Preparation method for manganic manganous oxide

A manganese tetraoxide, oxidizing technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of impurities in the product, low production efficiency, slow conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Weigh 9.0g of manganese hydroxide solid and 200mL of pure water and mix to obtain a reaction solution, add it into a sealed reactor (the reaction process does not have any form of gas exchange with the external connection), adjust the gas phase pressure of the air in the sealed reactor to 3.2-3.4MPa , heating the reaction solution to 100°C for 0.5h to obtain the crude trimanganese tetraoxide;

[0088] The crude trimanganese tetraoxide is subjected to solid-liquid separation, washing and drying to obtain trimanganese tetraoxide powder.

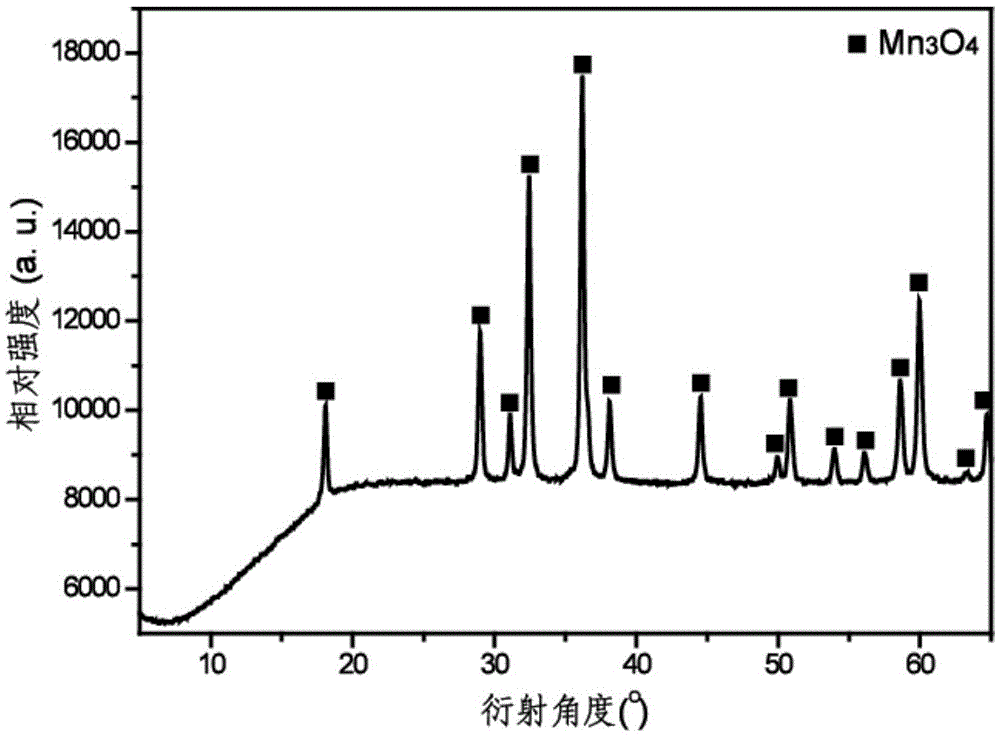

[0089] figure 1 is the particle size and morphology of the crystals of trimanganese tetraoxide prepared in Example 1 of the present invention;

[0090] figure 2 is the crystal XRD pattern of trimanganese tetraoxide prepared in Example 1 of the present invention.

Embodiment 2

[0092] Weigh 7.0g of manganese monoxide solid and 100mL of pure water to mix to obtain the reaction solution, add it into a sealed reactor (the reaction process does not have any form of gas exchange with the external connection), and feed oxygen into the sealed reactor until the gas phase pressure of oxygen is 2.92 ~2.93MPa, raise the temperature of the slurry to 230°C and react for 0.1h to obtain the crude manganese tetraoxide;

[0093] The crude trimanganese tetraoxide is subjected to solid-liquid separation, washing and drying to obtain trimanganese tetraoxide powder.

Embodiment 3

[0095] Take by weighing manganese monoxide solid 7.0g and pure water 100mL and mix to obtain the reaction solution, add in the sealed reactor (the reaction process does not have any form of gas exchange with the external connection), feed air into the sealed reactor, so that the gas phase pressure is 50.0 Between ~52.0MPa, react the reaction liquid at 25°C for 1.0h to obtain the crude trimanganese tetraoxide;

[0096] The crude trimanganese tetraoxide is subjected to solid-liquid separation, washing and drying to obtain trimanganese tetraoxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com