Method for preparing trimanganese tetroxide by using rhodochrosite

A technology of trimanganese tetroxide and rhodochrosite, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of high impurity content, low quality, chemical impurity removal and incomplete purification, etc., so as to improve product quality and reduce production cost , The effect of eliminating the electrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

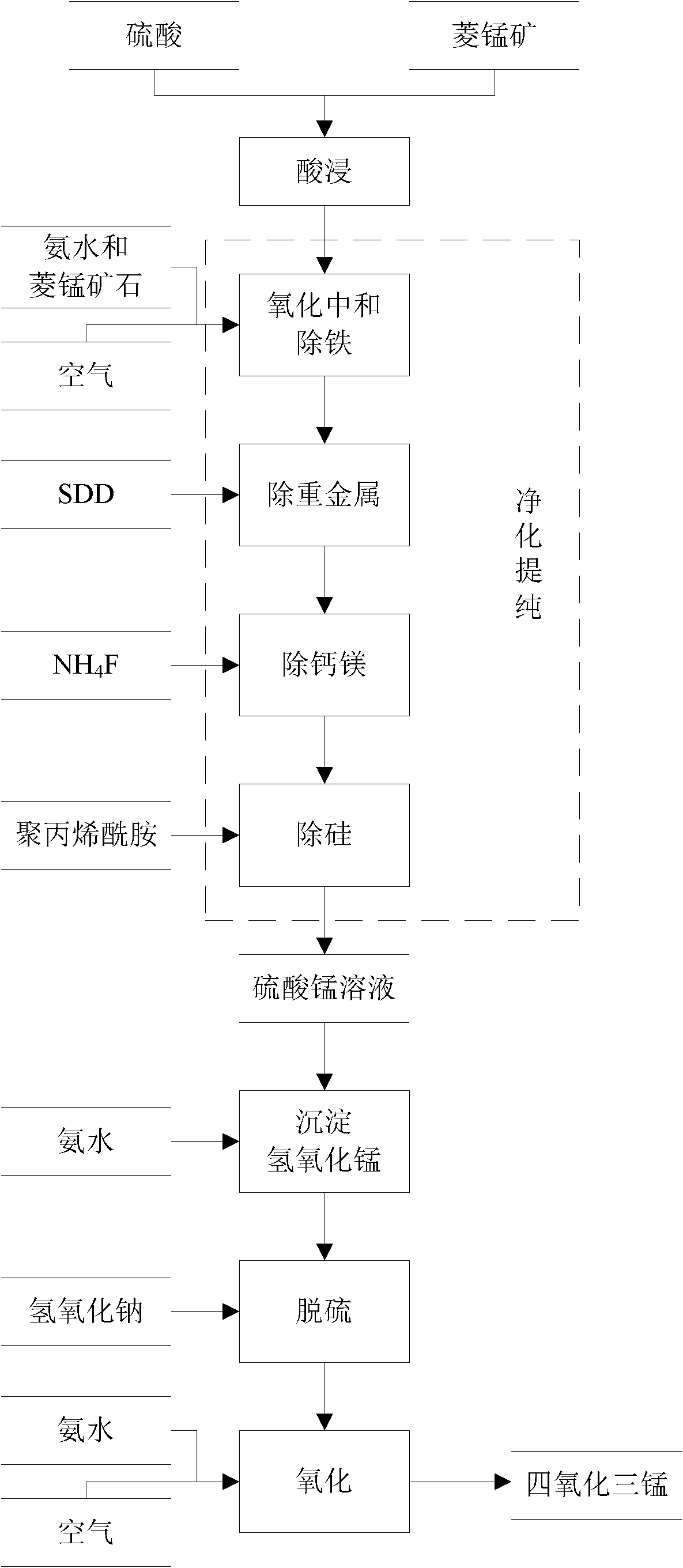

[0031] a kind of like figure 1 In the shown method for preparing trimanganese tetroxide from rhodochrosite, the manganese content of the rhodochrosite ore is 15.14%, and the grinding fineness is: -100 mesh 100%. The preparation method specifically includes the following steps.

[0032] 1. Acid leaching: select sulfuric acid solution to leach the above-mentioned rhodochrosite at normal temperature and pressure, in the acid leaching process, the mass ratio (i.e. acid ore ratio) of sulfuric acid and this rhodochrosite is 0.6: 1, and the sulfuric acid solution used and the rhodochrosite The mass ratio of manganese ore (ie liquid-solid ratio) is 4:1, the acid leaching time is 30min, and manganese sulfate solution is obtained after filtration. The leaching of rhodochrosite with sulfuric acid can be carried out at room temperature, the reaction time is short, the leaching rate of manganese can reach over 99% when leaching for 30 minutes, and the recovery rate of manganese leaching ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com