Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Interfacial Force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface tension of the surfaces at the boundary between two immiscible liquids.

Electrostatic spraying antirust oil

The invention discloses an electrostatic painting antirust oil to solve the problem of plain carbon steel surface erosion, which is characterized by the following: this product is composed by 70.0-90.0 mass percent base oil, 5.0-29.0 mass percent antirust agent, 0.1-5.0 mass percent atomized property improver and 0.1-5.0 mass percent antioxidant. This invention possesses merits of low cost, high flash point, good washable and lower interfacial force.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

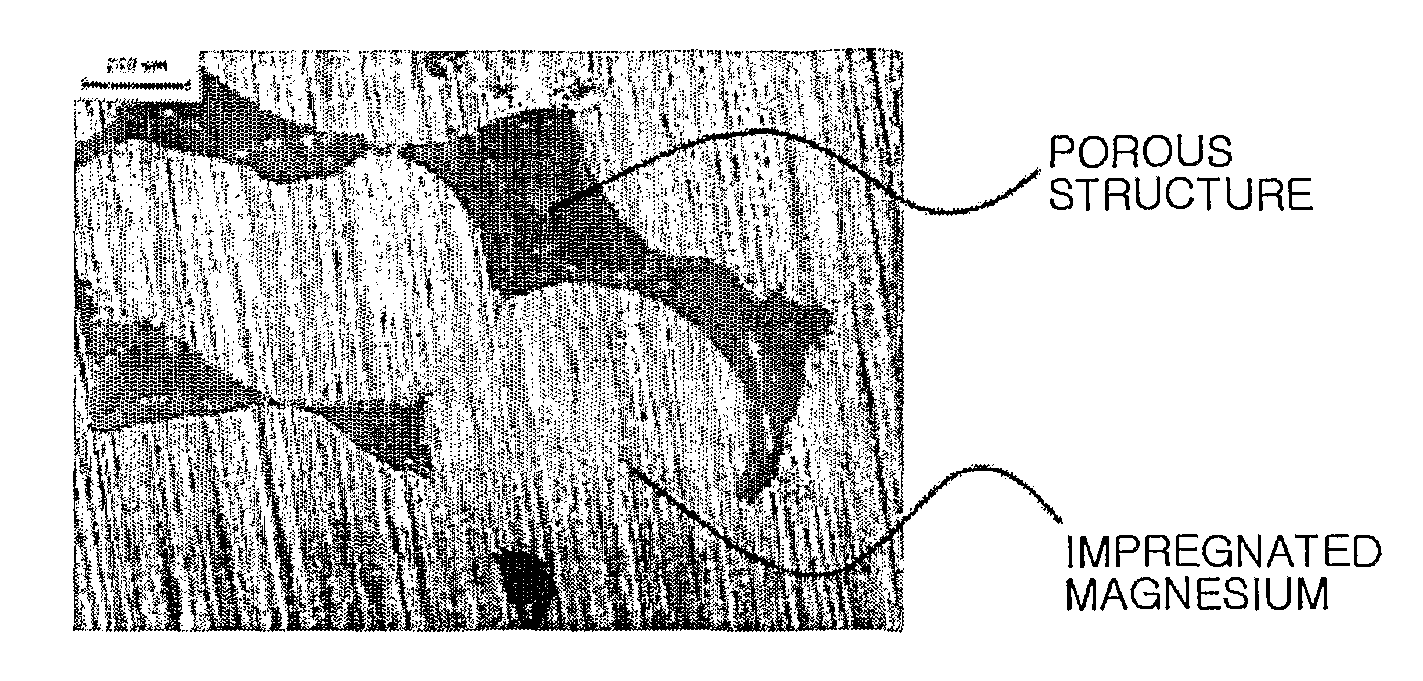

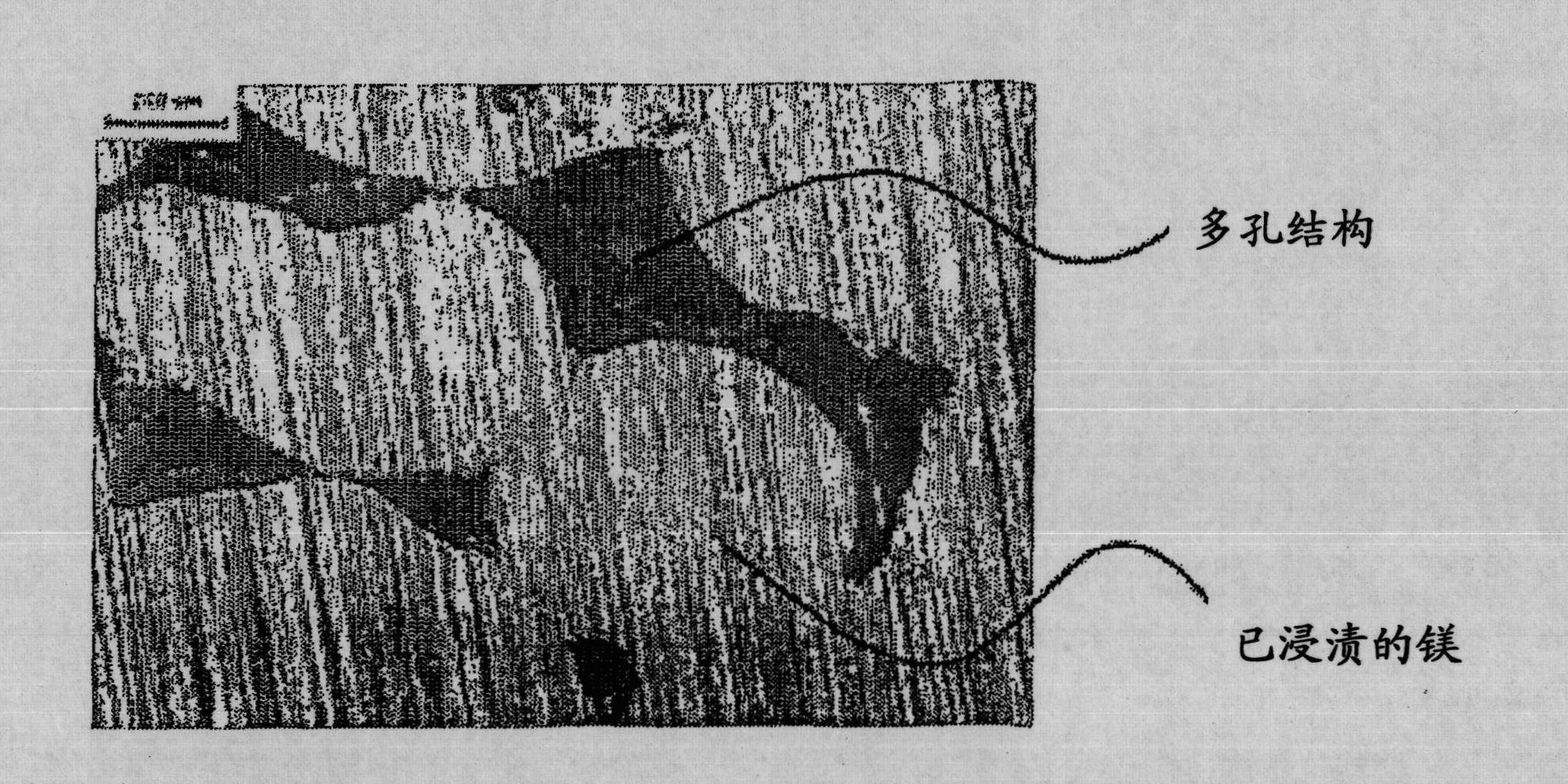

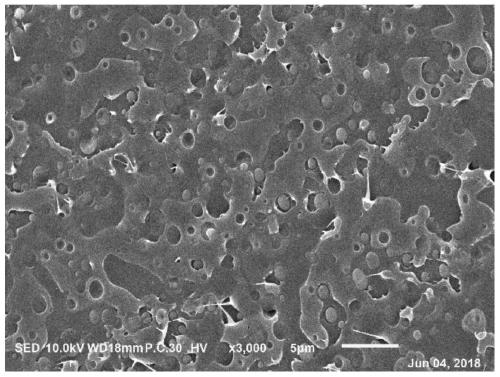

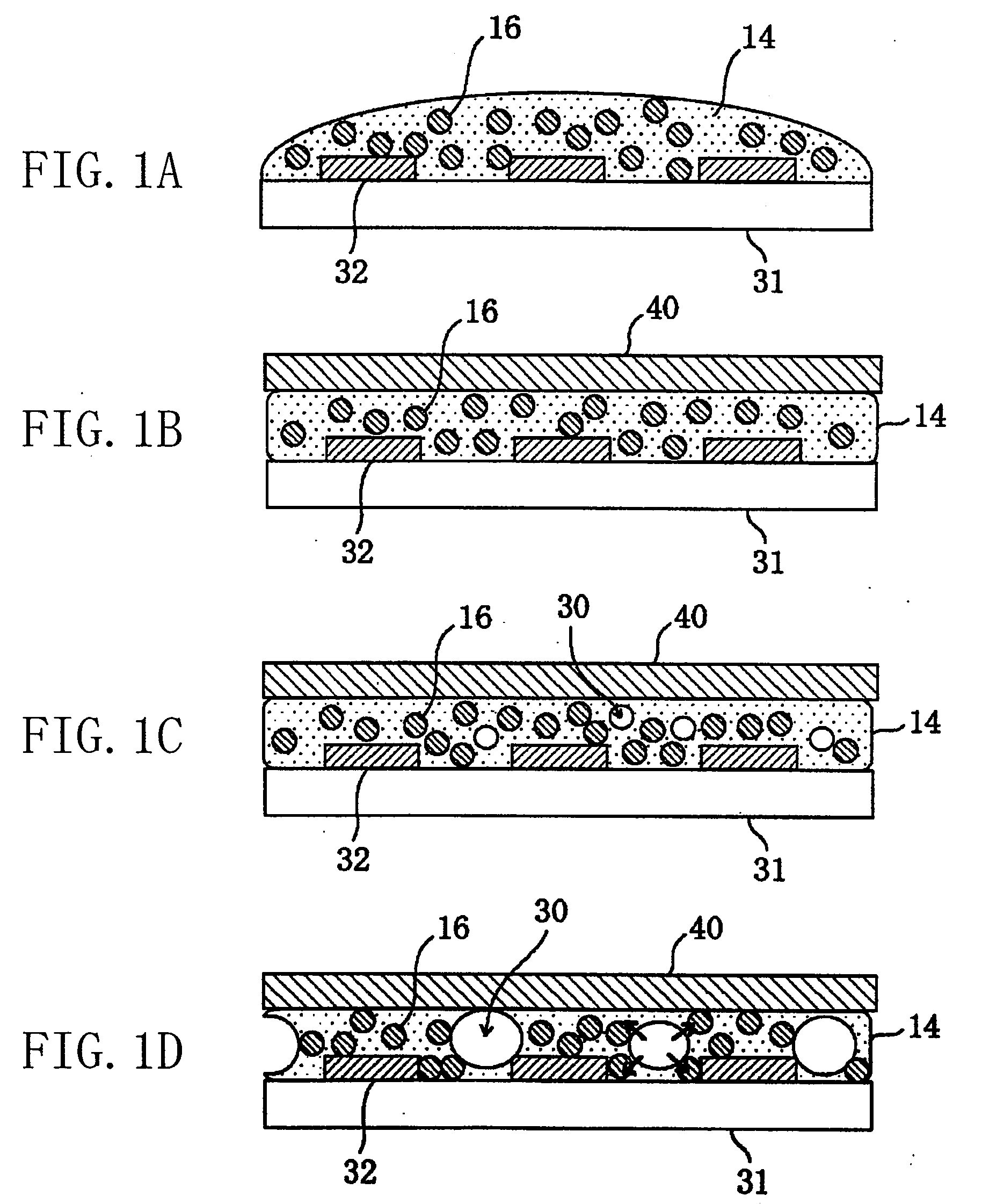

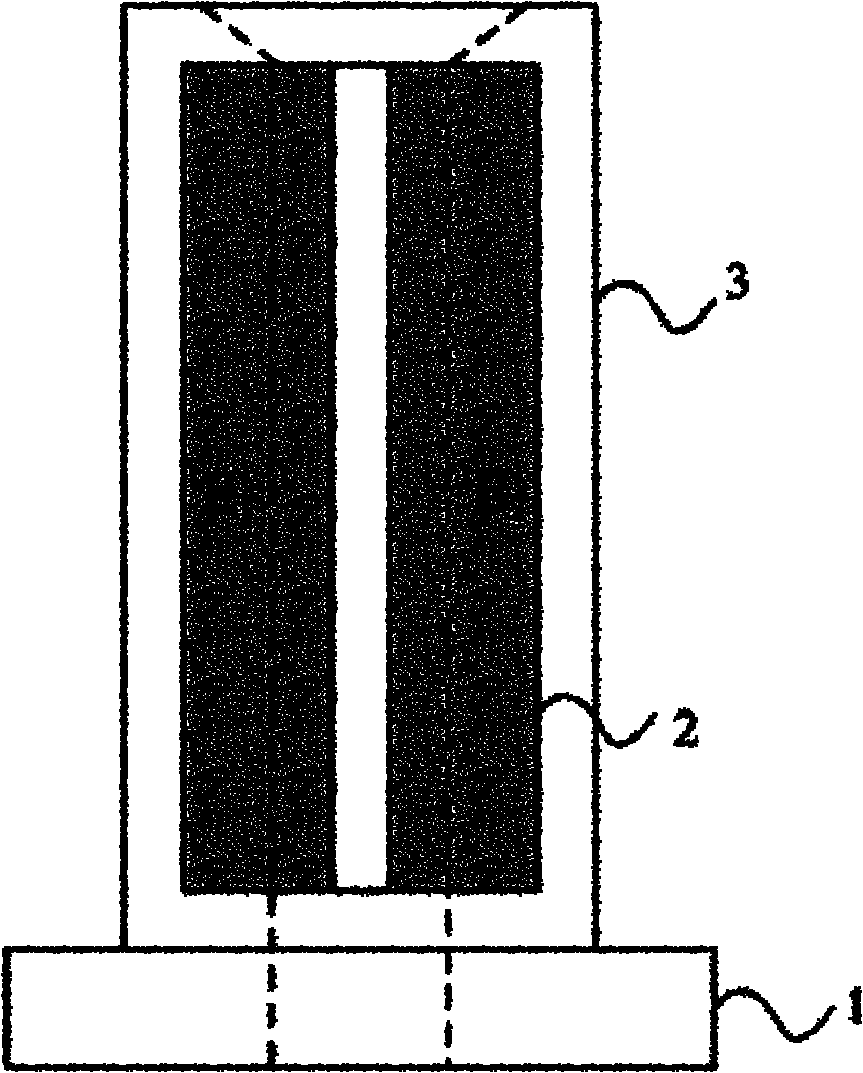

Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

InactiveUS20110054629A1Improve bone formationImproved rate of bone formationDental implantsImpression capsAlloyMechanical property

The present invention provides a composite implant comprising pores of a porous structure filled with a biodegradable magnesium-based alloy. Further, the present invention provides a composite implant which filles pores of the porous structure prepared by a metal, a ceramic or a polymer with a biodegradable magnesium-based alloy. Mechanical properties of the composite implant of the present invention are improved because a magnesium-based alloy filled in its pores increases the strength of a porous structure comprised of a metal, a ceramic or a polymer. Further, it can be expected that the magnesium-based alloy filled in the porous structure is decomposed in a living body, thus increasing bone formation rate. Accordingly bone tissue can be rapidly formed because the composite implant of the present invention has high strength and excellent interfacial force between the composite implant and bone tissue, compared to conventional porous materials.

Owner:U & I INC

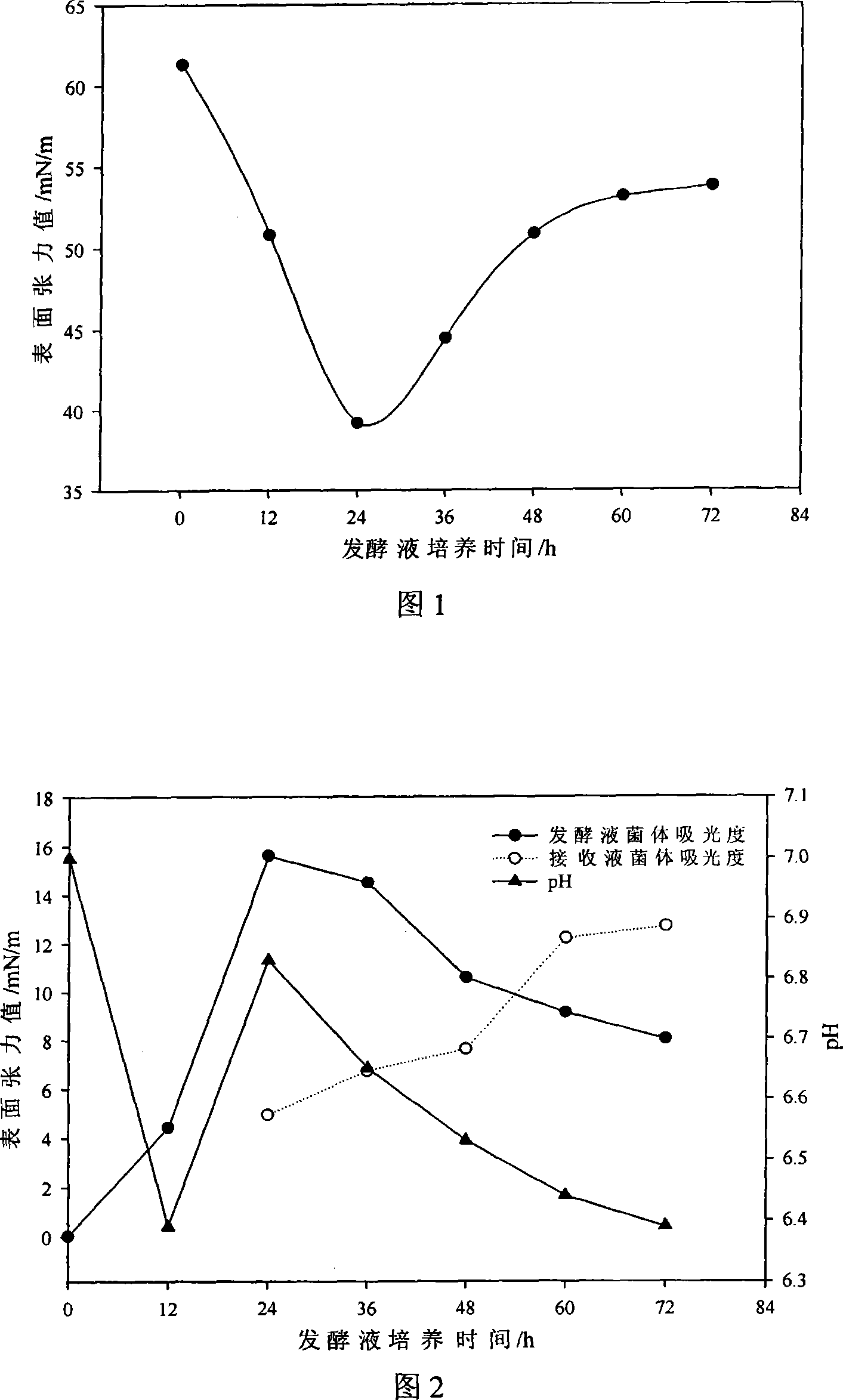

Composite type biological surfactant and its production method

InactiveCN101086006ARich varietyIncrease varietyTransportation and packagingClimate change adaptationCritical micelle concentrationDistilled water

The invention relates to a kind of complex biological surface active agent and the preparation method. It is prepared with bacillus subtilis, and the comprised component and their weight proportion are as follows: fat 98.1+- 0.2%, protein 19.1+- 0.2%, sugar 0.7+-0.1%, the critical micelle concentration of said complex biological surface active agent are 4.2- 5.0 g / l and 1.25- 1.39 g / l respectively, and they reduce interfacial force of distilled water from 78 m / m to 38.4- 39.8 mN / m, and 40.3- 40.8 mN / m. The invention is characterized in that it enriches biological surface active agent species generated by bacillus subtilis, and make it possible for bacillus subtilis wide application in environmental pollution treatment.

Owner:HUNAN UNIV

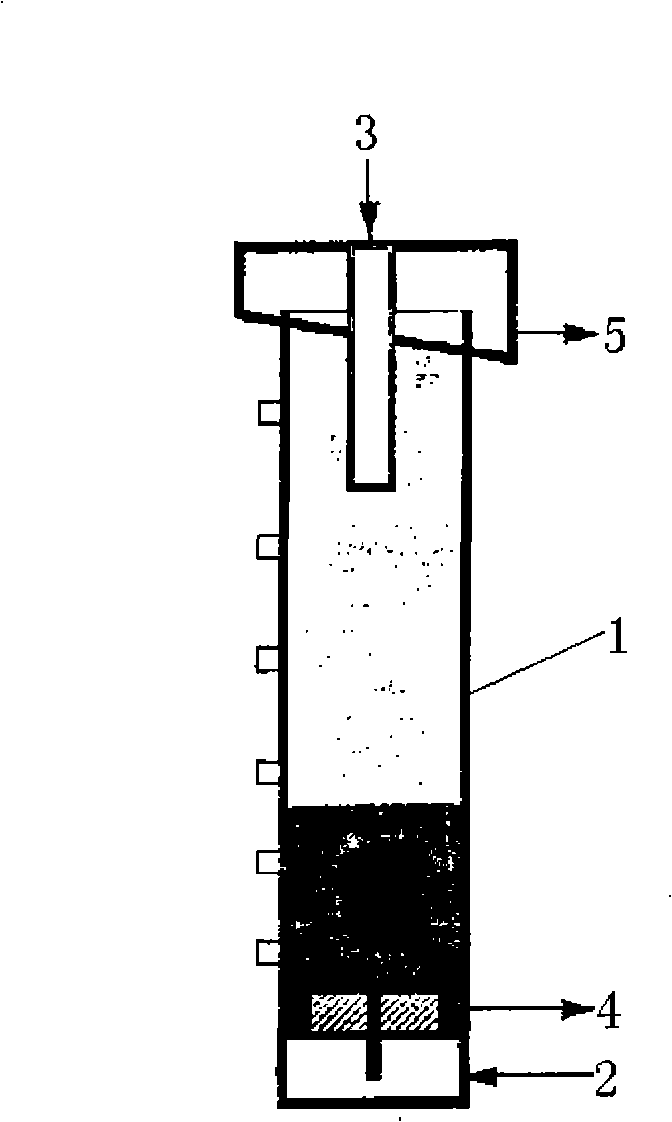

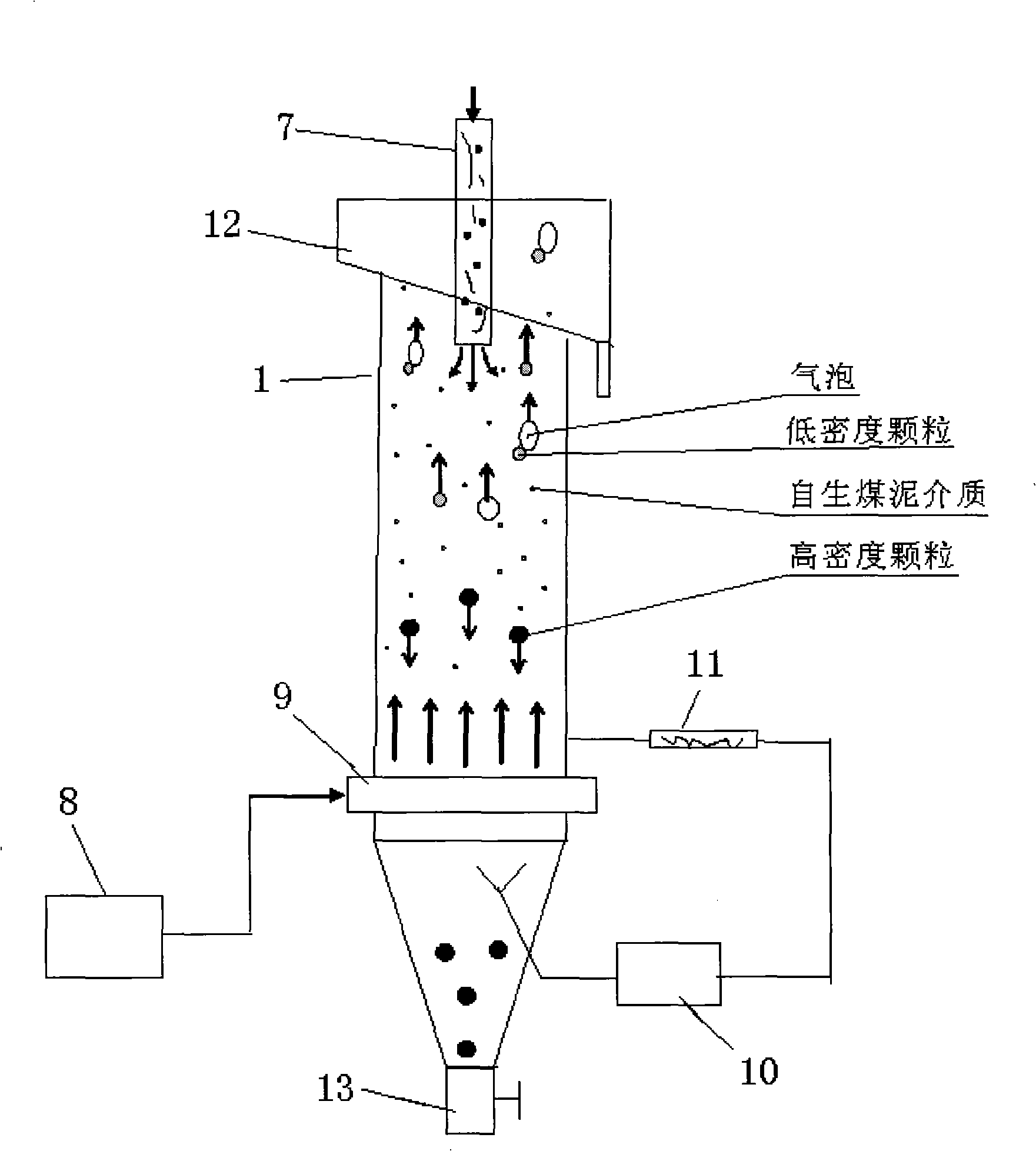

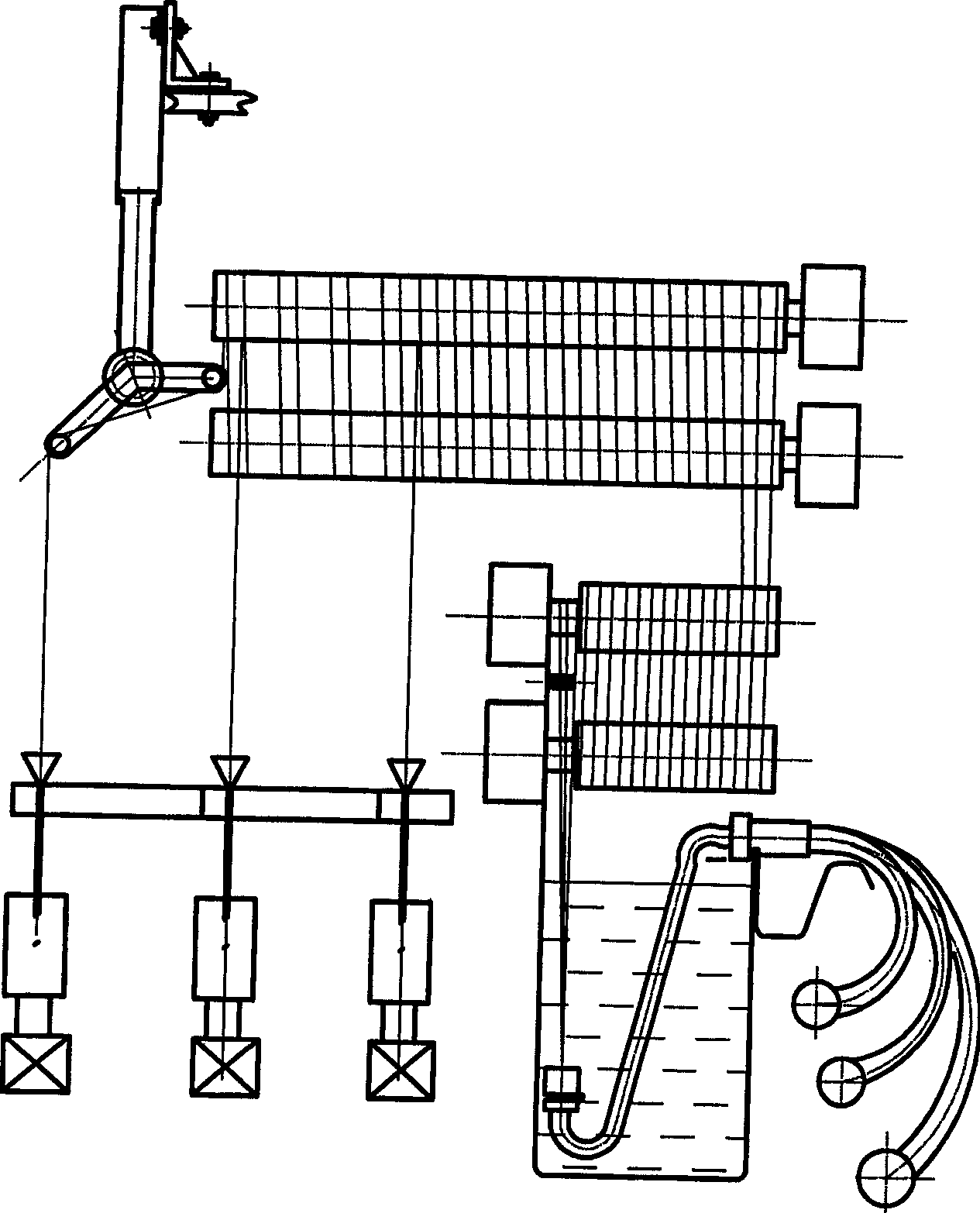

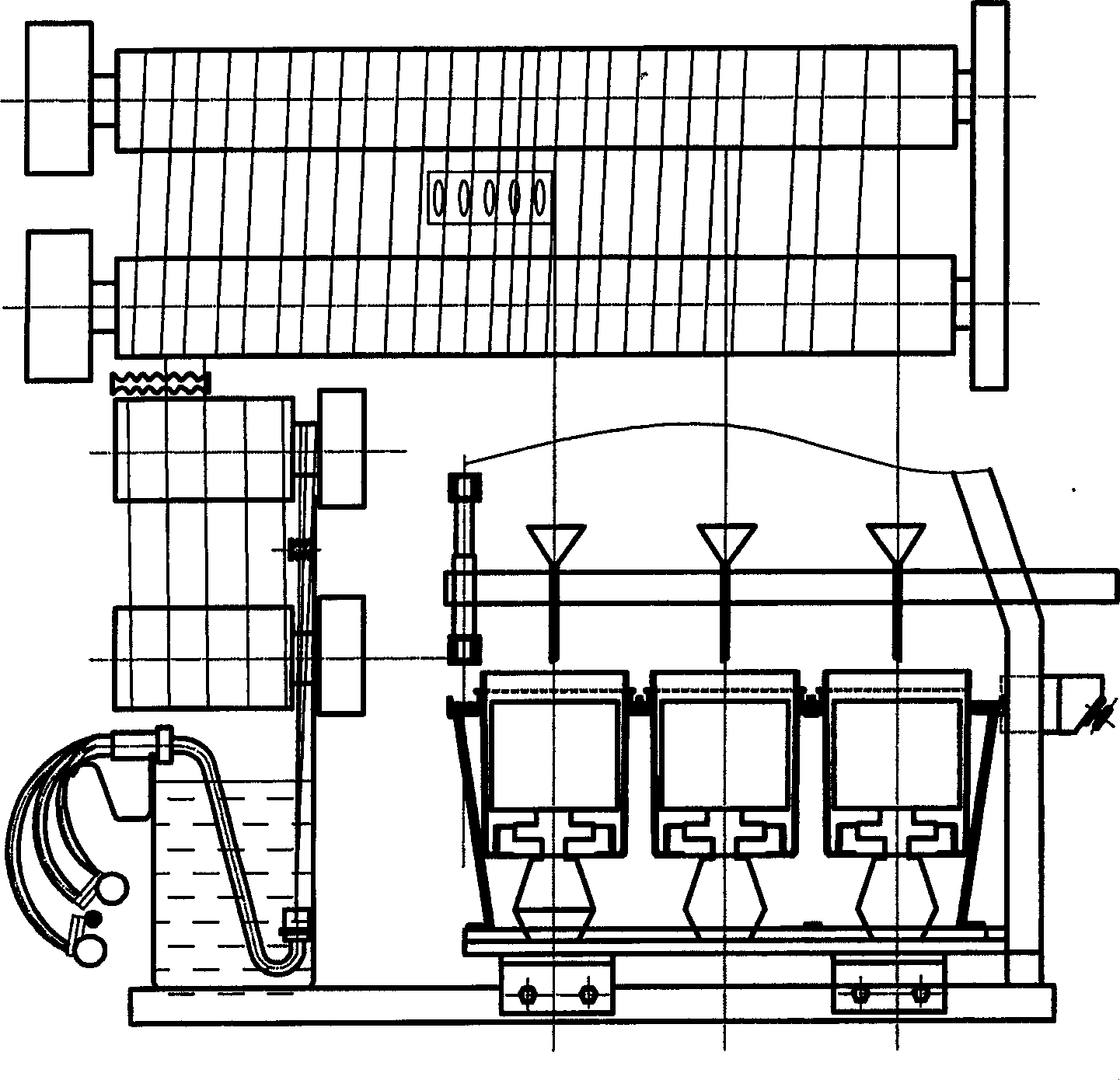

Coarse slime interference bed separation equipment based on gravity force and interfacial force, method and uses thereof

InactiveCN101402063AEfficient sortingHigh sorting accuracyWet separationVolumetric Mass DensityEngineering

The invention discloses a sorting device for a coarse coal slime interference bed based on gravity and interfacial force, a method and application thereof, wherein air bubbles are introduced into the sorting device of the interference bed. Under the action of ascending water flow, an environment similar to heavy medium sorting is formed by using fluidization of fine coal slime carried in fed materials; and the introduced air bubbles are attached to hydrophobic low density particles so that the real density of an air bubble-hydrophobic particle polymer is reduced and the density difference between head coals and minerals is increased. The sorting device realizes the sorting based on the combined action of gravity and interfacial force in a solid-liquid-gas three-phase interference bed, has large adaptation range to the particle size of the fed materials and high sorting precision, can effectively sort coarse coal slime which has wide level and is difficult to sort, and is in particular applicable to the sorting of the coarse slime of which the particle diameter is between 2 and 0.3 millimeter.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Xanthochromia-resistance dacron afterprocessing oil solution and manufacturing method thereof

The invention discloses terylene afterprocessing oil agent for preventing xanthochromia, which is mainly formed by smoothing agent, emulsifying agent, cleaning agent and addition agent, and is characterized in that weight percentage of each component is smoothing agent 85%-90%, emulsifying agent 5%-10%, cleaning agent 2%-4% and addition agent 1%-1.5%. According to the weight percentage of each component, the method for preparation is that firstly packing emulsifying agent and cleaning agent with precise measure into an autoclave to heat from 50 DEG C to 80 DEG C, secondly packing smoothing agent into the autoclave to mix for 40-60 min, thirdly charging addition agent to mix homogeneously, and then cooling, filtering and packaging. The terylene after-processing oil agent for preventing xanthochromia has the advantages that interfacial force is low, permeability and diffusibility are good, the applying oil process is quick and homogeneous, the volume for applying oil is easy to be controlled, after-processing is smooth and has no imperfect effect on weave process and causticity component, and the invention is easy for washing and not influence on coloration and topical finish, and is good in cohesion property and forming of silk can, high in oil film strength, and strong in ability of preventing xanthochromia, thereby being favorable to store silks.

Owner:TONGKUN GRP

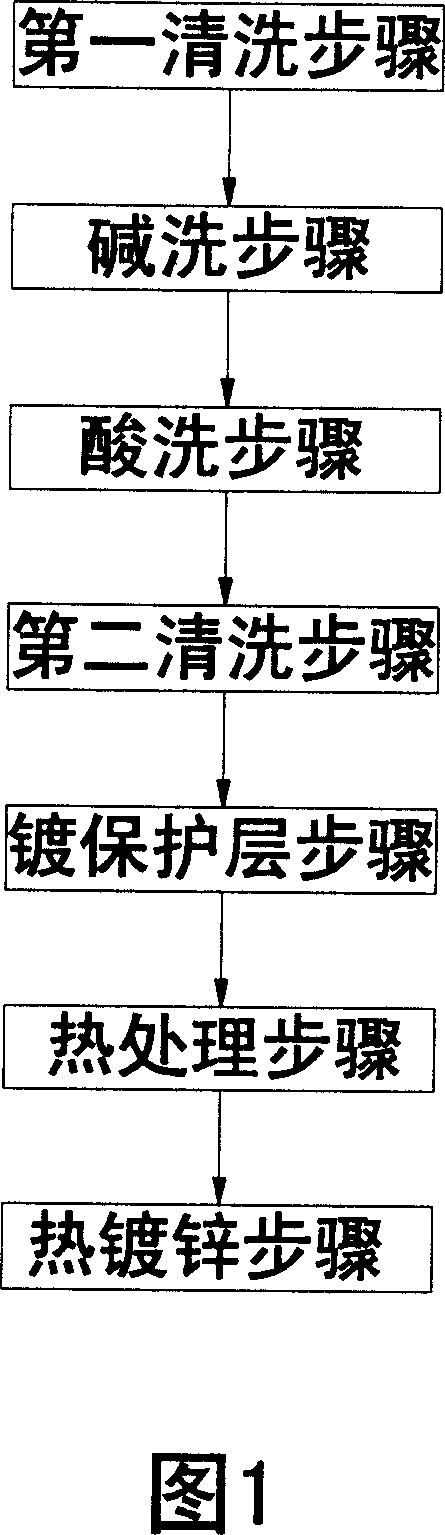

Strip steel continuous zinc heat coating process

InactiveCN101078096AReduce surface tensionImprove wettabilityHot-dipping/immersion processesFurnace typesShielding gasCarbon Dioxide / Helium

A technology method about continuous hot dip galvanizing on zonal steel, the method contains: the first cleaning step to clean and get rid of the remainder on the surface of zonal steel; The alkaline cleaning step to get rid of the fat on the surface of it; The acidwashing step to get rid of the oxidation skin on the surface of it. The second cleaning step: To get rid of the product of the alkaline cleaning and acidwashing on the surface of zonal steel. Heat treatment step: to realize the heat treatment of the zonal steel in the shielding gas and deliver the zonal steel to the zincification step in the ambience of shielding gas. Heat zincification step: to install clad layer on the surface of zonal steel. The benefit of this patent is: the patent contains the first cleaning step, alkaline cleaning step, acidwashing step and the second cleaning step, it can get rid of oxidation skin, fat and the remainder on surface, and it can activate the surface of steel, decrease interfacial force of molten metal, improve the soakage ability of zinc liquid, and increase the binding capacity of the zinc clad layer.

Owner:福建爱溥环保设备有限公司

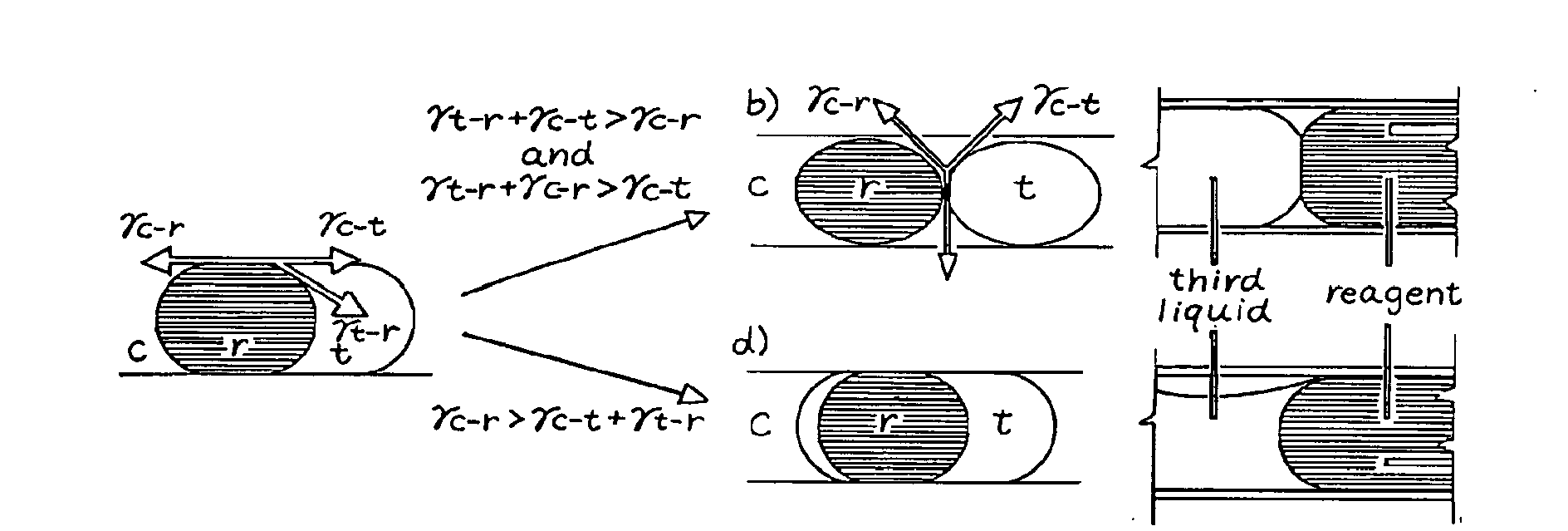

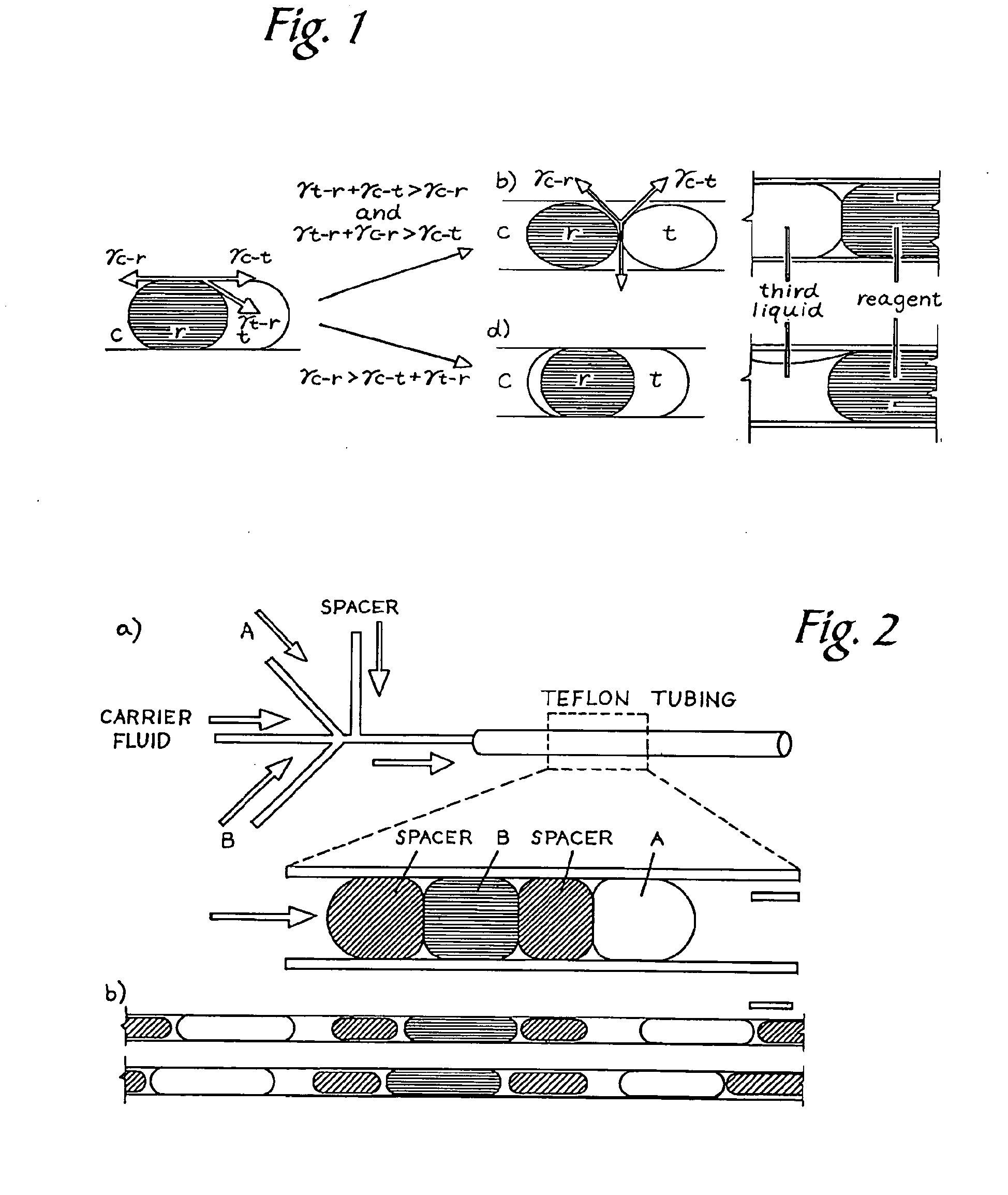

Spacers for Microfluidic Channels

A microfluidic system comprises a microchannel, a carrier fluid in the microchannel, and at least two plugs in the microchannel. Each plug comprises a plug fluid that is substantially immiscible with the carrier fluid. The microfluidic system further comprises at least one spacer in the microchannel between two plugs. Each spacer comprises a spacer fluid that is substantially immiscible with the carrier fluid and the plug fluid, and both of the following conditions are satisfied: (γc-r+γt-r>γc-t) and (γc-t+yt-r>yc-r), where γc-r is the interfacial force between the carrier fluid and the plug fluid, γt-r is the interfacial force between the spacer fluid and the plug fluid, and γc-t is the interfacial force between the carrier fluid and the spacer fluid.

Owner:UNIVERSITY OF CHICAGO

Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

InactiveCN102014798AIncrease spawn ratePromote generationDental implantsBone implantAlloyMechanical property

The present invention provides a composite implant comprising pores of a porous structure filled with a biodegradable magnesium-based alloy. Further, the present invention provides a composite implant which filles pores of the porous structure prepared by a metal, a ceramic or a polymer with a biodegradable magnesium-based alloy. Mechanical properties of the composite implant of the present invention are improved because a magnesium-based alloy filled in its pores increases the strength of a porous structure comprised of a metal, a ceramic or a polymer. Futher, it can be expected that the magnesium-based alloy filled in the porous structure is decomposed in a living body, thus increasing bone formation rate. Accordingly bone tissue can be rapidly formed because the composite implant of the present invention has high strength and excellent interfacial force between the composite implant and bone tissue, compared to conventional porous materials.

Owner:U & I INC

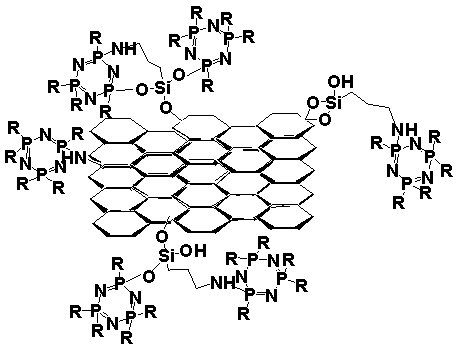

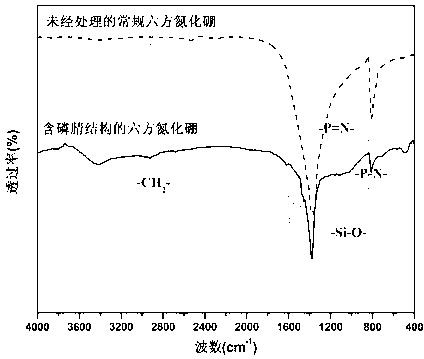

Fire-retarding hexagonal boron nitride/thermosetting resin composite material and preparation method thereof

InactiveCN103059567AImprove flame retardant performanceLow coefficient of thermal expansion and highHexagonal boron nitrideThermal expansion

The invention discloses a fire-retarding hexagonal boron nitride / thermosetting resin composite material and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing hexagonal boron nitride with methylbenzene; adding silane coupling agent to obtain coupled hexagonal boron nitride; mixing the hexagonal boron nitride with a solvent, and adding a catalyst to obtain a mixer; dissolving chloride phosphonitrile in the solvent, and slowly adding the phosphonitrile chloride into the mixture to obtain chloride phosphonitrile hexagonal boron nitride; mixing the solvent and a reagent with the chloride phosphonitrile hexagonal boron nitride, and then adding a catalyst to obtain hexagonal boron nitride with a phosphonitrile structure; uniformly mixing the hexagonal boron nitride with molten thermocuring resin, and then obtaining a fire-retarding hexagonal boron nitride / thermosetting resin composite material after curing. The hexagonal boron nitride with the phosphonitrile structure is a function body with both organic resin high fire resistance and low thermal expansion coefficient, contains lots of active groups, ensures good dispersion of the hexagonal boron nitride in resin basal body and obtains a good interfacial force, and the prepared composite material has both high fire resistance and low thermal expansion coefficient.

Owner:SUZHOU UNIV +1

Method for preparing composite talcum powder filled material of polypropylene

This invention relates to a method for preparing talcum powder-filled polypropylene composite material. The method comprises: adding maleic anhydride-grafted polypropylene, talcum powder, epoxy resin and curing agent to polypropylene resin in an internal mixer, open mill or screw extruder at a certain blending temperature, blending, and curing epoxy resin in situ. The interfacial force between epoxy resin and polypropylene or talcum powder increased, and the mechanical properties of the obtained composite material are obviously improved. Compared with traditional surface treatment of talcum powder with coupling agent, or the addition of compatibilizer, the talcum powder-filled polypropylene composite material in this invention has improved rigidity and toughness. The method has such advantages as simple process, high processability and high adaptability. The talcum powder-filled polypropylene composite material can be used in buildings, automobile fittings and electric appliances.

Owner:SHANGHAI JIAO TONG UNIV

Semi-continuous centrifugal spinning process

The invention discloses the semi-continuous centrifugal spinning technology, comprising the following steps: three strand silks on one ingot, 1 in making glue procedure, viscose ripening between 8.8-13ml, interfacial force between 40-52dny, bubble below 25 / 500ml, thrice filtering, controlling candle filter particle population above 100 / 10ª–m; 2 in coagulating bath procedure, glue from spinneret with acid bath forming strand silk, the acid bath temperature between 52-55Deg.C, hydric sulphate concentration between 132-136 g / l, sodium sulfate concentration between 220-265g / l, acid bath interfacial force being less than glue interfacial force, and acid bath specific density being below 1.265g / ml. Using the method meets the requirement for quality, and reaches the spinning three silks on every ingot at the same time.

Owner:YIBIN GRACE

Cellulose fiber modification method, modified cellulose fibers and application

ActiveCN106283641AImprove hydrophobicityEnhance the interface forceFibre treatmentDispersityPolymer science

The invention discloses a cellulose fiber modification method, modified cellulose fibers prepared according to the method and application of the modified cellulose fibers. The method includes: pretreating cellulose fibers with alkoxide, drying, mixing with epoxy monomers, stirring, allowing reaction under heating, removing the epoxy monomers in a reaction system after reaction is finished, cleaning residues, and drying to obtain the modified cellulose fibers. The modified cellulose fibers are applied to filling modification of polymer materials. The cellulose fiber modification method has advantages of simplicity, safety, low cost and improvement of interfacial compatibility and interfacial force between the modified cellulose fibers and the polymer materials. The modified cellulose fibers are excellent in fiber dispersity, and the polymer materials adopting the modified cellulose fibers for filling modification are remarkably improved in water resistance.

Owner:BEIJING UNIV OF CHEM TECH

Wafer-like aluminum phosphate/thermosetting resin composite and preparation method thereof

ActiveCN103804941AGood for flame retardant effectGood dispersionPhosphorus compoundsPhosphateFiltration

The invention relates to a wafer-like aluminum phosphate / thermosetting resin composite and a preparation method thereof. A preparation process of wafer-like aluminum phosphate comprises the steps of enabling an aluminum-contained compound and a phosphorus-contained compound to react at the temperature of 40-100 DEG C for 10-30min according to the aluminum-to-phosphorus molar ratio of 1:3 to 1:5 to prepare an aluminum dihydrogen phosphate precursor, and then, adding 5.5-17 mol of deionized water to obtain an aluminum dihydrogen phosphate precursor solution; cooling to 0-20 DEG C, regulating the pH value to 4-6 by using an alkaline solution, preserving the heat at the temperature of 0-20 DEG C for 8-12h, and after the reaction is ended, washing, carrying out suction filtration and removing impurities to obtain wafer-like aluminum phosphate with the diameter of 1-1.5mu m; uniformly mixing 100 parts by weight of molten thermosetting resin and 3-50 parts by weight of wafer-like aluminum phosphate, and curing to obtain the wafer-like aluminum phosphate / thermosetting resin composite with flame retardance. The wafer-like aluminum phosphate contains a great number of hydroxyls, has favorable dispersibility in a resin matrix, and also has favorable interfacial force so as to ensure that the composite has a flame retardant effect. The preparation method provided by the invention has the characteristics of wide applicability and simple operation process.

Owner:扬州华上新材料有限公司

High-tenacity PLA/PBAT blending alloy and preparation method thereof

ActiveCN110079065AWide variety of sourcesSuitable for mass productionFlexible coversWrappersAlloyInterfacial Force

The invention relates to the field of the high polymer material blending alloy, and specifically relates to a high-tenacity polylactic acid PLA / PBAT blending alloy and a preparation method thereof. The PLA, the PBAT, the PDLA-PBAT-PLDA triblock copolymer are used as the raw material, and a banburying machine is used for preparing the PLA / / PBAT / PDLA-PBAT-PDLA blending alloy, the content of the PDLA-PBAT-PLDA triblock copolymer in a blending system is 1%-10%. The PLA / PBAT blending alloy prepared by the invention takes the PDLA-PBAT-PDLA triblock copolymer as the compatilizer, the PDLA chain segment can form the steric composite crystal (SC) in-situ with the PLA when performing the melt blending, the PLA and PBAT two-phase interfacial force is improved, and the mechanical performance of the alloy is obviously improved. The blending alloy disclosed by the invention is simple in process, normal in equipment and easy to realize industrial production.

Owner:CHANGZHOU UNIV

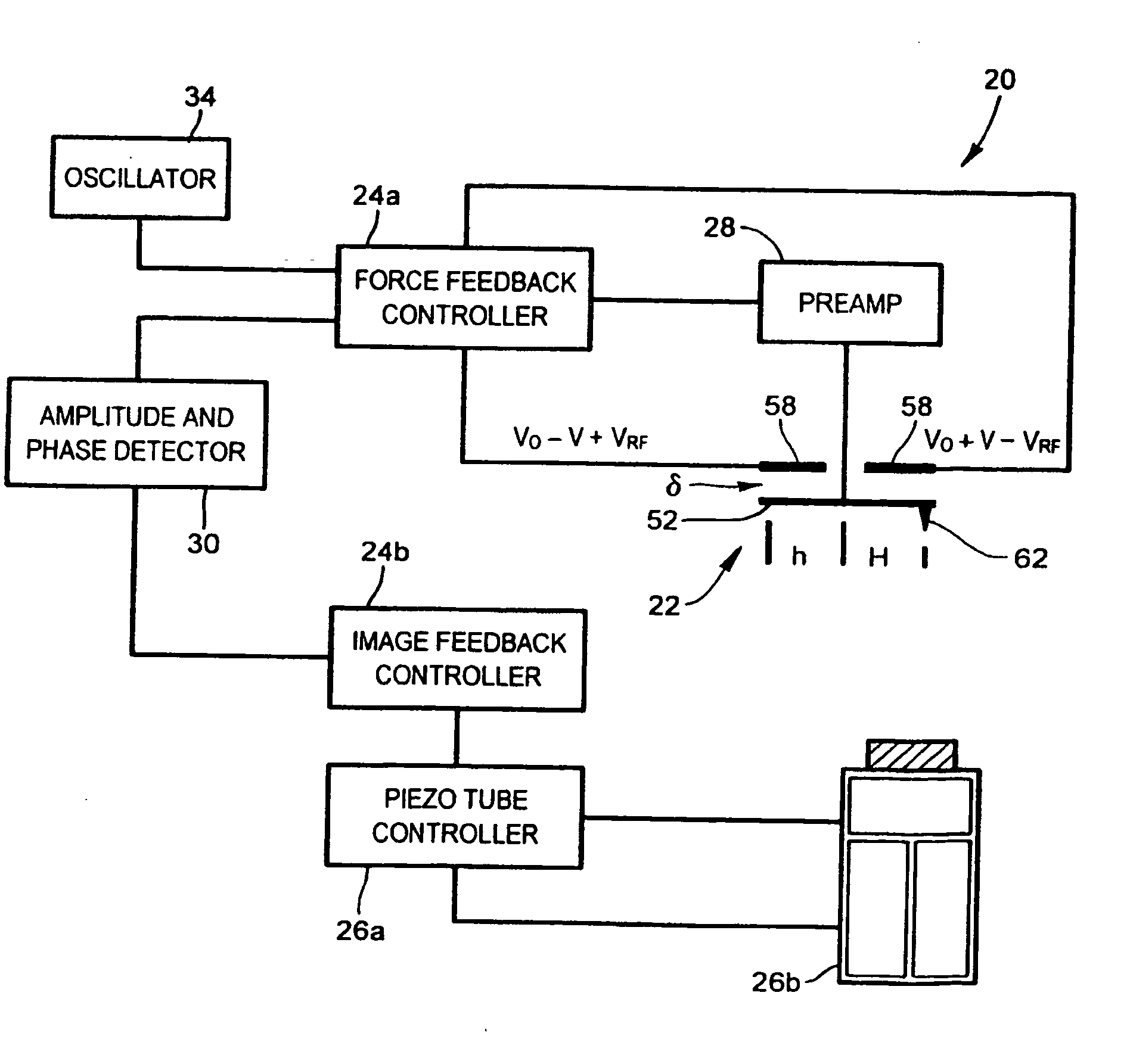

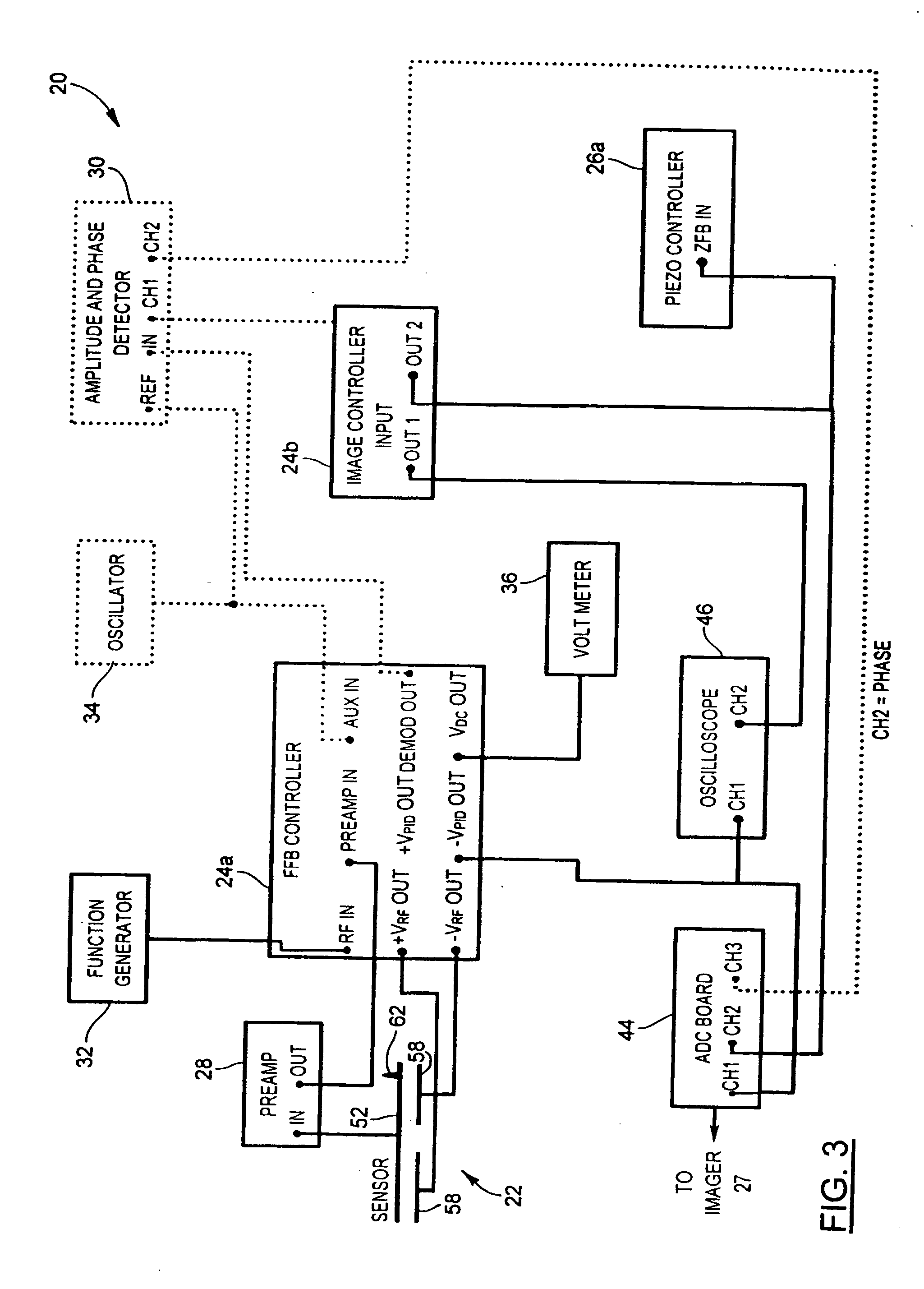

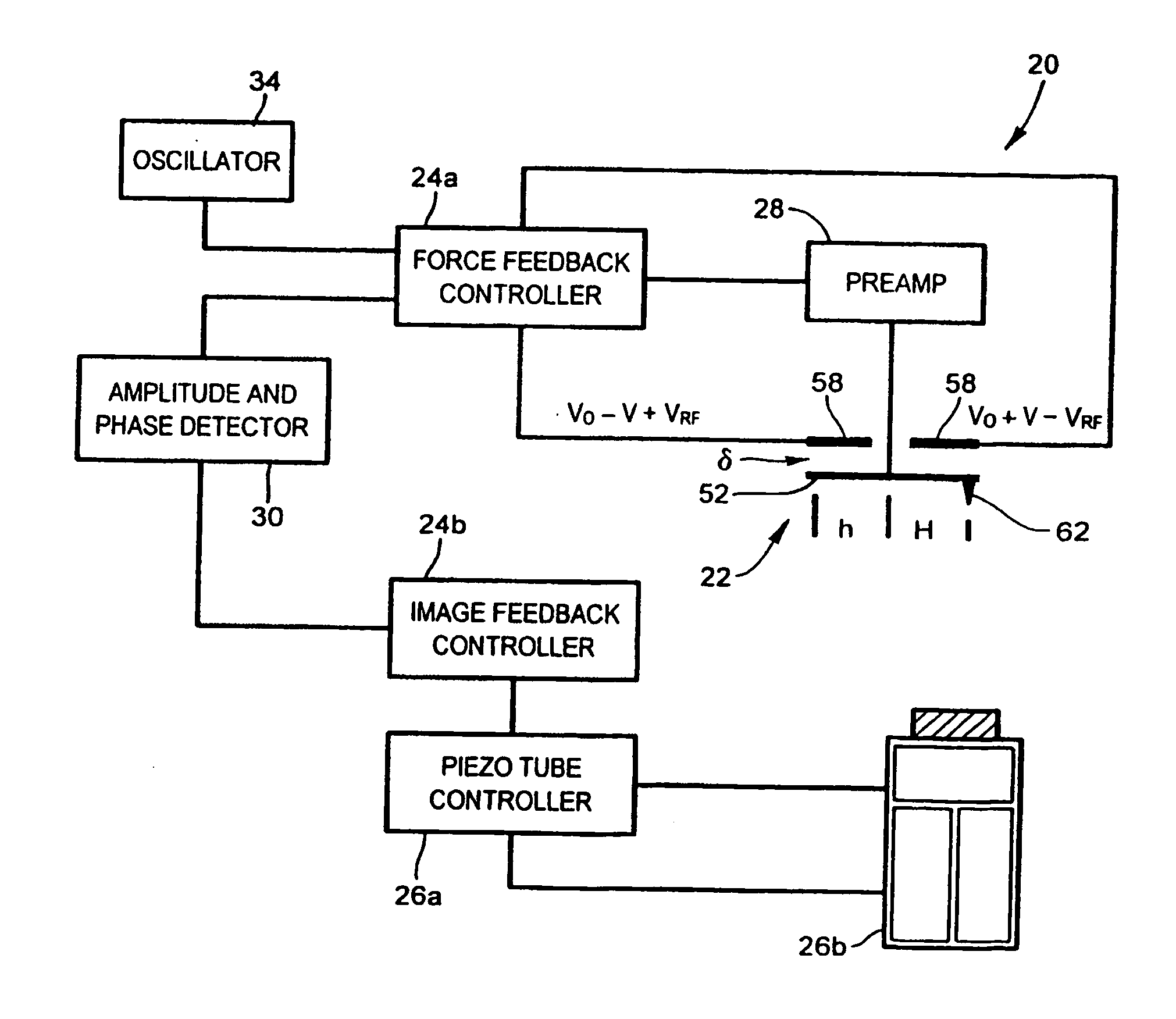

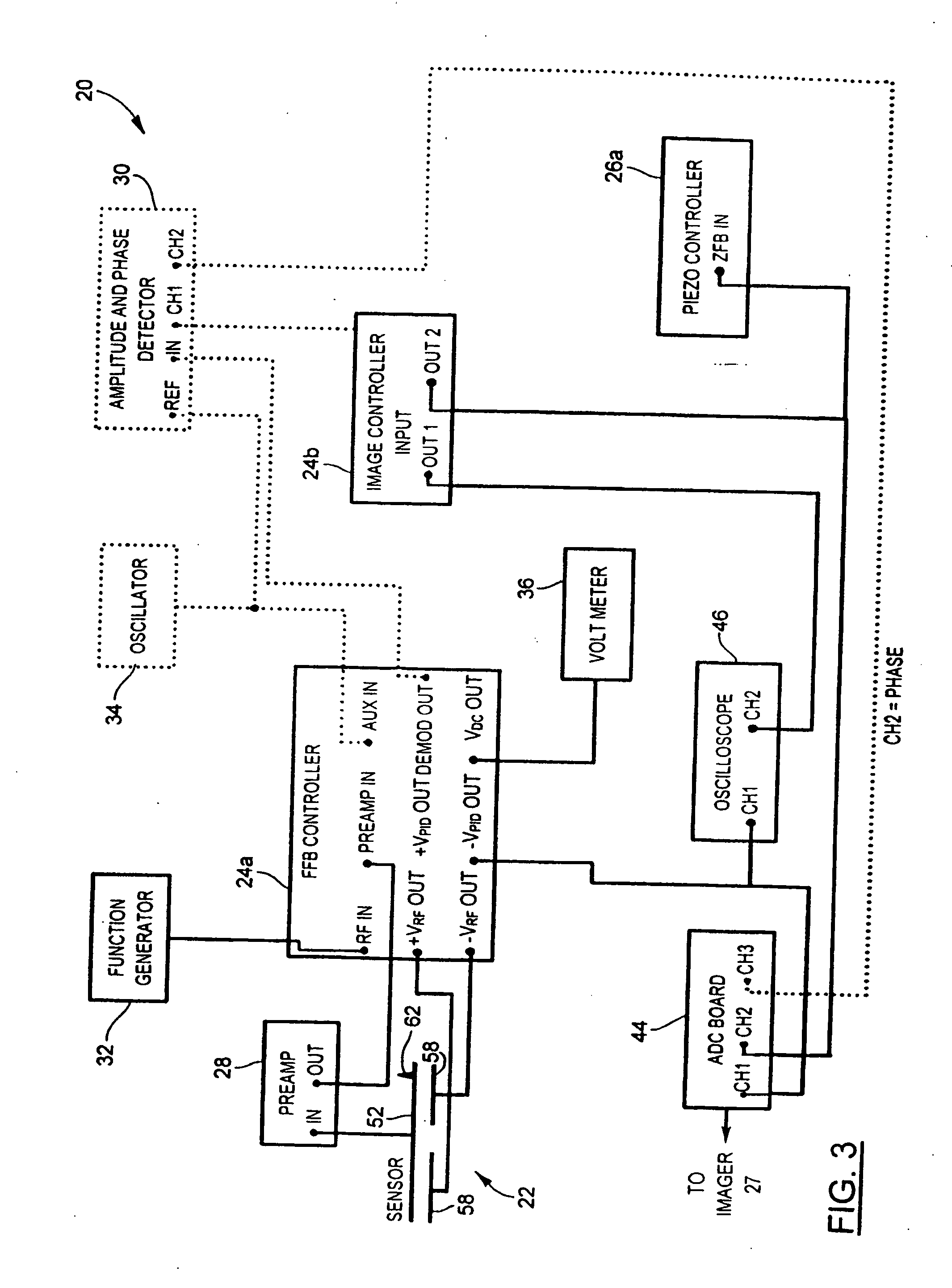

Scanning probe microscope and method

InactiveUS20060027739A1Reduce shear forceBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansFeedback circuitsInterfacial Force

An interfacial force microscope includes a differential-capacitance displacement sensor having a tip mounted on an oscillating member. The sensor generates displacement signals in response to oscillations of the member. A scanner is adjacent the sensor and supports a sample to be imaged. The scanner is actuable to move the sample relative to the sensor to bring the tip into intermittent contact with said sample as the member oscillates. A controller is in communication with the sensor and the scanner. The controller includes a sensor feedback circuit receiving the displacement signals and an AC setpoint signal. The AC setpoint signal has a frequency generally equal to the frequency at the peak of the displacement versus frequency curve of the sensor. The output of the sensor feedback circuit is applied to the sensor to oscillate the member. The controller also provides output to the scanner in response to the displacement signals to control the separation distance between the sensor and the sample.

Owner:WARREN ODEN L +2

Feedback influenced increased-quality-factor scanning probe microscope

InactiveUS20060261264A1Material analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsFeedback circuitsInterfacial Force

An interfacial force microscope includes a differential-capacitance displacement sensor having a tip mounted on an oscillating member. The sensor generates displacement signals in response to oscillations of the member. A scanner is adjacent the sensor and supports a sample to be imaged. The scanner is actuable to move the sample relative to the sensor to bring the tip into intermittent contact with said sample as the member oscillates. A controller is in communication with the sensor and the scanner. The controller includes a sensor feedback circuit receiving the displacement signals and an AC setpoint signal. The AC setpoint signal has a frequency generally equal to the frequency at the peak of the displacement versus frequency curve of the sensor. The output of the sensor feedback circuit is applied to the sensor to oscillate the member. The controller also provides output to the scanner in response to the displacement signals to control the separation distance between the sensor and the sample.

Owner:WARREN ODEN L +2

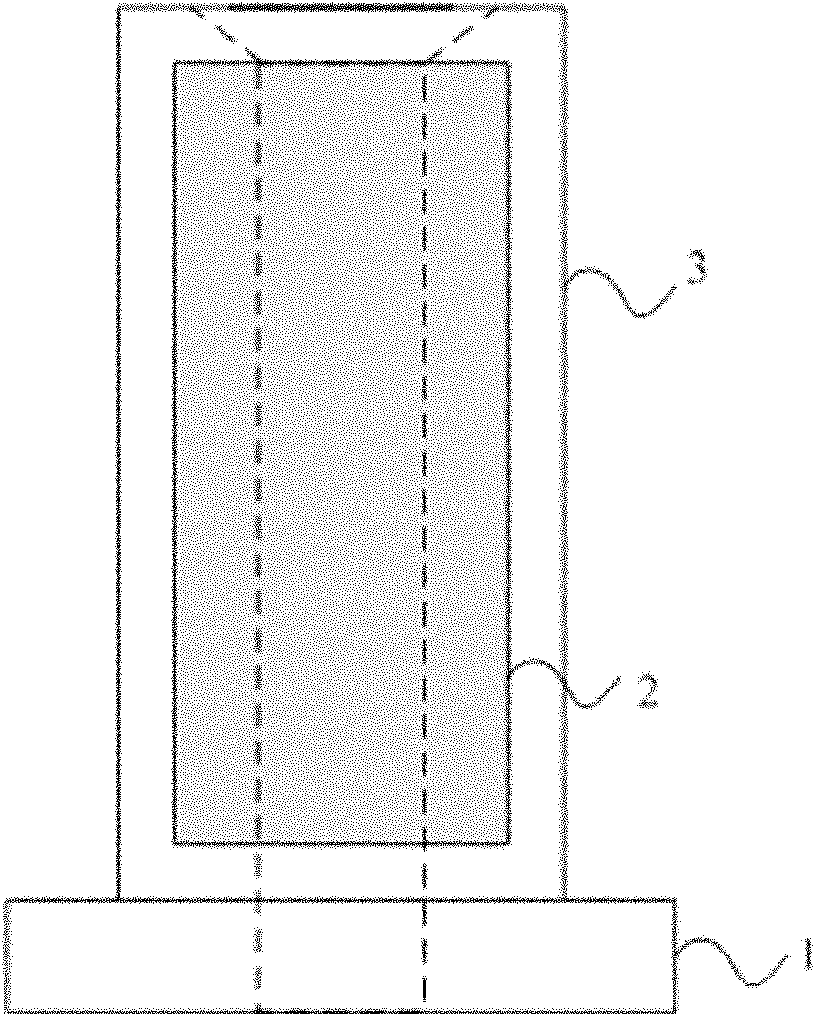

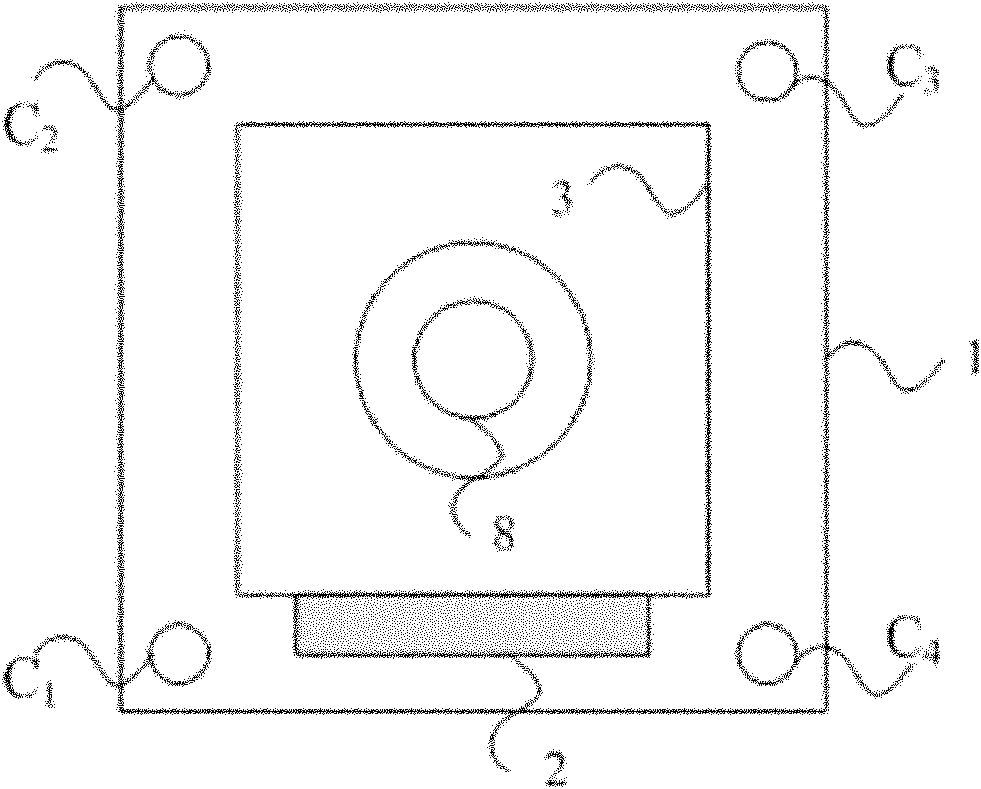

Boundary condition-based single-drive two-way piezoelectric motor

InactiveCN102005966AChange directionRealize positive and negative two-way rotationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsInterfacial Force

The invention discloses a boundary condition-based single-drive two-way piezoelectric motor. The boundary condition-based single-drive two-way piezoelectric motor comprises a base, a stator and a rotor, wherein the stator is fixedly connected with the base; the rotor can rotate relative to the stator and the base; the stator comprises a driving body with a center hole and a piezoelectric sheet connected to a plane on one side of the driving body through an interfacial force; the center hole of the driving body passes through the base; the rotor comprises a rotating body and a cap body; the rotating body passes through the center hole of the driving body; the cap body is fixedly connected with one end of the rotating body; the cap body is contacted with the driving body; a gap is reserved between the rotating body and the wall of the center hole of the driving body; and four screw holes are symmetrically formed on the edge of the base. The boundary condition-based single-drive two-way piezoelectric motor is small in volume and low in power consumption and plays an important role in the microminiaturization of the piezoelectric motor.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for forming conductive pattern and wiring board

ActiveUS20090133901A1Well formedGood body shapeMechanical working/deformationVacuum evaporation coatingEngineeringInterfacial Force

[Summary][Problem] To provide a conductive pattern formation method in which a fine pattern can be formed in a simple way at low cost.[Means for solving problem] A flat plate having a convex pattern on its surface is provided so as to oppose a substrate, a fluid body including conductive particles and a gas bubble generating agent is supplied into a gap between the substrate and the flat plate, and thereafter, the fluid body is heated for generating gas bubbles from the gas bubble generating agent included in the fluid body. The fluid body is forced out of the gas bubbles as the gas bubbles generated from the gas bubble generating agent grow, so as to self-assemble between the convex pattern formed on the flat plate and the substrate owing to interfacial force, and an aggregate of the conductive particles included in the fluid body having self-assembled is made into a conductive pattern formed on the substrate.

Owner:PANASONIC CORP

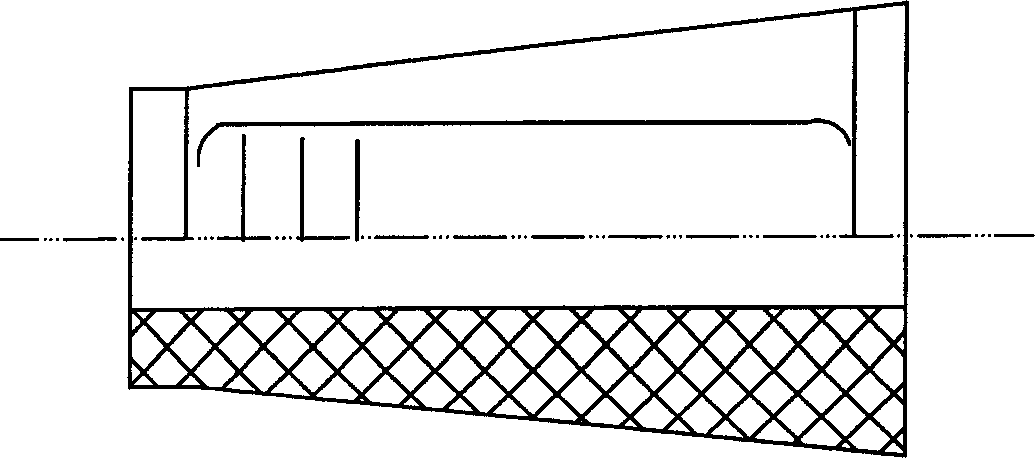

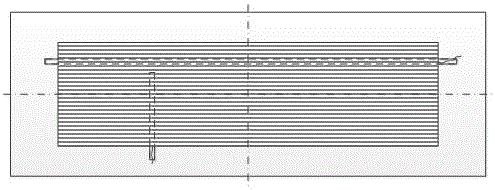

Curing procedure oriented method for monitoring interfacial force between composite materials and molds

ActiveCN105758793AInterfacial force repeated monitoringUsing mechanical meansMaterial analysisInterfacial ForceStrain sensor

The invention provides a method for monitoring interaction force between composite materials and molds in curing procedures.The method includes forming a plurality of grooves in composite material contact surfaces of the molds, embedding strain sensors in the grooves and fixing two ends of a measurement region of each sensor to the corresponding mold; converting strain signals measured by the sensors into values of stress between the composite materials and the molds so as to monitor the interaction force between the composite materials and the molds in the curing procedures.The method has the advantages that the interaction force between the composite materials and the molds can be effectively monitored in the curing procedures, and technical support can be provided for predicting and controlling curing deformation of the composite materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A processing auxiliary agent having compatibility-enabling and coupling functions and a preparing method thereof

A processing auxiliary agent having compatibility-enabling and coupling functions and a preparing method thereof are provided. The processing auxiliary agent includes, by weight, 65-85 parts of polypropylene wax, 10-30 parts of a modified oligomer, 0-15 parts of an unsaturated functional monomer, 0-5 parts of vinyl silane and 0.5-2.5 parts of a free radical initiator. The processing auxiliary agent integrates compatibility-enabling and coupling functions, has obvious functions in the fields of plastic alloys, plastic filing, inorganic filler surface treatment, and the like, and can improve interfacial force between resin and resin as well as interfacial force between resin and a filler, thus improving appearance quality of a final product and improving macroscopic performance and processing performance of products.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

Electrode segmentation type single drive and two-way piezoelectric motor

InactiveCN102013834AReduce volumeReduce power consumptionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsInterfacial Force

The present invention discloses an electrode segmentation type single drive and two-way piezoelectric motor, comprising a stator and a rotor rotating relative to the stator; the stator comprises a driving body with a centre hole and a piezoelectric sheet connected to one side of the driving body by an interfacial force; the rotor comprises a rotating body penetrating through the centre hole of the driving body and a cap fixedly connected to one end of the rotating body; the cap is contacted with the driving body; a gap is disposed between the rotating body and the wall of the centre hole of the driving body; the piezoelectric sheet comprises two mutually independent piezoelectric sheets or two piezoelectric sheet areas separated by the gap. The volume of the piezoelectric motor is small, and the power consumption is low; and the piezoelectric plays an important role in microminiaturization of piezoelectric motor.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

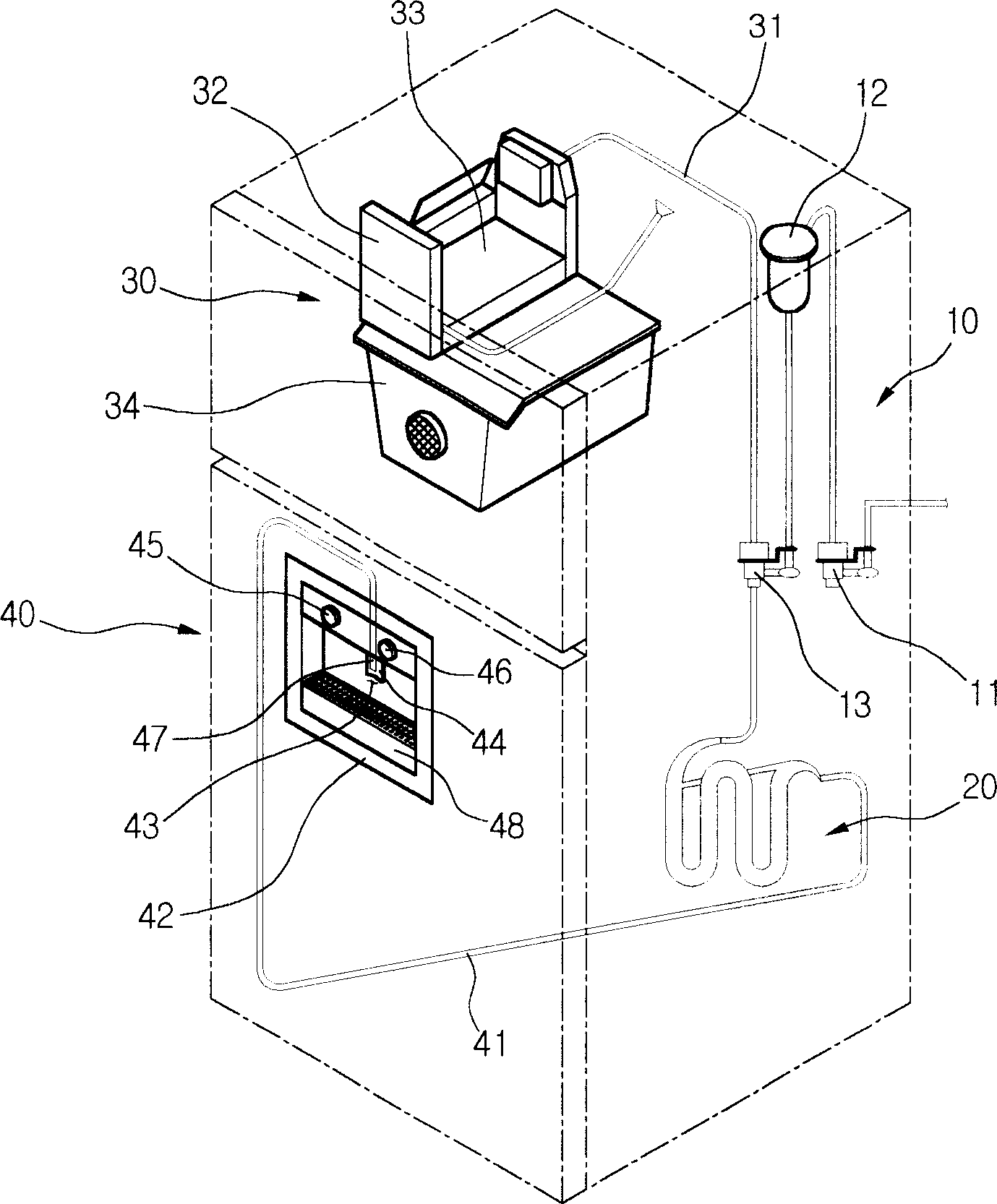

Takeoff pipe structure of refrigerator distributor

InactiveCN1690622AIncrease surface tensionLighting and heating apparatusDomestic refrigeratorsInterfacial ForceCold store

The invention discloses a refrigerator allotter take-off pipe structure. Refrigerator is divided into chilling chamber and cold room by baffle. Allotter, which is set at certain position at the front of cold room door, sets with front panel at interval of one side of cold room door. Front panel sets with water intake key and ice intake key to fetch object and inboard of front panel forms take-off pipe to export object, which specially sets fetching beam-handling allotter. Purified water or ice block is fetched out of take-off pipe by fetching beam. Interior of fetching pipe sets with several haunched structures with certain length to increase interfacial force of water and prevent residual water in water fetching pipe falling into residual water pallet. In the effect of haunched structures in pipe, interfacial force of residual water increases, so residual water in water fetching pipe won't fall into residual water pallet and remains in fetching pipe.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

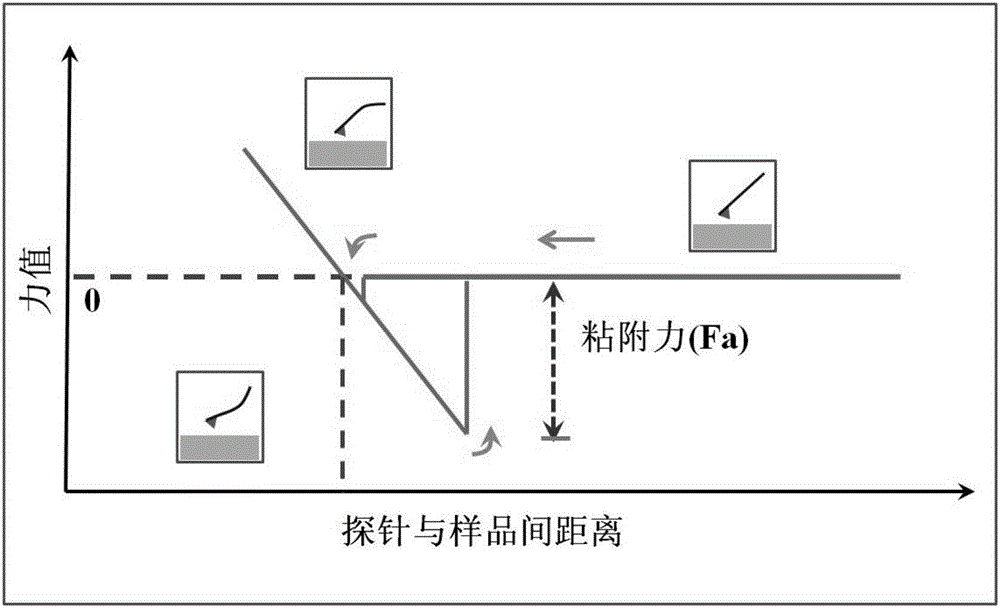

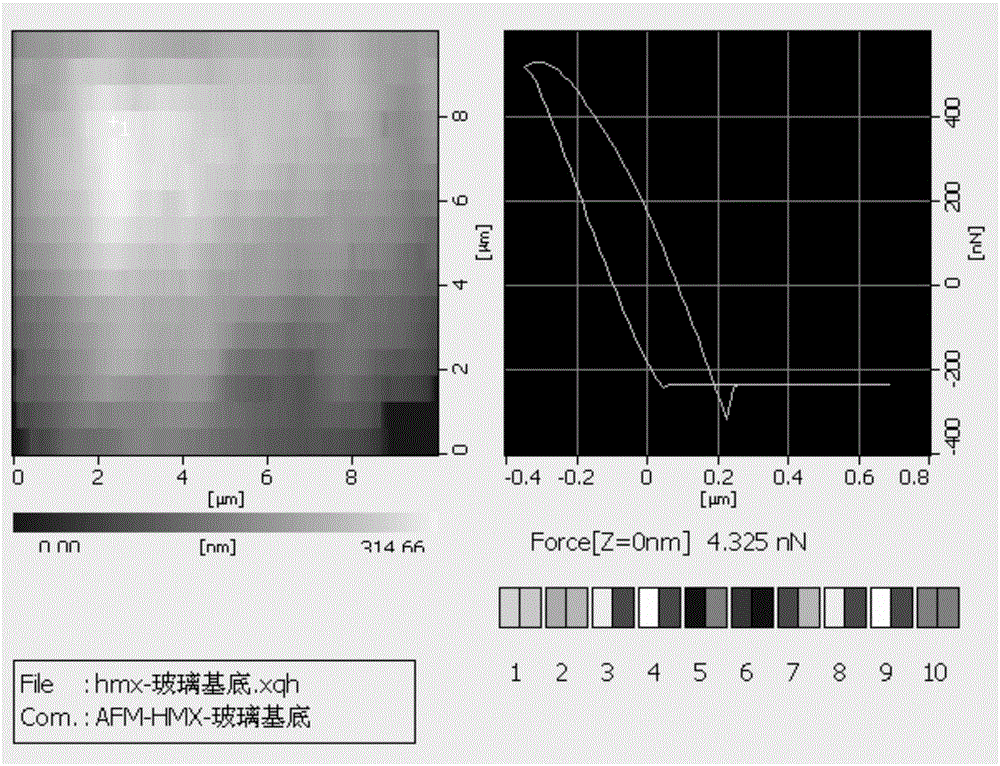

Method for representing interfacial force between explosive and bonding agent

InactiveCN106841686ASimple processSimple and fast operationScanning probe microscopyAdhesiveEngineering

The invention discloses a method for representing an interfacial force between explosive and bonding agent. The method comprises the following steps of modifying the tip end of an AFM probe micro-cantilever by explosive particles through a binding medium, or directly modifying the tip end of the AFM probe micro-cantilever by adhesive, thereby obtaining a modified probe; applying the adhesive on a flat substrate, or fixing the explosive particles on the flat substrate; by means of a force spectrum scanning mode of an atomic force microscope, performing force curve representation by means of the modified probe on the surface of the bonding agent or explosive particles; and extracting a corresponding bonding force parameter according to a force curve, thereby obtaining the interfacial force between the explosive and the bonding agent. The method realizes direct and quantitative representation of the interfacial force between explosive and components of the bonding agent, thereby realizing a new facility for mechanical characteristic research of a crystal / adhesive interface in PBX explosive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

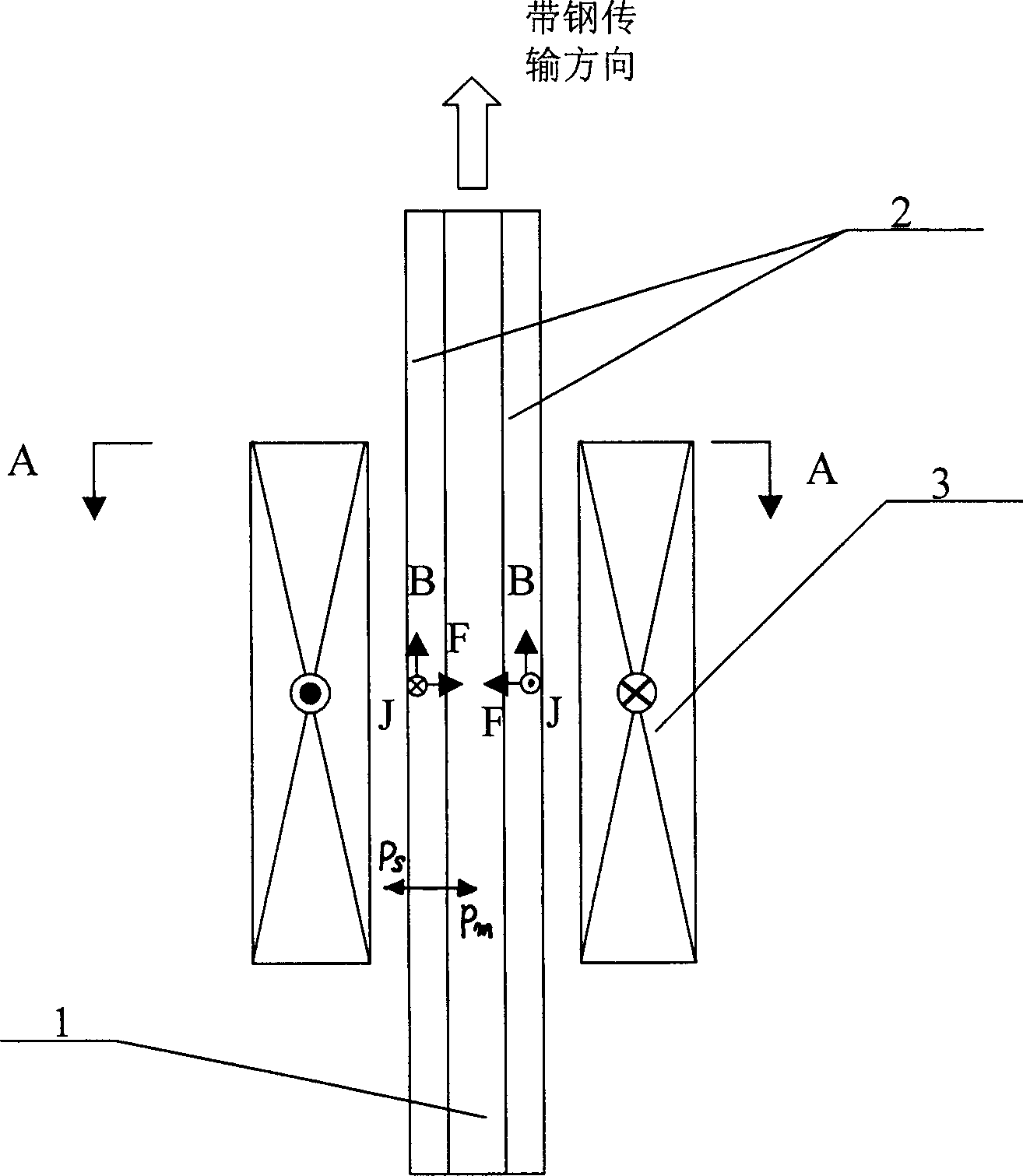

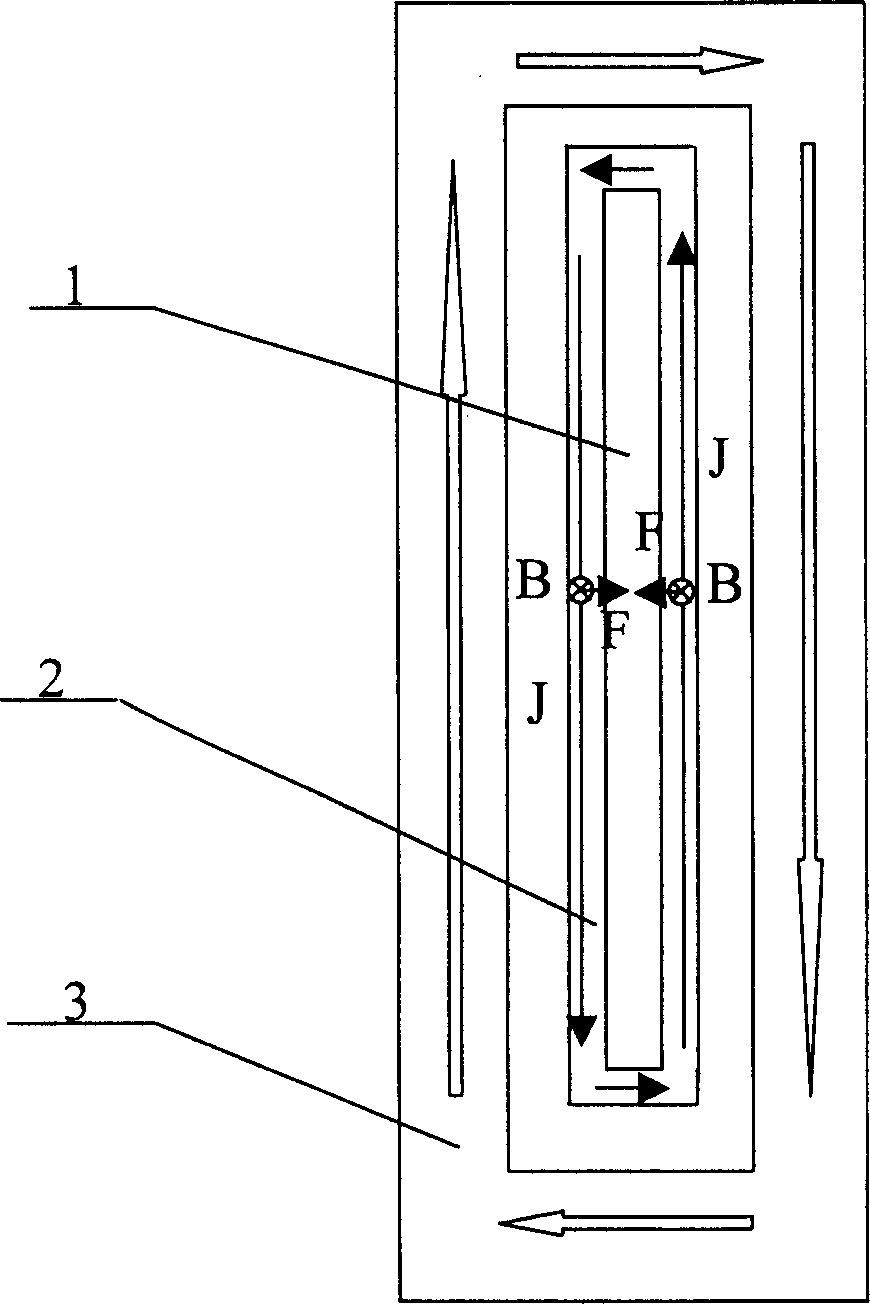

Hot dip galvanized coating control method and apparatus

ActiveCN1827831AImprove quality and efficiencyIncrease productivityHot-dipping/immersion processesEngineeringStrip steel

The invention relates the hot galvanizing zinc layer controlling means and device. On the around of strip there is electromagnetic means to make the zinc coating produce electromagnetic force to make the zinc coating surface produce pressure, and if the electromagnetic force is more than the interfacial force, the thick of zinc coating is reduced, controlling the intensity of alternating field to control electromagnetic force. The invention has the advantages of easy adjustment, high control accuracy, and improving the surface quality and product efficiency of strip.

Owner:BAOSHAN IRON & STEEL CO LTD

Polypropylene composite material available for chemical micro-foaming and preparation method thereof

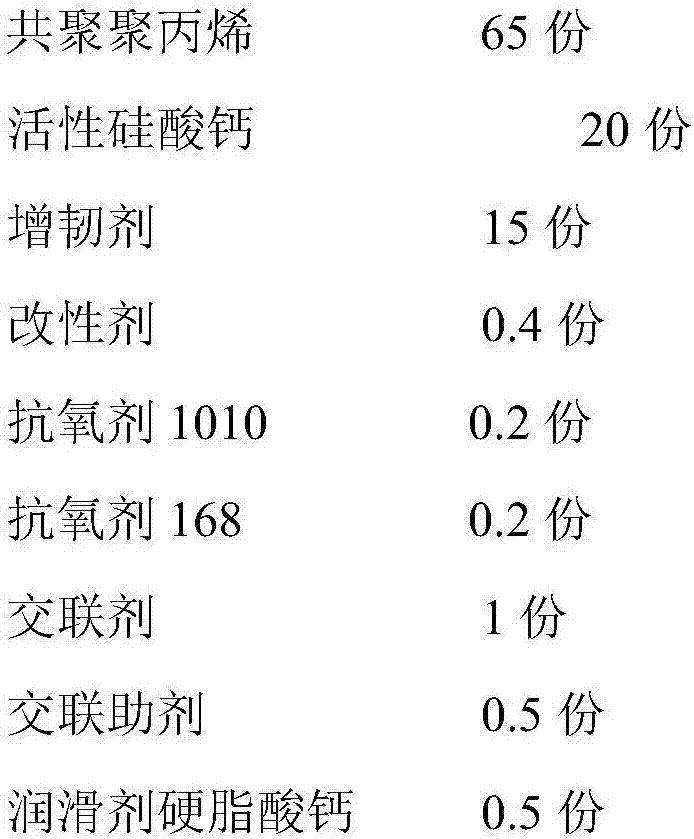

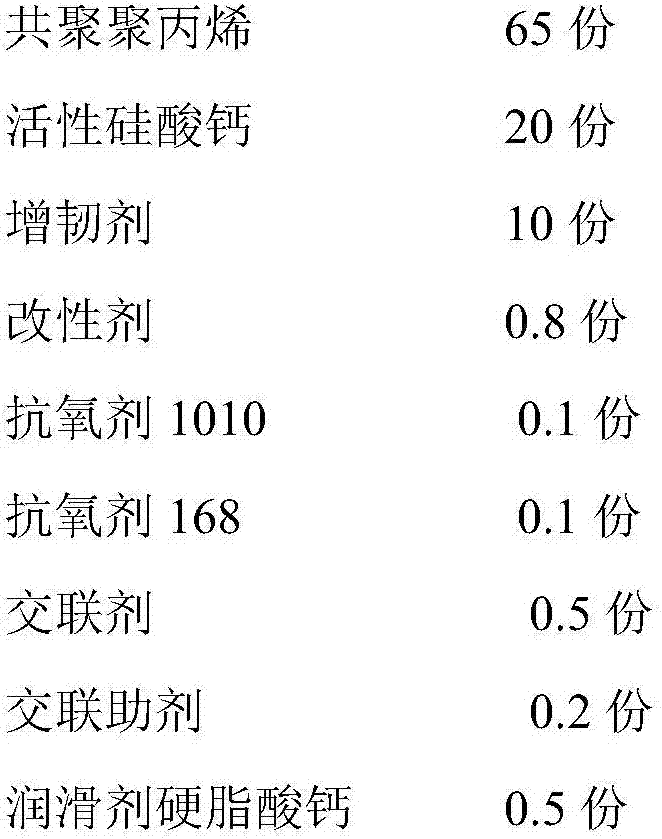

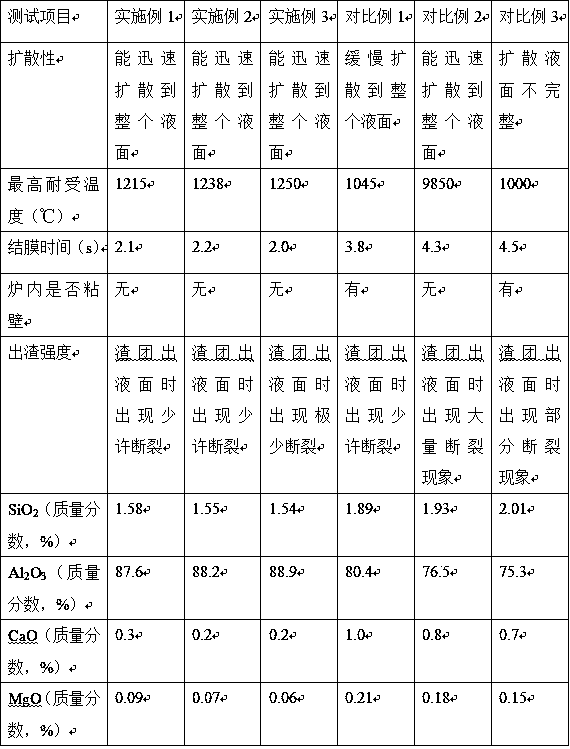

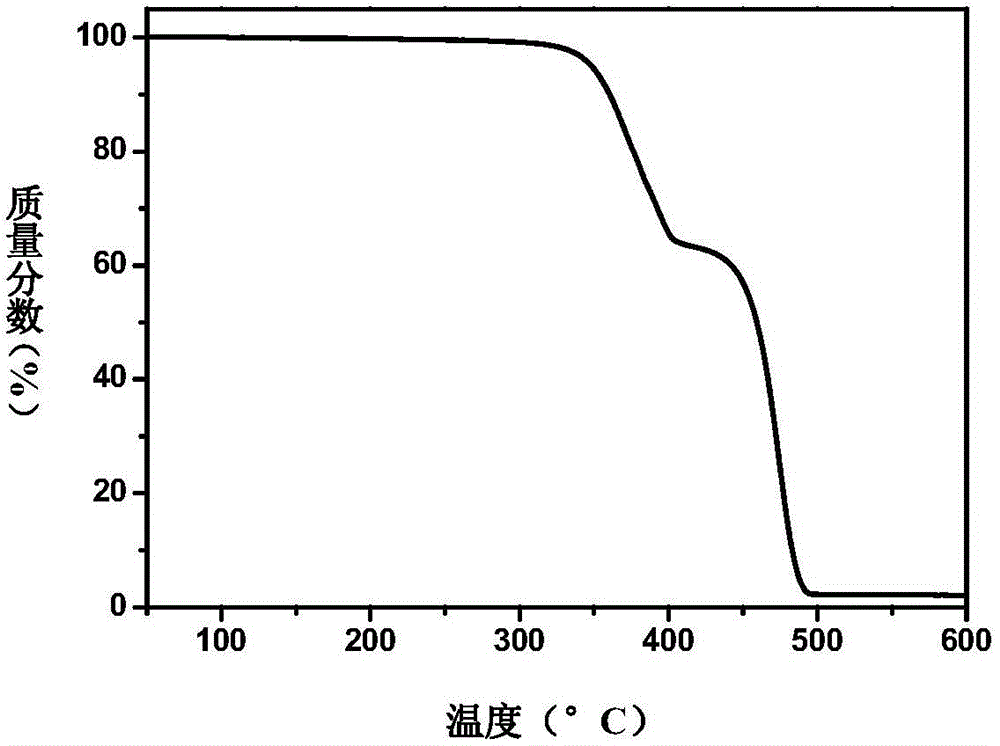

The invention discloses a polypropylene composite material available for chemical micro-foaming and a preparation method thereof. The polypropylene composite material is uniformly mixed with a composite foaming agent, and the polypropylene composite material is formed by adopting secondary mold-opening injection molding, wherein the polypropylene composite material is prepared from the following components in parts by weight: 65 to 85 parts of polypropylene, 10 to 20 parts of active calcium silicate, 10 to 15 parts of a flexibilizer, 0.4 to 0.8 part of a modifier, 0.2 to 0.4 part of an antioxidant ,0.5 to 1 part of a lubricating agent, 0.5 to 1 part of a cross-linking agent, 0.2 to 0.5 part of a cross-linking assistant and 0 to 3 parts of other assistants. The surface of the active calcium silicate is coated by adopting synergy of the cross-linking assistant and the surface active agent, the interfacial force with resin is strengthened, the dispersion is more uniform, and simultaneously a polypropylene cross-liking reaction is triggered through the cross-linking agent to form a network-shaped structure, so that the melt strength of the composite system is improved, and the composite material has excellent foaming performance; and the composite material has the characteristics of wide source of raw materials, low cost, small density, high dimensional stability, excellent mechanical performance, heat insulation, sound insulation and noise reduction.

Owner:ORINKO NEW MATERIAL CO LTD

Preparation method of dregs remover for smelting aluminum alloy

The invention belongs to the technical field of casting material preparing, specially relates to a preparation method of a dregs remover for smelting an aluminum alloy. According to the preparation method, amorphous kaolinite powder is prepared from kaolinite processed as raw materials, modified amorphous kaolin particles are prepared from mixing the amorphous kaolinite powder and sodium silicate,and finally the dregs remover is prepared from mixing and grinding ball-milling mixed powder, cryolite powder, titanium boron crystal powder and the like. According to the preparation method of the dregs remover for smelting the aluminum alloy, sodium aluminate salt at the interface between the kaolinite and cryolite can improve interfacial force of a cryolite overlying coating, the good heat preservation covering effect is performed, the molten drop spattering preventing effect is performed, microdilatancy of prepared amorphous kaolinite under the high temperature can prevent growth and gathering of tiny grains of the aluminium alloy, strengthening phase silicification is generated and distributed uniformly in an a-Al substrate, and thus anti-cracking performance of aluminum melt after solidification is improved; In addition, titanium and boron in the added titanium boron crystal powder can refine alloy grains, toughness of the prepared aluminum alloy is increased, and the application prospect is wide.

Owner:常州西夏墅东方工具有限公司

Slag-forming constituents used for lead and lead-base alloy fusion casting

The invention relates to a slag-forming constituent in casting lead and lead-base alloy, which comprises 35-70wt% of CaF2, 3-5wt% of Na3AlF6, 3-8wt% of KCl, 8-10wt% of NaCl, 2-5wt% of ZnCl2, 20-50wt% of C powder and 3-5wt% of NH4Cl. The invention makes use of the principle that inorganic salt can improve interfacial force and boundary tension between lead fondant and oxidate so as to de-slag in casting and using of lead-base product, improve quality of casting and using, ensure slag to carry on powder, and recovery metal efficiently. The invention the properties of simple preparation, low input of apparatus and capital and extensive usages such as lead ingot casting, lead-base alloy product casting and lead-base product later usage.

Owner:株洲冶炼集团有限责任公司

Polypropylene-polyester-carbon nano tube ternary composite alloy and preparation method thereof

The invention provides polypropylene-polyester-carbon nano tube ternary composite alloy and a preparation method thereof. The preparation method includes the steps that 1, an alkene monomer, dual-functional carbon nano tubes and a promoter are used for undergoing an in-situ coordination polymerization reaction, so that an intermediate product is obtained, wherein the alkene monomer comprises a propylene monomer and a mixture of the propylene monomer and ethylene and / or 1-butene; 2, the intermediate product is subjected to acid alcohol treatment, hydroxyl used for modifying a polyolefin catalyst is made to be recovered, in the existence of the catalyst system, the recovered hydroxyl is used as an initiator to trigger ring-opening polymerization of cyclic ester monomers, and accordingly the polypropylene-polyester-carbon nano tube ternary composite alloy is obtained. According to the polypropylene-polyester-carbon nano tube ternary composite alloy and the preparation method thereof, polypropylene and polycaprolactone are used for establishing strong interfacial force through the chemical attachment of the carbon nano tubes, and the polycaprolactone and the carbon nano tubes are stably dispersed in a polypropylene matrix at the same time. The polypropylene has a good mechanical property and a good thermal property, has good wettability, printing and dyeing properties and the compatibility with other polar polymers, and further has certain biocompatibility, and thus the polypropylene is turned into a high performance resin material with excellent overall performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-performance polyolefin composite material and preparation method thereof

The invention relates to a high-performance polyolefin composite material and a preparation method thereof. The composite material is prepared from, by weight, 60-80 parts of polyolefin, 20-40 parts of elastomer, 6-10 parts of an ethylene-octylene segmented copolymer, 0.1-0.5 parts of antioxidant, and 0.4-0.8 parts of a lubricant. In the technical scheme, the ethylene-octylene segmented copolymer (OBC) is a polymer surfactant of the polyolefin / elastomer two-phase system, wherein the OBC not only contains an amorphous soft segment being low in glass-transition temperature but also contains a hard segment being high in melting temperature and being crystallizable. The OBC has excellent compatibility with both the polyolefin and the elastomer, thereby enhancing the two-phase interfacial force between the polyolefin and the elastomer.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation method of PBO fiber composite material with high-temperature dielectric property

InactiveCN108610630AImprove interface performanceIncreased interfacial shear strengthPhysical treatmentFibre typesFiber bundleStructure and function

The invention discloses a preparation method of a PBO fiber composite material with a high-temperature dielectric property, aims at improving the interfacial force of the composite material on the basis of guaranteeing excellent dielectric property of the PBO fiber cyanate ester composite material, and solves the problems that PBO fiber is smooth in surface and the bonding strength between the surface of the PBO fiber and a resin interface is low. The preparation method comprises the following steps: firstly, preparing a hyperbranched PBO polymer grafting solution; secondly, performing infiltration treatment on a PBO fiber bundle; thirdly, performing deacidification treatment on the PBO fiber bundle; fourthly, performing irradiation grafting treatment on the PBO fiber bundle; fifthly, preparing the PBO fiber cyanate ester composite material. The method has the advantages that the surface of the PBO fiber is grafted with hyperbranched PBO polymer through a Co60 gamma ray irradiation method, the interface bonding strength of the PBO fiber cyanate ester composite material is enhanced, the increased range of the interface strength is 32 to 45.65 percent, the formed PBO fiber cyanate ester composite material has excellent dielectric property, and the method is beneficial to the preparation of structure and function integrated wave-transmitting composite materials.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com