Fire-retarding hexagonal boron nitride/thermosetting resin composite material and preparation method thereof

A technology of resin composite material and hexagonal boron nitride, which is applied in the field of flame retardant hexagonal boron nitride/thermosetting resin composite material and its preparation, can solve the problems of flame retardancy, low thermal expansion coefficient and the like, and achieves simple operation, abundant sources and good quality. The effect of interfacial forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

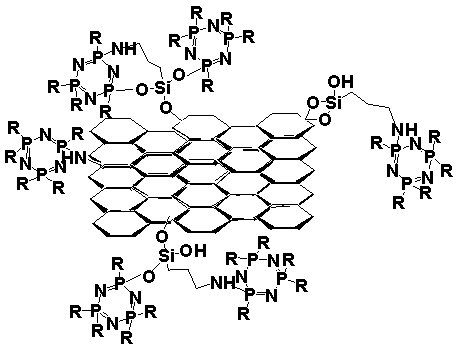

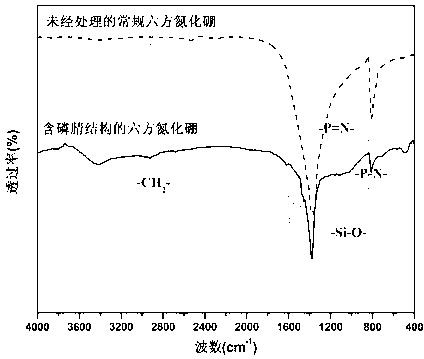

[0026] 1. Preparation of hexagonal boron nitride with phosphazene structure

[0027] in N 2 Under protection, 150 g of toluene and 3 g of hexagonal boron nitride were mixed in 1# reactor to obtain a uniform suspension. Add 0.15g of γ-aminopropyltriethoxysilane into the reactor, and then reflux at 100°C for 8h. After the reaction, filter with suction, wash with toluene and absolute ethanol for 5 times, and dry to obtain hexagonal boron nitride treated by coupling.

[0028] In the 2# reactor, 3 g of coupling-treated hexagonal boron nitride and 150 g of tetrahydrofuran were mixed to obtain a uniform suspension. 24g triethylamine is added into 2# reactor, under N 2 Under atmosphere and cooling with ice water, the reactant was stirred for 1.5 h. Dissolve 9g of chlorophosphazene in 50g of tetrahydrofuran, slowly add to 2# reactor within 1h, heat the 2# reactor, and make the material in the reactor react at 75°C for 8h. After the reaction, wash with tetrahydrofuran and absolute ...

Embodiment 2

[0042] Weigh 45.7g N,N'-4,4'-diphenylmethane bismaleimide and 34.3g O,O'-diallyl bisphenol A in a beaker, mechanically stir at 135°C for prepolymerization After 15 minutes, a brownish-yellow transparent clear liquid was obtained; 8.89g of hexagonal boron nitride (accounting for 10wt% of the total mass of the resin system) prepared in Example 1 containing a phosphazene structure was added to the liquid, and mechanically stirred for prepolymerization for 15min to obtain a prepolymer . Pour the prepolymer into the preheated mold, vacuumize at 135°C for 1h, and then follow the processes of 150°C / 2h+180°C / 2h+200°C / 2h+220°C / 2h and 230°C / 4h respectively After curing and post-treatment, the hexagonal boron nitride / bismaleimide resin composite material is obtained. For its thermal expansion coefficient and limiting oxygen index in the glassy state (50-250°C), see Figures 5 and 6, respectively.

Embodiment 3

[0044] Weigh 45.7g N,N'-4,4'-diphenylmethane bismaleimide and 34.3g O,O'-diallyl bisphenol A in a beaker, mechanically stir at 135°C for prepolymerization After 15 minutes, a brownish-yellow transparent clear liquid was obtained; 20 g of hexagonal boron nitride containing a phosphazene structure (accounting for 20 wt% of the total mass of the resin system) prepared in Example 1 was added to the liquid, and mechanically stirred for 15 minutes to prepolymerize to obtain a prepolymer. Pour the prepolymer into the preheated mold, vacuumize at 135°C for 1h, and then follow the processes of 150°C / 2h+180°C / 2h+200°C / 2h+220°C / 2h and 230°C / 4h respectively After curing and post-treatment, the hexagonal boron nitride / bismaleimide resin composite material is obtained. For its thermal expansion coefficient and limiting oxygen index in the glassy state (50-250°C), see Figures 5 and 6, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com