Variable-frequency control electromagnetic torsion coupler and use thereof

A technology of torque coupling and frequency conversion speed regulation, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of sensitive materials and working environment, heavy maintenance workload, short operating life, etc., and achieve low voltage ride through The effects of weaker capacity, improved operating efficiency, and high operating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

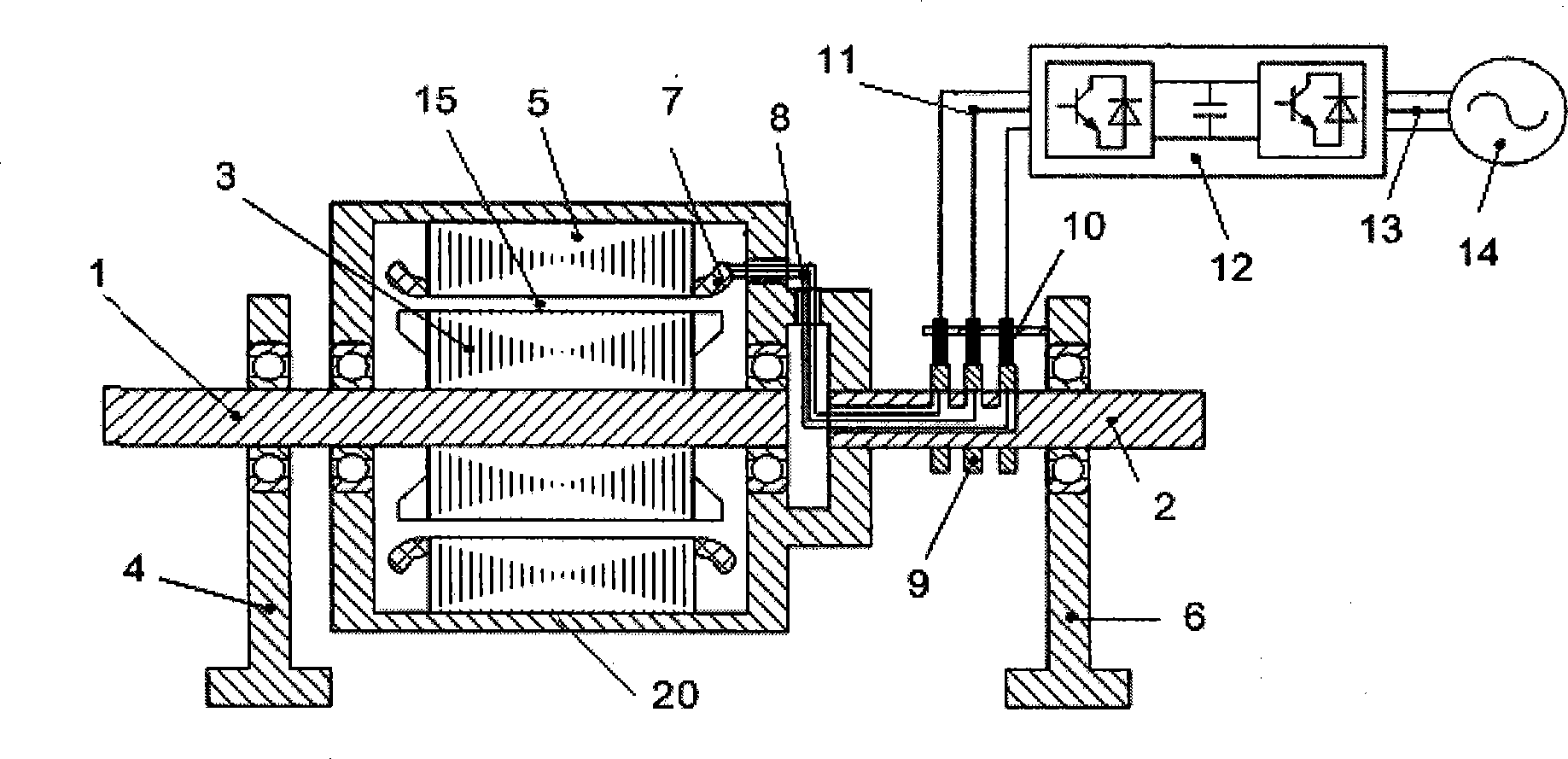

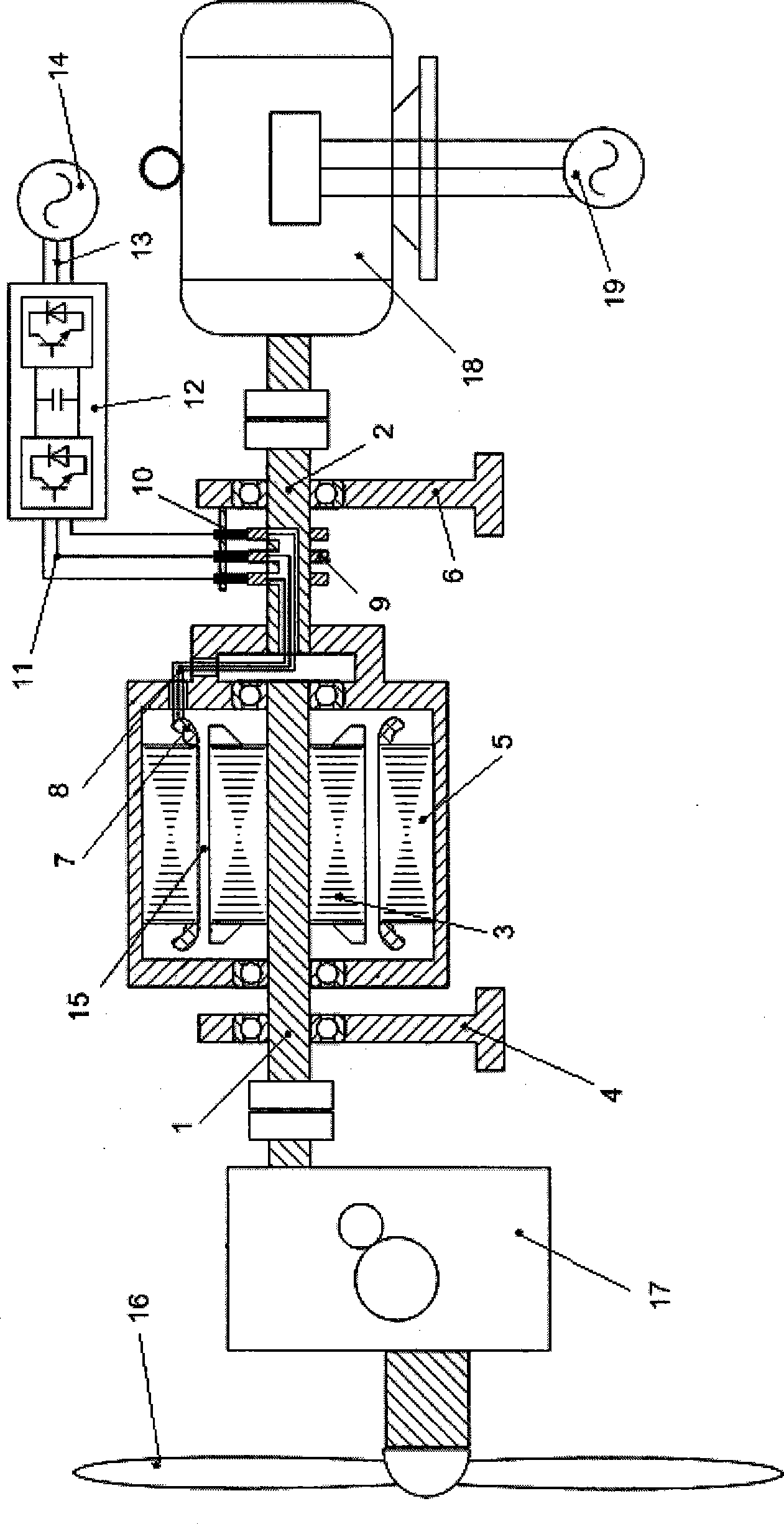

[0016] Such as figure 1 As shown, the frequency conversion speed regulation electromagnetic torque coupling provided by the present invention adopts a non-contact torque transmission structure, and specifically includes a housing 20, and an inner rotor mechanical shaft 1 and an outer rotor are arranged in the housing 20 The mechanical shaft 2, the inner rotor The mechanical shaft 1 is connected with the inner rotor 3 of an ordinary AC motor rotor, the inner rotor 3 is supported on an inner rotor stationary bearing bracket 4, and can rotate freely, and the outer rotor mechanical shaft 2 is connected with an ordinary AC motor The outer rotor 5 of the stator is connected, and the outer rotor 5 is supported on an outer rotor stationary bearing bracket 6 and can also rotate freely, forming an electromagnetic coupling working air gap 15 between the inner ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com