Aqueous zinc-ion battery positive electrode material

A technology of zinc ion battery and positive electrode material, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., to achieve good electrical conductivity, improve electrical conductivity, and improve electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1mmol KMnO 4 Add in 40ml of distilled water, stir at room temperature to obtain a dark purple solution, then transfer the resulting solution to an autoclave, and then add a piece of stainless steel mesh (2x3cm 2 ), water heating at 160°C for 24 hours, after cooling, the stainless steel mesh was washed several times, and then dried in an oven at 60°C. The trimanganese tetroxide material grown on the stainless steel mesh is obtained.

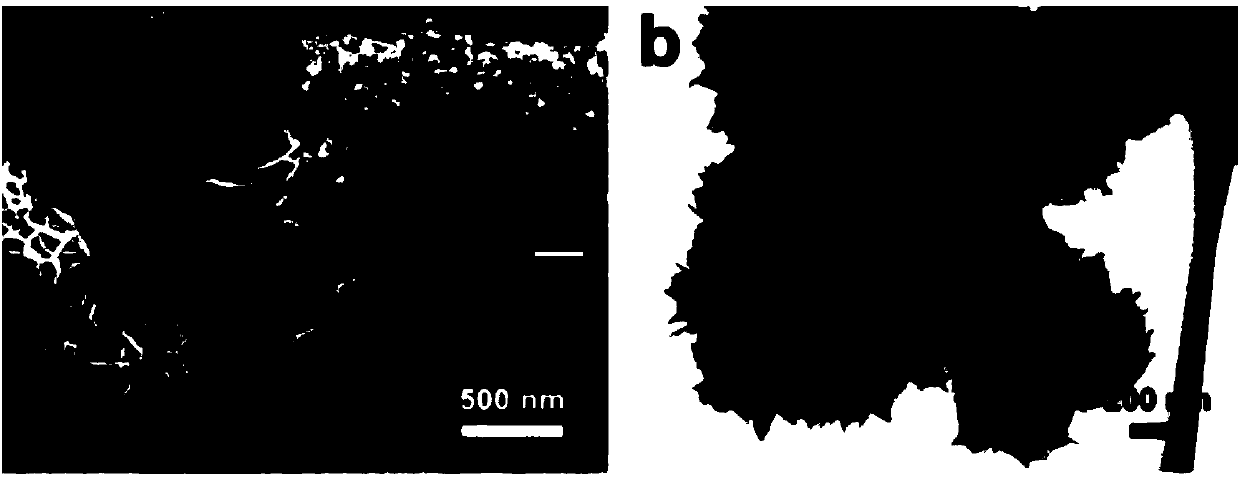

[0023] figure 1 (a) is the XRD spectrum of Example 1 of the present invention. As can be seen from the figure, except for the three peaks of stainless steel mesh, it is very good with Mn 3 o 4 correspond. figure 1 (b) Analysis studies the valence state of manganese, showing the 2p of Mn 3 / 2 and 2p 1 / 2 the peak position. figure 2 (a) is a scanning electron microscope picture of the trimanganese tetroxide material grown on the stainless steel net prepared in Example 1. It can be seen that it has uniform and closely arranged nano-curd...

Embodiment 2

[0027] 1mmol KMnO 4 Add in 40ml of distilled water, stir at room temperature to obtain a dark purple solution, then transfer the resulting solution to an autoclave, and then add a piece of stainless steel mesh (2x3cm 2 ), water heating at 160°C for 6 hours, after cooling, the stainless steel mesh was washed several times, and then dried in an oven at 60°C. Obtain the target product. Figure 4 It is the SEM picture of the material obtained in Example 2.

Embodiment 3

[0029] 1mmol KMnO 4 Add in 40ml of distilled water, stir at room temperature to obtain a dark purple solution, then transfer the resulting solution to an autoclave, and then add a piece of stainless steel mesh (2x3cm 2 ), at 160°C for 12 hours, and after cooling, the stainless steel mesh was washed several times, and then dried in an oven at 60°C. Obtain the target product. Figure 5 It is the SEM picture of the material obtained in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com