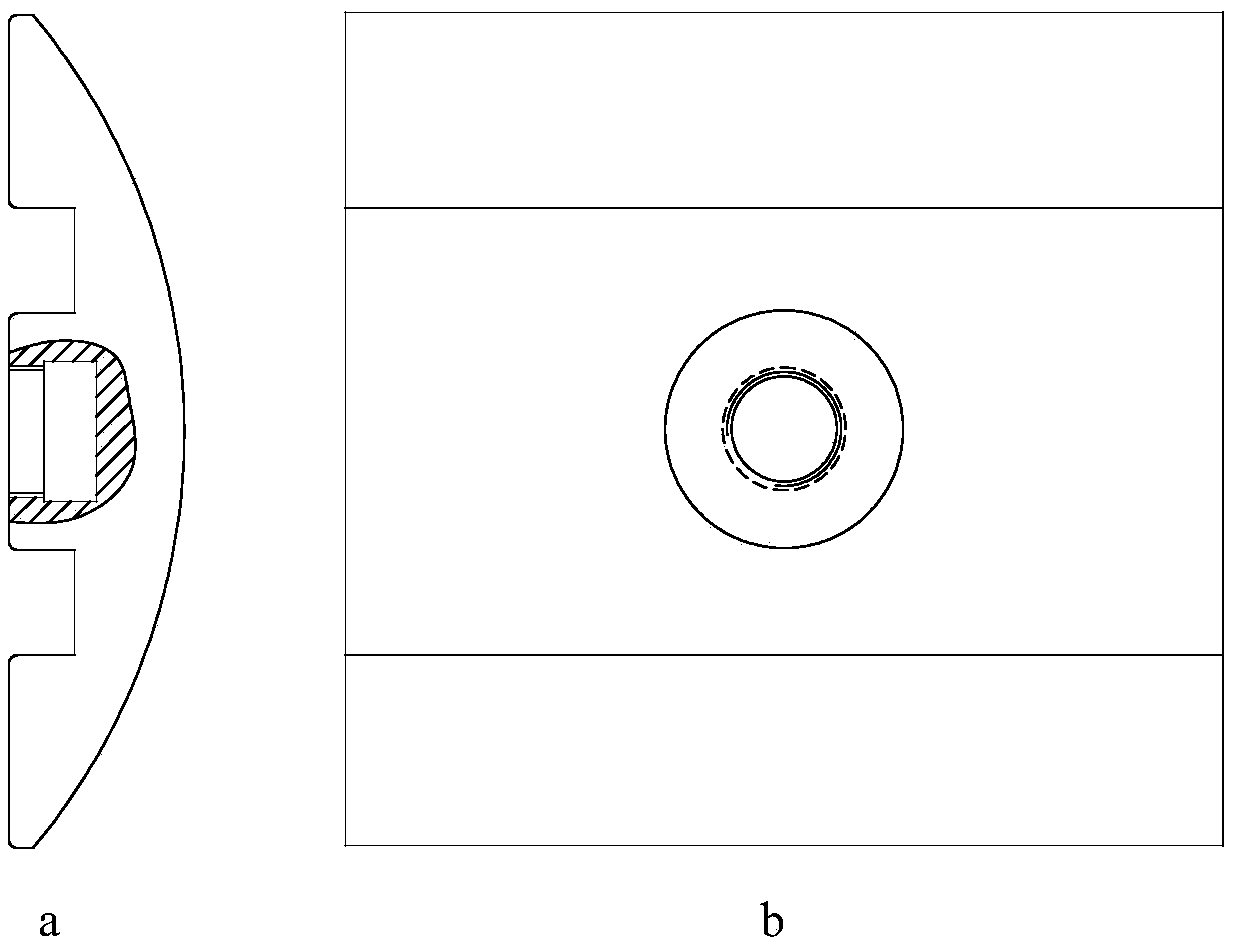

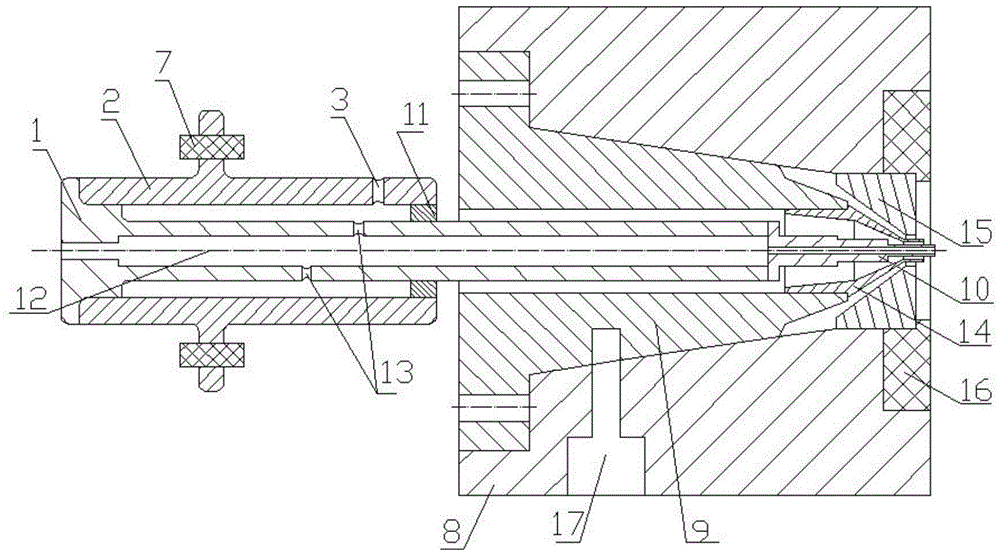

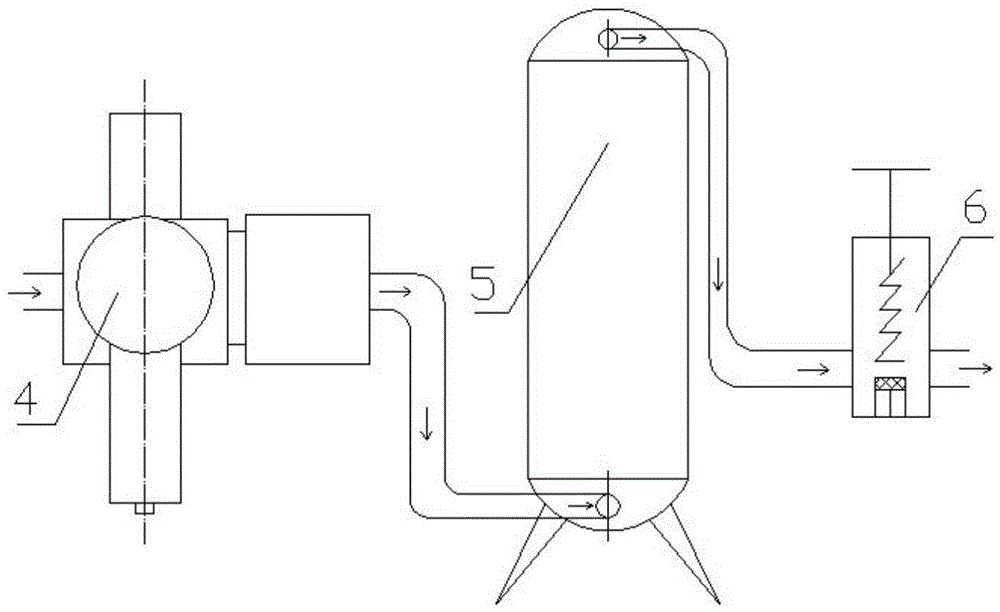

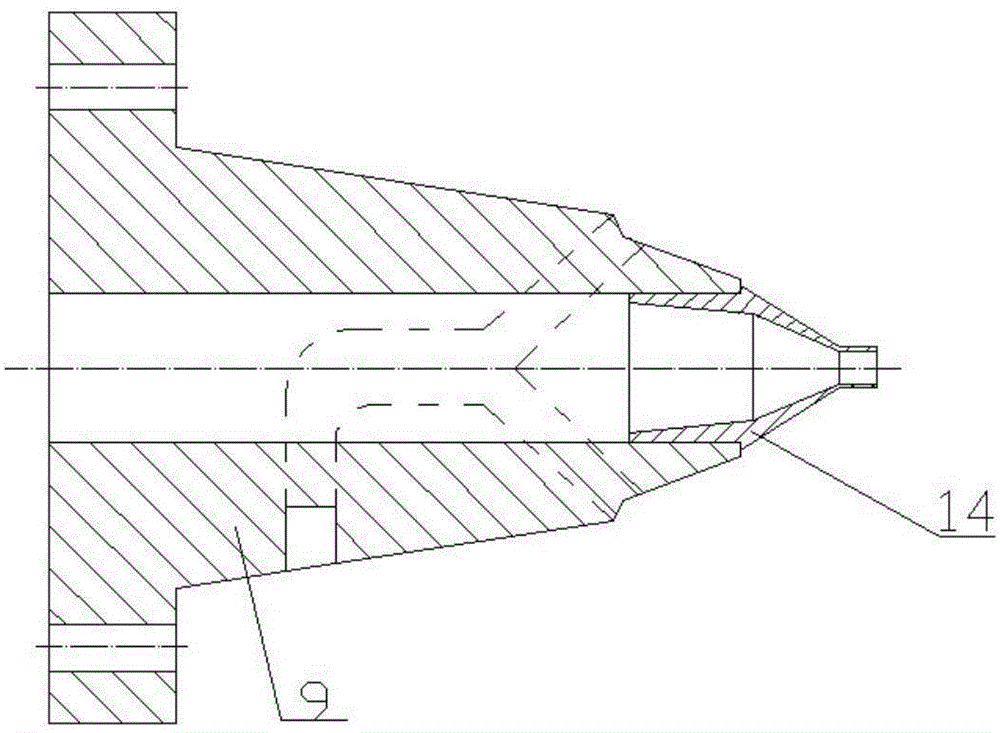

Mold for inflating, filling and forming of full-dry optical-cable loose tube

The invention discloses a mold for inflating, filling and forming of a full-dry optical-cable loose tube. The mold comprises a plastic extruding mold, a fiber guide tube, an inflating support and an air source mechanism, wherein the inflating support sleeves the fiber guide tube so as to form a sealed cavity, and air guide holes and an air inlet are dissymmetrically formed in the fiber guide tube and the inflating support; filtration and graded depressurization are performed twice on compressed air when the compressed air sequentially passes through a filter device and a pressure regulating device, the depressurized air enters the fiber guide tube through the air guide holes, the air, water blocking yarn and optical fibers are uniformly and stably injected in a formed loose tube through the fiber guide tube so as to form a full-dry optical-fiber loose tube through plastic extruding. The mold disclosed by the invention is simple in structure, the after shrinkage of the loose tube is small, and the fiber excess length is stable and controllable.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

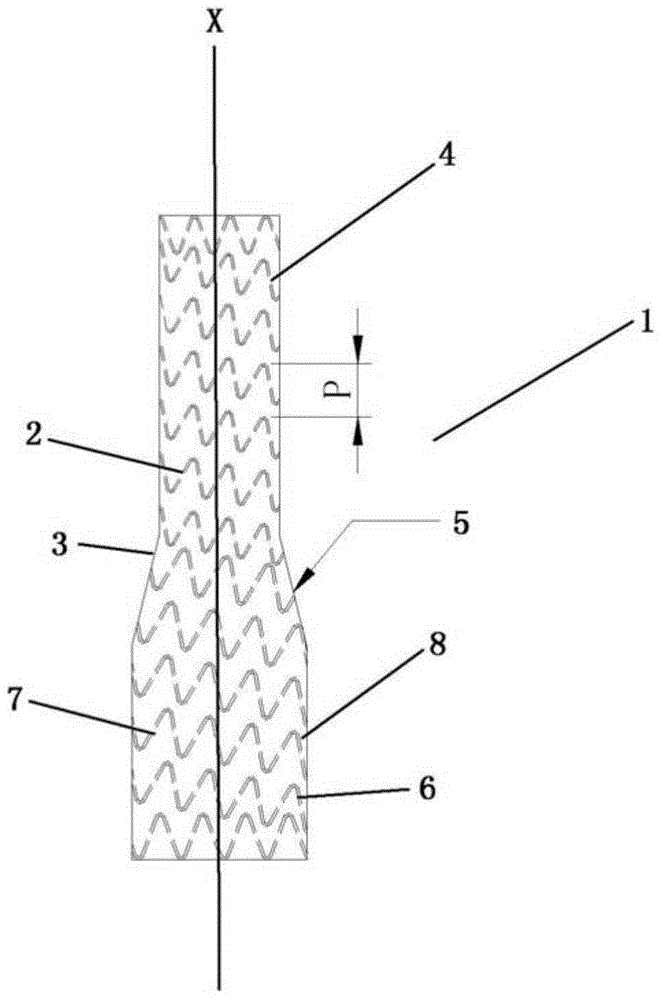

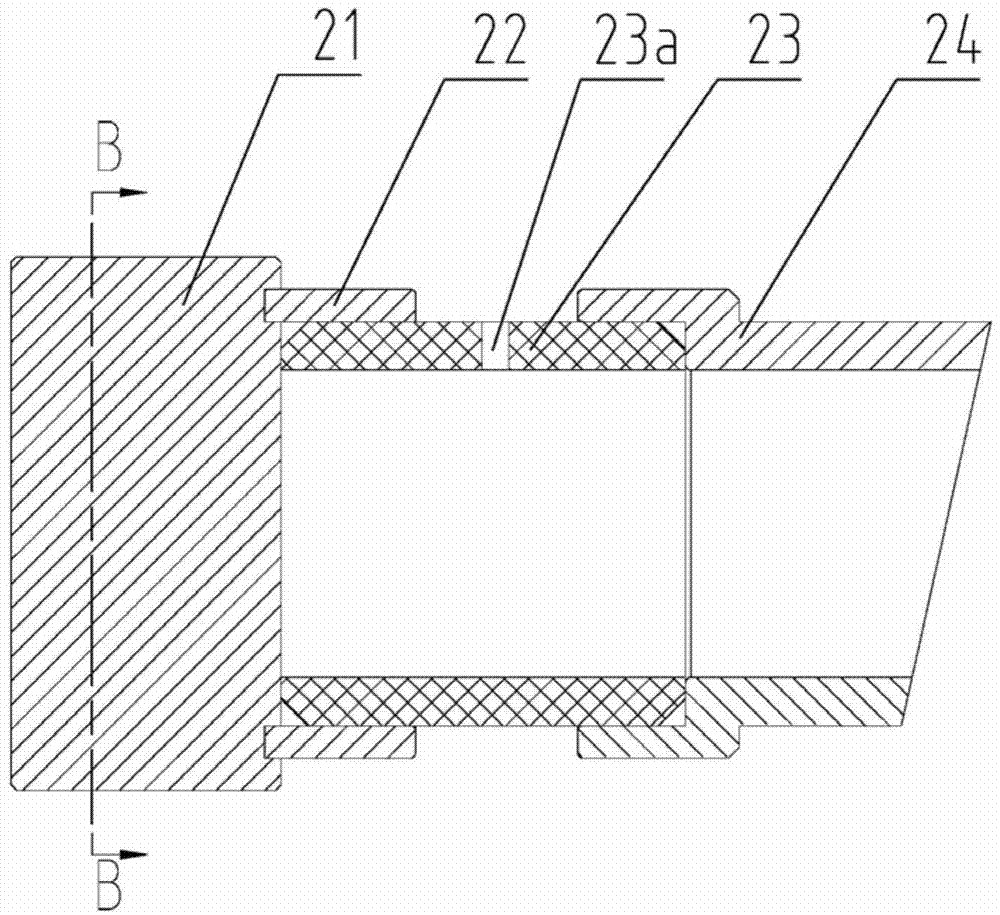

Covered stent

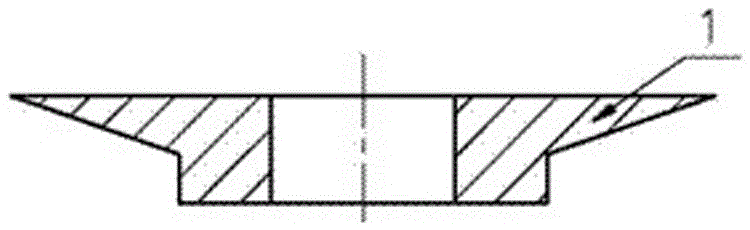

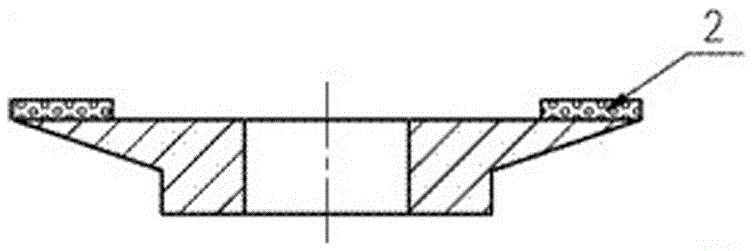

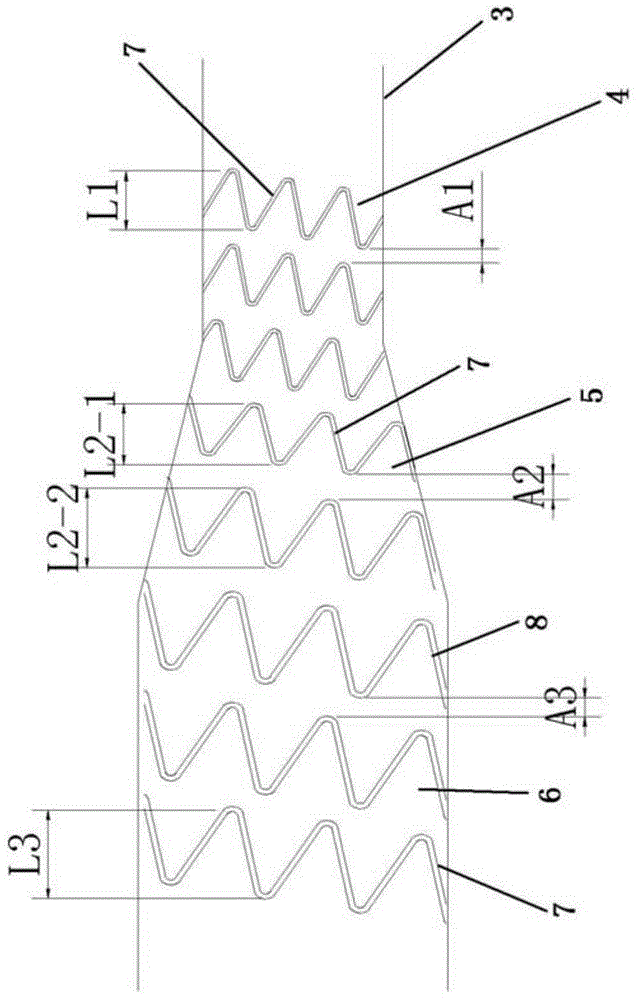

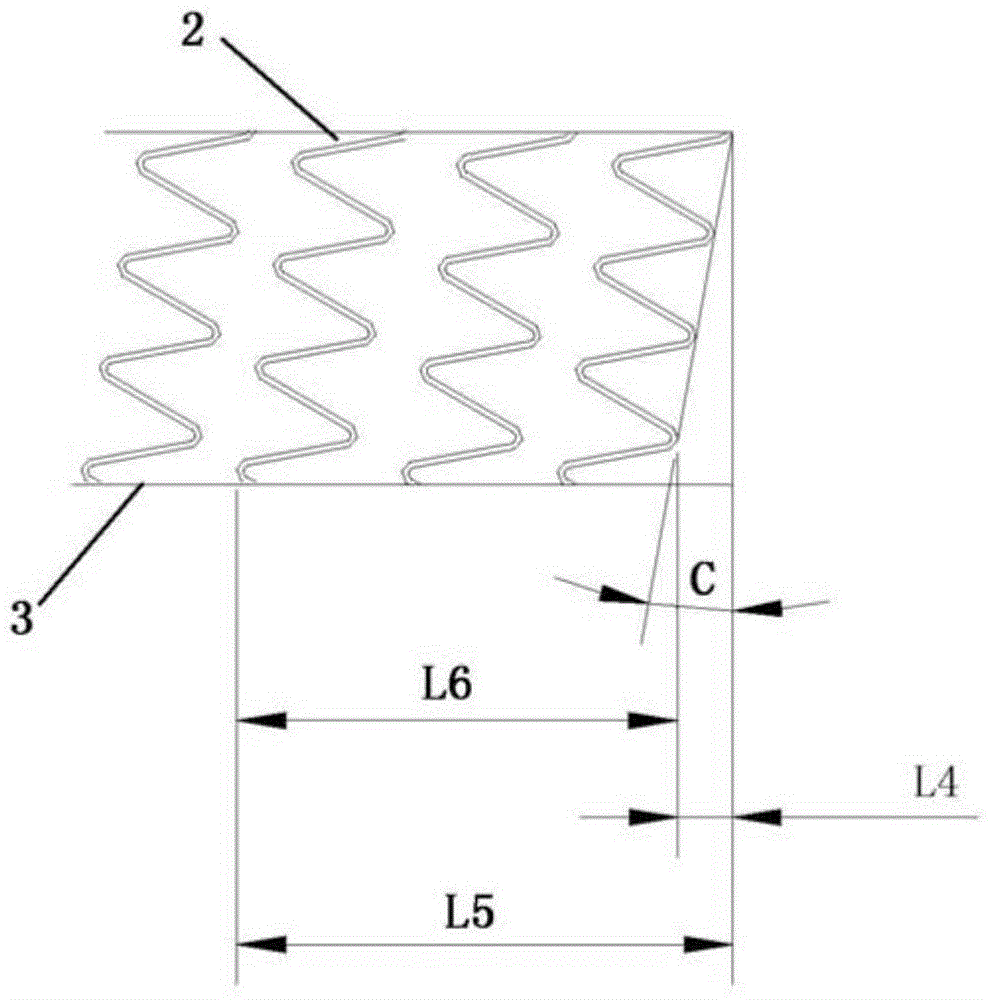

ActiveCN104586536AImprove bending performanceIncrease mating lengthStentsBlood vesselsStent graftingWave shape

A coated stent graft (1) comprises a stent graft main body (2) and a coat (3) fixed on the stent graft main body (2). The stent graft main body (2) is divided into multiple stent graft segments (7) along a central axis (X) of the coated stent graft (1), each stent graft segment (7) extends for a circle around the central axis (X) and each stent graft segment (7) is formed by connecting multiple wave rods (8) end-to-end in a wave-shaped structure. The stent graft main body (2) is formed by a small-diameter segment (4), a transition segment (5) and a large-diameter segment (6) along the central axis (X). The transition segment (5) connects the small-diameter segment (4) to the large-diameter segment (6). A space between adjacent stent graft segments in the transition segment (5) is greater than a space between adjacent stent graft segments in the small-diameter segment (4) and less than a space between adjacent stent graft segments in the large-diameter segment (6). The coated stent graft (1) is provided with improved bending performance.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

Circle measuring frame for large-size hydro-generator rotor and use method thereof

InactiveCN102829701AMeet the needs of assemblyGuaranteed roundnessMechanical counters/curvatures measurementsEngineeringLarge size

The invention provides a circle measuring frame for a large-size hydro-generator rotor and a use method thereof, in order to solve the problem of the prior art that no testing tool can be used for measuring a radius of each point on an external circle of a pole of a hydro-generator rotor at any time during an assembling process. The circle measuring frame for the large-size hydro-generator rotor comprises a spindle connecting mechanism, a counterweight shaft, a counterweight, a horizontal supporting frame and a measuring arm. If the circle measuring frame for the large-size hydro-generator rotor provided by the invention is used for measuring the assembling of the hydro-generator rotor, the radius of the external circle of each pole can be measured at any time, the circular degree and the concentricity of the external circle of each pole are checked and the central height of the each pole and the central height of a stator are kept consistent. The circle measuring frame for the large-size hydro-generator rotor has the beneficial effects that the circular degree and the concentricity of the external circle of each pole during the assembling process of the rotor are ensured, the central height of each pole is ensured and the circle measuring frame plays an important role in ensuring the safe running of a machine set. Besides, the circle measuring frame has generality and can meet the requirements of the assembling of the hydro-generator rotors in various sizes.

Owner:CHONGQING WATER TURBINE WORKS

Integrated tooling clamp for welding and heat treatment of thin-wall case and assembling method of integrated tooling clamp

ActiveCN110340495AEasy to install and removePrevent upward warpingWelding/cutting auxillary devicesAuxillary welding devicesThin walledThermal treatment

The invention discloses an integrated tooling clamp for welding and heat treatment of a thin-wall case and an assembling method of the integrated tooling clamp. The integrated tooling clamp comprisesa base, a positioning block and a gland; a plurality of lower end face pressing mechanisms used for pressing the lower end face of the thin-wall case are uniformly distributed in the circumferential direction of the base; a positioning spigot matched with the lower end face of the thin-wall case is further arranged on the base; the gland is arranged on the periphery of the upper end face of the thin-wall case and is located in an upper spigot of the positioning block, an upper end face pressing mechanism is arranged between the gland and the upper end face of the thin-wall case, and one end ofthe positioning block is arranged on the base through a fixing mechanism; and the other end of the positioning block is connected with the upper end face of the thin-wall case. The deformation of a part in the radial direction in the welding and heat treatment processes can be effectively controlled, and it is ensured that the roundness and flow channel surface runout after welding and heat treatment meet design requirements.

Owner:CHENGDU ENGINE GROUP

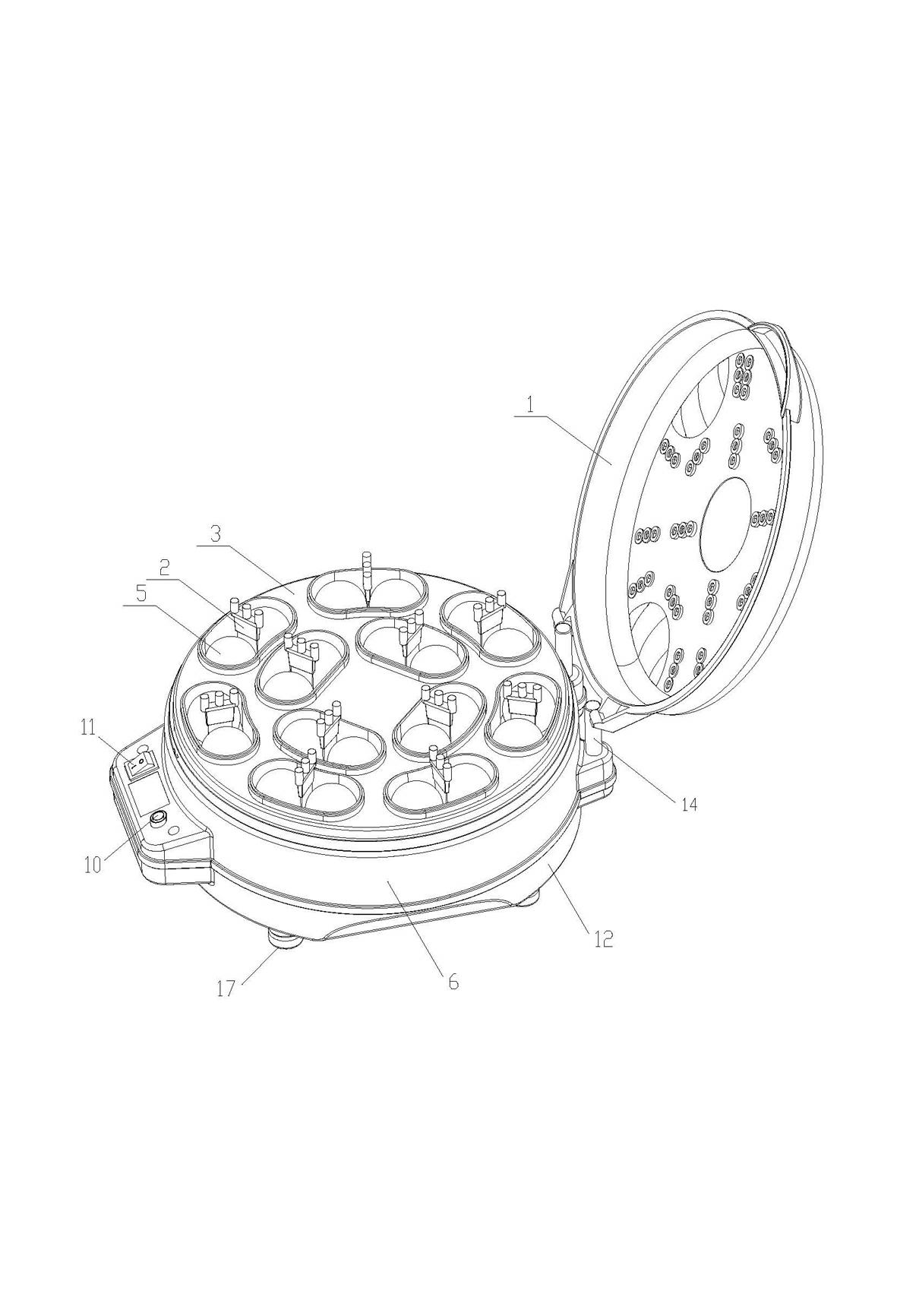

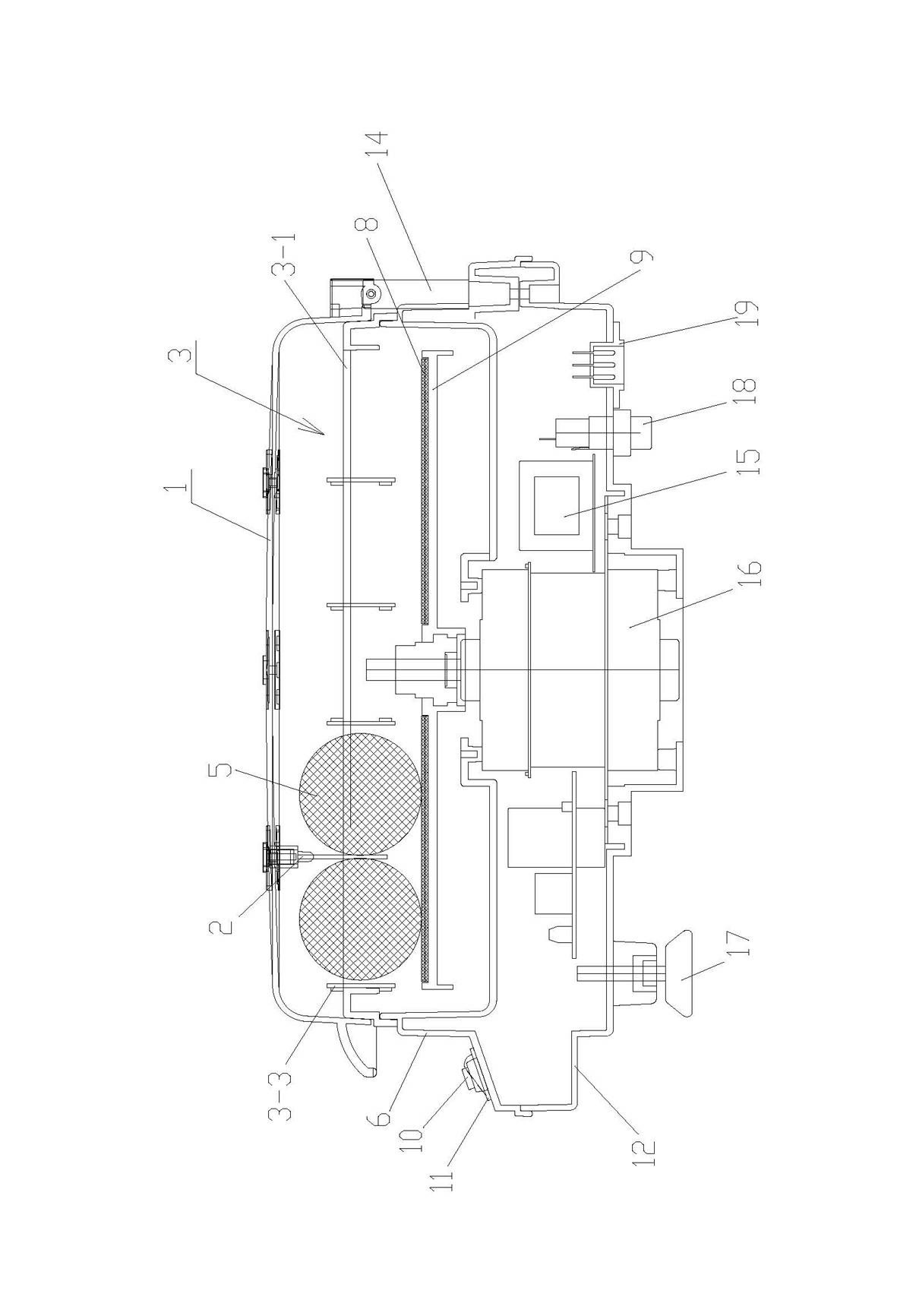

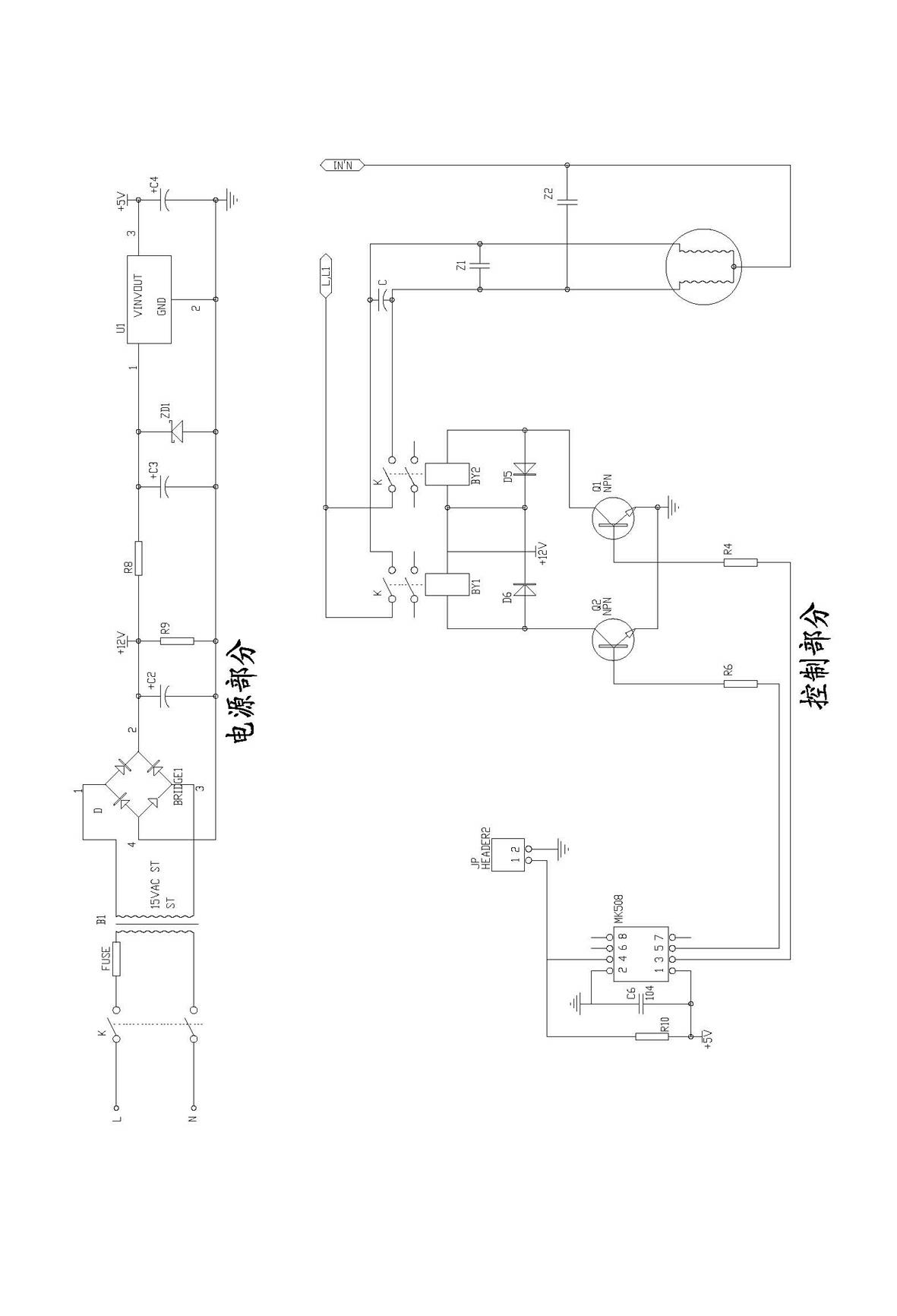

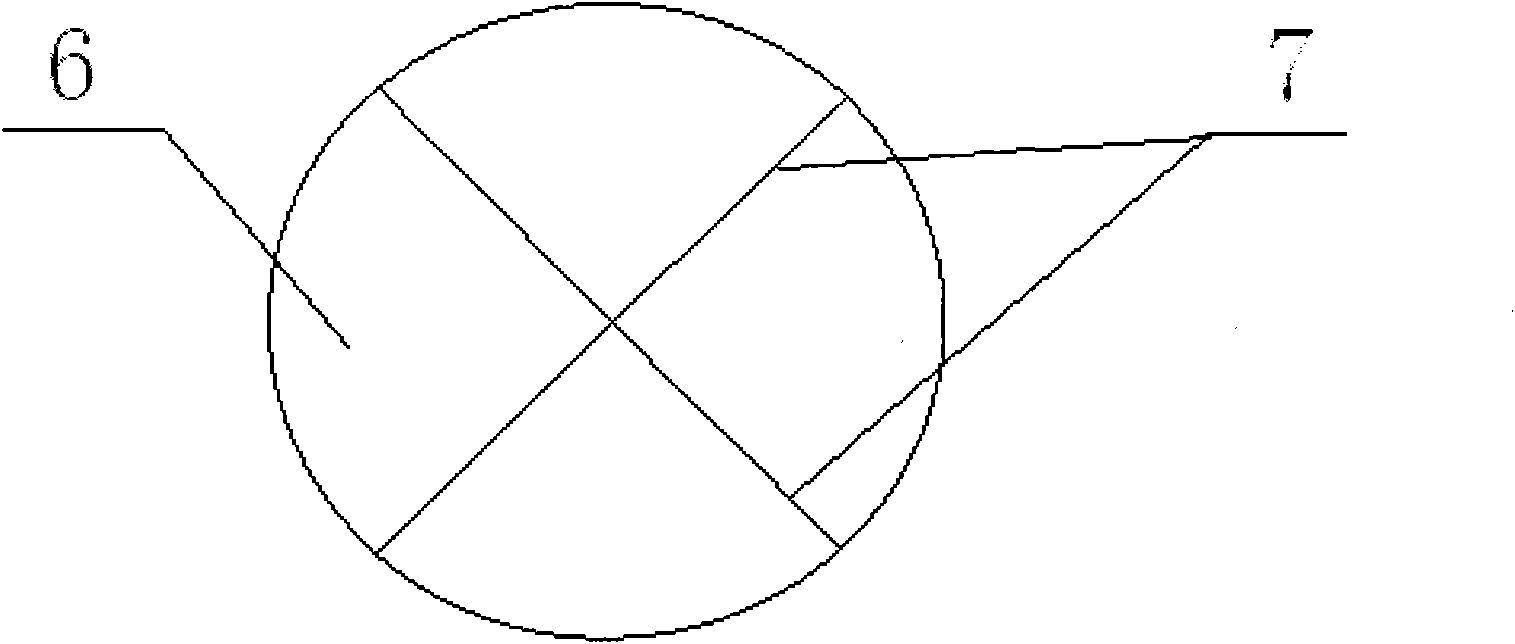

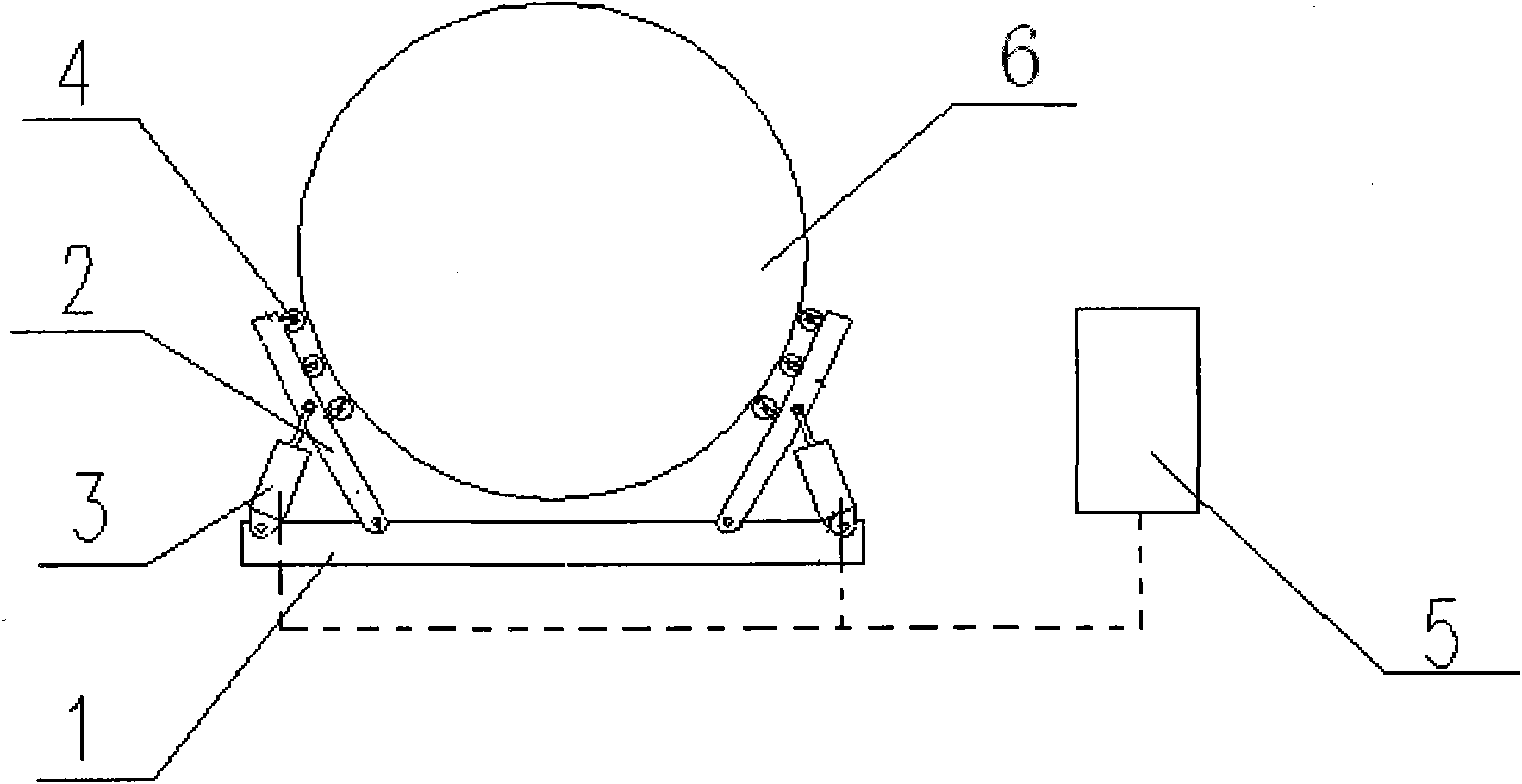

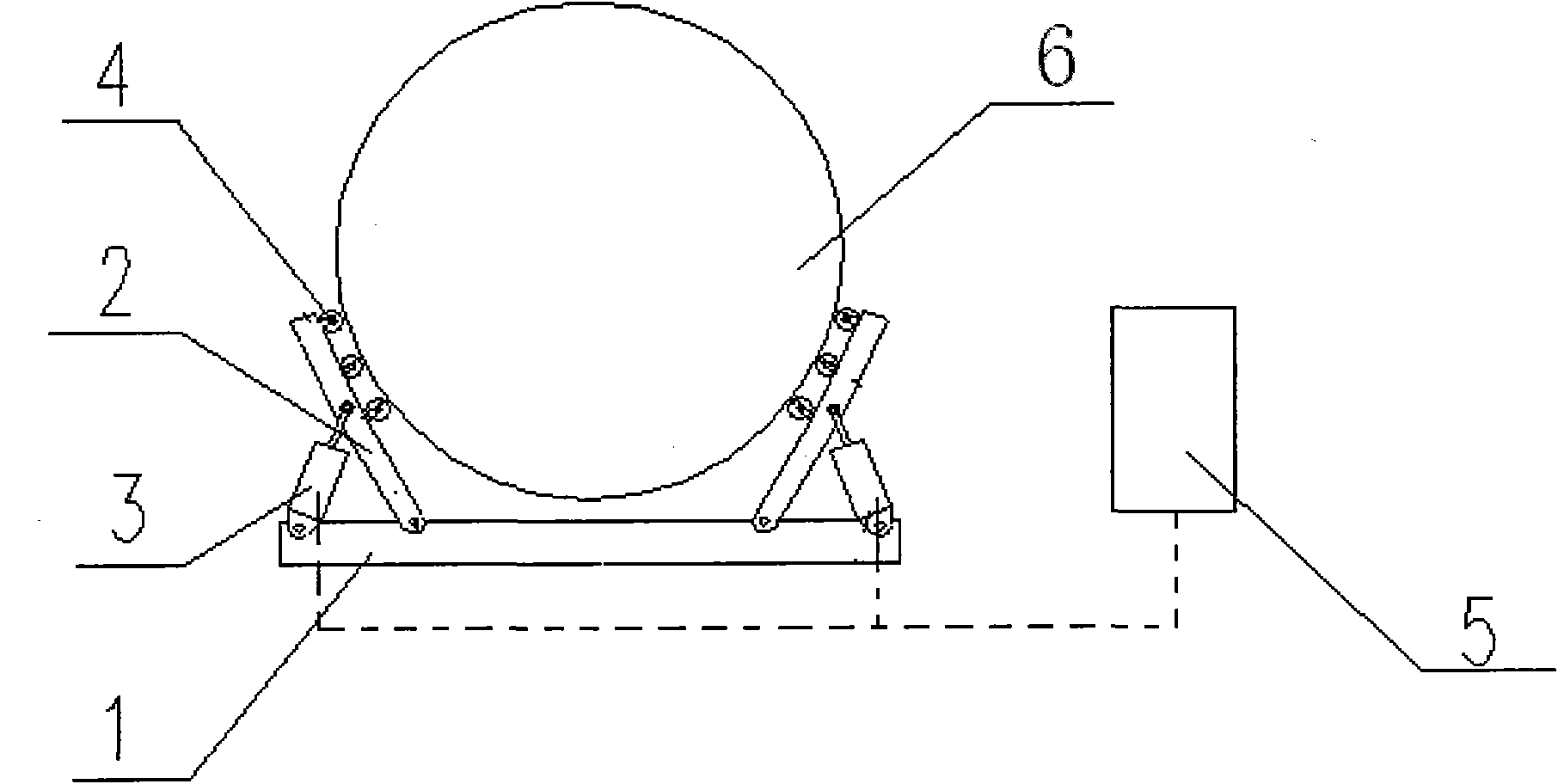

Billiard ball cleaning machine

ActiveCN102671363AGuaranteed roundnessGuaranteed uniformityPolishing machinesCleaning using toolsEngineeringBilliard ball

The invention relates to a billiard ball cleaning machine, and aims to provide a billiard ball cleaning machine which is simple in structure, convenient in operation and good in cleaning and polishing effect so as to achieve the purposes of reducing the labor cost and improving the working efficiency. The technical scheme of the invention is as follows: the billiard ball cleaning machine comprises a base with a groove, and is characterized in that the base is internally provided with a motor; the output shaft of the motor is coaxially provided with a rotating disc which is wholly positioned in the groove; the upper surface of the rotating disc is provided with a wool felt; simultaneously the base is provided with a separating disc which is partially embedded into the groove and is matched with the wool felt and the rotating disc to realize cleaning of billiard balls; and the base is hinged with an overturning cover for sealing the separating disc in the groove. The billiard ball cleaning machine is applicable to cleaning and polishing of the billiard balls with the types of America, Russia and Snooker.

Owner:慈溪市皓锋电器厂(普通合伙)

Deformed cylindrical section straightening device

The invention discloses a deformed cylindrical section straightening device which comprises a frame, two correction components and a control system, wherein the two correction components are in the mirror symmetry, and each correction component comprises a guiding frame and a driving cylinder; one end of each guiding frame is hinged on the frame; the surface facing to a corrected deformed cylindrical section, of each guiding frame, is an arc surface matched with the excircle of the deformed cylindrical section; one end of each driving cylinder is hinged with the frame, and the other end of the driving cylinder is hinged with one side far away from the corrected cylinder joint, of the guiding frame; and the control system is electrically connected with the driving cylinders respectively. The deformed cylindrical section straightening device has simple, reasonable and compact structure, overcomes many disadvantages of the prior art and realizes the mechanical adjustment of the roundness of the deformed cylindrical section; and by adopting the deformed cylindrical section straightening device, the degree of automation of the equipment and the adjustment precision of the roundness of the cylinder joint can be increased, the working efficiency of correction can be increased, and wastes can be reduced.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Turning tool for machining inner hole of thin-wall part

ActiveCN103639717AAvoid deformationGuaranteed roundnessAuxillary equipmentPositioning apparatusPiston rodComputer engineering

The invention discloses a turning tool for machining an inner hole of a thin-wall part. The turning tool for machining the inner hole of the thin-wall part is characterized by comprising a connecting disk and a press plate, the axis of the connecting disk and the axis of a locating disk are arranged on the same straight line, the right portion of the connecting disk is fixedly connected with the left portion of the locating disk, and a locating spigot is formed in the right end of a center hole of the locating disk; and two to four air cylinders are arranged between the connecting disk and the locating disk in the circumferential direction, piston rods of the air cylinders are parallel to the axis of the locating disk, and cylinder bodies of the air cylinders are fixedly connected with the outer wall of the locating disk; the number of the press plate is one, a lathe tool receding hole is formed in the center of the press plate, and connecting screws are fixedly connected with the right ends of the piston rods of the corresponding air cylinders after penetrating through threaded installing holes formed in the press plate. According to the turning tool for machining the inner hole of the thin-wall part, due to the facts that locating is carried out on the outer circle surface of the thin-wall part, and the end face of the thin-wall part is tightly pressed through the air cylinders and the press plate, the side wall of the thin-wall part cannot bear radial force, deformation, in the radial direction, of the thin-wall part is avoided, and then the roundness of the inner hole of the thin-wall part is ensured.

Owner:CHONGQING XINGJI GEAR

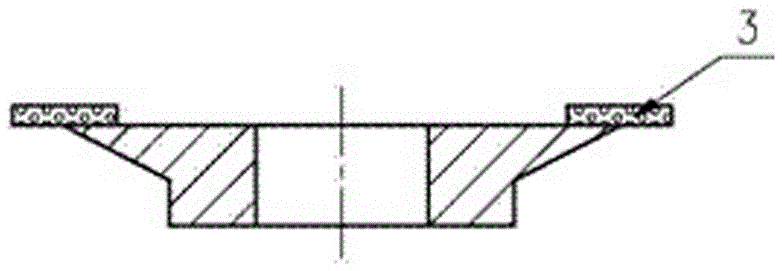

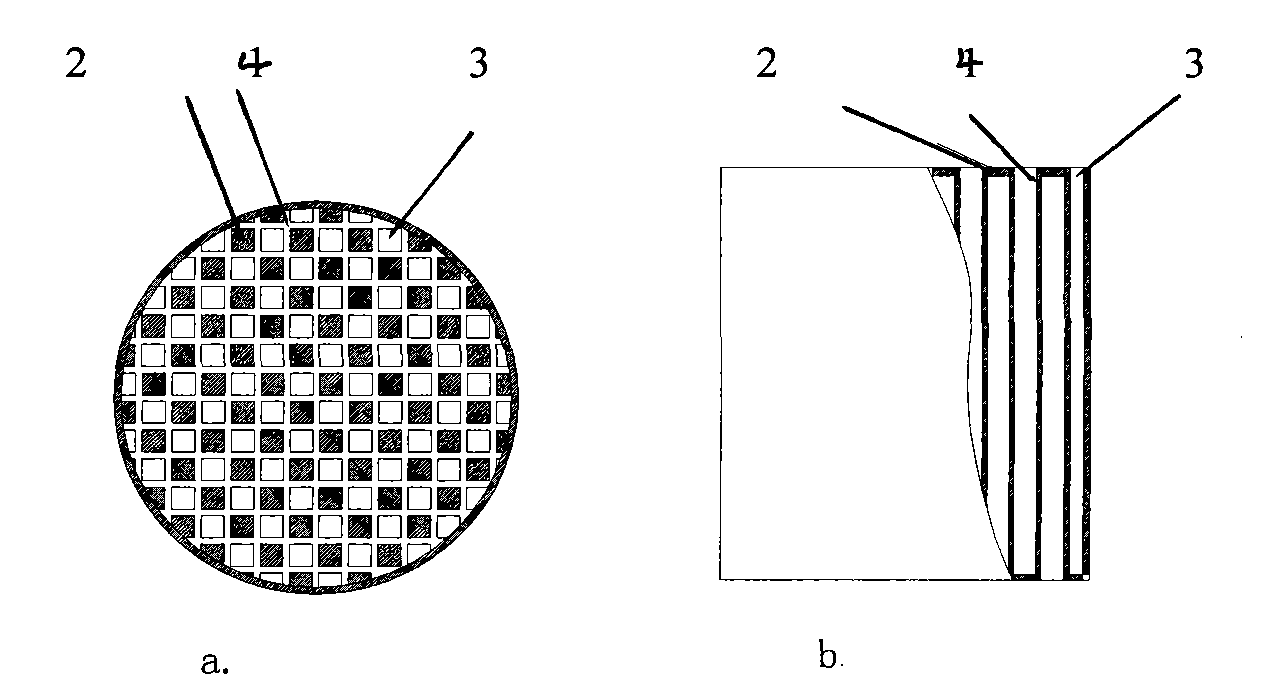

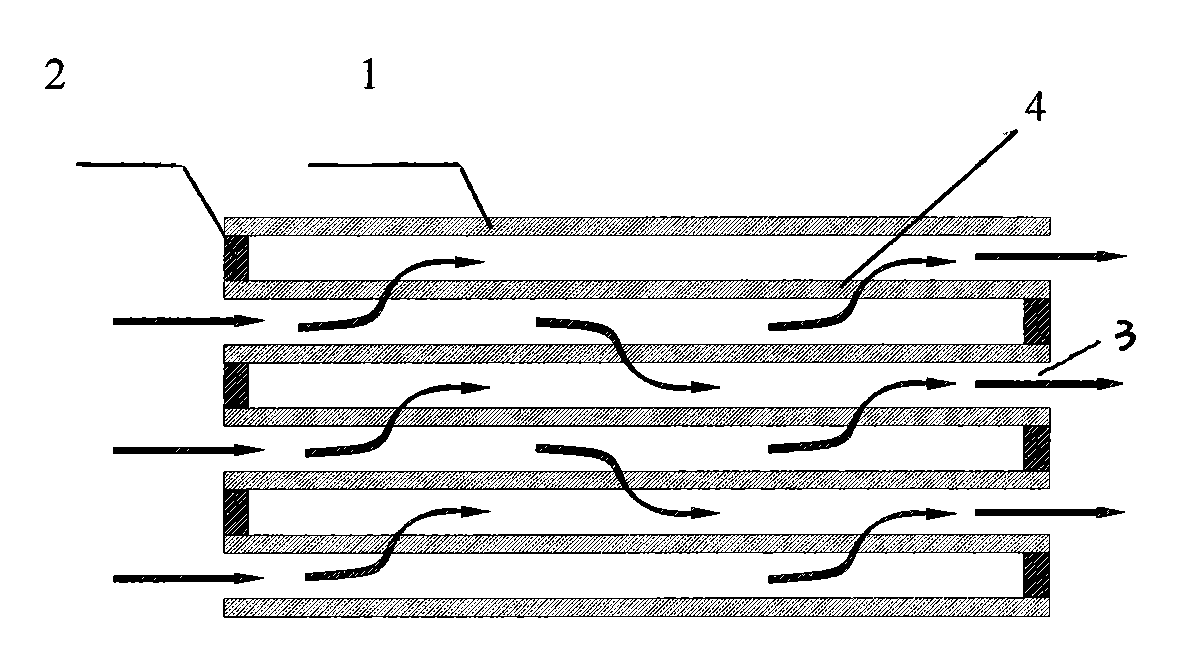

Wall-flow honeycomb ceramic filter

ActiveCN101612500ALarge apertureEffective in filtering black smokeExhaust apparatusSilencing apparatusMicrowaveHoneycomb

The invention relates to a wall-flow honeycomb ceramic filter, which combines a cordierite honeycomb ceramics material and a special pore-forming agent. Raw materials of a blank of the filter comprise the following components, mass portions and grain diameters: kaolin is 35 to 45 portions, and the average grain diameter is less than or equal to 5 mu m; talcum is 20 to 30 portions, and the average grain diameter is 15 mu m; alpha-alumina is 4 to 9 portions, and the average grain diameter is less than or equal to 2 mu m; the pore-forming agent consisting of carbon granules or / and organic polymeric particles is 5 to 15 portions, and the average grain diameter is 10 to 20 mu m; and a bonding agent is 3 to 7 portions. A method for preparing the wall-flow honeycomb ceramic filter comprises the following steps: evenly mixing the components and 20 to 30 portions of water to prepare a blank; completing the conversion from the blank to plastic mud after performing vacuum degassing for 2 to 3 times; staling the plastic mud for 24+ / -8 hours, and squeezing out the plastic mud through a mould of an extruder, wherein the density of mould holes is 100 to 250 holes per square inch; cutting the mud after extrusion into a wet blank with certain length; and performing microwave drying on the wet blank to obtain a dry blank, performing cross hole blocking and drying on the dry blank, and finally performing a sintering working procedure on the dry blank to manufacture a product.

Owner:NANJING KERUI SPECIAL CERAMICS

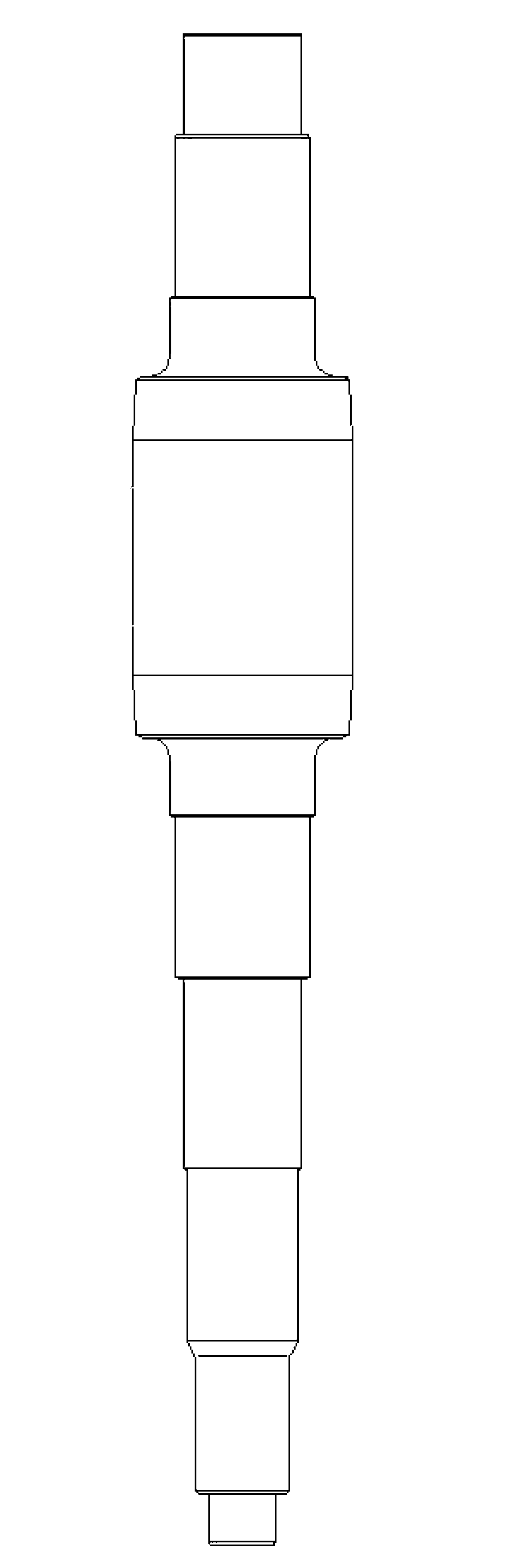

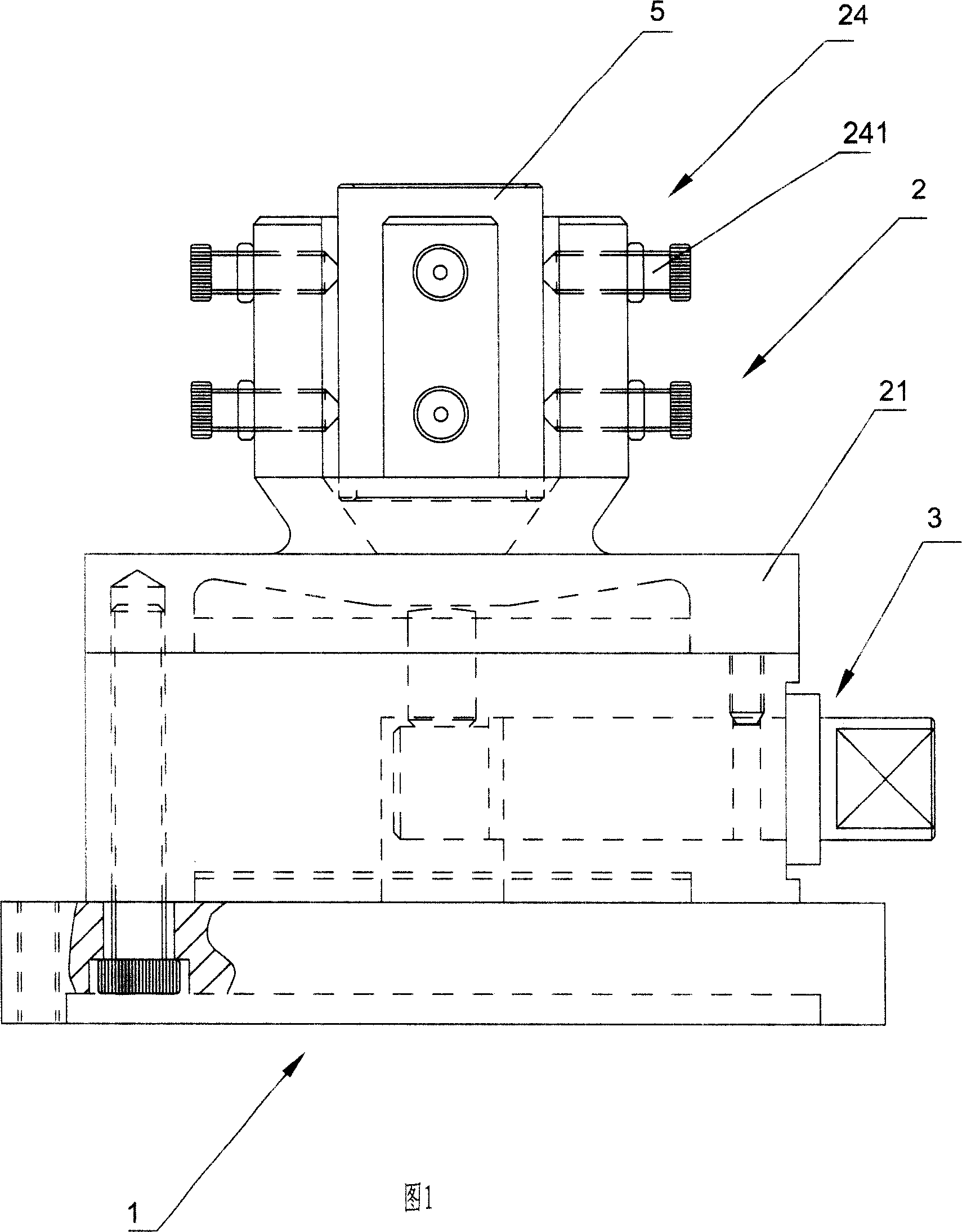

Vehicle transmission shaft straightening device

ActiveCN105127248AAccurate correction of circular axisExtended service lifeMetal working apparatusDrive shaftEngineering

Owner:SHANGHAI UNIV OF ENG SCI

Fixing clamp for shaft sleeve

ActiveCN100999055AEasy clampingGuaranteed coaxialityChucksPositioning apparatusEngineeringMechanical engineering

The present invention relates to a shaft sleeve retaining clamp. It includes seat body, clamp body and ejector pin positioned between above-mentioned seat body and clamp body. Said clamp body includes base seat and several jaws, on the upper portion of said base seat a conical hole is cut, said several jaws are uniformly distributed on the periphery of said conical hole, the lower portion of said base seat has a hollow cavity, and the base seat between the conical hole and hollow cavity is formed into an elastic portion, the upper end portion of said ejector pin is tightly supported on the elastic portion. Besides, said invention also provides its working principle and concrete operation method.

Owner:SUZHOU ZHOUYANG PRECISION MACHINERY TECH CO LTD

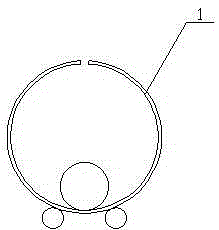

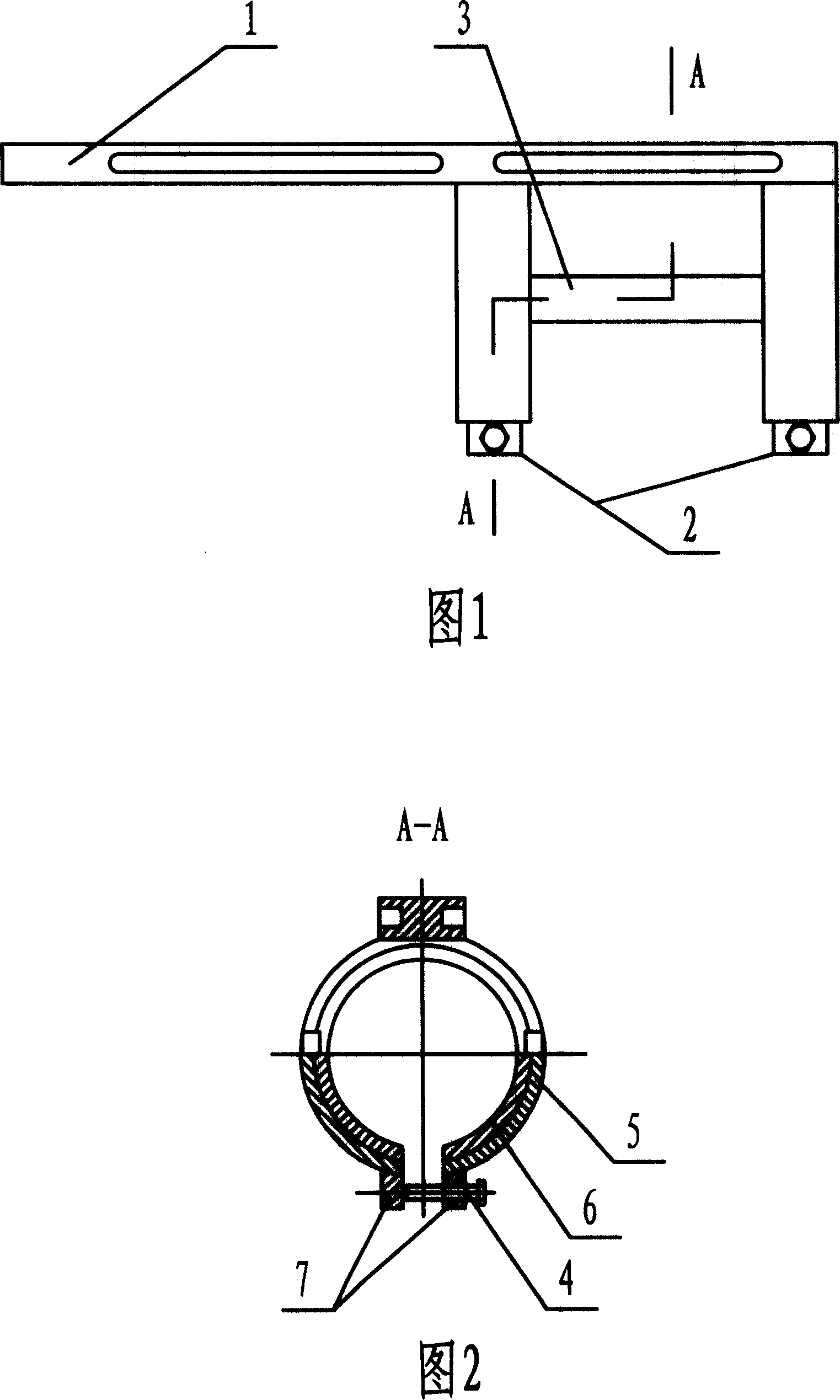

Circle supporting device for the inner side of a thin-wall metal pipeline

ActiveCN111791014AImprove general performanceGuaranteed roundnessWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention discloses a circle supporting device for the inner side of a thin-wall metal pipeline. The circle supporting device comprises a cam shaft body capable of rotating and a plurality of pushrod assemblies extending and retracting along the cam shaft body, and the cam shaft body and the push rod assemblies are covered with shells. The cam shaft body comprises a rotating shaft arranged inthe middle. The two sides of the rotating shaft are each provided with a windmill-shaped cam with a plurality of fan blades evenly distributed in the circumferential direction, and the two cams on the two sides are arranged in a staggered mode at a certain angle. Each push rod assembly is sleeved with a spring, and a reset spring clamping groove is formed in each shell. The reset spring clampinggrooves enable the springs to be in a compressed state all the time, and then one end of each push rod assembly is driven to abut against the corresponding fan blade all the time. The outer sides of the shells are provided with a hydraulic cylinder used for providing power for rotation of the cam shaft body. The circle supporting device is ingenious in design, easy and convenient to use, high in accuracy and capable of being applied to inner side anti-deformation supporting when the outer sides of metal pipelines whose inner side areas are unreachable via various paths are welded, and the inner diameter and the roundness of the pipelines are guaranteed.

Owner:YANSHAN UNIV

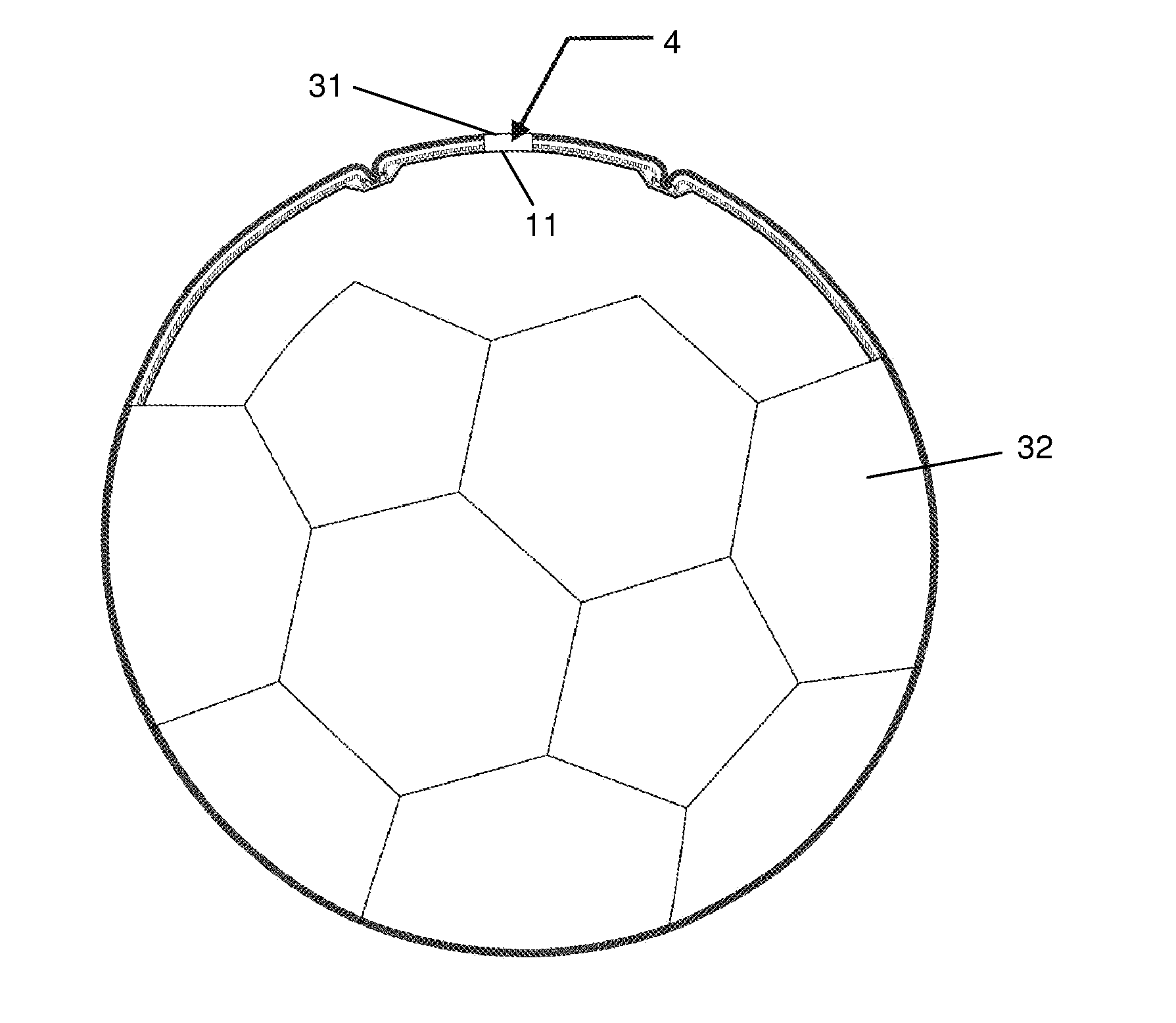

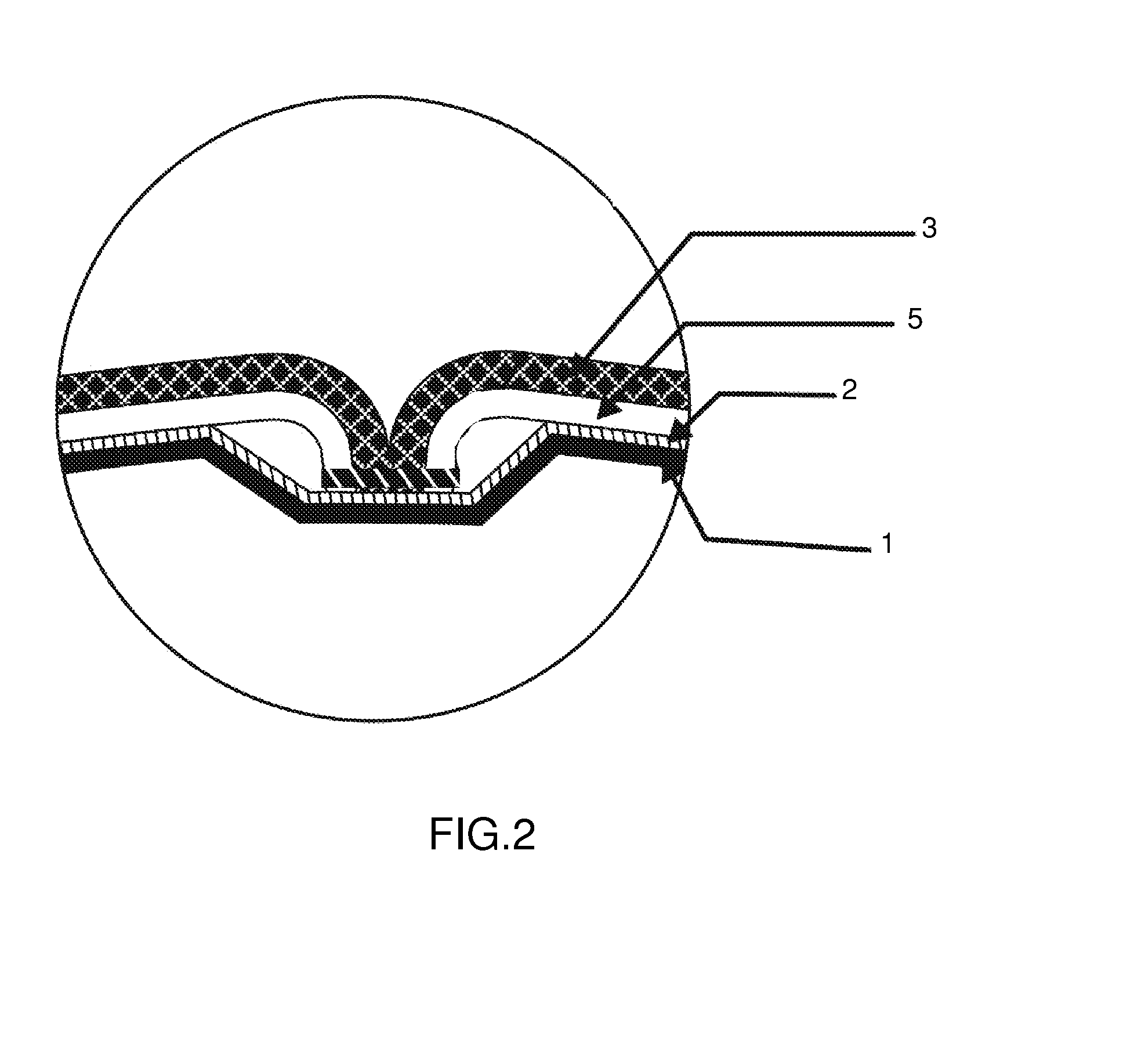

Inflatable sports ball

InactiveUS20130035182A1Simple manufacturing processReduce manufacturing costHollow inflatable ballsHollow non-inflatable ballsEngineeringValve stem

An inflatable sports ball which comprises an inflatable bladder which is provided with a bladder valve; a bladder pocket which encloses the bladder; an outer carcass which encloses the bladder pocket and is provided with an outer carcass valve hole; and a valve stem which extends from the bladder valve hole through the bladder pocket to the outer carcass valve hole. The bladder pocket is in form of a hosohedron with a plurality of identical lune faces, and each of the lune faces is formed by a panel which is made of a material cheaper in costs in comparison with materials which form the bladder or the outer carcass.

Owner:NOBLE STAR HLDG

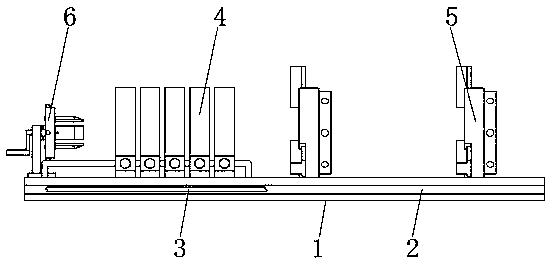

Full-automatic pipe punching production line and machining process thereof

InactiveCN107442638AAccurate length and sizeGuaranteed roundnessMetal-working feeding devicesHollow article cleaningProduction linePunching

The invention discloses a full-automatic pipe punching production line. The full-automatic pipe punching production line can be connected with a pipe manufacturing line in a seamless joint manner. Firstly, a high-pressure pneumatic gun is used for being matched with a pulley block and directly clears away welding ribs in a welding pipe on equipment, the welding ribs are blown out of the pipe fitting and clamped out through the pulley block, and the situation that the welding ribs disturb the following pipe cutting process in resistance is prevented. Then, the high-pressure pneumatic gun can further carry out two end chamfering on the pipe fitting so as to set the length size, milling mechanisms located at the two ends of the pipe fitting carry out milling and chamfering on the margins of the pipe fitting, and therefore the precise length size can be set, and it is guaranteed that the lengths of the pipe fitting from the transportation working procedure to the pipe cutting working procedure are equal. In addition, the pipe fitting to be machined is fed in a full-automatic manner and transported to a punching station to be clamped and punched, the waste material of the previous pipe fitting can be cleared away without shutdown, time is saved, and the working efficiency is improved. In addition, in the punching working procedure, punching is adopted to replace a saw web, and the working efficiency during volume production is remarkably improved.

Owner:NINGBO TRIZ AUTOMATIC EQUIP

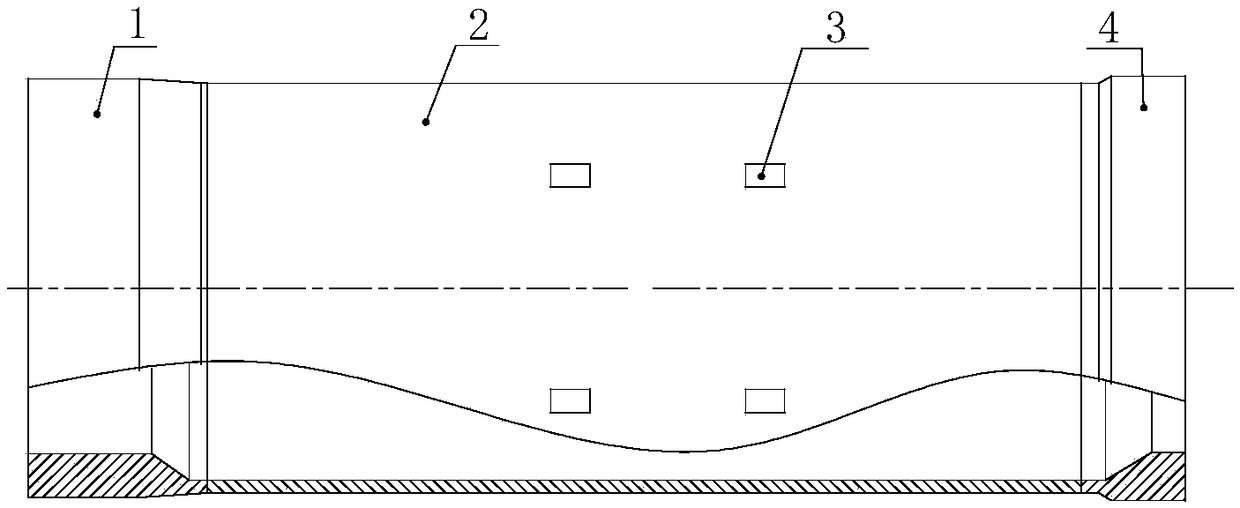

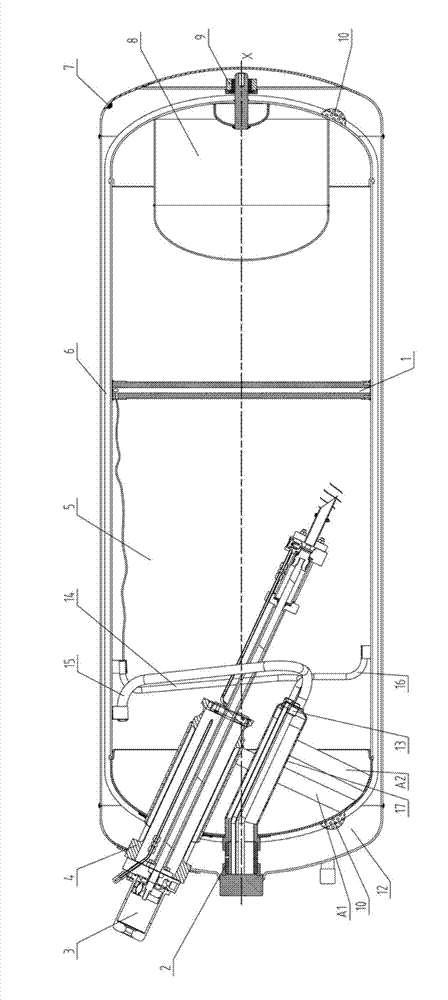

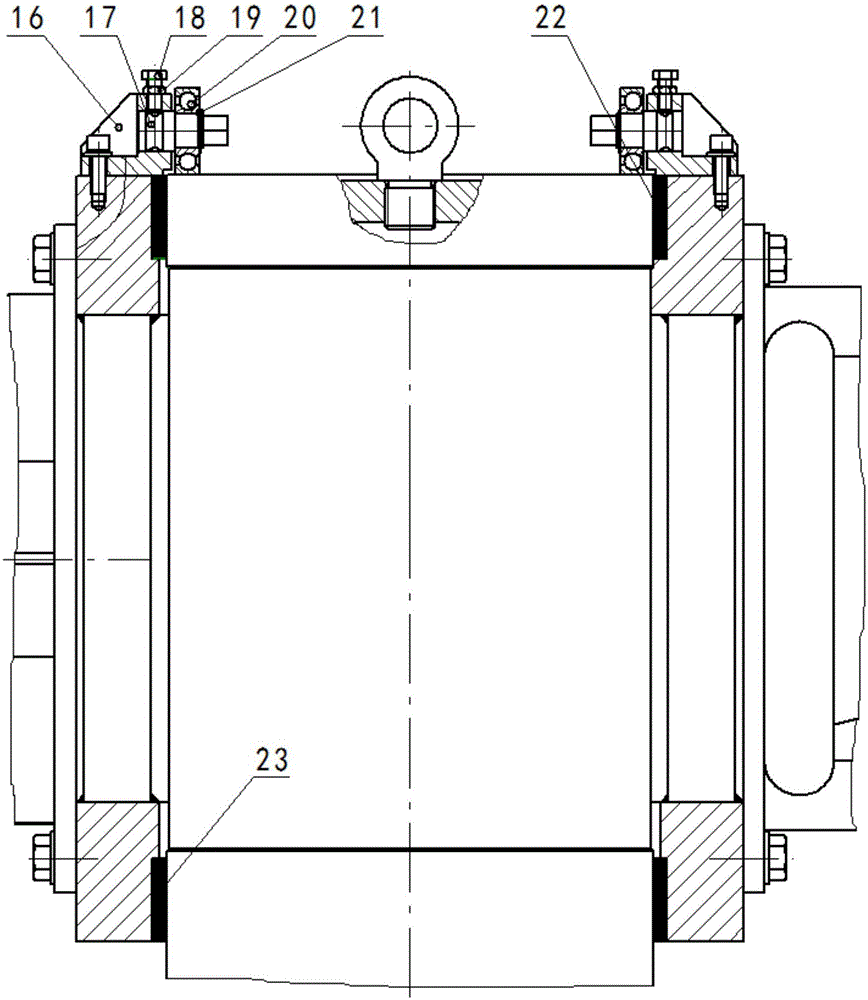

Automotive liquefied natural gas cylinder

InactiveCN104728594ASolve the inconvenience of use and potential safety hazardsReduce heat transferContainer filling methodsPressure vesselsLiquefied natural gasFlange

The invention relates to an automotive liquefied natural gas cylinder, and provides a liquefied natural gas cylinder integrating a low-temperature pump. Through redesign and reasonable allocation of a support sleeve of the low-temperature pump, the low-temperature pump can be stably arranged, and the heat leakage can be effectively reduced. The automotive liquefied natural gas cylinder comprises a housing, an inner tank and a low-temperature pump, wherein a heat-insulating space is formed between the housing and the inner tank; the inner tank respectively penetrates through a front-end support device, a low-temperature pump sleeve device and a rear-end support device and is connected to the housing; the low-temperature pump sleeve device comprises an inner side sleeve and an outer side sleeve; the inner side sleeve is of an integral structure; a flange plate is arranged on the upper part of the inner side sleeve; a base is arranged on the lower part of the inner side sleeve; a heat-insulating layer is formed between the flange plate and the base on the outer wall of the inner side sleeve; the bottom of the outer side sleeve is welded with the base on the inner side sleeve; and the low-temperature pump is fixedly arranged on the flange plate.

Owner:SHAANXI AUTOMOBILE GROUP +1

Plastic pipe expanding device capable of processing pipe openings in different sizes

The invention discloses a plastic pipe expanding device capable of processing pipe openings in different sizes. The plastic pipe expanding device comprises a supporting base and a lead; an external wire slot is formed in the outer side of the supporting base, and the lead is fixed inside the external wire slot; a heating mechanism, a fixing mechanism and an expanding mechanism are mounted on the upper side of the supporting base, the heating mechanism is positioned between the fixing mechanism and the expanding mechanism, an internal wire slot is formed in the upper side of the supporting base, and the heating mechanism is mounted on the upper side of the internal wire slot. The plastic pipe expanding device capable of processing the pipe openings in different sizes, disclosed by the invention, has the benefits that as the heating mechanism, the fixing mechanism and the expanding mechanism are arranged on the device, the use of a connector during the plastic pipe connection can be avoided, and the problem that the use cost of plastic pipes is increased due to the use of the connector is also solved; only one connection position can exist between the two plastic pipes, so that the probability of leakage at the connection of the plastic pipes is reduced, and the service performances of the plastic pipes are improved.

Owner:重庆西洲管业有限公司

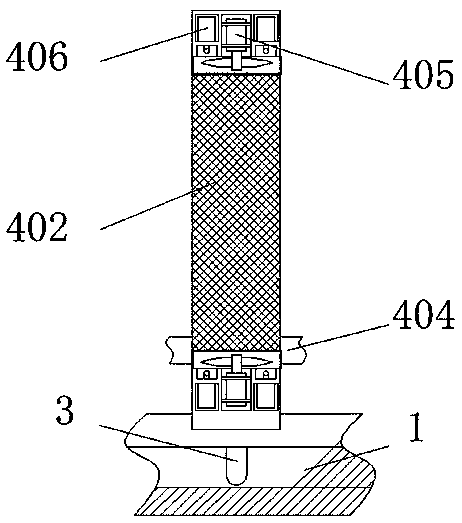

Semi-passing honeycomb ceramic grain filter and preparation method thereof

InactiveCN105833620AGuaranteed roundnessReduce energy consumptionDispersed particle filtrationTransportation and packagingWater solubleSkin grafting

The invention provides a semi-passing honeycomb ceramic grain filter and a preparation method thereof. A filter is made of honeycomb ceramic with blocking holes alternately crossed at one end and no block hole at the other end. The raw material comprises the following components in parts by weight: 25-30 parts of flake kaolin, 15-20 parts of alumina powder, 37-40 parts of flake talcum, 6-10 parts of fused quartz powder, 8-20 parts of pore forming materials, 3-10 parts of water-solubility binder and a defined amount of water. The preparation method comprises the following steps: mechanically mixing and uniformly kneading the raw materials; performing vacuum processing on the mixture for 2-3 times at the vacuum degree of 90-95KPa and then ageing for 20-40h, thereby acquiring plastic slurry; extruding a honeycomb ceramic wet green body in a certain size through a mold; performing microwave drying for 2h at 8-12Kw, cutting and trimming, thereby acquiring a dry green body; increasing the temperature according to the procedure and sintering into a semi-finished product at high temperature; and mechanically stripping the irregular outer wall of the green body, performing skin-grafting again, performing microwave drying, crossing the blocking holes at single end at intervals and then performing microwave drying, thereby acquiring a finished product.

Owner:NANJING KERUI SPECIAL CERAMICS

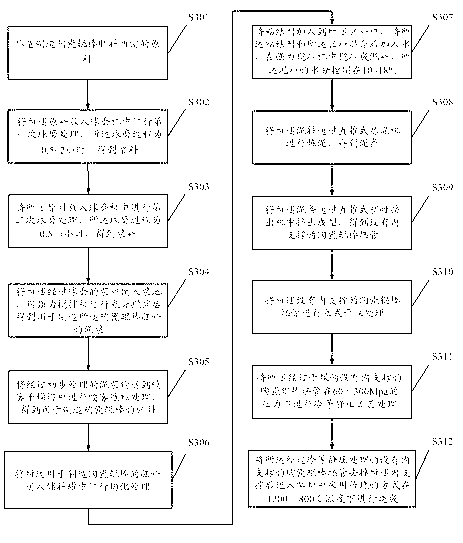

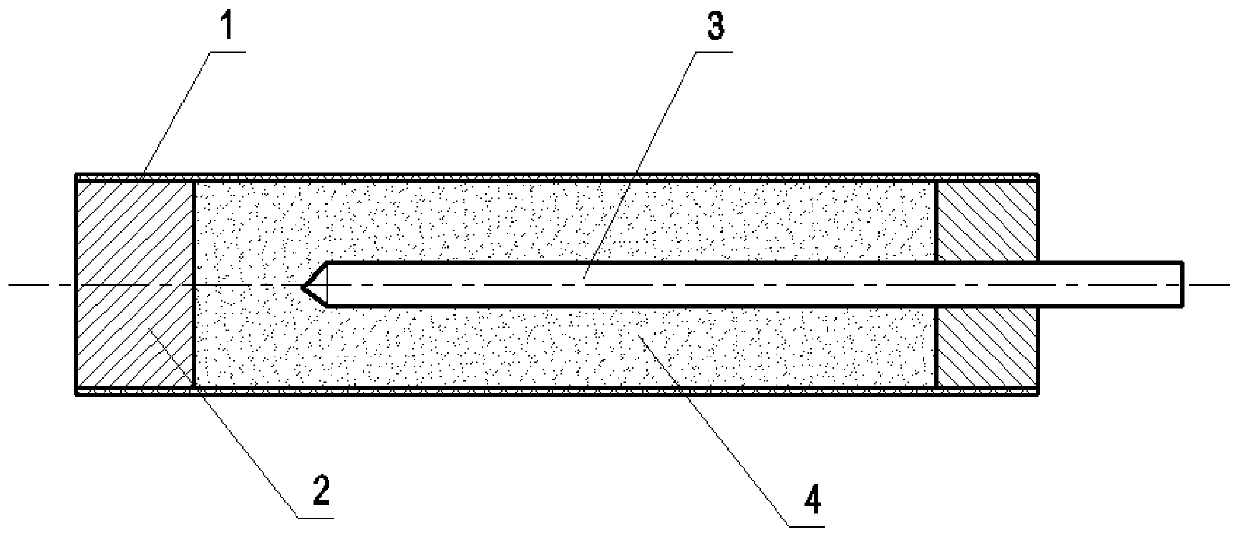

Machining method of capillary wick and assembly method of capillary wick and pipe casing

ActiveCN110303153ASolve the problem of high precision requirements for external dimensionsImprove capillary suctionTransportation and packagingIndirect heat exchangersLoop heat pipeMetal powder

The invention belongs to the technical field of evaporators of loop heat pipes, particularly relates to a machining method of a capillary wick and further discloses an assembly method of the capillarywick and a pipe casing. According to the machining method of the capillary wick, a binding agent is added to an existing metal powder material, a green body is prepared after isostatic compaction, channels are machined in the green body, and the capillary wick is prepared after sintering. According to the assembly method of the capillary wick and the pipe casing, the inner wall of the pipe casingis coated with paste containing the binding agent, so that an adhesive coating is formed; the capillary wick is inserted into the pipe casing, left to stay still until the capillary wick is dried andsintered at a high temperature, then the pipe casing and the capillary wick are closely adhered together, and the problem of high requirements for the accuracy of the overall size of the capillary wick in assembly manners in the prior art is solved; and additionally, the whole process has the advantages of simple machining manner, relatively short machining time and relatively low machining costs.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD +1

Turbine generator rotor assembly roundness measuring device

InactiveCN105135993ARaise the axisHigh precisionMechanical counters/curvatures measurementsMeasurement pointEngineering

The invention discloses a turbine generator rotor assembly roundness measuring device. A central rotating body is axially supported on the upper end face of a column, and radially rotates around the column. By adjusting the eccentric amount of an eccentric shaft, the central rotating body can be adjusted to be parallel to and coaxial with the axis of the column. By adjusting a top wire I, the horizontal rotating accuracy of a measuring arm around the column can be adjusted. By adjusting a top wire II, the rotating center of the measuring arm can be adjusted to be concentric with a rotor. A gauge stand can slide along a measuring rod, so that the device can accurately measure the roundness and the concentricity of measurement points of different heights and positions in a rotor assembly process. The turbine generator rotor assembly roundness measuring device provided by the invention has the advantages of simple structure, easy installation and debugging, high measuring accuracy, safe and reliable use and low cost. A universal, serialized and standardized product can be realized.

Owner:HARBIN ELECTRIC MASCH CO LTD

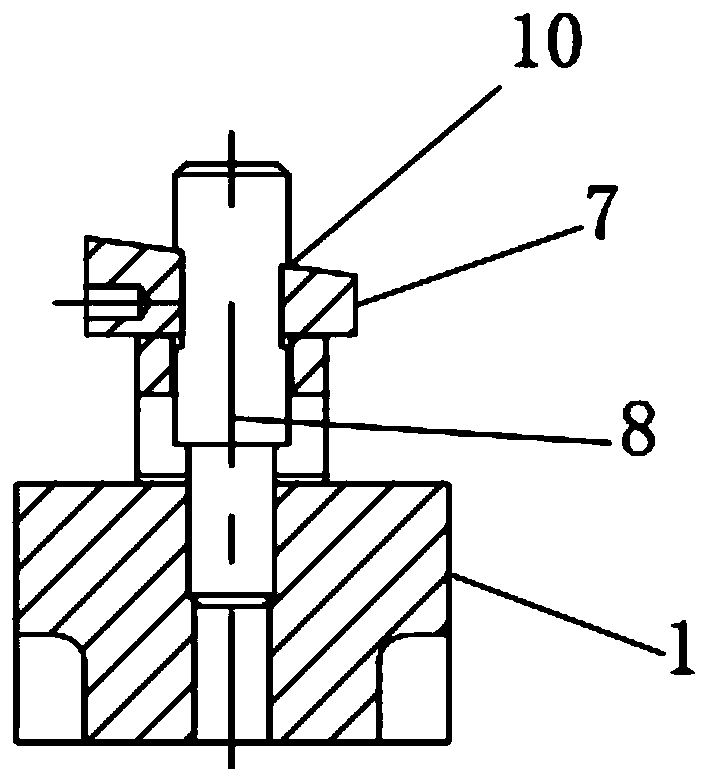

Non-flange shafts centring device

InactiveCN101021407AGuaranteed roundnessWarranty requirementsAngles/taper measurementsEngineeringSet distance

The checking center device without the flange axis includes the measure arm, the cutting sleeve, the installment bolt and the dial indicator. The cutting sleeve is made up of the crust and the inner cutting sleeve which is installed in the crust and fixed with it. The open mouth with ear plate fixed on both sides is set in the cutting sleeve. The screw is installed on the ear plate of one side which supports the other ear plate by the rotating installment screw, so the inner diameter of the cutting sleeve is made big. The cutting sleeve is two which are set on one end of the measuring arm in a setting distance; the dial indicator is installed in the other end of the arm. The invention has the simple structure. So the device can promise the round degree of every parts of the axis and the same axis degree.

Owner:BOHAI SHIP HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com