Turning tool for machining inner hole of thin-wall part

A technology of thin-walled parts and inner holes, which is applied in the direction of metal processing machinery parts, metal processing equipment, positioning devices, etc., can solve the problems that the roundness of the inner holes of thin-walled parts is difficult to be guaranteed and easily deformed, and is easy to implement, The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

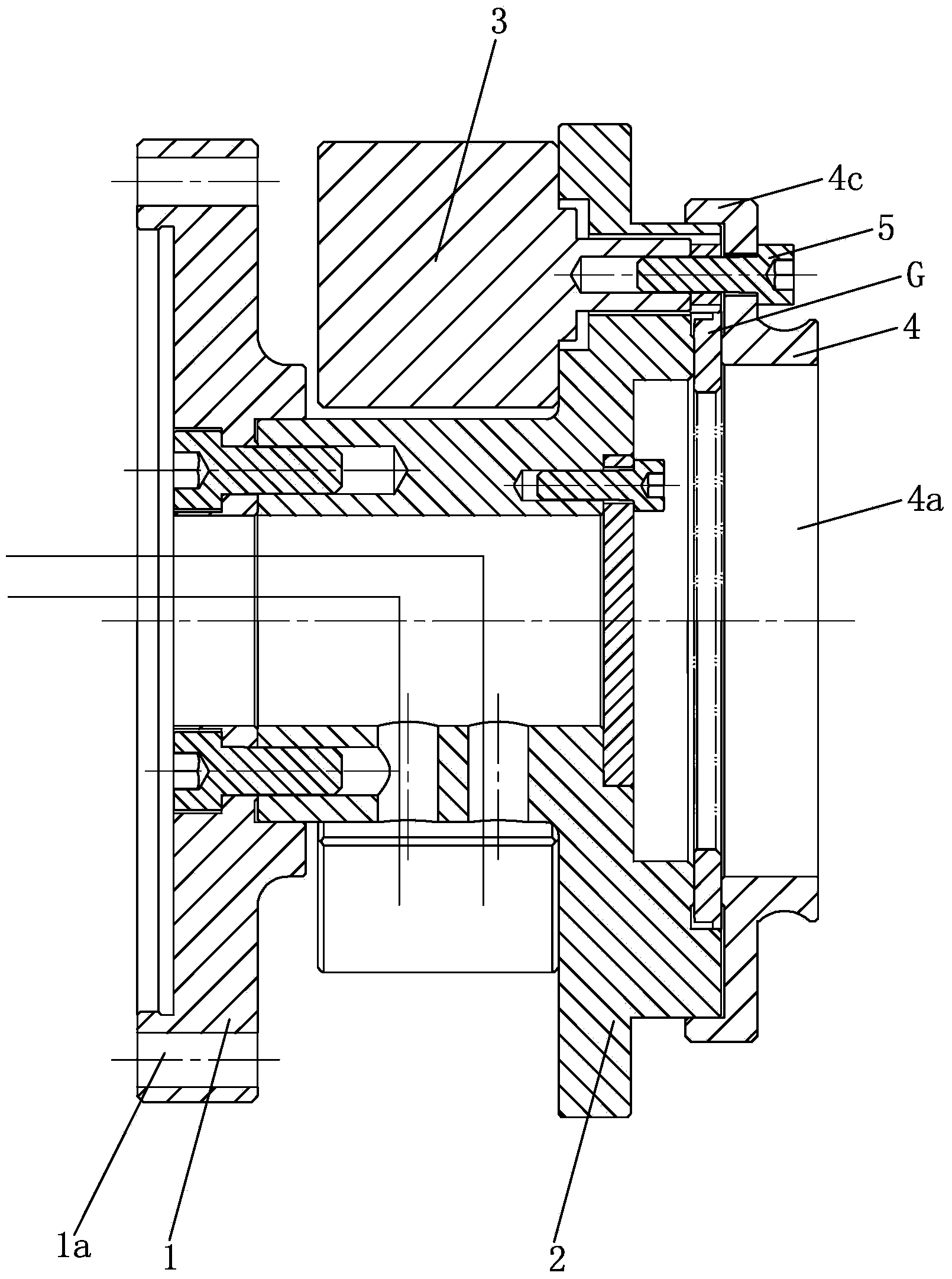

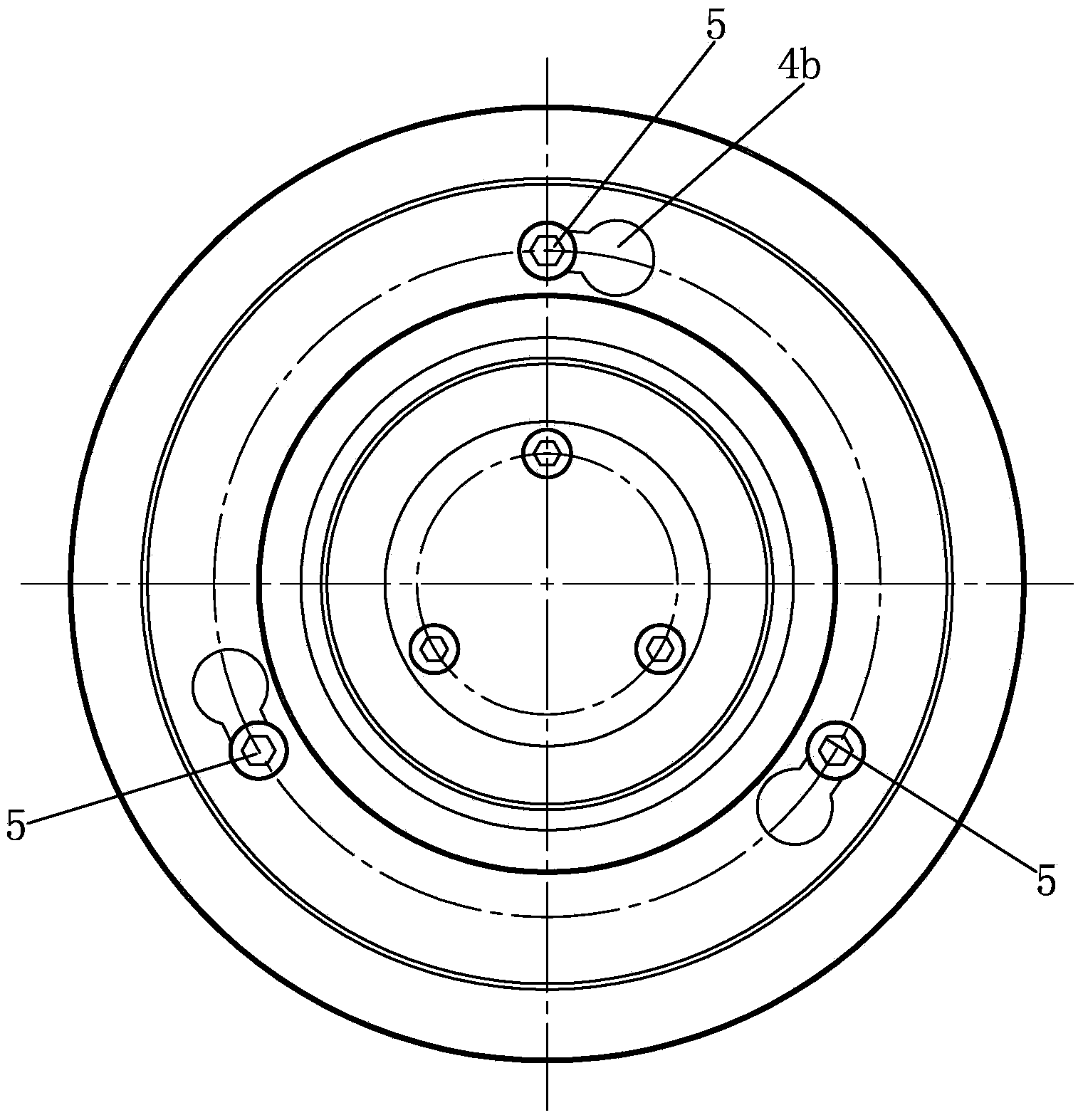

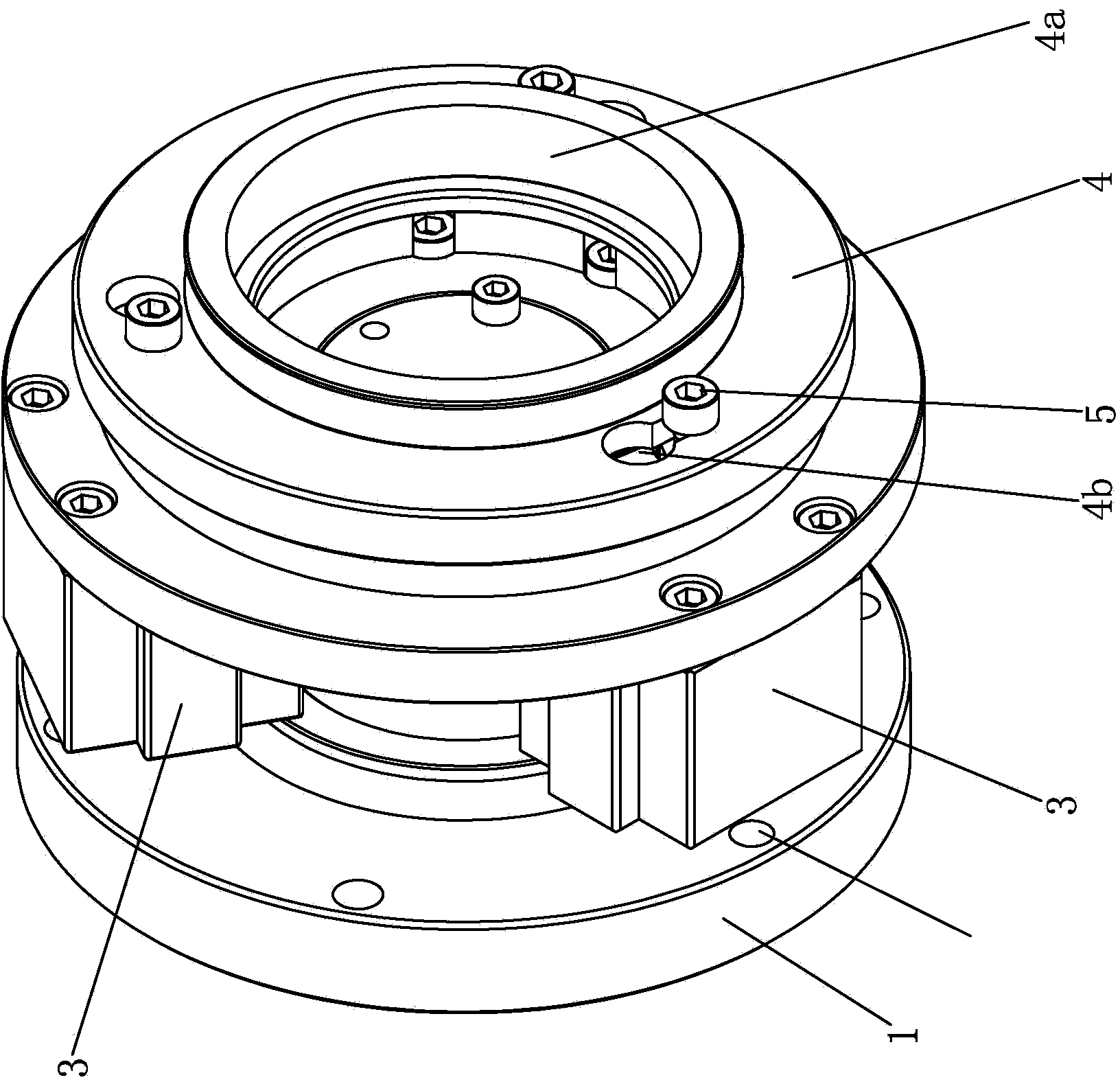

[0018] Such as figure 1 , 2 And shown in 3, a kind of vehicle tooling that is used to process the inner hole of thin-walled part, mainly is made of connecting plate 1, positioning plate 2, cylinder 3, pressure plate 4 and connecting screw 5 etc. Wherein, the diameter of the left part of the connecting plate 1 is greater than the diameter of the right part, and bolt through holes 1a are uniformly distributed along the circumferential direction on the disc portion on the left side of the connecting plate 1, and the axis line of the bolt through hole 1a is connected with the connecting plate. 1 axis parallel to each other.

[0019] The axis line of the connecting plate 1 and the axis line of the positioning plate 2 are on the same straight line, the right part of the connecting plate 1 and the left part of the positioning plate 2 are fixedly connected by screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com