A spiral pressure divider and its measuring method capable of measuring and adjusting the pressure in real time

A spiral and pressure technology, which is applied in the field of partial pressure injection devices, can solve the problems of inability to measure pressure and non-adjustable structure of partial pressure injection tools, etc., and achieve real-time measurement, save a lot of cost and time, and reduce viscosity loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

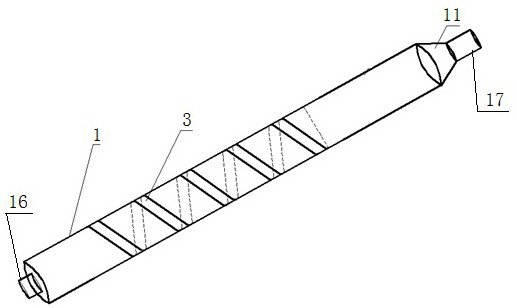

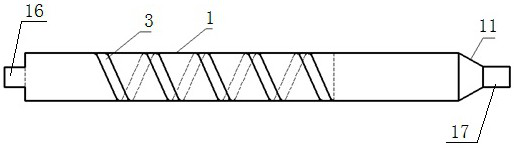

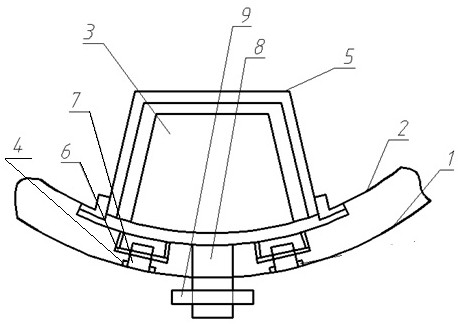

[0030] to combine Figure 1-Figure 9 As shown, the spiral pressure divider that can measure and adjust the pressure in real time includes an outer cylinder 1, an inner cylinder 2, a spiral throttle groove 3, a pressure sensor 11, a computer, an outer cylinder 1 and an inner cylinder 2 are coaxially arranged, and the inner cylinder 2 The two ends are provided with inlet 16 and outlet 17 respectively. The spiral throttling groove 3 is installed on the wall surface of the inner cylinder 2. Between the inner cylinder 2 and installed on the inner wall of the outer cylinder 1; the telescopic spiral groove is made of a telescopic spiral stripe plate 5, and the cross section is trapezoidal. The telescopic spiral groove is formed by telescopically connecting together a section of the trough along the spiral direction. The first section of the section of the trough is closed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com