Internal supporting type fixture for turning external circles of thin-wall parts and application of fixture

A technology of thin-walled parts and fixtures, which is applied in the field of CNC lathe machinery and equipment, can solve the problems of small rigidity of thin-walled parts, increase production costs, and large processing errors, and achieve large roundness errors, avoid secondary damage, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

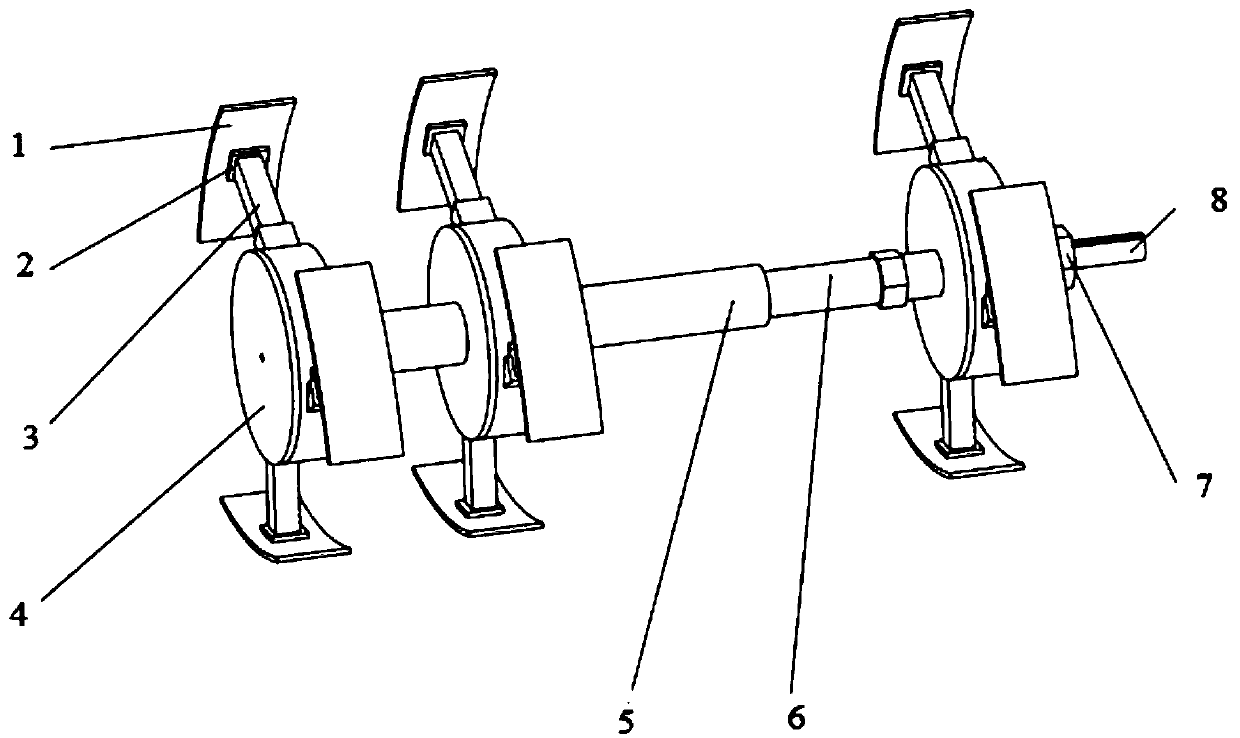

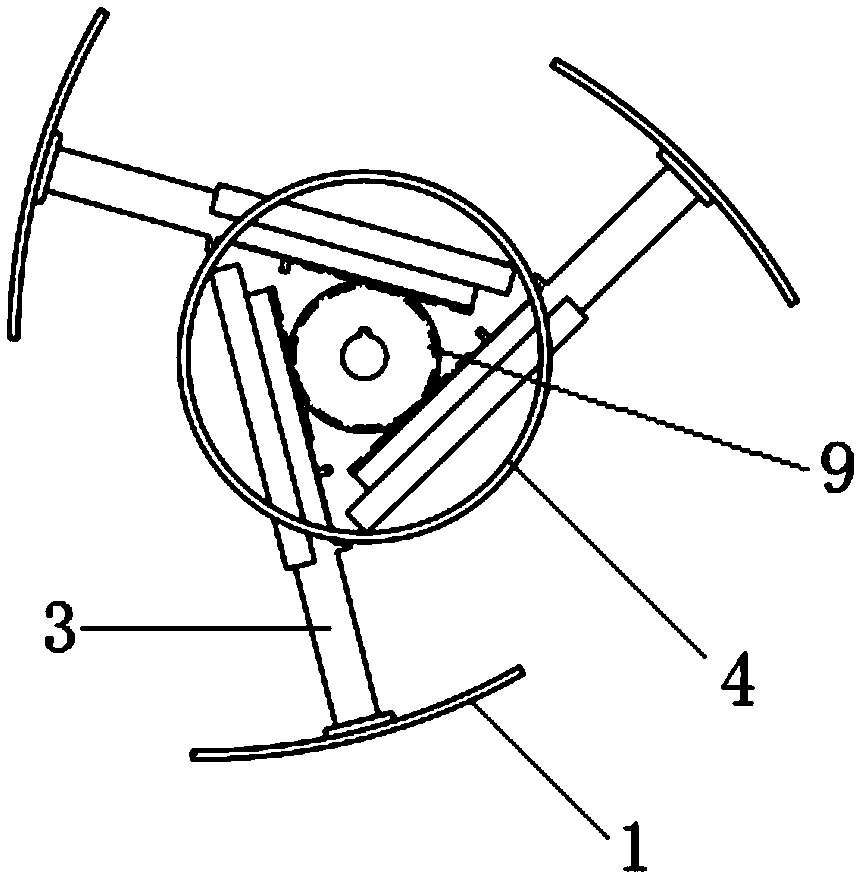

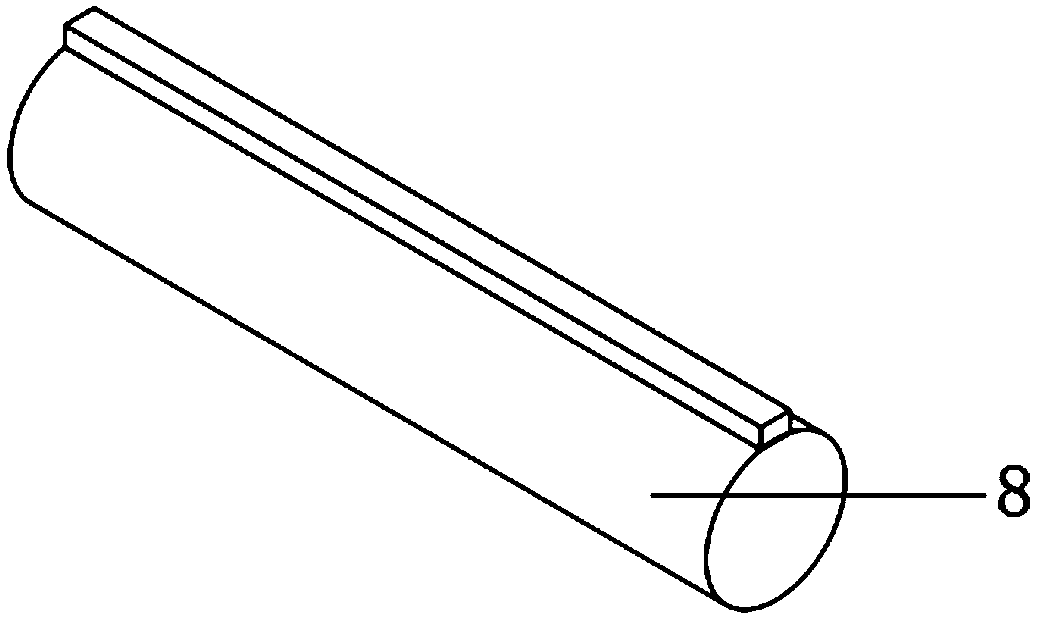

[0033] refer to Figure 1-11 , an inner support fixture for the outer circle of thin-walled parts, including 3 support units, the support units are connected by telescopic axial connection members, and the support unit includes support mounting plates 4, 3 A support plate 1 and a radially telescopic arm 3, a gear 9 is provided inside the supporter mounting plate 4, a rack is provided at one end of the radially telescopic arm 3, and one end of the radially telescopic arm 3 is inserted into the circumferential side of the supporter mounting plate 4 and The internal gear 9 meshes, and the other end is fixedly connected to the support plate 1. The length of the radial telescopic arm 3 is adjusted by inserting the rocker arm 8 of the support mounting plate 4, thereby controlling the support plate 1 to be supported on the inner wall of the thin-walled part. A reinforcement plate 2 is provided between the radially telescopic arm 3 and the support plate 1 . The axial connecting membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com