Polymer-surfactant solution ground injection system applicable to mine field and its injection method

An injection system and surface-polymerizing agent technology, which is applied to the ground injection system of surface-polymerizing agent solution and its injection field, can solve the problems that cannot meet the needs of diversification of curing time of surface-polymerizing agent, defoaming of surface-polymerizing agent solution, and diversification. Requirements and other issues to achieve the effect of realizing the aging time, improving the performance retention rate, and realizing diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

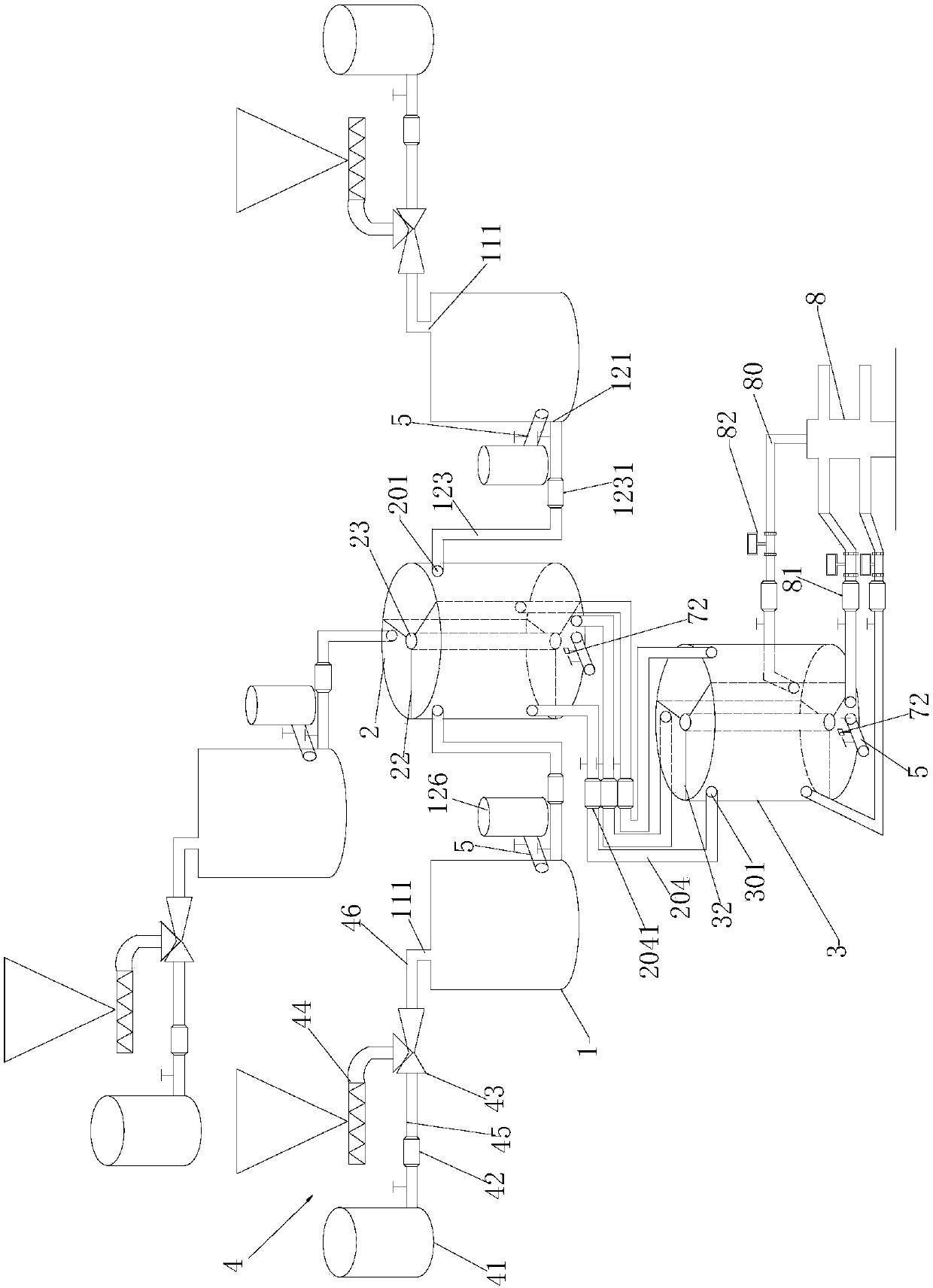

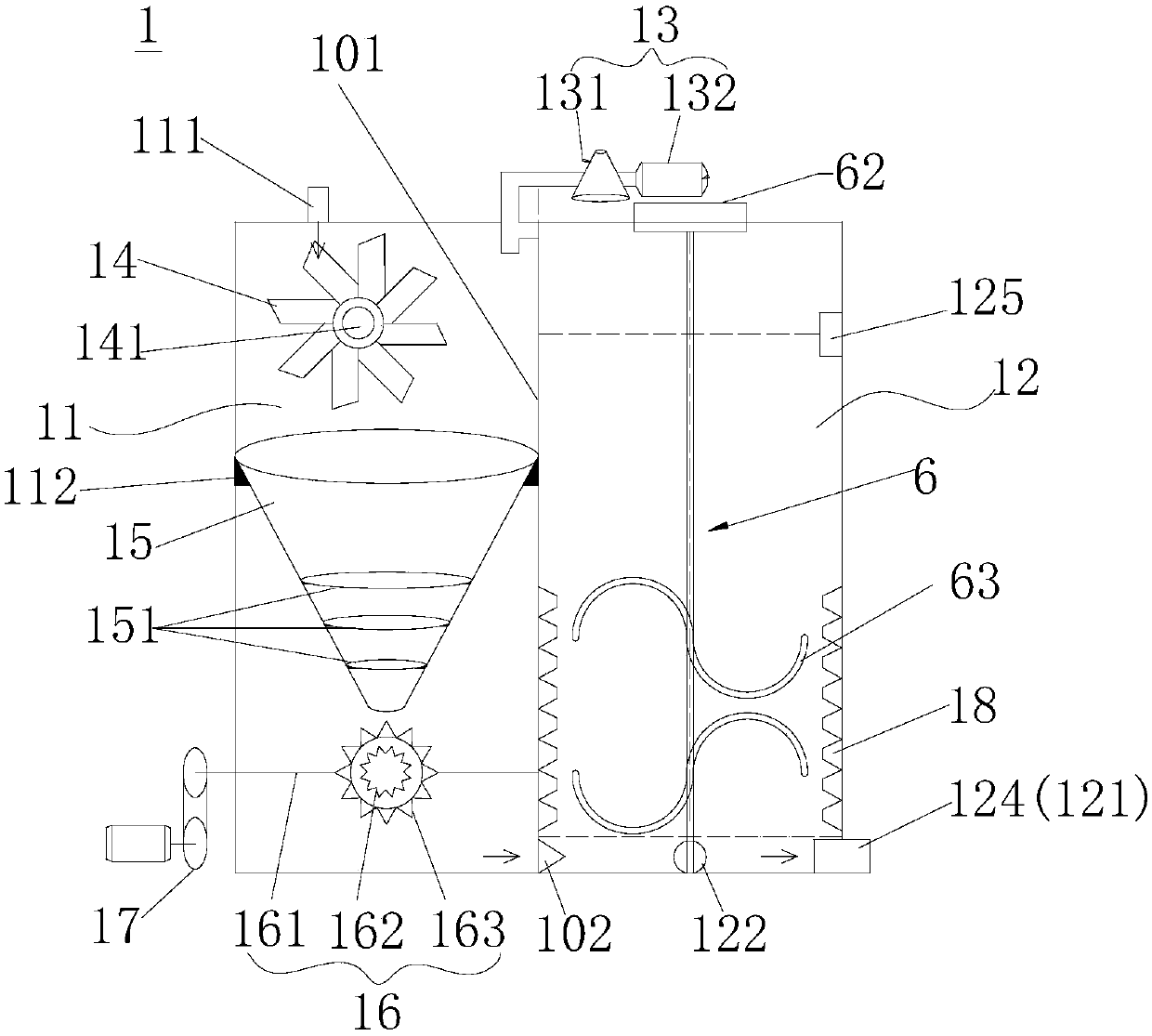

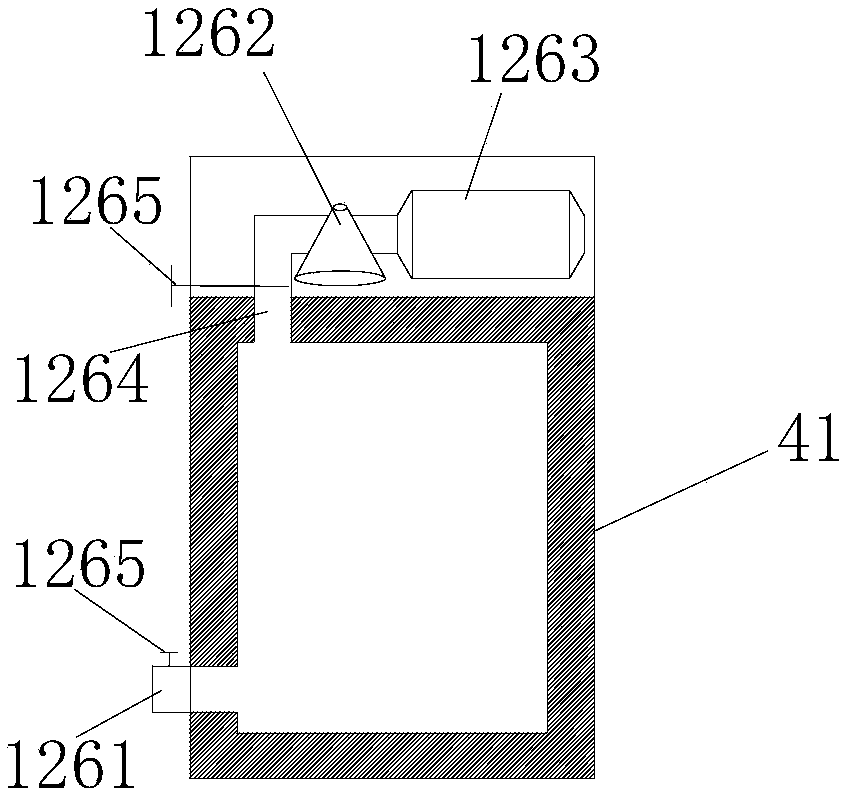

[0106] For this reason, the present invention proposes a kind of polymer surface agent solution ground injection system that is applicable to mine field, and it comprises: at least two mixing tanks, the inner chamber of described mixing tank is divided into a mixing chamber and a confluence chamber by a neutral plate, A vacuum device connected to the mixing chamber and the confluence chamber is installed on the top, a check valve is provided at the through hole at the bottom of the neutral plate, and a first liquid inlet is opened on the top of the mixing chamber. The bottom of the confluence chamber is provided with a first liquid outlet and a first sampling port; a ripening tank, the inner cavity of which is divided along the circumferential direction with at least two ripening chambers, corresponding to each of the ripening chambers on the side wall of the ripening tank A second liquid inlet is respectively provided, and a second sampling port and a second liquid outlet are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com