Three-dimensional network porous heat-conducting heat radiation device and preparation method thereof

A three-dimensional network and heat dissipation device technology, which is applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of heat pipes with small heat dissipation area, large weight, and thick thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

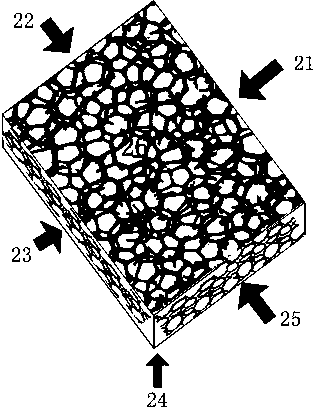

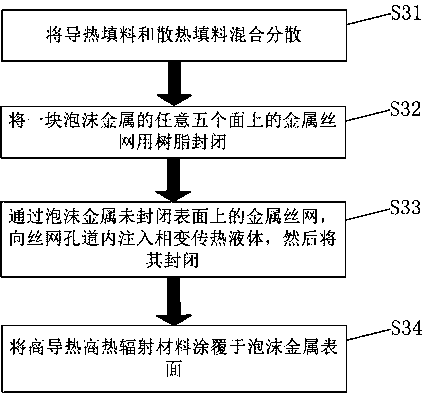

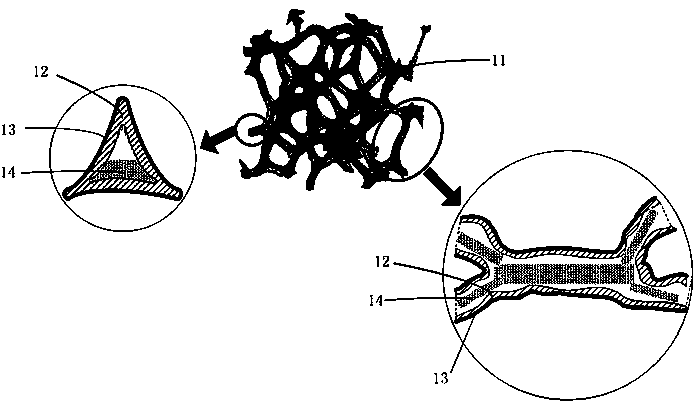

[0035] The copper foam with a thickness of 5mm and an average hole diameter of 1mm is used as the substrate, and the average cross-sectional area of the internal channels of the wire mesh constituting the foam metal is 1mm. 2 .

[0036] The thickness of the high thermal conductivity and high heat radiation material is 3 μm, and its composition is: main resin accounts for 40%, thermal conductive filler 8%, thermal radiation filler 12%, auxiliary agent 8%, diluent 32%, of which the main resin is epoxy resin, thermally conductive The filler is boron nitride, and the thermal radiation filler is mica. The average particle size of boron nitride is 1 μm, and its thermal conductivity is 125 W / m K. The average particle size of the thermal radiation filler is 0.5 μm, and its thermal radiation coefficient It is 0.91; additives include dispersant, coupling agent, defoamer, leveling agent, diluent is toluene. First add the thermally conductive filler and the thermal radiation filler int...

Embodiment 2

[0040] The foamed aluminum with a thickness of 10mm and an average pore diameter of 8mm is used as the substrate, and the surface of the foamed aluminum is covered with a copper deposition layer. 2 .

[0041] The average thickness of the material with high thermal conductivity and high heat radiation is 10 μm, and its composition is: 40% of the main resin, 10% of thermally conductive filler, 15% of thermal radiation filler, 6% of auxiliary agent, and 29% of diluent. The main resin is polyurethane, and the thermally conductive filler is Silicon nitride with an average particle size of 5 μm, expanded graphite with an average particle size of 30 μm, zirconia with an average particle size of 10 μm, silicon dioxide with an average particle size of 0.5 μm, and graphite with an average particle size of 1 μm alumina. Auxiliaries include dispersant, coupling agent, defoamer, leveling agent, diluent is ethyl acetate. First add the thermally conductive filler and the heat radiation fil...

Embodiment 3

[0045] With a foamed copper-nickel alloy with a thickness of 45mm and an average pore diameter of 10mm as the substrate, the average cross-sectional area of the internal pores of the wire mesh constituting the foam metal is 6mm 2 .

[0046] The average thickness of the high thermal conductivity and high heat radiation material is 100 μm, and its composition is: main resin accounts for 35%, thermal conductive filler 10%, thermal radiation filler 10%, auxiliary agent 12%, diluent 33%, of which the main resin is acrylic resin, thermal conductive filler It is aluminum nitride with an average particle size of 0.5 μm, graphene with an average particle size of 0.01 μm, and the heat radiation filler is manganese dioxide with an average particle size of 10 μm, iron oxide, copper oxide and cobalt oxide with an average particle size of 5 μm . Auxiliaries include dispersant, coupling agent, defoamer, leveling agent, diluent is water. First add the thermally conductive filler and heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com