Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3729 results about "Bearing (mechanical)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bearing is a machine element that constrains relative movement to the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

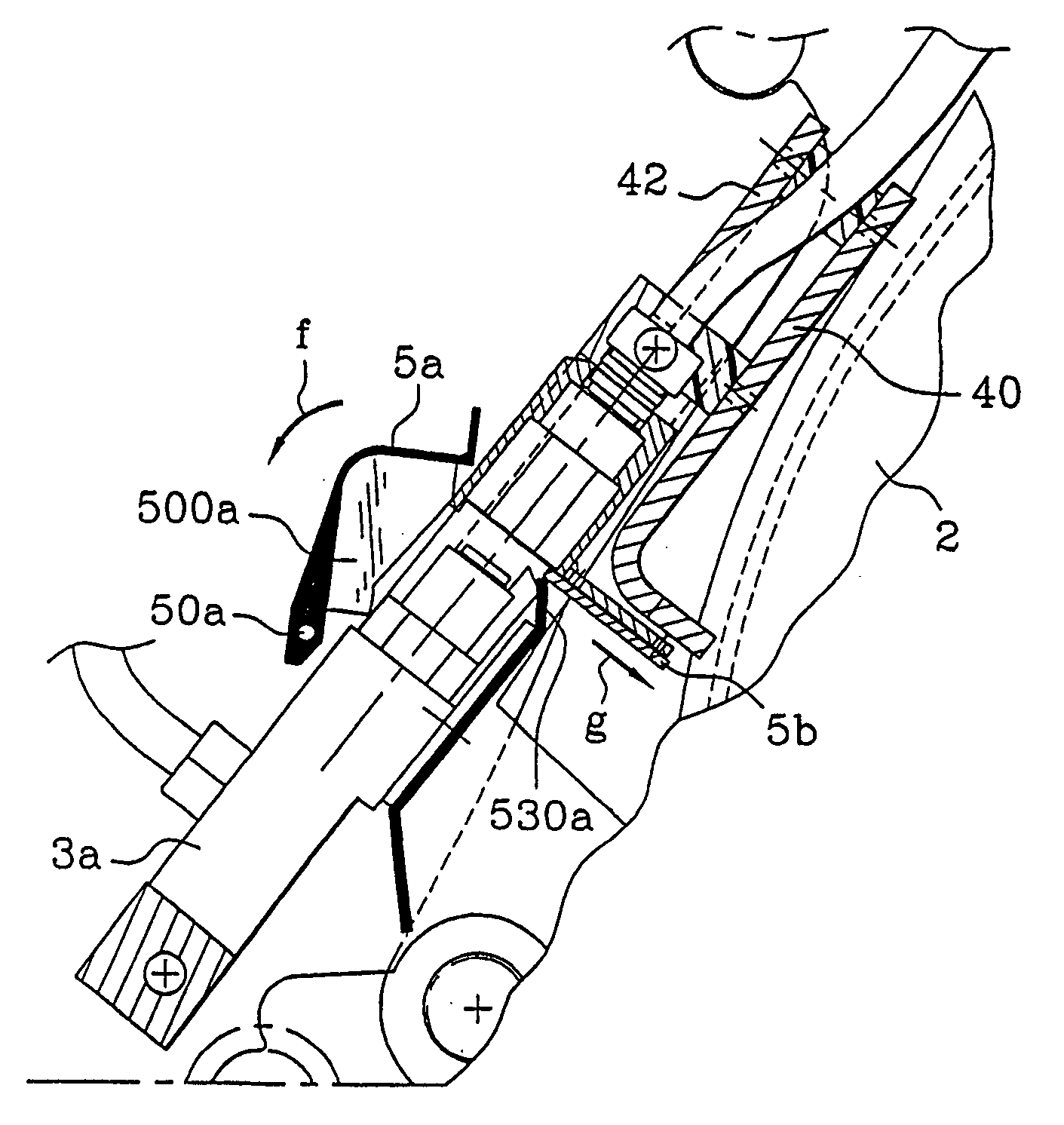

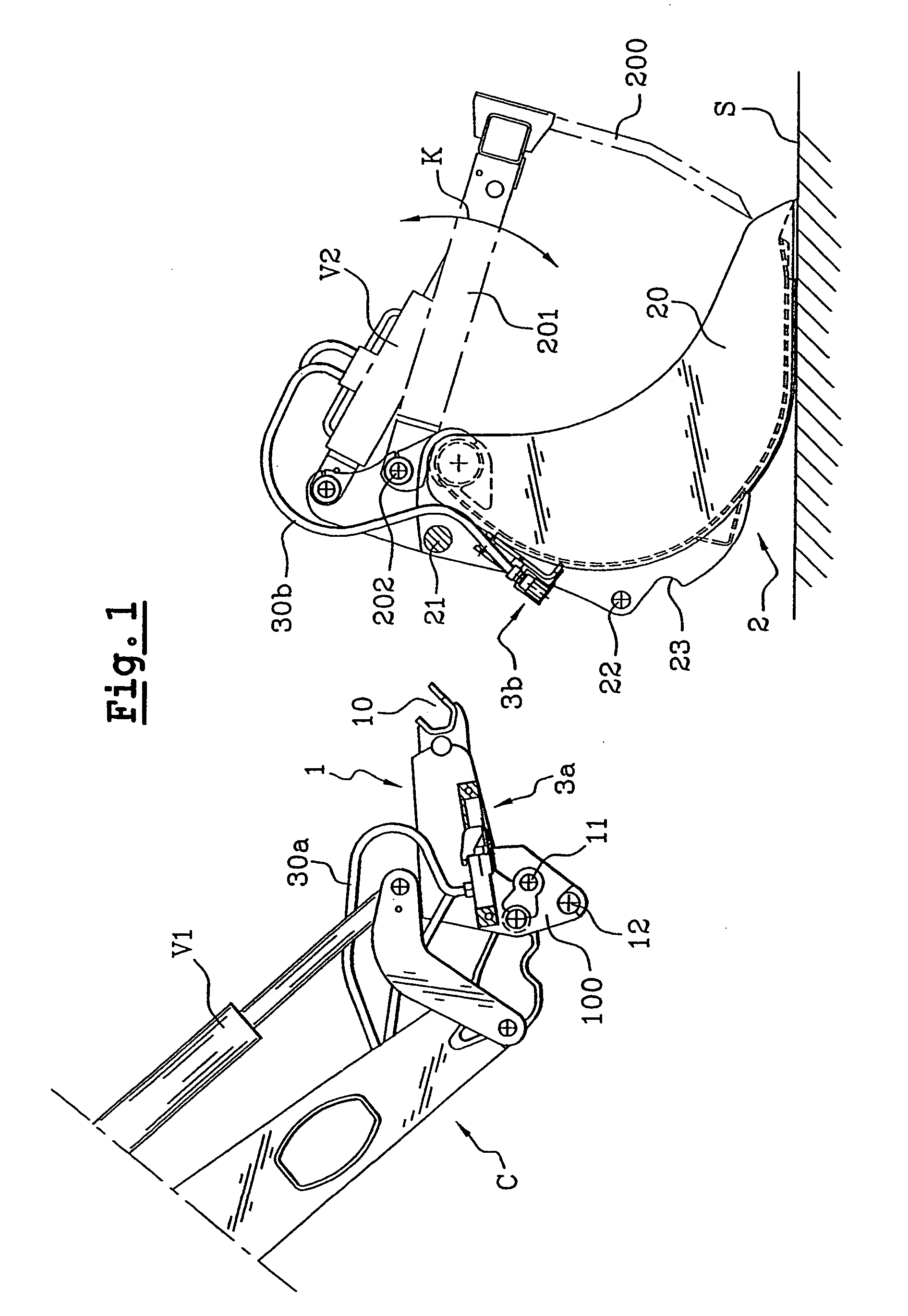

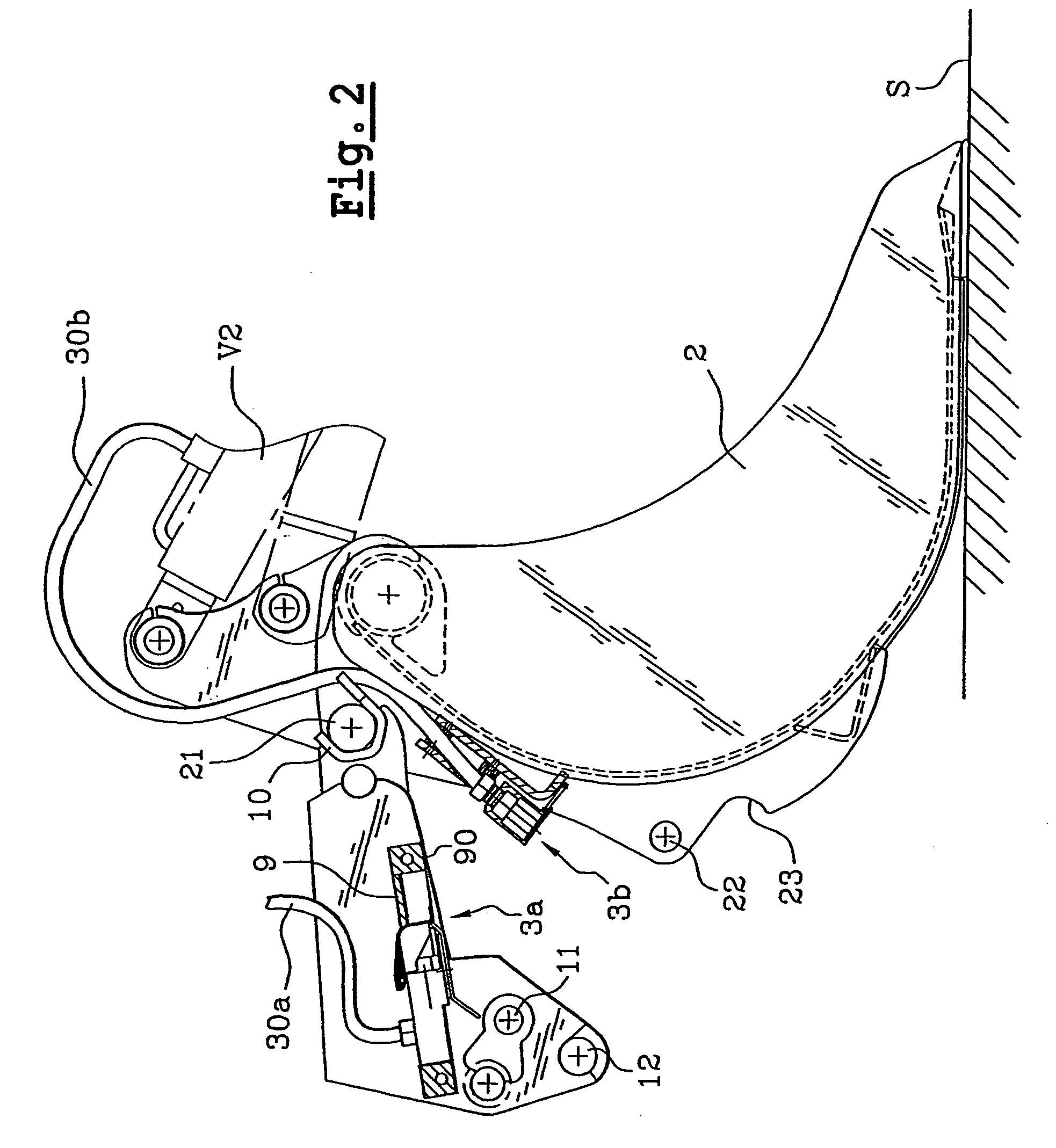

Method and a system for establishing mechanical and multiple-fluid couplings between a tool and a tool-carrier frame

InactiveUS6899509B1Actuation can be preventedReduce riskMechanical machines/dredgersLifting devicesFluid couplingClassical mechanics

The invention concerns a system wherein the tool-bearing frame (1) and the tool (2) are each equipped with a multiple fluidic connection box, for example hydraulic provided with complementary male-female connecting members: each of said boxes is provided with a mobile and retractable protective cover, which normally covers the connecting members contained in said box. Said covers are arranged such that, in a first phase, the proper positioning of the tool-bearing-frame opposite the tool automatically causes the covers to retract, directly matching the fluidic connection members of the two boxes, so as to enable subsequently, in the second and third phases, the mechanical followed by the fluidic connection of the tool-bearing frame and the tool. The system protects the connecting members from the outside environment, while enabling easy and secure connection of the tool with the tool-bearing frame, without any risk of deterioration of the fluidic connectors.

Owner:MAILLEUX

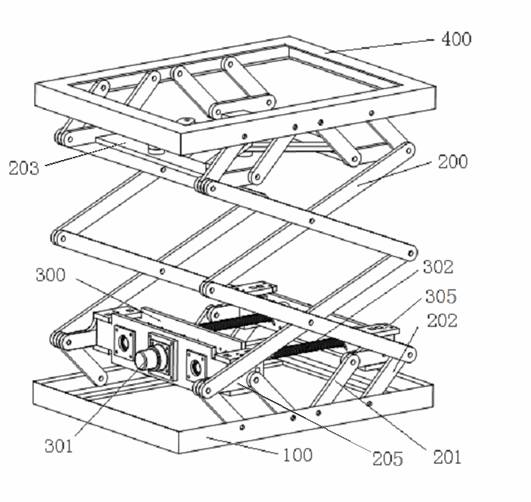

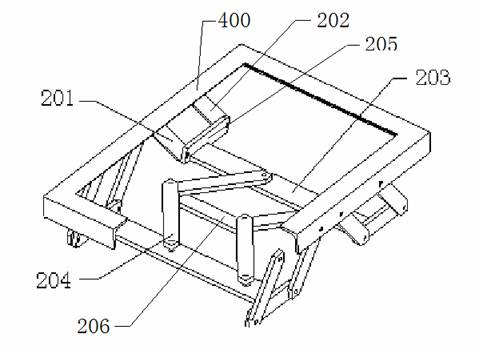

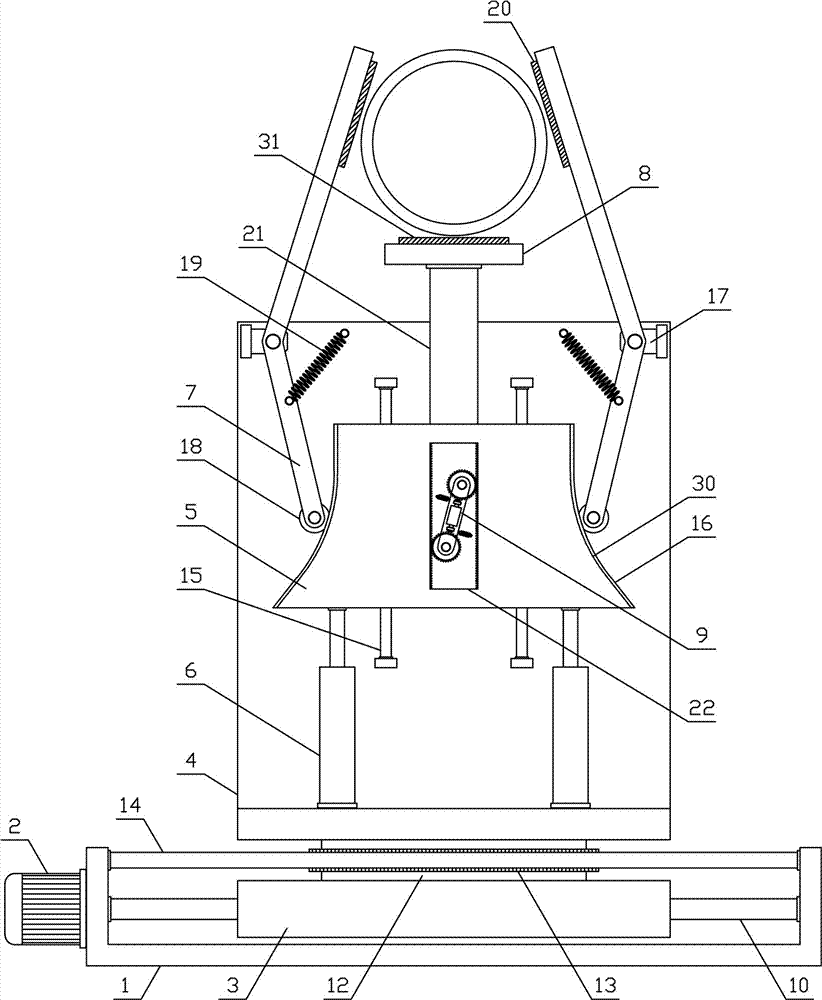

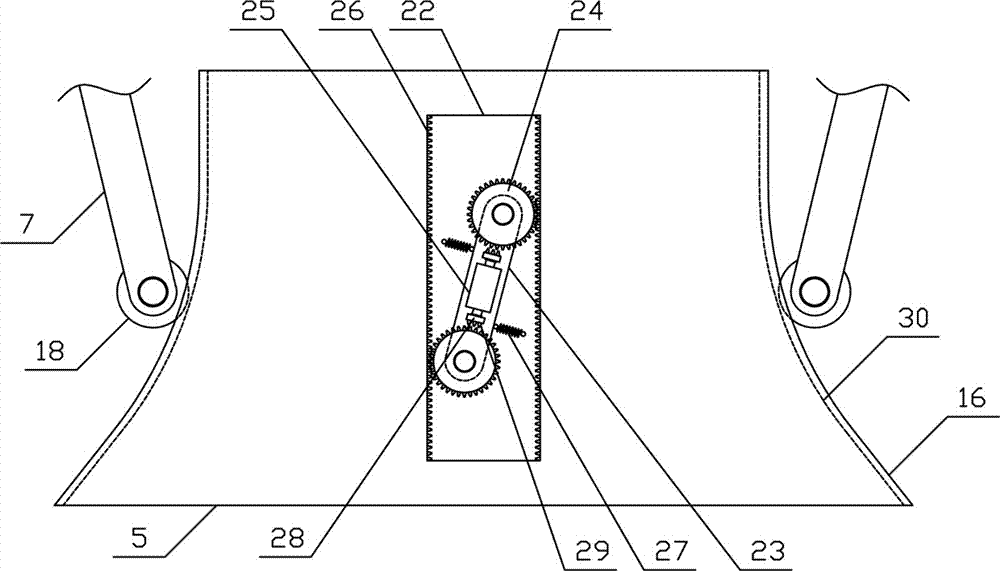

Electric shear type lifting platform

InactiveCN102556892ASimple structureReduce power lossGearingLifting framesClassical mechanicsScrew thread

The invention discloses an electric shear type lifting platform, which comprises an upper movable bearing platform, a lower base, a mechanical lifting mechanism and a power driving mechanism, wherein the mechanical lifting mechanism is provided with a plurality of shear fork components, the power driving mechanism is a screw horizontal track feed actuating mechanism and comprises two screws which are parallel to each other and correspondingly arranged side by side, a driven end of each screw is in rotating connection with the position at the bottom end of one side of the bottom shear forks through a bearing, threaded sections of the screws are movably connected with a parallel moving block with internal threads matched with the threaded sections, the parallel moving block is fixedly connected with the bottom end of the other side of the bottom shear forks, folding and unfolding of the bottom shear forks can be realized by the aid of the parallel moving block and horizontal track feed along the screws, and further the upper movable bearing platform is supported to ascend and descend. The power driving mechanism is controlled by means of motor drive, so that folding and unfolding of the shear forks are realized, the upper movable bearing platform is kept parallel to the lower base, and further the lifting platform is stable in operation, low in manufacture cost and wide in application.

Owner:SHANGHAI UNIV

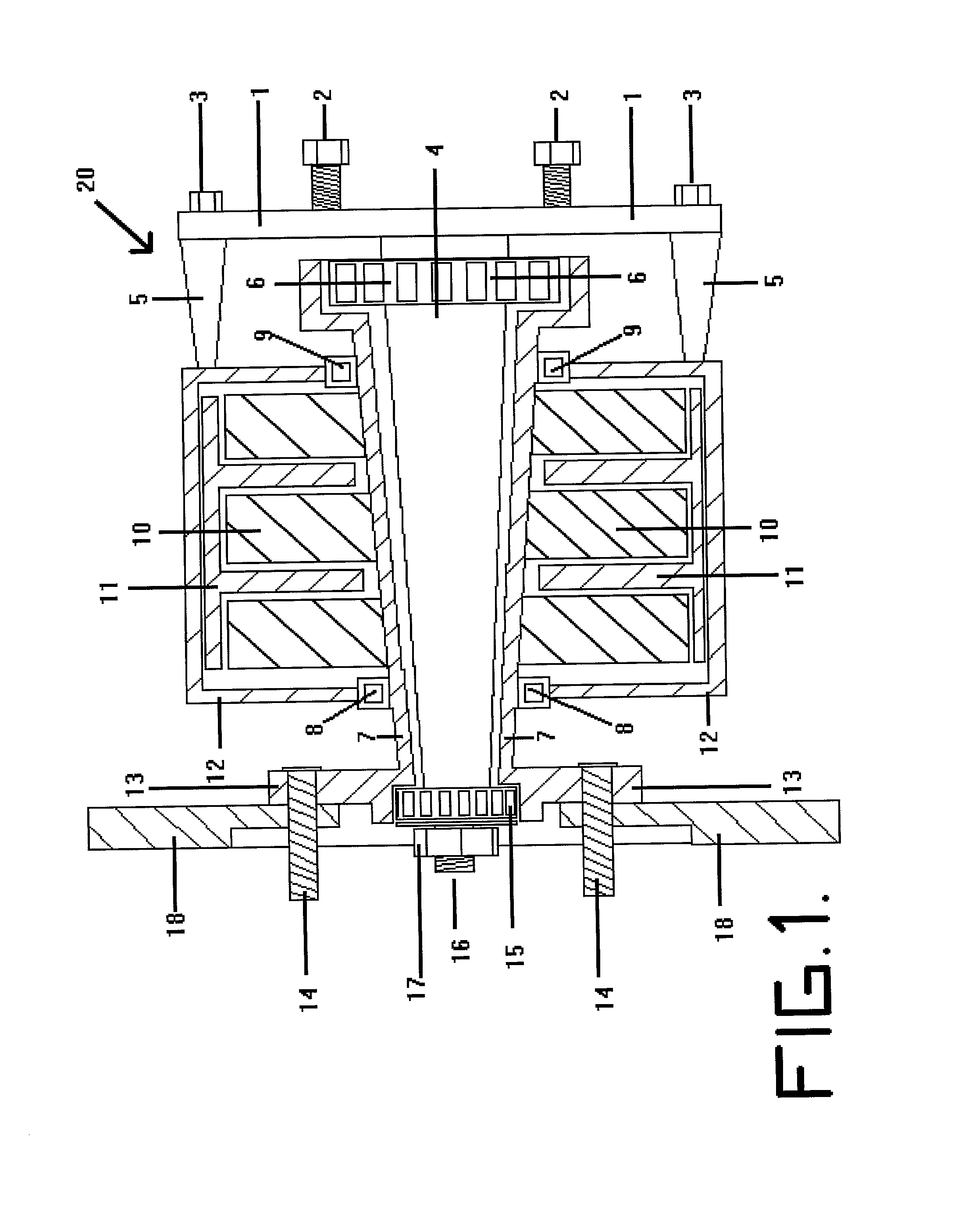

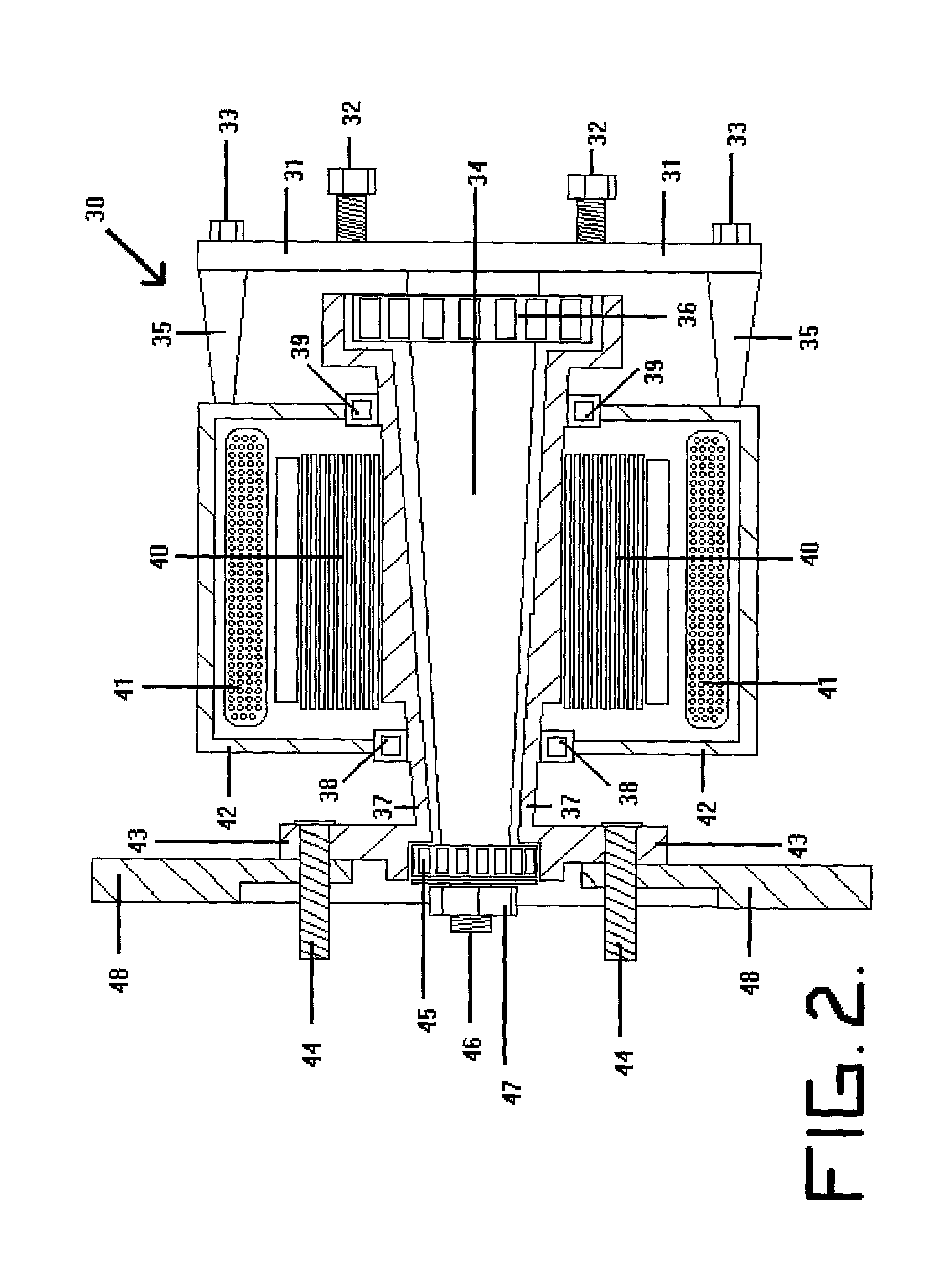

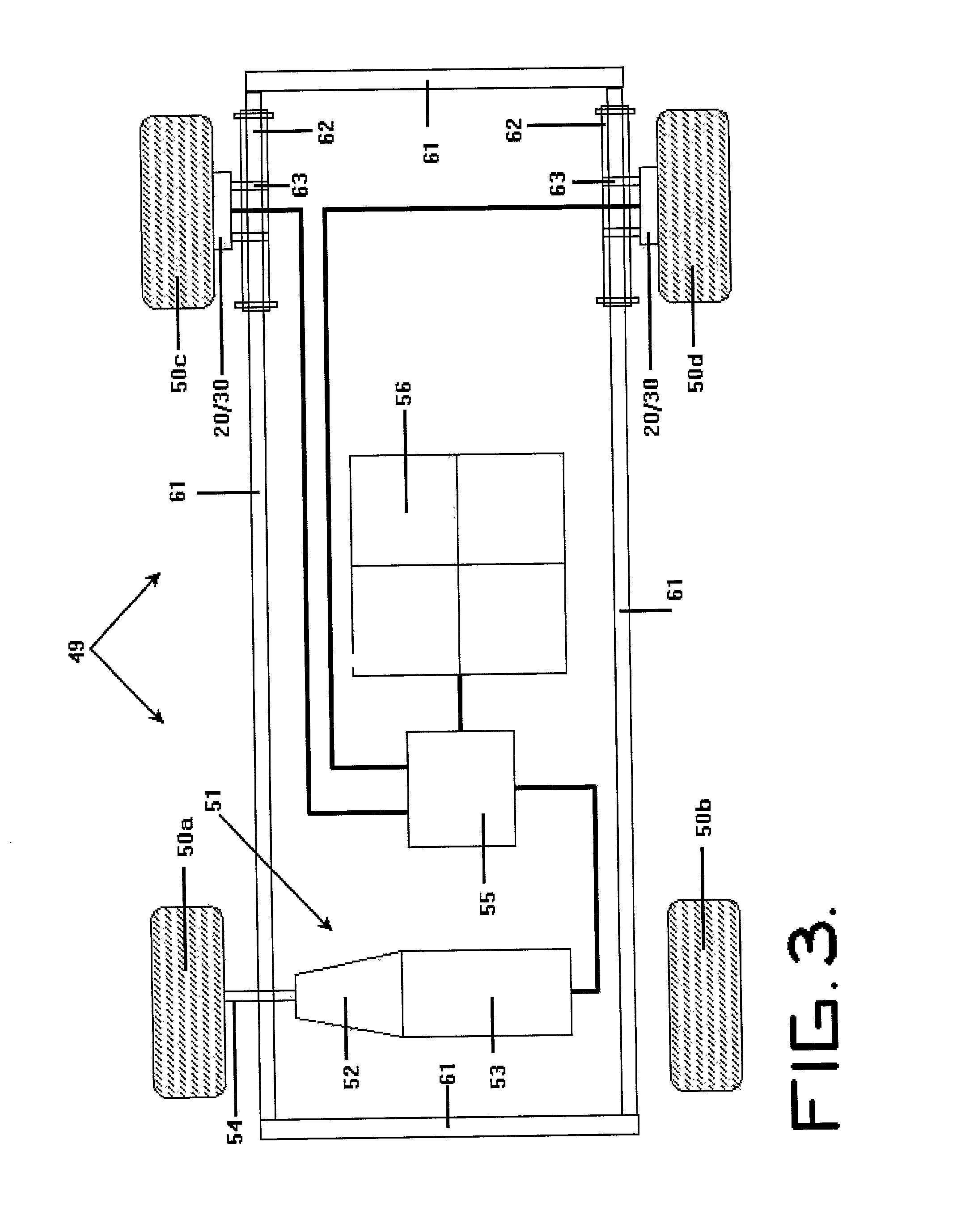

Electric power generation system for electric vehicles

An electrical power generating system is described for generating electrical energy for an electric vehicle, via the motion of the non-drive wheels, which converts kinetic energy to electrical energy to replenish the batteries of said vehicle. The preferred version places one or more alternator / generator(s) at the non-driven wheels of the vehicle. Each alternator / generator is unitarily formed with respect to a mounting plate unitarily formed with respect to said mounting plate and said vehicle's suspension, and each alternator / generator includes a rotating field means integrated with the rotating mounting plate attached to the wheel and a stationary stator means stationarily attached to the frame through the suspension. Conventional electrical contact means attached to between said rotating field means and said stationary stator means for generating electrical current for said vehicle. Since the mechanical loading on the spindle bearing assemblies has been substantially increased, the bearing assemblies of the invention are of a heavy-duty design. That is, such bearing assemblies are large enough to handle the weight of said vehicle, including that of the alternator, as well as the weight of the wheel assembly, including tire and brakes. As the vehicle moves forward or backward, the rotational force applied to the vehicle's wheels will rotate the integrated rotating field means relative to the stationary stator means to produce alternating current (AC). Alternating current is converted to direct current (DC) either by a diode bridge, transformer, or controller, for distribution to the EV's electrical system. DC electricity is used to recharge storage batteries, provide electricity for the drive motor and operate the vehicle's electrical equipment. Thus, the regenerative system, does not add any additional load on the drive motor. Wheel bearing assemblies are usually used for all wheels on vehicles and the very nature of bearing assemblies are to reduce friction. By the incorporation of alternators into the wheel bearing assemblies, a vehicle can generate electricity when moving, without additional workload to the drive train; since wheel bearing assemblies are a necessary and integral part of any rolling vehicle and by their very nature reduce friction and resistance.

Owner:SMITH VINCENT A +2

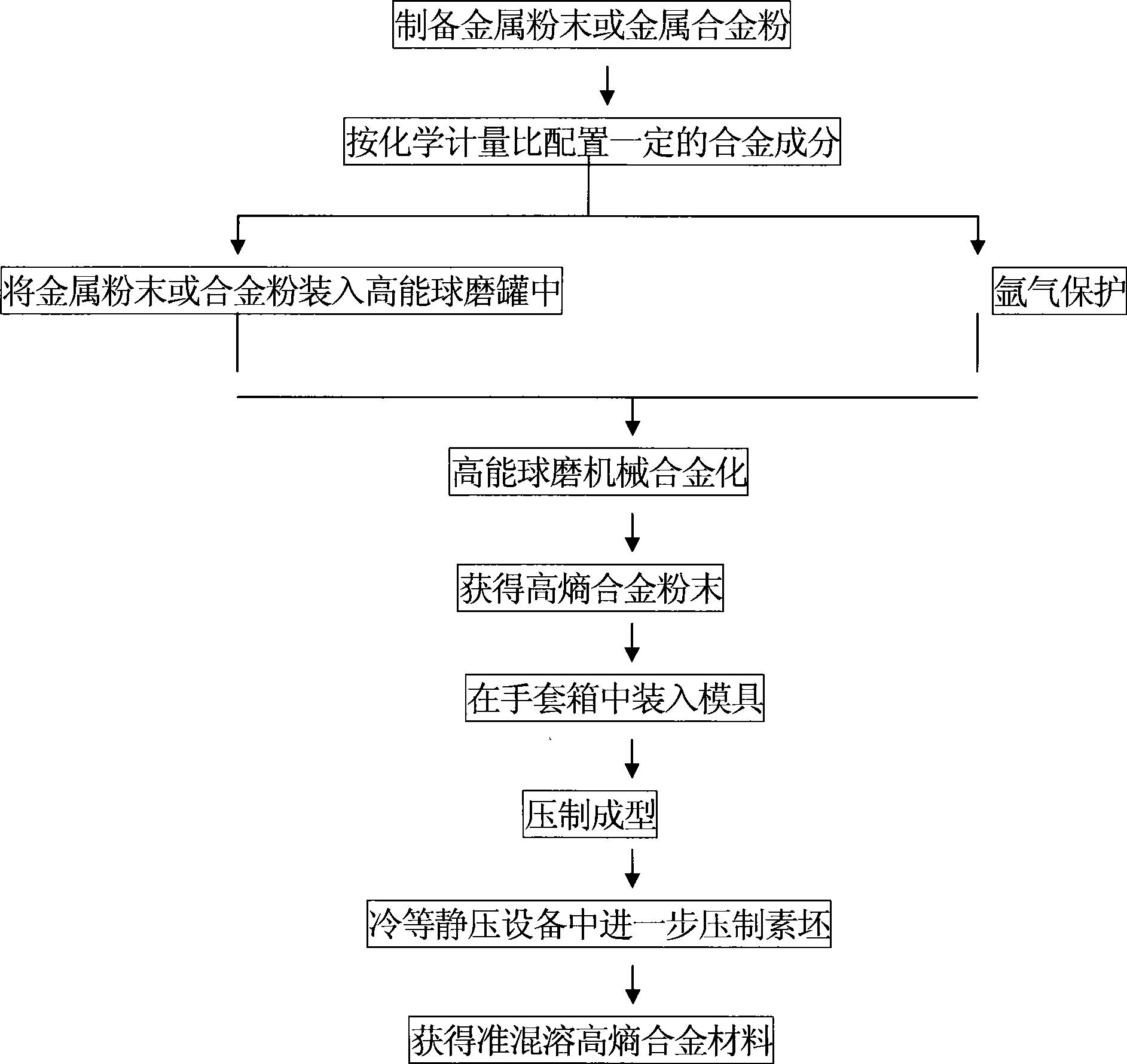

Method for preparing high-entropy alloy containing immiscible element

The invention discloses a preparation method for a novel high-entropy alloy structure material. A plurality kinds of alloy element powder which can not form a miscible system are used as raw materials, thereby solving the solid solution problem of the alloy elements without solid solution region during the high-entropy alloy preparation, that is, mixing the powders in a planetary high-energy ball milling machine and obtaining ultra-fine powder of an immiscible system simultaneously through strong mechanical alloying function. When the alloy powder is pressed into a pressing blank, the heating treatment process condition is controlled to allow the alloy elements to diffuse through a short path and form a uniform multi-principal element mixing body containing no intermetal compound in a blank body, and a single-phase solid solution is obtained. The novel alloy prepared by the method is widely used in engine parts made of a high-temperature and creep resistance material, skins and tails of large thrust weight ratio high-speed aircrafts, corrosion resistant and wear resistant parts, wear-resistant materials such as pipes, gears and bearings and other structural material fields.

Owner:KUNMING UNIV OF SCI & TECH

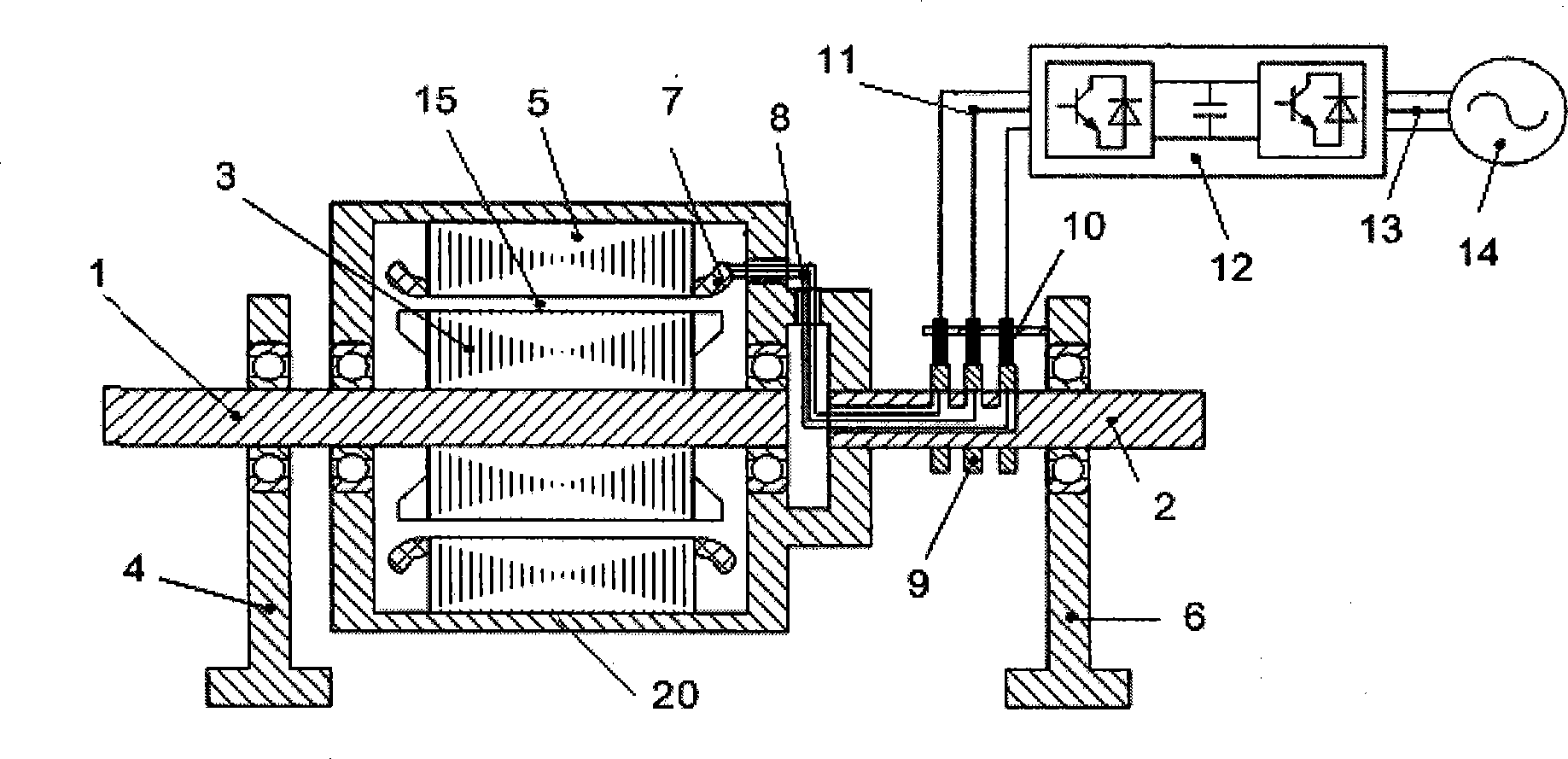

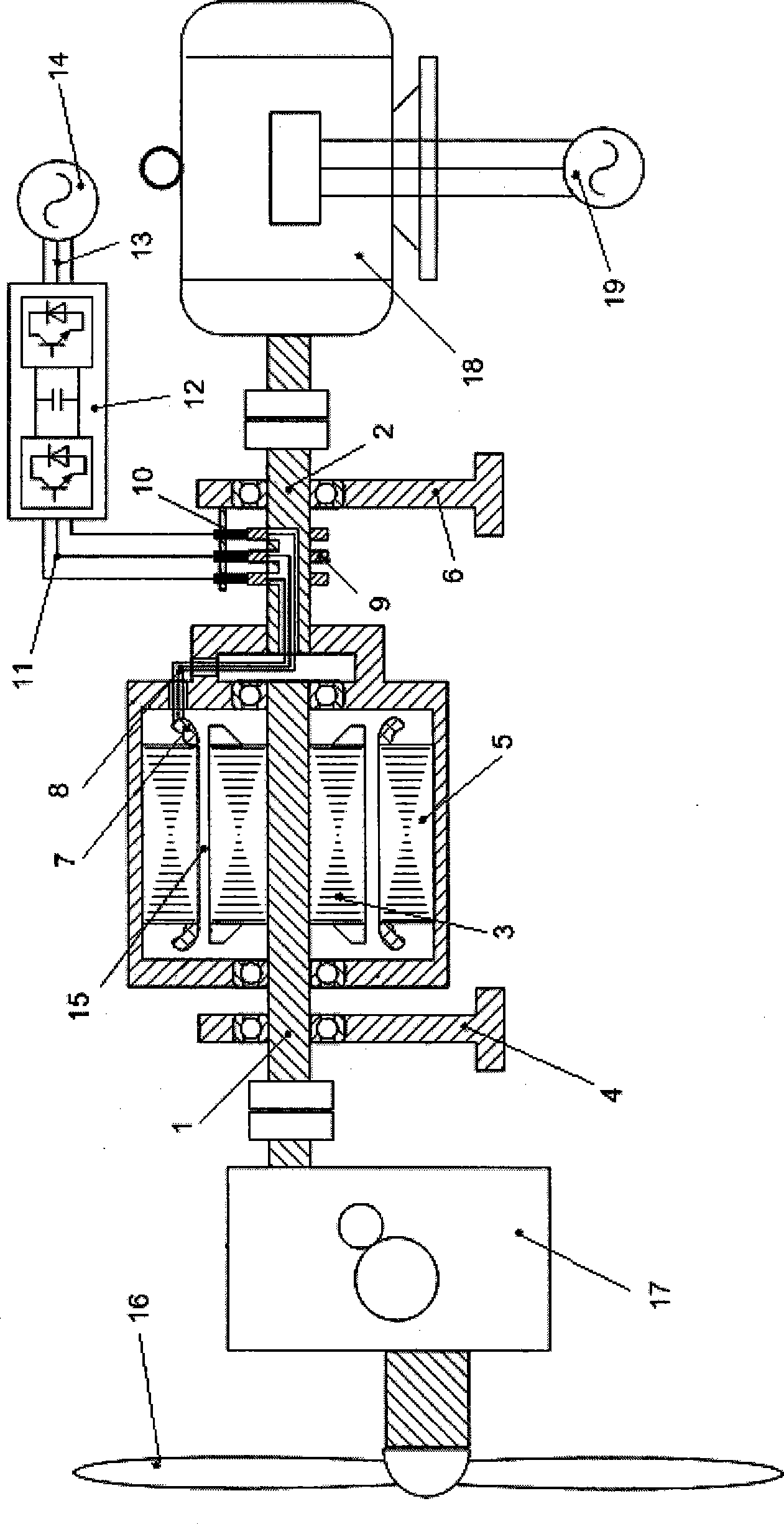

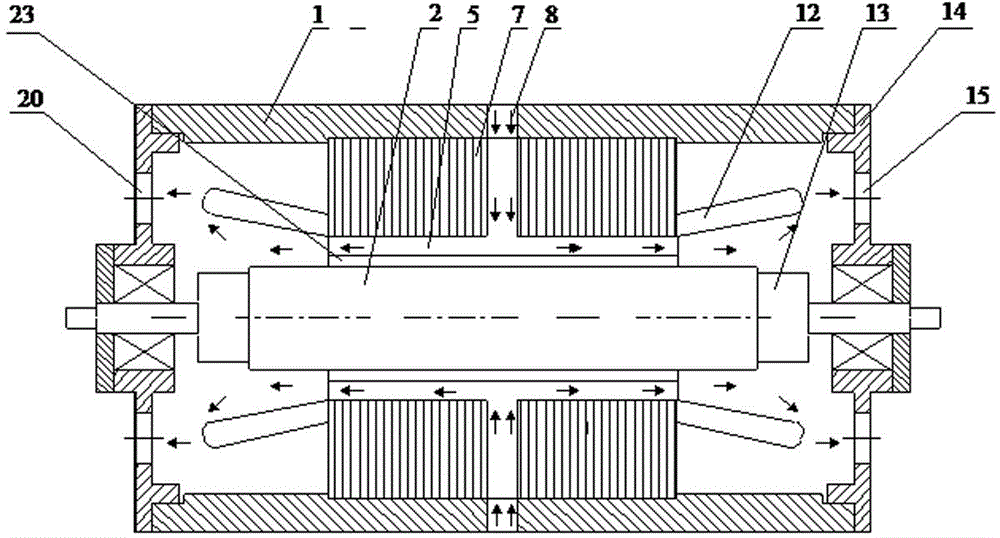

Variable-frequency control electromagnetic torsion coupler and use thereof

InactiveCN101465592AHard mechanical propertiesRealize stepless speed regulationDynamo-electric gearsDynamo-electric gear controlFrequency changerAlternating current

The invention relates to a variable-frequency speed-regulating magnetic torque coupler which is characterized in that: the coupler comprises a shell, and an inner rotor mechanical axis and an outer rotor mechanical axis are arranged in the shell; the inner rotor mechanical axis is connected with an inner rotor which is supported on a static bearing frame of the inner rotor, and the outer rotor mechanical axis is connected with an outer rotor which is supported on the static bearing frame of the outer rotor; an electromagnetic coupling working air gap is formed between the inner rotor and the outer rotor; the outer rotor is internally provided with an armature winding which is connected with a group of three-phase static electric brushes by three drainage slipping rings; the three-phase static electric brush is connected with the output end of a frequency converter, and the input end of the frequency converter is connected with a three-phase alternating-current electric fence. As a variable-frequency speed-regulating technology is introduced in a simple electric transmission system, non-contact torque transmission and stepless speed regulation between two rotary mechanical shafts can be realized by utilizing the principle of variable-frequency motors. The variable-frequency speed-regulating magnetic torque coupler can be widely applied to transmission systems.

Owner:TSINGHUA UNIV

Wave-powered water wheel type generator

A Styrofoam-filled plastic cylinder that has collapsible paddle wheel fins attached about the circumference. Two shafts extend from the ends of the cylinder. The shafts are held by bearings. The bearings are attached to a frame structure that is embedded into the seabed. The shafts then extend past the bearings and are connected to a gear drive system that, in turn, connected to generators or other mechanical devices. When installed in the sea, the cylinder will turn in the swells / tidal action for as long as the ocean produces waves. Platforms on either side of the cylinder rise and fall with tidal action to maintain effective contact with the water at all times. Moreover, because the structure is positioned at or near the water surface, maintenance is much simpler for this device.

Owner:NEESE STEPHEN L

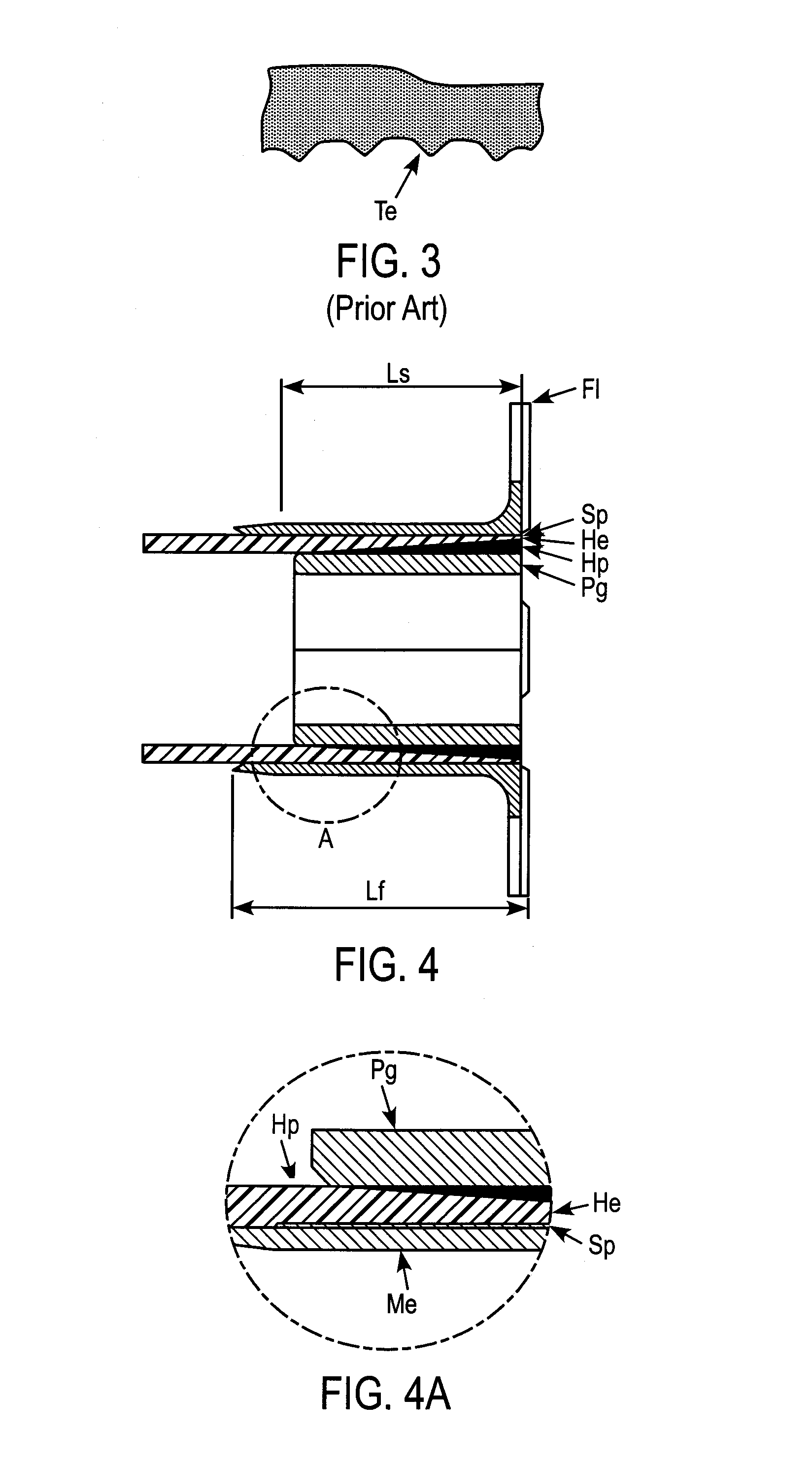

Transmission shaft joint design

ActiveUS7874925B2Improve joint stabilityImprove tensile propertiesJoints with sealing surfacesShaftsDrive shaftCoupling

A fiber reinforced composite shaft bearing a metallic flanged end coupling attached to the outside diameter through a concentric cylindrical torsional joint is provided. The composite shaft is press fitted into a flanged metallic end coupling including a multiplicity of teeth running parallel to the tube axis which cut longitudinal channels into the outside diameter of the composite shaft wall during the press fit process. Pairs of inverted troughs adjacent to and running parallel to the cutting teeth in the serrated region allow space for the redistribution of the composite material and debris formed during the press fitting process. This combined action forms a mechanical interface capable of supporting torsional and axial stresses. A structural adhesive may be applied to the joint region to form a secondary joint. In this case the composite formed between the cutting debris and the adhesive fills the trough channels.

Owner:CROMPTON TECH GROUP

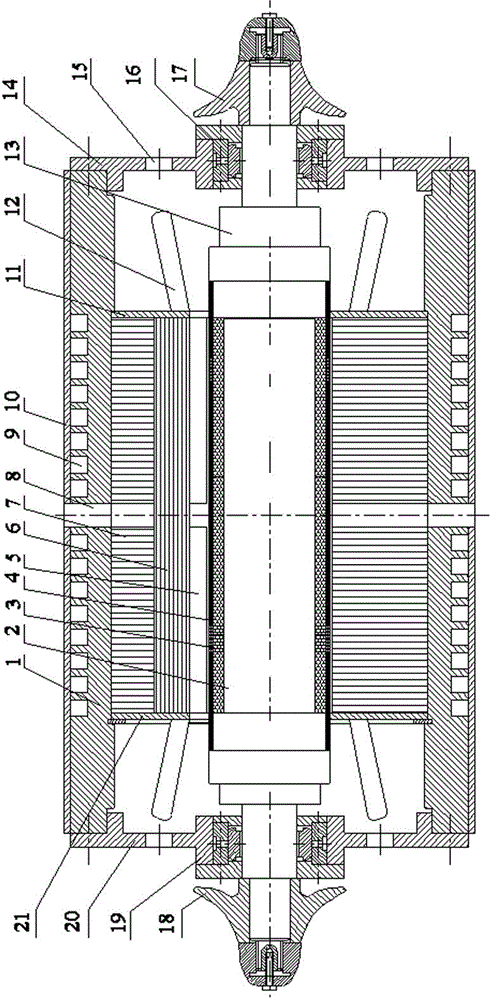

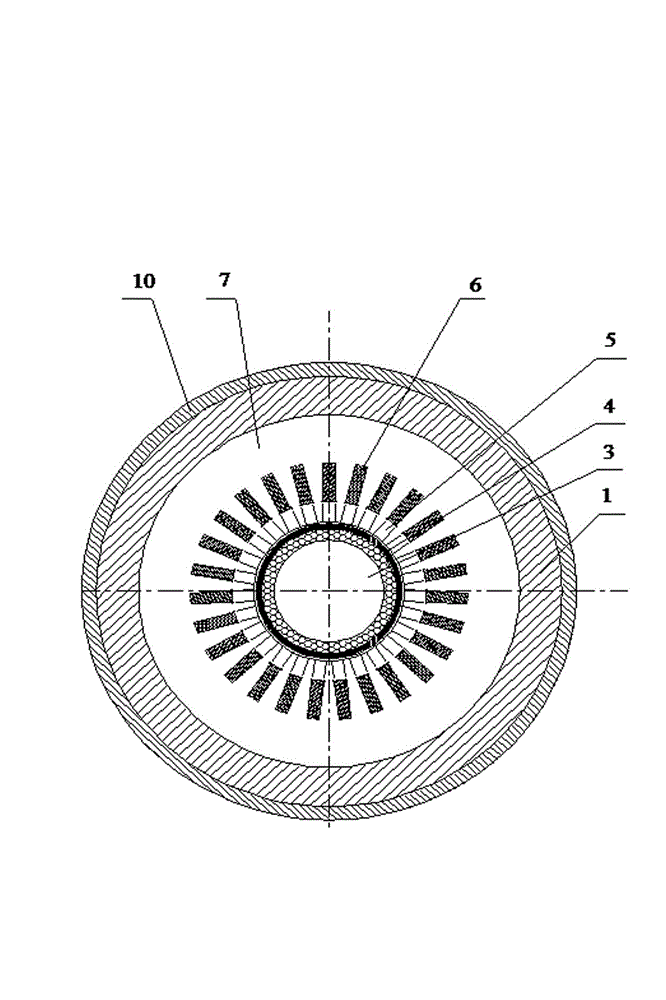

In-slot self-cooling high-speed permanent magnetic motor system for compressor

InactiveCN102983679AAvoid additional lossSafe and effective protectionMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorImpeller

The invention relates to an in-slot self-cooling high-speed permanent magnetic motor system for a compressor and belongs to the technical field of motors. The megawatt high-speed variable-frequency motor comprises a cooling water jacket, a stator core, a stator winding, a stator radial air channel, an inner stator air channel, a permanent magnet rotor, two sliding bearings and two compressor impellers. The system has the advantages that the problems of severe heat and uneven temperatures of a high-speed motor rotor can be solved effectively; the problems of the over-temperature and overlarge axial temperature gradient of the stator core are solved; and not only the strength problem of a permanent magnet under a condition of high-speed rotation of the rotor can be solved mechanically, but also higher harmonics can be effectively prevented from entering the permanent magnet and generating added losses electromagnetically.

Owner:SHENYANG POLYTECHNIC UNIV

Painting device and associated method

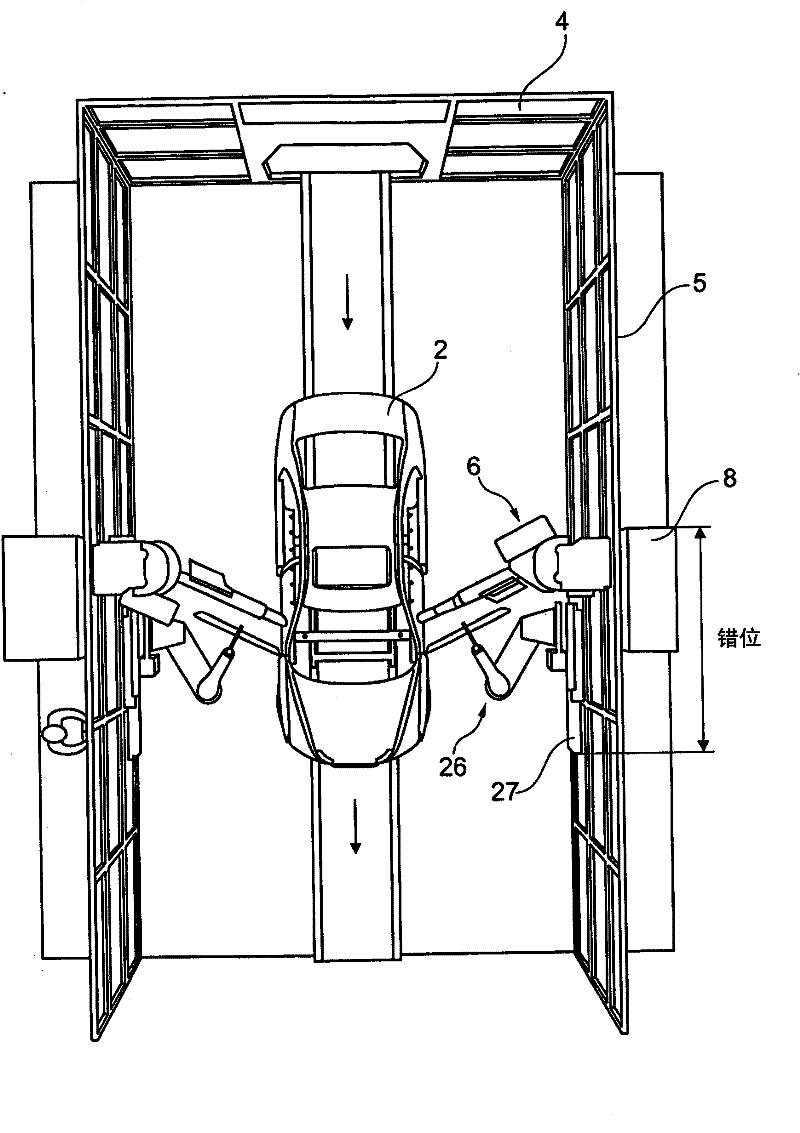

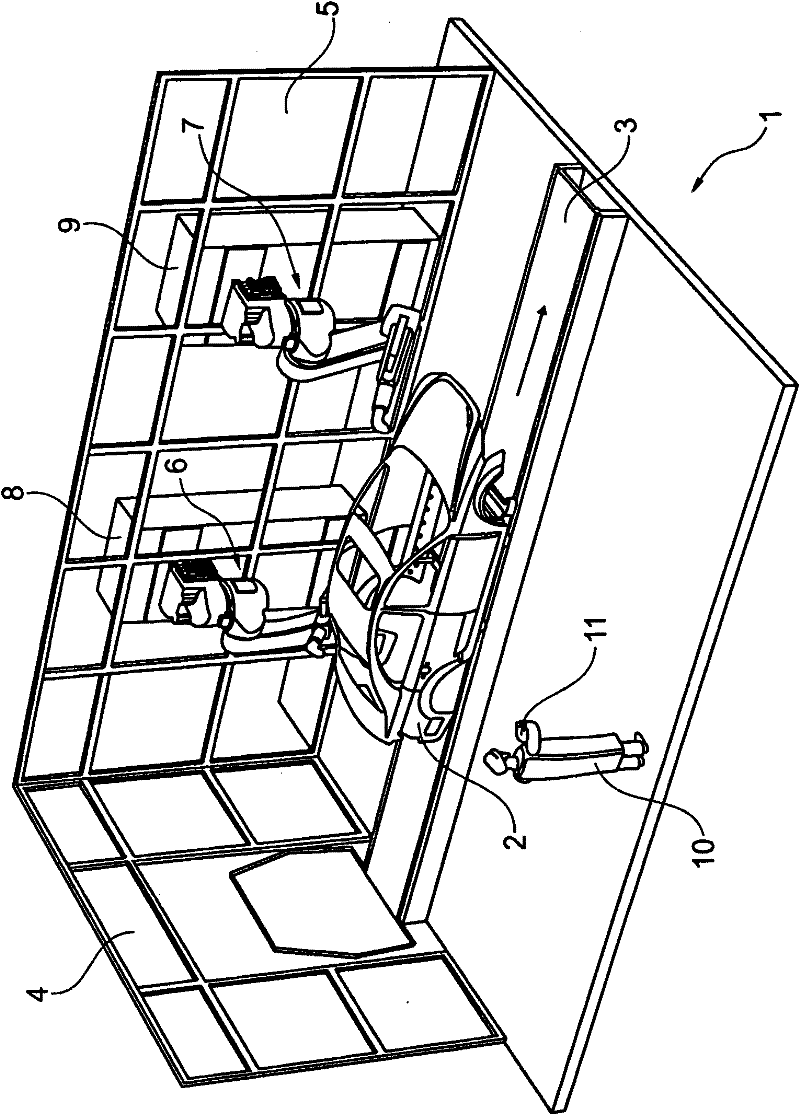

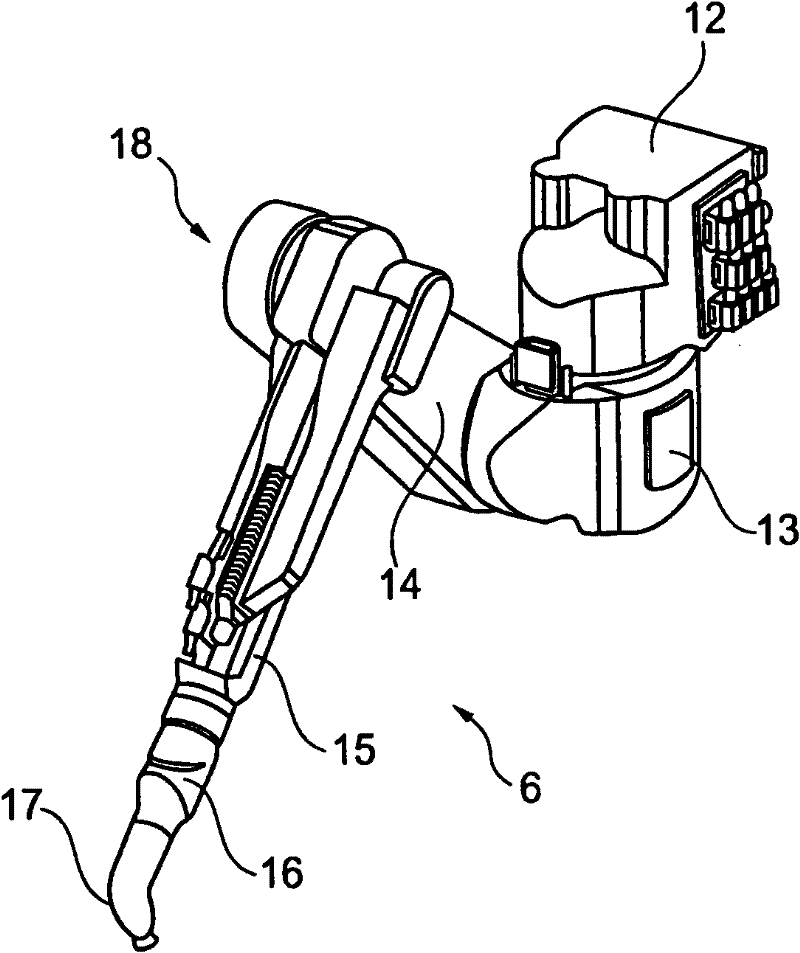

ActiveCN102177002AEasy and fast pre-assemblyMeet the mechanical load-bearing functionProgramme-controlled manipulatorLiquid spraying plantsMulti axisRobot control

The invention relates to a painting device (1) for painting components (2), particularly for painting motor vehicle bodies or parts thereof, having a multi-axis painting robot (6, 7) positioning an atomizer, a robot controller for controlling the painting robot (6, 7), and a controls enclosure (8, 9) comprising the robot controller. The invention proposes that the controls enclosure (8, 9) is in the form of a load-bearing column that mechanically supports the painting robot (6, 7). The invention further relates to an associated method.

Owner:DUERR SYST GMBH

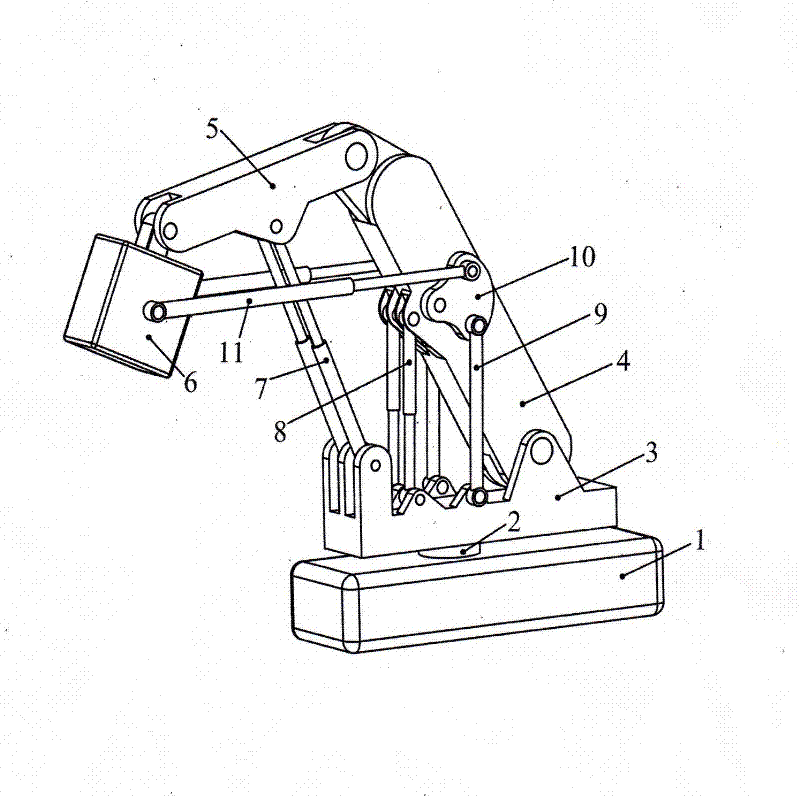

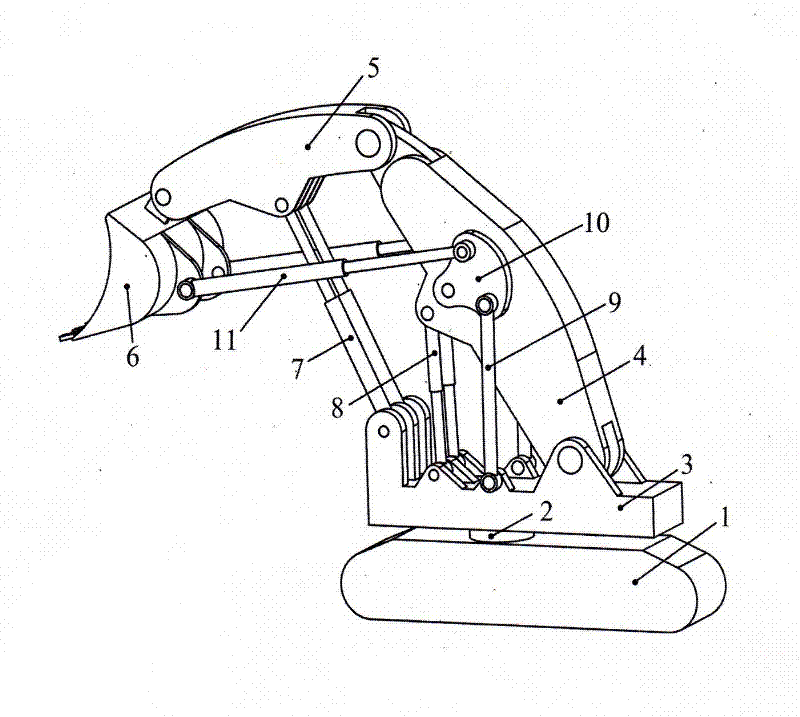

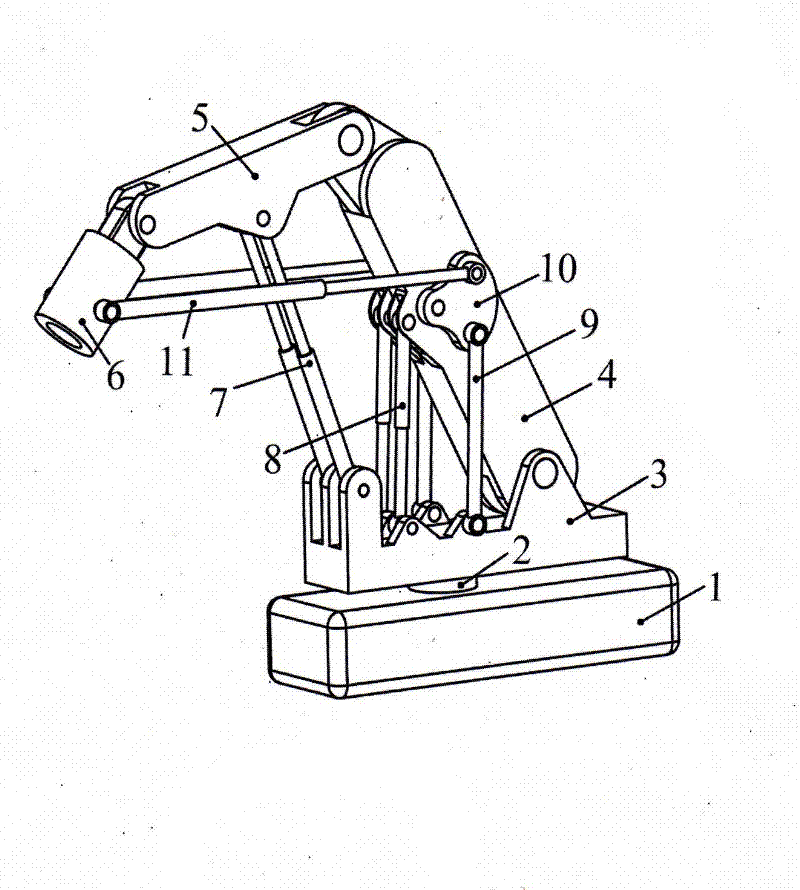

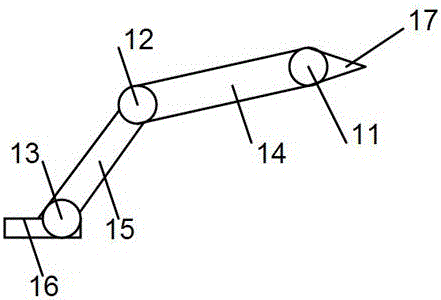

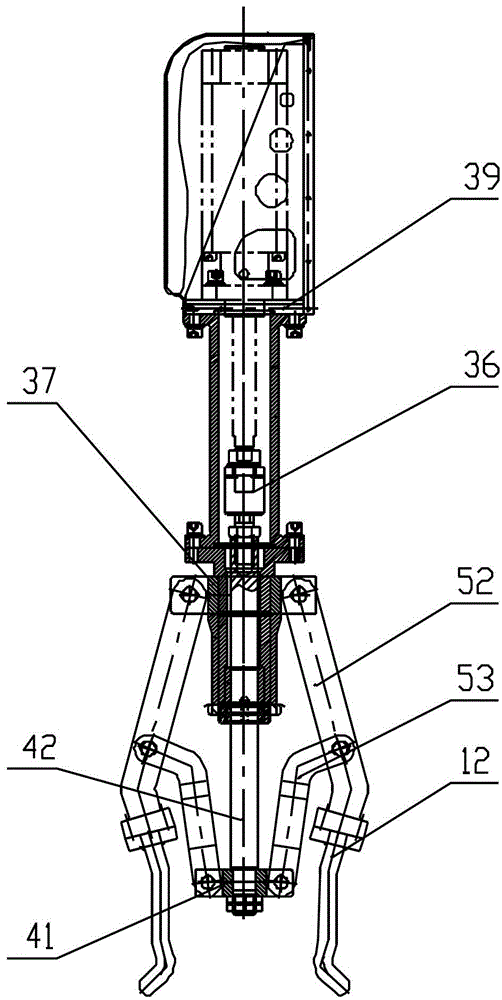

Four-degree-of-freedom series-parallel combined heavy-load mechanical arm

InactiveCN102357897AImprove carrying capacityIncrease stiffnessProgramme-controlled manipulatorArmsDegrees of freedomEngineering

The invention discloses a four-degree-of-freedom series-parallel combined heavy-load mechanical arm, wherein a rack is connected with an upper frame, the upper frame can rotate for a complete cycle relative to the rack, and is hinged with the lower end of a large arm, the upper end of the large arm is hinged with one end of a small arm, the other end of the small arm is hinged with one fulcrum ofan end effector, the middle part of the small arm is respectively hinged with the end parts of piston rods of a pair of small arm cylinders, and cylinder sleeves of the small arm cylinders are respectively hinged with the through holes of the other end of the upper frame; the middle part of the large arm is respectively hinged with the end parts of cylinder sleeves of a pair of large arm cylinders, and the end parts of piston rods of the large arm cylinders are respectively connected with the upper frame; the lower ends of support rods are hinged with the upper frame, and the upper ends of the pair of support rods are respectively hinged with a pair of rockers; the rockers are also respectively connected with the end parts of piston rods of a pair of end effector cylinders through anotherpair of hinges, and the end parts of cylinder sleeves of the end effector cylinders are connected with the other fulcrum of the end effector; and the pair of symmetrical rockers are hinged with the middle part of the large arm, and three hinges on the rockers are in triangle distribution. The invention has the advantages of high bearing capability, large work space, correct movement, easiness in inverse solution and realized real-time control.

Owner:YANSHAN UNIV

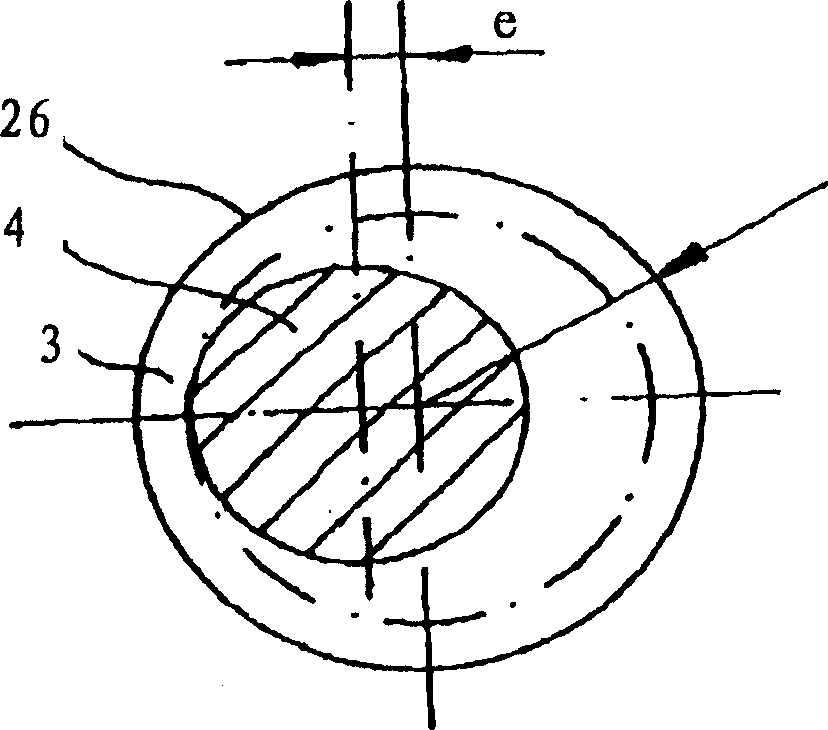

Variable valve lift control system for a combustion engine with underneath camshaft

InactiveCN1802490ATo offer comfortLow adjustmentValve arrangementsMachines/enginesCombustionExternal combustion engine

In order to produce a variable valve lift device for the lift adjustment of the gas-exchange valves of an internal combustion engine, by means of which with adjustment forces and holding forces, independently from whether said holding forces and adjustment forces are applied mechanically, hydraulically or electrically, with an adjustment of the valve lift being as cost-effective as possible, and with maximum accuracy of the adjustment or control of the valve lift to be taken between the individual cylinders of a multi-cylinder internal combustion engine, and, moreover, the adjustment possibility of the valve lift of the valves of an internal combustion engine with several cylinders is obtained within smallest tolerances, it is suggested that a valve lift device (1) has a rotatable eccentric shaft (3), which consists of several eccentrics (4, 5) and whereby all possible contours of the eccentrics (4, 5) are positioned within a circle, which is formed by means of the external diameters of a bearing (6, 7) of the eccentric shaft (3).

Owner:HYDRAULIK RING +1

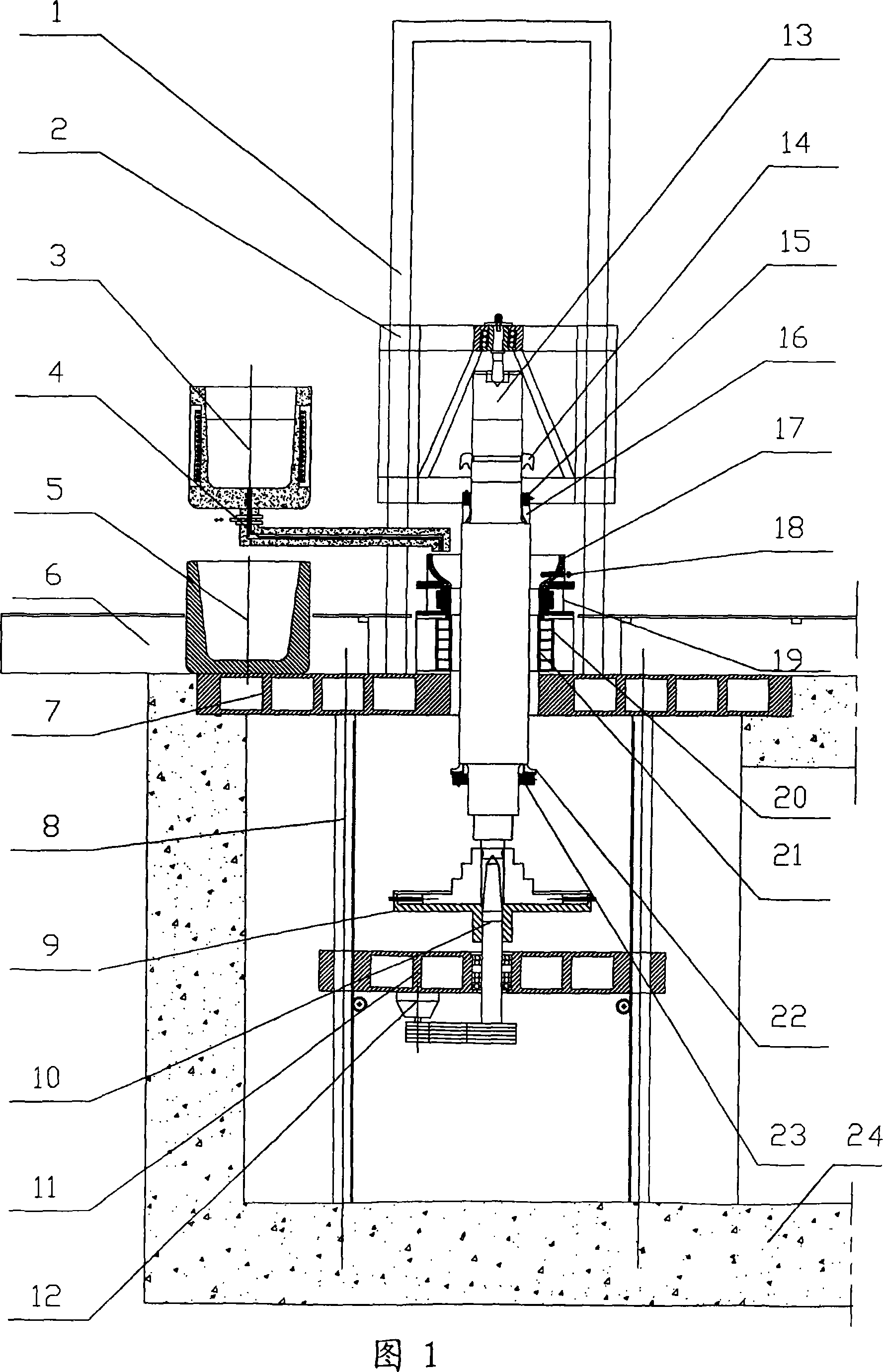

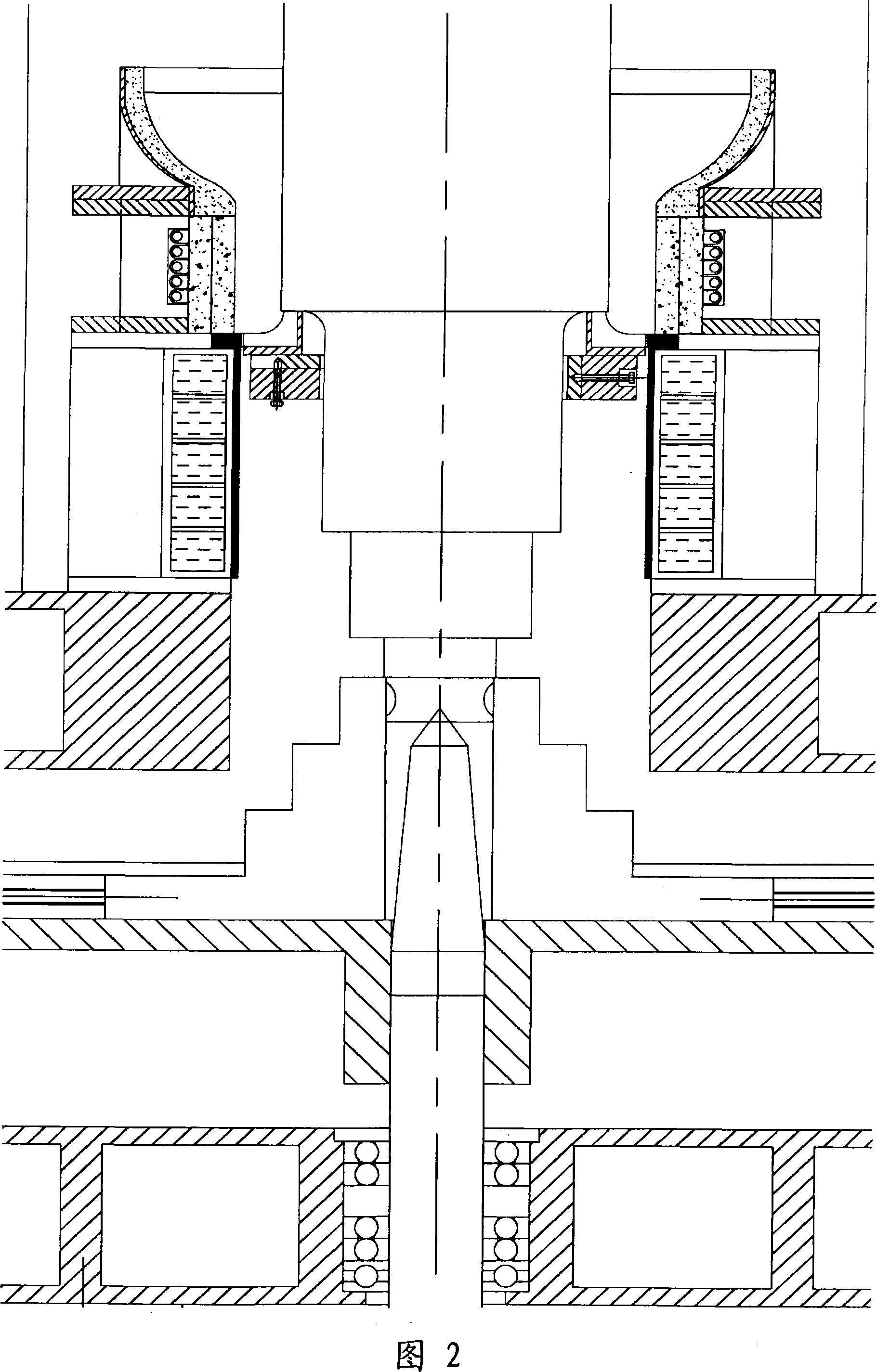

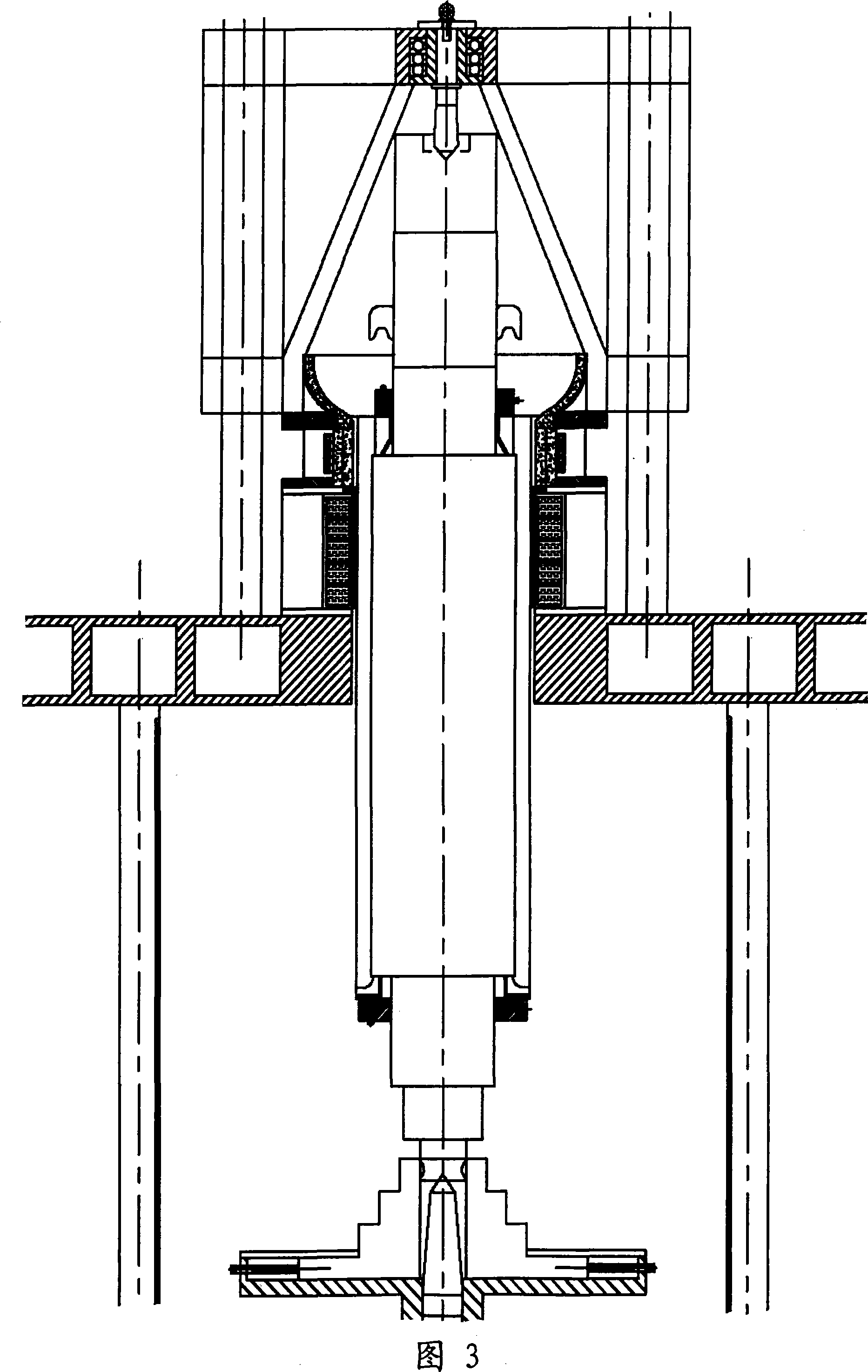

Large-scale shaft products vertical casting and repairing device and using method

The invention relates to a large scale axle kind product vertical casting and restoration apparatus and a use method thereof, belonging to mechanical fields. A frame is fastened with an operation table and a frame station and is movably connected with a mobile arm, a temperature holding pot is fastened with the operation table and a base and is screwed connected with a guide tube, a leak protection pot is fastened with the operation table and the frame station and the base, and the operation table is fastened with the frame station and the base, a column is fasened with the operation table and the base and is movably connected with a lifting table which is connected with a center shaft by bearing and is fastened with an electric machine. The center shaft is connected with a gear box of the electric machine and is connected with a chuck by key. The center shaft, basic parts and a location tip of the mobile arm are provided for supporting. The chuck is buckled with the basic parts. The frame station, a crystallizer, an inductor, and a pouring cup are connected with each other by flanges. The crystallizer is covered by a liner, and the basic parts are covered by a seal ring and a leak protection groove. The pouring cup is inlayed with a thermocouple, the basic parts are fastened with a fixture, an upper lock loop and a lower lock loop. A product / a restoration product can be obtained by treating, assembling, processing, stopping process and post-treating the basic parts, which is applicable for casting or repairing the axle kind product, with high quality.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

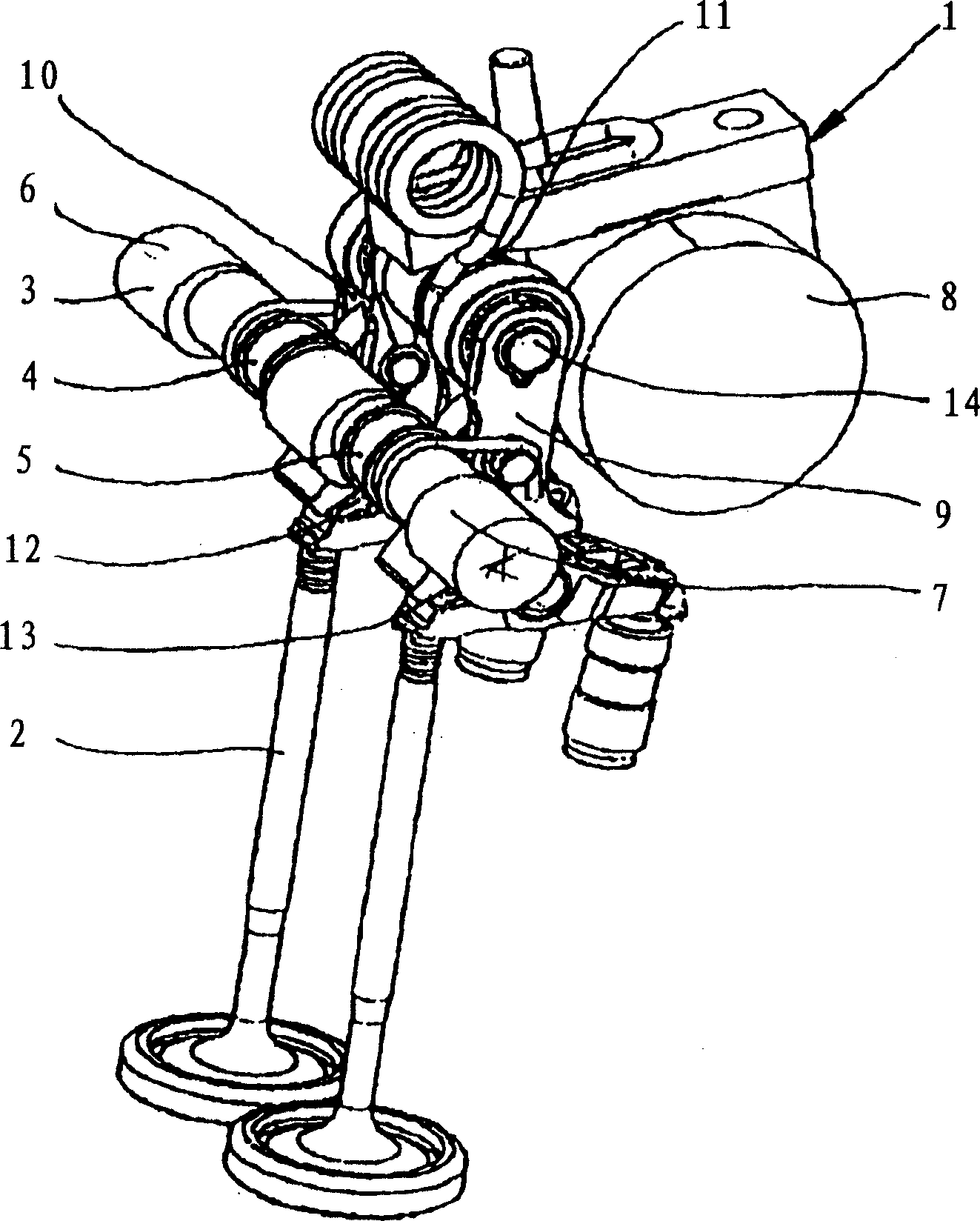

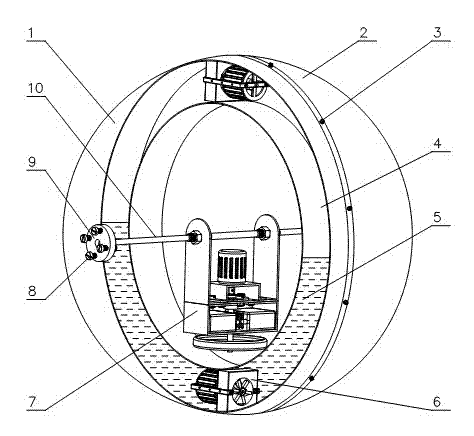

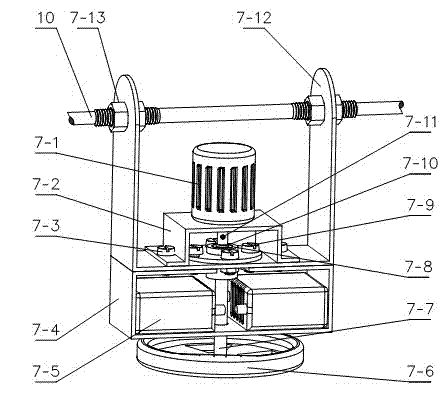

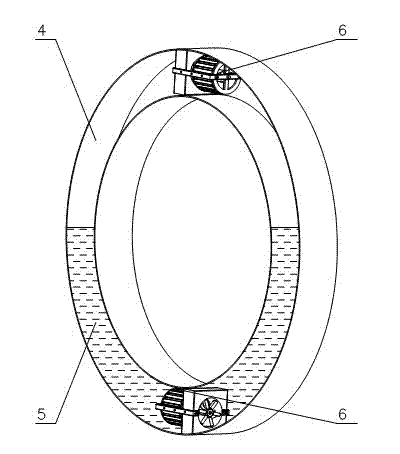

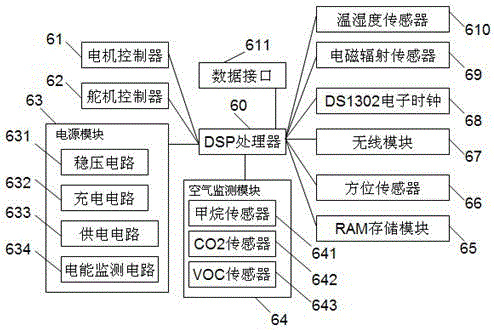

Fluid driving spherical robot

The invention belongs to the field of electromechanical technique, and relates to a spherical moving robot, and in particular relates to a fluid driving spherical robot which comprises a spherical shell, an annular seal container, axial flow devices, an inner driving rotating mechanism and a main shaft. The fluid driving spherical robot is characterized in that the spherical shell consists of two hemispherical shells including a left hemispherical shell and a right hemispherical shell; the annular seal container is positioned in the spherical surface; the outer annular surface of the container is concentric with the spherical surface of the spherical shell; the container is filled with fluid; the volume of the fluid is half of the volume of the container; two axial flow devices are symmetrically installed in the annular seal container; the axial flow devices drive a liquid to flow in the annular seal container, thus the mass center of the spherical robot is changed, thus the spherical robot can move forwards and backwards; the inner driving rotating mechanism positioned in the spherical shell mainly comprises an inner driving bracket, a motor, a motor support, a flywheel shaft, a flywheel, an electricity supply power supply and a controller; the main shaft is fixedly connected with the inner driving bracket through the motor support; the fly wheel is installed on the inner driving bracket through a bearing; the motor shaft is connected with the fly wheel through a coupling; and the motor drives the lower part of the motor to rotate together with the flywheel shaft vertical to the main shaft and the fly wheel, and the spherical robot takes a turn under the driving of the fluid on the basis of an angular momentum conservation principle.

Owner:TAISHAN UNIV

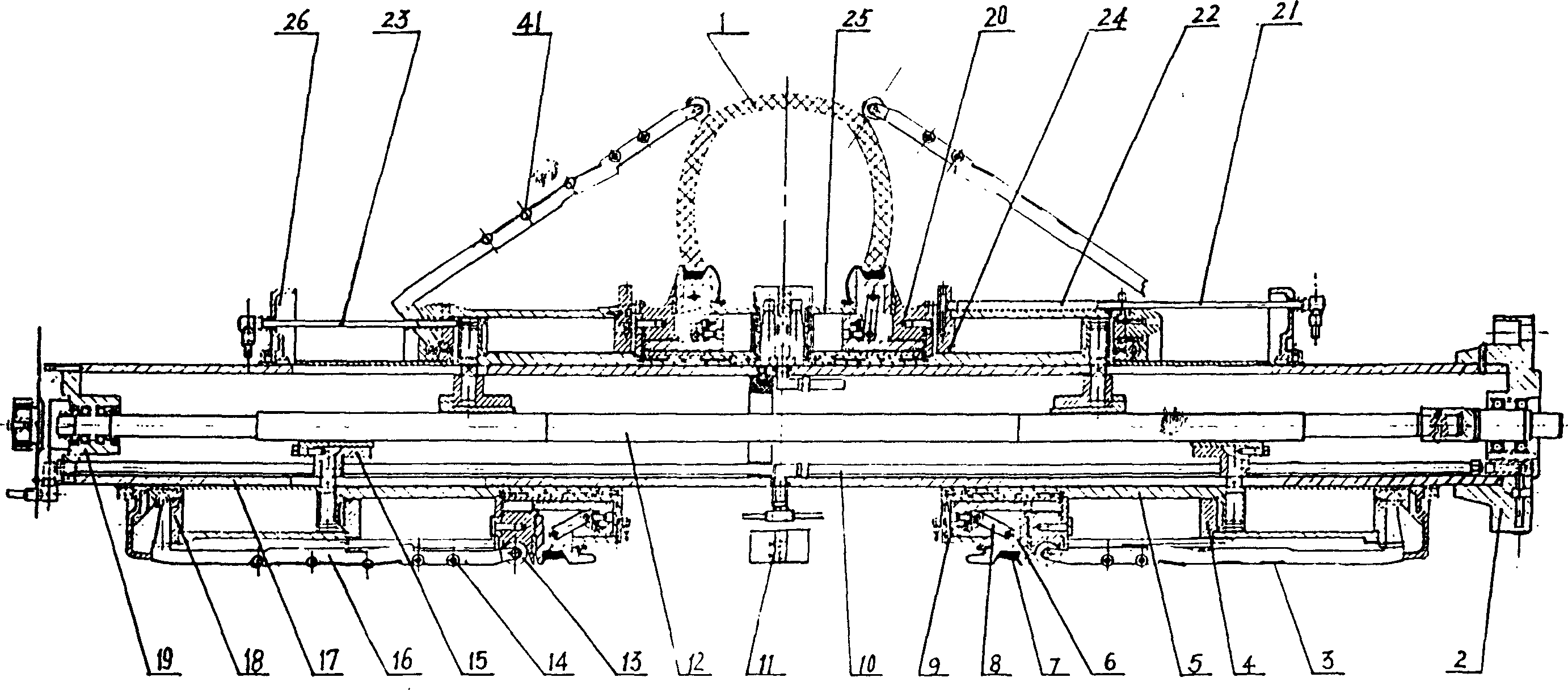

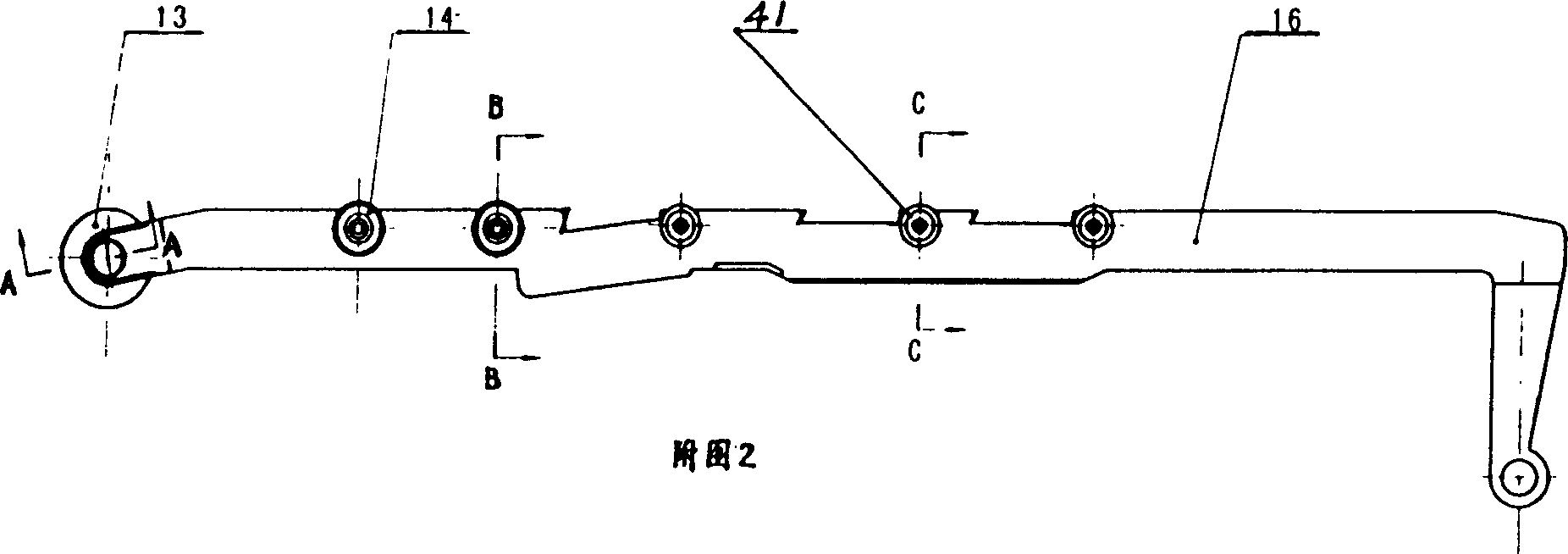

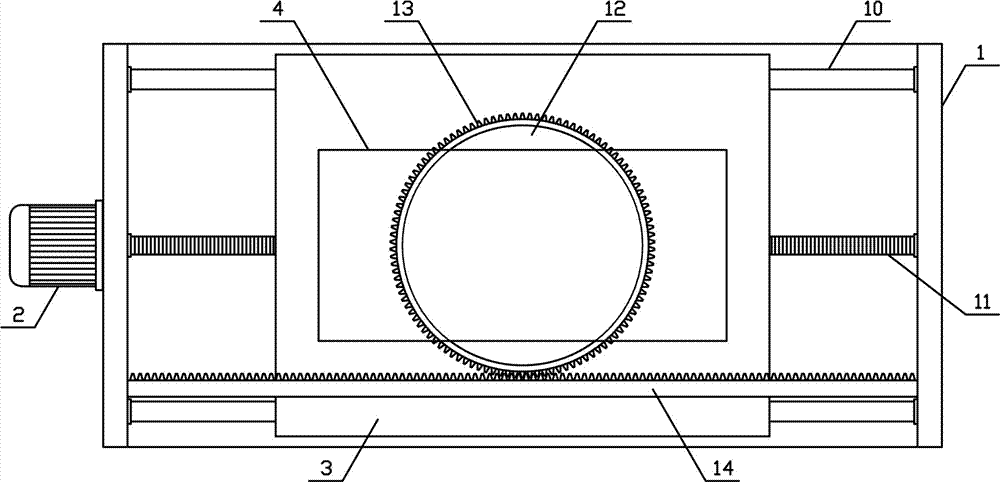

Formation drum of automatic back-edging roller press

The present invention relates to an automatic back contact rolling mechanical forming drum, including coupling flange, back contact rolling arm elastic rubber ring, drive back contact rolling piston component and cylinder body sleeve the the front end of which is equipped with sector block cylinder body, drive sector block piston group, sector block connecting bar group, fastening tire body sector block group and sector guide disk. The rear end of the described piston component is symmetrically equipped with back contact rolling arm component, back contact rolling wheel group and free guide bearing group. The rear end of the described cylinder body sleeve is equipped with dished pushing disk, and a slide-fit cylinder body rear end cover is mounted on the cylinder body sleeve, and the rear portion of the described back contact rolling arm component is connected at the rear end cover place of the cylinder body.

Owner:TIANJIN PLASTIC RUBBER MACHINERY INST

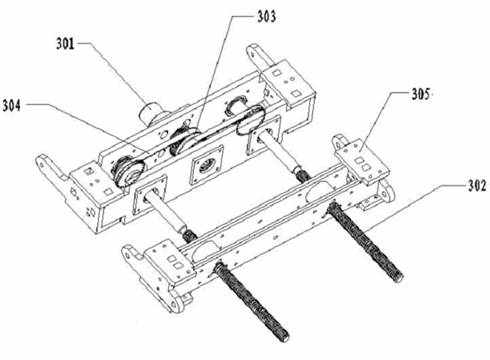

Pipe fitting pinching mechanism

InactiveCN107416518AReasonable structural designEasy clampingConveyorsConveyor partsPipe fittingElectric machinery

The invention discloses a pipe fitting pinching mechanism, and belongs to the field of pipe machining conveyance mechanical equipment. The pipe fitting pinching mechanism comprises a translation base, a translation motor, a translation support, a pipe clamping support, a lifting push plate, lifting air cylinders, pipe clamping plates, a pipe bearing plate and a plate clamping mechanism. The translation support is arranged on translation guide rods in a sliding mode in the horizontal direction. The pipe clamping support is vertically arranged at the upper side of a fixed rotating shaft. The lifting push plate is arranged on lifting guide rods in a sliding mode in the vertical direction. Arc-shaped plate push surfaces are symmetrically arranged at the two sides of the lifting push plate correspondingly. The pipe clamping plates are symmetrically arranged at the two sides of the pipe clamping support separately. The pipe bearing plate is horizontally arranged at the upper side of a pipe bearing supporting rod. The plate clamping mechanism is arranged on the pipe clamping support and located at one side of a lifting clamping groove. The pipe fitting pinching mechanism is reasonable in structural design, pipe fittings of various sizes and dimensions can be clamped and fixed firmly, the pipe fittings can be stably rotated and adjusted synchronously in the translation process of the pipe fittings, and the production and use needs are met.

Owner:浙江绿康农产品配送有限公司

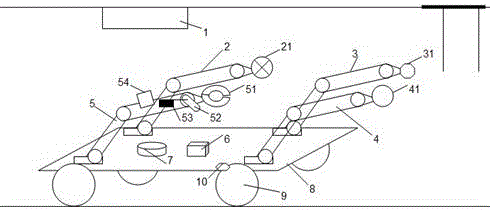

Intelligent patrol inspection robot for cable tunnel

ActiveCN105945895AFind faults with partial dischargeStrong real-timeManipulatorPower batteryElectricity

The invention provides an intelligent patrol inspection robot for a cable tunnel. The intelligent patrol inspection robot for the cable tunnel is characterized in that communication management machines are installed in the cable tunnel at intervals of 10 km and used for communicating with the robot; the robot adopts a wheel drive mode and comprises four wheels composed of wheel hub motors; the wheels are installed on a bearing chassis; a first mechanical arm, a second mechanical arm, a third mechanical arm, a fourth mechanical arm, a power battery pack, a controller and a speed measurement sensor are installed on the bearing chassis; an LED illuminating lamp, a thermal infrared imager and a camera are installed on the first mechanical arm, the second mechanical arm and the third mechanical arm correspondingly; and an electricity taking CT which can be opened and closed, a spray nozzle, a booster pump and a color marking liquid box are installed on the fourth mechanical arm. According to the intelligent patrol inspection robot for the cable tunnel, various parameters of the tunnel environment are comprehensively monitored and collected, the manual patrol inspection work can be replaced, and partial discharge faults of circuits can be rapidly found out.

Owner:东营市航宇工贸有限责任公司

Telescoping support bar

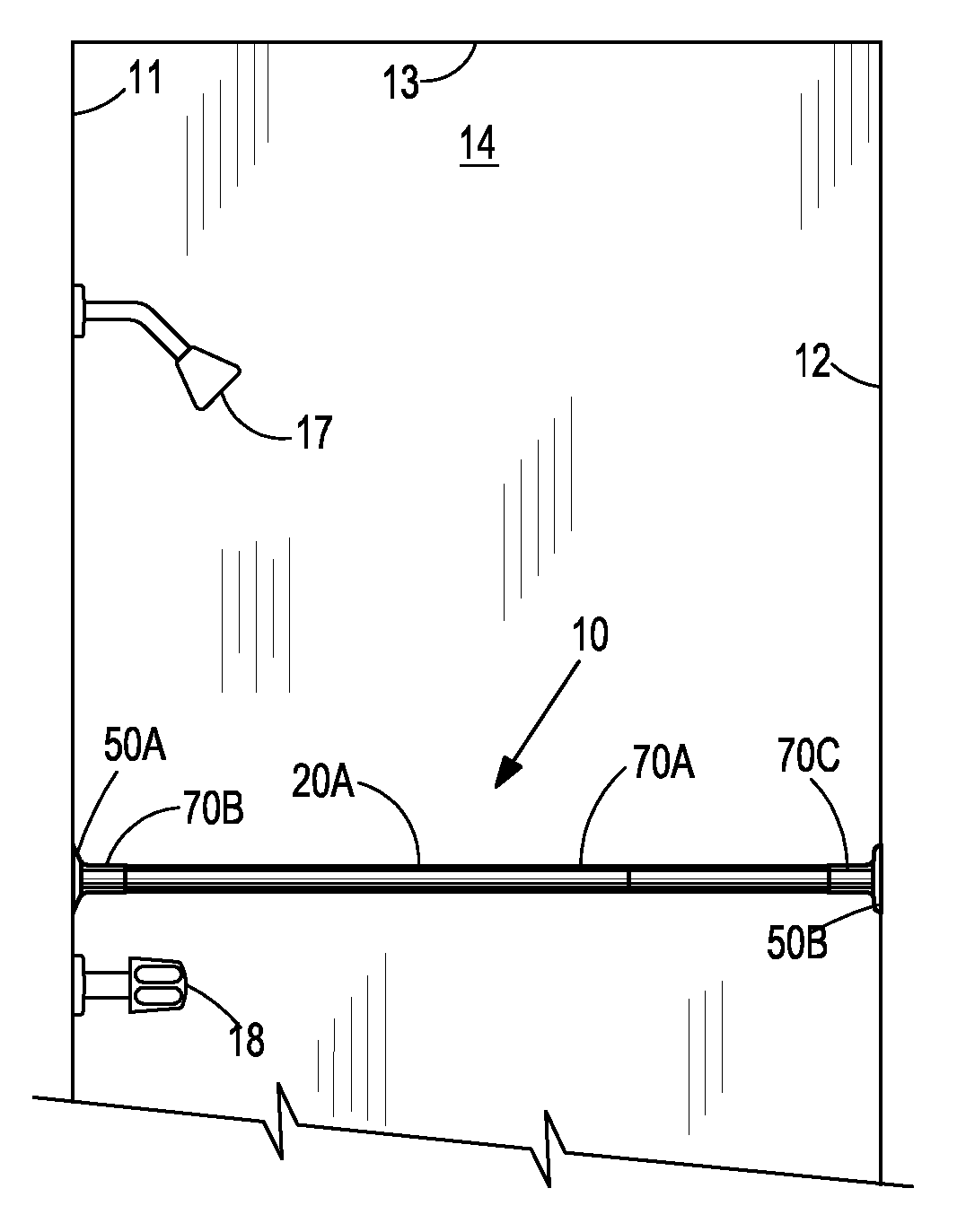

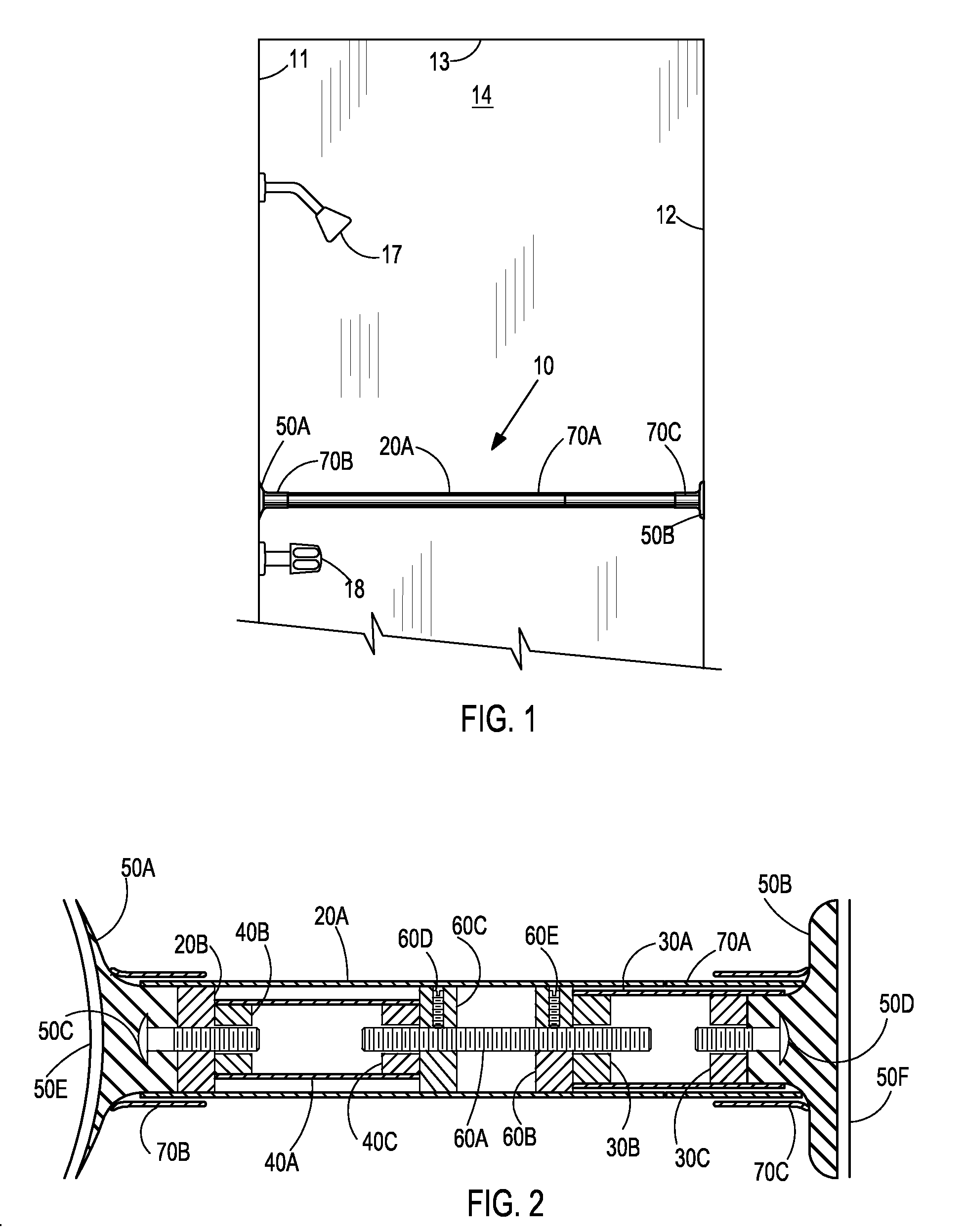

InactiveUS20090223917A1Easily assembled and and removedEliminate needBathsDouchesEngineeringAxial force

A telescoping support bar installed in a shower enclosure and similar facilities requires no mechanical wall fasteners. The support bar includes telescoping tubes with end retainers gripping walls of the enclosures. Length of the support bar is governed by fixed length spacer means and internal extensible means. Extensible means, having bearings movable along a rod, provides the lengthening and shortening of the support bar as the distance between the bearings is increased or decreased. This change in distance likewise changes the overall length of the support bar. With the retainers snug against the walls, one of the tubes, being rotatable, is turned in circular motion. This rotation is converted into an axial force along the bar causing the retainers to forcefully grip the walls, providing a rigid and strong bar installation.

Owner:GRANT WILLIE T +1

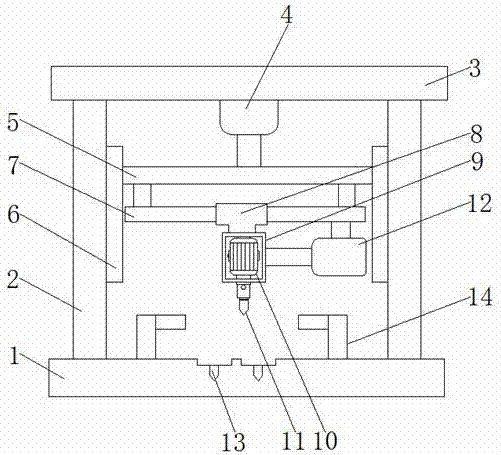

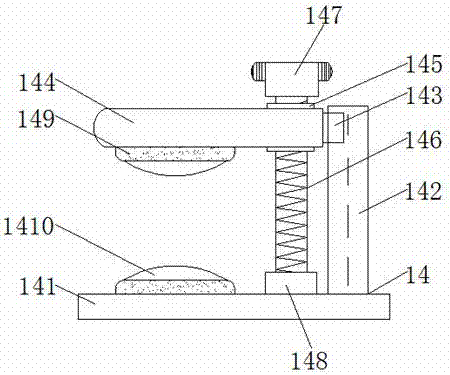

Mechanical part drilling device capable of preventing deviating

PendingCN107498078AAvoid offsetSolve the problem of drilling failureBoring/drilling machinesEngineeringStructural engineering

The invention discloses a mechanical part drilling device capable of preventing deviating. The mechanical part drilling device comprises a bottom plate. Supporting plates are fixedly connected to the two sides of the top of the bottom plate correspondingly, and a cross plate is fixedly connected to the tops of the supporting plates; the bottom of the cross plate is fixedly connected with an air cylinder, and the bottom end of the air cylinder is fixedly connected with a cross rod; the sides, opposite to each other, of the two supporting plates are fixedly connected with sliding rails, and the two ends of the cross rod are slidably connected with tracks of the sliding rails; and the two sides of the bottom of the cross rod are both fixedly connected with vertical rods, and the bottom ends of the vertical rods are fixedly connected with a sliding rod which is movably sleeved with a sleeve. According to the mechanical part drilling device capable of preventing deviating, through the structural design of a positioning plate, a vertical plate, a sliding block, a clamping plate, positioning nuts, a screw rod, a handle, a bearing, a non-slip mat and non-slip protruded points, during part drilling, the good fixing effect on parts is achieved, the parts are prevented from deviating during drilling, and the working efficiency is improved while the drilling quality is improved.

Owner:ZHENJIANG COLLEGE

Method for measuring and selecting gasket of taper bearing

ActiveCN102564379AMeet the actual needs of preloadHigh measurement accuracyMeasurement devicesEngineeringIndustrial engineering

The invention relates to the field of mechanical assembly, disclosing to a method for measuring and selecting a gasket of a taper bearing. The method comprises the following steps of: 1, assembling all workpieces except the gasket to be measured according to the normal work state of a taper bearing drive system; 2, simulating the pressure and the speed during the normal work of the taper bearing drive system, and measuring the overall dimension under actual working conditions; and 3, comparing the dimension measured in the step 2 with the dimensions of the bearing inner rings of an upper taper bearing and a lower taper bearing and spacer bushes in static states, wherein the difference value is the thickness of the gasket to be measured. According to the method, the actual operation conditions of the workpieces can be completely simulated for measuring, the measurement accuracy is high, and the real value of the thickness of the actually required gasket can be measured. Meanwhile, the invention also provides a gasket measuring device, which can ensure that the assembled gasket conforms to the actual needs of pretightening the bearings. The detection can be completed by means of the device, and the production efficiency is greatly improved.

Owner:北京泰诚信测控技术股份有限公司

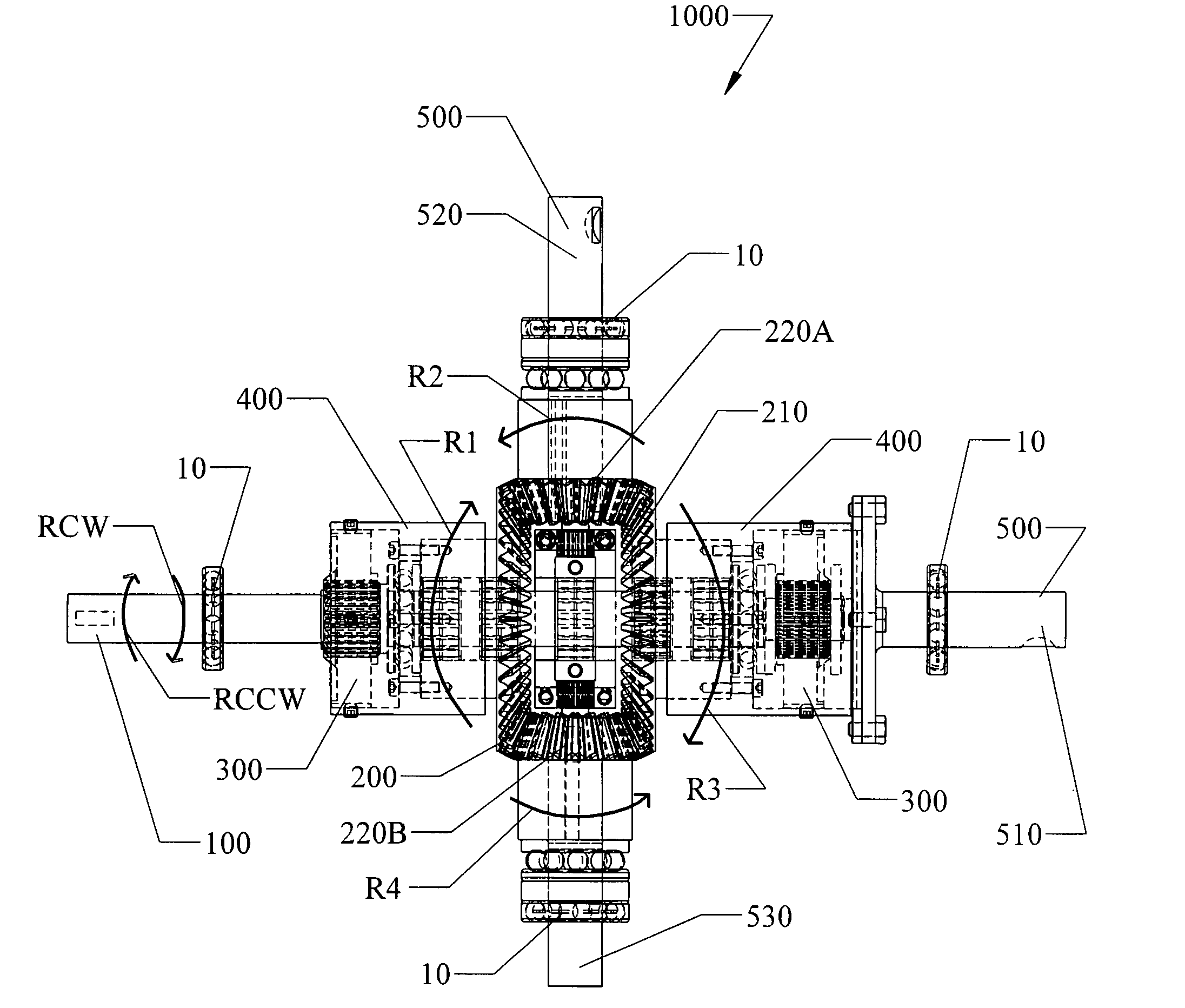

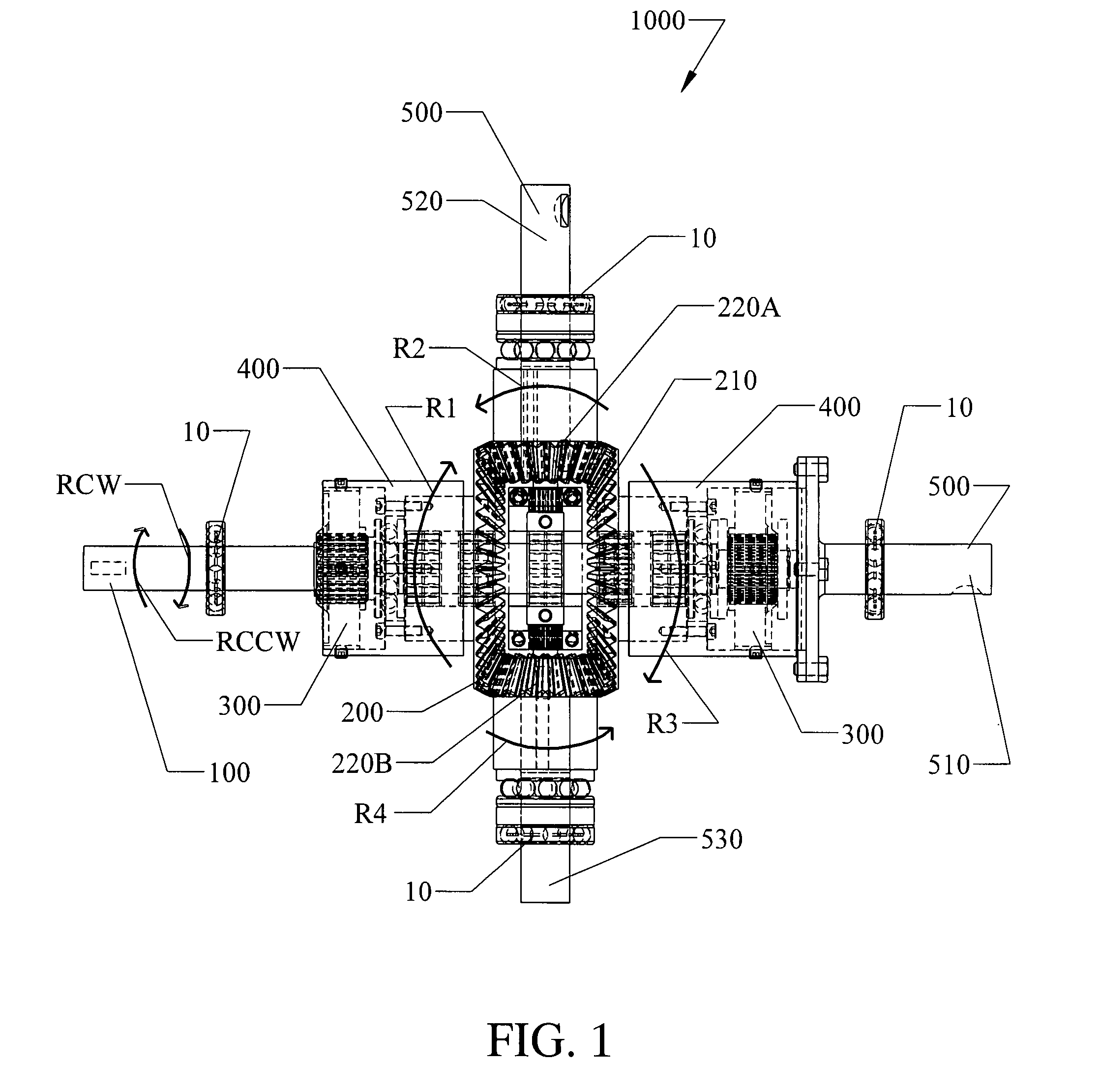

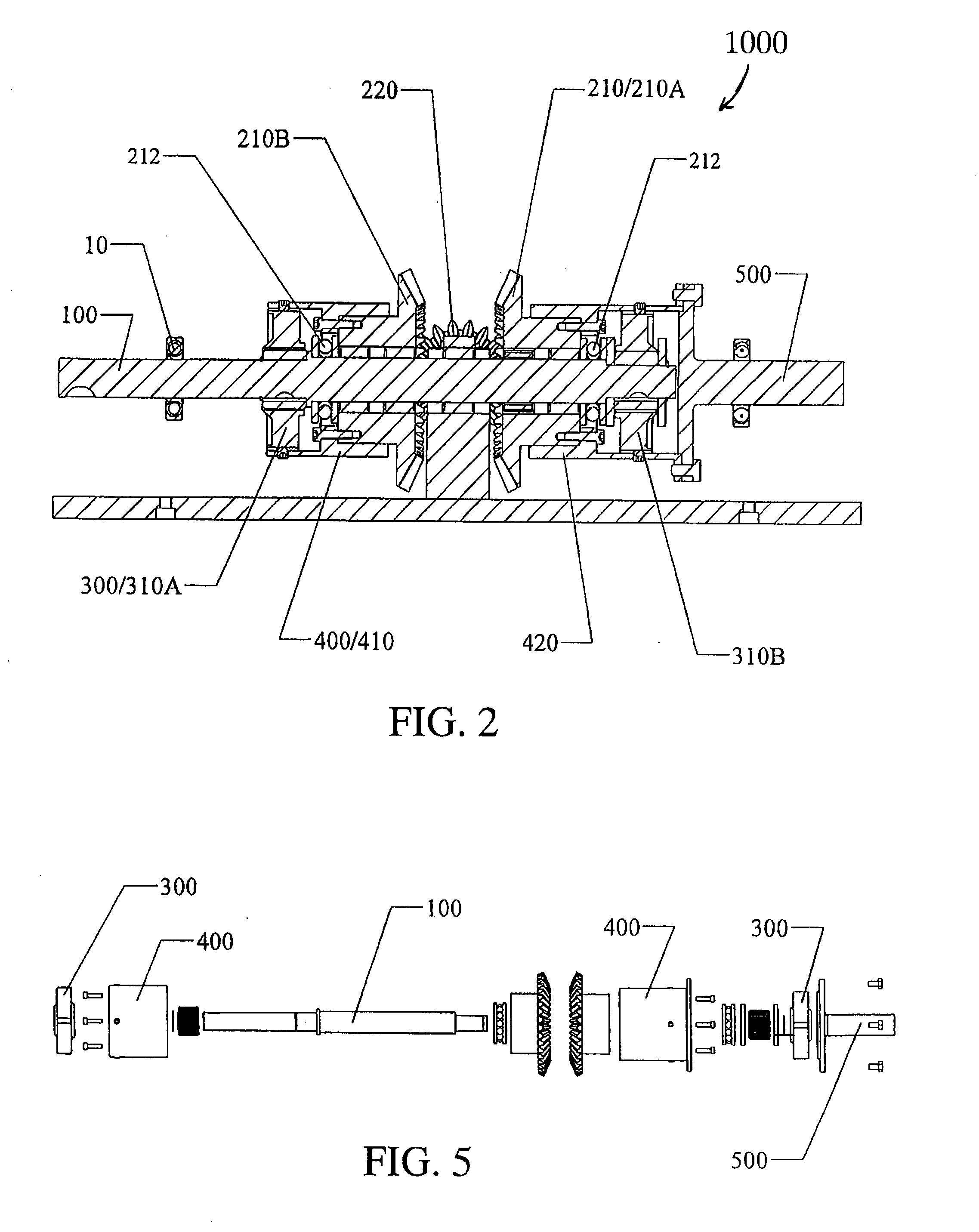

Reciprocating to rotary mechanical conversion device

InactiveUS20080236332A1Short timeImpact of engagement is minimizedToothed gearingsGear wheelEngineering

A mechanical conversion system for receiving input from a toroidal engine that outputs an oscillating motion. The system has a gear set with facing bevel gears that mesh with radially mounted pinions. The bevel gears are mounted on a splined input shaft via bearings and one-way clutches. An overrunning clutch is coupled with each bevel gear. As the input shaft rotates in one direction, the overrunning clutch of one bevel gear is engaged and drives the one gear in the first direction, while the overrunning clutch of the second bevel gear is disengaged and allows the second bevel gear to overrun the input shaft. The overrunning clutch is a type known as a MECHANICAL DIODE®, which engages within 4.5 degrees of rotation, without significant slippage.

Owner:HOOSE KARL V +2

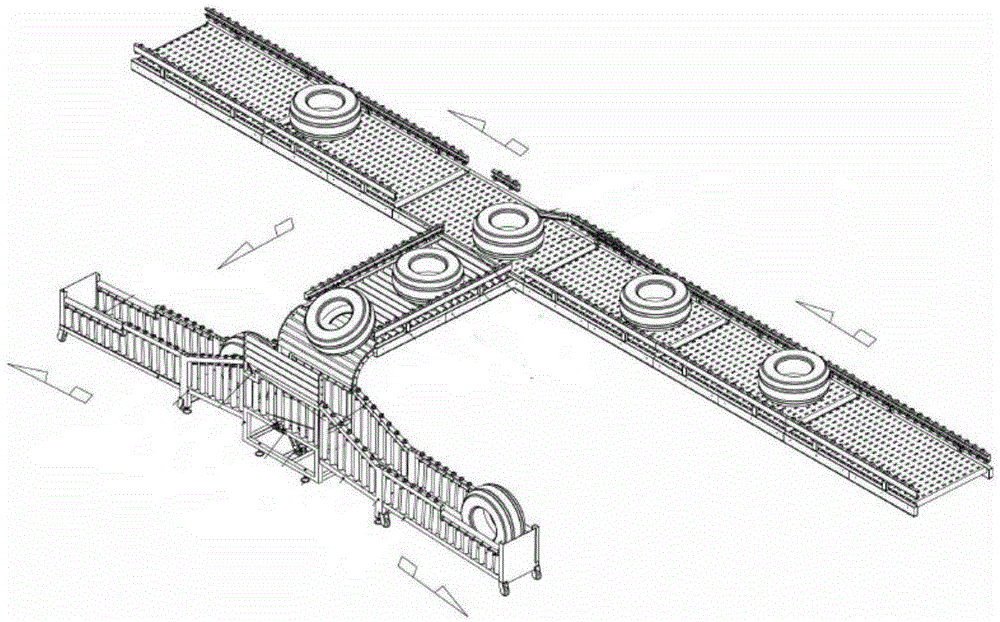

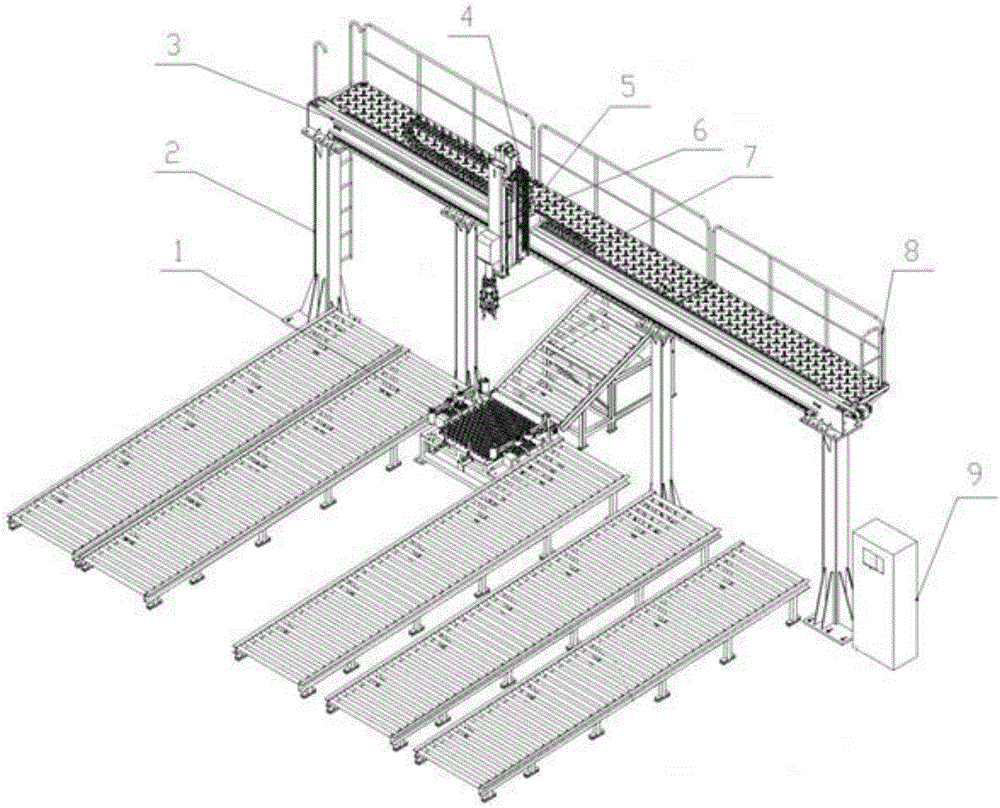

Tyre sorting device and tyre sorting method

ActiveCN103332487AEasy to moveMeet automatic classificationConveyor partsEngineeringDegrees of freedom

The invention discloses a tyre sorting device and a tyre sorting method. The tyre sorting device comprises a supporting mechanism, a sorting mechanism and a power mechanism. The supporting mechanism comprises stand columns, a cross beam and a sorting platform, the cross beam is arranged above the stand columns transversely, and the sorting platform is used for bearing tyres. The sorting mechanism comprises a mechanical arm, the mechanical arm is matched with the cross beam in a sliding mode, the mechanical arm comprises a grasping part and a lifting assembly, the grasping part is used for grasping the tyres and the lifting assembly is used for controlling the grasping part and making the grasping part to move perpendicularly. The power mechanism comprises a first power unit which drives the mechanical arm to move along the cross beam in the transverse direction. According to the tyre sorting device and the tyre sorting method, the mechanical arm can slide along the cross beam in the transverse direction and in the longitudinal direction, the grasping part is used for grasping the tyres, the degree of freedom of the grasping part in four directions is controlled, and therefore the tyres are sorted and stacked automatically. Further, labor cost is reduced, labor intensity is reduced, and the risk of manual misoperation is avoided.

Owner:青岛科捷机器人有限公司

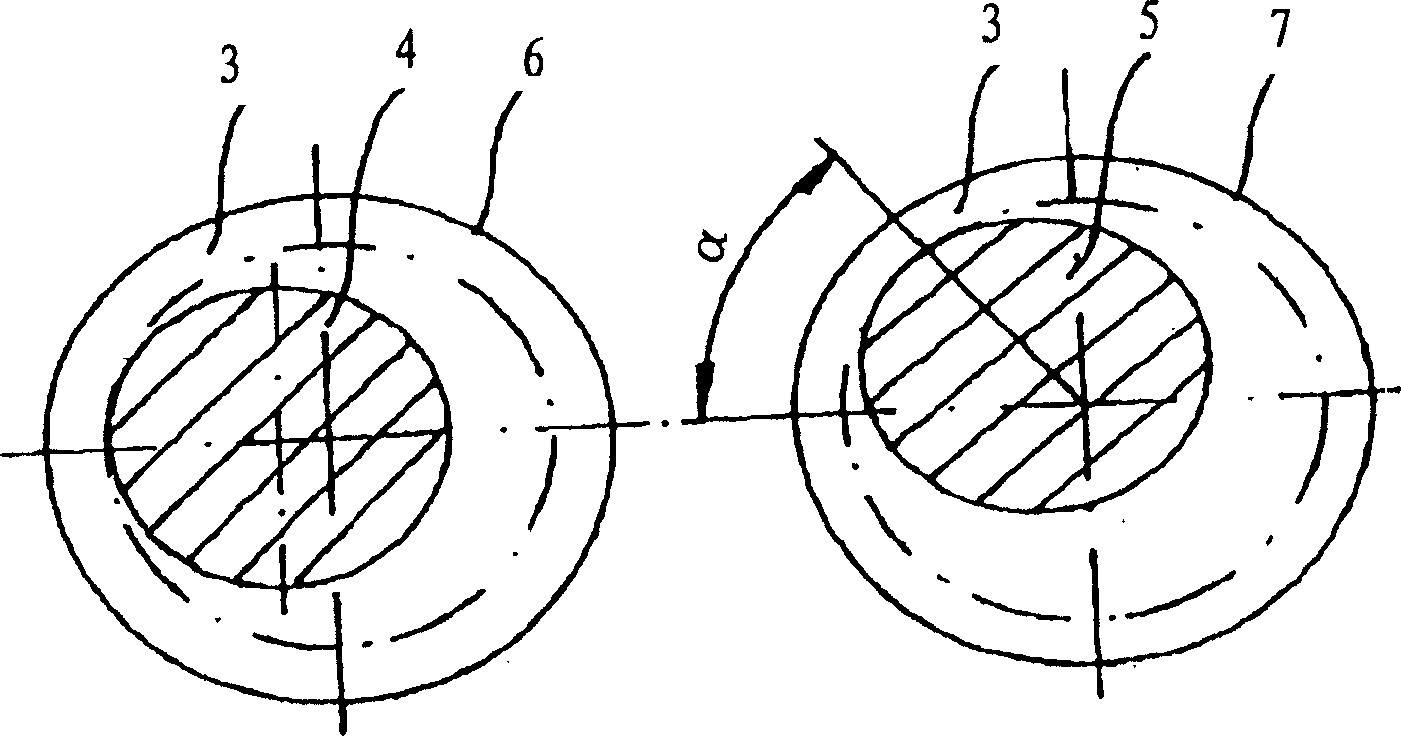

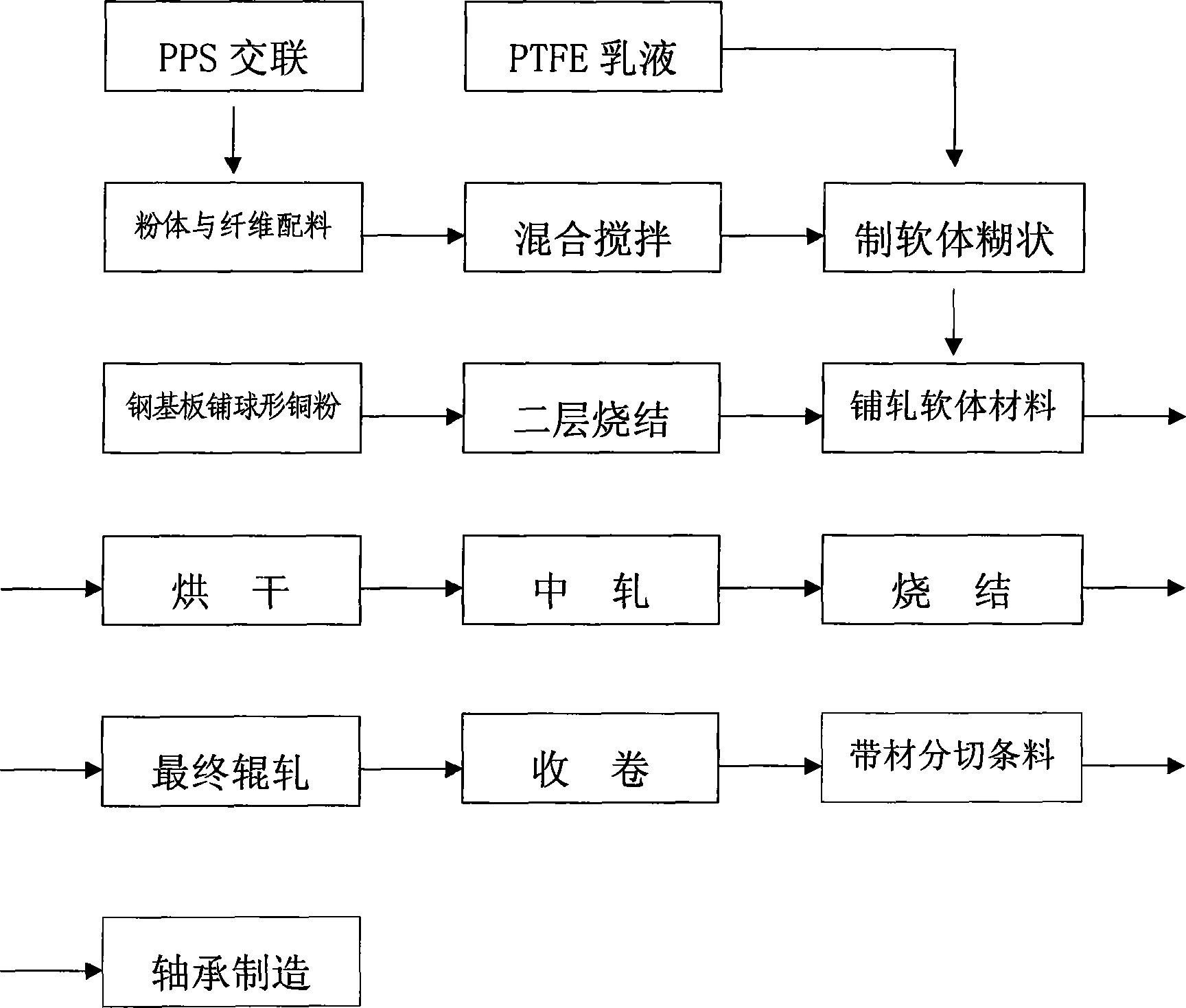

Lead-free self-lubricating bearing and its production

The invention relates to a mechanical components industry regulation hole coaxial between the methodology and regulation components, in particular the aviation, aerospace, civil and other mechanical structure of the multi-hinge assembly point. Double eccentric bushing from the eccentric bushing and the eccentric bushing composition, the eccentric bushing diameter and the outer diameter of a round circle of eccentric and the eccentric bushing diameter and the outer diameter of a round of the same circle of eccentric, and, Bushing end of the shaft is the first shoulder. Double eccentric bushing used in the eccentric bushing and the eccentric bushing with a certain amount of tolerance, through the inner and outer sleeve of repeated eccentric rotation adjustment can be realized coaxial connection points more than the match, and for each hub Heart of the biggest angle adjustment of not more than 360 degrees, adjust volume small. This greatly reduces the difficulty of assembling and because of the internal and external sleeve with tolerance, as well as components and assembly hub between the matching hole in the machining tolerances can be very good at that in the assembly, so there is no need to conduct a follow-up processing, reducing assembly time.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

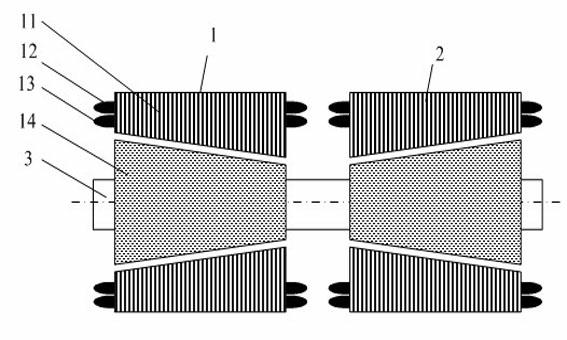

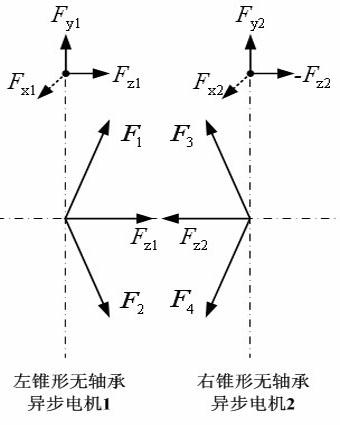

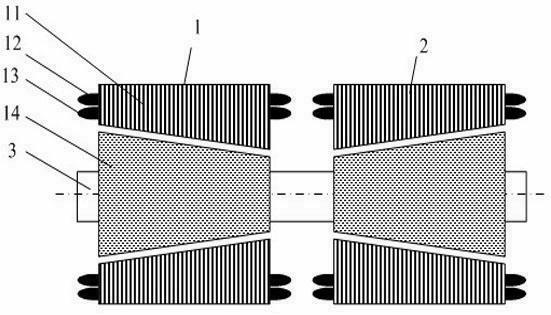

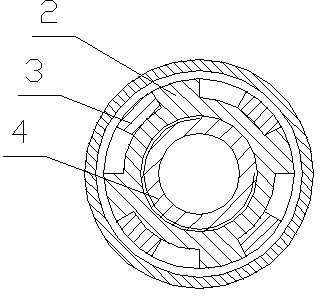

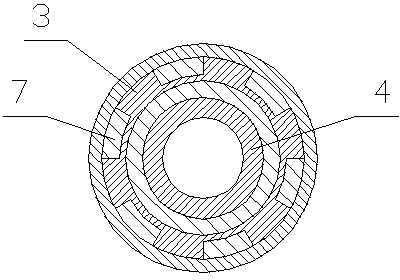

Tapered bearingless asynchronous motor

InactiveCN102510197ARealize active controlReactive lossMagnetic circuit stationary partsAsynchronous induction motorsLevitationElectric machine

The invention discloses a tapered bearingless asynchronous motor. A left tapered bearingless asynchronous motor and a right tapered bearingless asynchronous motor which are identical to each other and respectively arranged at the left end and the right end of a motor casing are symmetrically connected to a mechanical rotating shaft; the left tapered bearingless asynchronous motor, as well as the right tapered bearingless asynchronous motor, consists of a tapered stator, a torque control winding, a levitation force control winding and a tapered rotor; the tapered rotors are fixedly connected with the mechanical rotating shaft; a plurality of stator slots are axially formed on each tapered stator; each stator slot is provided with an inner layer and an outer layer in the radial direction, and the levitation force control winding and the torque control winding are respectively arranged in the inner layer and the outer layer; and the difference between the number of pole-pairs of the levitation force control windings and the number of pole-pairs of the torque control windings is 1. The tapered bearingless asynchronous motor dispenses with magnetic levitation bearings indispensable for a traditional five-degree-of-freedom bearingless asynchronous motor, and has the advantages of simple structure, short axial length, high critical rotational speed, small reactive loss and the like.

Owner:JIANGSU UNIV

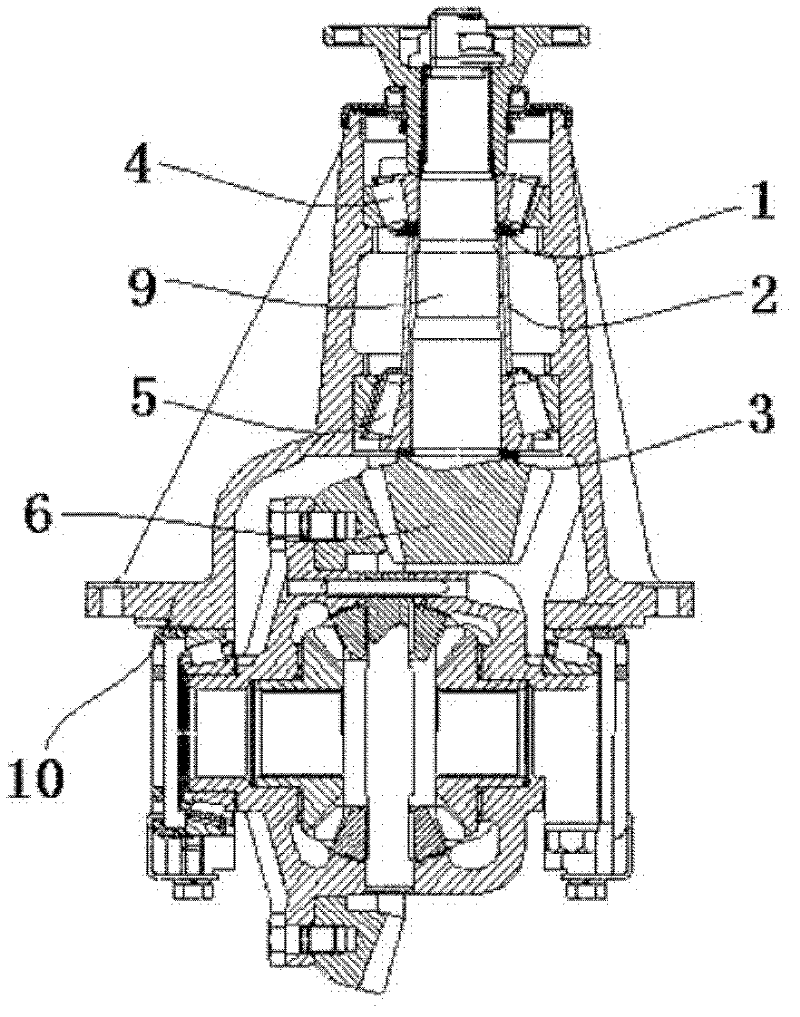

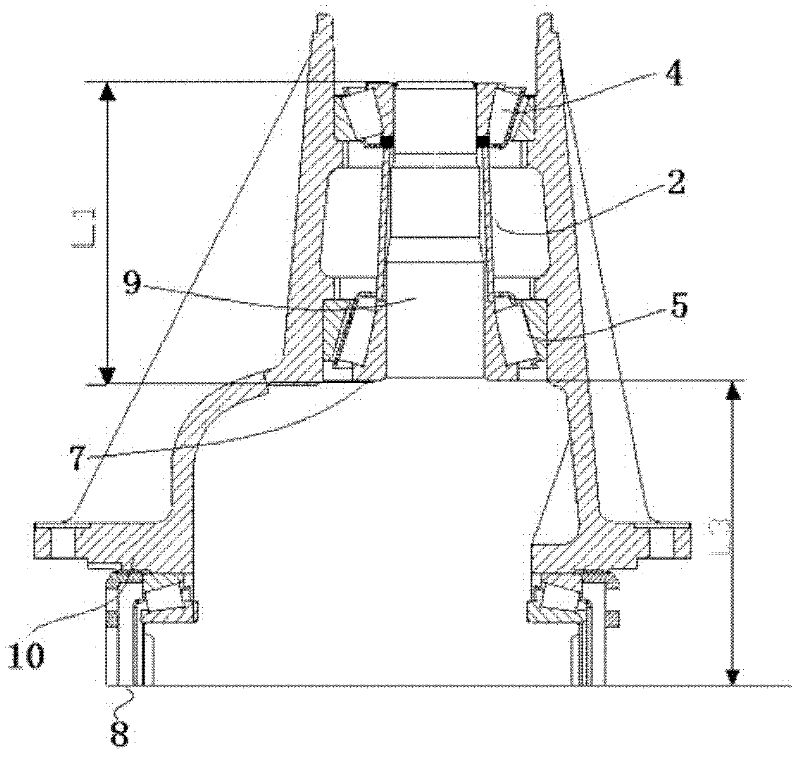

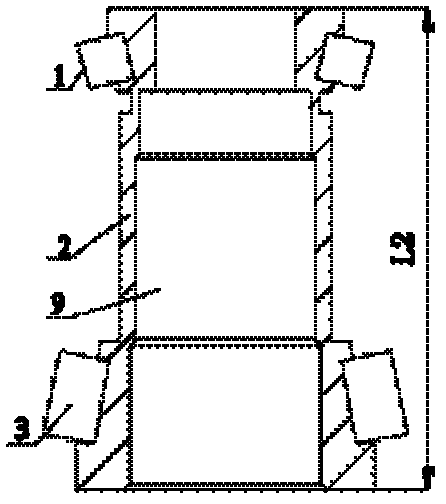

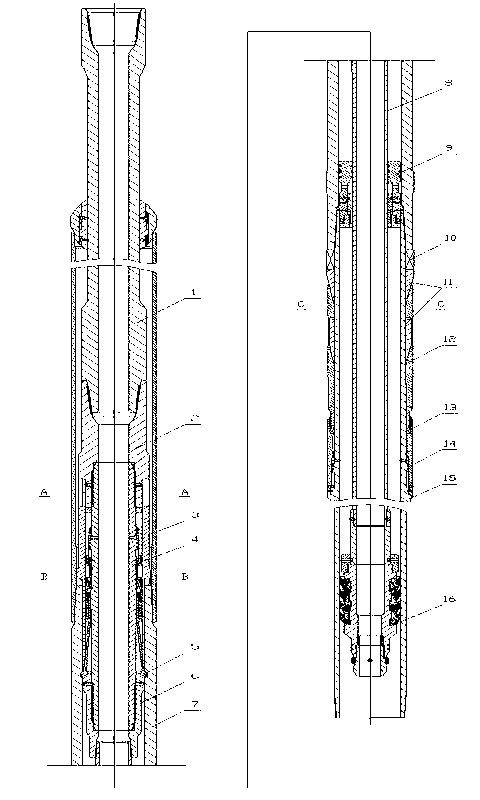

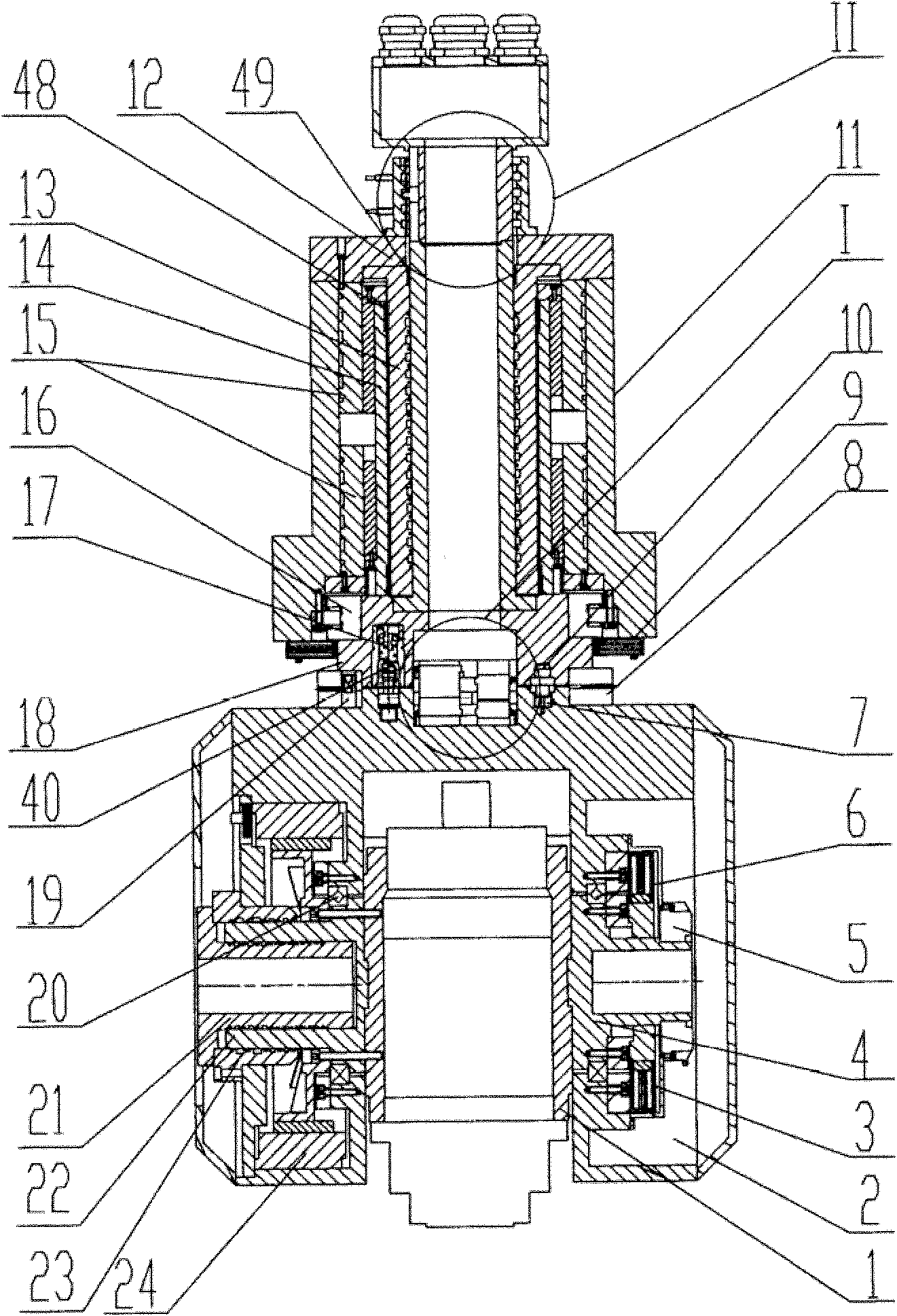

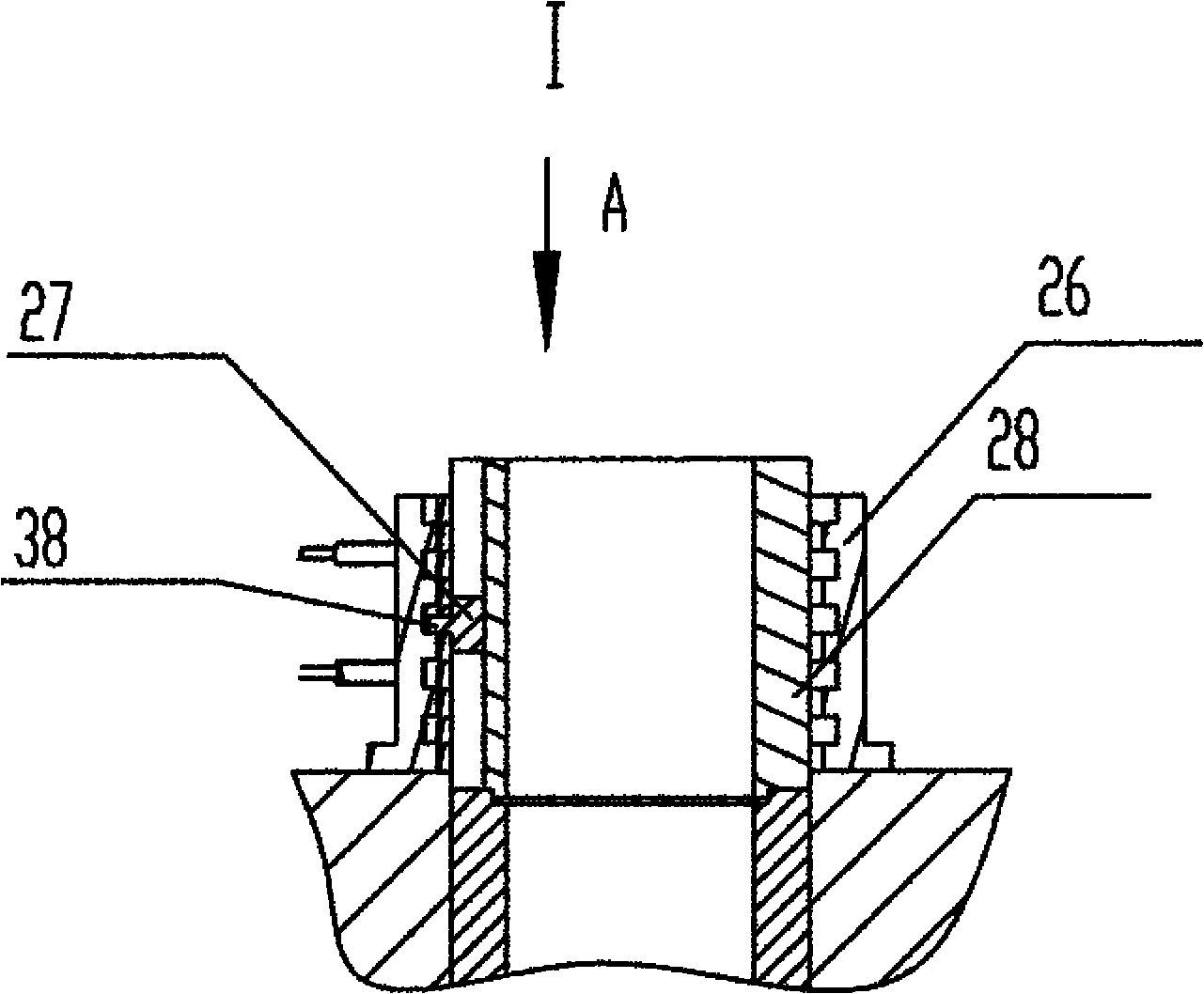

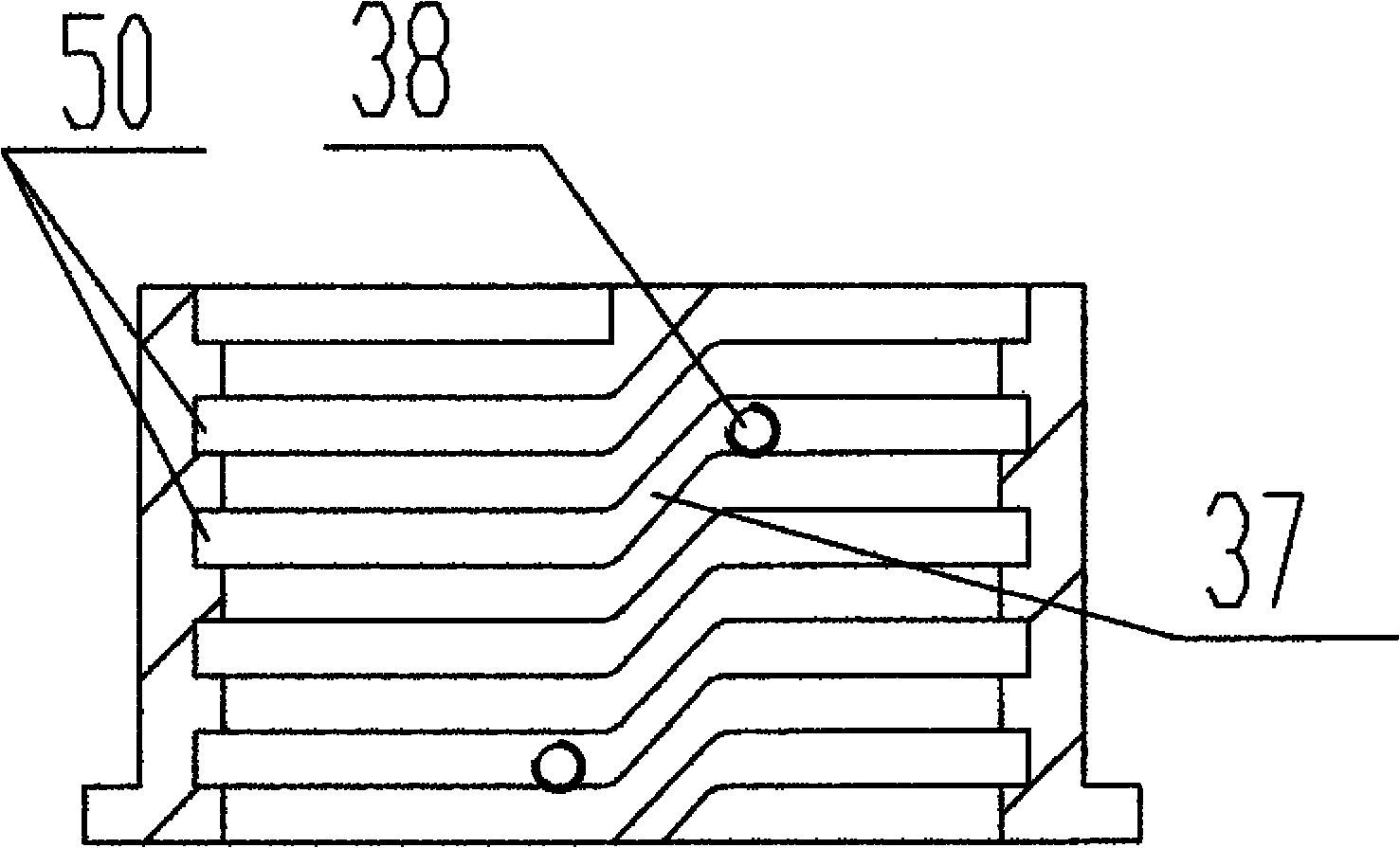

Mechanical-hydraulic double-acting release rotary tail pipe hanger

The invention discloses a mechanical-hydraulic double-acting release rotary tail pipe hanger, and belongs to the technical field of manufacturing downhole tools for oil and gas well cementing operations in oil and gas development. The mechanical-hydraulic double-acting release rotary tail pipe hanger comprises a short drill pipe, an upper joint, a release mechanism, a double male joint, a male and female joint and a lower joint. The short drill pipe, the upper joint, the double male joint and the lower joint are connected in a threaded manner from up to down sequentially. The mechanical-hydraulic double-acting release rotary tail pipe hanger further comprises a loading mechanism comprising a hanger set hydraulic cylinder, a light-load bearing, conjoined twin slips, a conjoined twin cone, a heavy-duty bearing and a central pipe. The hanger set hydraulic cylinder, the light-duty bearing, the conjoined twin slips, the conjoined twin cone and the heavy-duty bearing are arranged on the central pipe from down to up sequentially. The central pipe is connected at the lower end of the male and female joint. The heavy-duty bearing is arranged between the male and female joint and the conjoined twin cone. By the aid of the mechanical-hydraulic double-acting release rotary tail pipe hanger, a tail pipe can rotate when the a tube pillar enters, after the hanger is set and is separated from a releasing release, the slips and the bearings bear the hanger, and functions of rotating and well cementing of a heavy-duty tail pipe is realized.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Double-swing cutter head driven by alternating-current permanent-magnet synchronous inner rotor torque motor

ActiveCN102069409AImplement automatic exchangeImprove adaptabilityLarge fixed membersDriving apparatusNumerical controlTorque motor

The invention belongs to the field of machine tools, in particular to a double-swing cutter head driven by an alternating-current permanent-magnet synchronous inner rotor torque motor. The double-swing cutter head is divided into an upper part and a lower part by an end-toothed disc, wherein the upper part is a shaft C which can rotate around a vertical shaft, the lower part is a shaft A which can swing around the vertical shaft, and the shaft A and the shaft C are respectively connected by an exchangeable interface; a spindle box of the shaft A, a spindle-box support shaft, and an inner rotor of the torque motor are connected to a box body of the shaft A by bearings; the box body of the shaft A is equipped with an outer rotor of the torque motor; the cutter head is connected with the shaft C by a hydraulic pulling claw through the positioning of the end-toothed disc, and the exchange of the shaft A is realized by the pulling claw through hydraulic control; and the torque motor on theshaft C transmits twisting moments by the end-toothed disc so as to realize the peripheral rotation of the shaft A, and the swing of the spindle box is realized by the torque motor on the shaft A. Byusing the double-swing cutter head provided by the invention, the problems that the traditional mechanically operated double-swing is large in additional rotation inertia and complicated in installation and has a transmission clearance, and the like caused by excessive middle transmission links are solved, therefore, the double-swing cutter head provided by the invention can be widely applied to high-grade numerical control machining centers subjected to surface machining.

Owner:通用技术集团沈阳机床有限责任公司

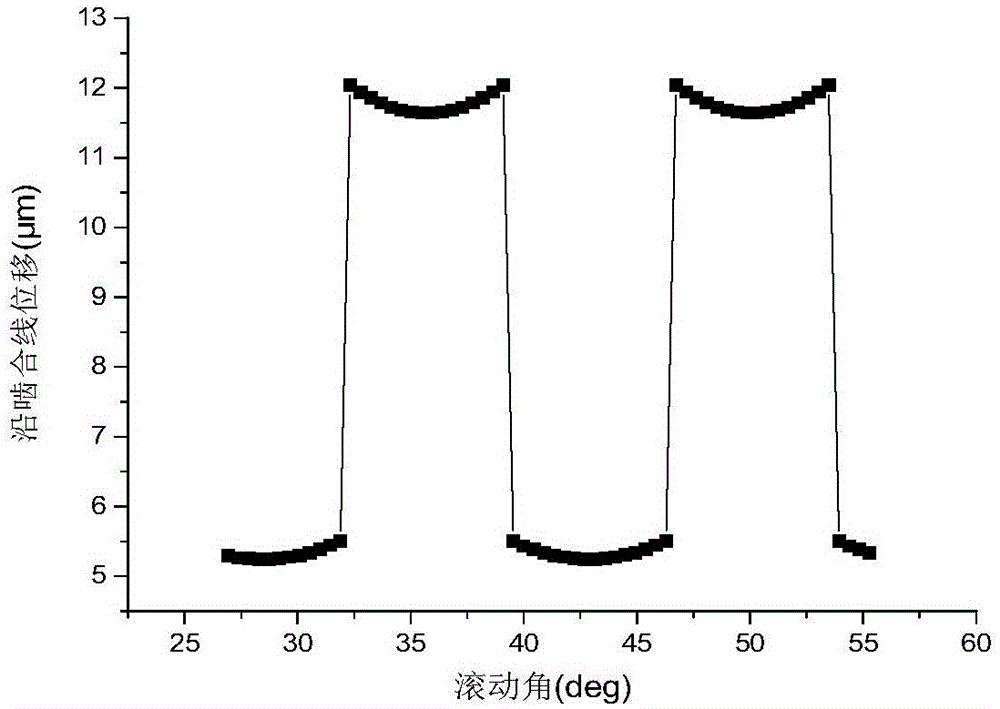

Modification method of secondary straight-tooth planetary gear

ActiveCN105626820AReduce meshing shockReduce vibrationPortable liftingGearing elementsGear wheelCoupling

The invention provides a modification method of a secondary straight-tooth planetary gear. The modification method comprises the following steps: b, determining the load value of gear modification quantity, wherein the load value refers to the interfacial force of a rotating system bearing of the secondary straight-tooth planetary gear in a running state; c, according to the load action of a complex mechanical coupling relationship, obtaining a transmission error curve, and at the same time, obtaining the normal load distribution diagram of the tooth surface of each gear tooth in unit length when the gear is in contact; and d, respectively carrying out profile modification and axial modification on the two different contact surfaces of the planetary gear, and determining modification parameters. According to the modification method of the secondary straight-tooth planetary gear, provided by the invention, the engagement impact of a pinion pair can be reduced under the condition of keeping gear processing precision and saving materials as far as possible, so that the vibration and noise of a planetary gearbox are effectively reduced, and the unbalance load phenomena of planetary gear engagement are greatly reduced; accordingly, the gear transmission stability is improved, the gear bearing capability is improved, the gear service life is prolonged; and the cost is saved, and the hurt of noise to the physical and psychological health of a human body is also reduced.

Owner:CHONGQING UNIV

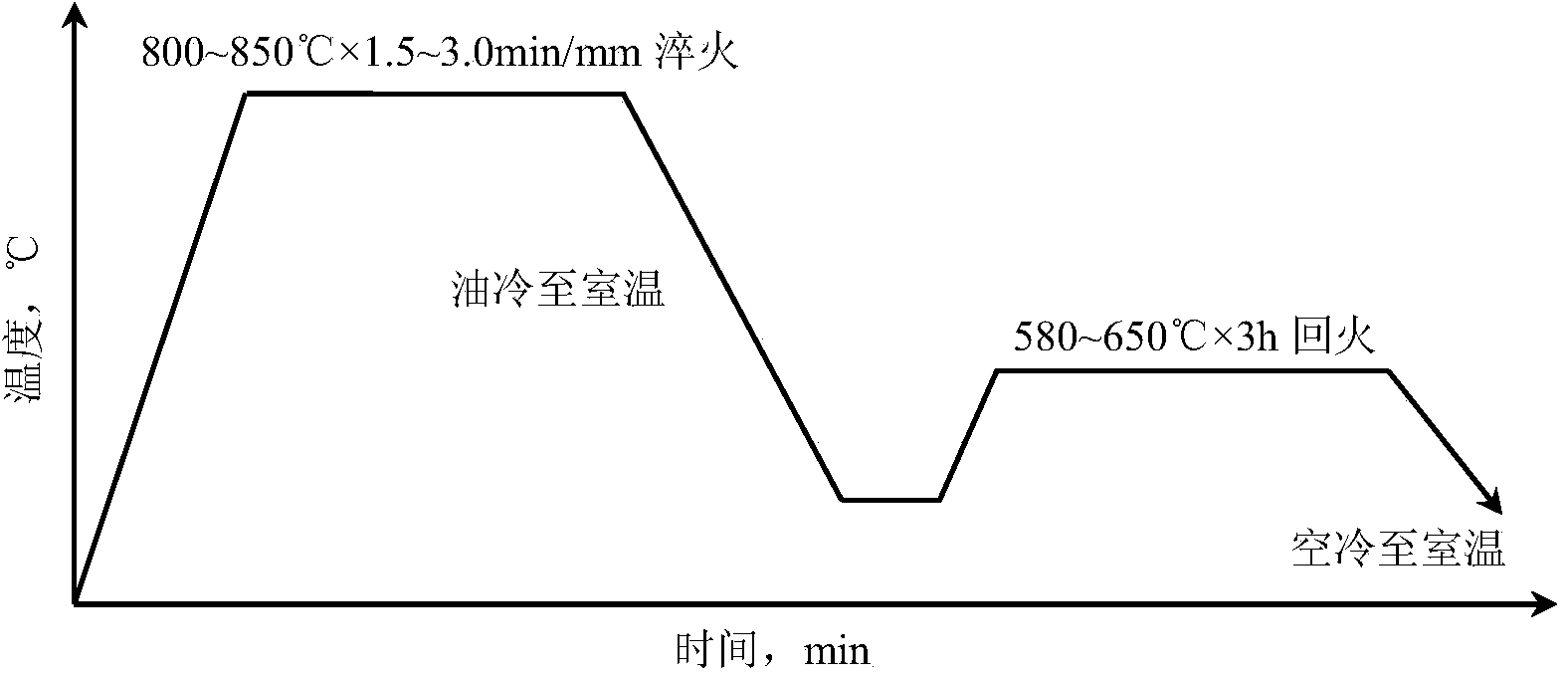

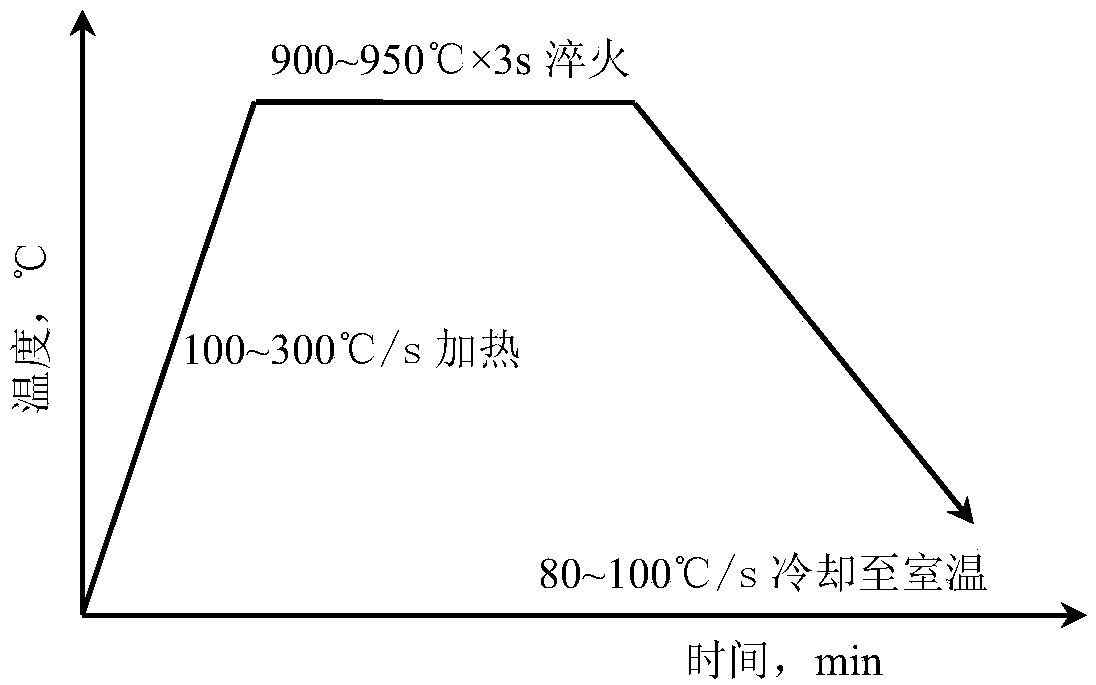

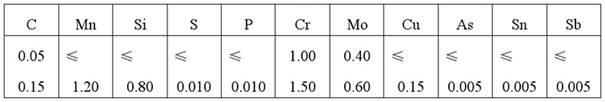

Heat treatment process of bearing ring (3m) of shield tunneling machine

InactiveCN104232875AMeet the requirements of comprehensive mechanical propertiesGuaranteed impact toughnessFurnace typesHeat treatment furnacesTemperingEngineering

The invention relates to a heat treatment process of a bearing ring (3m) of a shield tunneling machine. The method comprises the following steps: carrying out alloying design on an ordinary middle carbon alloy steel 42CrMo to obtain a steel meeting requirements of the bearing ring (3m) of the shield tunneling machine; heating a bearing ring blank produced by utilizing the steel to reach a certain temperature and carrying out heat preservation within a certain time, then carrying out oil cooling on the bearing ring blank until a room temperature reaches, carrying out high-temperature tempering on the bearing ring blank at a certain temperature and then carrying out heat preservation within a certain time, taking out the bearing ring blank and carrying out air cooling until a room temperature reaches; and carrying out induction heating on the surface of a machined bearing ring at a certain heating speed until a certain temperature reaches, and then quenching. After the experimental steel is treated by virtue of the process, the tissue of a hardening layer on the surface of the bearing ring of the shield tunneling machine is of cryptocrystalline martensite, and the matrix structure of the bearing ring is of tempered sorbite; the surface of the bearing ring is high in hardness, wherein the mean value of the hardness of the surface of the bearing ring is 57.9HRC; and the core part of the bearing ring is good in toughness and has proper hardness, wherein the mean value of the impact toughness Akv of the core part of the bearing ring at -20 DEG C is 115J, and the mean value of the hardness at the core part of the bearing ring is 293HB. Thus, the requirements of comprehensive mechanical properties of the steel for the bearing ring (3m) of the shield tunneling machine can be met.

Owner:UNIV OF SCI & TECH BEIJING

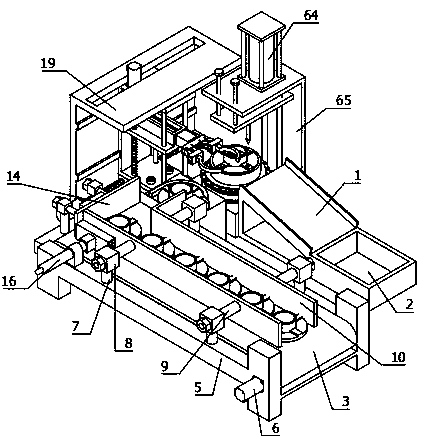

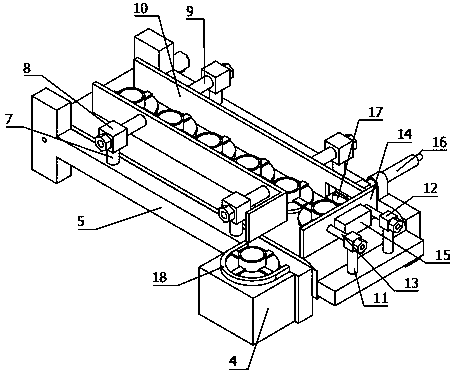

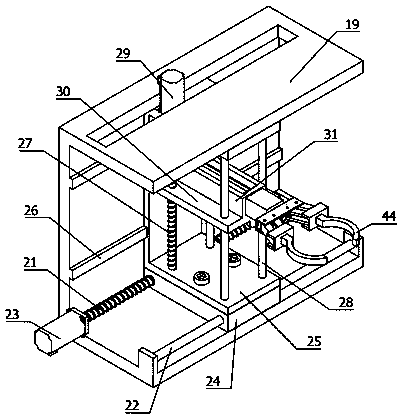

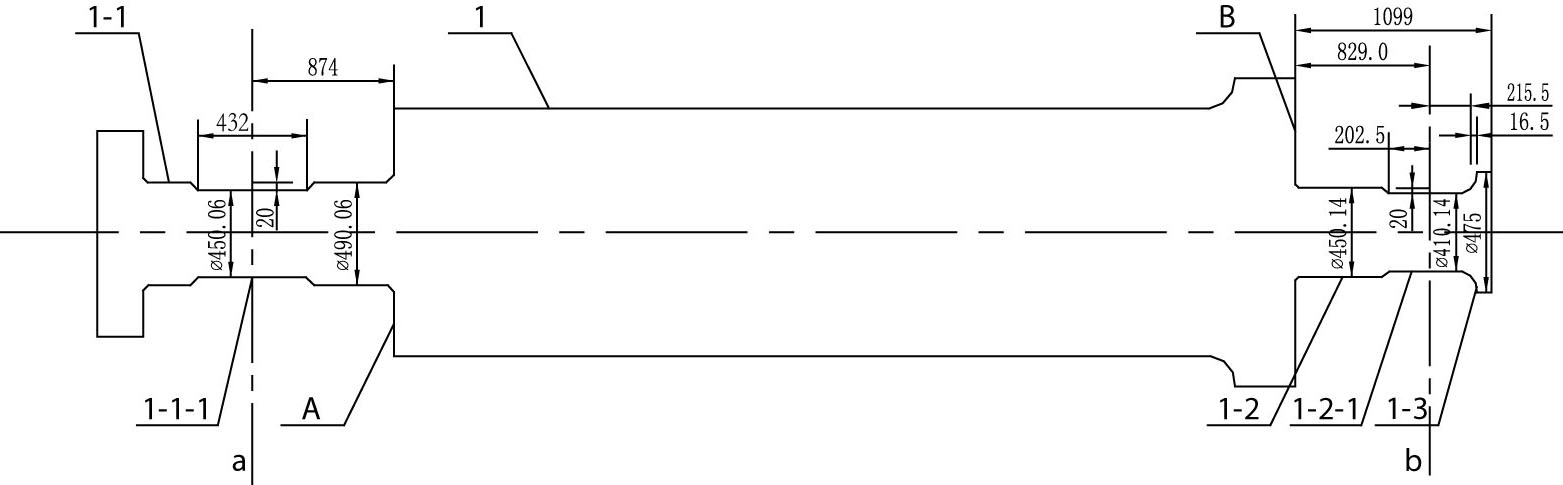

Multi-batch high-efficiency drilling machining equipment for automobile bearing seat

InactiveCN111250758AImprove processing efficiencyReduce manual laborFeeding apparatusChucksEngineeringMachining

The invention relates to the field of mechanical machining, and particularly relates to multi-batch high-efficiency drilling machining equipment for an automobile bearing seat. The equipment comprisesa feeding assembly, a feeding assembly, a rotating assembly, a drilling assembly and a blanking groove, wherein the feeding assembly is arranged beside one end of the feeding assembly, the rotating assembly is arranged on one side of the feeding assembly, and the rotating assembly is positioned below the feeding assembly; the drilling assembly is arranged on the side, far away from the feeding assembly, of the rotating assembly, the blanking groove is arranged on the side, far away from the feeding assembly, of the rotating assembly, and a discharging end of the blanking groove is further provided with a blanking box; and the feeding assembly comprises a conveying belt used for conveying the plurality of automobile bearing seats and a material placing table facilitating feeding of the feeding assembly, and the conveying belt is arranged on one support in a horizontal state. According to the drilling machining equipment, the problems that the automobile bearing seat cannot be machinedin batches and the automobile bearing seat needs to be positioned manually are solved, the labor is reduced, and the machining efficiency of the automobile bearing seat is improved.

Owner:孙义彬

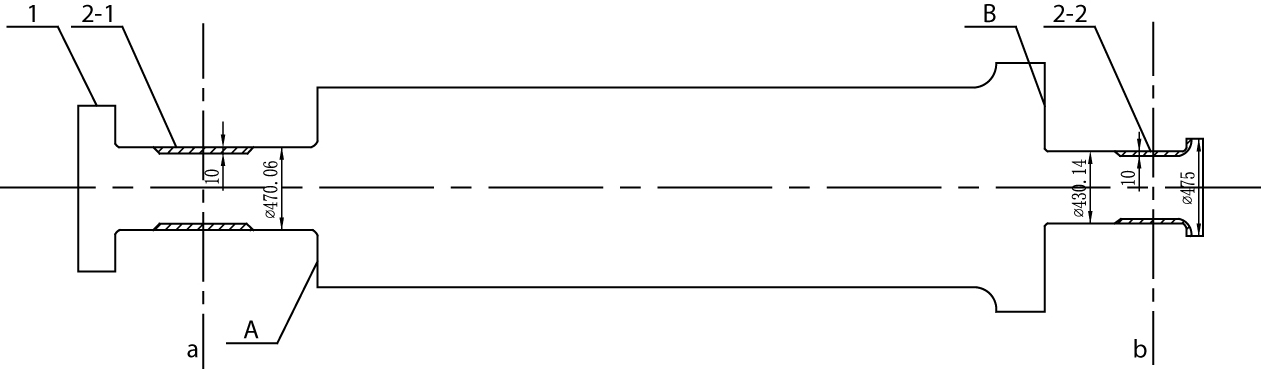

Surfacing method of 12-percent Cr steel high and middle pressure rotor journal of ultra supercritical steam turbine

ActiveCN101837501AAvoid stickingPrevent sintering failure phenomenonArc welding apparatusEngineeringAdhesive wear

The invention relates to a surfacing method, in particular to a surfacing method of a 12-percent Cr steel high and middle pressure rotor journal of an ultra supercritical steam turbine, solving the problem of mechanical adhesive wear of the surfaces of the 12-percent Cr steel high and middle pressure rotor journal and a bearing. The surfacing method comprises the following steps of: firstly, respectively turning a first journal and a second journal of a blank rotor in a groove mode; secondly, carrying out dye inspection on a turning surface; thirdly, assembling the blank rotor to a special surfacing device; fourthly, preheating a surface to be surfaced of the rotor journal; fifthly, surfacing the surface to be surfaced; sixthly, distressing and heating a rotor; seventhly, turning and finishing the surfaced rotor; and eighthly, carrying out nondestructive inspection detection on the finished rotor. The surfacing method is used for surfacing the 12-percent Cr steel high and middle pressure rotor of the ultra supercritical steam turbine.

Owner:HARBIN TURBINE +1

Conformal wear-resistant bearing assembly

Bearing apparatus includes: (a) a first member comprising rigid material and having a bore defining a first contact surface; (b) a second member disposed in the bore, the second member comprising rigid material and having a cylindrical surface defining a second contact surface; (c) wherein both contact surfaces are wear-resistant, and wherein the first and second members are positioned relative to each other by a plurality of protruding bearing elements contacting at least one of the first and second contact surfaces, so as to transfer mechanical loads between the members, each bearing element including a raised central portion flanked by a pair of beam portions, while allowing relative translation and / or rotation between the members; and (e) wherein the bearing elements are shaped and sized so as to deform elastically and conform in an irregular shape to the at least one contact surface.

Owner:LITTLE ENGINE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com