Electric machine driving device used on light electromobile

A motor-driven, electric vehicle technology, applied in the direction of electric power devices, power devices, wheel transmissions, etc., can solve problems such as poor climbing ability, short driving mileage, and large driving current on flat roads, and achieve high efficiency, Strong climbing ability and long driving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

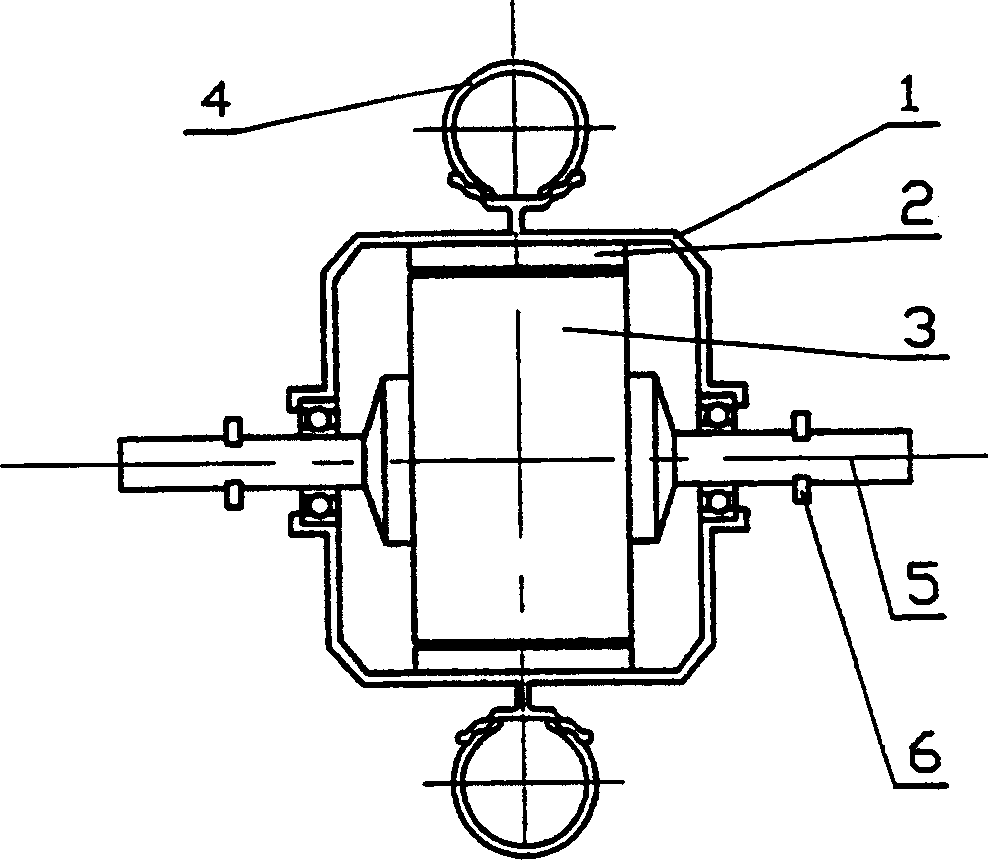

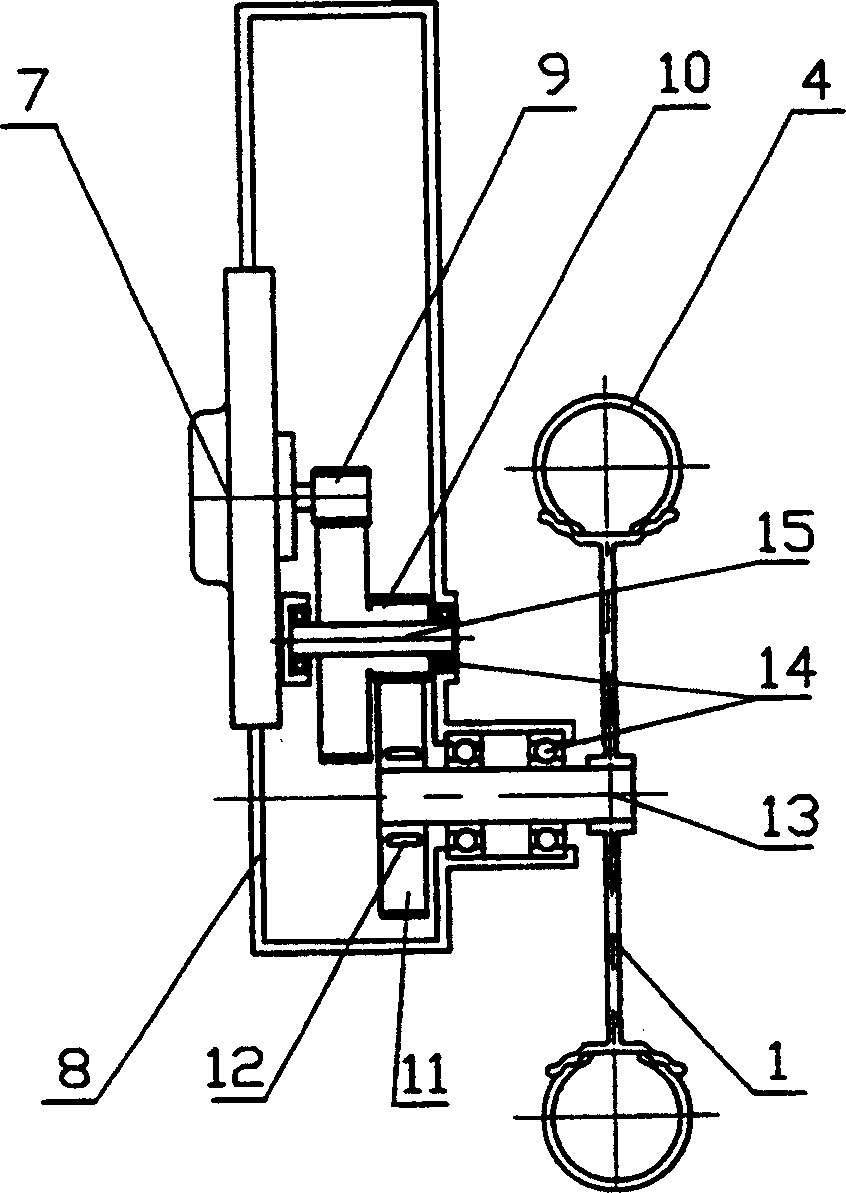

[0012] The driving device of the light electric vehicle proposed by the present invention has two structures, wherein the first structure, such as figure 2 As shown, including motor 7, transmission system and casing 8. The motor is installed on the casing, and the transmission system is placed in the casing 8, and is connected to the wheel hub 1 of the electric vehicle wheel outside the casing. The transmission system includes a pinion 9, an intermediate gear 10, a bull gear 11 and an overrunning clutch 12, the pinion 9 is connected to the output shaft of the motor 7, the pinion 9 is linked with the bull gear 11 through the intermediate gear 10, and the bull gear 11 is connected through the overrunning clutch 12 It is connected with the drive shaft 13 of the electric vehicle.

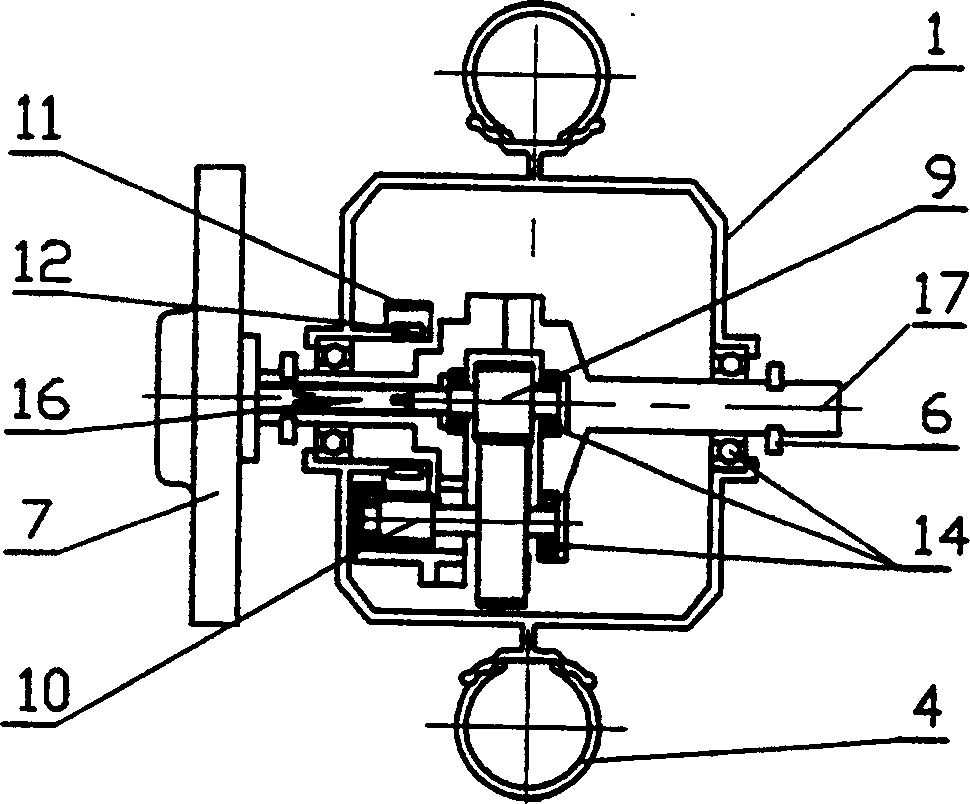

[0013] The second structure of the present invention, such as image 3 Shown, comprise motor 7 and transmission system. Motor 7 is fixed on the outside of the wheel hub 1 of the electric vehicle tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com