Non-flange shafts centring device

A technology without flanges and shafts, applied in the direction of angle/taper measurement, etc., it can solve the problems of large measurement error, irregularity, vibration, etc., and achieve the effect of strong operability, simple structure, and guarantee of technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

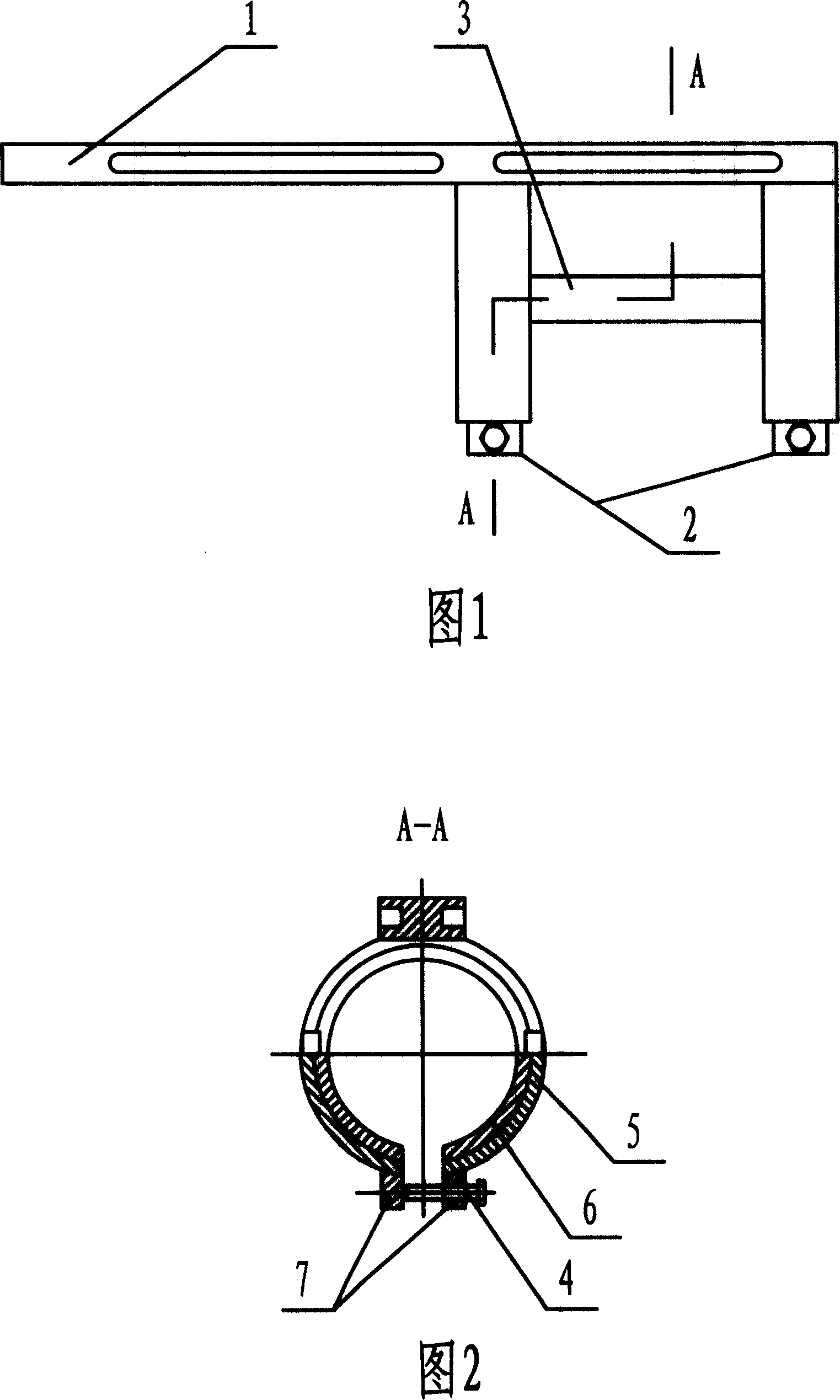

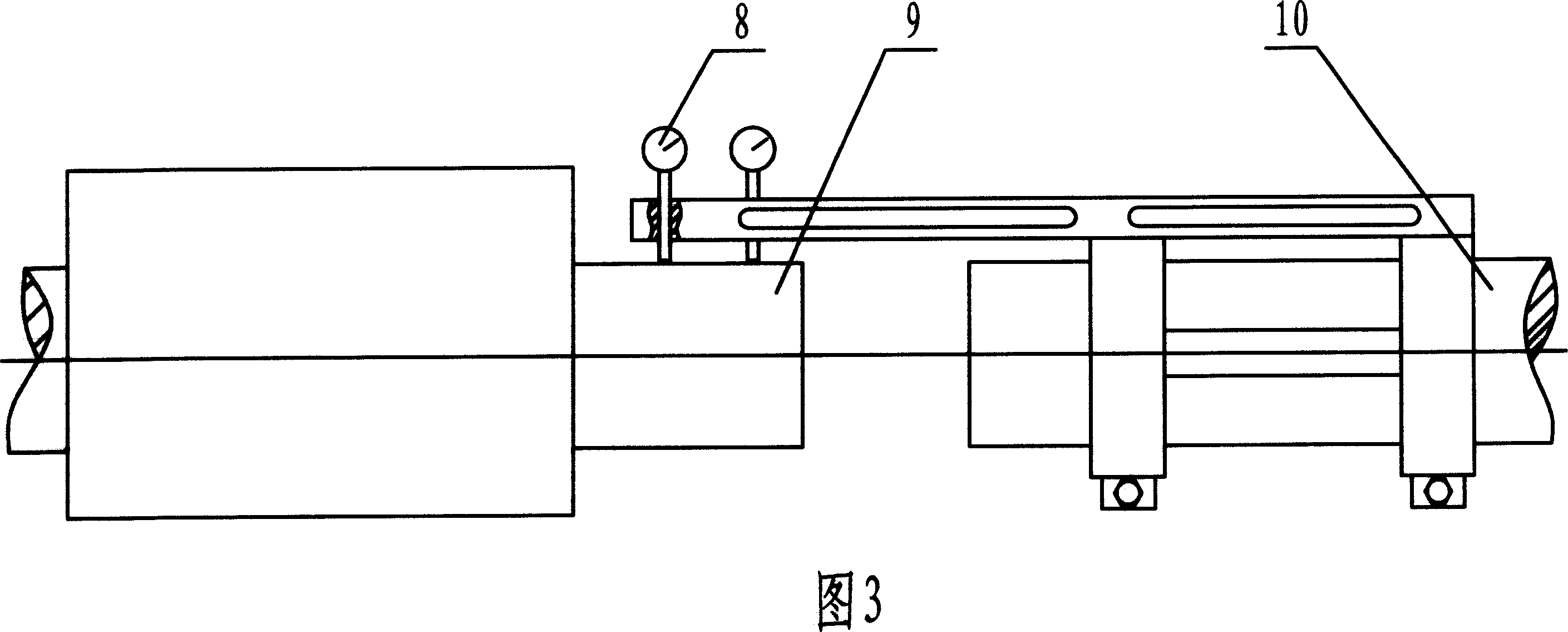

[0014] Shaftless alignment device without flange, including measuring arm 1, ferrule 2, mounting screw 4 and dial gauge 8. The measuring arm adopts the I-shaped steel structure, which not only ensures the strength, but also reduces its own weight, and also avoids the measurement error caused by the deformation of the measuring arm. The ferrule 2 is composed of the ferrule shell 5 and the inner ferrule 6. The inner ferrule 6 is made of H62 brass. Its purpose is to protect the surface of the shaft from damage. The ferrule 6 is installed in the ferrule shell 5 and fastened by screws. , the ferrule 2 is provided with an opening, on both sides of the opening is fixed with lug plate 7, the mounting screw 4 is mounted on the lug plate on one side of the opening, and the mounting screw 4 is rotated to make it abut against the lug plate on the other side of the opening. ear plate. There are two ferrules 2, which are respectively fixedly connected to one end of the measuring arm 1 at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com