High-proportion manganous-manganic oxide and preparation method thereof

A technology of manganese tetroxide and high specific gravity, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of difficult to increase tap density, low process cost, long oxidation time, etc., and achieve high product specific gravity, low process cost, The effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

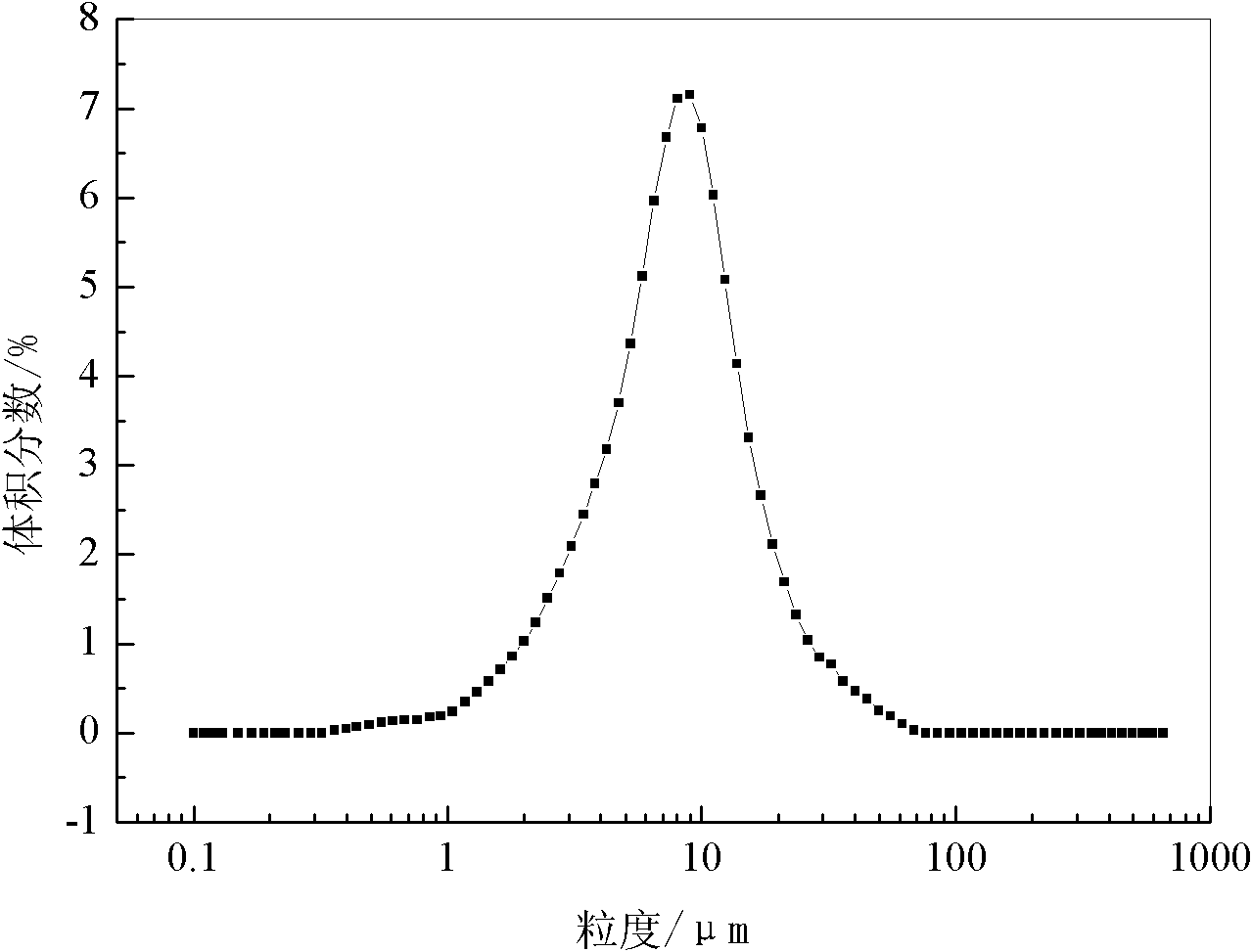

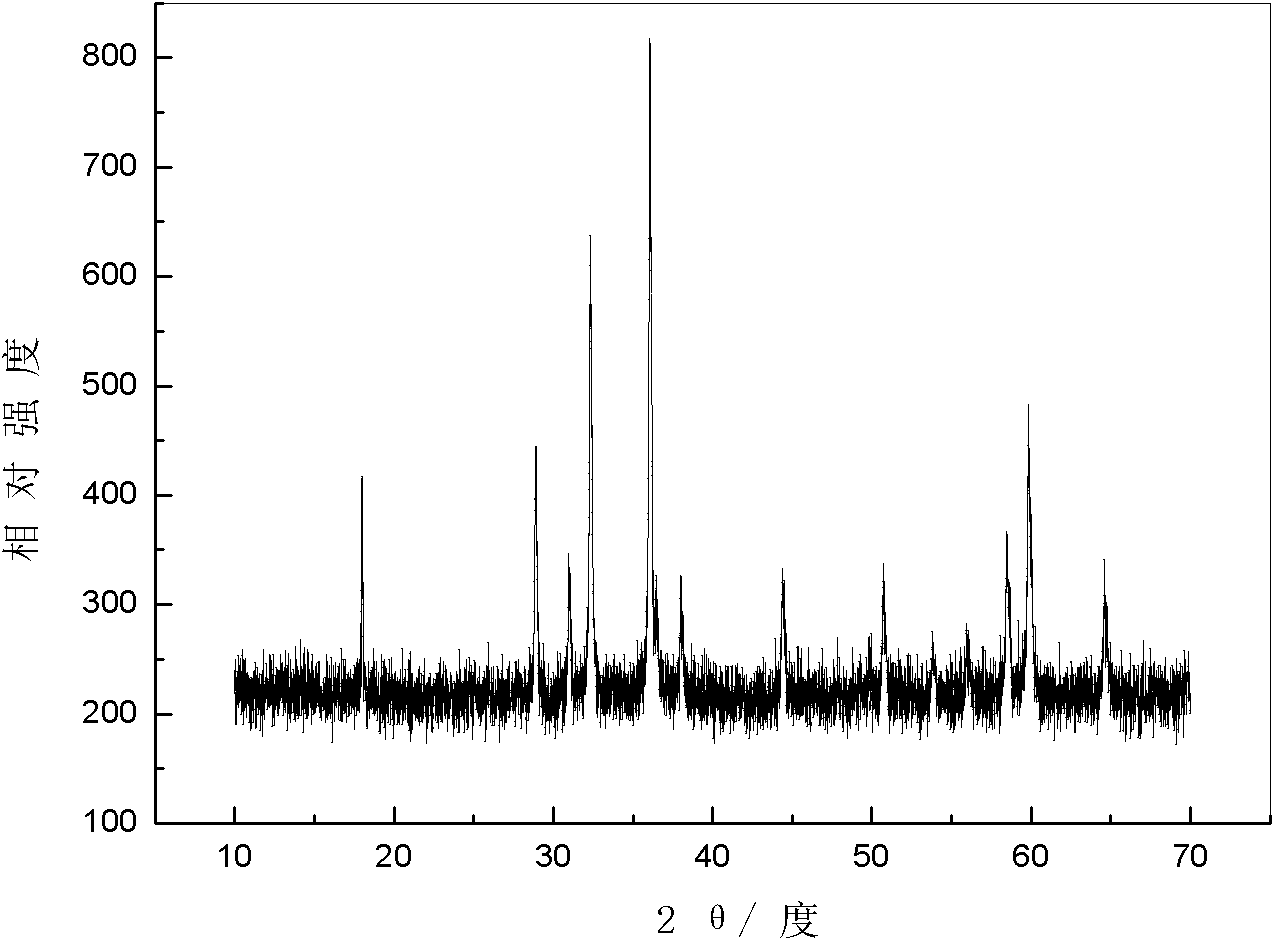

[0025] a kind of like Figure 1 ~ Figure 2 The high specific gravity trimanganese tetraoxide of the present invention shown, the tap density of this high specific gravity trimanganese tetraoxide is 2.25g / cm 3 , the specific surface area is 1.9419m 2 / g, the median particle size is 8.42 μm.

[0026] The high specific gravity trimanganese tetraoxide of the present embodiment is prepared by the following method:

[0027] First, prepare the Mn 2+ Concentration is the manganese sulfate solution of 60g / L, 50g / L, add 5L Mn 2+ Air is directly passed through the manganese sulfate solution with an initial concentration of 60g / L for oxidation, the oxidation temperature is controlled at 55°C, the air flow rate is controlled at 900L / h-1200L / h, the initial pH value is 6.5, and the stirring intensity is 75r / min; With the Mn in the reaction system 2+ Slowly decrease the concentration, then slowly add Mn 2+ Manganese sulfate solution with a concentration of 50g / L, and slowly add ammonia ...

Embodiment 2

[0030] a kind of like Figure 3 ~ Figure 4 The high specific gravity trimanganese tetraoxide of the present invention shown, the tap density of this high specific gravity trimanganese tetraoxide is 2.10g / cm 3 , the specific surface area is 2.3276m 2 / g, the median particle size is 7.21 μm.

[0031] The high specific gravity trimanganese tetraoxide of the present embodiment is prepared by the following method:

[0032] First, the preparation of Mn 2+ Concentration is the manganese sulfate solution of 50g / L, to 5L, Mn 2+ Air is directly passed through the manganese sulfate solution with an initial concentration of 50g / L for oxidation, the oxidation temperature is controlled at 70°C, the air flow rate is controlled at 800L / h-1000L / h, the initial pH value is 6.0, and the stirring intensity is 85r / min; With the Mn in the reaction system 2+ Slowly decrease the concentration, then slowly add ammonia water dropwise, so that the pH value of the reaction system increases slowly, and ...

Embodiment 3

[0035] a kind of like Figure 5 ~ Figure 6 The high specific gravity trimanganese tetroxide of the present invention shown, the tap density of this high specific gravity trimanganese tetraoxide is 1.95g / cm 3 , the specific surface area is 2.9015m 2 / g, the median particle size is 10.72 μm.

[0036] The high specific gravity trimanganese tetraoxide of the present embodiment is prepared by the following method:

[0037] First, prepare 5L, Mn 2+ Concentration is the manganese sulfate solution of 80g / L, to Mn 2+ Air is directly passed through the manganese sulfate solution with an initial concentration of 80g / L for oxidation, the oxidation temperature is controlled at 80°C, the air flow rate is controlled at 800L / h-1000L / h, the initial pH value is 5.5, and the stirring intensity is 85r / min; With the Mn in the reaction system 2+ Slowly reduce the concentration, and then slowly add ammonia water dropwise, so that the pH value of the reaction system increases slowly, and is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com