Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

330 results about "Manganese(II,III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese(II,III) oxide is the chemical compound with formula Mn₃O₄. Manganese is present in two oxidation states +2 and +3 and the formula is sometimes written as MnO.Mn₂O₃. Mn₃O₄ is found in nature as the mineral hausmannite.

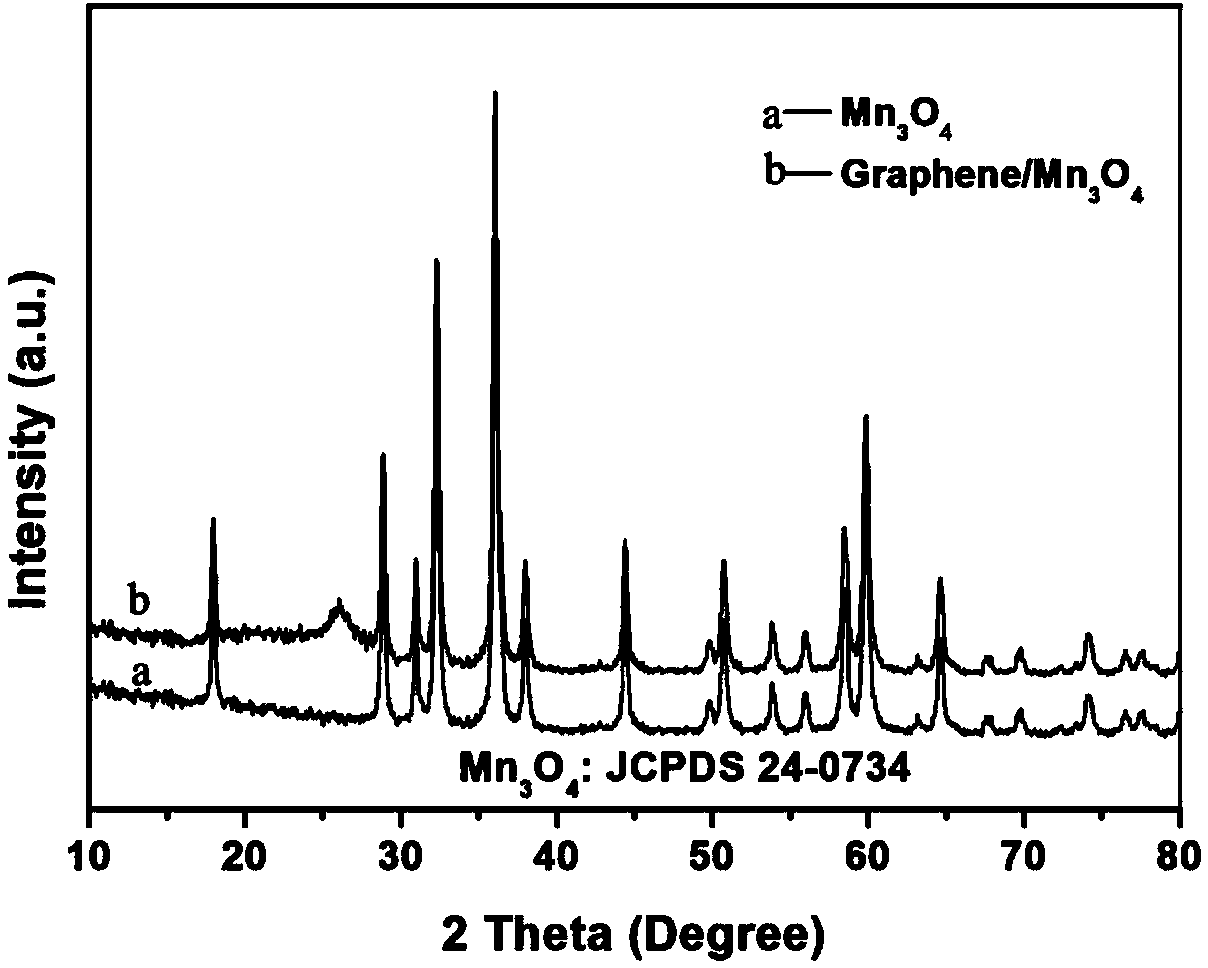

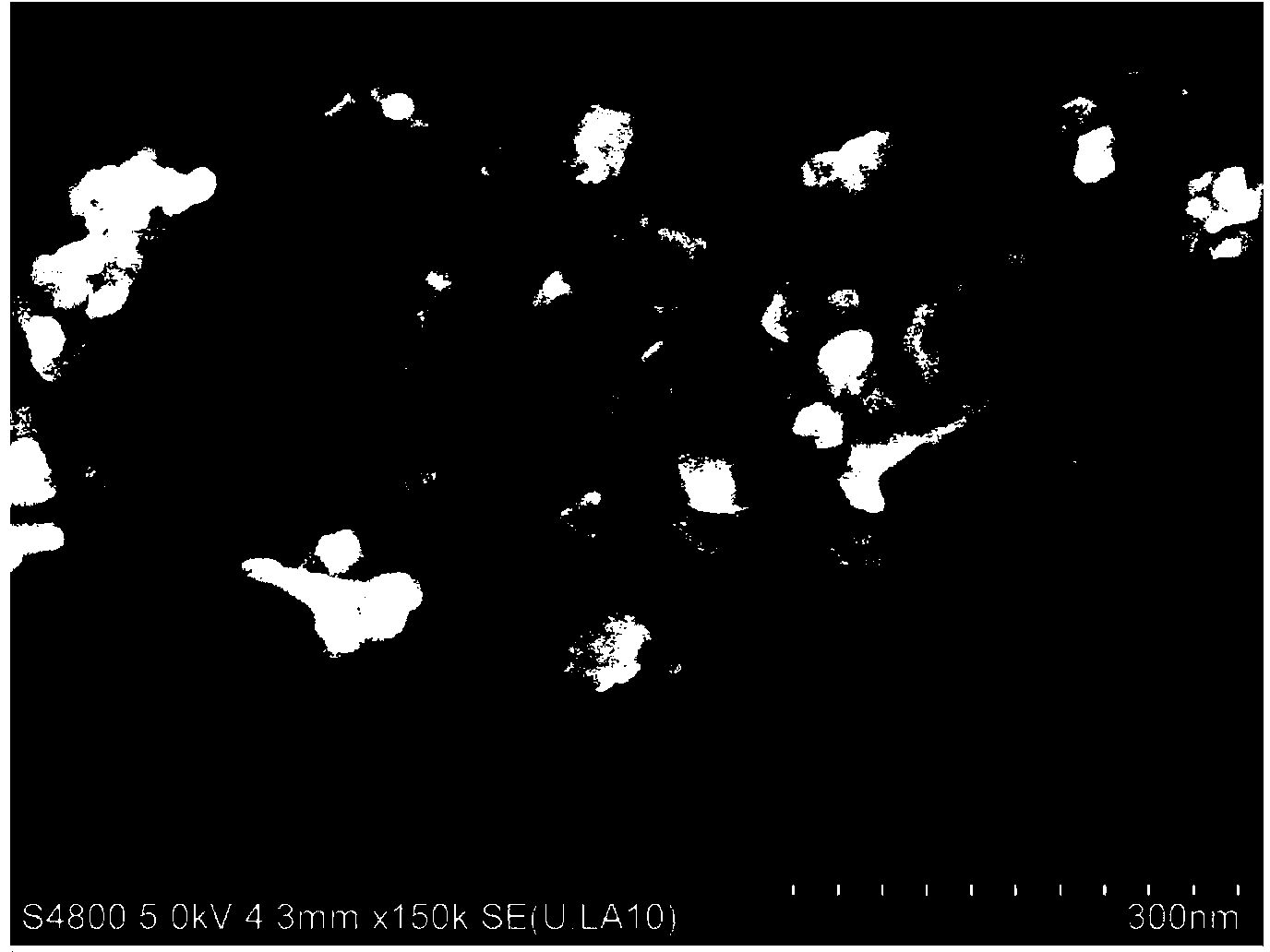

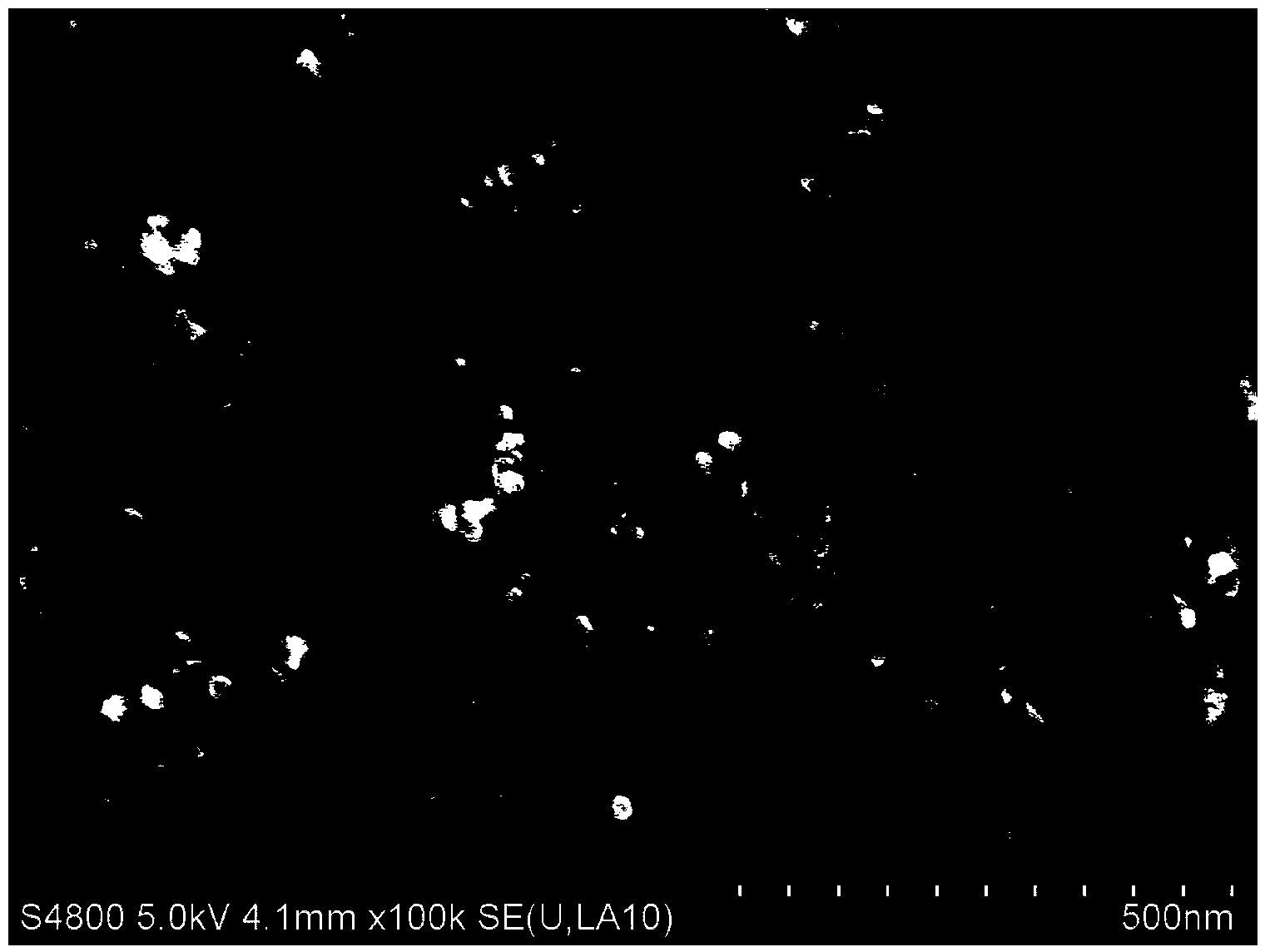

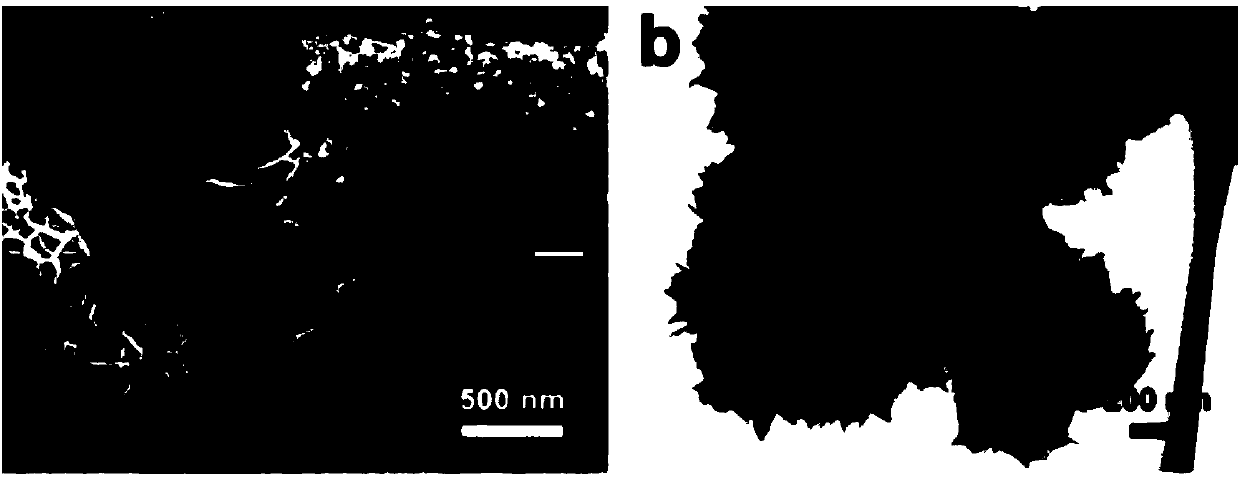

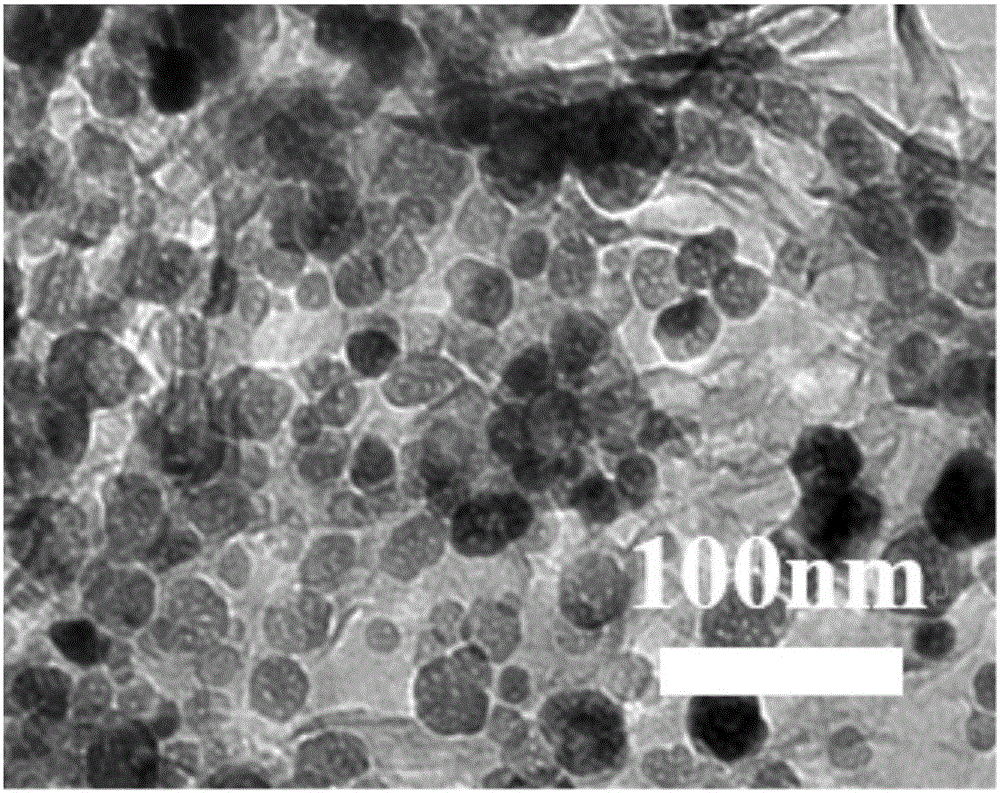

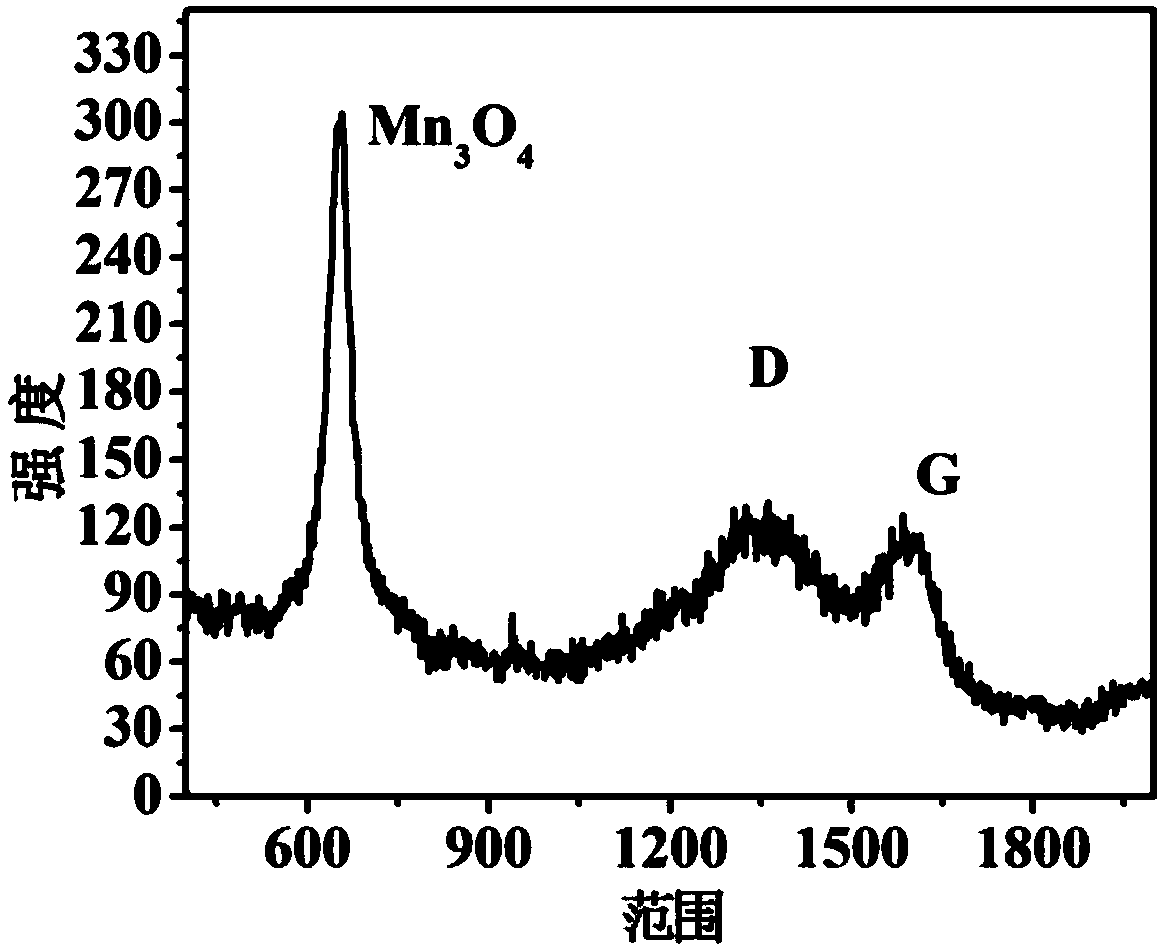

Graphene/manganese tetraoxide nanocomposite and preparation method thereof

ActiveCN103771406APlay a role in restoringSimple methodMaterial nanotechnologyCarbon compoundsWater bathsIce water

The invention discloses a graphene / manganese tetraoxide nanocomposite and a preparation method thereof. The method comprises the following steps of firstly, diluting graphite oxide concentrated solution to be 0.1-5mg / mL with deionized water, stirring uniformly, after water bath ultrasonic at room temperature, putting a beaker into ice-water bath, and carrying out ultrasonic treatment by a probe ultrasonic processor to obtain graphene oxide solution; secondly, adding permanganate into the graphene oxide solution, stirring till the permanganate is dissolved completely, adding a reducing agent, and stirring uniformly; thirdly, reacting the solution obtained in step two at 80-120 DEG C, after reacting, cooling, centrifuging and washing, and vacuum-drying, so as to obtain the graphene / manganese tetraoxide nanocomposite. The graphene / manganese tetraoxide nanocomposite is prepared by one-step hydrothermal method, the reducing agent simultaneously reduces the two raw materials, and the method is simple and easy to operate.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

Aqueous zinc-ion battery positive electrode material

ActiveCN107863485AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyElectrode thermal treatmentHigh pressurePotassium permanganate

The invention discloses an aqueous zinc-ion battery positive electrode material. A preparation method of the material is a one-step hydrothermal method and comprises the steps of adding a certain amount of potassium permanganate into deionized water, performing stirring under a room temperature to obtain a deep violet solution, transferring the solution into a high-pressure kettle, and adding a three-dimensional substrate material into the solution for hydrothermal solution; washing the three-dimensional substrate material for many times after cooling of hydrothermal solution, and performing drying in a baking oven to obtain a uniform nanometer flower spherical Mn3O4 material grown on the three-dimensional substrate material. The prepared material is initially applied to prepare the aqueous zinc-ion battery positive electrode material, has high specific capacity and favorable cycle stability, is moderate in reaction condition and simple in process and is suitable for production on a large scale.

Owner:CENT SOUTH UNIV

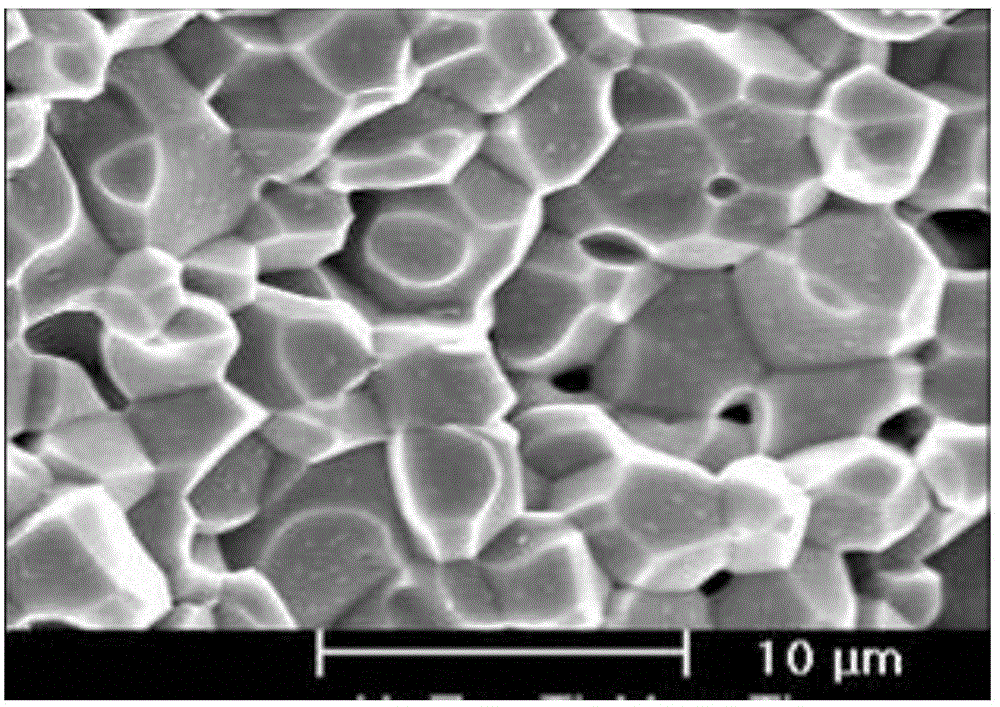

High-proportion manganous-manganic oxide and preparation method thereof

InactiveCN101898796ASmall specific surface areaLess impuritiesManganese oxides/hydroxidesManganous-manganic oxideSlurry

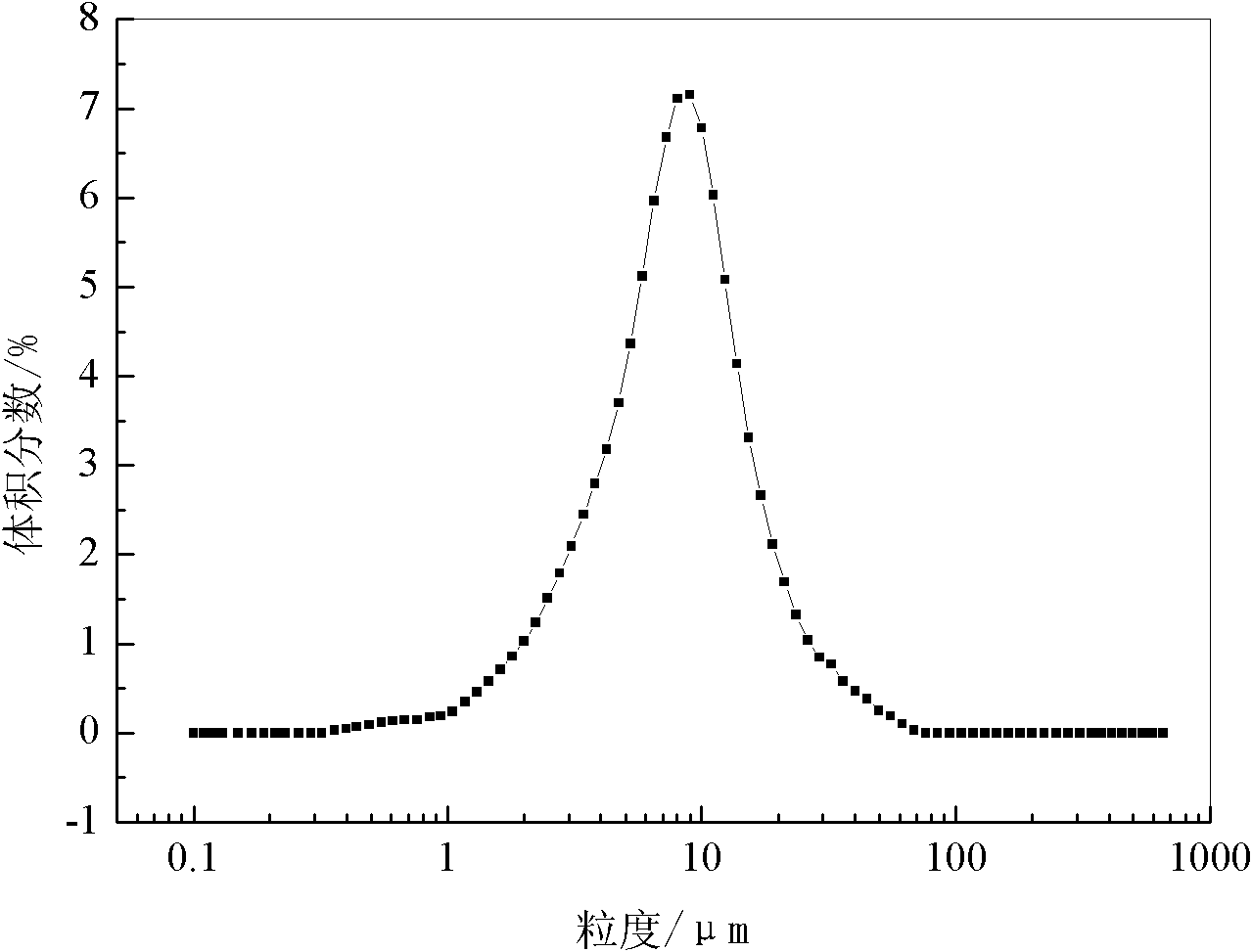

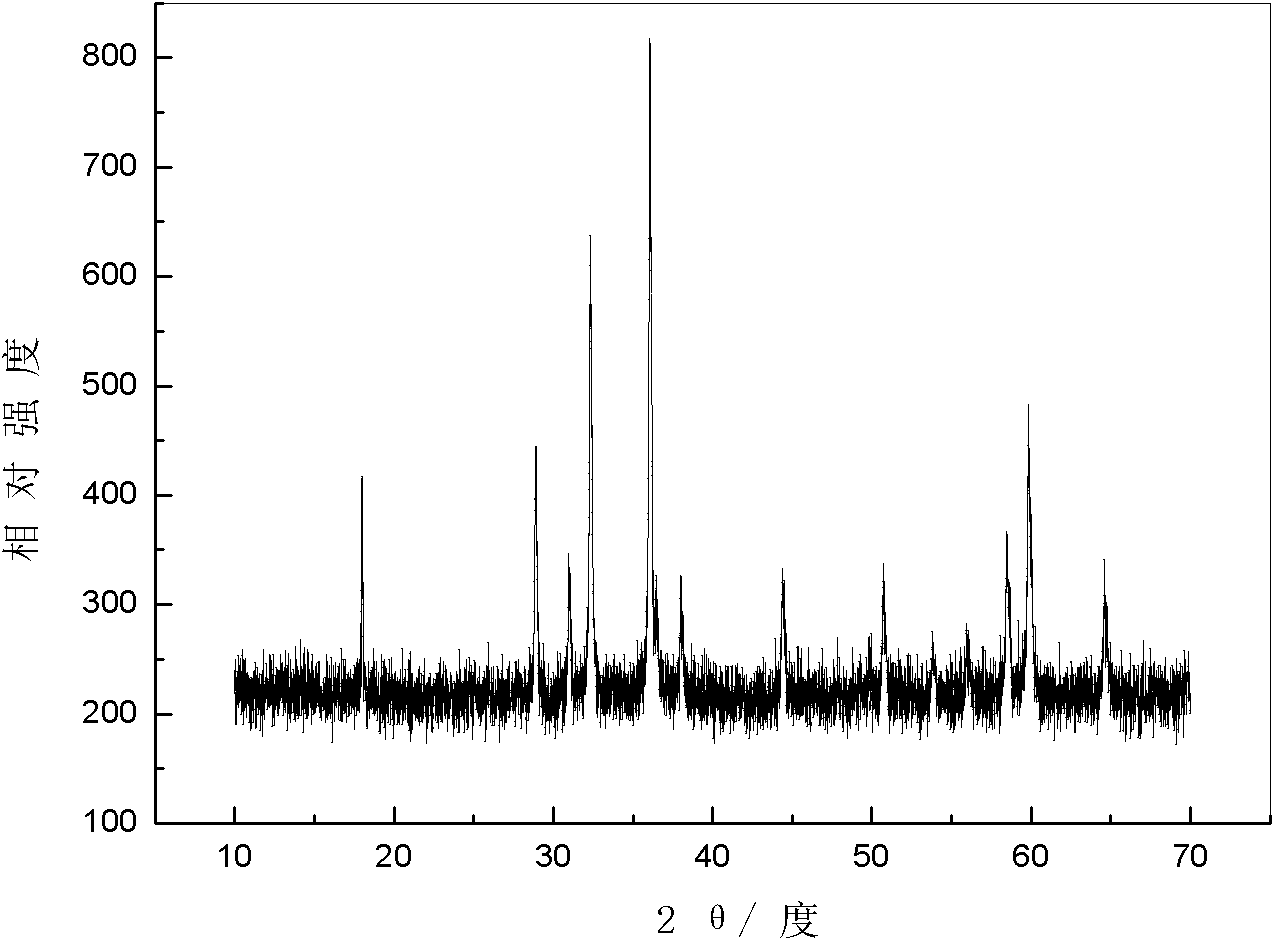

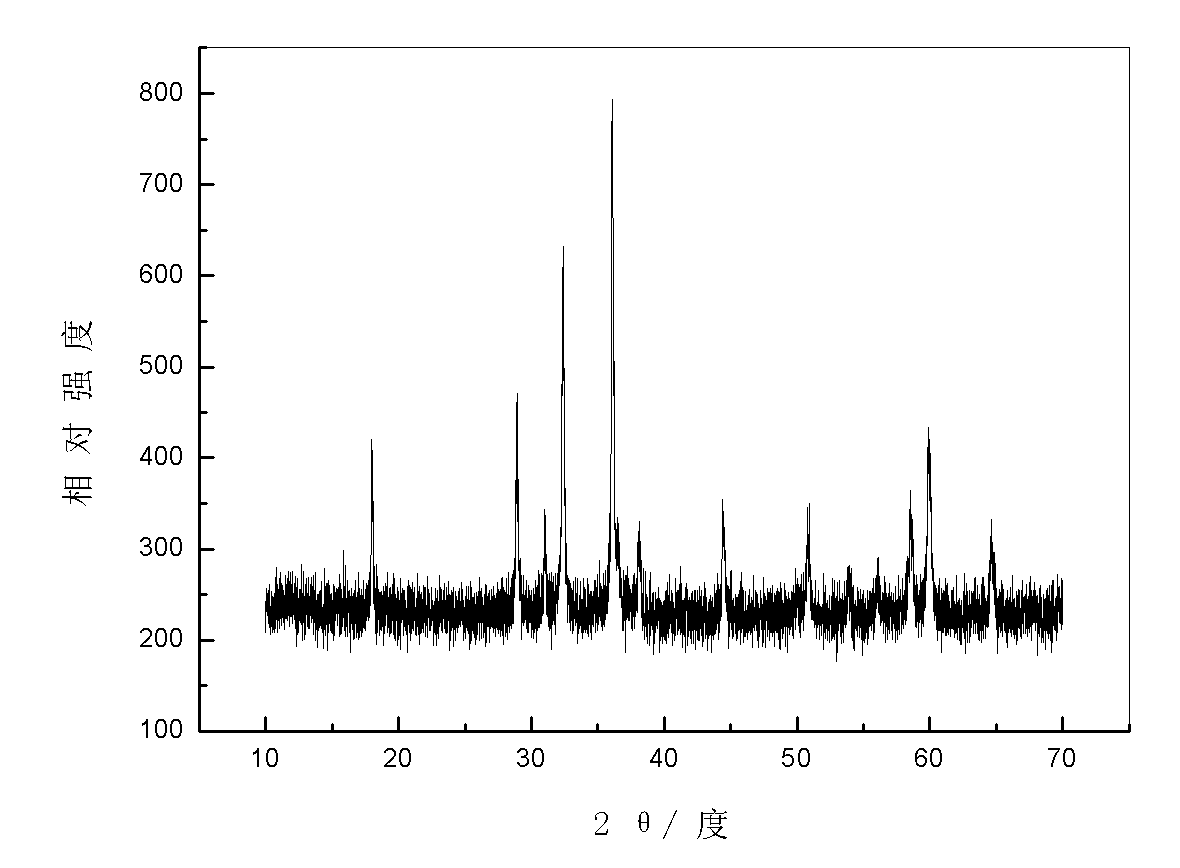

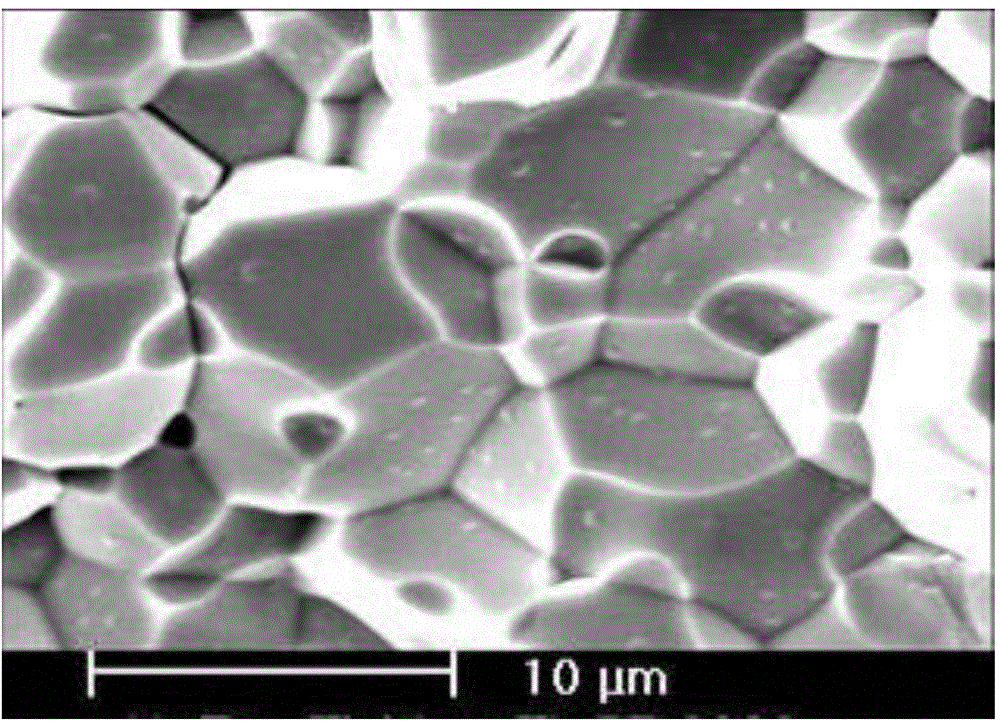

The invention relates to an oxide of manganese and a preparation method thereof, in particular to a high-proportion manganous-manganic oxide and a preparation method thereof. The tap density of the high-proportion manganous-manganic oxide is at least 1.8g / cm<3>, and the specific surface area thereof is 1.5m<2> / g-3.0m<2> / g. The preparation method comprises the following steps of: directly introducing air into a manganese sulfate solution for oxidation, wherein the air flow is controlled to be 800L / h-2500L / h, the oxidation temperature is controlled to be 50-80 DEG C, and the stirring strength in the oxidation process is 75r / min-200r / min; dropwise adding ammonia water in the oxidation process so as to neutralize H<+> generated by oxidization reaction to make the pH value of a reaction system controlled to be 4.5-8.0; repeatedly rinsing manganous-manganic oxide slurry obtained after the reaction is completely ended by using pure water and then drying to obtain the high-proportion manganous-manganic oxide. The high-proportion manganous-manganic oxide not only has higher tap density, smaller specific surface area and even particle size distribution but also has low impurity content and low preparation cost.

Owner:HUNAN HUITONG SCI & TECH

High-purity trimanganese tetroxide and preparation method thereof

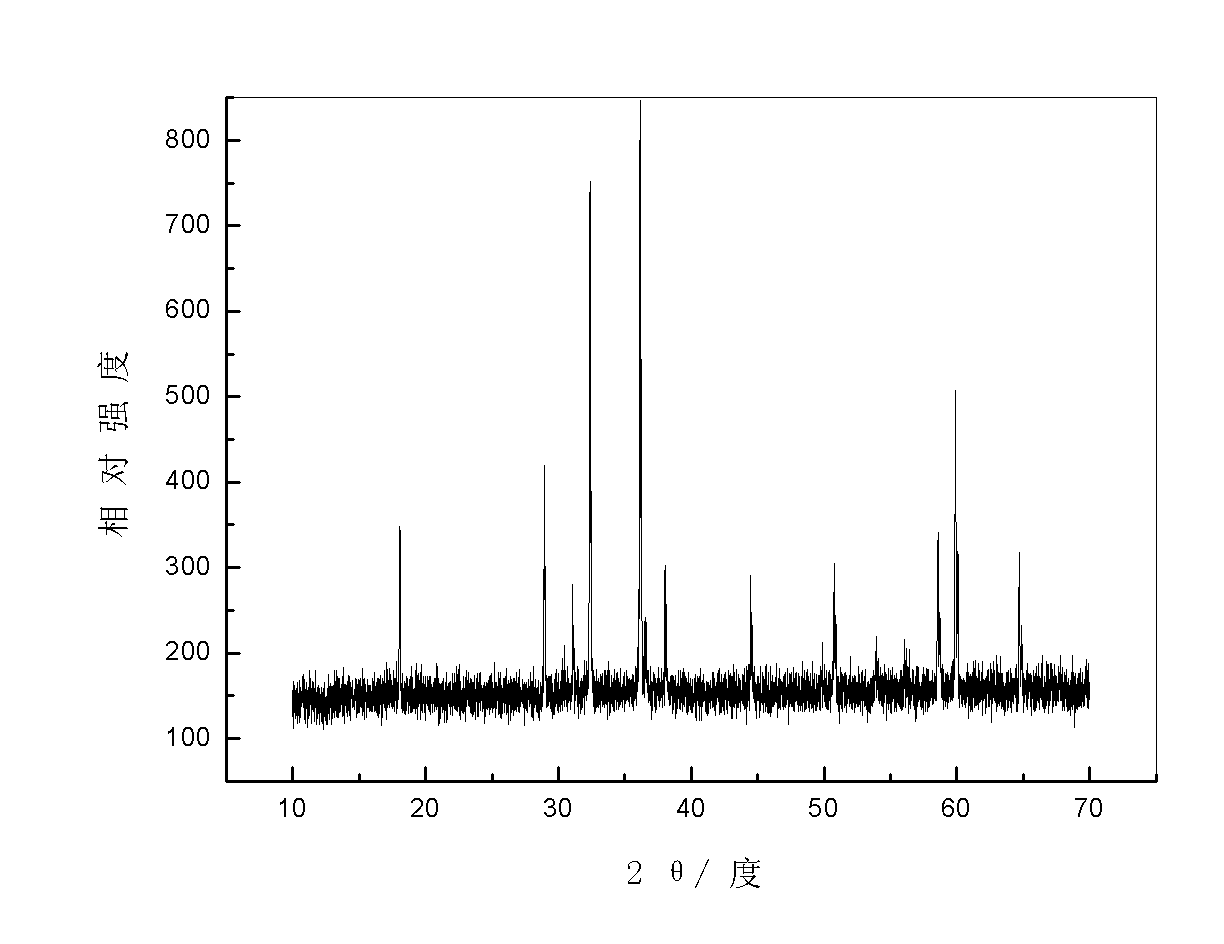

The invention relates to an oxide of manganese, and in particular discloses high-purity trimanganese tetroxide and a preparation method thereof, wherein the Mn content in the high-purity trimanganese tetroxide is larger than 71.5 percent, and the S content is smaller than 0.03 percent. The preparation method thereof comprises the following steps of: 1. firstly dissolving high-purity manganese sulfate into water to obtain a manganese sulfate solution, then neutralizing the manganese sulfate solution with ammonia water, using the pH value of a neutralization system reaching 9.0-10.0 as the end point of a neutralization reaction, filtering, and rinsing to obtain a manganese hydroxide suspension; 2. introducing air into the manganese hydroxide suspension prepared in the step 1 at the temperature of 45-85 DEG C for oxidation, and filtering, rinsing and drying to obtain the high-purity trimanganese tetroxide after the manganese hydroxide in an oxidation system is completely converted into trimanganese tetroxide. The high-purity trimanganese tetroxide has the advantages of lower impurity content, good quality, controllable specific surface area, low preparation cost and the like.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

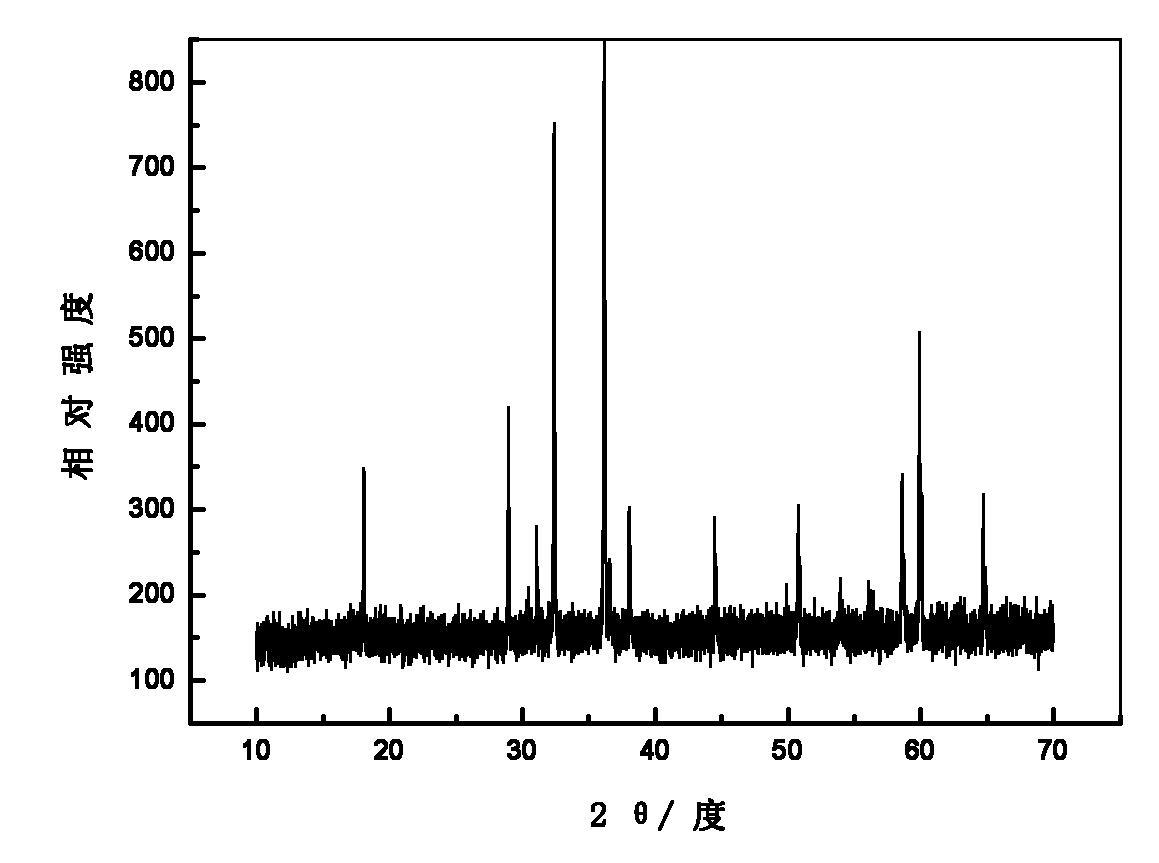

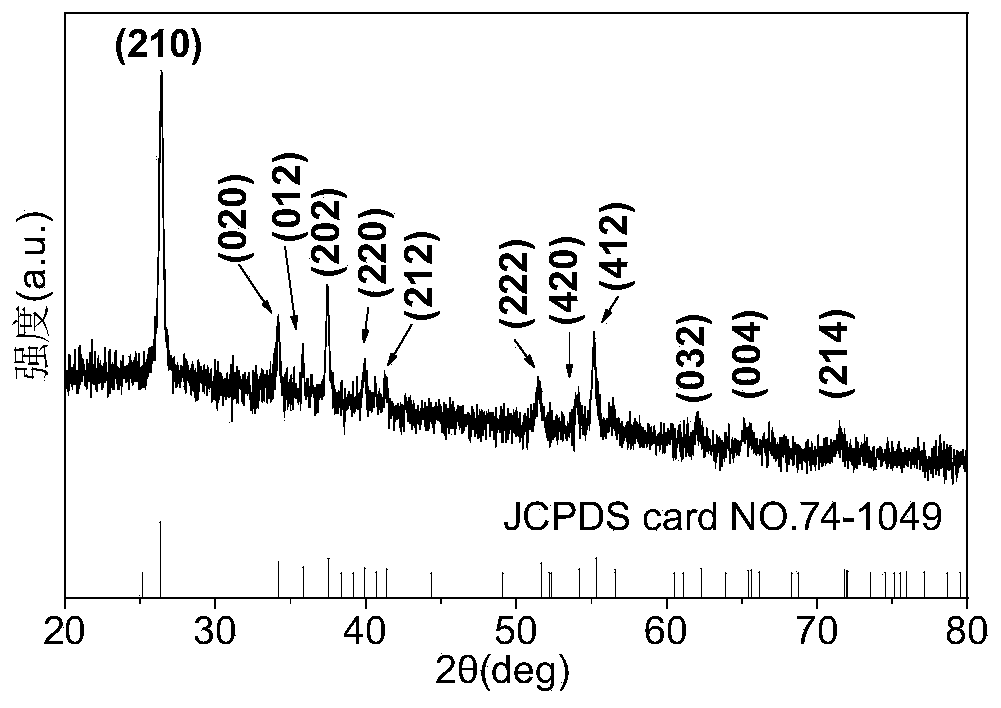

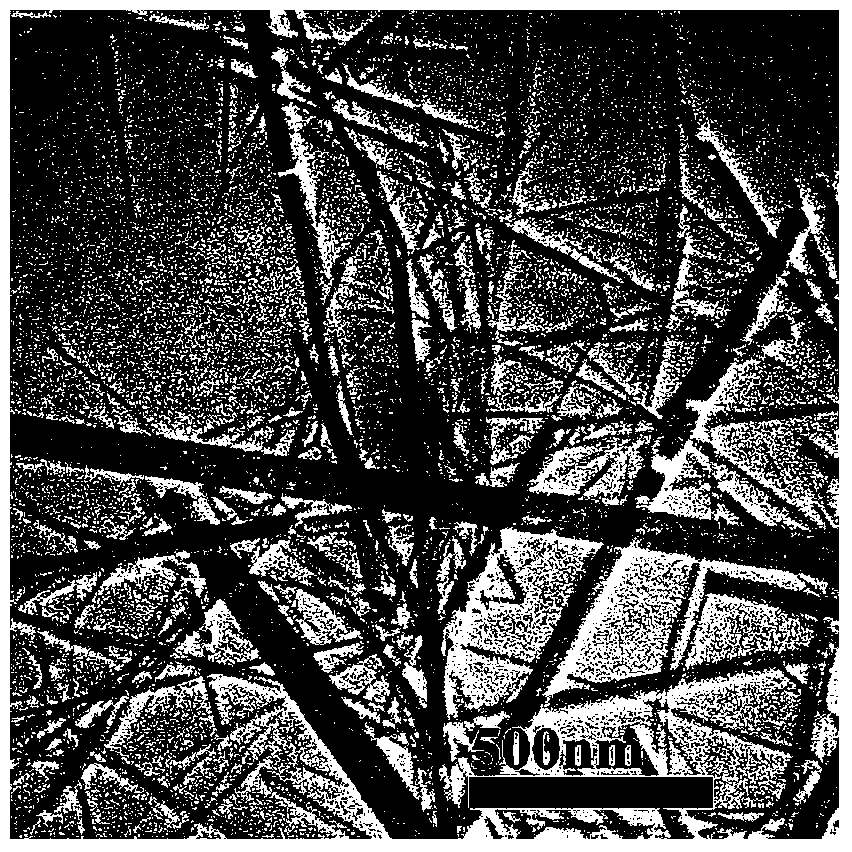

Preparation method for manganese oxide nano rods

InactiveCN104211123ASmall diameterUniform size distributionMaterial nanotechnologyManganese oxides/hydroxidesSesquioxideReaction temperature

The invention relates to a preparation method for manganese oxide nano rods, belonging to the field of nano function materials. According to the preparation method, rod-shaped alkaline manganese oxide can be prepared by using hypermanganate and ethylene glycol under a hydrothermal condition, wherein the longest length of the alkaline manganese oxide can be up to six microns and the diameter size is 10nm-130nm; alkaline manganese oxide precursors are calcined under different calcining conditions to obtain the manganese oxide nano rods with different valence states and different sizes, namely manganese dioxide nano rods, manganese sesquioxide nano rods and trimanganese tetraoxide nano rods. By adopting the preparation method, the problems of an existing solvothermal method that the reaction time is long and the reaction temperature is high when the alkaline manganese oxide nano rods are synthesized and the diameters of the products are great and the products are not uniformly distributed are solved; and the preparation method has the advantages of simplicity in operation and many product varieties.

Owner:JILIN UNIV

MnZn ferrite material with high magnetic conductivity and manufacturing method thereof

ActiveCN101859621AImprove permeabilityOvercoming featureInorganic material magnetismCurie temperatureDiiron Trioxide

The invention provides an MnZn ferrite material with high magnetic conductivity, which comprises the following main components: 50 to 54mol% of ferric oxide calculated by Fe2O3, 22 to 30mol% of trimanganese tetroxide calculated by MnO, 20 to 24mol% of zinc oxide calculated by ZnO and auxiliary components selected from at least four of TiO2, Co2O3, V2O5, Bi2O3, MoO3, SiO2 and CaCO3. In the MnZn ferrite material with high magnetic conductivity, which is provided by the invention, the initial magnetic conductivity is greater than 15000, the Curie temperature is greater than 120 DEG C, and the normal-temperature saturation magnetic induction strength is greater than 410mT. The invention also provides a manufacturing method of the MnZn ferrite material with high magnetic conductivity, which comprises the steps of mixing, drying, pre-sintering, ball milling, granulating, pressing, forming and sintering. The method provided by the invention has the advantages of simple process and low cost.

Owner:江门江益磁材有限公司

Method for preparing high-purity trimanganese tetraoxide in ammonia medium using manganese sulfate solution

InactiveCN1814551AControl the amount of sedimentFast oxidation reactionManganese oxides/hydroxidesSulfateManganous-manganic oxide

The invention discloses a method to produce high purity manganous-manganic oxide by manganese sulfate solution in ammonia medium. Adding ammonia into manganese sulfate solution that the concentration is 2g.L-1-120g.L-1, controlling the adding speed to make the pH value rising speed at 0-1.00 / minute, using air or oxygen as oxidizing agent to oxide bivalent manganese into manganous-manganic oxide, the reaction temperature is 20-100 degree centigrade, controlling the highest pH value of the solution at the range of 6.0-14.0 in reacting process, and the lowest pH value range at 4.0-9.0. The invention has the advantage of fast reaction, the amount of precipitation of impurity calcium and magnesium could be controlled, and the yield of manganese would be improved, the cost is low.

Owner:郝鹏飞

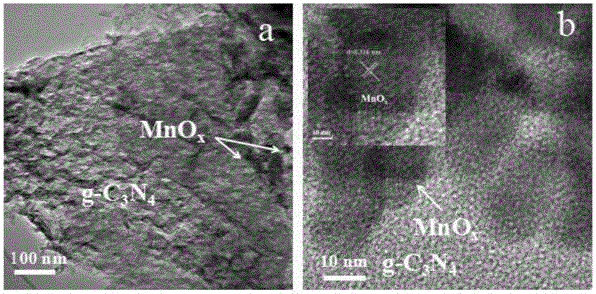

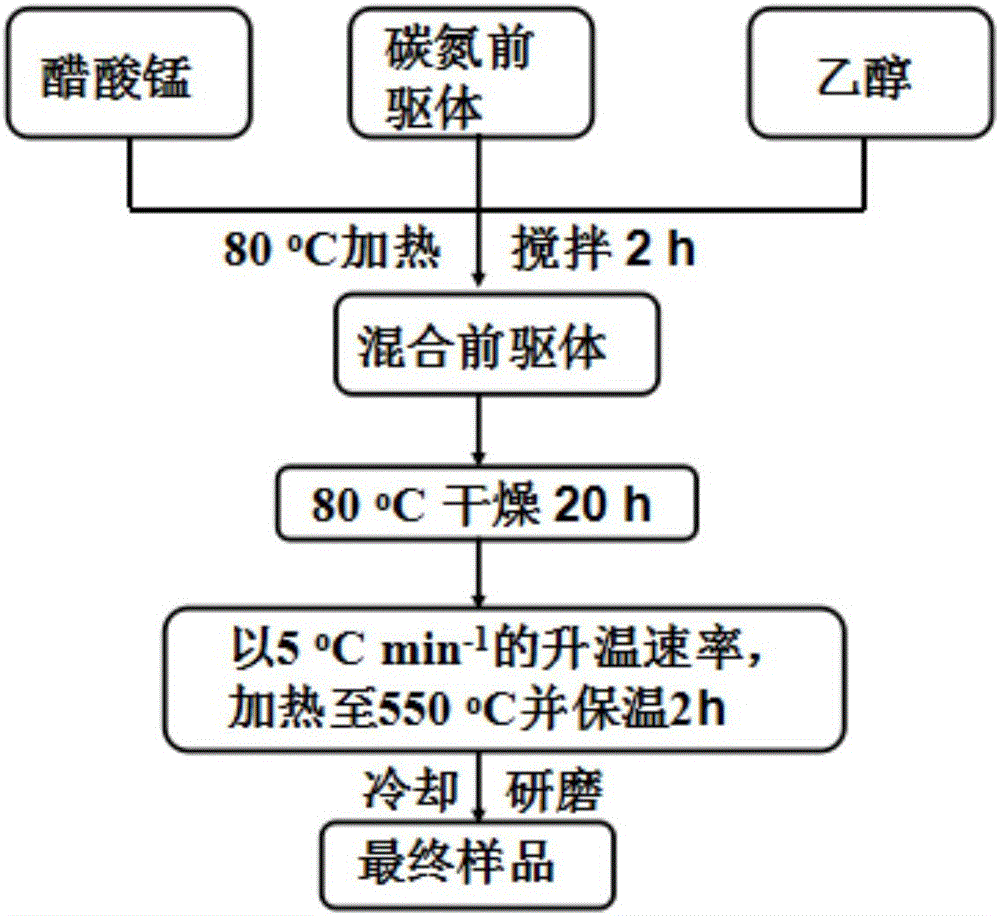

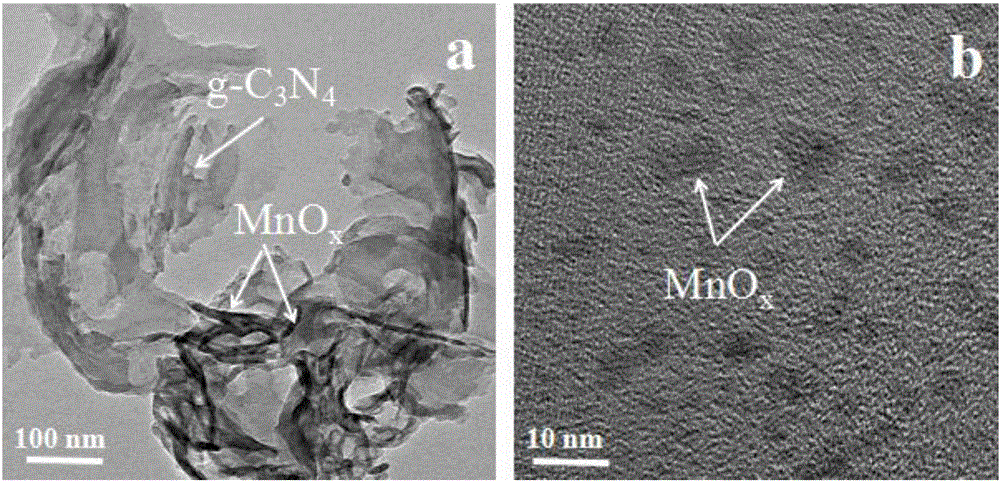

Manganese oxide-graphite phase carbon nitride composite photocatalytic material and preparation method thereof

InactiveCN105817255AImprove thermal stabilityGood chemical stabilityPhysical/chemical process catalystsEnergy inputManganese oxideElectrochemistry

The invention relates to a manganese oxide-graphite phase carbon nitride composite photocatalytic material and a preparation method thereof. The manganese oxide-graphite phase carbon nitride composite photocatalytic material is prepared by depositing manganese oxide nanoparticles on the surface of layered graphite phase carbon nitride, and the manganese element loading capacity of manganese oxide in the composite photocatalytic material is 0.3-1.2 mol%; manganese dioxide or trimanganese tetroxide or dimanganese trioxide or a mixed oxide of manganese dioxide, trimanganese tetroxide and dimanganese trioxide is adopted as manganese oxide. Manganese oxide in the composite photocatalytic material is uniformly loaded on graphite phase carbon nitride, the loading capacity is controllable, the good catalytic capacity is achieved, a manganese oxide cocatalyst is closely combined with graphite phase carbon nitride, therefore, the defects that a single photocatalyst is high in photoproduced electron hole pair composite ratio and low in photocatalytic efficiency are effectively overcome, the solar utilization efficiency is greatly improved, and the excellent catalytic activity is achieved when the composite photocatalytic material is used for photocatalytic hydrogen production. The composite photocatalytic material has the wide application prospect in the fields of photocatalysis, electrochemistry, energy, environments and the like.

Owner:WUHAN UNIV OF TECH

Method for circularly producing mangano-manganic oxide by manganous sulfate

The invention relates to a method for circularly producing mangano-manganic oxide by manganous sulfate, which fulfills the aim of circularly producing the mangano-manganic oxide by the manganous sulfate by absorbing a mixed gas of sulfur dioxide and sulfur trioxide generated by calcining the manganous sulfate at a high temperature by mixed slurry which is formed by pyrolusite (or manganese dioxide), manganese carbonate and water. The method for producing the mangano-manganic oxide has the advantages of low cost, high product purity, no pollution and the like.

Owner:湖南昊宏新材料科技有限公司

Manganese zinc ferrite material and preparation method thereof

The invention relates to a manganese zinc ferrite material and a preparation method thereof. The manganese zinc ferrite material comprises main components in mole percentage: 54-56 percent of ferric oxide, 38-42 percent of trimanganese tetraoxide and 4-6 percent of zinc oxide, and auxiliary components selected from at least five of CaCO3, SiO2, K2CO3, Y2O3, NiO, Co3O4 and Al2O3. The manganese zinc ferrite material is low in self-power loss in a (0.1-1) MHz wide frequency range.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

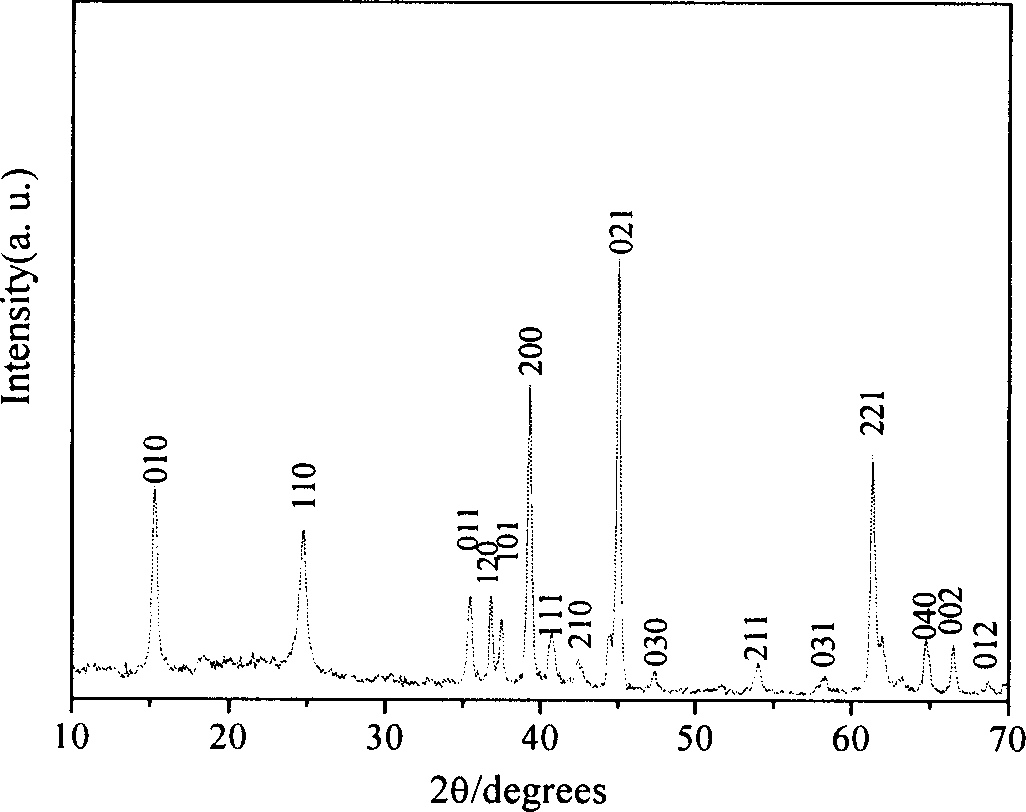

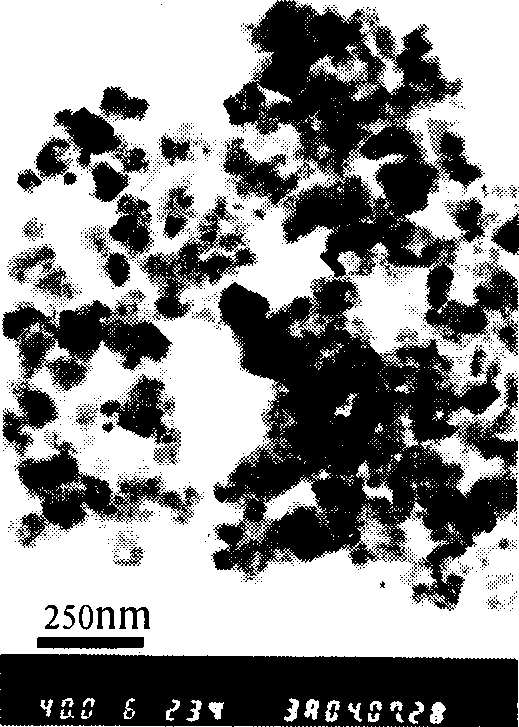

Process for producing mangano-manganic oxide nanocrystalline with controllable sizing and shape

ActiveCN101219809AEasy to prepareMild reaction conditionsNanostructure manufactureManganese oxides/hydroxidesReaction temperatureAtmospheric pressure

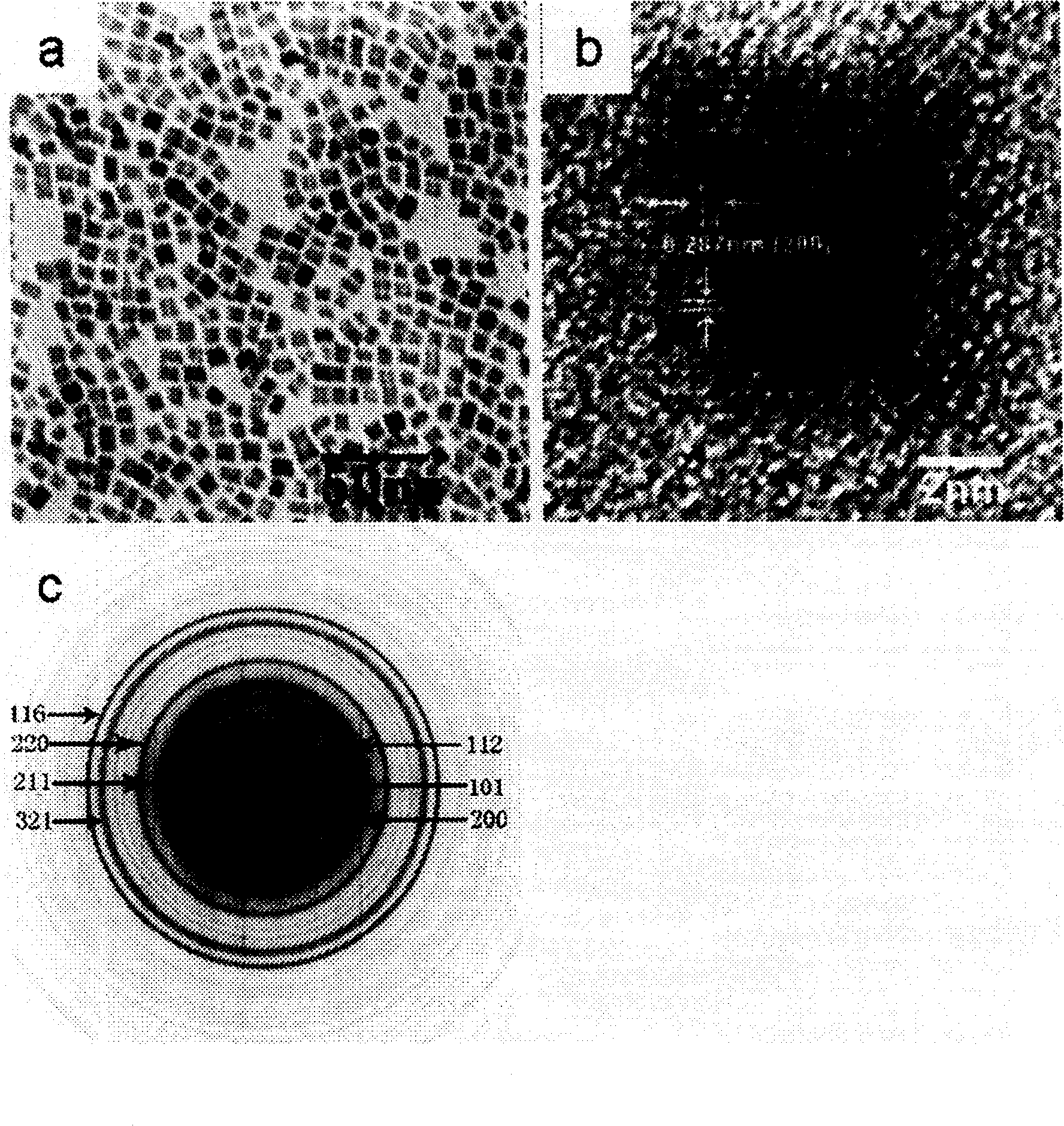

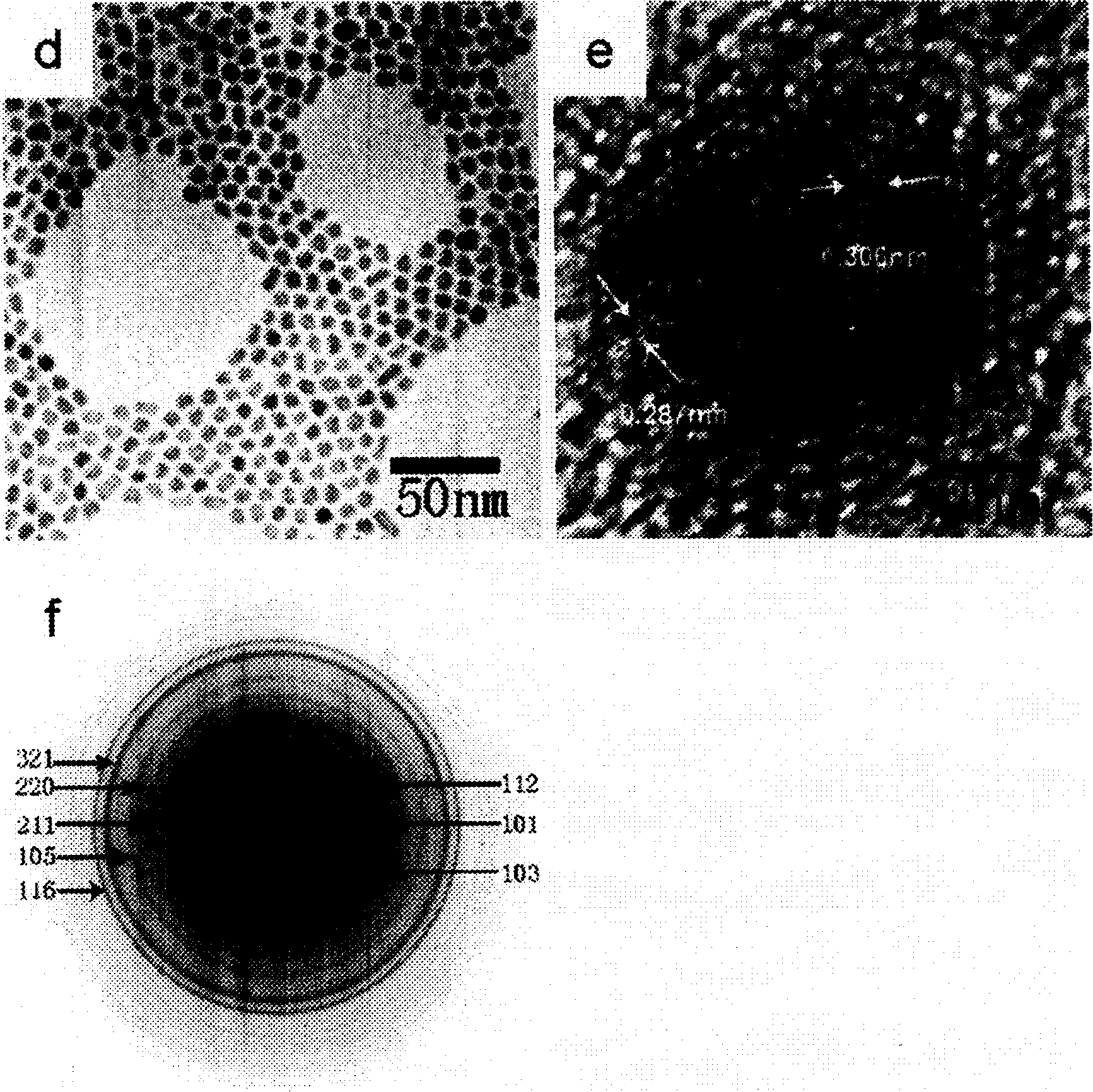

The invention provides a method for preparing manganic manganous oxide nano-crystalline with controllable size and shape. aThe manganes source and organic coating agent are put into toluene to be heated and dissolved; water solution added alkaline matter is reacted for 10 minutes to 240 hours under a temperature ranging from 25 DEG C to 280 DEG C; the reaction is carried out under an atmospheric pressure or in an autoclave; under a heating condition, the manganese source is hydrolyzed; through the process of formation and growth of crystal nucleus, the manganic manganous oxide nano-crystalline coated by the organic ligand is formed finally. The method for preparing the total material of the invention is characterized by moderate reaction condition, simple and easy operation and short preparing period, thus, the preparation is easy to be enlarged. The prepared manganic manganous oxide nano-particle can disperse in non-polar organic solution. By regulating reaction time, reaction temperature, alkali amount, water amount and type of the organic coating agent, spherical, square and polygonal manganic manganous oxide nano-crystalline coated by the organic ligand of different sizes (3-50nm) can be compounded.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

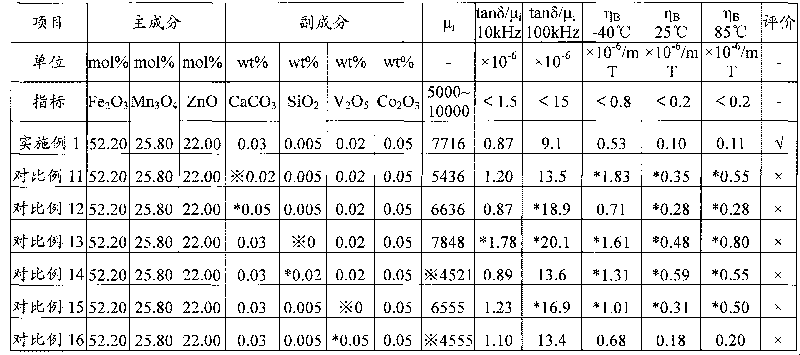

Wide-temperature low-distortion mangan zinc ferrite and preparation method thereof

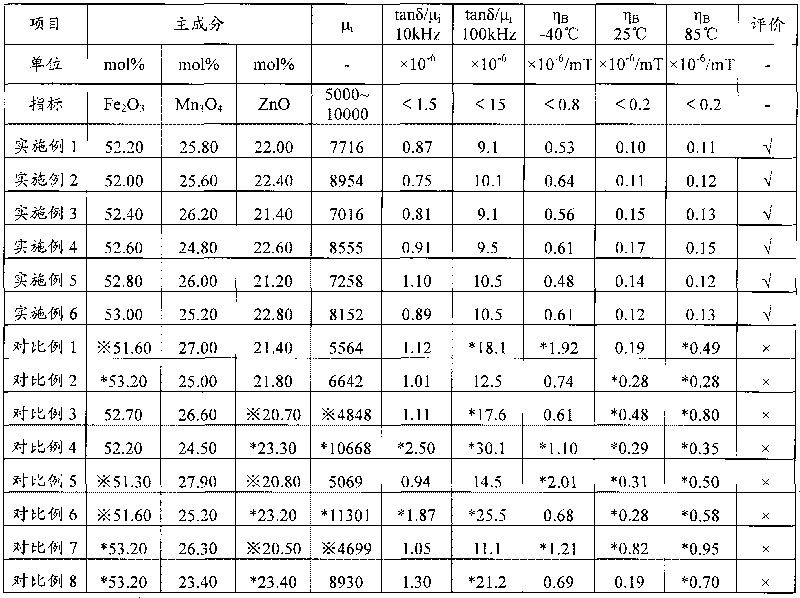

ActiveCN101728048AReduce production energy consumptionBurn-in lowInorganic material magnetismLow distortionTransformer

The invention relates to a wide-temperature low-distortion mangan zinc ferrite applicable to a broadband network transformer and a preparation method thereof. The mangan zinc ferrite mainly comprises the following components: 52.0 to 53.0 mol percent of iron oxide computed by Fe2O3, 21.0 to 23.0 mol percent of zinc oxide computed by ZnO, and the balance of trimanganese tetroxide, and also comprises the following auxiliary components in percentage by weight (wt %) computed by respective standard substance CaCO3, SiO2, V2O5 and Co2O3: 0.03 to 0.04 of CaCO3, 0.005 to 0.01 of SiO2, 0.01 to 0.03 of V2O5 and 0.03 to 0.1 of Co2O3. The mangan zinc ferrite is prepared by an oxide method and sintered under the condition of bell-type furnace densification. A product has higher initial magnetic permeability mu i, low relative loss factor tan delta / mu i, and wide-temperature low-magnetic hysteresis coefficient eta B (-40 to 85 DEG C), is capable of reducing waveform distortion, reducing transmission errors and prolonging transmission distance in the process of transmitting signals, and meets the requirement of the application in outdoor severe environment.

Owner:TDG HLDG CO LTD

Preparation method for manganic manganous oxide

ActiveCN105417586AImprove solubilitySpeed up replenishmentManganese oxides/hydroxidesReaction rateAtmospheric pressure

The invention relates to a preparation method for manganic manganous oxide. The method is as follows: in an enclosed reaction container, a manganese source with an average valence of manganese being less than 8 / 3 is placed in a reaction solution, the reaction is carried out with heating, the situation is kept that the pressure or partial pressure of oxidizing gases in the reaction system is more than or equal to 1 standard atmospheric pressure, and a crude product of manganic manganous oxide can be prepared after the reaction is completed. Optionally, the enclosed reaction container has an oxidizing gas inlet or has an oxidizing gas inlet and a generation gas outlet simultaneously. The oxidation reaction rate is raised, the oxidation reaction time is shortened, the manganic manganous oxide crystal growth integrality is raised, the crystal defect is reduced, and high purity and high quality are obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

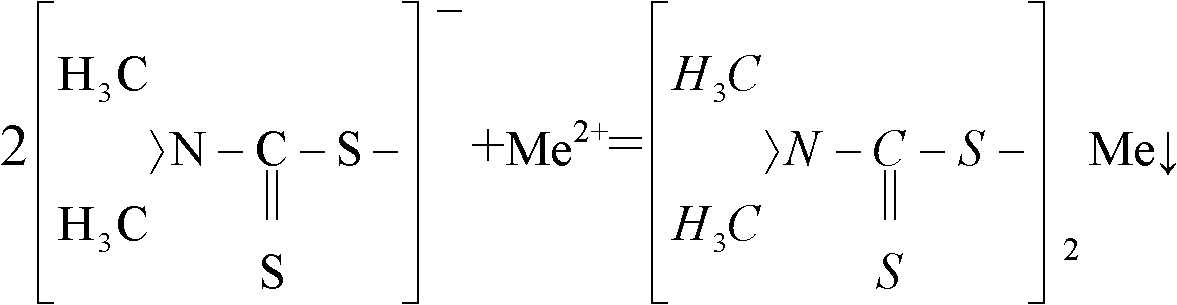

Direct production of electron grade high purity trimangnese tetraoxide from ores

InactiveCN1644513AImprove resource utilizationImprove product qualityManganese oxides/hydroxidesOxygenManganese oxide

Production of electronic high purity manganic manganous oxide by manganese oxide ore is characterized by taking manganese oxide ore as materials, immersing manganese from manganese oxide ore under ordinary pressure and temperature by sulfur dioxide, removing iron, copper, nickel, lead heavy metal ion in manganese sulfate mother liquid, obtaining purified manganese sulfate solution, coordinating the ammonia water and ammonium acid carbonate, depositing manganese, obtaining hydrated manganic hydroxide and manganese carbonate mixture, high temperature roasting the mixture, cooling washing for 3-5 times, drying to obtain manganic manganous oxide or inducing directly the purified manganese sulfate solution into ammonia water, regulating pH value 8-10 with solution temperature 50-70deg.C, inducing the dried air or oxygen for 6-9hrs, washing 3-5 times, filtering, drying to obtain manganic manganous oxide . It achieves low cost, high utilizing rate and product purity.

Owner:UNIV OF SCI & TECH BEIJING

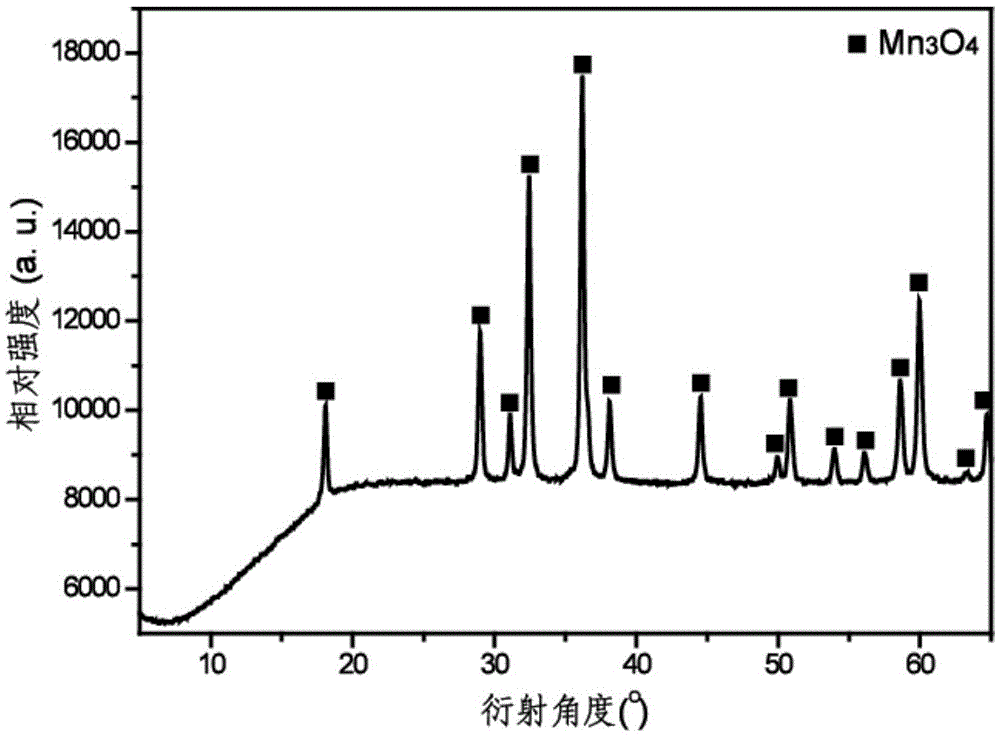

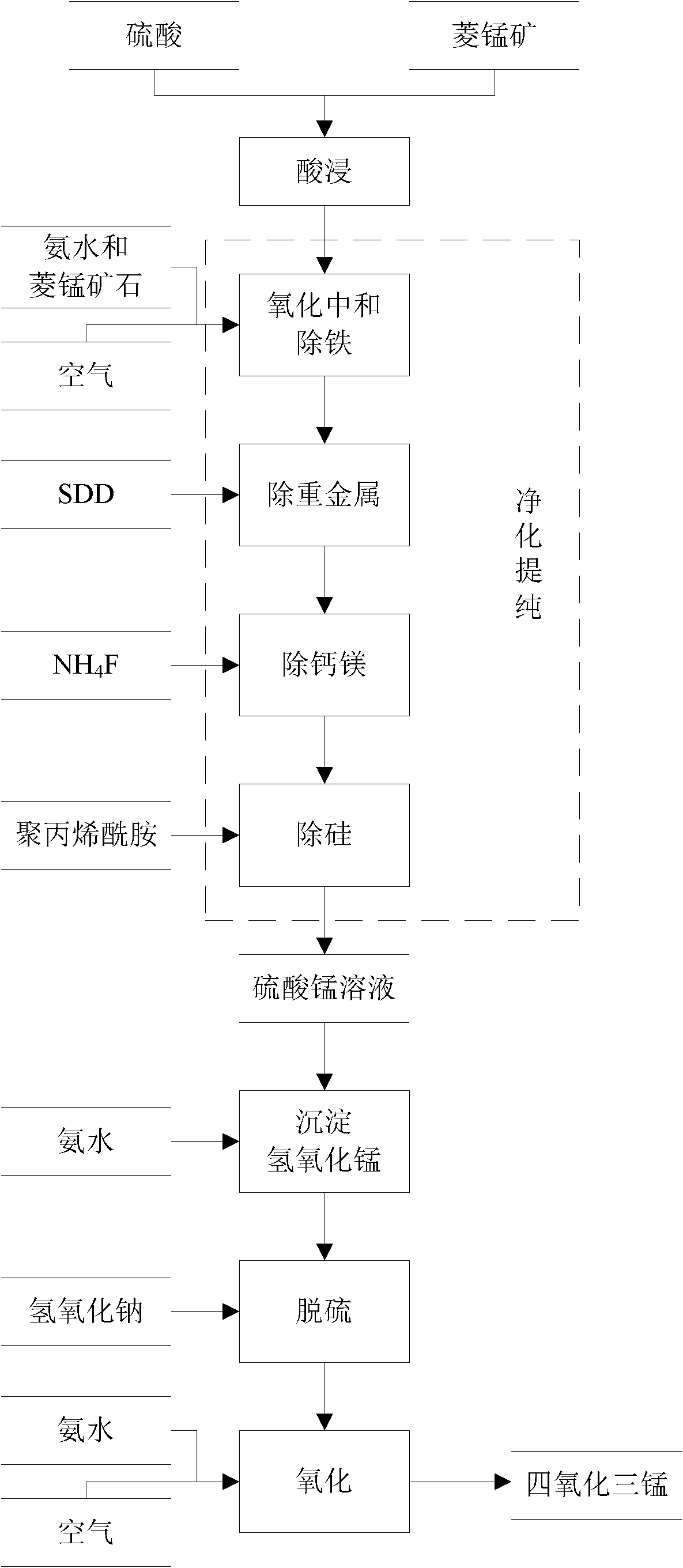

Method for preparing trimanganese tetroxide by using rhodochrosite

ActiveCN102134101ALarge specific surface areaImprove technical indicatorsManganese oxides/hydroxidesSulfateOxygen

The invention discloses a method for preparing trimanganese tetroxide by using rhodochrosite, comprising the following steps of: lixiviating the rhodochrosite by using a sulfuric acid solution to prepare a manganese sulfate solution; then purifying the manganese sulfate solution; then adding ammonia water to the purified manganese sulfate solution so that divalent manganese ions contained in the manganese sulfate solution generate manganese hydroxide precipitates; desulphurizing and washing the manganese hydroxide precipitates, and then oxidizing the washed manganese hydroxide precipitates by utilizing air or oxygen; and finally washing and drying to obtain a trimanganese tetroxide finished product. The preparation method not only has a simple process and low cost, but also has high purity and recovery rate and large specific surface area of a prepared product.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing electronic grade non-selenium manganomanganic oxide from dialogite

InactiveCN101348280AReduce power consumptionLess investmentManganese oxides/hydroxidesLower gradeLow graded

Owner:花垣县科信新材料有限责任公司

Method for preparing spherical lighium manganate anode material of lighium ion batteries

InactiveCN1447464AImprove high temperature performanceElectrode specific capacity is highElectrode manufacturing processesActive material electrodesLithium hydroxideManganate

A spherical managanic manganeous oxide is created through the reaction among the aqueous solution of manganese salt with concentration 0.5-3 mol / liter, the alkaline aqueous solution with concentration 2-6 mol / liter and one, two or more than two aqueous solutions from ammonia, ethylene diamine, oxalic acid and citric acid create. With being washed and dried, spherical manganic manganous oxide is mixed with lithium hydroxide or lithium carbonate passing through the 700-800 deg.C heat treatment so as to obtain the product of spherical lithium manganate. The material prepared by the invention possesses the advantages of high specific capacity, 2.2-2.5 g / cm-3 tap density, improved cycling stability by adulterating other elements (for ex. Co, Cr) and has great application value.

Owner:TSINGHUA UNIV

Method for preparing carbon-coated manganese-doped lithium titanate negative electrode material of lithium ion battery

InactiveCN101800307AEasy to controlImprove electrochemical performanceCell electrodesBall millCarbon coated

The invention relates to a method for preparing a carbon-coated manganese-doped lithium titanate negative electrode material of a lithium ion battery. In the method, the amount of doped manganese and experimental conditions are controlled; lithium salt, manganese dioxide or manganese tetroxide, titanium dioxide and sugar or glucose are used as raw materials; and the raw materials are put in a ball mill for ball milling, and are dried and sintered to obtain a carbon-coated manganese-doped lithium titanate composite material. In the method, carbon coating is performed on the doping inside lithium titanate cells and the outside of grains by using manganese ions and the lithium titanate is modified simultaneously, so the electrical conductivity of the lithium titanate is greatly improved, the cyclical stability and the reversible capacity of large currents are obviously improved, and the performance requirements of the negative electrode material of a power lithium ion battery are met. The method has a simple preparation process and is easy to realize industrialization; and the carbon-coated manganese-doped lithium titanate composite material obtained by the method has excellent electrochemical performance, realizes the optimal combination of the maximum reversible circulation capacity and the optimal high electrical conductivity, and can be applied to high-power lithium ion batteries.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Mesoporous manganese oxide nano granule and preparation method thereof

InactiveCN101597085AImprove protectionSimple preparation processManganese oxides/hydroxidesMANGANESE ACETATESesquioxide

The invention relates to a mesoporous manganese oxide nano material and a preparation method thereof. In the invention, a uniformly distributed mesopore with the aperture of 2 to 10 nanometers and a mixture of oxyhydrogen manganese oxide and manganic manganous oxide or a mangano-manganic octoxide monocrystal granule or a manganese sesquioxide monocrystal granule with the granule particle diameter controlled within the range of 20 to 80 nanometers are prepared by the hydrothermal function of manganese metal, manganese acetate and ammonia and the subsequent calcination control, and the uniformly distributed mesoporous, the mixture of oxyhydrogen manganese oxide and manganic manganous oxide, the mangano-manganic octoxide monocrystal granule and the manganese sesquioxide monocrystal granule play a catalytic action to a toluene combustion reaction. The invention has simple preparation method, loose synthesizing condition, easy repetition and cheap raw materials and can carry out large-scale production.

Owner:HEBEI UNIV OF TECH

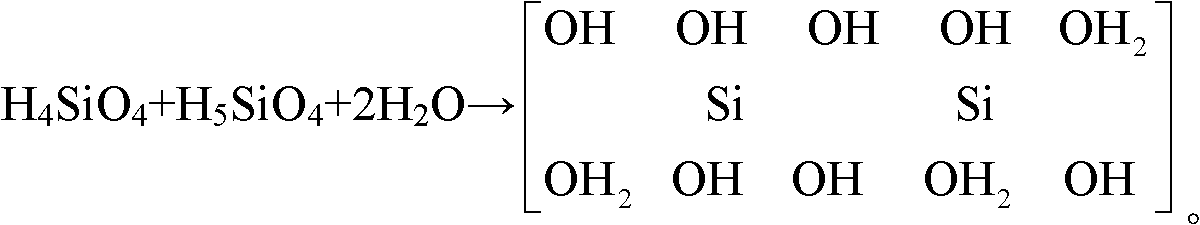

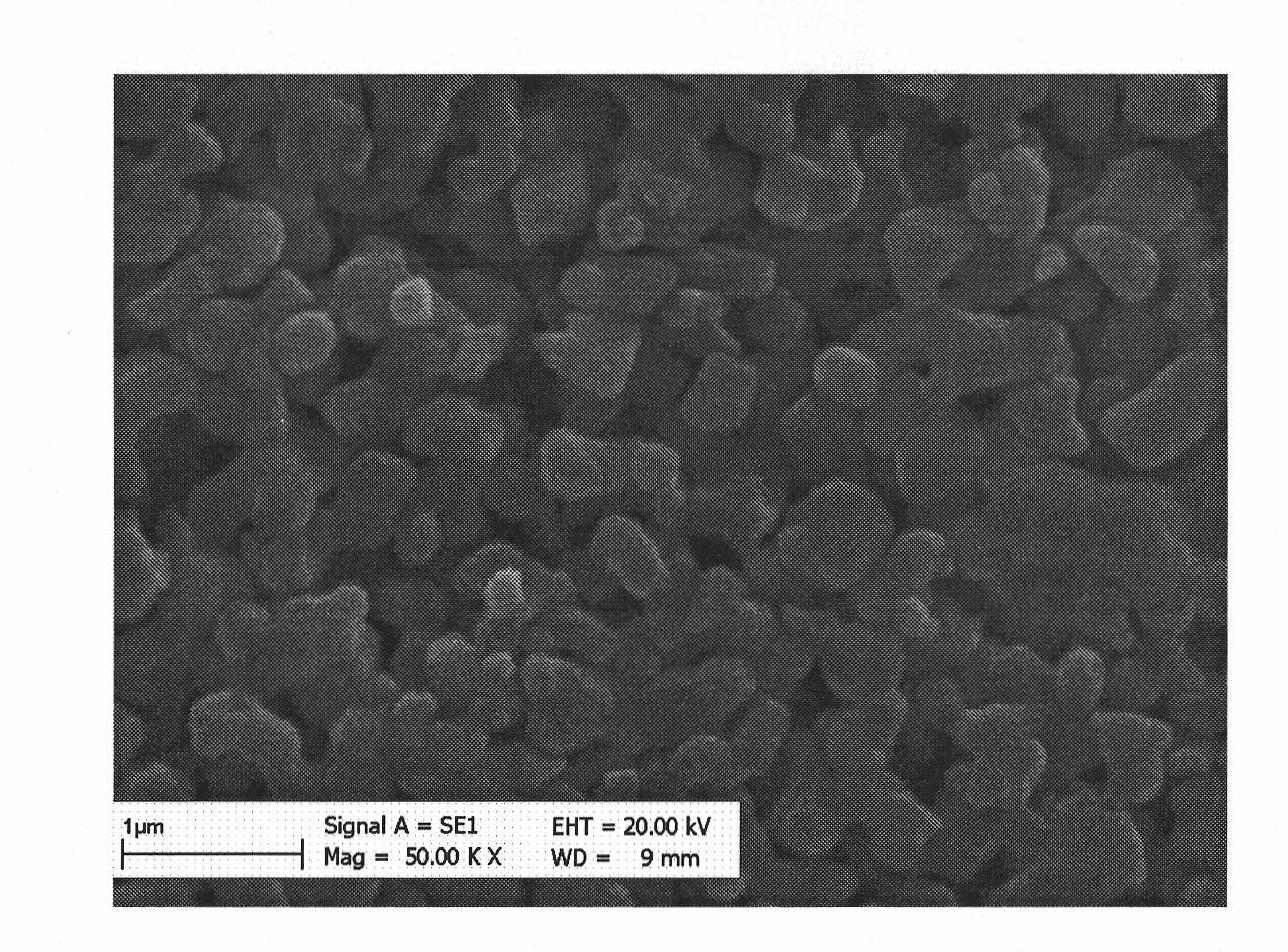

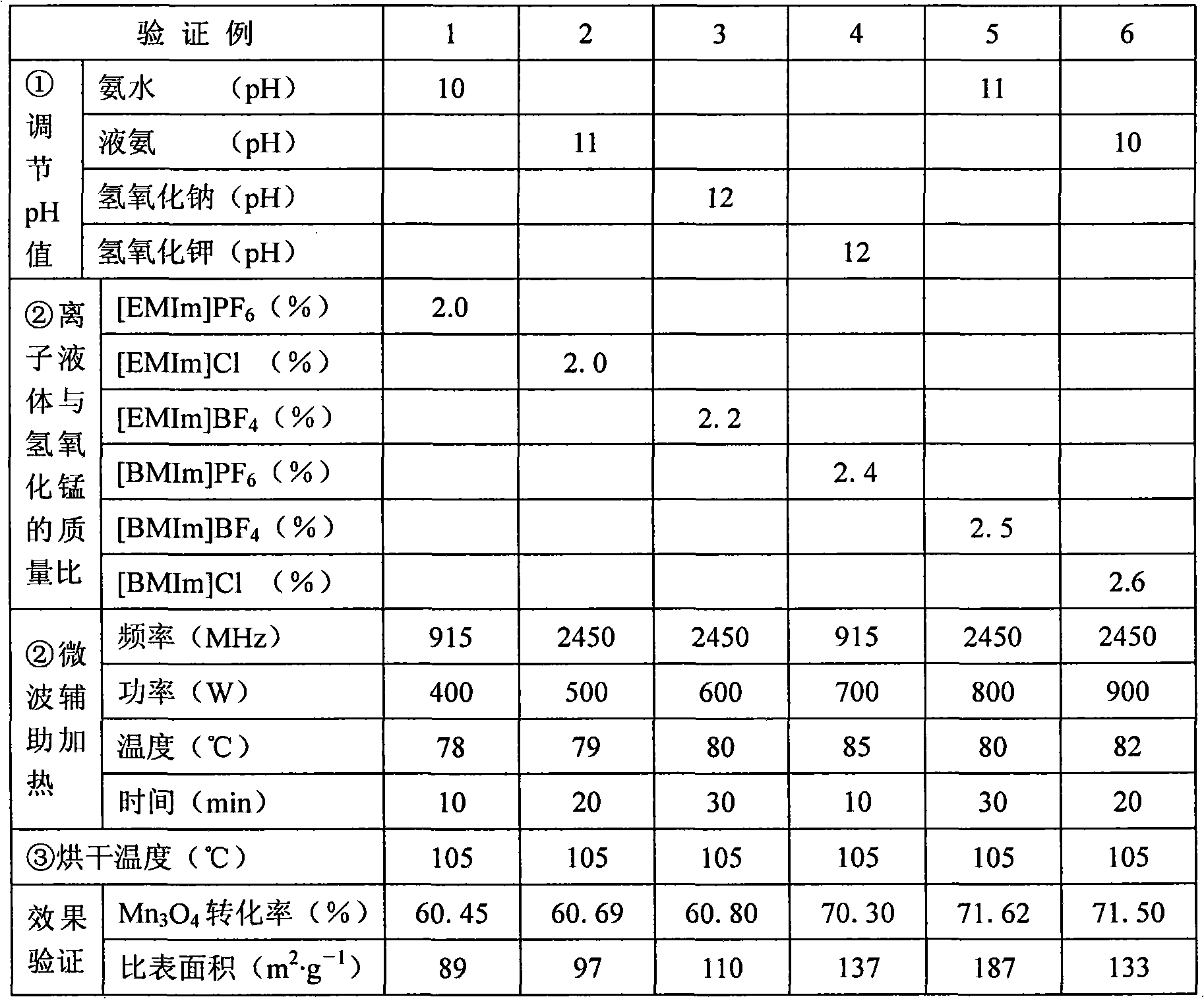

Method for preparing trimanganese tetroxide by using manganese sulfate solution

InactiveCN101948138AImprove conversion rateSimple processManganese oxides/hydroxidesSulfatePhysical chemistry

The invention discloses a method for preparing trimanganese tetroxide by using manganese sulfate solution. The method comprises the following steps of: regulating the pH value of the manganese sulfate solution by using an alkali substance to convert the manganese sulfate solution into manganese hydrate solution; and adding ion liquid into the solution, performing microwave auxiliary heating in a state of exposing in the air, oxidizing manganese hydrate into the trimanganese tetroxide, and filtering, washing and drying the trimanganese tetroxide to obtain brown red trimanganese tetroxide solid. The method has the advantages of high conversion rate (the lowest conversion rate is not less than 60.45 percent) of the trimanganese tetroxide and large specific surface area (the largest specific surface area can reach 187m<2> / g). The invention also has the advantages of low production cost, easy operation and convenience for realizing industrialized production.

Owner:CHONGQING UNIV

Synthesis of series nanometer lithium and manganese oxide for lithium ion battery

InactiveCN1817800AThe synthesis method is simpleEasy to operate and controlCell electrodesManganese oxides/hydroxidesLithium hydroxideSodium-ion battery

Synthesis of series nanometer lithium manganese oxide for lithium ion battery is carried out by taking mangano-manganic oxide or basic manganese oxide as precursor, hydrothermal reacting with excessive lithium hydrate in water or alcohol solution of autoclave, inserting lithium ion into lattice of manganese oxide, separating, washing and drying to obtain final product. It is simple and safe, has lower energy consumption, uniform granularity, better electrical performance and no environmental pollution.

Owner:HEFEI UNIV OF TECH

Preparation method of manganous-manganic oxide/graphene composite material

InactiveCN104022262AWide variety of sourcesLow priceCell electrodesSecondary cellsHydrazine compoundFiltration

The invention discloses a preparation method of a manganous-manganic oxide / graphene composite material. The preparation method comprises the following steps: mixing oxidized graphene, manganese sulfate and water together at room temperature, and stirring for 1-10 hours; adding potassium permanganate and continuing stirring for 1-10 hours; dropwise adding 30wt% of hydrogen peroxide, applying ultrasound for 1-10 hours; finally, dropwise adding hydrazine hydrate, and increasing the temperature to the range of 50-150 DEG C for reacting for 10-30 hours; carrying out suction filtration after the reaction is finished, washing the material filtered out with water and drying to obtain the manganous-manganic oxide / graphene composite material; the obtained manganous-manganic oxide / graphene composite material has the characteristics such as high capacity, good electrical conductivity, high cycling stability and good large current discharge performance, and thus being widely applied to the fields of high-performance lithium-ion batteries and the like as a lithium-ion battery anode material.

Owner:ZHEJIANG UNIV OF TECH

Reduction oxidation graphene-trimanganese tetraoxide three-dimensional composite material preparation method

ActiveCN106848233AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsMaterials preparationFreeze-drying

The invention discloses a reduction oxidation graphene-trimanganese tetraoxide three-dimensional composite material preparation method, which comprises: mixing a graphene oxide dispersion liquid and a single or mixed metal salt solution, completely mixing the obtained mixture and an amine substance, placing in a high temperature reaction kettle, carrying out a complete reaction at a certain temperature, soaking, and carrying out freeze drying treatment to directly prepare the graphene-metal oxide three-dimensional composite material having a self-supporting structure. According to the present invention, the reduction oxidation graphene-trimanganese tetraoxide three-dimensional composite material prepared through the preparation method can be directly used as the lithium ion battery positive electrode without the additional addition of the electric conduction agent and the binder, and has excellent cycle stability and excellent rate performance.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as preparation method and application thereof

InactiveCN108520944AImprove stabilityImprove conductivityCell electrodesSecondary cellsMANGANESE ACETATEManganous-manganic oxide

The invention belongs to the field of materials for lithium ion batteries, and discloses a nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as a preparation method andapplication thereof. The preparation method comprises the steps of dissolving manganese acetate and ammonium bicarbonate into ethylene glycol, carrying out solvent heat treatment at the temperature of 180 to 220 DEG C, and obtaining manganese carbonate; reacting with dopamine hydrochloride, and obtaining a manganese carbonate / polydopamine composite material; then calcining under an inert atmosphere, and finally oxidizing in a muffle furnace to obtain the nitrogen-doped carbon-coated manganous-manganic oxide composite material. The preparation method provided by the invention is simple and lowin cost; the prepared nitrogen-doped carbon-coated manganous-manganic oxide composite material is stable in structure and good in electrical conductivity, and has excellent rate performance and cyclic stability when being used as a lithium ion battery cathode material.

Owner:SOUTH CHINA UNIV OF TECH

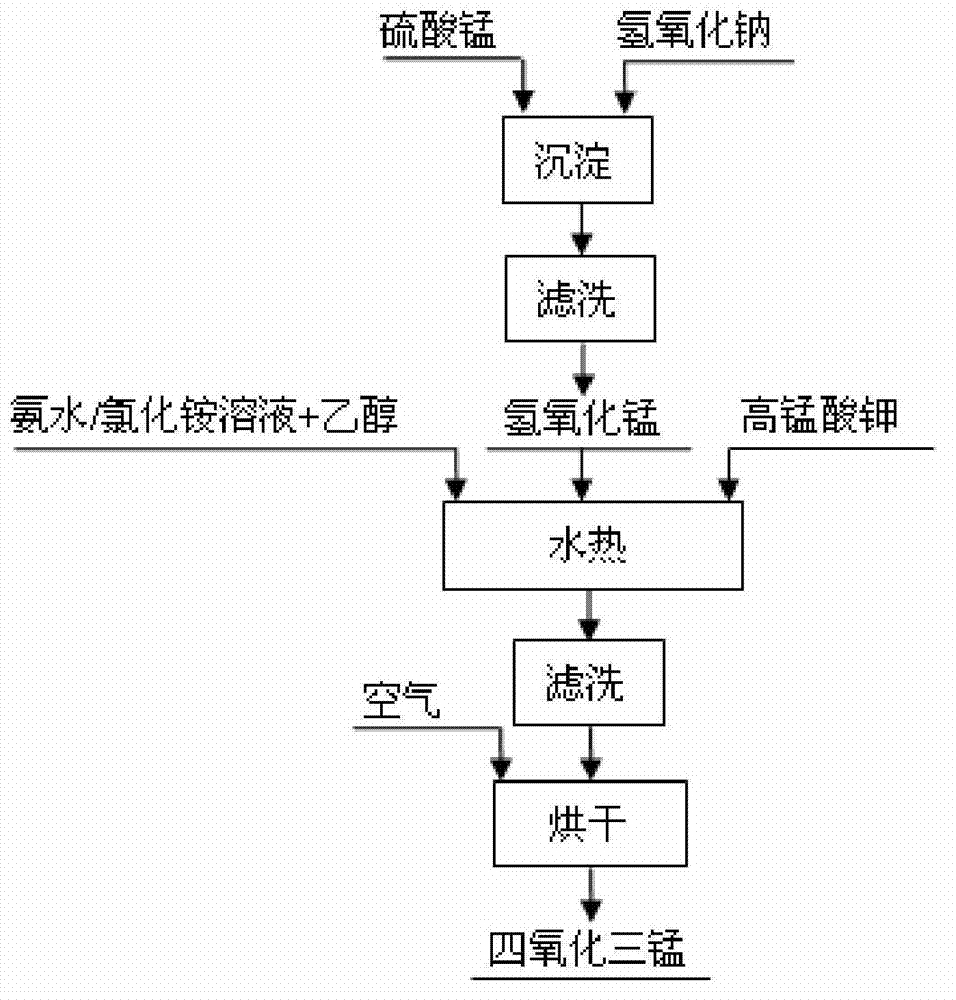

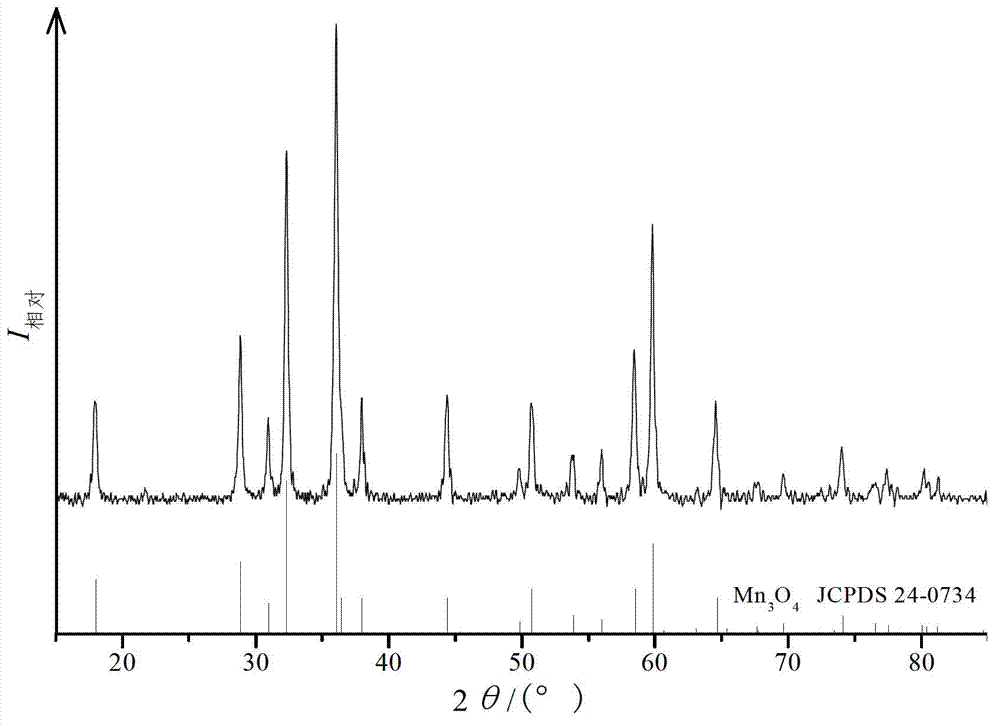

Method for preparing manganous manganic oxide

ActiveCN102786095ALow costIncrease profitManganese oxides/hydroxidesManganous-manganic oxideManganese(II,III) oxide

The invention relates to a method for preparing manganous manganic oxide, belonging to the technical field of chemical production. The technical problem to be solved by the invention is to provide a method for preparing manganous manganic oxide with low production cost. The method comprises the following steps of a, adding manganous hydroxide and potassium permanganate in solvent, mixing the mixtures, and reacting the obtained slurry at 100-200 DEG C for 2-6 h, wherein the dosage of potassium permanganate is as 10-100 percent of a theoretical dosage through which the manganous hydroxide can be oxidized as the manganous manganic oxide; the solvent is mixed solution of ammonium chloride, ammonia and ethanol; the concentration of the NH4Cl in the mixed solution is 5-50 g / L; the concentration of the NH3 H2O in the mixed solution is 5-50 g / L; and the volume concentration of the ethanol in the mixed solution is 10-90 percent; b, cooling the reactant, filtering and washing the cooled reactant with ions for several times, and then filtering and washing the reactant with ethanol; and c, drying the product which is filtered and washed by step b to obtain the manganous manganic oxide.

Owner:四川中创启源新材料科技有限公司

Method for preparing manganic manganous oxide

The invention relates to a preparation method of mangano-manganic oxide, belonging to the technical field of inorganic non-metallic material, wherein the purified manganese ore extract, manganese sulfate solution, is used as raw material; carbonate (bicarbonate) is used as precipitating agent; the manganese ion in the manganese sulfate solution is precipitated into manganese carbonate sediment, which is then thermal oxidized and decomposed into a manganese admixture containing manganese dioxide, manganese monoxide and manganese carbonate with air or oxygen at a temperature of 120 DEG C to 800 DEG C, and then calcined into mangano-manganic oxide at a temperature of 800 DEG C to 1200 DEG C. The invention has the advantages that the dust cloud of manganese admixture is practically avoided during the process of preparation; the recovery rate of manganese is high; the obtained mangano-manganic oxide has dramatic activity and the cost is low.

Owner:李宏亮

Method for preparing nano trimanganese tetroxide

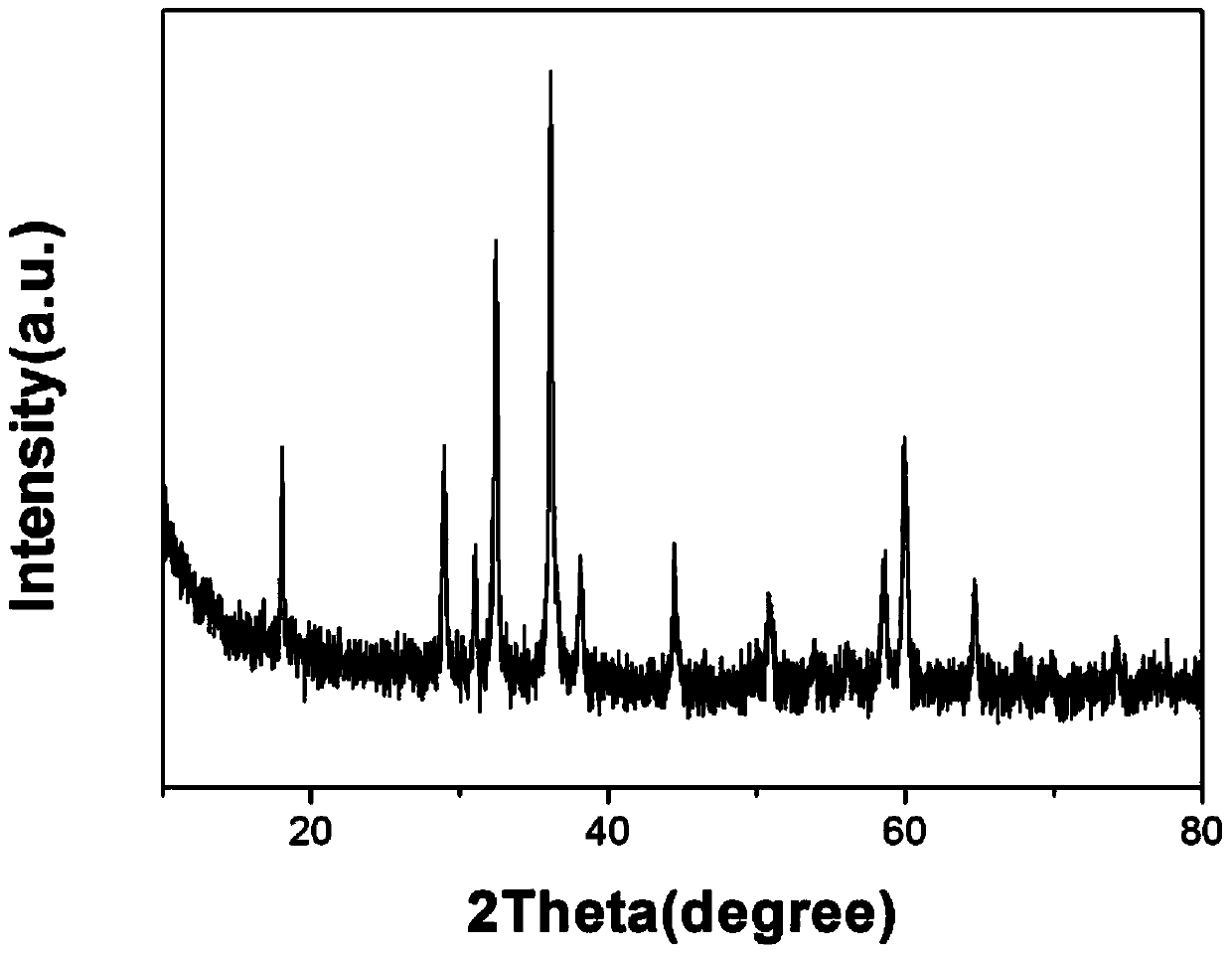

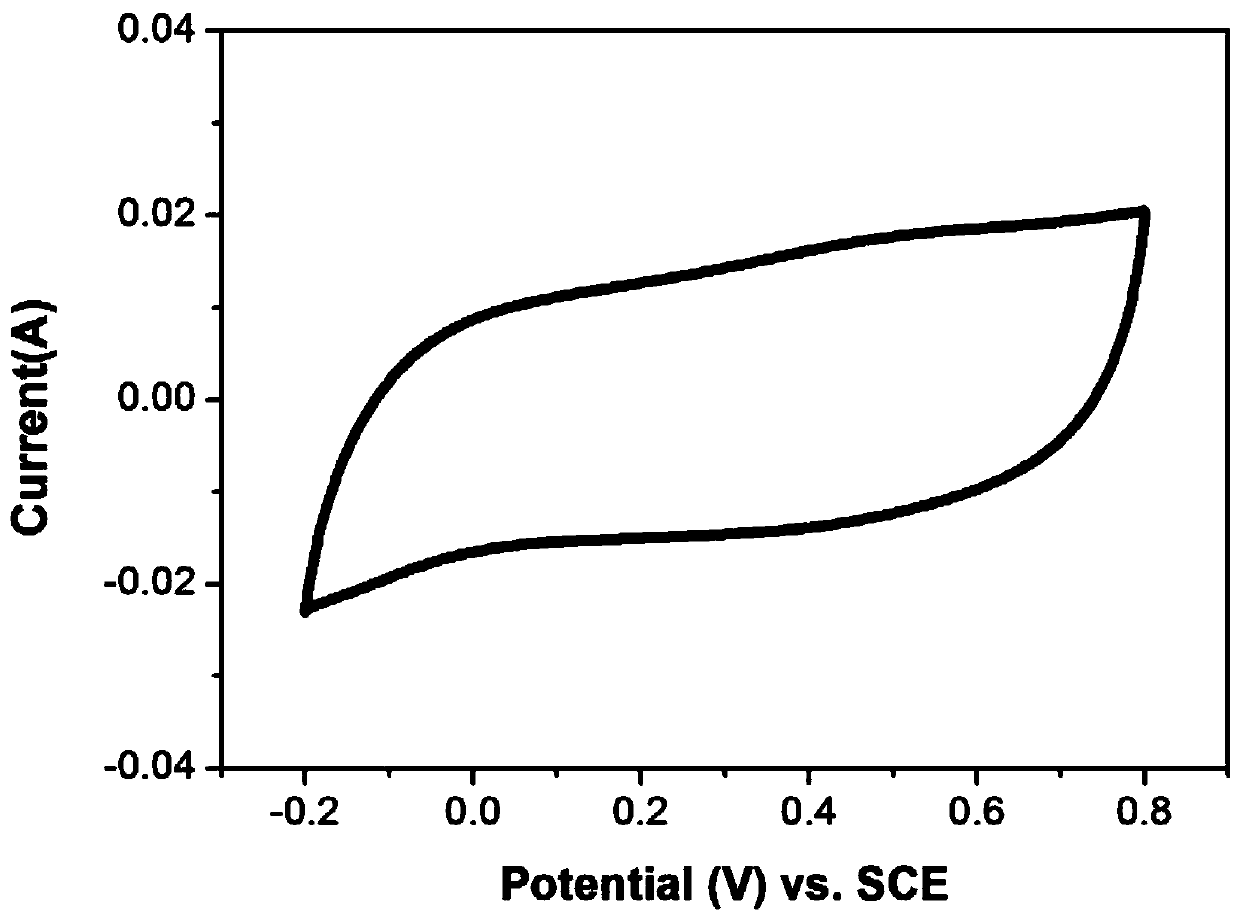

InactiveCN103991910ATake advantage ofGood capacitance characteristicsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceBanana peel

The invention discloses a method for preparing nano trimanganese tetroxide. The method is characterized by comprising the steps of by selecting waste banana peels as a raw material, drying in air, cutting into small pieces, heating with water, extracting active ingredients, reacting with potassium permanganate, filtering, and drying to obtain the nano trimanganese tetroxide which has the particle size of 10-80 nanometers, has good capacitance property and high energy storage property and serves as an electrode material for supercapacitors. Compared with the prior art, the method has the advantages that the preparation process is simple, low in cost, environmental friendly and rich in resource, and the product has the application advantage and has good economic, social and ecological benefits.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Manganese oxide catalyst used for toluene liquid phase catalytic oxidation, its preparation method and application

InactiveCN1824383AHigh activityGood choiceOrganic compound preparationCarboxylic compound preparationBenzoic acidBenzaldehyde

The present invention relates to a manganic oxide catalyst for toluene liquid-phase catalytic oxidation to prepare benzoic acid and benzaldehyde, its preparation method and application. The described manganic oxide can be manganese dioxide, manganese sesquioxide, trimanganese tetraoxide and manganese monoxide and other mixed valence manganic oxide, and said catalyst can be prepared by means of thermolysis method, hydropyrolysis process or precipitation process. Said catalyst has higher activity, selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

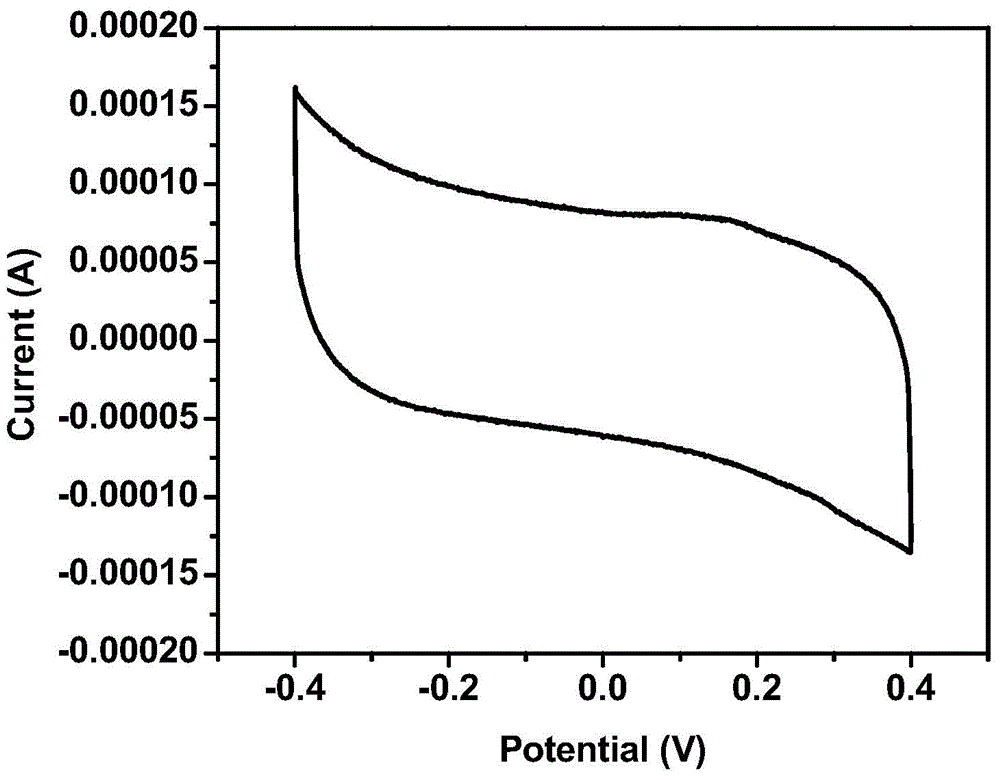

Preparation method of manganic manganous oxide/ carbon matrix composite nanoelectrode material

InactiveCN104882299AMake up for the disadvantage of low specific capacitanceImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCarbon compositesMANGANESE ACETATE

The invention discloses a preparation method of a manganic manganous oxide / carbon matrix composite nanoelectrode material. The method comprises the following steps: preparing a spinning solution by taking polyacrylonitrile (PAN) as a precursor, taking manganese acetate as an additive, and taking N,N-dimethyl formamide as a solvent; preparing a Mn / PAN composite nanofiber via an electrostatic spinning method; and performing drying, pre-oxidation and carbonization of the obtained fiber to obtain the manganic manganous oxide / carbon composite nanofiber material. The method has advantages of simple process, high spinning controllability, and easy adjustable structure of the fiber, and the prepared manganic manganous oxide / carbon composite nanofiber material can be directly used as an electrode material of a super capacitor without adding a conductive agent or a binding agent. The obtained composite electrode is high in utilization ratio of an active material and mechanical strength, and relatively stable in chemical property, and is an ideal material for preparing the super capacitor.

Owner:YANGZHOU UNIV

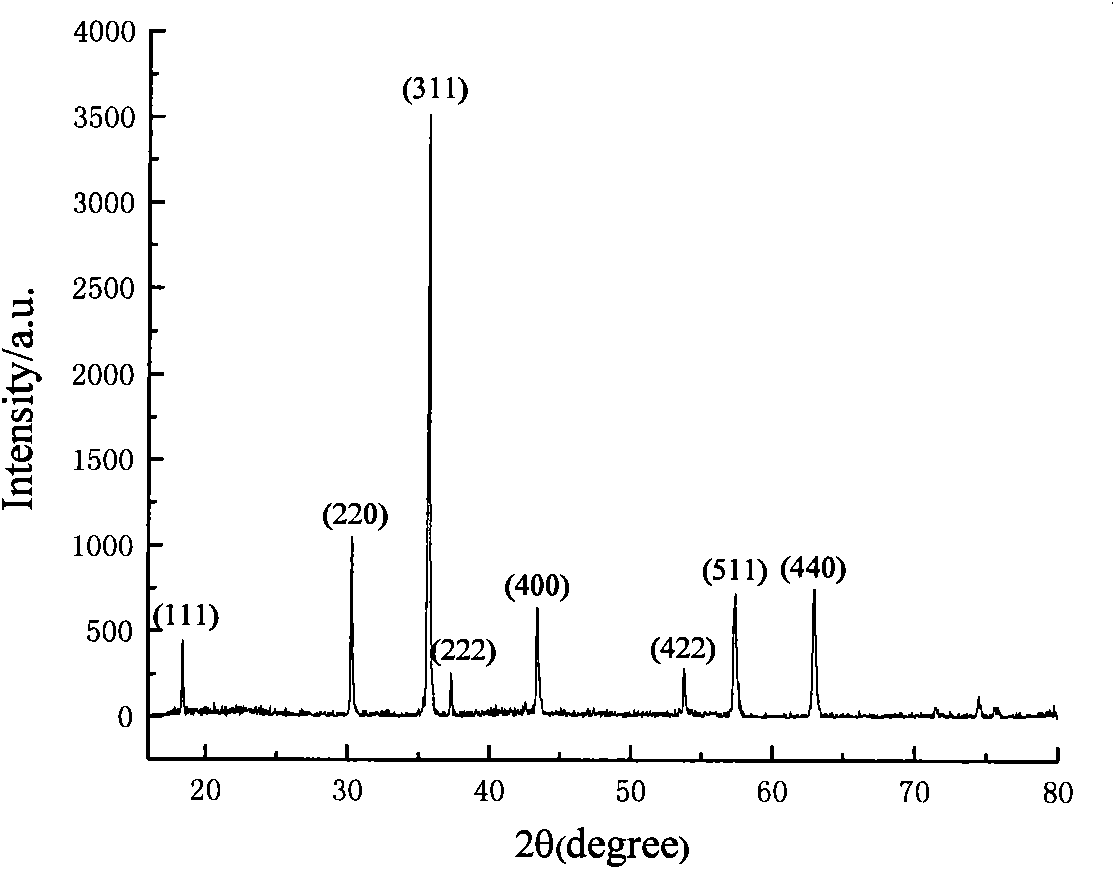

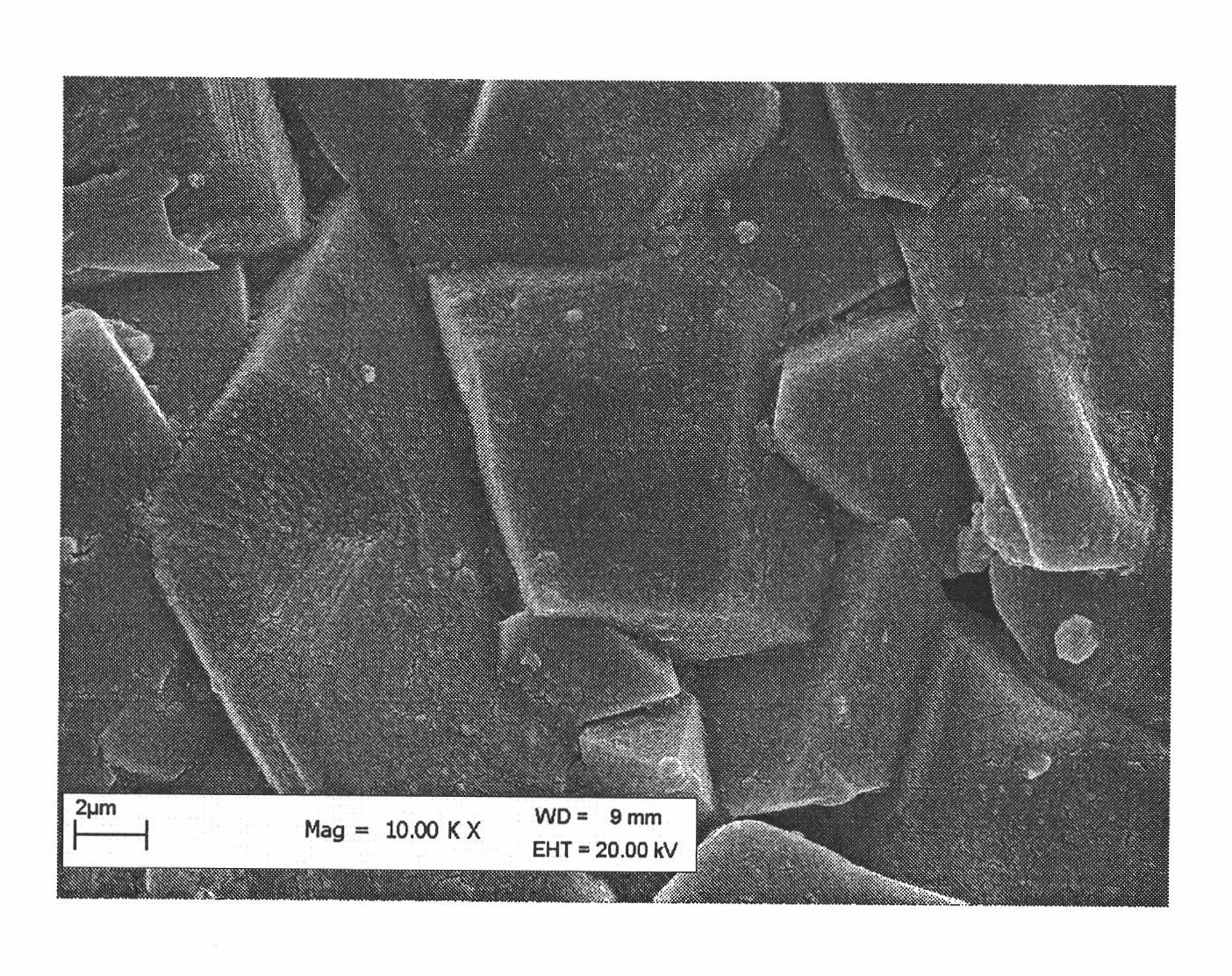

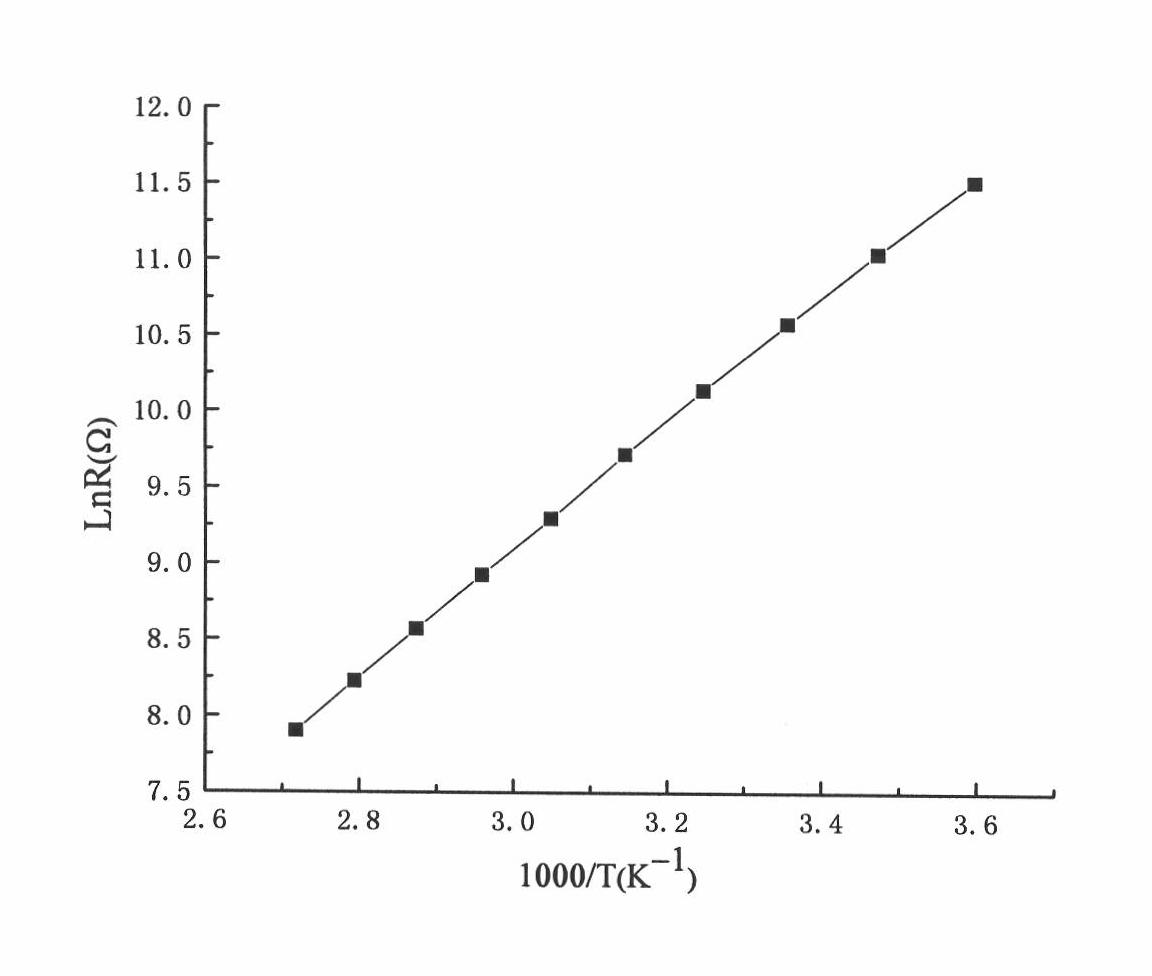

Preparation method of laminated chip negative temperature coefficient thermistor

InactiveCN102270531AHigh precisionNegative temperature coefficient thermistorsNegative temperatureCobalt(II,III) oxide

The invention relates to a laminated chip type negative temperature coefficient thermistor and a preparation method thereof. The thermistor uses trimanganese tetroxide, tricobalt tetroxide, nickel trioxide and silicon dioxide as raw materials, and the raw material powder is mechanically The negative temperature coefficient thermal fine powder is synthesized by ball milling method, and then the laminated chip negative temperature coefficient thermistor can be obtained by tape casting (ribbon casting), sintering and coating metal electrode technology, and the obtained laminated negative temperature coefficient thermistor The temperature coefficient thermistor is small in size and high in precision. Its material constant B value is 4030-4105, and the allowable deviation of B value is ±1%. KΩ.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com