Lead-free self-lubricating bearing and its production

A technology of self-lubricating bearings and manufacturing methods, applied to bearings, bearing components, shafts and bearings, etc., can solve the problems of poor mechanical strength and elastic modulus, low friction coefficient, etc., achieve long service life, simple manufacturing process, and high-quality products The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

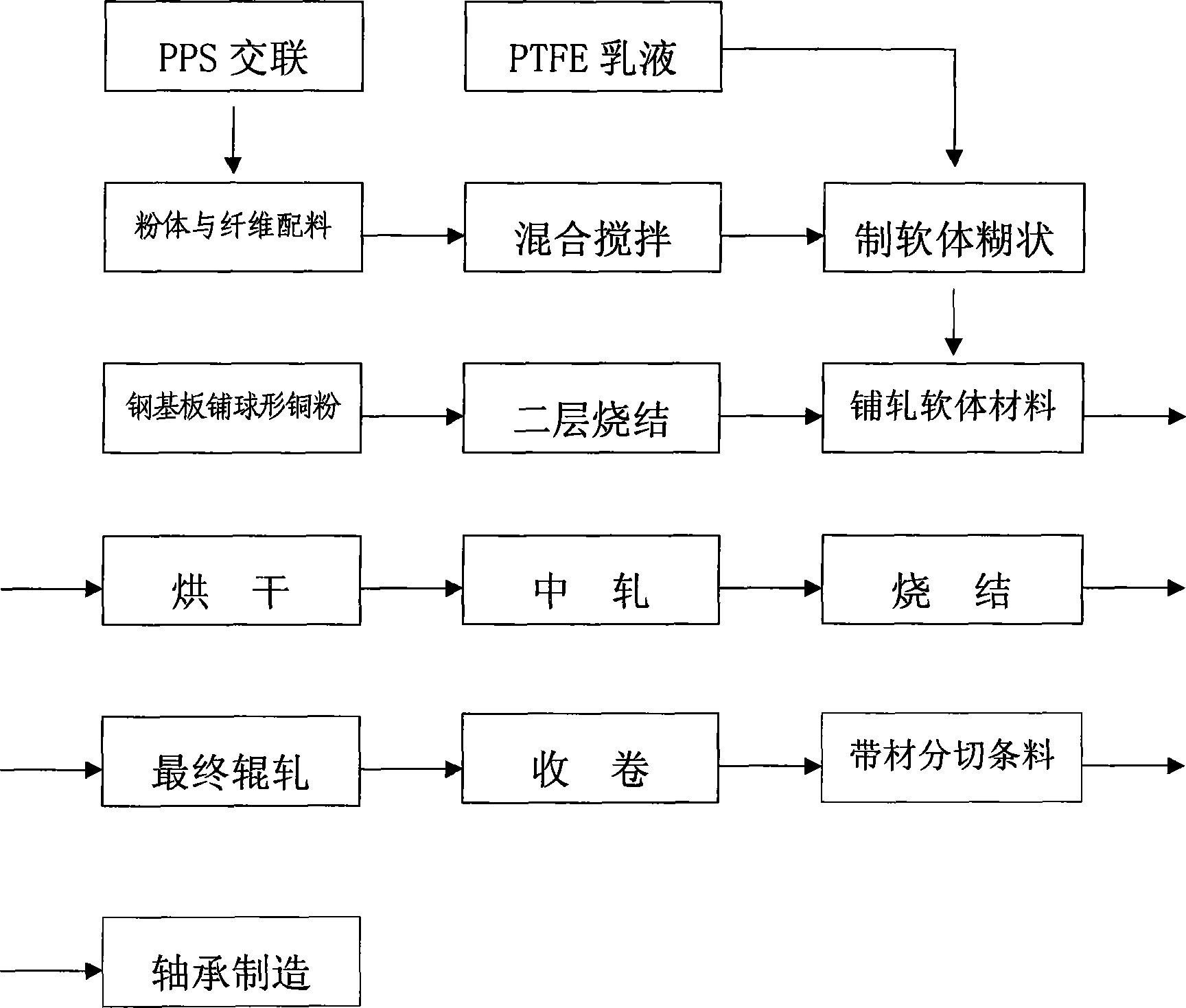

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments: the present invention is mainly composed of a metal substrate, a spherical porous copper powder layer sintered on the substrate, and a friction-reducing and wear-resistant plastic layer that infiltrates and covers the copper powder layer, and Rolling process is used to manufacture sliding bearings; the spherical bronze powder does not contain lead and the friction layer plastic formula does not contain lead; the anti-friction and wear-resistant plastic layer is composed of polymer materials of the bearing lining layer, by weight 10-20% polyphenylene sulfide ultra-fine powder, 10-20% polyphenylene resin ultra-fine powder, 10-20% aramid fiber, fiber length 40-120μm, molybdenum disulfide ultra-fine powder 6-20% 10%, the rest is PTFE ultrafine powder.

[0043] The metal substrate is a steel coil made of high-quality low-carbon steel. The steel coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com