Pipe cutting system

A technology for a pipe cutting device and a steel pipe, which is applied in the field of pipe cutting systems and can solve the problems of difficulty in improving production efficiency, affecting the roundness of steel pipes, and complex structure of the pipe cutting device.

Active Publication Date: 2012-09-26

SHENZHEN CEMCN

View PDF5 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this method, the structure of the pipe cutting device is complicated, and the cutting time is too long, so it is difficult to improve the production efficiency, and it will also affect the roundness of the steel pipe.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

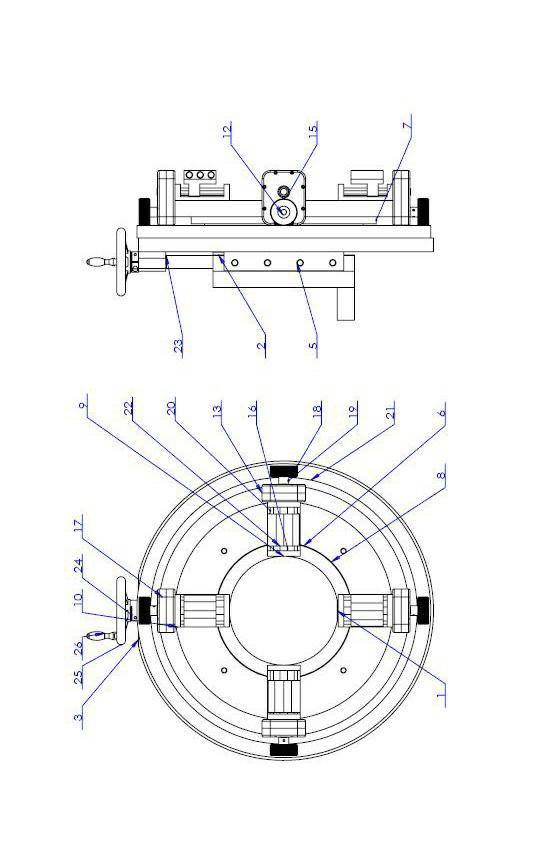

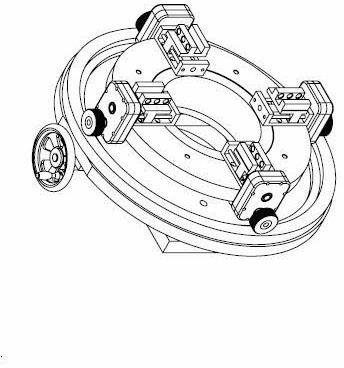

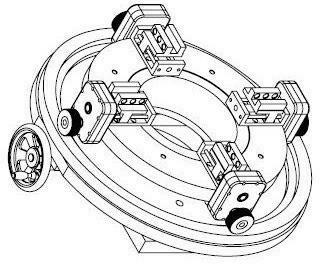

[0005] figure 2 3D drawing of the overall structure of the pipe cutting system

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a system for cutting off a steel pipe or a tubular object. The system mainly comprises an automatic storage loading cabin, a steel pipe conveying device, a multi-specification caliber pipe cutting device and an electrical control system, and is mainly characterized in that the automatic storage loading cabin is connected to the steel pipe conveying device and then is connected to the multi-specification caliber pipe cutting device, and the whole machining process is fully automatically performed under the control action of the electrical control system. Four cutting tools are arranged on unfolding and folding nuts of a screw rod respectively, and the screw rod is driven to rotate through a friction wheel in the process of rotating a rotary cutter plate rack so as to feed the cutting tools. The four cutting tools are used for circumferentially cutting the steel pipe in a laminated mode, so that the roundness of the steel pipe is ensured, and the cutting efficiency is improved.

Description

technical field [0001] The invention is a system for cutting steel pipes or tubular objects, mainly used in steel pipes or tubular workpiece cutting processing equipment, and is a complete set of devices from storage and feeding of steel pipes, pipe cutting and feeding to completion of pipe cutting. Background technique [0002] In the current large-diameter pipe cutting devices, most of the systems use a rotating blade to cut a small opening smaller than the diameter of the rotating blade on one side of the steel pipe when cutting the pipe, and then rotate the steel pipe for a circle. The steel pipe is gradually cut off. In this method, while the structure of the pipe cutting device is complicated, the cutting time is too long, the production efficiency is difficult to be improved, and the roundness of the steel pipe is also affected. Contents of the invention [0003] The purpose of the present invention is to adopt the most reasonable structure to realize fast and effi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23D21/04B23D35/00B23D33/04

Inventor 不公告发明人

Owner SHENZHEN CEMCN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com