Preparation method of dregs remover for smelting aluminum alloy

A technology of aluminum alloy and slag agent, which is applied in the field of preparation of slag remover for aluminum alloy smelting, can solve the problems of affecting the safety of operators, poor toughness of aluminum alloy, unstable slag removal effect, etc., so as to facilitate slag removal and prevent The effect of droplet splashing and good insulation coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

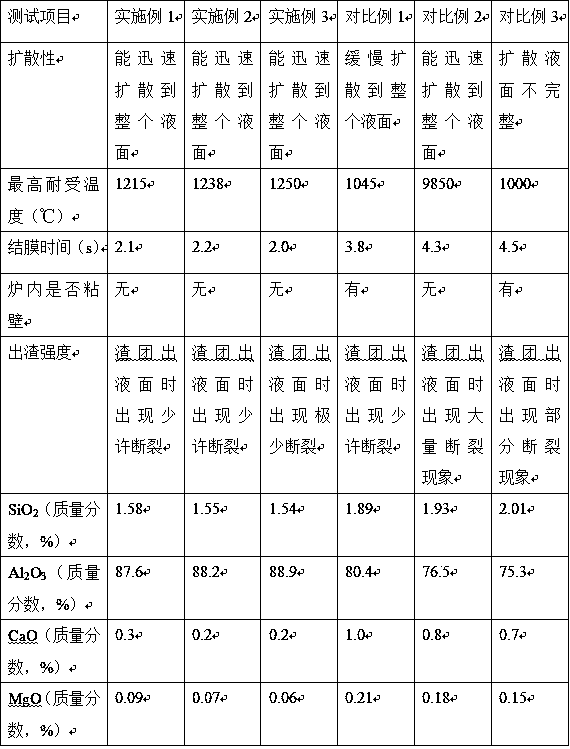

Examples

Embodiment 1

[0030] Preparation of kaolinite powder:

[0031] Take kaolinite, put it in a hydraulic crusher and break it into pieces, put the kaolinite pieces in a ball mill tank, control the mass ratio of balls to material to 15:1, ball mill with a speed of 450r / min for 6h, pass 150 mesh sieve to obtain kaolinite powder.

[0032] Preparation of amorphous kaolinite powder:

[0033] Put the kaolinite powder in a tubular resistance furnace, heat up to 150°C, and preheat for 1 hour. After the preheating is completed, program the temperature to 1150°C at a rate of 5°C / min. The ridge stone was quenched in an ice-water bath for 20 minutes to obtain amorphous kaolinite, and the amorphous kaolinite was put into a mill for grinding treatment, and passed through a 100-mesh sieve to obtain amorphous kaolinite powder.

[0034] Preparation of modified amorphous kaolinite particles:

[0035] Stir and mix the sodium silicate and the amorphous kaolinite powder obtained above for 5 minutes at a mass rat...

Embodiment 2

[0043] Preparation of kaolinite powder:

[0044] Take kaolinite, put it in a hydraulic crusher and break it into pieces, put the kaolinite pieces in a ball mill tank, control the mass ratio of balls to material to 15:1, ball mill at 470r / min for 7h, pass 150 mesh sieve to obtain kaolinite powder.

[0045] Preparation of amorphous kaolinite powder:

[0046] Put the kaolinite powder in a tube-type resistance furnace, heat up to 170°C, and preheat for 1 hour. The ridge stone was quenched in an ice-water bath for 23 minutes to obtain amorphous kaolinite, and the amorphous kaolin was put into a mill for grinding treatment, and passed through a 100-mesh sieve to obtain amorphous kaolinite powder.

[0047] Preparation of modified amorphous kaolinite particles:

[0048] Sodium silicate and the amorphous kaolinite powder obtained above were stirred and mixed for 7 minutes according to the mass ratio of 1:5 to obtain the mixed powder, which was placed in a ball mill jar, and the mass...

Embodiment 3

[0056] Preparation of kaolinite powder:

[0057] Take kaolinite, put it in a hydraulic crusher and break it into pieces, put the kaolinite pieces in a ball mill tank, control the mass ratio of ball to material to 15:1, ball mill at 500r / min for 8h, pass 150 mesh sieve to obtain kaolinite powder.

[0058] Preparation of amorphous kaolinite powder:

[0059] Put the kaolinite powder in a tube-type resistance furnace, heat up to 200°C, and preheat for 2 hours. The ridge stone was quenched in an ice-water bath for 25 minutes to obtain amorphous kaolinite, and the amorphous kaolinite was put into a mill for grinding treatment, and passed through a 100-mesh sieve to obtain amorphous kaolinite powder.

[0060] Preparation of modified amorphous kaolinite particles:

[0061] Stir and mix the sodium silicate and the amorphous kaolinite powder obtained above for 10 minutes according to the mass ratio of 1:5 to obtain the mixed powder, put the mixed powder in a ball mill jar, and mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com