Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

A porous structure, magnesium-based alloy technology, applied in the direction of bone implants, dental implants, medical science, etc., can solve the problems of indistinguishable mechanical properties, poor impact resistance, difficult to control the biodegradability rate, etc., to avoid stress The effect of occlusion, accelerated bone formation, and improved bone formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

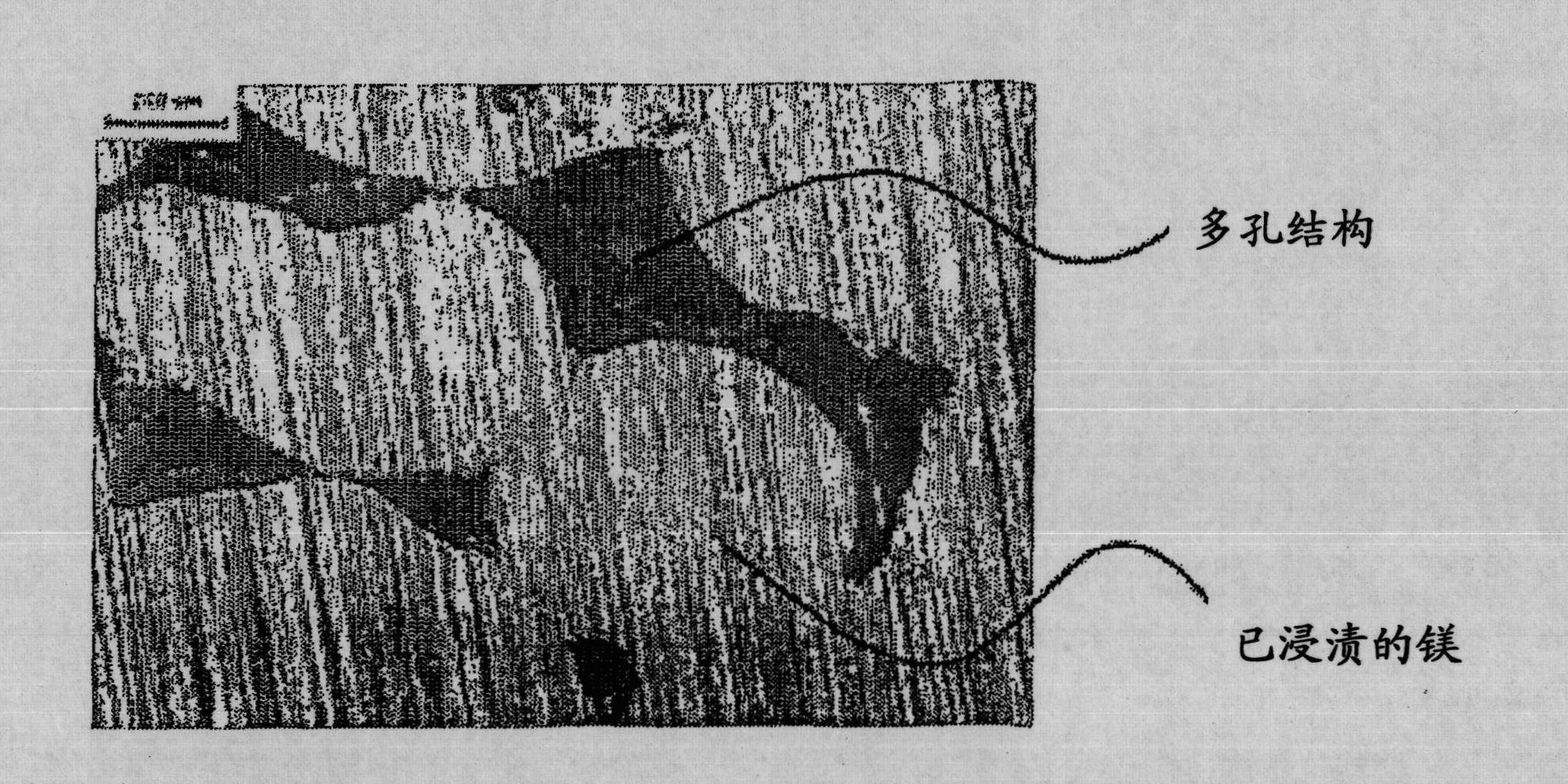

[0074] Example 1: Fabrication of Magnesium-Filled Alumina Implants

[0075] 200mL of alcohol, 6g of polyvinyl butyral (polyvinyl butyral-co-vinylalcohol-co-vinyl acetate, PVB), 6mL of trialkylphosphate (triethylphosphate, 99.8%), 50g of alumina were mixed and stirred for 2 hours to form The mixed solution is used as solvent, binder, dispersant and biodegradable ceramics respectively. Subsequently, spherical zirconia was added to the mixed solution and ball-milling was performed for about 24 hours. Next, immerse polyurethane (polyurethane) cut into a predetermined size and shape into the mixed solution, take it out, and then turn it at room temperature to avoid blocking the holes. Subsequently, the polyurethane was dried in the air for about 5 minutes, so that the high-concentration zirconia covered the polyurethane foam. As described above, the procedure of immersing the polyurethane into the mixed liquid and then drying the polyurethane may be performed repeatedly, thereb...

Embodiment 2

[0078] Example 2: Manufacture of Magnesium-Filled Titanium Implants

[0079] The titanium porous structure is prepared by the rotating electrode method. The spherical titanium powder with a diameter of 100-200 μm is placed between the conductive electrodes, and then a 450 μF capacitor is used under the condition of 1.0kj or 1.5kj by using a high vacuum switch. The voltage is immediately discharged, and the current and voltage flowing through the powder during the discharge are controlled, thus performing rapid sintering of the spherical titanium powder.

[0080] A copper electrode rod was provided in a quartz tube with an inner diameter of 4.0 mm, and 0.7 g of classified titanium powder was added into the quartz tube, followed by fully packing the titanium powder using a vibrator. At the same time, use an automatic charging device to apply a load of 10g to the upper part of the copper electrode rod, so that the copper electrode is in contact with the upper part of the titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com