Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "High retention performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

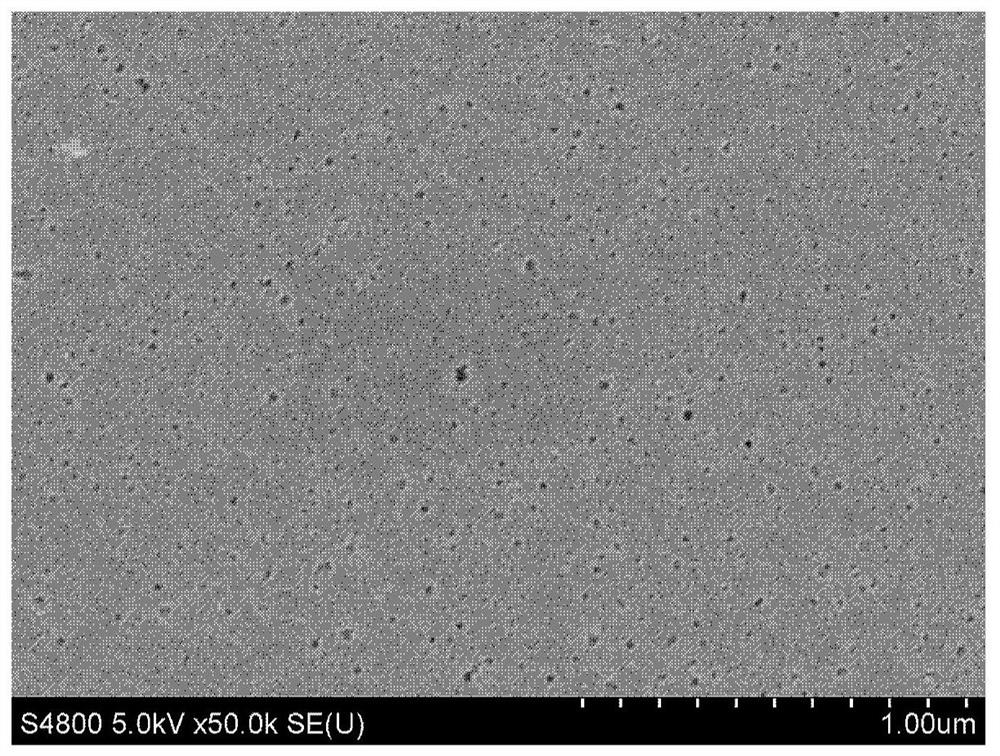

Preparation method of nano tio2 modified pvdf ultrafiltration membrane

InactiveCN102294180AImprove hydrophilicityExtended service lifeSemi-permeable membranesHydrophilic monomerUltrafiltration

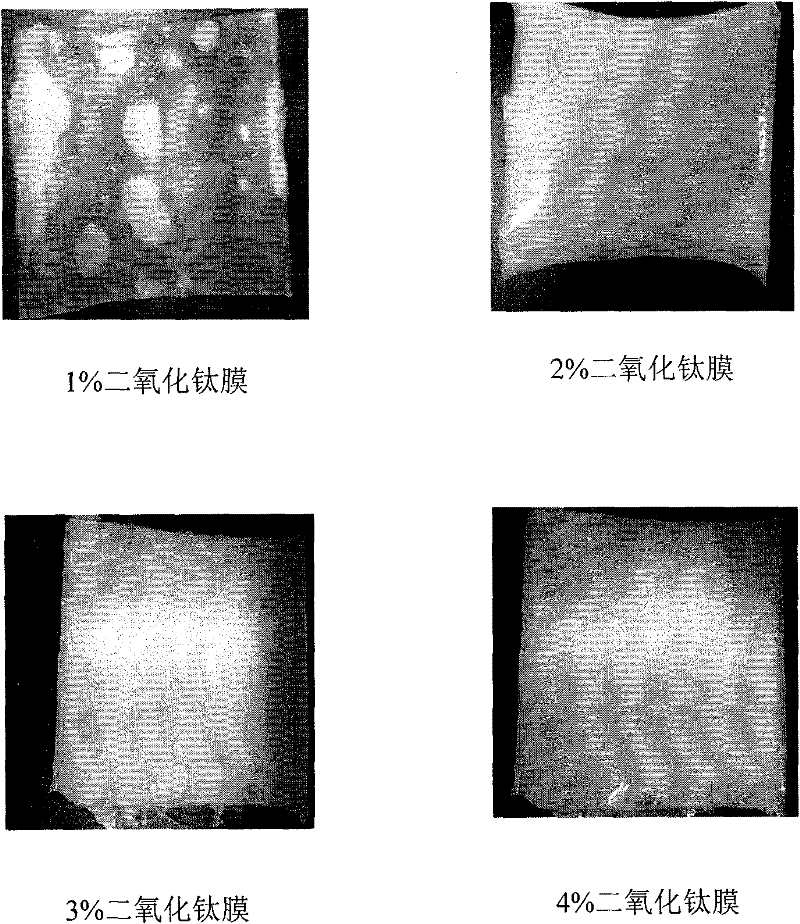

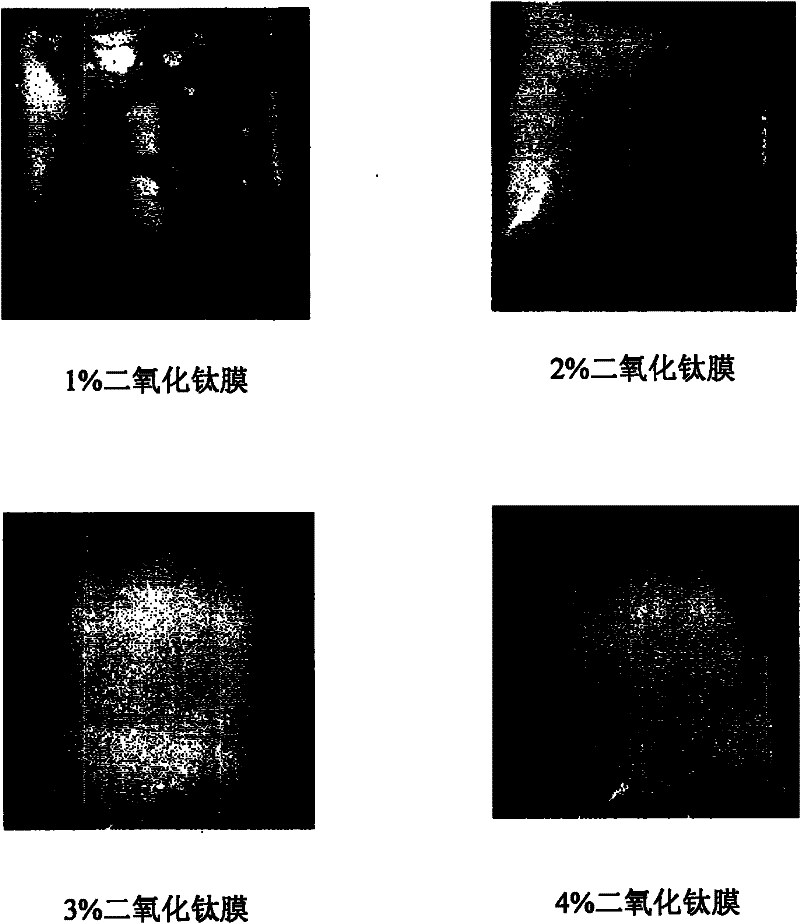

The invention relates to a preparation method of a nano TiO2-modified PVDF (Polyvinylidene Fluoride) ultrafiltration membrane. The preparation method comprises the following steps of: preparing a membrane making liquid from 15-20 percent by mass of PVDF, 1-3 percent of pore-foaming agent, 1-4 percent of nano TiO2, 3-5 percent of surfactant and 70-80 percent of solvent, ultrasonically oscillating the membrane making liquid for 5-10 minutes, leaching and defoaming; scraping with a membrane scraping machine to form a liquid membrane, standing in the air for 20-60 seconds, soaking into a coagulation bath and coagulating the liquid membrane into an ultrafiltration membrane; and after the ultrafiltration membrane falls off, taking the ultrafiltration membrane out, soaking into distilled water and cutting according to required size for later use. A nano TiO2 hydrophilic monomer is arranged on the surface of the PVDF ultrafiltration membrane, sodium dodecyl sulfate serving as a surfactant is used simultaneously, and dispersion is performed by ultrasonically oscillating, so that agglomeration of nano TiO2 is reduced, nano TiO2 is quickly and uniformly distributed into the membrane making liquid, the hydrophilicity of the PVDF ultrafiltration membrane is enhanced effectively, the energy consumption is enhanced greatly, the anti-pollution capacity and pollutant intercepting performance of the membrane are enhanced, and the service life of the membrane is prolonged.

Owner:ZHEJIANG OCEAN UNIV

Crosslinked alginate-bacterial cellulose sponge and preparation method thereof

ActiveCN103536954AImprove mechanical propertiesSimple structureAbsorbent padsBandagesPolymer scienceFreeze-drying

The invention relates to the field of a biomedical material, and particularly discloses a crosslinked alginate-bacterial cellulose sponge and a preparation method thereof. The crosslinked alginate-bacterial cellulose sponge takes an alginate biomaterial and bacterial cellulose as raw materials. The crosslinked alginate-bacterial cellulose sponge is characterized in that a sponge product is prepared from the alginate biomaterial and the bacterial cellulose in manners of crosslinking and freeze-drying after being compounded, wherein the alginate biomaterial accounts for 80-95% of the sponge product in mass fraction; the bacterial cellulose accounts for 5-20% of the sponge product in mass fraction. The crosslinked alginate-bacterial cellulose sponge is abundant in used material sources, low in cost, controllable to process, and simple in production technology; the prepared crosslinked alginate-bacterial cellulose sponge has good mechanical property, liquid absorption property, water retention capacity and air permeability, and is applicable to bleeding healing of large seepage or a bleeding wound.

Owner:山东颐诺生物科技有限公司

A tread rubber compound with good cut and tear resistance and low dynamic heat generation

The invention discloses tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation. Natural rubber, which serves as a main material, and butadiene styrene rubber, intermediate and super wear-resisting carbon black, anti-crack resin, a multifunctional vulcanizing active agent and an anti-vulcanizing reversion agent, which serve as main auxiliary materials, areblended in an internal mixer to manufacture blended rubber, and the blended rubber is formed into a tread semi-finished product in a mode of extrusion by an extruder. The rubber has the advantages ofhigh tensile strength, high tearing strength, high stretching stress, high cutting resistant performance, low dynamic heat generation, high stability, high wear-resisting property and high anti-flexure crack performance. By using tires with the tread rubber, dumpers can be used on sharp ore road surfaces at a high speed, and the service life of the tires is long.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

High temperature and high humidity resistant polycarbonate composition and preparation method thereof

The invention discloses a high temperature and high humidity resistant polycarbonate composition. In terms of a total of 100 weight parts, the raw materials include: 65-95 parts of polycarbonate; 0-20parts of a reinforcing component; 2-6 parts of a flame retardant; 0.2-0.5 part of an anti-dripping agent; 2-5 parts of a toughening agent; 0.2-1 part of a chain extender; and 0.1-2.5 parts of other additives. The toughening agent is selected from an organosilicon toughening agent, and the chain extender is selected from an oxazolinyl chain extender. The invention provides the high temperature andhigh humidity resistant polycarbonate composition, the prepared polycarbonate has excellent high temperature and high humidity resistance, and still has very high performance retention rate after 1000h of "double 85" (a humidity of 85% and a temperature of 85DEG C) hydrothermal aging, and can be applied to airtight basements and other occasions with high temperature and high humidity resistance requirements.

Owner:CGN JUNER NEW MATERIALS +1

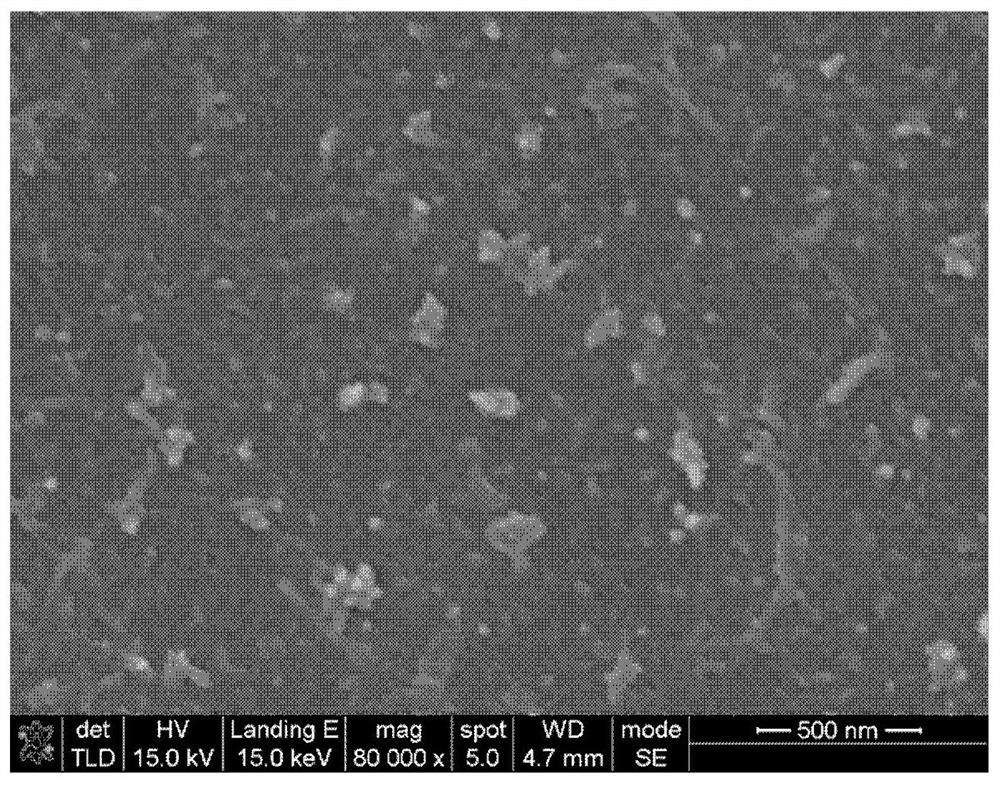

Method for preparing loose nanofiltration membrane based on interfacial polymerization

ActiveCN110180402AImprove hydrophilicityImprove structural stabilitySemi-permeable membranesMembranesNanoparticlePolyamide

The invention discloses a method for preparing a loose nanofiltration membrane based on interfacial polymerization. The method comprises the following steps: preparing a polymer casting solution, dispersing nanoparticles in an aqueous phase monomer and an oil phase monomer, and preparing a flat plate support membrane; immersing the flat plate support membrane in the water phase monomer, then pouring the oil phase monomer into the aqueous phase monomer, and loading a nano membrane onto the surface of the flat plate support membrane after the two phase monomers are subjected to an interfacial polymerization reaction. The composite nanofiltration membrane prepared by the method has a loose structure on the surface; nano materials are embedded into a polyamide nano thin layer during the interfacial polymerization reaction; on the one hand, the hydrophilicity of the surface of the membrane can be improved; on the other hand, in the process of polycondensation, polyamide is simultaneously grown around the materials in the direction perpendicular to the nano materials to form such a sandwich structure; upper and lower polyamide layers can protect the nano materials from being damaged under high operating pressure; the structure of the polyamide nano membrane is regulated; meanwhile, the structural stability, permeability and retention property of the nanofiltration membrane are improved.

Owner:TSINGHUA UNIV

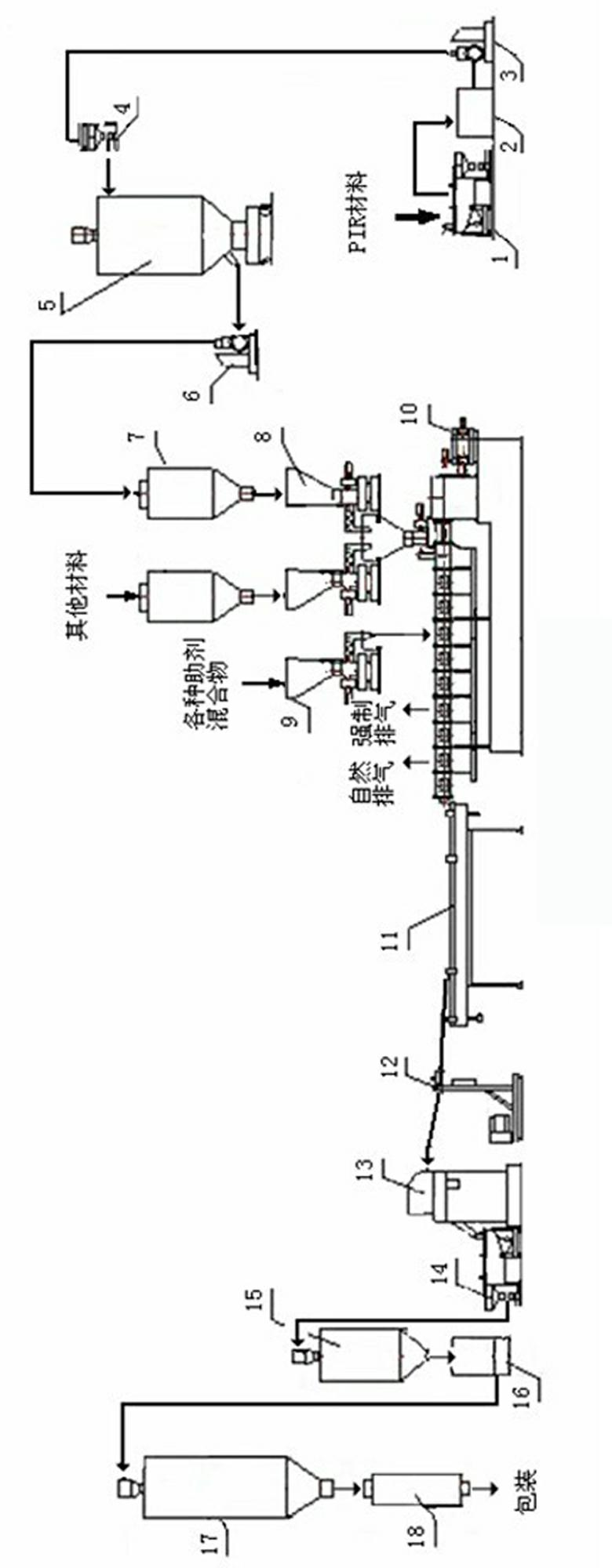

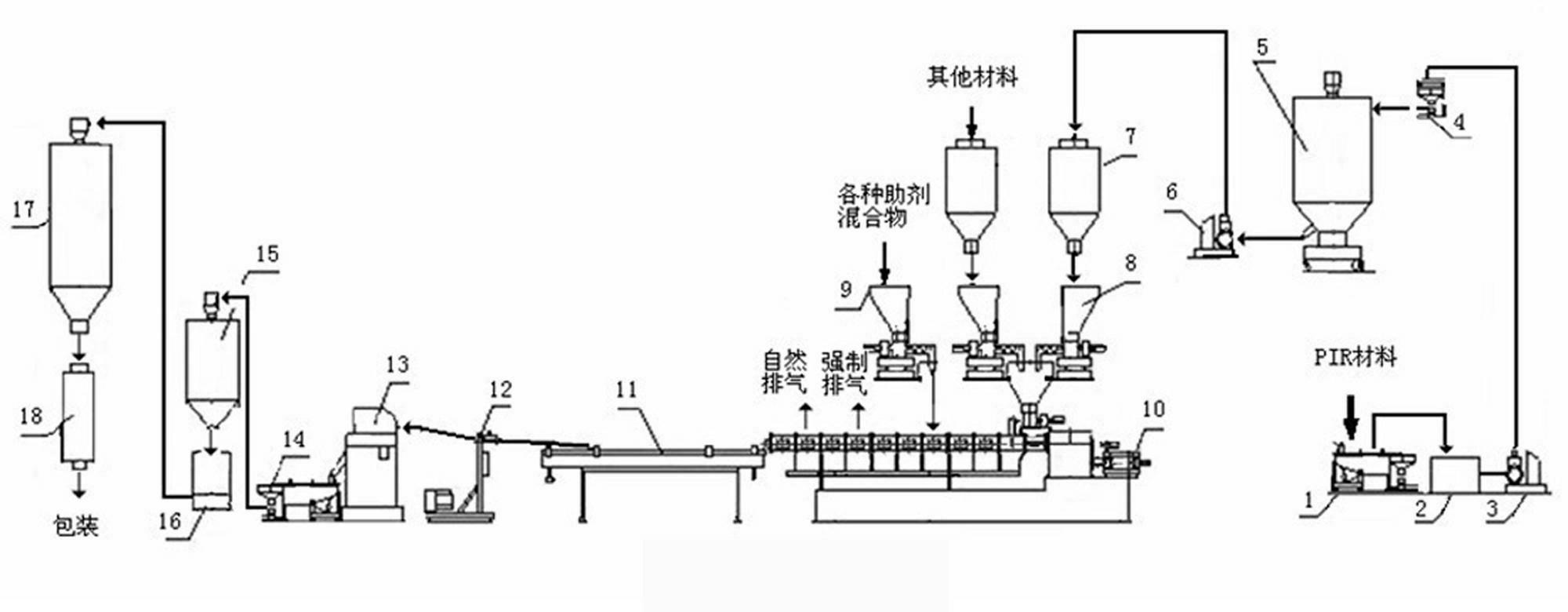

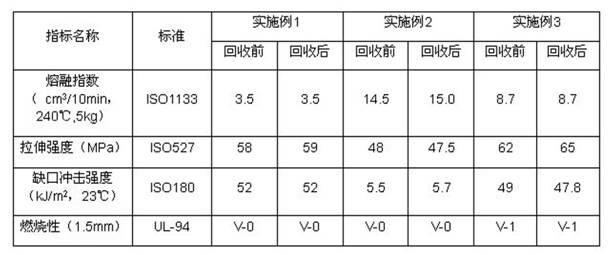

Method for recycling post-industrial recycling waste plastic

ActiveCN102581986AAvoid performance degradationThe process method is compact and completePlastic recyclingMechanical material recoveryPlasticultureProcess engineering

The invention discloses a method for recycling a post-industrial recycling waste plastic, which is mainly used for recycling wastes such as gate materials, leftover materials, imperfect products and outmoded products in the production machining process of manufacturing a plastic product. The method provided by the invention comprises the following steps of: primary separation of a vibration screen, secondary separation of a metal separator, drying of a hot drier, blending, granulation and post-treatment of a full-engaged homonymous dual-screw extruder. With the adoption of the method disclosed by the invention, the problem of bad properties of a recycled material, caused by the traditional recycling manner, can be better avoided, the process method is compact and complete, and the continuous operation can be realized. The blending and plastification process can be completed by using the full-engaged homonymous dual-screw extruder with small cutting force and high exhaust effects, so that the problem that the waste plastic is easy to degrade during a fusion and plastification process is solved. Therefore, the recycled material product has a very high property retention rate.

Owner:大河宝利材料科技(苏州)有限公司

Covalent organic framework membrane with high rejection rate as well as raw material composition and preparation method thereof

ActiveCN112808006AHigh permeation fluxImprove long-term stabilitySemi-permeable membranesMembranesPolymer scienceOrganic solvent

The invention relates to a covalent organic framework membrane with high rejection rate as well as raw material composition and preparation method thereof. The raw material composition comprises a water-phase monomer solution, an organic-phase monomer solution and a modified solution, the water-phase monomer solution comprises 0.01-2% by mass of a water-phase monomer, an acid regulator and the balance of water, wherein the water-phase monomer is selected from one or more of diamine or polyamine; the organic phase monomer solution comprises 0.01-2% by mass of an organic phase monomer and the balance of an organic solvent, and the organic phase monomer is selected from one or more of dialdehyde or polyaldehyde; the modifying solution comprises a modifying agent with the mass fraction of 0.01-5%, an oxidizing agent with the mass fraction of 0.01-3%, an acid-base regulator and the balance of water, wherein the modifying agent is selected from one or more of arylamine, heterocyclic amine or polyphenol. The covalent organic framework membrane provided by the invention improves the interception performance on small molecules, and has large permeation flux and good long-term operation stability.

Owner:TIANJIN UNIV

Intermediate-high temperature acid-corrosion-resisting glass fiber treating compound and preparation method thereof

InactiveCN103964708AImprove temperature and weather resistanceGood adhesive properties and thermal stabilityPrepolymerEmulsion

The invention relates to an intermediate-high temperature acid-corrosion-resisting glass fiber treating compound and a preparation method thereof. The method comprises the following steps: putting bisphenol-A epoxy resin and benzoyl peroxide into a flask, and carrying out stirring and rising temperature; then dropwise adding methacrylic acid, and preserving heat; cooling the obtained product, adding paraxylene and dibutyltin dilaurate to continue to stir, dropwise adding vinyltriethoxysilane, and preserving heat to obtain a pale yellow modified epoxy resin prepolymer; adding deionized water and emulsifier into the flask, and then carrying out full stirring and heating for dissolving; adding the modified epoxy resin prepolymer slowly, and continuing to stir after dropwise adding; rapidly cooling the obtained film former emulsion to room temperature, then mixing the film former emulsion, a coupling agent, nanosilicon dioxide, a lubricating agent and an antistatic agent so as to obtain the glass fiber treating compound. The method has the benefit that the temperature resistance of a film former is improved. The treating compound can improve the performance retention rate of glass fiber reinforced plastics materials under the intermediate-high temperature acidic condition.

Owner:WUHAN UNIV OF TECH

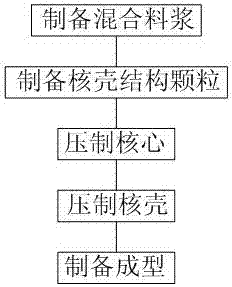

Rapid preparation process of inert dispersion fuel pellet

ActiveCN106971764AGood sphericityControllable thicknessNuclear energy generationReactors manufacturePrillVolume fraction

The invention discloses a rapid preparation process of an inert dispersion fuel pellet. The rapid preparation process comprises the five steps of preparation of mixed material slurry, preparation of core-shell structure particles, core pressing, core-shell pressing and preparation forming. The preparation process overcomes the shortcomings of an existing inert dispersion fuel pellet preparation method, and the inert dispersion fuel pellet high in TRISO particle content, good in particle integrity, uniform in dispersion and high in silicon carbide matrix compactness can be obtained within a shorter process period. In the prepared inert dispersion fuel pellet, the silicon carbide matrix compactness is up to 92% or above, and the volume fraction content of TRISO particles in whole fuel is 30%-45%.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

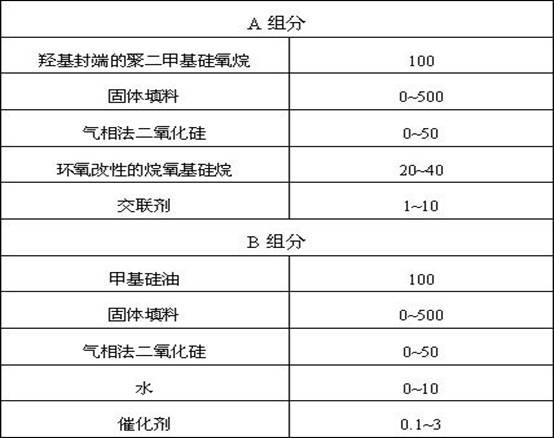

Epoxy resin modified two-component silicone rubber adhesive

InactiveCN102504755AGood adhesionHigh retention performanceNon-macromolecular adhesive additivesEpoxyPolymer science

The invention is an epoxy resin modified two-component silicone rubber adhesive which comprises an A component and a B component; the composition of the A component and the B component by weight are as follows: the A component comprises 100 parts of polydimethylsiloxane terminiated by hydroxyl, 0-500 parts of solid fillers, 0-50 parts of gas-phase method silica, and 0-5 parts of water; the B component comprises 50-100 parts of epoxy modified alkoxy silane, 0-100 parts of methyl silicone oil, 10-80 parts of cross-linking agents, 0-300 parts of solid fillers, 0-30 parts of gas-phase method silica, and 0.1-3 parts of catalysts. The adhesive of the invention combines the high bonding force of epoxy resin with the high-temperature and high weather resistance of silicone rubber; the curing speed meets the production rhythm of solar cell modules, and has very good bonding effect and an excellent performance conservation rate for the modules; in industries of household appliances, automobile, and the like, the advantage of satisfiability of rapid production rhythm is brought into play.

Owner:TONSAN ADHESIVES INC

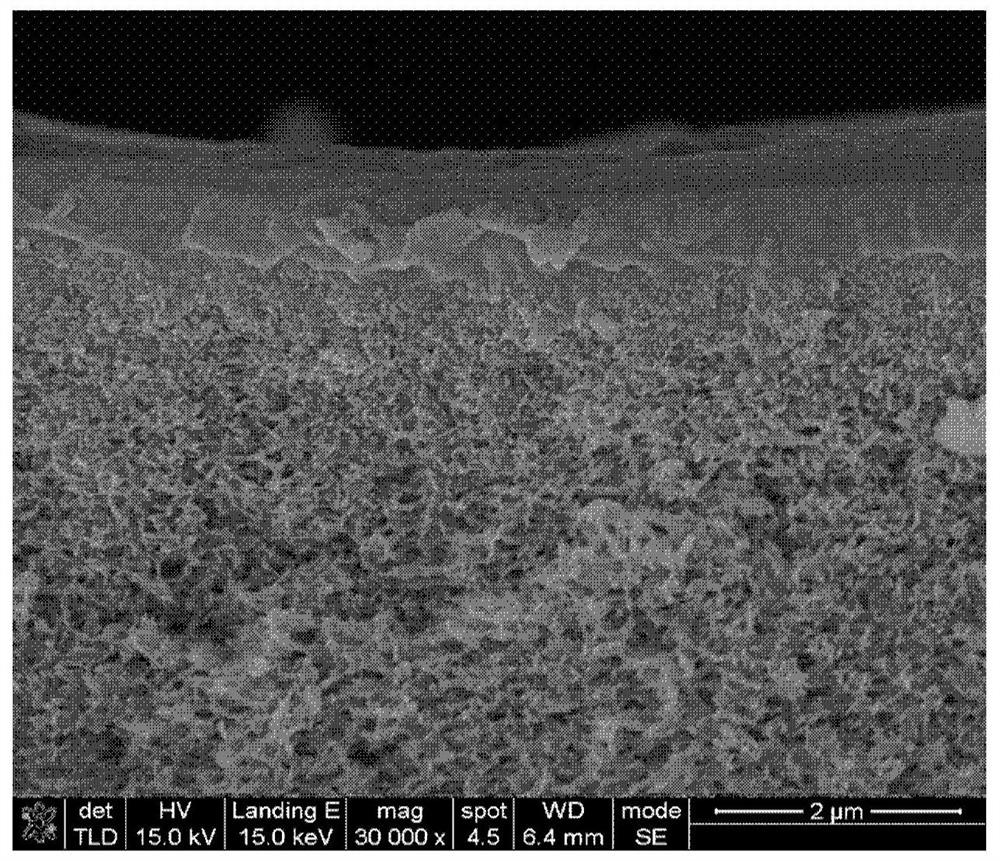

Preparation method of dispersion fuel pellet with high uranium loading capacity

ActiveCN108335760AHigh thermal conductivityHigh retention performanceNuclear energy generationReactor fuel susbtancesCore shellMaterials science

The invention discloses a preparation method of a dispersion fuel pellet with high uranium loading capacity, which comprises the steps of firstly adopting means such as pelleting, self-grinding balling and rolling coating to realize the balling of a uranium-based fuel and the coating with a reinforcing phase, then performing high temperature plasma sintering on a coated ball to obtain the uranium-based fuel pellet; forming a large amount of pores in a core pellet of the fuel by utilizing the volatilization of a pore-forming agent under high temperature, then promoting the low-temperature rapiddensification sintering of the reinforcing phase by combining the high temperature plasma sintering technology and a sintering aid, thus obtaining the dispersion fuel pellet with high uranium loadingcapacity, wherein the dispersion fuel pellet has a special core-shell structure in which the compact reinforcing phase coats the porous fuel core pellet, and the special core-shell structure is loosein the interior and compact in the exterior. The method has the advantages that the preparation is simple and the preparation cost is low, can be used for the scale production of the uranium-based fuel pellet; the uranium-based fuel pellet prepared by the method has the advantages of high thermal conductivity, high safety, high uranium loading capacity and high economy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

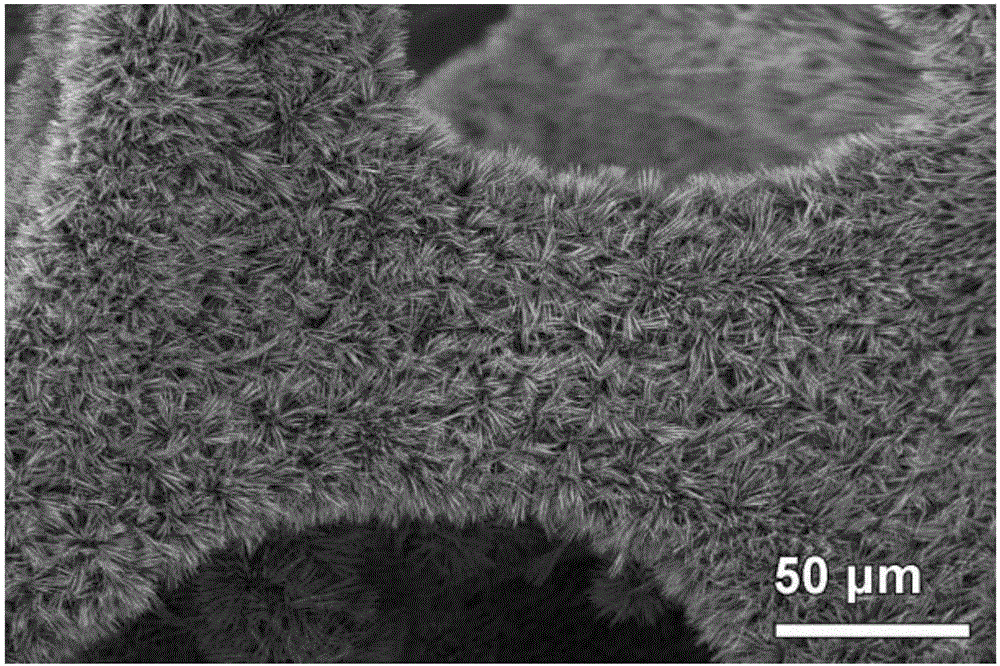

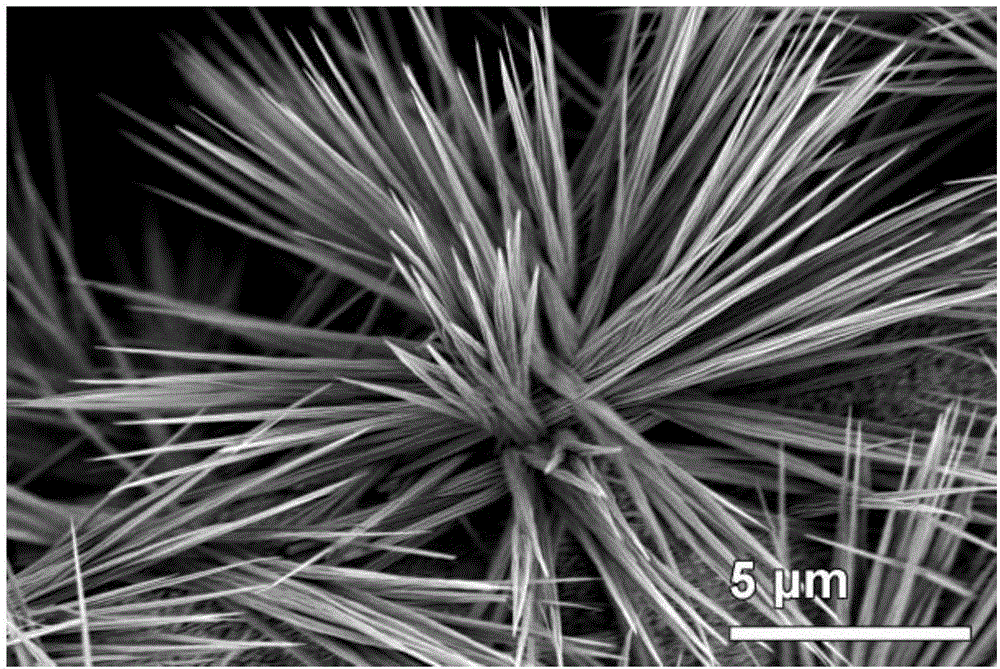

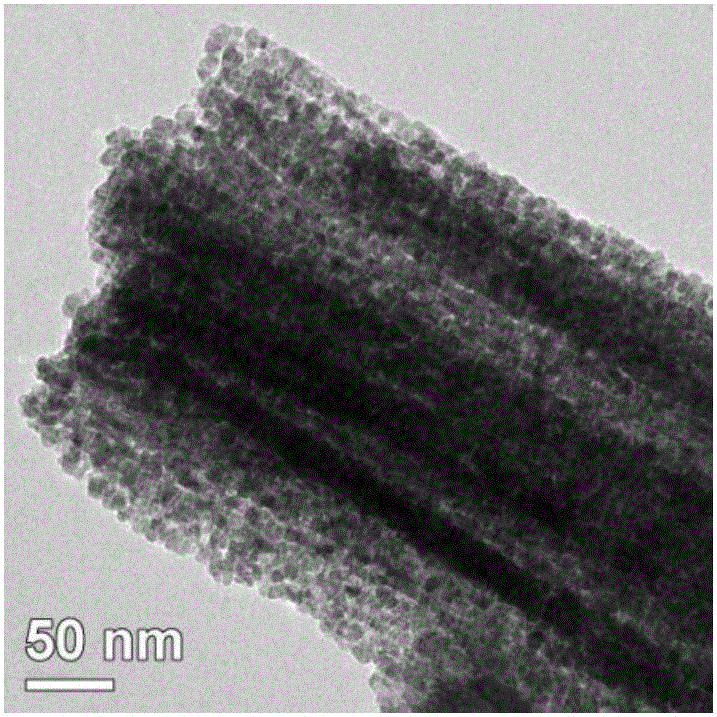

Foam copper-supported porous copper oxide nanowire composite material and preparation method and application thereof

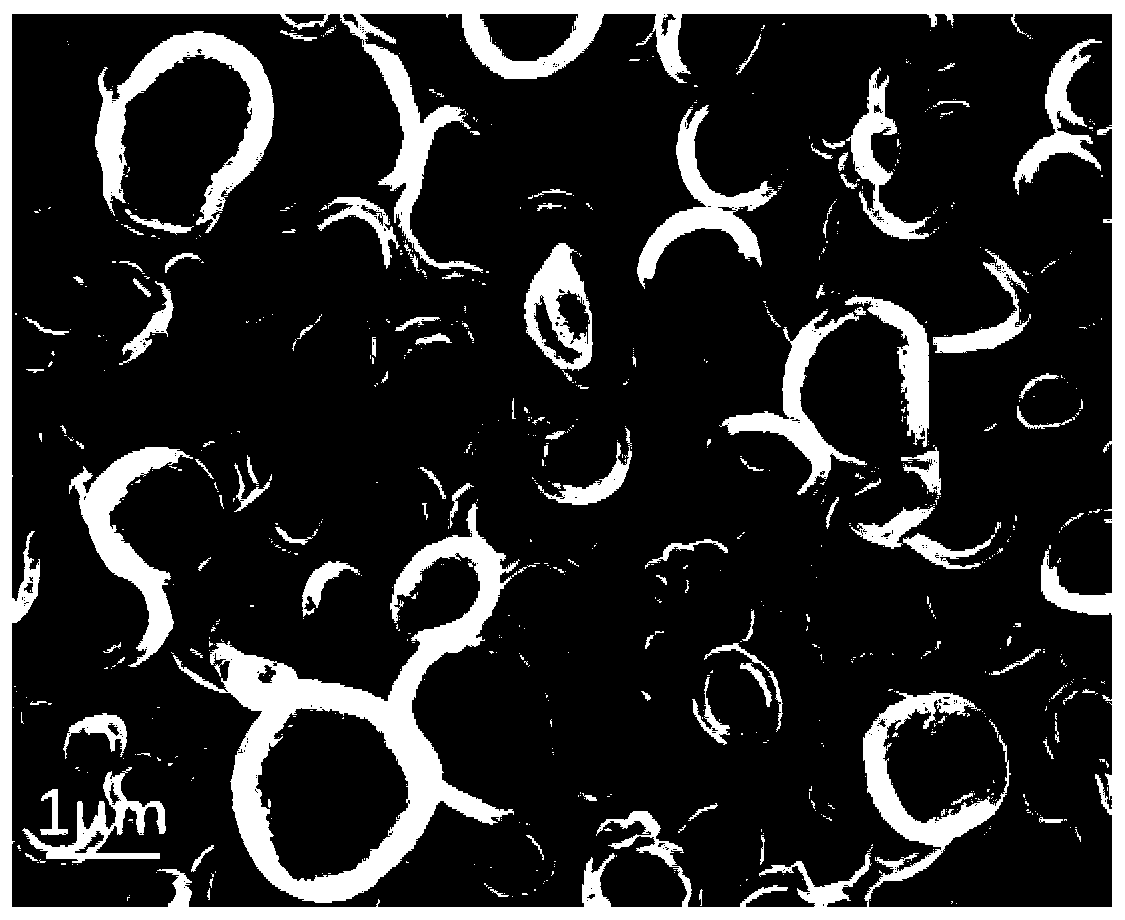

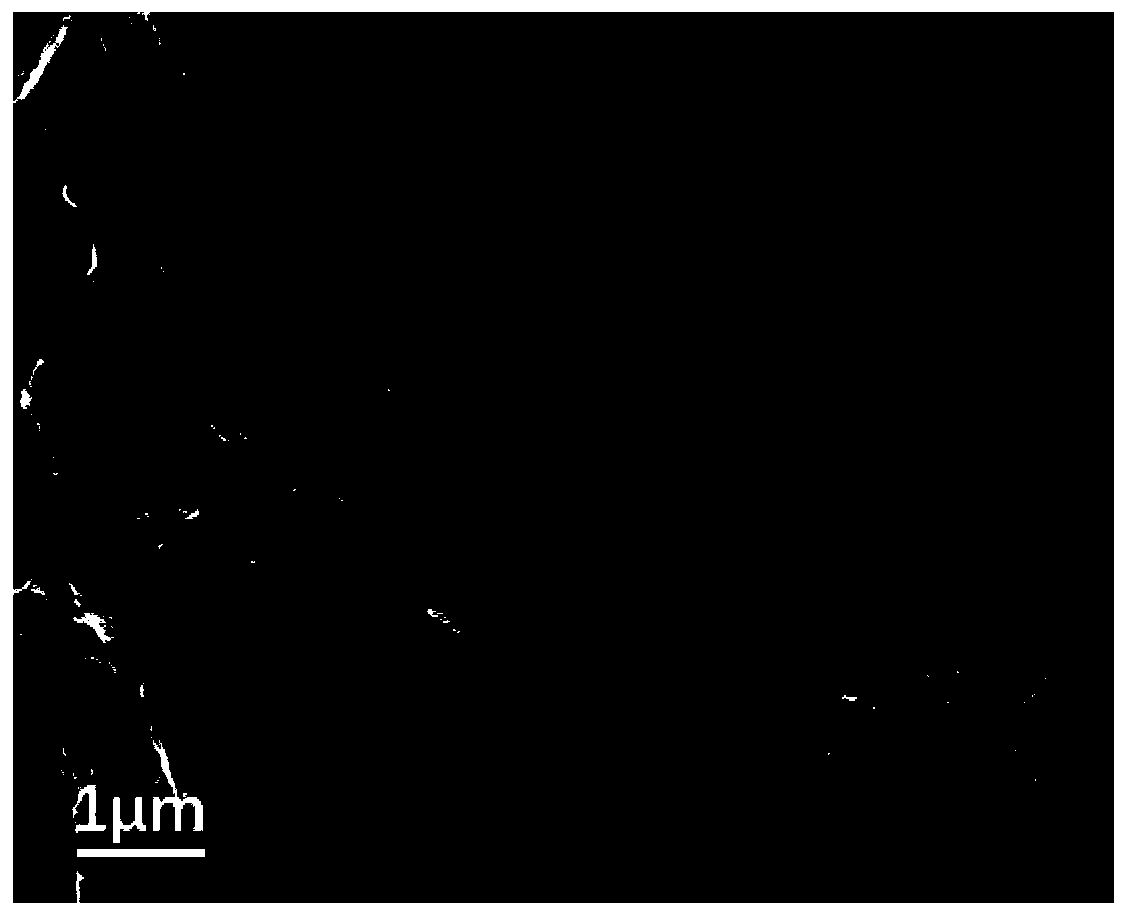

The invention discloses a foam copper-supported porous copper oxide nanowire composite material. The material comprises a foam copper substrate and a copper oxide nanowire supported on the surface, wherein the copper oxide nanowires are 8 to 12 mum in lengths, and are 150 to 250 nanometers in widths; the nanowires do not crack or fall easily; microscopically, the nanowires have porous structures, and pore diameters are 2 to 4 nanometers; macroscopically, the nanowires are distributed radially, and every 60 to 150 nanowires constitute a copper oxide micro-flower. The obtained composite material has a multi-grade and porous structure, and the whole three-dimensional structure is rich in apertures which are suitable for the permission of light rays and ion transport. When the composite material is taken as a photocatalytic degradation organic dye, the degradation efficiency can be increased by over 10 times; when the composite material is taken as a negative electrode material of a lithium ion battery, the capacity retention ratio can be increased by over 30 percent.

Owner:HEBEI UNIV OF TECH

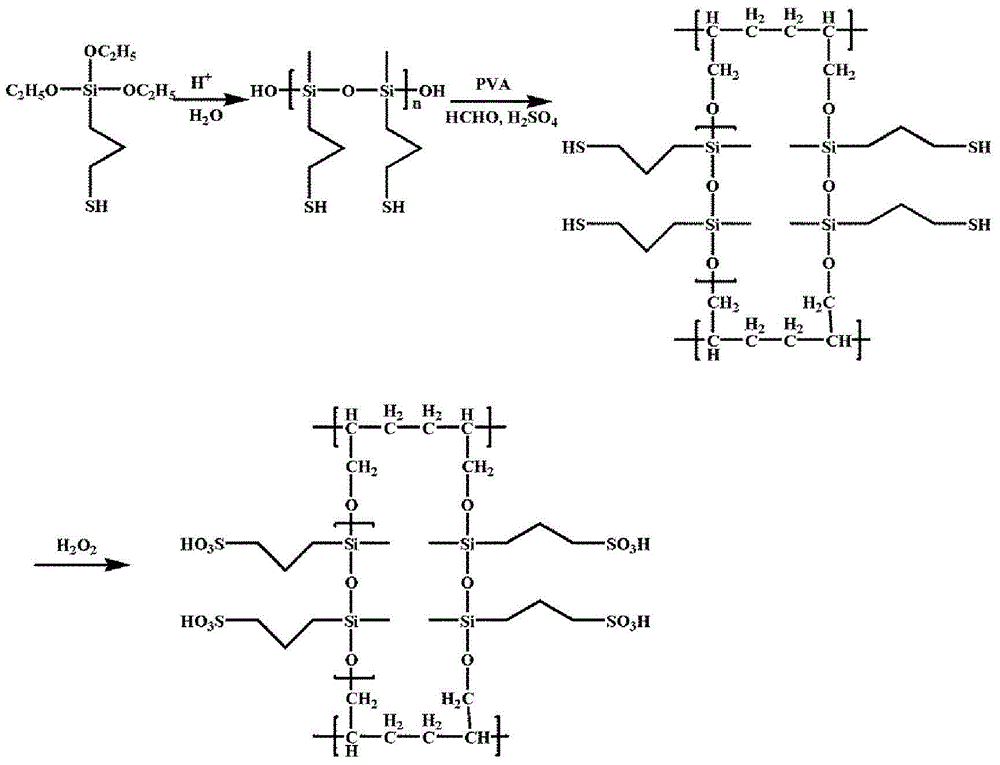

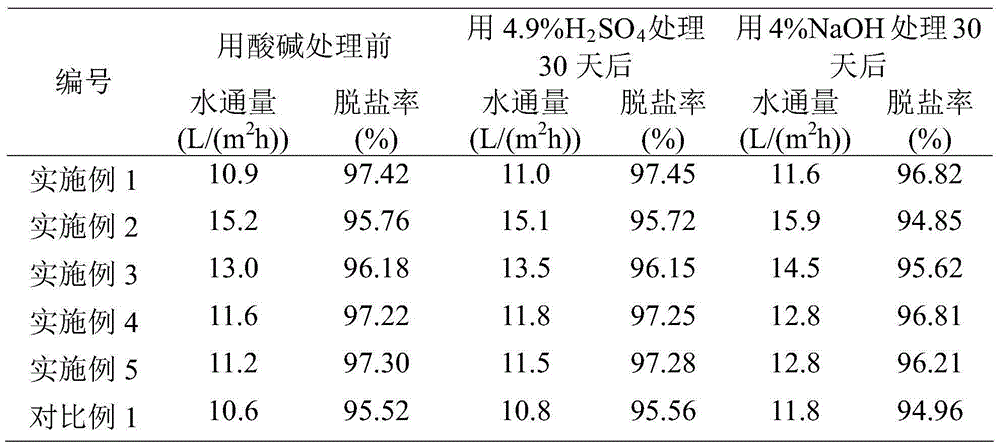

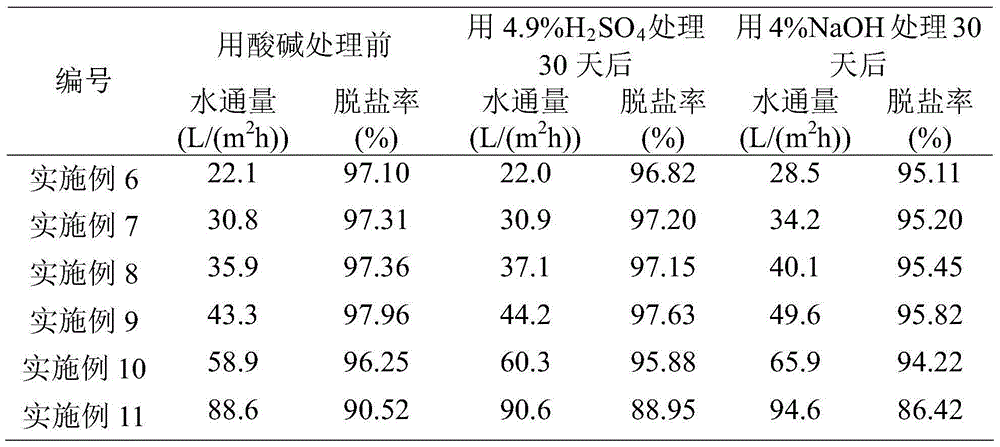

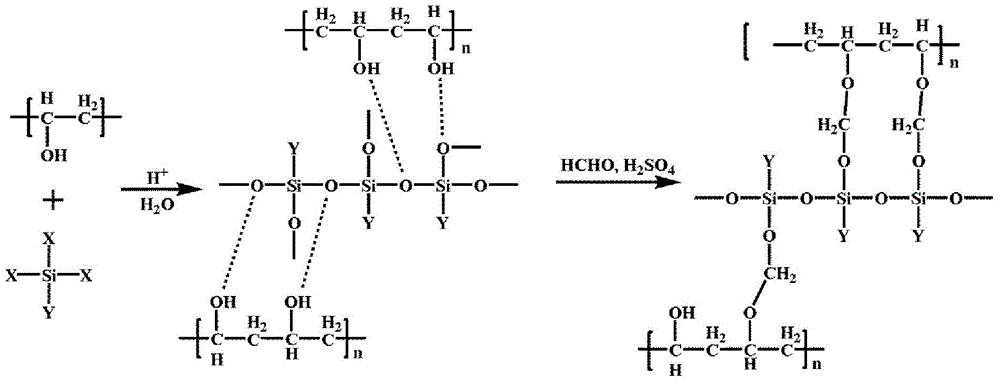

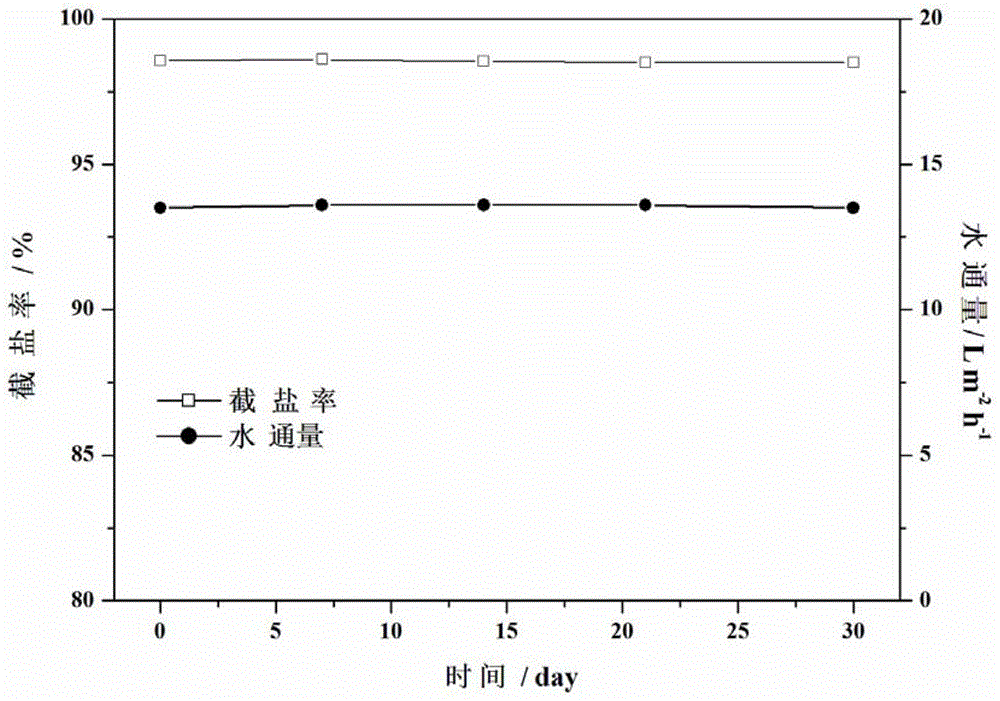

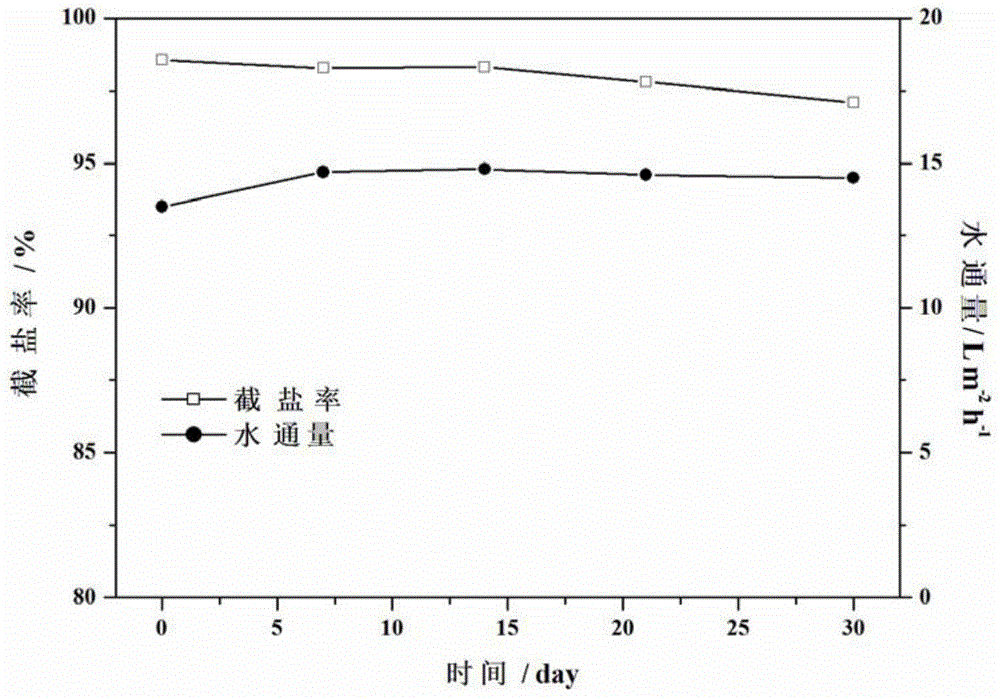

Composite nanofiltration membrane and preparation method thereof

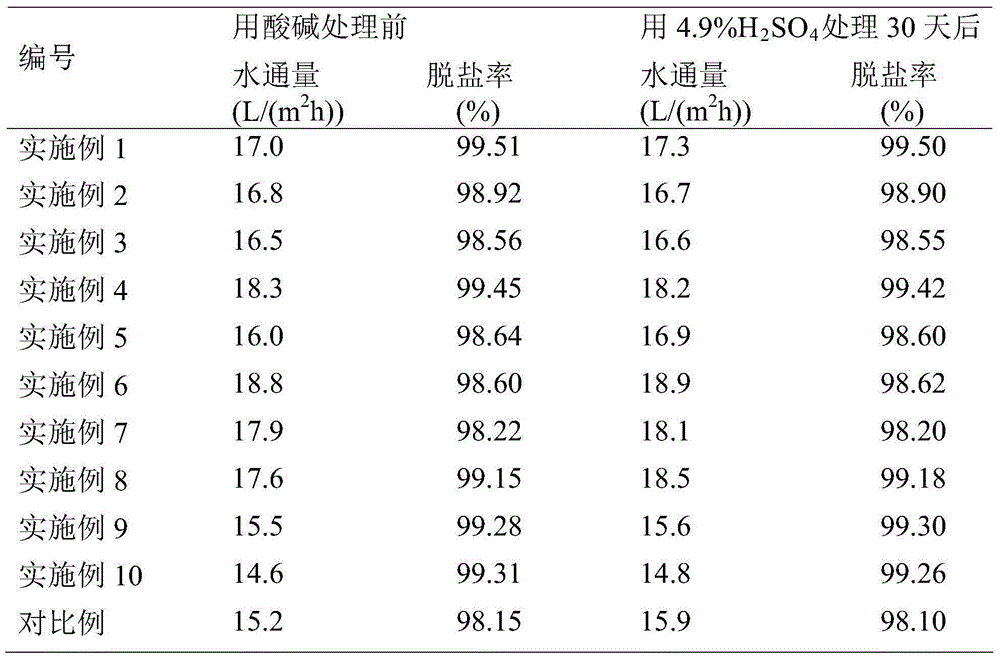

ActiveCN105435656AStrong acid and alkali resistanceGuaranteed uptimeSemi-permeable membranesMembranesPolymer scienceNanofiltration

The present invention discloses a composite nanofiltration membrane and a preparation method thereof and application of the composite nanofiltration membrane prepared by the preparation method in the field of water treatment. The composite nanofiltration membrane comprises a support layer and a separation layer which are stacked together, wherein the separation layer is obtained by forming of an initial composite nanofiltration membrane by sol-gel and thermal crosslinking reaction of a polymer containing a hydroxyl group and a silane coupling agent containing a mercapto group and then post-treatment of the initial composite nanofiltration membrane by use of a water solution containing an oxidizing agent, wherein the initial composite nanofiltration membrane is located on the surface of the support layer and is in a crosslinking net structure. The composite nanofiltration membrane may be stable to operate in a water solution of pH = 0-14, has a high salt removing rate and water permeability (water flux), also has strong acid and base resistance, is simple in preparation method, and has great prospects for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

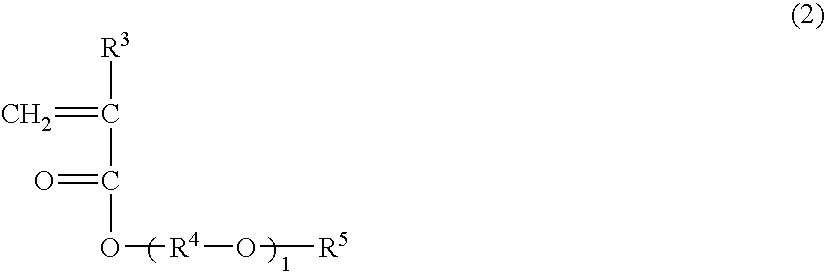

Cosmetic

InactiveUS20050271611A1High retention performanceImprove emulsion stabilityCosmetic preparationsHair cosmeticsEyelashWater in oil emulsion

This invention relates to cosmetic, in particular, relates to improvements of retaining performance and film-line feeling of makeup cosmetic for lips, eyelashes and skin, makeup cosmetic, and improvements of emulsion stability and dispersibility of powder in water-in-oil emulsion cosmetic. This invention is to provide cosmetic comprising a copolymer comprising specific acrylic acid monomer (A), specific polyoxyalkylene monomer (B) and specific organopolysiloxane monomer (C) as constituting monomers, wherein the content of monomer (A) is 20% by mass or more relative to the total amount of the constituting monomers.

Owner:SHISEIDO CO LTD

FRP (fiber reinforced plastic) rib preparation method and FRP rib prepared thereby

ActiveCN102233669AImprove performanceLow high temperature degradation rateExcavationsBulkheads/pilesFiberMolten state

The invention discloses an FRP (fiber reinforced plastic) rib preparation method. The preparation method solves the technical problems that in the prior art, the requirement for the equipment is high, the energy consumption is large, the production cost is high and the resins are in a high-temperature molten state for a long time to cause serious degradation and the like due to adoption of the process of dipping thermoplastic resins when the FRP rib is prepared. In order to solve the technical problems, the adopted technical scheme comprises the following steps of: taking thermoplastic resin fibers and inorganic reinforcing fibers as raw materials, and then carrying out the steps of drying, bundling, winding, drawing, preforming, forming, cooling, curing and cutting and the like. The adopted technical scheme has the advantages that the preparation process is simple, the energy consumption is less and the production cost is low. The invention also provides the FRP rib prepared by the method, and can be rapidly and widely applied in various engineering.

Owner:SHANGHAI KNP CHEM +1

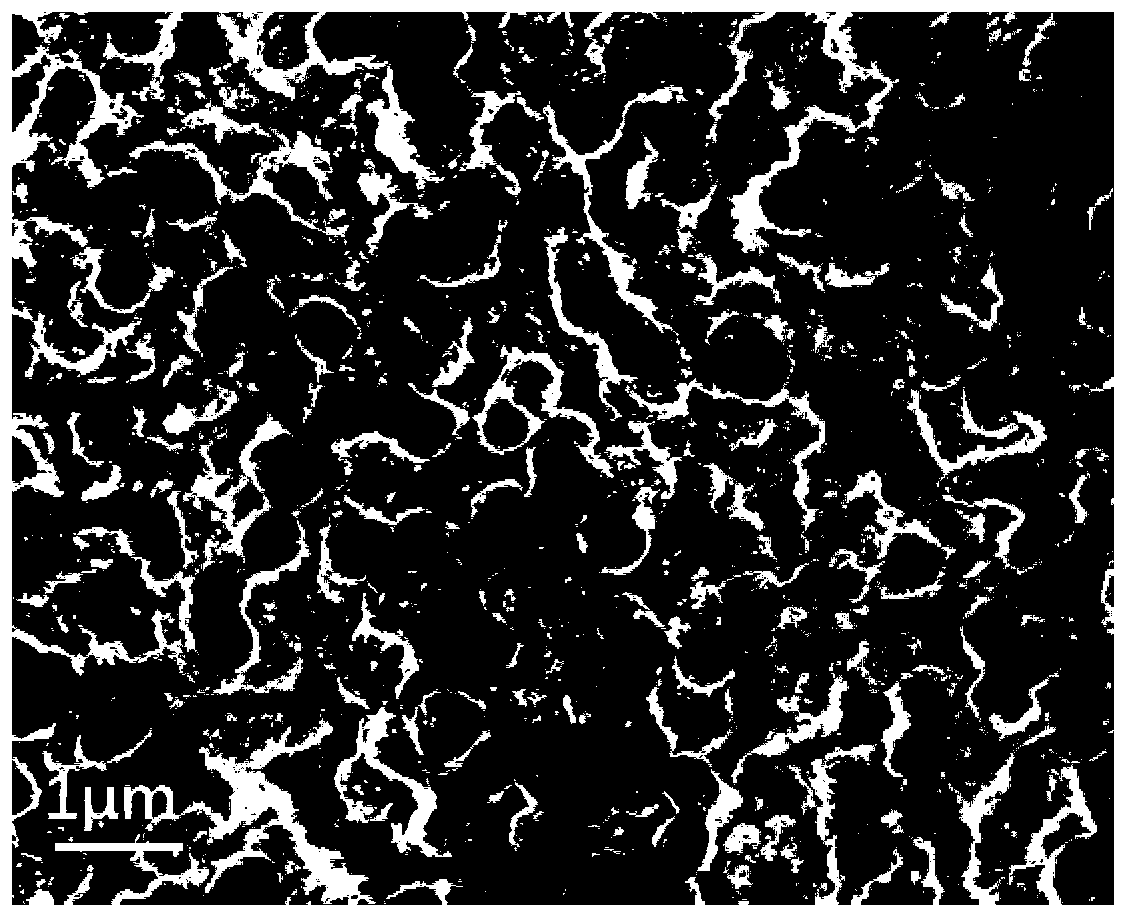

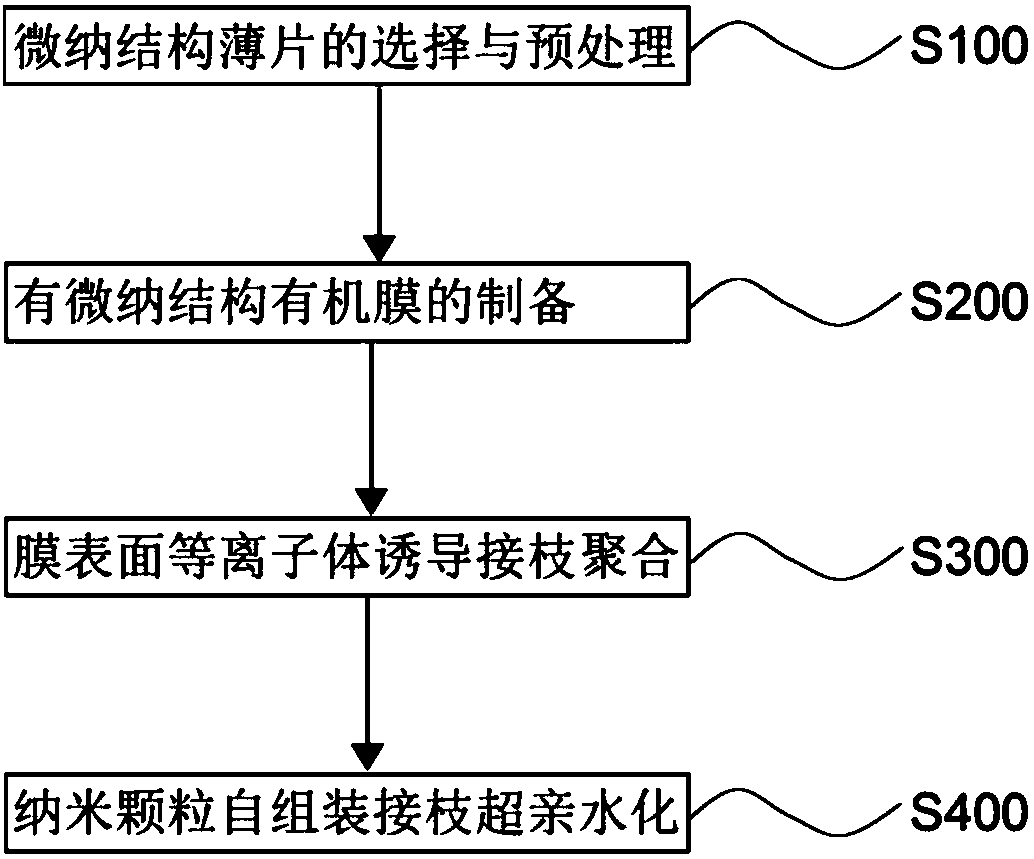

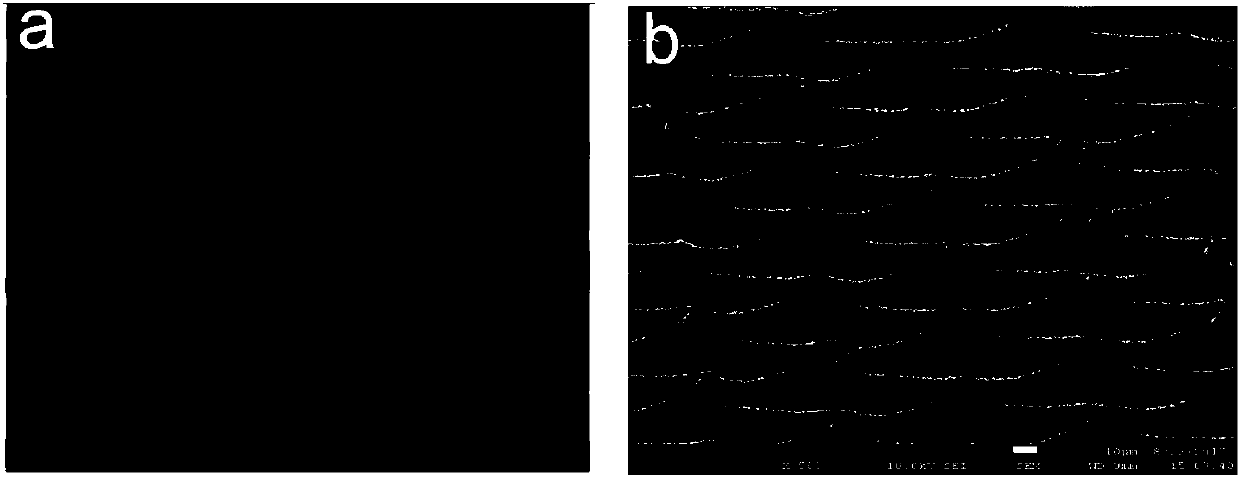

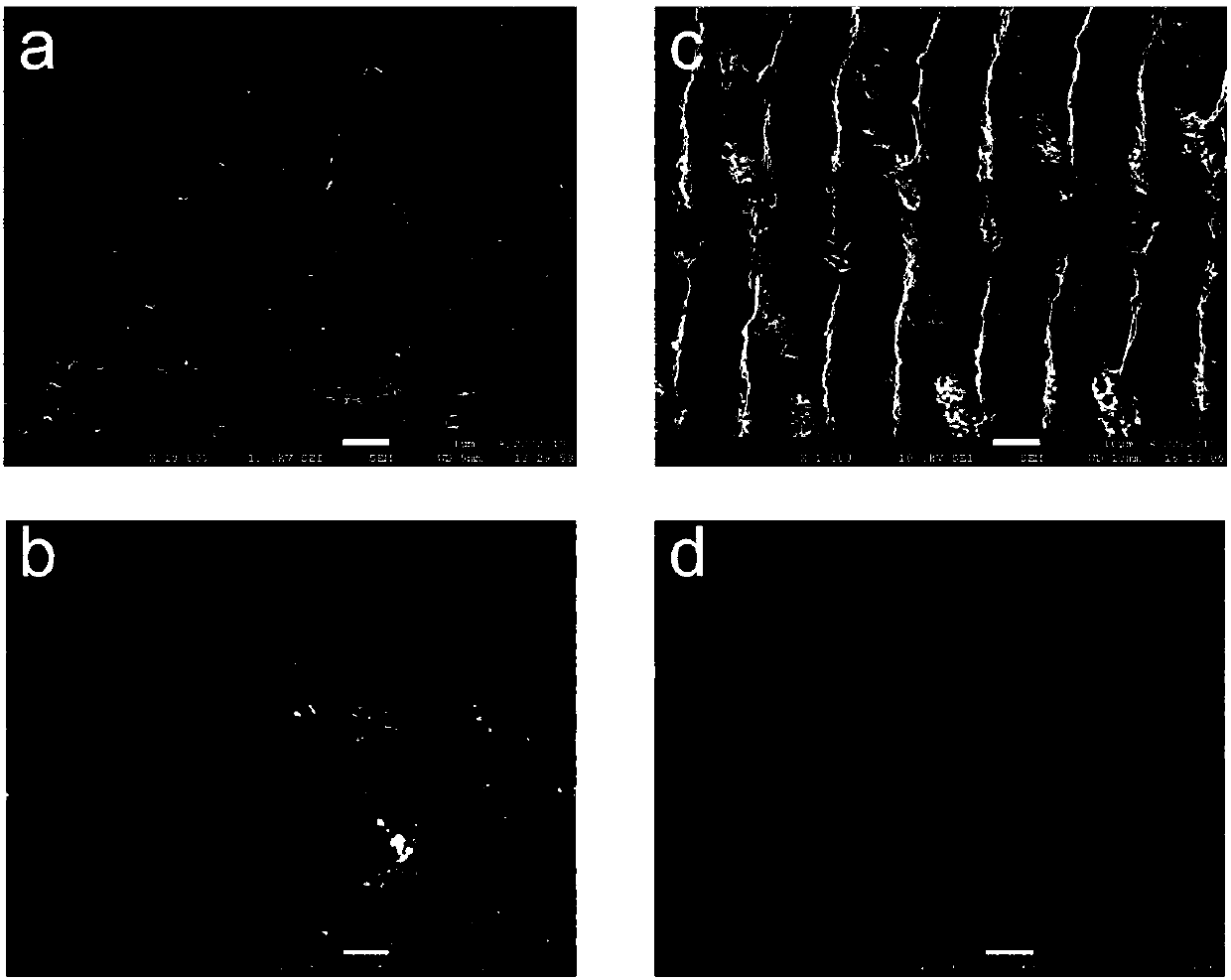

Preparation method of super-hydrophilic organic membrane based on surface covered with micro-nano structure

ActiveCN108043246AAchieve superhydrophilicityLong-term stable superhydrophilic propertiesSemi-permeable membranesMembranesMicro nanoSilicon dioxide

The invention provides a preparation method of a super-hydrophilic organic membrane. The method comprises the following steps: (1) providing a sheet with a micro-nano structure on the surface; (2) providing a membrane casting solution, and forming a membrane casting solution film on a glass plate; (3) arranging a cushion layer with adjustable height on the periphery of the membrane casting solution film; (4) covering the surface of the membrane casting solution film with the sheet with the micro-nano structure and supporting the sheet with the cushion layer; (5) placing the glass plate in a coagulation bath to form an organic membrane with a complementary micro-nano structure on the surface; (6) grafting a polymethylacrylic acid polymer to the micro-nano structured surface of the organic membrane through plasma induced graft polymerization to obtain a modified organic membrane; (7) soaking the modified organic membrane in a silica nanoparticle suspension with surface modified with a silane coupling agent. The organic membrane prepared with the method has a multi-level micro-nano structure, has the characteristics of being super-hydrophilic, high in flux, persistently anti-pollutionand the like and has good application prospect in the field of membrane-process water treatment.

Owner:BEIJING FORESTRY UNIVERSITY

Composite reverse osmosis membrane as well as preparation method and application thereof

InactiveCN107297158AImprove mechanical propertiesHigh desalination rateMembranesSemi-permeable membranesCross-linkReverse osmosis

The invention relates to the field of water treatment and discloses a composite reverse osmosis membrane as well as a preparation method and application thereof. The composite reverse osmosis membrane comprises a supporting layer, a separation layer and a hydrophilic and pollution-resisting layer, which are stacked in sequence, wherein the separation layer is a layer formed by cross-linked polyamide; and the hydrophilic and pollution-resisting layer is a layer formed by carrying out a crosslinking reaction on a polymer containing hydroxyl and a silane coupling agent containing zwitterions. The reverse osmosis membrane provided by the invention not only has relatively high water flux and desalting rate, but also has relatively strong pollution-resisting performance; and the preparation method of the reverse osmosis membrane is simple and has an extremely good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrolysis-resistant aliphatic-aromatic copolyester and preparation method thereof

The invention discloses hydrolysis-resistant aliphatic-aromatic copolyester and a preparation method thereof. The preparation method comprises the following steps of: (1) carrying out ester exchange reaction on aromatic binary acid ester or aromatic binary acid and excessive dihydric alcohol to obtain ester P1; (2) reacting aliphatic binary acid, cyclized aliphatic binary acid, an esterification derivative of aliphatic binary acid or an esterification derivative of cyclized aliphatic binary acid with aliphatic dihydric alcohol to obtain ester P2; and (3) mixing P1 with P2, adding an antioxidant to carry out condensation polymerization, then adding a carbonate mineral and a silane compound, and evenly mixing, thus the hydrolysis-resistant aliphatic-aromatic copolyester is obtained. The aliphatic-aromatic copolyester disclosed by the invention has better hydrolysis stability, properties of a polymer in storing and processing processes can be ensured to be stable, and the property retention rate of the polyester product can be improved; and meanwhile, the polyester product also has degradation performance after the application task of the product is completed, and a hydrolysis-resistant component is added in a synthetic process, thus addition during modification is avoided and process is simplified.

Owner:KINGFA SCI & TECH CO LTD +1

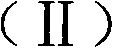

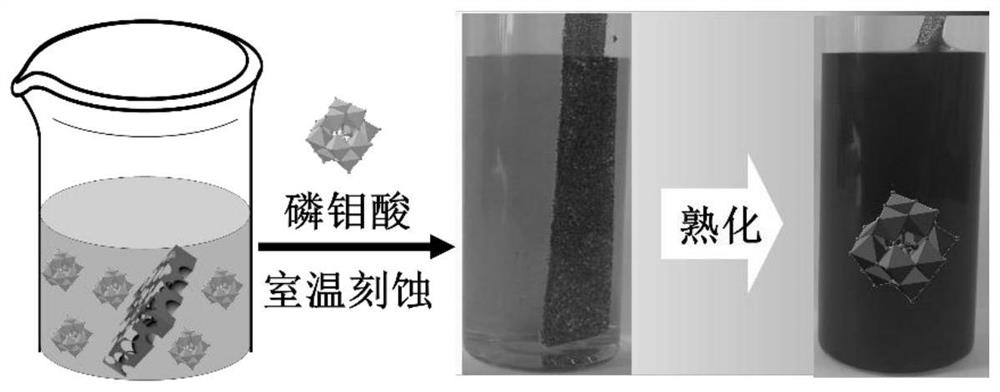

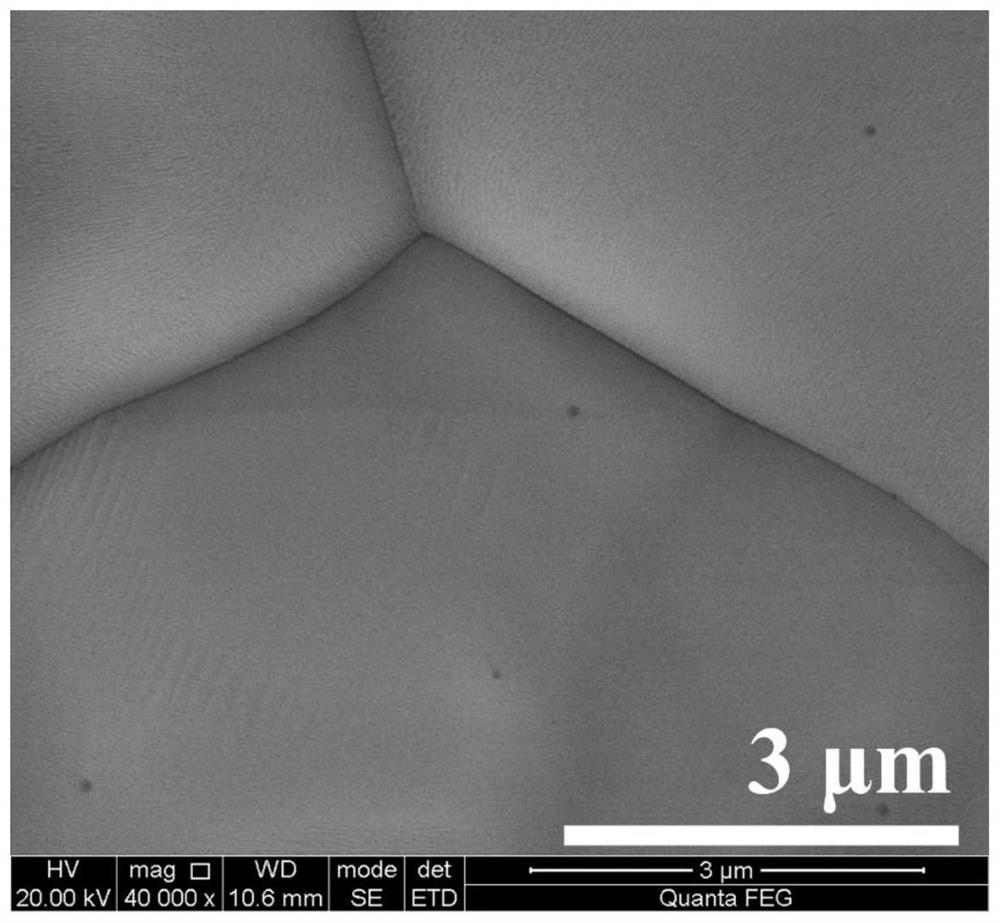

Preparation method of foamed nickel-loaded amorphous phosphorus-doped nickel molybdate bifunctional electrocatalytic electrode and application thereof

ActiveCN111663152ASimple preparation processMild conditionsCatalyst activation/preparationElectrolytic organic productionPhosphomolybdic acidElectrolysis

The invention provides a preparation method of a foamed nickel-loaded amorphous phosphorus doped nickel molybdate bifunctional electrocatalytic electrode and an application thereof, and belongs to thetechnical field of hydrogen energy and fuel cells. The preparation method comprises the following steps: soaking foamed nickel into an HCl solution, removing metal oxide on the surface, soaking the pickled foamed nickel into a phosphomolybdic acid aqueous solution, carrying out a spontaneous oxidation-reduction reaction, taking out, washing with deionized water, and drying for later use, therebyobtaining the foamed nickel-loaded amorphous phosphorus-doped nickel molybdate nanostructure. The foamed nickel is etched by using the phosphomolybdic acid aqueous solution, and can be directly used after drying, the material can be used as a bifunctional electrode material for urea electrooxidation and water and electricity reduction; a urea electrooxidation reaction with low oxidation potentialis used for replacing an electrocatalytic oxygen evolution reaction, a two-electrode urea auxiliary electrolysis hydrogen production system based on a bifunctional electrocatalyst is constructed in analkaline solution, low-cost, low-energy-consumption and stable electrochemical hydrogen production is achieved, and the method is suitable for large-scale industrial electrochemical hydrogen production application.

Owner:HARBIN INST OF TECH

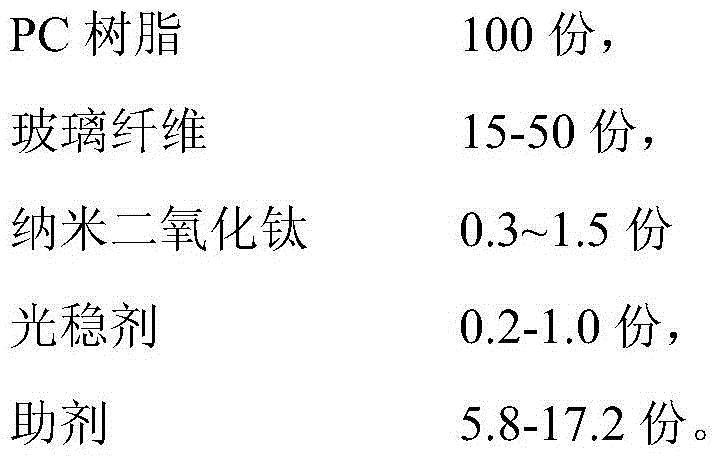

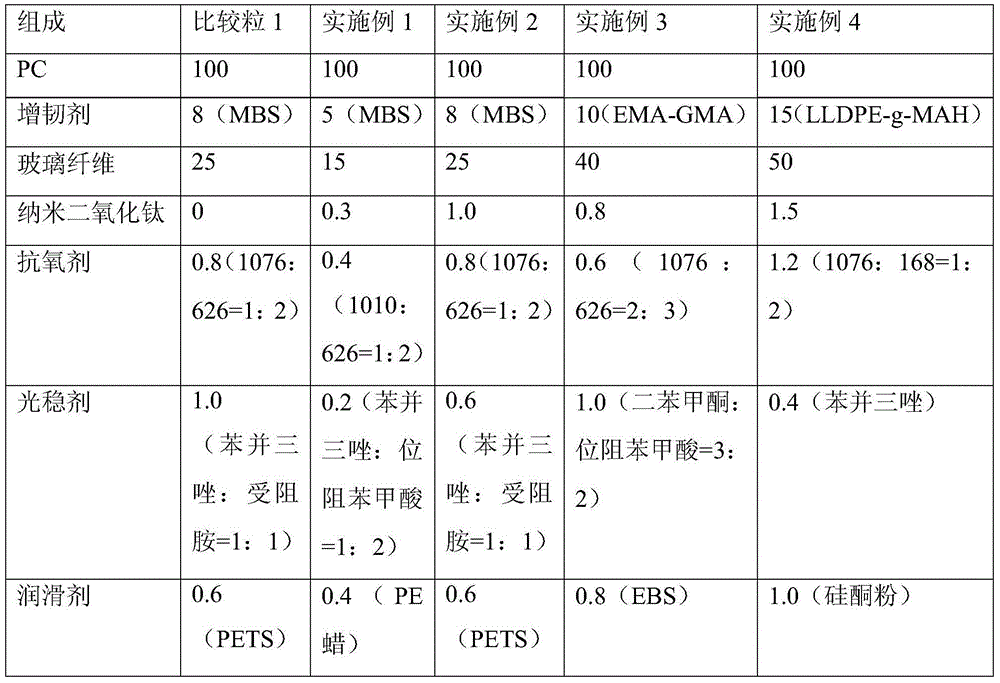

High-weather-resistant glass fiber reinforced PC material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and relates to a high-weather-resistant glass fiber reinforced PC material and a preparation method thereof. The glass fiber reinforced PC material is prepared from the following components in parts by weight: 100 parts of PC resin, 15 to 50 parts of glass fiber, 5 to 15 parts of a toughening agent, 0.3 to 1.5 parts of nano titanium dioxide, 0.2-1.0 part of a light stabilizer, 0.4 to 1.0 part of a lubricant, and 0.4 to 1.2 parts of an antioxidant. The glass fiber reinforced PC material provided by the invention has excellent lasting weather resistance, the color stability of light colored products can be ensured for a long term, and the color difference after photoaging is obviously reduced. The glass fiber reinforced PC material can be widely applied to various fields of social life such as home appliance shells, packaging materials, pipelines, building profiles and boards, and has great economic and social values.

Owner:上海昶勤实业有限公司

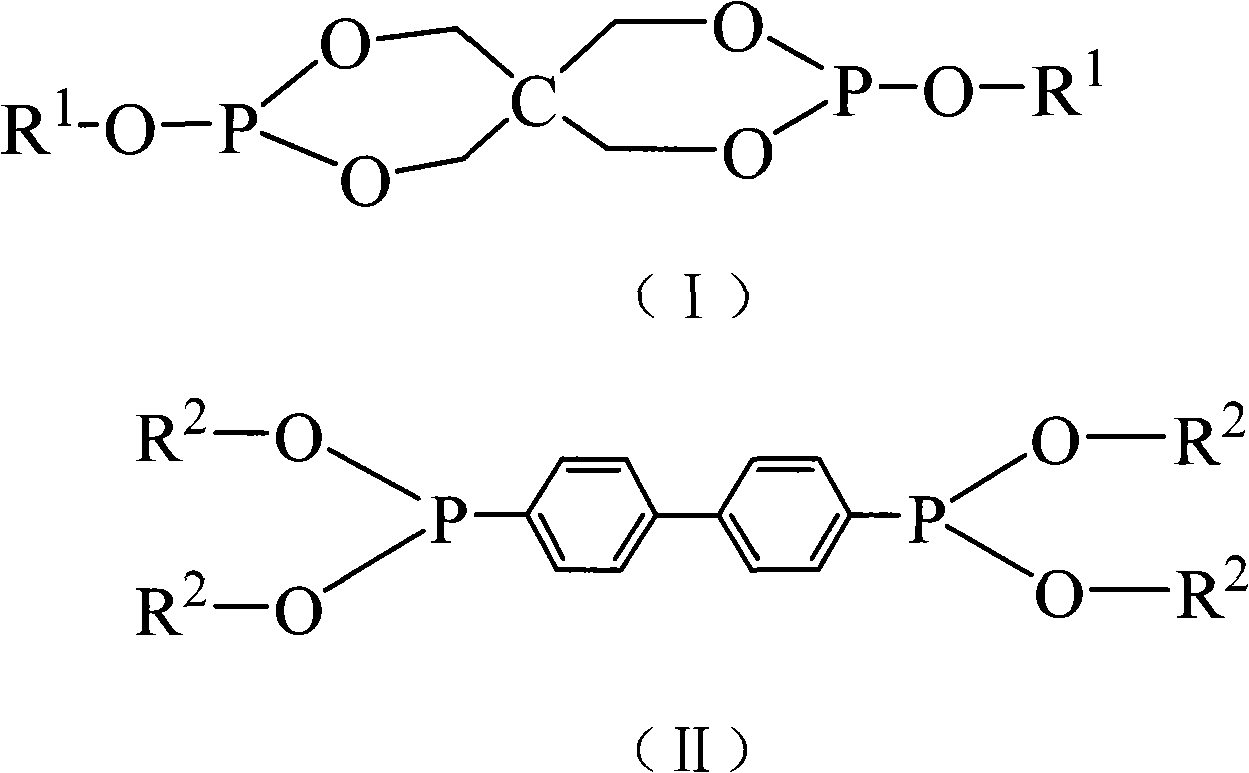

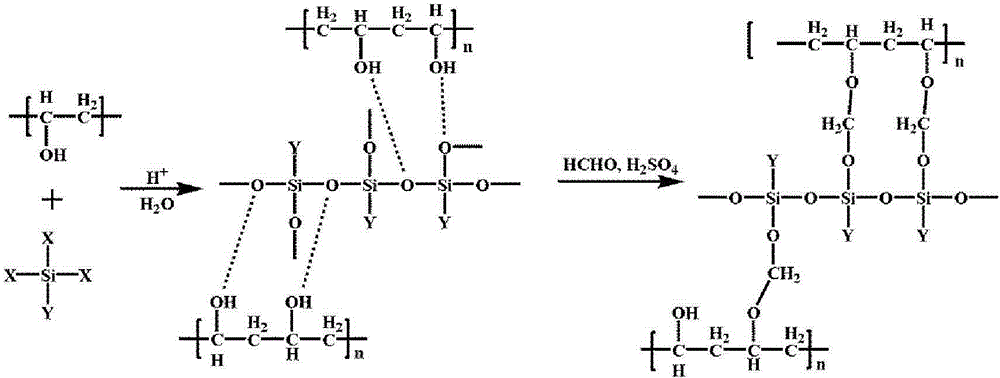

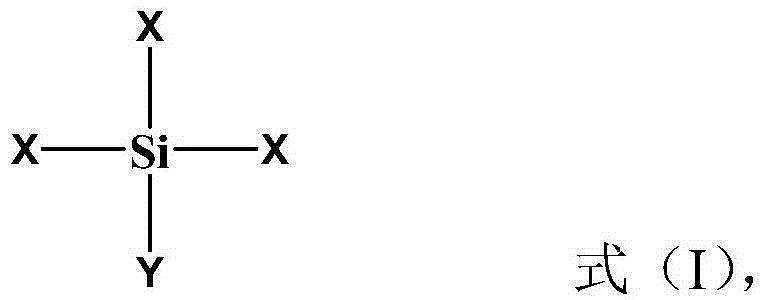

Composite nanofiltration membrane and preparation method thereof

ActiveCN105435657AImprove antibacterial propertiesImprove mechanical propertiesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkSolvent

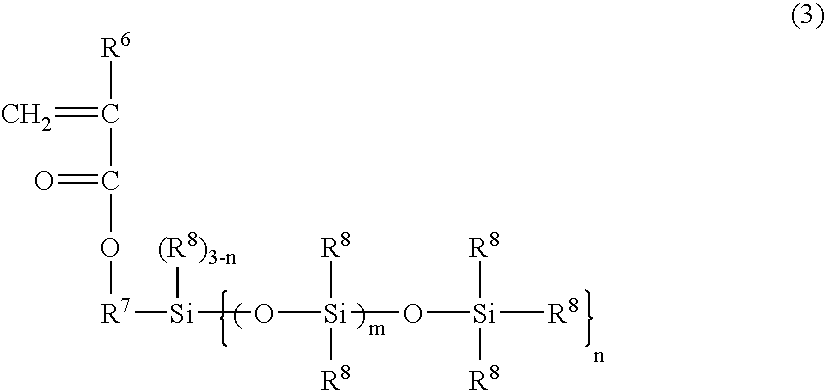

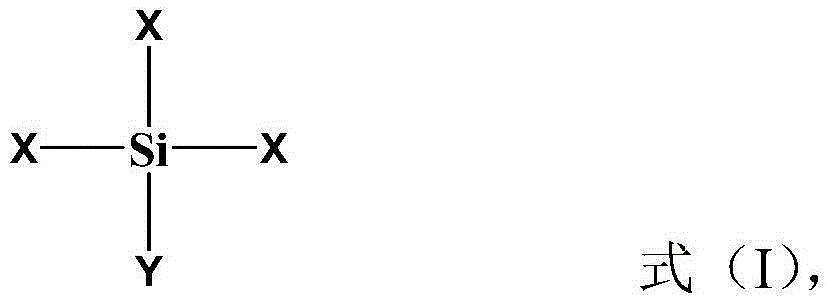

The present invention discloses a composite nanofiltration membrane and a preparation method thereof and application of the composite nanofiltration membrane prepared by the preparation method in the field of water treatment. The composite nanofiltration membrane comprises a support layer and a separation layer which are stacked together, wherein the separation layer is a cross-linked net structure formed by dissolving of a polymer containing a hydroxyl group and a silane coupling agent containing a structure as shown in formula (I) in a solvent for sol-gel and thermal crosslinking reaction, the cross-linked net structure is located on the surface of the support layer, Y is a C2-C10 linear or branched chain alkyl group, the terminal end of the C2-C10 linear or branched chain alkyl group is quaternary ammonium group, and X is one or more of Cl, OMe, OEt, OC2H4OCH3, OSiMe3 and OAc. The composite nanofiltration membrane has a high salt removing rate and water permeability (water flux), also has strong antibacterial property, is simple in preparation method, and has great prospects for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature superconduction coil and fabrication method of same

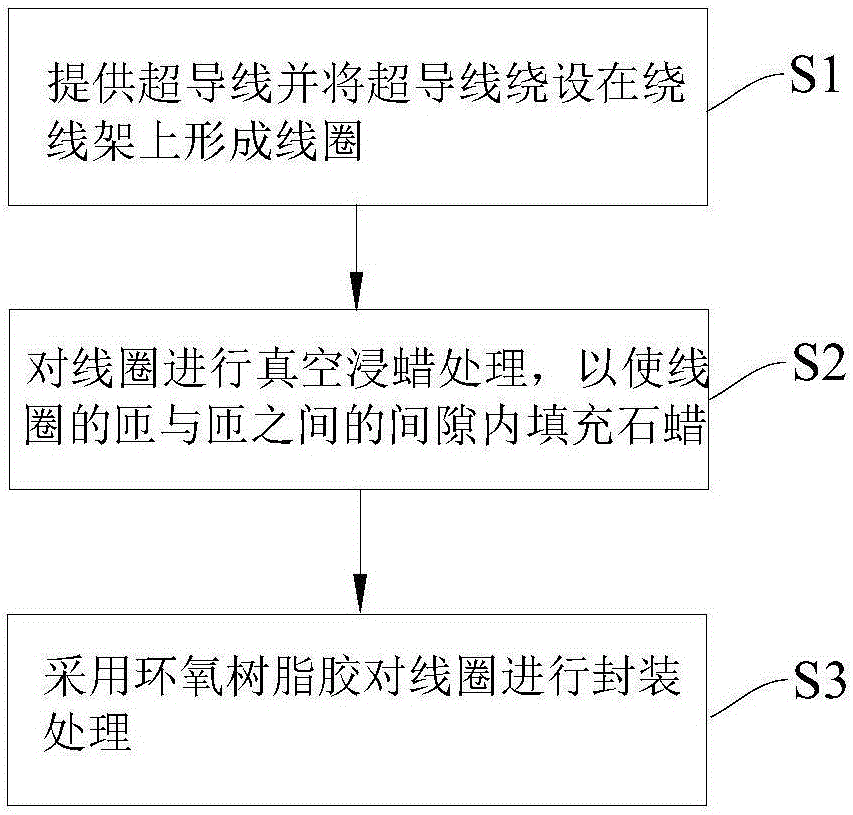

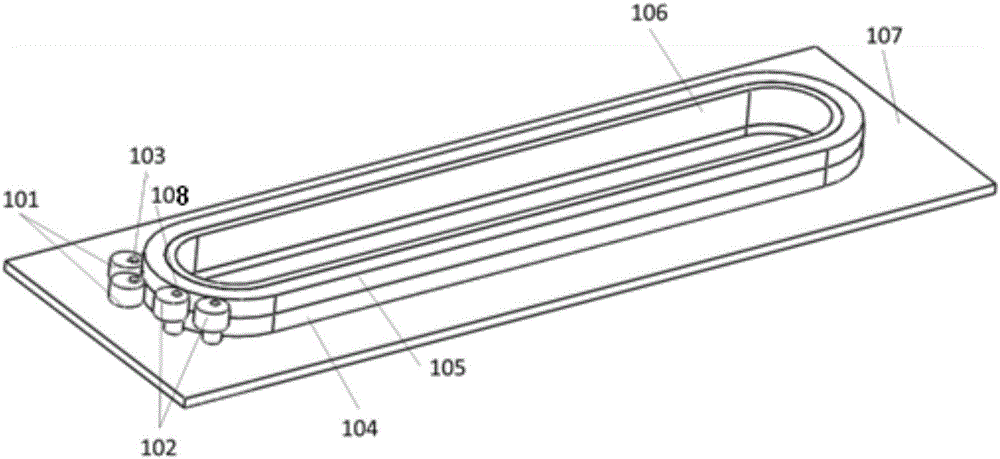

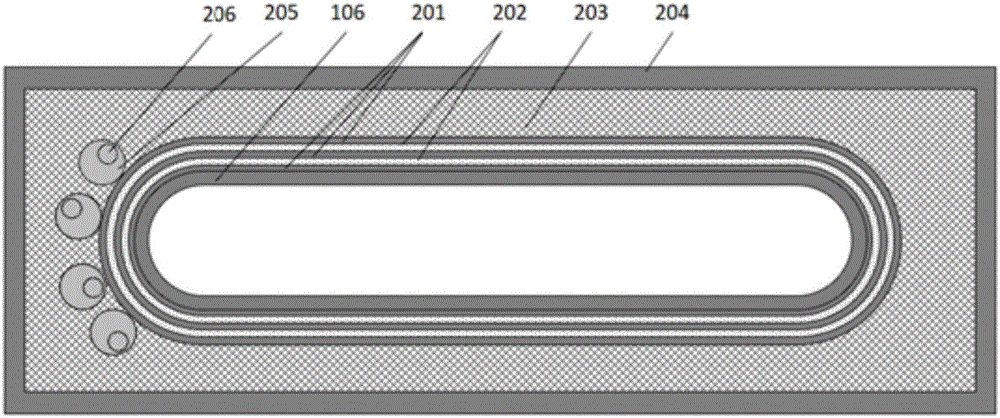

ActiveCN106373772AHigh mechanical strengthImprove thermal conductivitySuperconducting magnets/coilsCoils manufactureWaxEpoxy

The invention discloses a high-temperature superconduction coil and a fabrication method of the same. The fabrication method comprises the following steps of S1, providing a superconduction wire, and winding the superconduction wire around a winding rack to form a coil; S2, performing vacuum wax immersion processing on the coil so that a gap between turns of the coil is filled with wax; and S3, packaging the coil with an epoxy resin adhesive. According to the fabrication method of the high-temperature superconduction coil, disclosed by the embodiment of the invention, the coil formed by packaging has relatively good heat conduction effect and relatively high mechanical strength, moreover, the superconduction wire is prevented from being locally damaged due to contraction of the epoxy resin adhesive in a low temperature to cause performance degradation of the coil, and the high-temperature superconduction coil is good in performance retentivity and has relatively high performance such as superconductivity and strength.

Owner:TSINGHUA UNIV

Composite nanofiltration membrane and preparation method thereof

ActiveCN105289321AStrong acid and alkali resistanceImprove mechanical propertiesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEpoxyCross-link

The invention discloses a composite nanofiltration membrane, a preparation method thereof, and application of the composite nanofiltration membrane prepared by adopting the preparation method to the field of water treatment. The composite nanofiltration membrane comprises a supporting layer and a separating layer which are overlapped together, wherein the separating layer is a cross-linked net structure which is positioned on the surface of the supporting layer and formed through thermal crosslinking reaction of polymer containing hydroxyl and a silane coupling agent with a structure as shown in the formula (I) (shown in the description) through sol-gel; in the formula (I), Y is alkenyl or carbon functional group, the carbon functional group is alkyl carried with Cl, NH2, epoxy, SH, N3, (methyl) acrylyl or isocyanate group; X is one or more of Cl, OMe, OEt, OC2H4OCH3, OSiMe3 and OAc. According to the composite nanofiltration membrane and the preparation method thereof, provided by the invention, stable operation of the composite nanofiltration membrane in an aqueous solution with the PH of 0-14 is achieved, a higher salt removing rate and water permeability are achieved, higher acid and alkali resistance is further achieved; besides, the method is simple, and an industrial application prospect is further realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-resistant modified asphalt waterproof coiled material and preparation method thereof

ActiveCN108081698AImprove thermal stabilityGood low temperature flexibilityFibre typesSynthetic resin layered productsThermal ageingFiber

The invention provides a high-temperature-resistant modified asphalt waterproof coiled material and a preparation method thereof. The modified asphalt waterproof coiled material comprises a tread baselayer, prepreg, a coating material and an isolating material; the tread base layer of the modified asphalt waterproof coiled material is fiberglass mesh cloth and polyester fiber composite tread base; and the prepreg is prepared from the following raw material components: 130# asphalt, chlorinated rubber, ethylene-vinyl acetate glyceride, elm tree wood powder and an anti-ageing agent. The modified asphalt waterproof coiled material has excellent thermal stability, thermal ageing resistance and low-temperature flexible performances.

Owner:富华防水科技股份有限公司

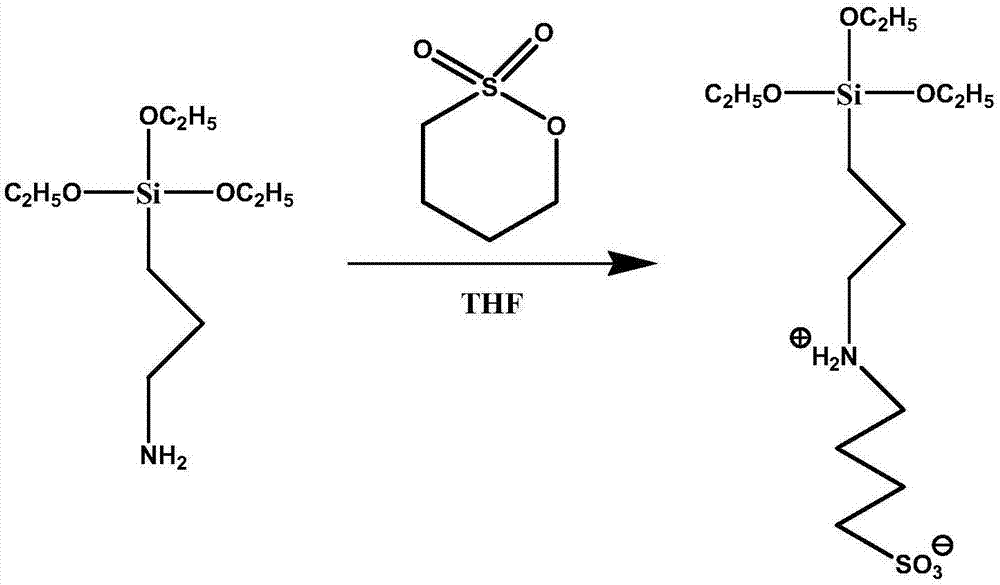

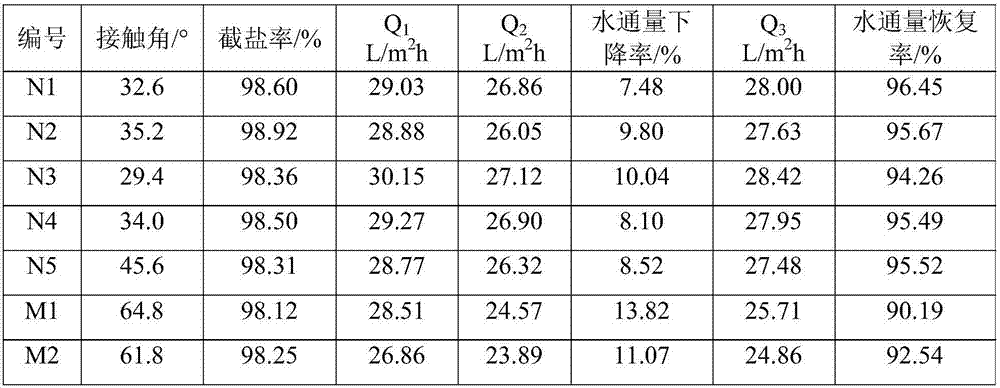

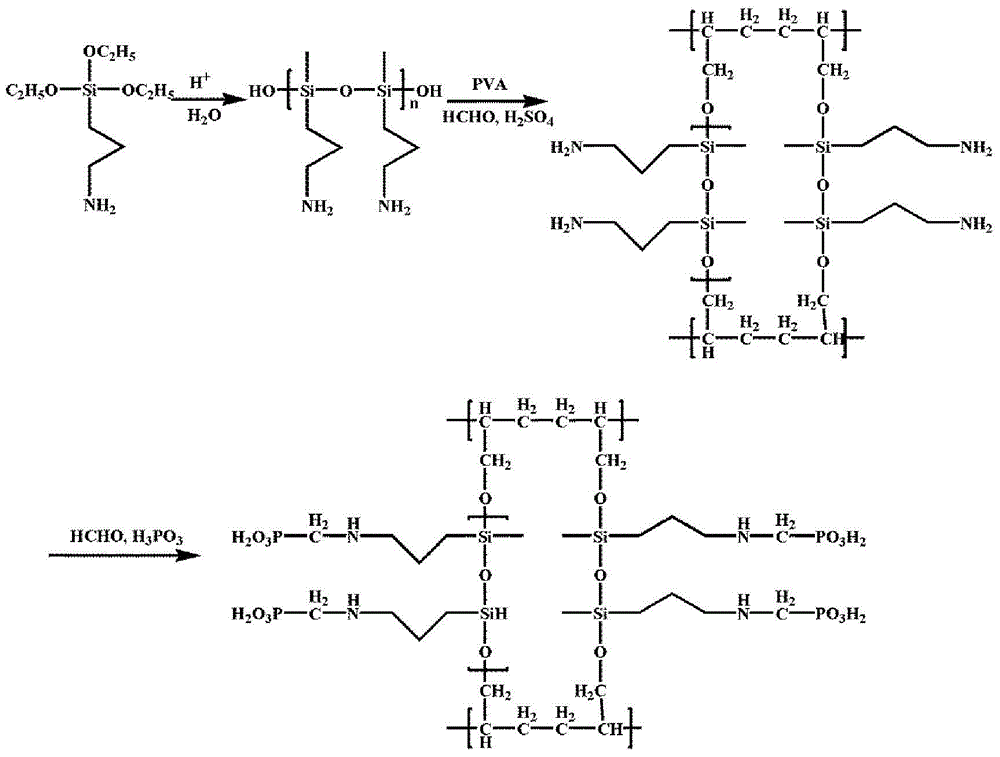

Composite nanofiltration membrane and preparation method thereof

ActiveCN105435645AStrong acid resistanceImprove mechanical propertiesSemi-permeable membranesPhosphorous acidStrong acids

The present invention discloses a composite nanofiltration membrane and a preparation method thereof and application of the composite nanofiltration membrane prepared by the preparation method in the field of water treatment. The composite nanofiltration membrane comprises a support layer and a separation layer which are stacked together, wherein the separation layer is obtained by forming of an initial composite nanofiltration membrane by sol-gel and thermal crosslinking reaction of a polymer containing a hydroxyl group and a silane coupling agent containing an amino group and then post-treatment by use of a water solution and / or an alcohol solution, and the water solution and / or the alcohol solution is a water solution of formaldehyde and phosphorous acid or an alcohol solution of formaldehyde and phosphite and perchlorate. The composite nanofiltration membrane may be stable to operate in a water solution of pH = 0, has a high salt removing rate and water permeability (water flux), also has strong acid resistance, is simple in preparation method, and has great prospects for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

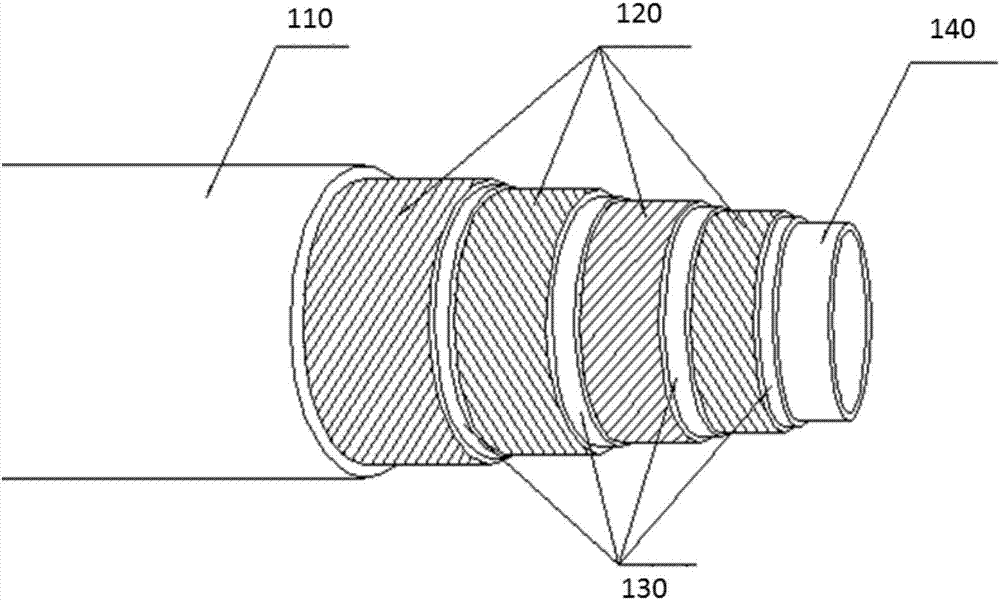

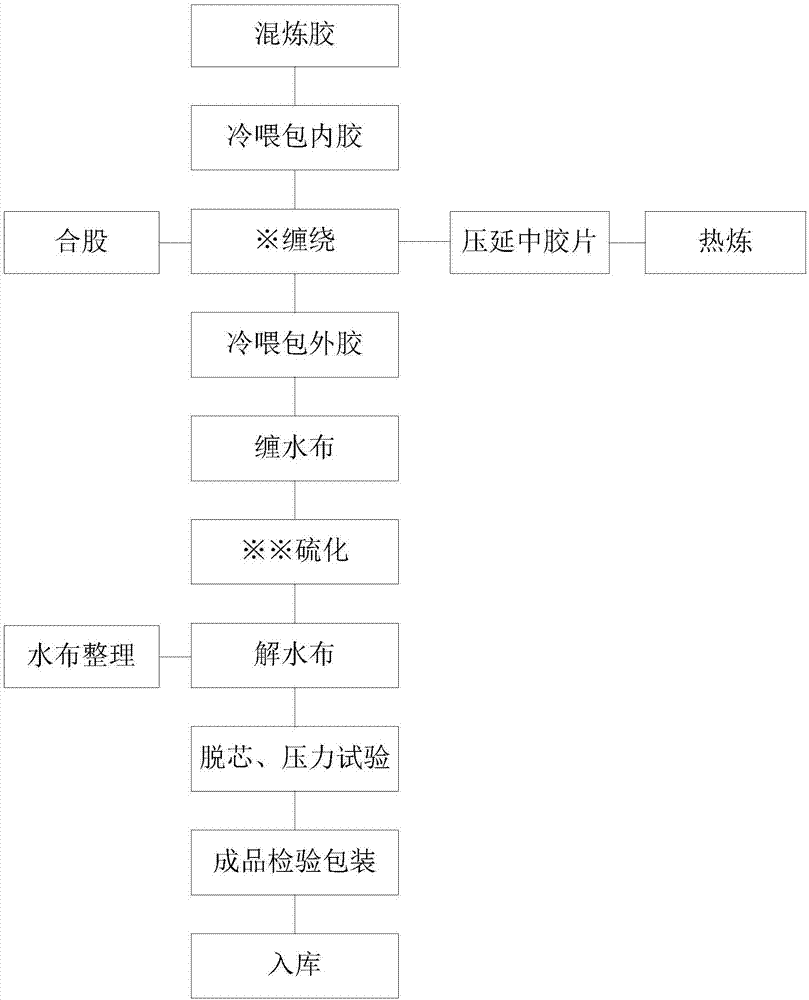

Rubber compound, rubber product, hydraulic rubber hose and preparation method of hydraulic rubber hose

ActiveCN106987040AImprove aging resistanceImproved liquid resistanceFlexible pipesRubber materialPolymer science

The invention relates to a rubber compound, a rubber product, a hydraulic rubber hose and a preparation method of the hydraulic rubber hose. The rubber compound comprises (i) hydrogenated butadiene-acrylonitrile rubber, (ii) thermal cracking carbon black and (iii) other selectable matching agents. A rubber material prepared by the rubber compound has excellent oil resistance and temperature resistance.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

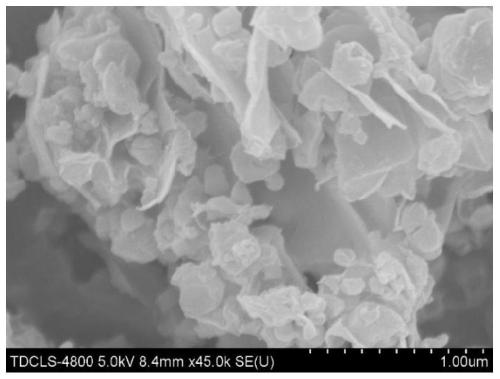

Preparation method of flexible graphene oxide/metal organic framework composite filter membrane

ActiveCN111569665AHigh retention performanceGood flexibilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMetal-organic frameworkComposite filter

The invention relates to a preparation method of a flexible graphene oxide / metal organic framework composite filter membrane. 2-methylimidazole zinc salt (ZIF-8) is used as a typical metal organic framework (MOFs), a hydrothermal method and a solvothermal method are used for preparing 2-methylimidazole zinc salt and graphene oxide composite particles (ZIF-8-coated GO composite particles) with chemical bonding, the composite particles and GO are subjected to cross-linking compounding, and the ZIF-8-coated GO / GO composite film with graphene oxide as a matrix and the composite particles as reinforcements is obtained. The obtained composite membrane can realize self-supporting, and can still keep complete under the bending action of a certain limit. Mesopores formed by the graphene oxide sheetlayer, micropores of the metal organic framework and macropores formed by adding the composite particles jointly endow the composite membrane with a hierarchical pore structure so that the compositemembrane has a richer pore channel structure, and the pollutant filtering performance is improved. Experimental data show that the membrane has excellent interception performance on pollutants such asPb < 2 + > and methylene blue.

Owner:TIANJIN UNIV

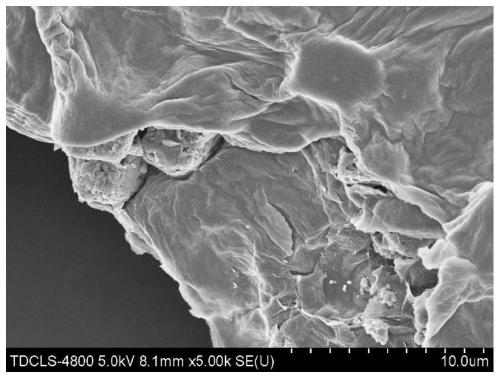

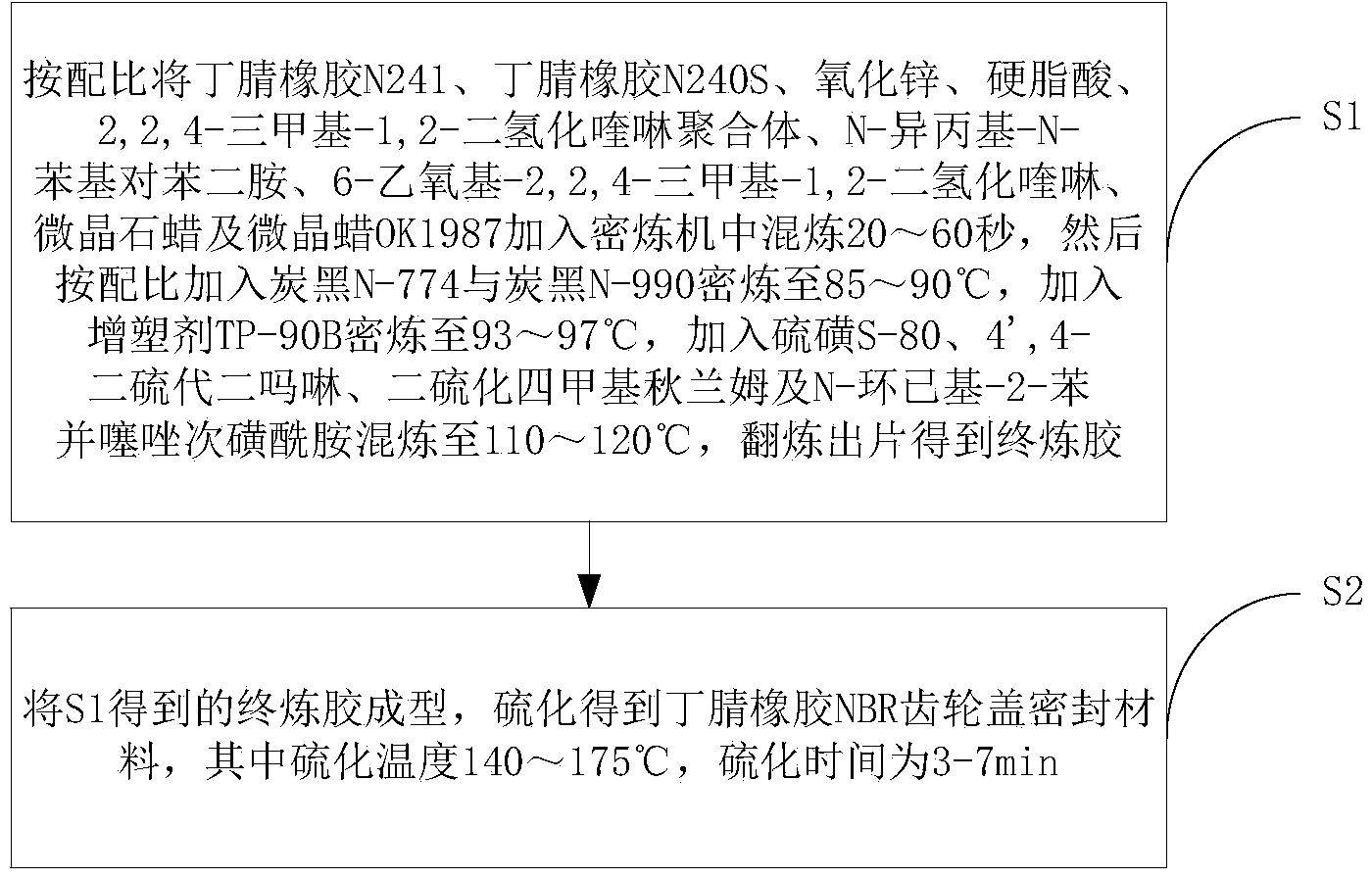

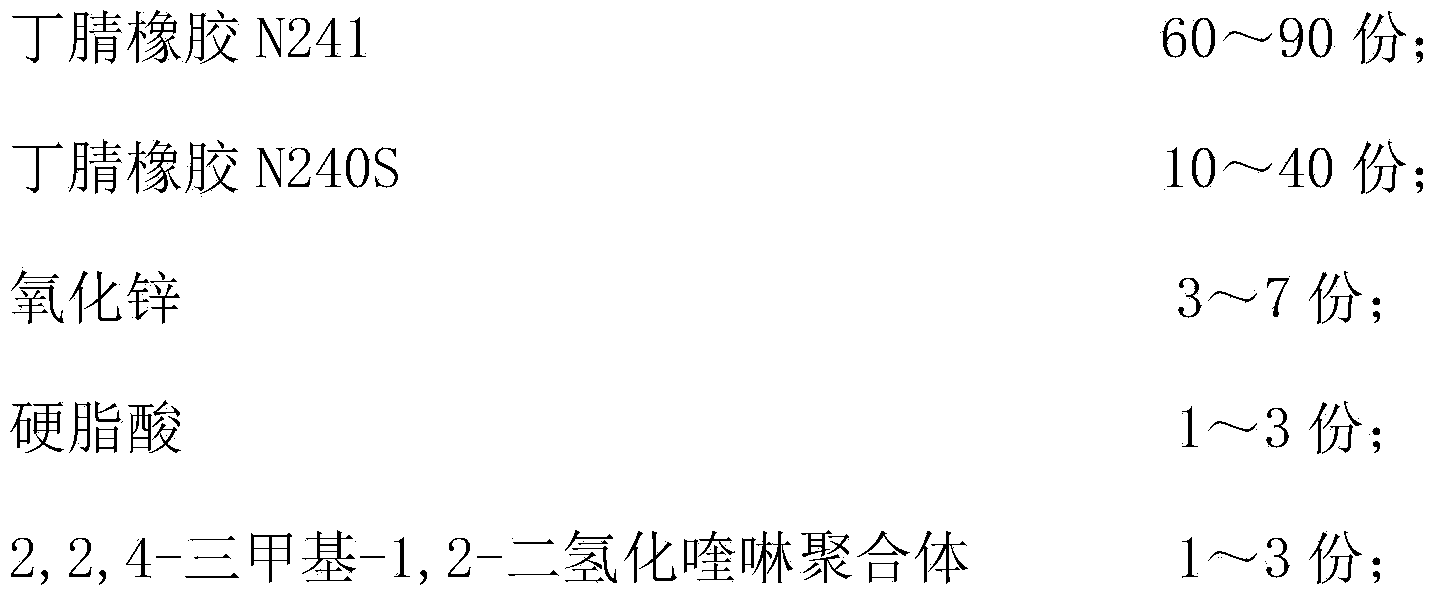

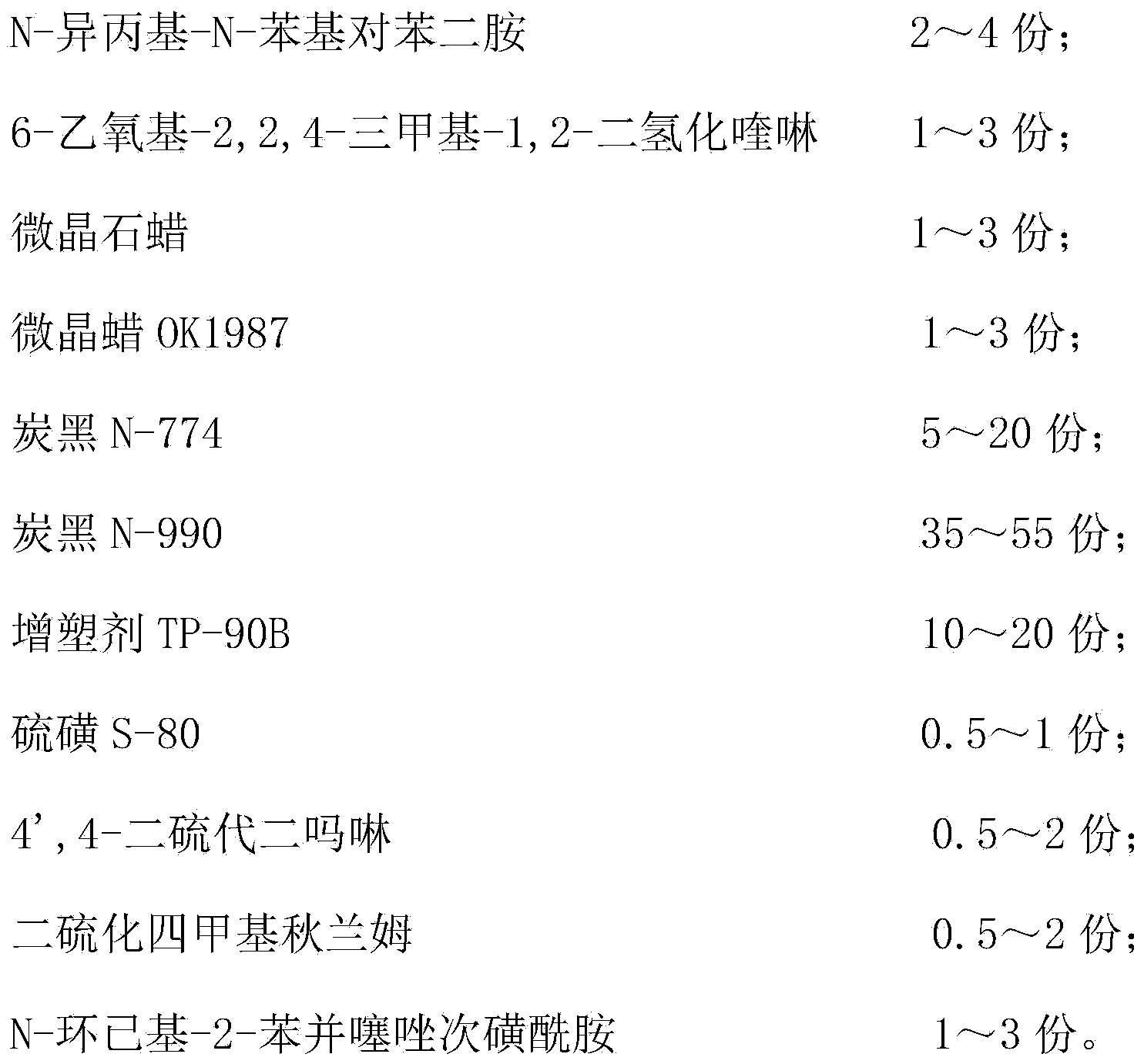

Nitrile-butadiene rubber NBR gear cover sealing material and preparation method thereof

ActiveCN103772765AImprove high and low temperature resistance and medium resistanceImprove low temperature resistanceAgricultural engineeringPlasticizer

The invention discloses a nitrile-butadiene rubber NBR gear cover sealing material which comprises the following raw materials in parts by weight: 60-90 parts of NBR N241, 10-40 parts of NBR N240S, 3-7 parts of zinc oxide, 1-3 parts of a stearic acid, 1-3 parts of RD, 2-4 parts of 4010 NA, 1-3 parts of 6-ethoxy-2-methyl-1,2,4-trimethyl-1,2-dihydroquinoline, 1-3 parts of microcrystalline wax, 1-3 parts of microcrystalline wax OK1987, 5-20 parts of carbon black N-774, 35-55 parts of carbon black N-990, 10-20 parts of a plasticizer TP-90-B, 0.5-1 part of sulfur S-80, 0.5-2 parts of 4',4-DTDM, 0.5-2 parts of tetramethyl thiuram disulfide, and 1-3 parts of N-cyclohexylbenzothiazole-2-sulphenamide. The invention also discloses a preparation method of the nitrile-butadiene rubber NBR gear cover sealing material.

Owner:ASIMCO NVH TECH CO LTD ANHUI

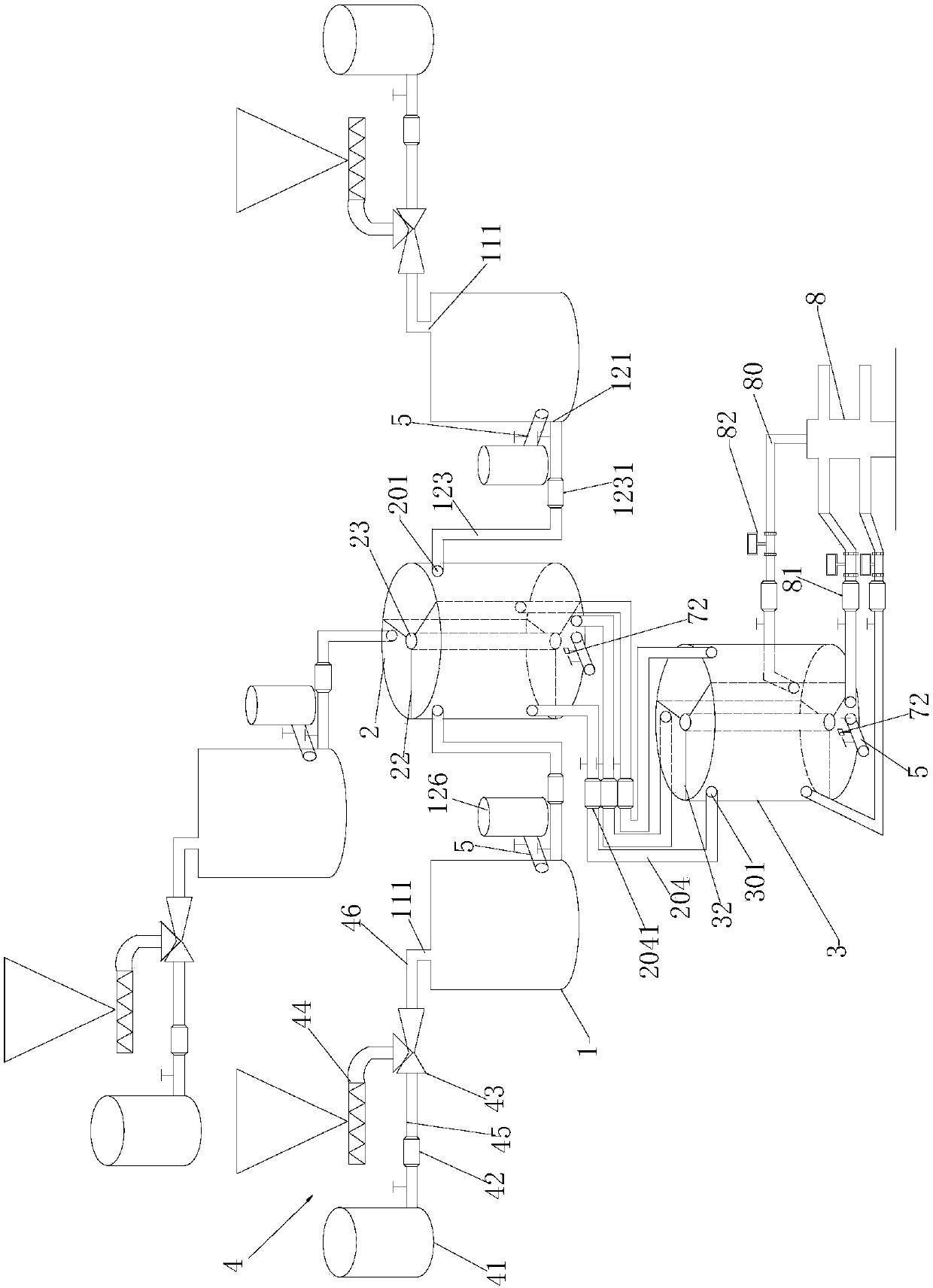

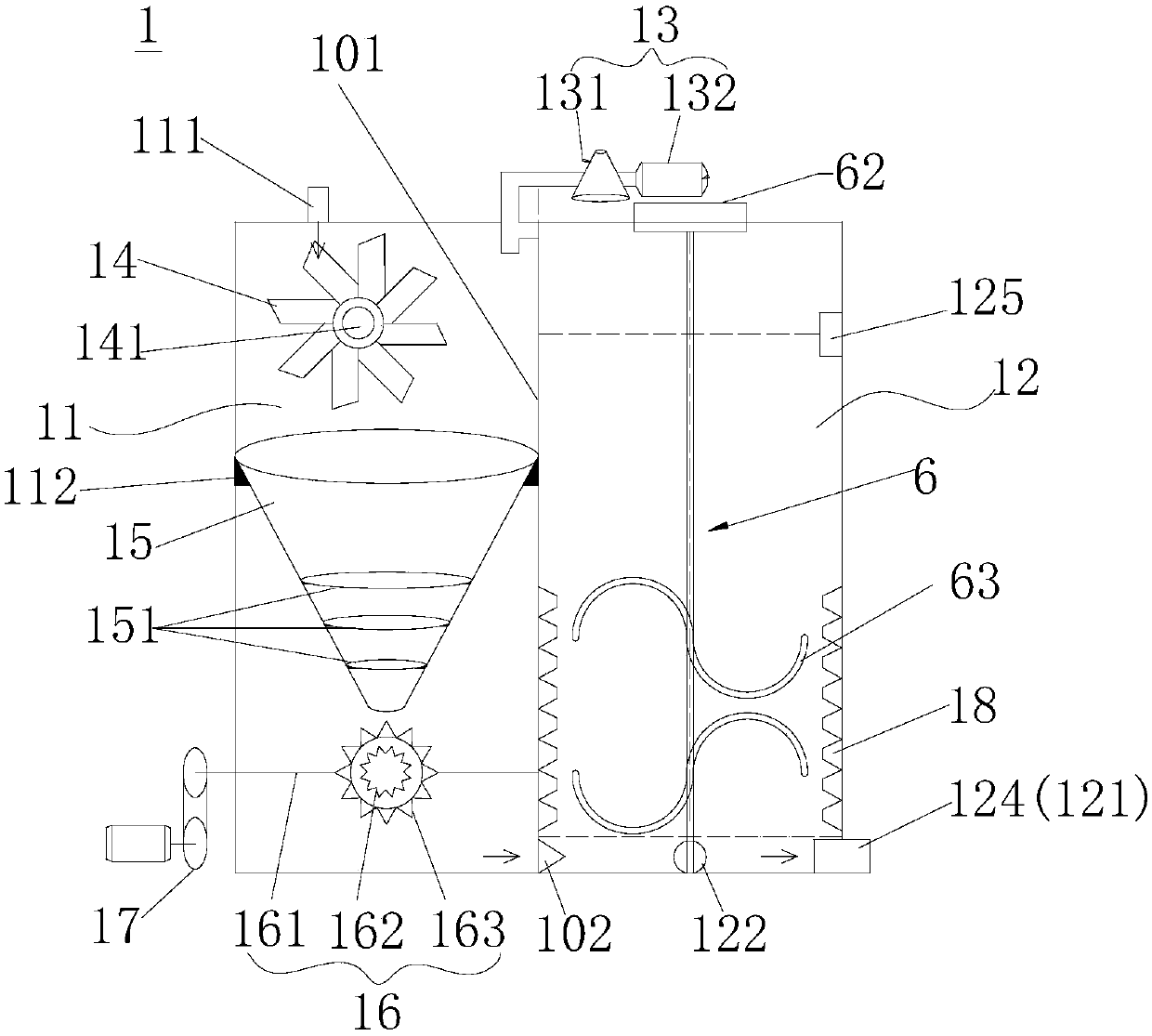

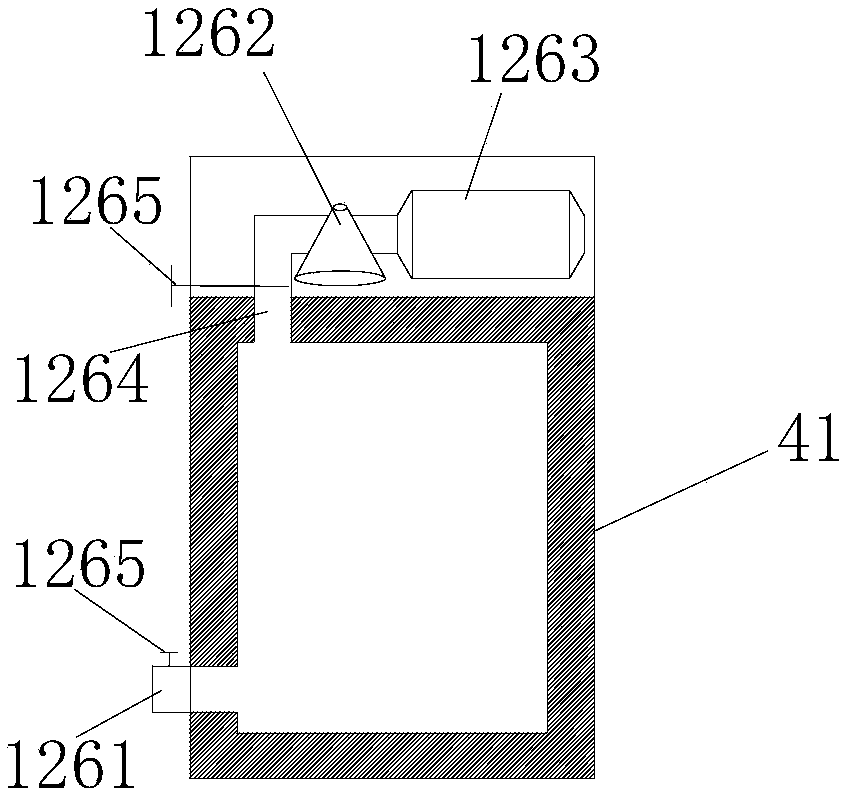

Polymer-surfactant solution ground injection system applicable to mine field and its injection method

ActiveCN107638715AMeet the requirements of diverse maturation timeReduce viscosity lossLiquid degasificationMixersEngineeringCheck valve

The invention provides a polymer-surfactant solution ground injection system applicable to mine field and its injection method. The polymer-surfactant solution ground injection system comprises at least two mixing tanks, a curing tank, and a fluid storage tank; the inner cavities of the mixing tanks are divided into a mixing room and a junction room by a middle board, and the top parts of the mixing tanks are equipped with vacuumizing devices connected to the mixing rooms; a check valve is arranged at the through hole of the bottom part of the middle plate, and the top part of the mixing roomis provided with a first fluid inlet; the bottom part of the junction room is provided with a first fluid outlet and a first sampling opening; the inner cavity of the curing tank is separated into atleast two curing rooms along the circumference, a second fluid inlet is arranged on the side wall of the curing tank corresponding to every curing room, and the bottom part corresponding to every curing room is provided with a second sampling opening and a second fluid outlet; the inner cavity of the fluid storage tank is separated to be at least two fluid storage rooms along the circumferential direction, and a third fluid inlet is arranged on the side wall corresponding to every fluid storage room; the bottom part corresponding to every fluid storage room is provided with a third sampling opening and a third fluid outlet.

Owner:PETROCHINA CO LTD

Non-asphaltic based self-adhered high polymer waterproof coiled material and preparation method thereof

InactiveCN108250999AStrong heat aging resistanceStrong UV protectionPressure sensitive film/foil adhesivesHeat-activated film/foil adhesivesHigh polymerBarium sulfate

The invention provides a non-asphaltic based self-adhered high polymer waterproof coiled material and a preparation method thereof. The non-asphaltic based self-adhered high polymer waterproof coiledmaterial is prepared from the following components: low-density polyethylene, high-density polyethylene, polyurethane, ethylene-vinyl acetate glyceride, barium sulfate, ultraviolet absorbent, antioxidant, silica gel, coupling agent, brucite powder, glycerin monostearate, cis-9-oleic alcohol and accelerant; the coupling agent is formed by mixing aluminic ester coupling agent DL-411, silane couplingagent KH-570 and titanate coupling agent 311 in mass ratio of 1: 2: 1. The non-asphaltic based self-adhered high polymer waterproof coiled material has good adhesion effect with the wooden basal plane, the heat-proof ageing performance and the anti-ultraviolet performance are strong.

Owner:富华防水科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com