Polypropylene composite material available for chemical micro-foaming and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene composite material and its preparation, can solve the problems of low melt strength, difficult control of cells, and collapse of cells, and achieves high melt strength, low cell diameter, and cell collapse. Even and fine hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

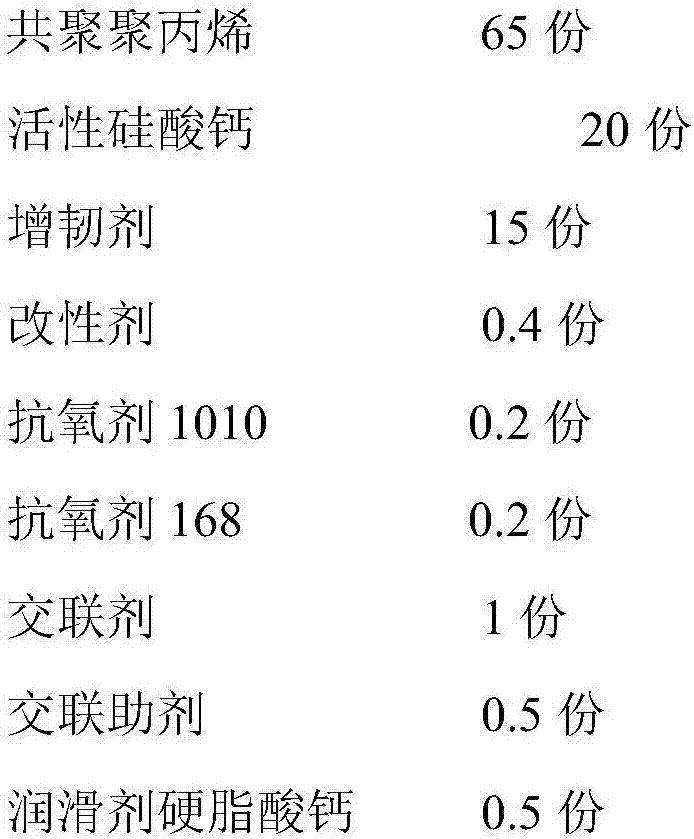

[0037] A polypropylene composite material that can be used for chemical micro-foaming in this embodiment is composed of the following raw materials in parts by weight:

[0038]

[0039] Concrete preparation method comprises the following steps:

[0040] (1) Preparation of modified active calcium silicate: Dissolve 0.4 parts of modifier and 0.5 parts of crosslinking aid in 1L of ethanol to form a solution, add 20 parts of active calcium silicate into a three-necked flask, and heat to 60°C , stirred for 60 minutes, poured into a large beaker, centrifuged, washed 3 times with deionized water, vacuum-dried the centrifuged product at 50°C for 24 hours, ball milled the dried product in a ball mill, and the speed of the ball mill was controlled at 100-250r / min to obtain Modified active calcium silicate;

[0041] (2) Preparation of polypropylene composite material: the modified active calcium silicate prepared in step (1) was mixed with 65 parts of polypropylene, 15 parts of tough...

Embodiment 2

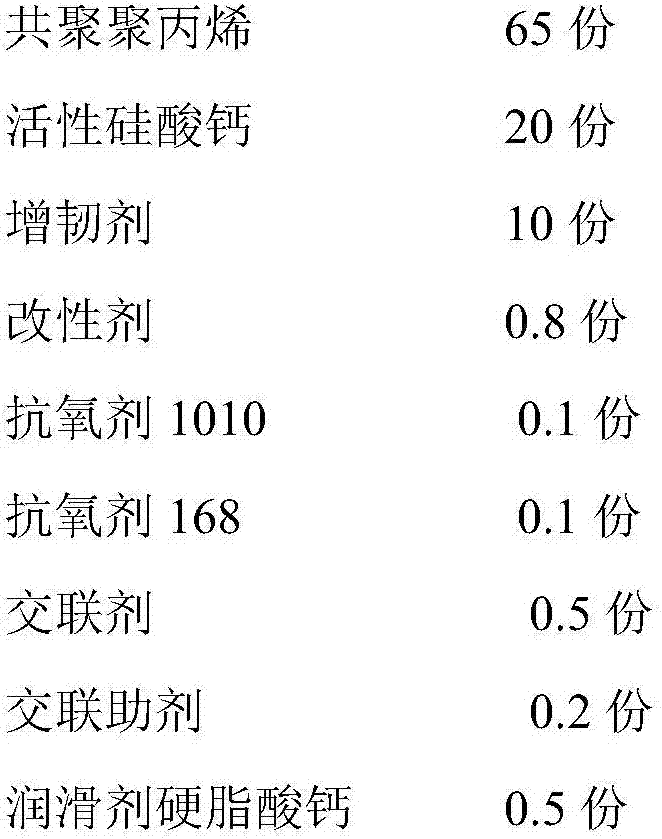

[0044] A polypropylene composite material that can be used for chemical micro-foaming in this embodiment is composed of the following raw materials in parts by weight:

[0045]

[0046] Concrete preparation method comprises the following steps:

[0047] (1) Preparation of modified active calcium silicate: Dissolve 0.8 parts of modifier and 0.2 parts of crosslinking aid in 1L of ethanol to form a solution, add 20 parts of active calcium silicate into a three-necked flask, and heat to 80°C , stirred for 30 minutes, poured into a large beaker, centrifuged, washed 3 times with deionized water, vacuum-dried the centrifuged product at 80°C for 48 hours, and ball milled the dried product in a ball mill. The speed of the ball mill was controlled at 100-250r / min to obtain Modified active calcium silicate;

[0048] (2) Preparation of polypropylene composite material: the modified active calcium silicate prepared in step (1) was mixed with 65 parts of polypropylene, 10 parts of tough...

Embodiment 3

[0051] A polypropylene composite material that can be used for chemical micro-foaming in this embodiment is composed of the following raw materials in parts by weight:

[0052]

[0053]

[0054] Concrete preparation method comprises the following steps:

[0055] (1) Preparation of modified active calcium silicate: Dissolve 0.4 parts of modifier and 0.4 parts of crosslinking aid in 1L of ethanol to form a solution, add 10 parts of active calcium silicate into a three-necked flask, and heat to 70°C , stirred for 50 minutes, poured into a 1000mL large beaker, centrifuged, washed 4 times with deionized water, vacuum-dried the centrifuged product at 70°C for 36 hours, and ground the dried product to obtain modified active calcium silicate;

[0056] (2) Preparation of polypropylene composite material: the modified active calcium silicate prepared in step (1) was mixed with 85 parts of polypropylene, 15 parts of toughening agent, 0.15 part of antioxidant 1010, 0.15 part of anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com