All-position welding fixture for steel wire rope ring

A welding tool and wire rope technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult processing and unstable quality of wire rope loops, and improve the quality of welding and ease of operation. , The effect of strong versatility and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

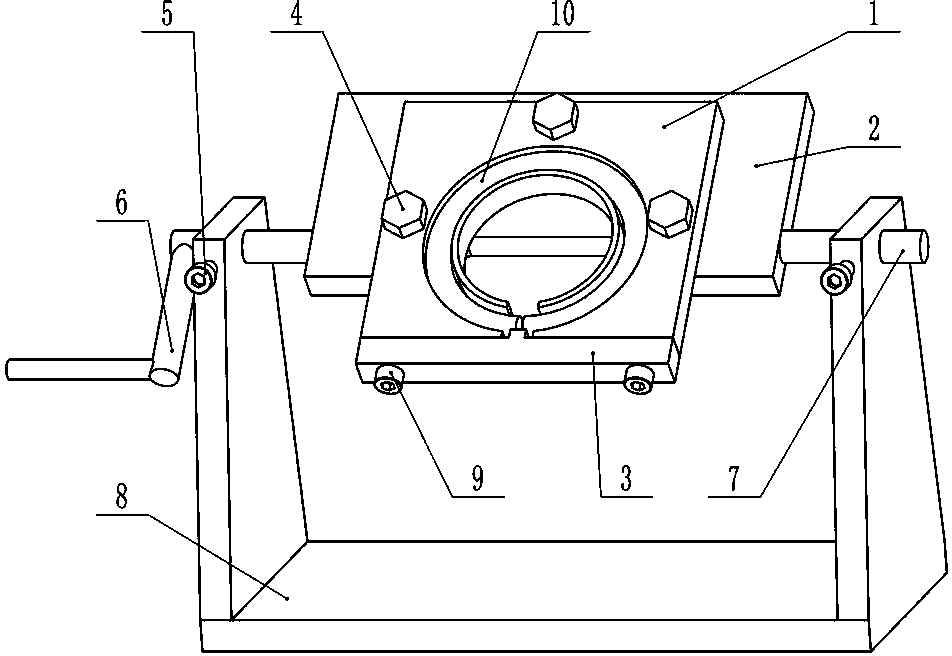

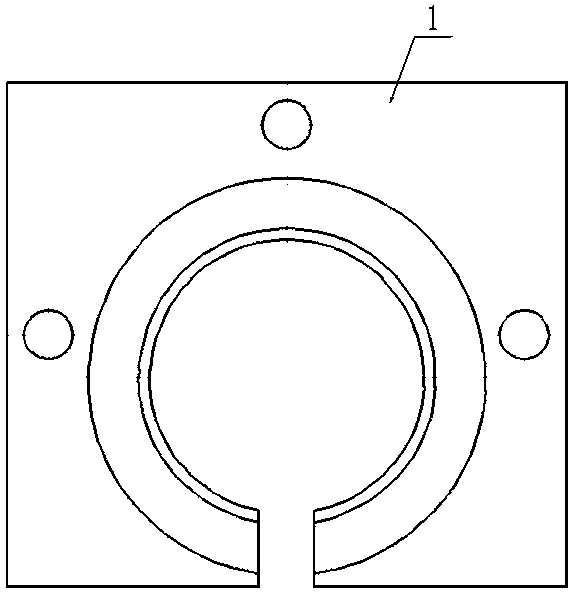

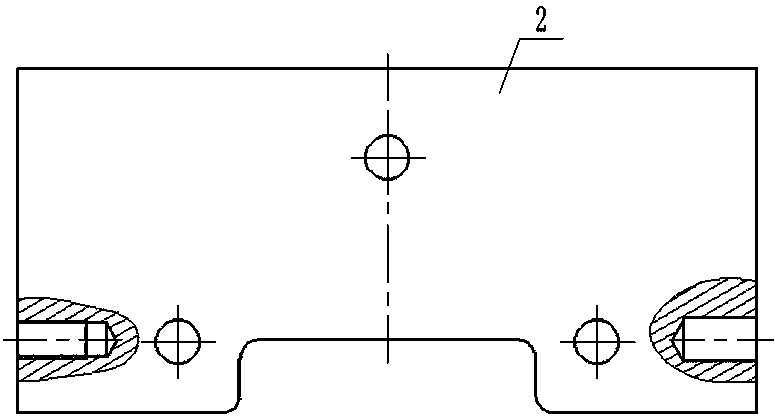

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an all-position steel wire rope ring welding tool includes a base 8, a vertical plate is provided at both ends of the base 8, a handle 6 is installed on one of the vertical plates, a threaded hole is provided at one end of the connecting block 2, and a handle 6 The handle rotation shaft is screwed into the threaded hole, so as to realize the fixed connection between the handle and one end of the connection block 2, and the other vertical plate is provided with a support shaft 7, and the other end of the connection block 2 is supported by the support shaft 7; on the connection block 2 A slot block 1 is fixedly connected with the bolt 4, the center of the slot block 1 is a through hole, and an annular groove is arranged around the through hole on the slot block 1, and the axis of the annular groove coincides with the axis of the through hole; The front end of the slot block 1 is provided with a through slot,...

Embodiment 2

[0052] Such as Figure 5 As shown, on the basis of Example 1, the two slot blocks are combined and installed in the front and rear directions to obtain a wire rope ring welding tool with multiple slot blocks, which can meet the needs of simultaneous processing of different types of wire rope ring welding tools . After the slot block 1 is increased, the height of the base vertical plate should also be increased correspondingly to meet the 360° full-position rotation of the slot block. Specifically, the slot block and the slot block are connected by bolts, and then fixed on the connection block. After the connection, the structural size of the entire tooling becomes larger correspondingly, but the number of wire rope rings to be processed at the same time increases, and the processing efficiency is improved. improve.

Embodiment 3

[0054] Such as Figure 6 , Figure 7 As shown, on the basis of Example 1, the two clamping groove blocks are combined and installed in the left and right directions to obtain another kind of steel wire rope ring welding tool with multiple clamping groove blocks to form a new steel wire rope ring welding tool, and the corresponding connecting block The length and structure of the joints should also be changed accordingly to achieve all-position welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com