Method for preparing trimanganese tetroxide by using manganese sulfate solution

A technology of trimanganese tetraoxide and manganese sulfate solution, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of small specific surface area, uneasy control of reaction conditions, low conversion rate of trimanganese tetraoxide, etc., and achieve large specific surface area, The effect of low production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

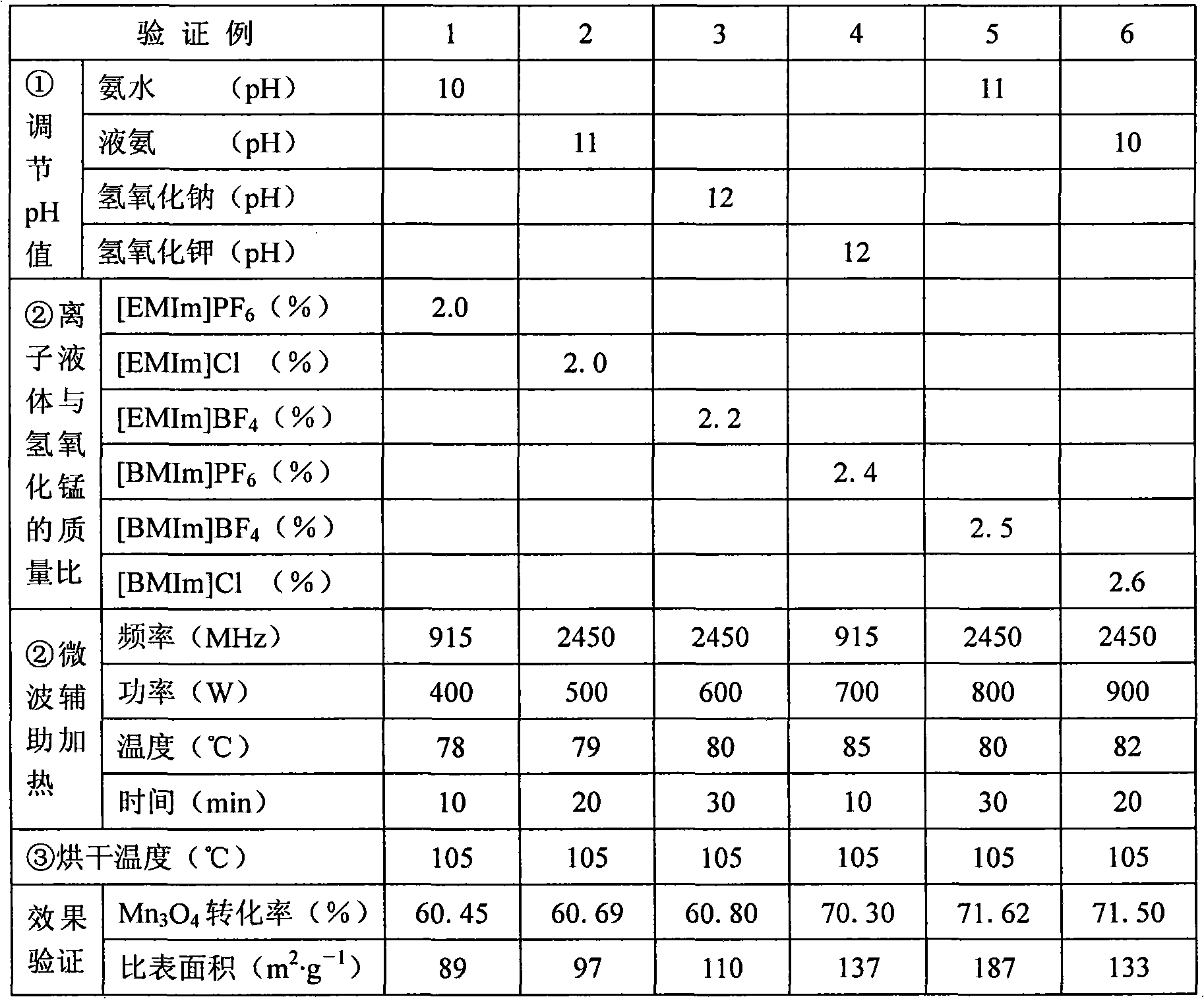

[0015] A method for preparing trimanganese tetraoxide with manganese sulfate solution, the steps are as follows:

[0016] ① Add alkaline substances to the manganese sulfate solution to adjust the pH value to convert the manganese sulfate solution into manganese hydroxide solution; specifically: select pure manganese sulfate solution, use ammonia water, liquid ammonia, sodium hydroxide and hydroxide One of the potassium, adjust its pH value to between 10 and 12. Obviously, the specific pH value should be such that the Mn in the original manganese sulfate solution 2+ All precipitated as manganese hydroxide [Mn(OH) 2 ] is the degree. Usually, the manganese hydroxide obtained by precipitation with these alkaline substances is relatively stable and has high purity, which is also helpful to increase the yield.

[0017] 2. the manganese hydroxide in step 1. gained solution is oxidized trimanganese tetraoxide;

[0018] ③ filter, wash with distilled water, and dry the sample at 105°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com