Method for preparing carbon-coated manganese-doped lithium titanate negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of capacity attenuation, reduce reversible specific capacity, and reduce cycle stability, etc. The effect of excellent electrochemical characteristics and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

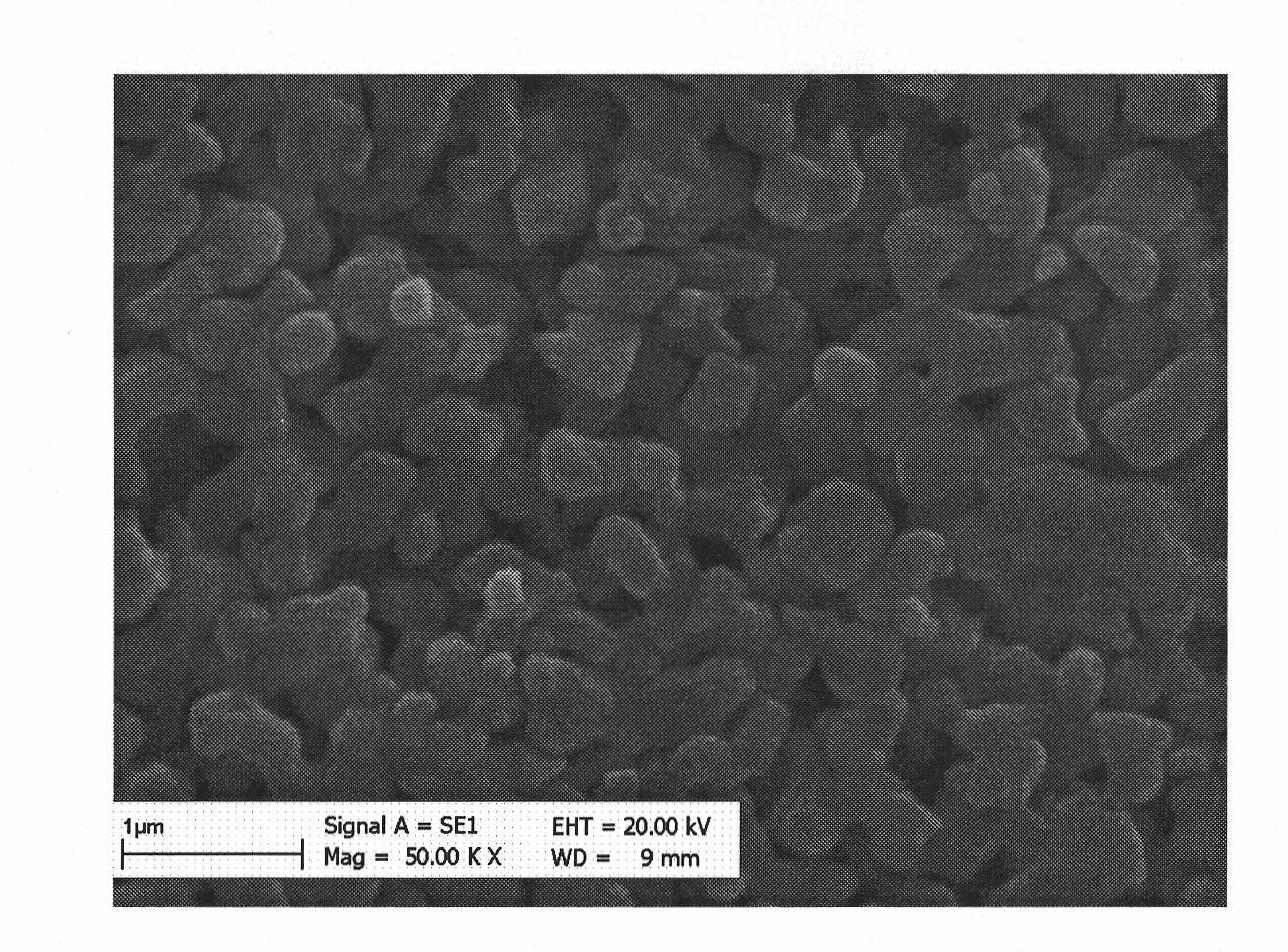

Image

Examples

Embodiment 1

[0031] a. Weigh lithium carbonate, manganese dioxide, titanium dioxide (anatase structure) and sucrose with a molar ratio of 3.9:0.1:5:31 and mix them, place the mixture in a ball mill with agate balls, and use analytical pure absolute ethanol As a dispersant, the rotation speed is 250r / min, the ball milling time is 2 hours, take out and dry;

[0032] b. fully grind the ball mill powder in step a, put it in an atmosphere furnace, heat up at a heating rate of 5°C / min, and have a purity of 99.99% in a nitrogen atmosphere, and roast at a temperature of 750°C for 16 hours;

[0033] c. Naturally cool down to room temperature to obtain a carbon-coated manganese-doped lithium titanate composite material.

Embodiment 2

[0035] a. Weigh lithium hydroxide, trimanganese tetraoxide, titanium dioxide (anatase structure) and glucose with a molar ratio of 3.8:0.2:5 and mix them, place the mixture in a ball mill, and use analytical pure ethanol as a dispersant , rotating speed 300r / min, ball milling time 6 hours, take out and dry;

[0036]b. fully grind the ball mill powder in step a, place it in an atmosphere furnace, heat up at a heating rate of 6°C / min, and roast it at a temperature of 800°C for 20 hours in an argon atmosphere with a purity of 99.99%;

[0037] c. Naturally cool down to room temperature to obtain a carbon-coated manganese-doped lithium titanate composite material.

Embodiment 3

[0039] a. Weigh lithium acetate, manganese dioxide, titanium dioxide (anatase structure) and sucrose with a molar ratio of 3.82:0.18:5:31 and mix them, place the mixture in a ball mill with zircon balls, use analytical pure anhydrous Ethanol is used as dispersant, rotating speed is 350r / min, ball milling time is 7 hours, take out and dry;

[0040] b. fully grind the ball mill powder in step a, put it in an atmosphere furnace, heat up at a heating rate of 8°C / min, and roast it at a temperature of 850°C for 24 hours in a nitrogen atmosphere with a purity of 99.99%;

[0041] c. Naturally cool down to room temperature to obtain a carbon-coated manganese-doped lithium titanate composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diffusion coefficient | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com