Manganese zinc ferrite material and preparation method thereof

A technology of manganese-zinc ferrite and zinc oxide is applied in the field of manganese-zinc ferrite material and its preparation, which can solve the problems of large microscopic grain size of magnetic core, disappearance of low power consumption characteristics, large eddy current loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

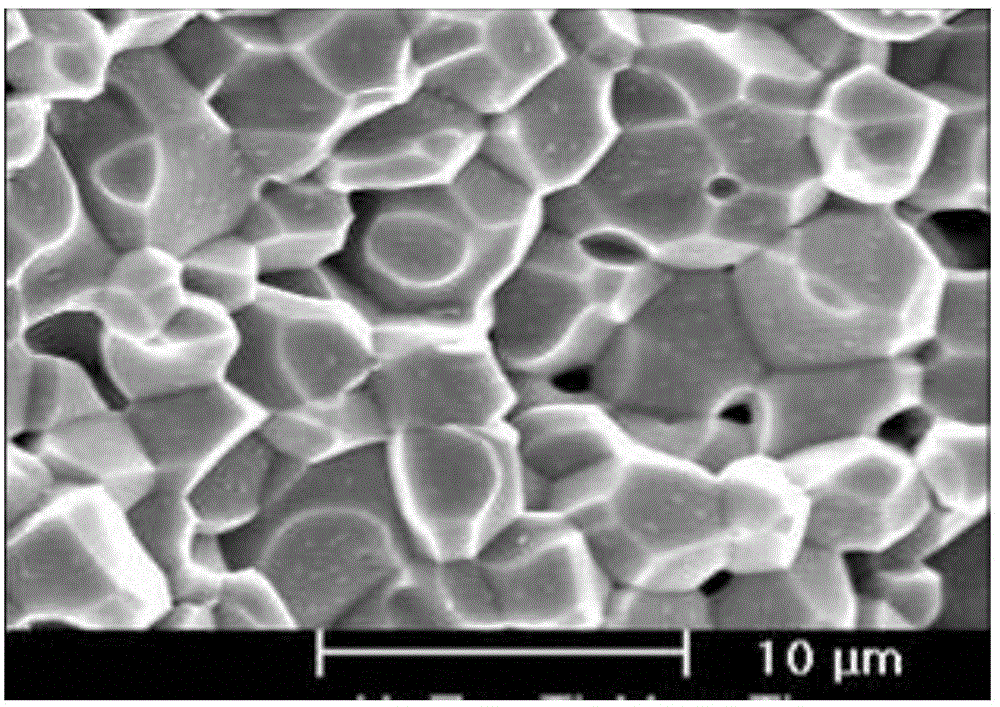

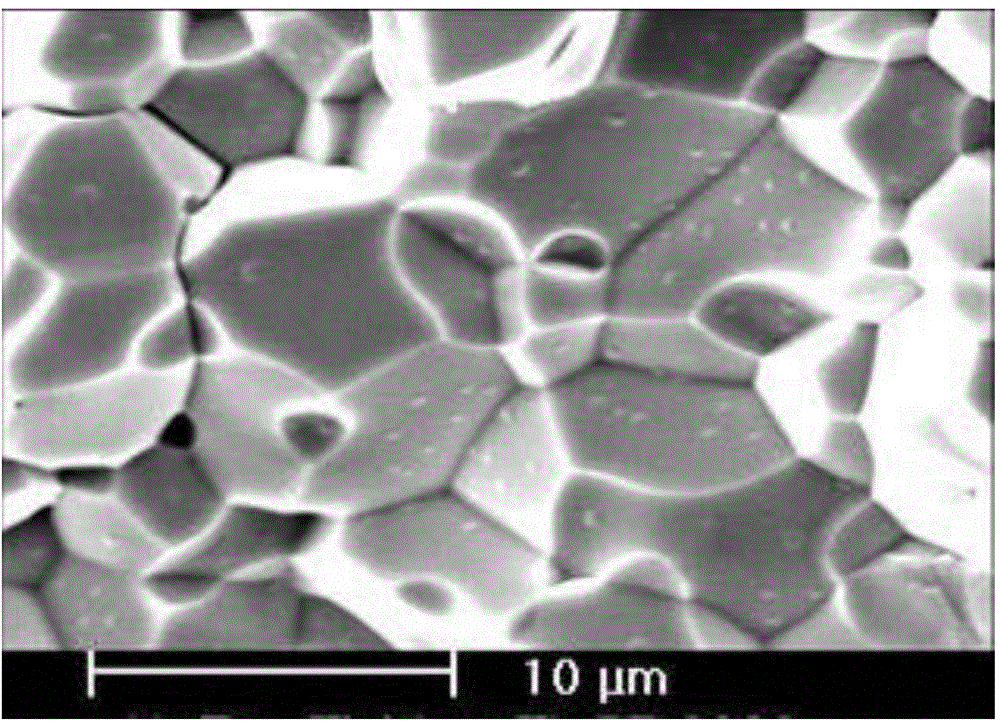

Image

Examples

preparation example Construction

[0029] The preparation method of the manganese zinc ferrite material of one embodiment, comprises the following steps:

[0030] Step S110, in molar percentage, mix 54%-56% of ferric oxide, 38%-42% of manganese tetroxide and 4%-6% of zinc oxide, and then stir slurry, sand mill, stir and add The glue is used to obtain a slurry, and the slurry is spray-dried to obtain a powder.

[0031] Preferably, the agitated pulp is mechanically agitated and paddled by a stirring tank.

[0032] Preferably, in the operation of stirring the pulp, add deionized water to stir the pulp, the mass ratio of the total amount of ferric oxide, trimanganese tetroxide and zinc oxide to deionized water is 1:0.7~0.9, the stirred The time is 60 minutes to 100 minutes.

[0033] Preferably, the sand mill is carried out with a sand mill, the mass ratio of the material to the steel ball is 1:1.25 to 1.3, the sand mill time is 40min to 90min, and the D50 average particle size of the sand milled material is 1.1 t...

Embodiment 1

[0059] 1) The raw material iron oxide Fe 2 o 3 , Trimanganese tetraoxide Mn 3 o 4 , Zinc oxide ZnO is accurately weighed according to the ratio of 54mol%, 42mol%, and 4mol%. After mixing, it is put into a stirring tank for mechanical stirring to make a slurry, and deionized water is added according to the ratio of material: deionized water = 1:0.7 (mass ratio) , the stirring time is 60min, and after the slurry is obtained, it is sanded by a steel ball double sand mill, wherein the slurry:steel ball=1:1.25 (mass ratio), and the sanding time is 50min, and a laser particle size analyzer is used to measure the particle size in the process Distribution, record D50 average particle diameter at 1.5 μm, after obtaining the micron-scale abrasive material, add the PVA (polyvinyl alcohol) solution that mass concentration is 8% while stirring in the storage tank, wherein the polyvinyl alcohol solution and the slurry The mass ratio is 0.1:1, and the stirring time is 30 minutes. After t...

Embodiment 2

[0069] 1) The raw material iron oxide Fe 2 o 3 , Trimanganese tetraoxide Mn 3 o 4 , Zinc oxide ZnO is accurately weighed according to the ratio of 55mol%, 40mol%, and 5mol%. After mixing, it is put into a stirring tank for mechanical stirring to make a slurry, and deionized water is added according to the ratio of material: deionized water = 1:0.8 (mass ratio) , the stirring time is 70min, and after the slurry is obtained, it is sanded by a steel ball double sand mill, wherein slurry: steel ball=1:1.27 (mass ratio), and the sanding time is 60min, and a laser particle size analyzer is used to measure the particle size in the process Distribution, record D50 average particle diameter at 1.3 μm, after obtaining the micron-scale abrasive material, add mass concentration while stirring in the storage tank and be 9% PVA (polyvinyl alcohol) solution, wherein the polyvinyl alcohol solution and slurry The mass ratio is 0.11:1, and the stirring time is 60 minutes. After the slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Power loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com