High-tenacity PLA/PBAT blending alloy and preparation method thereof

A PDLA-PBAT-PDLA, mixed gold technology, applied in the direction of flexible coverings, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of complex formula, multiple components, and insufficient strength of biological materials, and achieve Wide range of sources, enhanced interfacial adhesion, excellent biocompatibility and biodegradability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

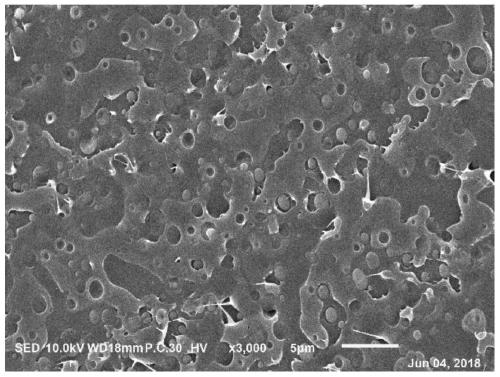

Image

Examples

Embodiment 1

[0035] A high-toughness PLA / PBAT blended alloy, the ratio of raw materials and components is as follows:

[0036] PLA mass fraction: 84g.

[0037] PBAT mass fraction: 15g.

[0038] PDLA-PBAT-PDLA triblock copolymer mass fraction: 1g.

[0039] A high-toughness PLA / PBAT blended alloy, the preparation process is as follows:

[0040] Place PLA, PBAT, and the PDLA-PBAT-PDLA triblock polymer synthesized in Step 2 in a vacuum drying oven at 70°C for 2 hours. Add the dried PLA, PBAT, and the PDLA-PBAT-PDLA tri-block polymer synthesized in step 2 into the internal mixer, melt and mix in the internal mixer for 5 minutes, the rotor speed is 100 rpm, and the heating temperature of the internal mixer is At 180°C, a PLA / PBAT blended alloy was obtained.

Embodiment 2

[0042] A high-toughness PLA / PBAT blended alloy, the ratio of raw materials and components is as follows:

[0043] PLA: 80g. ;

[0044] PBAT: 17g.

[0045]PDLA-PBAT-PDLA triblock copolymer: 3g.

[0046] A kind of high toughness PLA / PBAT blend alloy, the preparation of PLA / PBAT blend alloy:

[0047] PLA, PBAT, and PDLA-PBAT-PDLA triblock polymers were dried in a vacuum oven at 70°C for 2 hours. Add the dried PLA, PBAT, and the PDLA-PBAT-PDLA tri-block polymer synthesized in step 2 into the internal mixer, melt and mix in the internal mixer for 5 minutes, the rotor speed is 100 rpm, and the heating temperature of the internal mixer is At 180°C, a PLA / PBAT blended alloy was obtained.

Embodiment 3

[0049] A high-toughness PLA / PBAT blended alloy, the ratio of raw materials and components is as follows:

[0050] PLA mass fraction: 75g.

[0051] PBAT mass fraction: 20g.

[0052] PDLA-PBAT-PDLA triblock copolymer mass fraction: 5g.

[0053] A kind of high toughness PLA / PBAT blend alloy, the preparation of PLA / PBAT blend alloy:

[0054] PLA, PBAT, and PDLA-PBAT-PDLA triblock polymers were dried in a vacuum oven at 70°C for 2 hours. Add the dried PLA, PBAT, and the PDLA-PBAT-PDLA triblock polymer synthesized in step 2 into the internal mixer, melt and mix in the internal mixer for 5 minutes, the rotor speed is 100r / min, and the heating temperature of the internal mixer is 180 °C, the PLA / PBAT blended alloy was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com