Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Controllable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

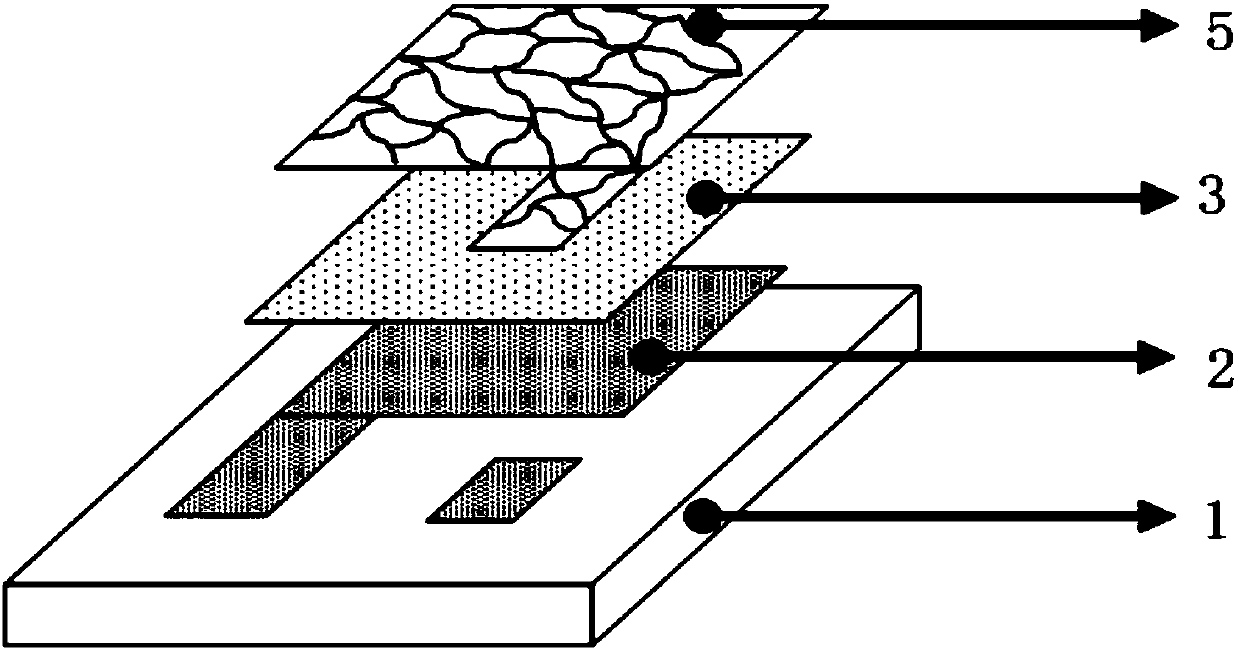

Multiple layer hydrogen infiltration -resistant compound film preparation method

InactiveCN101265603AControllable thicknessImprove compactnessAnodisationMetallic material coating processesMicro arc oxidationHome position

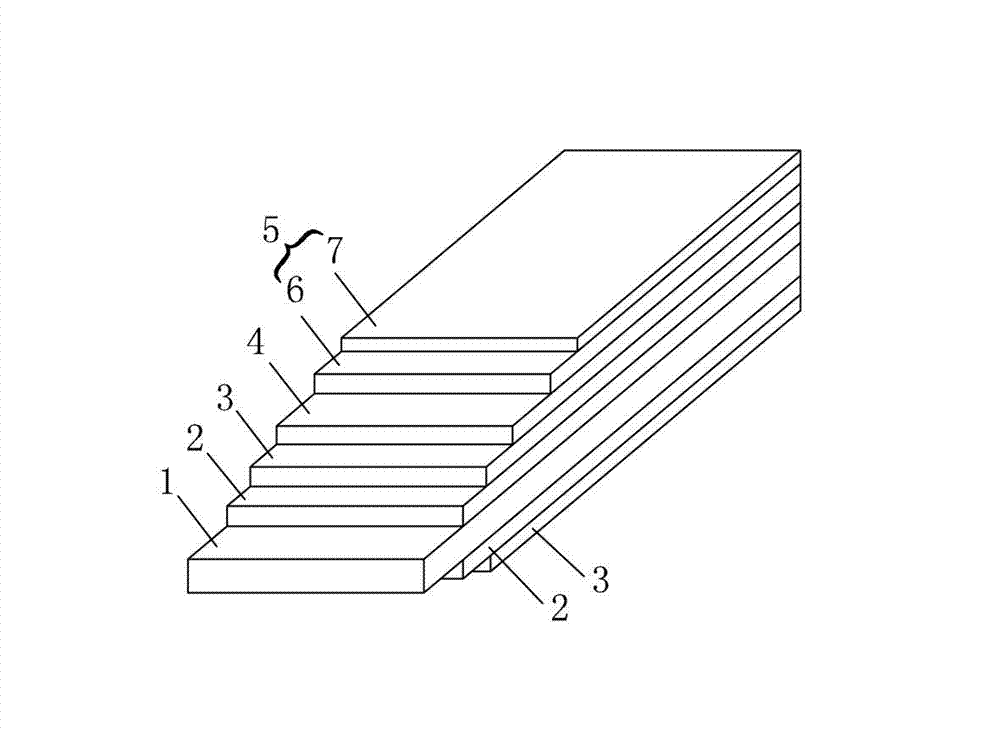

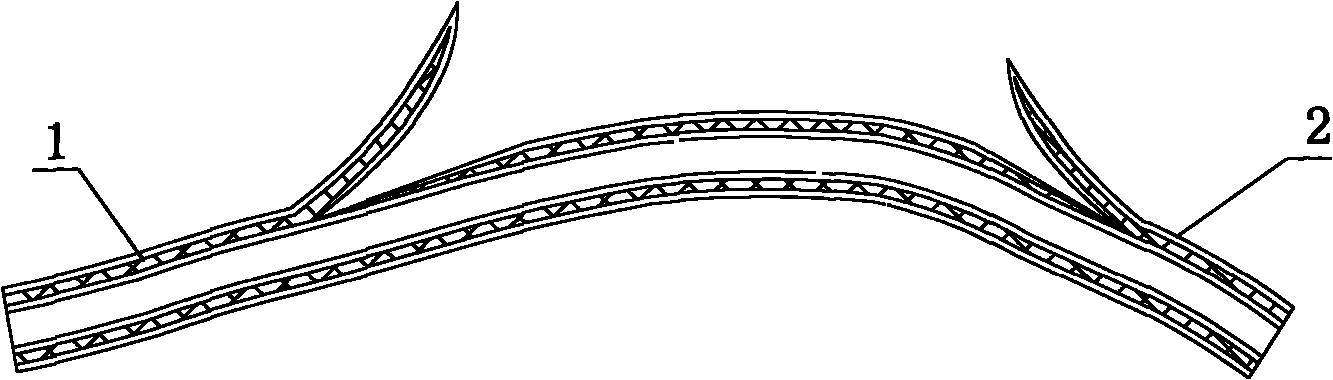

The invention relates to a method for preparing a multi-layer hydrogen-permeation-resisting composite membrane, and belongs to the material technology field. The method adopts a coupling technique of aluminum and aluminum alloy coating and micro-arc oxidation to form the multi-layer hydrogen-permeation-resistance composite membrane at the home position on a stainless steel basal body, the composite membrane comprises an alloy layer formed by the basal body and coating metal, a coating metal layer, a composite layer formed by the coating metal and oxide ceramic and an oxide ceramic layer, etc., as shown in picture 1. Compared with the prior art, the method has the advantages of the aluminum and aluminum alloy coating and the micro-arc oxidation, overcomes the defect of the prior single technique, and forms the multi-layer hydrogen-permeation-resistance composite membrane with high capability; the ceramic layer thereof has controllable thickness, high compactness, good quality, and firm combination with the basal body, thereby enhancing the hydrogen-permeation-resisting and the corrosion-resisting properties of the stainless steel, improving the hot oxidation resistance and the abrasion resistance of the stainless steel, prolonging service life of the stainless steel container, and strengthening safety precautions.

Owner:SICHUAN UNIV

Active Microfluidic Membranes

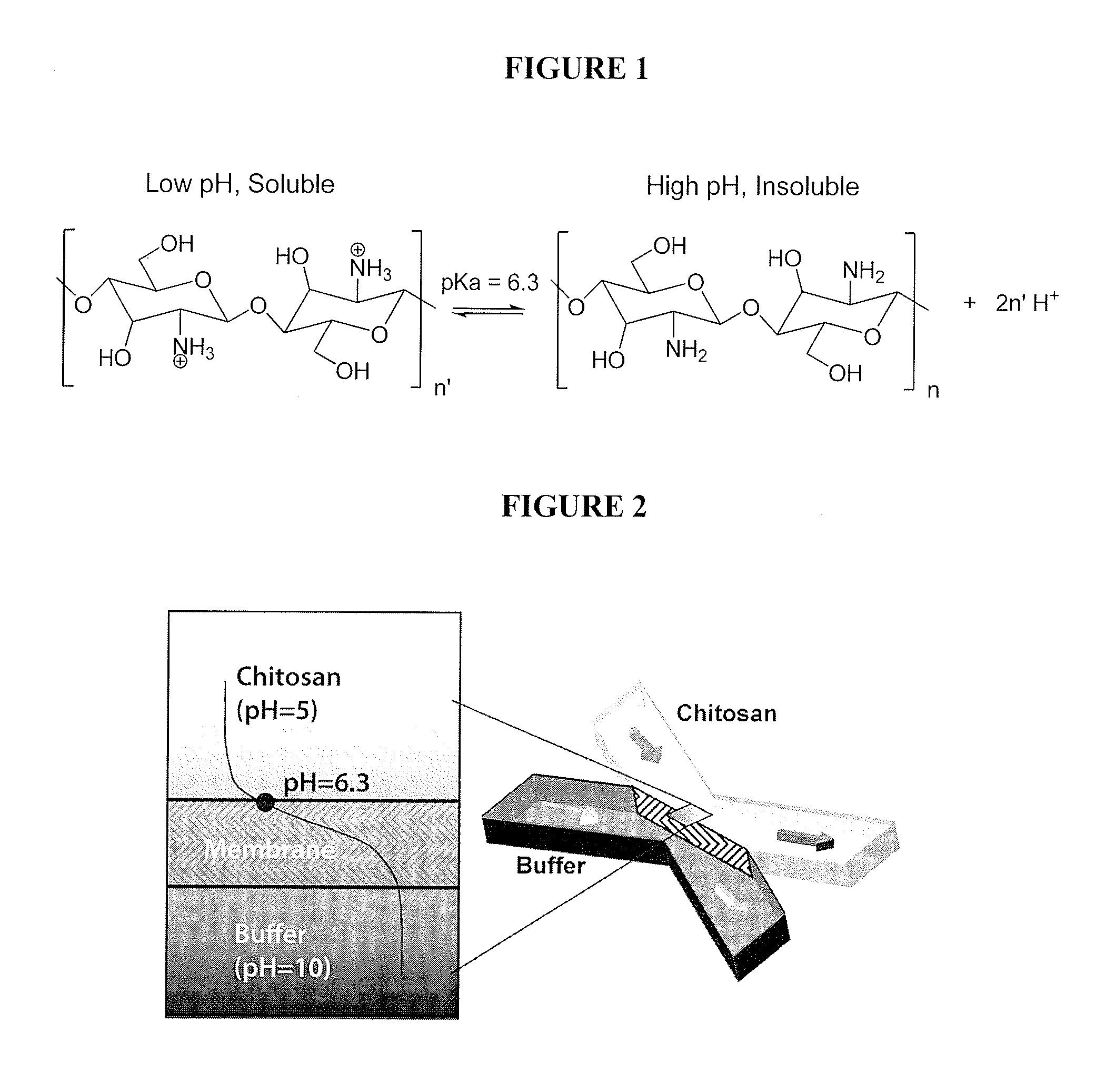

InactiveUS20110081677A1Controllable permeabilityControllable thicknessBioreactor/fermenter combinationsBiological substance pretreatmentsSingle typeMembrane matrix

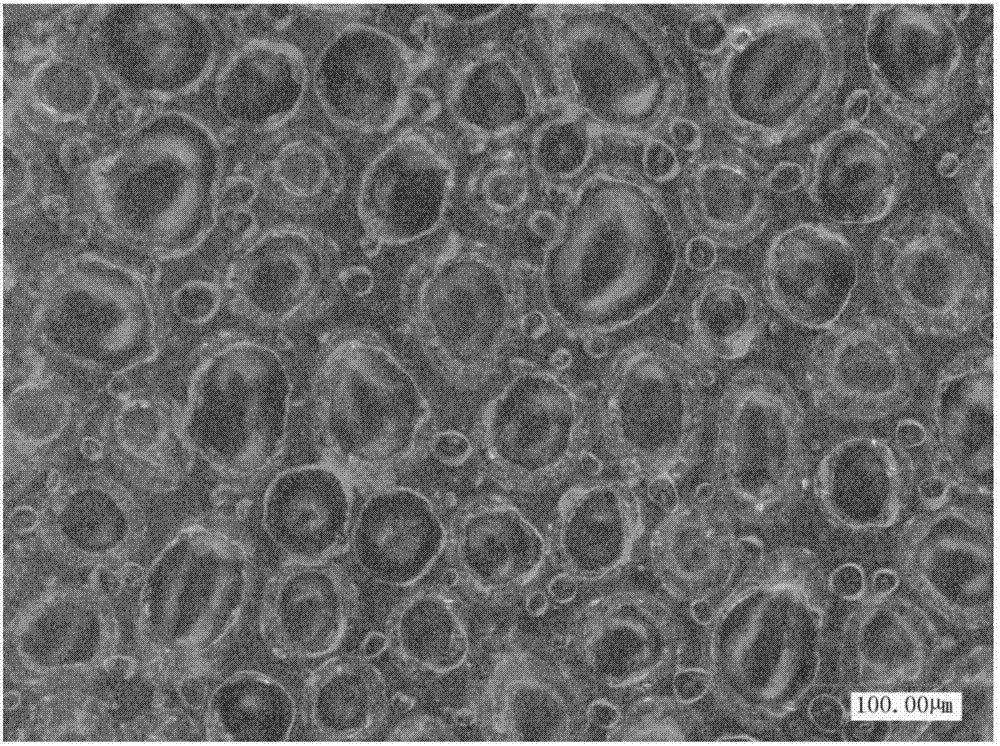

The present invention relates to a biofabricated Active Microfluidic Membrane (AMM) in a microfluidic network of a microfluidic device and a method for the in situ biofabrication of such a microfluidic network. More specifically, the invention relates to devices exhibiting (and methods of) positioning (i.e., erecting, modifying or removing a membrane matrix in situ in a microchannel of a microfluidic network of a microfluidic device. In one embodiment, the membrane comprises a single type of matrix constituent, such as chitosan, alginate, etc. Alternatively, the membrane may be composed of two or more matrix constituents, which may be integrated into one another or layered adjacent to one another.

Owner:UNIV OF MARYLAND

Rapid preparation process of inert dispersion fuel pellet

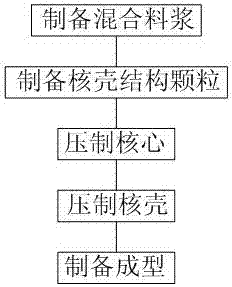

ActiveCN106971764AGood sphericityControllable thicknessNuclear energy generationReactors manufacturePrillVolume fraction

The invention discloses a rapid preparation process of an inert dispersion fuel pellet. The rapid preparation process comprises the five steps of preparation of mixed material slurry, preparation of core-shell structure particles, core pressing, core-shell pressing and preparation forming. The preparation process overcomes the shortcomings of an existing inert dispersion fuel pellet preparation method, and the inert dispersion fuel pellet high in TRISO particle content, good in particle integrity, uniform in dispersion and high in silicon carbide matrix compactness can be obtained within a shorter process period. In the prepared inert dispersion fuel pellet, the silicon carbide matrix compactness is up to 92% or above, and the volume fraction content of TRISO particles in whole fuel is 30%-45%.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

Method for preparing metal surface fullerene film by electrophoresis

ActiveCN102002747AControllable thicknessUniform coatingElectrophoretic coatingsPre treatmentSurface modification

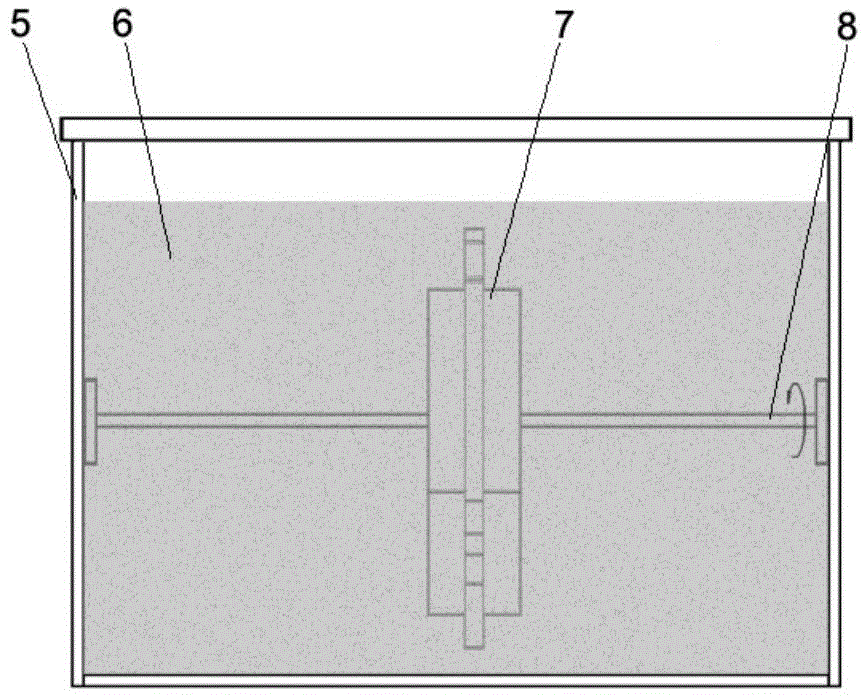

The invention provides a method for preparing metal surface fullerene film by electrophoresis, including the following steps: (1) pre-treatment is carried out on metal material surface, including oil removing cleaning, acid cleaning and activation on metal material; (2) electrophoresis solution is prepared, fullerene is dispersed in organic solution, ultrasonic oscillation, filtering and reducing are carried out, pH value is regulated to be 8-12; (3) film forming is carried out by adopting fullerene electrophoresis method; (4) heating is carried out. The method of the invention can be used for metal surface modification treatment, especially novel surface coated metal material can be derived by utilizing excellent characteristic of fullerene material, thus obtaining brand new metal product.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel high-strength low-volume-weight heat preservation fireproof decoration integration plate and preparation method thereof

ActiveCN102817453AControllable thicknessLight weightFireproof paintsCovering/liningsHeat conservationPolymer chemistry

The invention relates to a novel high-strength low-volume-weight heat preservation fireproof decoration integration plate. The technical scheme includes that the integration plate is composed of a heat preservation layer, a fireproof layer which is coated on the outer surface of the heat preservation layer, a strengthening layer and decorative surface layer. The heat preservation layer is composed of polyurethane foaming plate double-faced composite cement alkali-resistant glass fabric. According to the plate and the preparation method, the strength is high, the heat preservation performance is high, the volume weight of the integration plate is less than 8kg / m2, compared with the volume weight of a conventional integration plate, the volume weight of the integration plate is reduced by 4-6kgm2, fireproof interface agent processing is performed on six surfaces of a core material, compared with existing products, the plate improves the fireproof performance substantially, and fire is prevented from spreading along a wall body.

Owner:辽宁宝山生态涂料有限公司

Porous silicon rubber thin film containing graphene as well as preparation method and application thereof

ActiveCN107312188ASimple preparation processControllable thicknessAbsorbent padsProsthesisCvd graphenePore diameter

The invention discloses a porous silicon rubber thin film containing graphene as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a silicon rubber precursor, a non-solvent or pore-forming agent, a volatile solvent and the graphene according to a certain ratio; carrying out ultrasonic treatment or stirring a mixed solution to obtain a film forming solution; de-foaming the film forming solution to form a film on a template; removing a solvent in a liquid blank film and curing and molding; removing the non-solvent or the pore-forming agent. The porous silicon rubber thin film containing the graphene, which is prepared by the preparation method, can be used as artificial skin or surgical dressing for covering skin defect wounds of mammals. According to the porous silicon rubber thin film containing the graphene as well as the preparation method and the application thereof, phase-separation film forming is induced by utilizing solvent volatilization and pores are formed by adopting a non-solvent or pore-forming agent filtering-out method; a preparation technology is simple and the pore diameter and the thickness of the thin film are controllable; the porous silicon rubber thin film containing the graphene has an ordered porous structure; meanwhile, the graphene has excellent antibacterial activity and can be used for preventing the wounds from being infected by bacteria and promoting the healing of the wounds when the porous silicon rubber thin film is used for the artificial skin.

Owner:SICHUAN UNIV

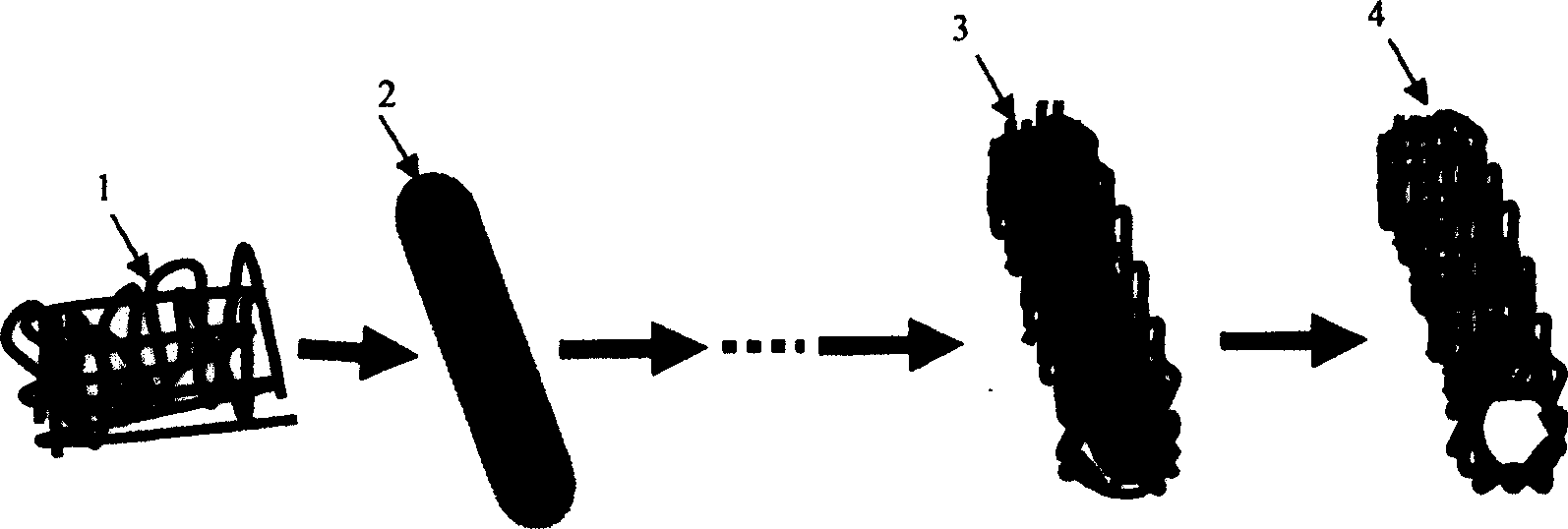

Multilayer hollow Nano fiber in use for cell culture, and preparation method

InactiveCN1958134ASimple methodThickness controllableSemi-permeable membranesTissue/virus culture apparatusFiberCulture cell

A multi-layer hollow nanofiber used to culture cells is prepared through providing electrically spun fibers as template, alternatively adsorbing the polymers with positive and negative charges onto the surface of template, and using organic solvent to remove said template.

Owner:SOUTHEAST UNIV

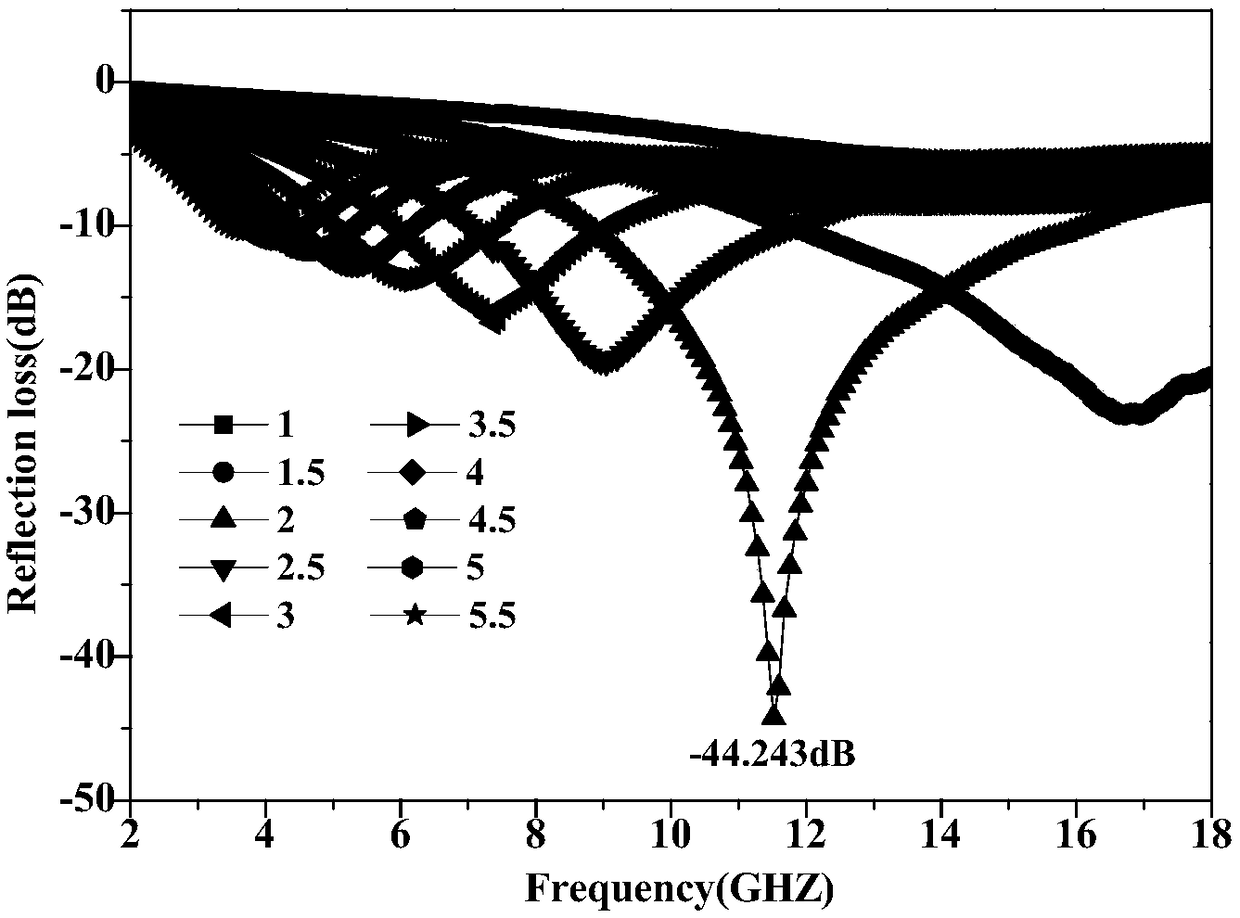

Double-shell-structure carbonyl iron powder composite wave-absorbing material and preparation method thereof

ActiveCN109207123ACoated evenlyControllable thicknessOther chemical processesMagnetic/electric field screeningCoprecipitationMagnetic layer

The invention discloses a double-shell-structure carbonyl iron powder composite wave-absorbing material and a preparation method thereof, wherein the composite wave-absorbing material is of a double shell layer core-shell structure, the core is carbonyl iron powder, the inner layer of the double-shell layer is an insulating layer, and the outer layer of the double-shell layer is a magnetic layer;the thickness of the insulating layer is 1 nm-1 [mu] m; and the thickness of the magnetic layer is 1nm-5 [mu] m; the preparation method comprises the following steps: coating the surface of the carbonyl iron powder with the insulating layer and coating the surface of a core-shell structure precursor by a chemical coprecipitation method. The surface of the carbonyl iron powder is coated with the double-shell layer by the chemical coprecipitation method. The impedance matching characteristic of the material is greatly improved, meanwhile, a large amount of nano-interface heterojunction is formedat the interfaces of the inner core and the double-shell layer, so that interface polarization is effectively induced, the scattering effect is formed for electron migration, and electromagnetic waveloss mechanisms such as multi-reflection absorption, strong ] ferromagnetic resonance and eddy current loss and the like of the material are greatly improved, so that the wave absorbing performance of the material is remarkably improved; the composite wave-absorbing material is simple in preparation method, is uniform and compact in coating and controllable in coating layer thickness and particlesize.

Owner:CENT SOUTH UNIV

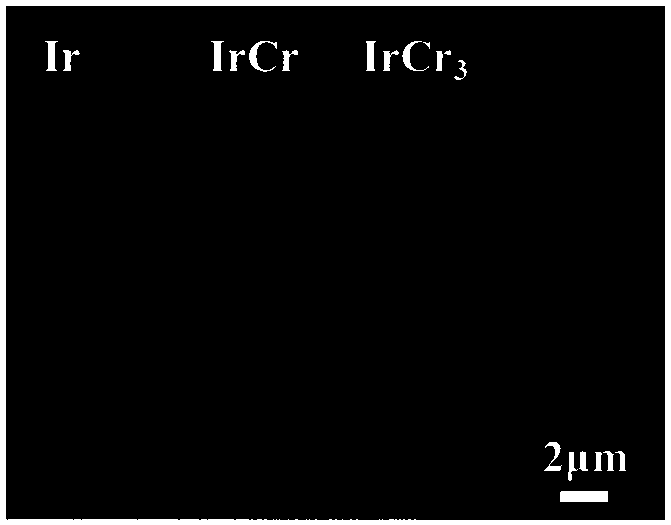

Ir-X coating based on surface alloying modification and preparation method thereof

InactiveCN107740039AControllable thicknessGood combinationSolid state diffusion coatingCoating systemIridium

The invention discloses an Ir-X coating based on surface alloying modification and a preparation method thereof. The preparation method of the Ir-X coating is characterized in that a transition layer,namely a rhenium coating and an iridium coating are deposited on a carbon composite material or a graphite substrate in sequence, and then metal X powder, metallic oxide XO powder corresponding to the metal X and a chloride activating agent are mixed to obtain a permeating agent, and a powder pack cementation method is adopted for enabling the iridium coating to be subjected to surface alloying modification, so as to obtain the Ir-X coating. The Ir-X coating based on surface alloying modification has a low surface catalytic effect and surface temperature in an aerodynamic environment, and isgreatly improved in service performance when compared with the conventional silicide coating system.

Owner:NAT UNIV OF DEFENSE TECH

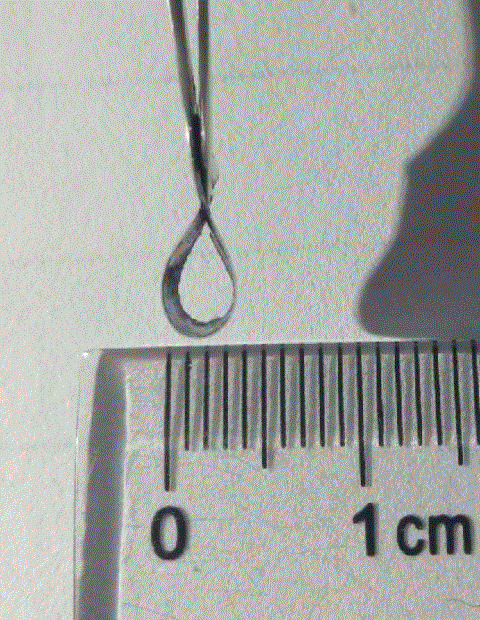

Nanometer silver antibacterial biliary duct bracket and preparation method thereof

InactiveCN102485184AControllable thicknessGreat promotion valueStentsCoatingsSecondary infectionAntibacterial effect

The invention relates to a nanometer silver antibacterial biliary duct bracket and a preparation method thereof. The nanometer silver antibacterial biliary duct bracket belongs to a medical appliance, in particular to a medical biliary duct bracket for human bodies. The nanometer silver antibacterial biliary duct bracket comprises a plastic biliary duct bracket, wherein a nanometer silver deposition layer with the nanometer silver particle size being 0.5 to 200cn is uniformly attached on the inner and outer wall surfaces of the plastic biliary duct bracket. Compared with the prior art, the nanometer silver antibacterial biliary duct bracket has the advantages that the attaching of the stable nanometer silver coating on the existing medical bracket can be realized, silver ions are continuously released for realizing the antibacterial effect on intestine liquid, the secondary infection is prevented, in addition, the problem of medical bracket blockage is avoided.

Owner:令狐恩强 +1

Preparation method and application of Ni/P-Ni/P/PTFE-PTFE composite coating

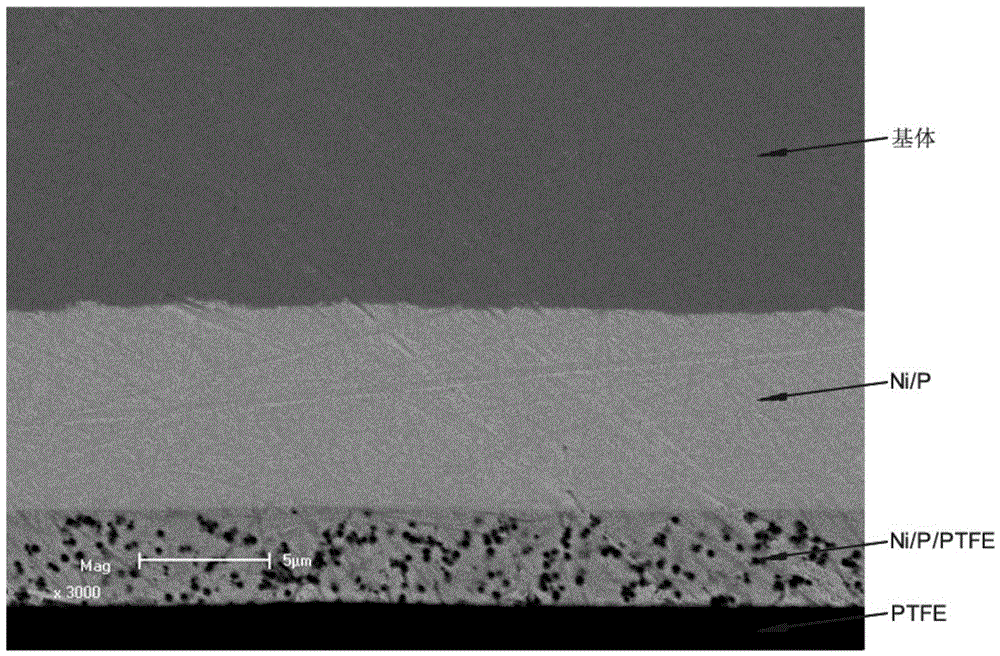

ActiveCN104451618AImprove corrosion resistanceControllable thicknessLiquid surface applicatorsLiquid/solution decomposition chemical coatingChemical industryChemical plating

The invention relates to the technical field of protective coatings on metal surfaces, and in particular relates to a preparation method and an application of a Ni / P-Ni / P / PTFE-PTFE composite coating. The method is applied to surfaces of mechanical components and can improve corrosion resistance, wear resistance and self-lubricating property of the mechanical components. A Ni / P plated layer is formed on the surface of a matrix by virtue of direct plating, a Ni / P / PTFE transition layer is formed on the surface of the Ni / P plated layer by virtue of composite chemical plating, and a polytetrafluoroethylene coating is sprayed on the surface of the Ni / P / PTFE transition layer to serve as a surface layer. The Ni / P-Ni / P / PTFE-PTFE composite coating provided by the invention is applied to surfaces of high-corrosivity vacuum pumps, semiconductor devices, scientific instruments and processes of biological pharmacy, medical treatment, chemistry & chemical industry and the like, and the protective coating can resist corrosion of high-corrosivity gases for a long time and can improve the service lives of the mechanical components.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Titanium Oxide Spacing by SIP

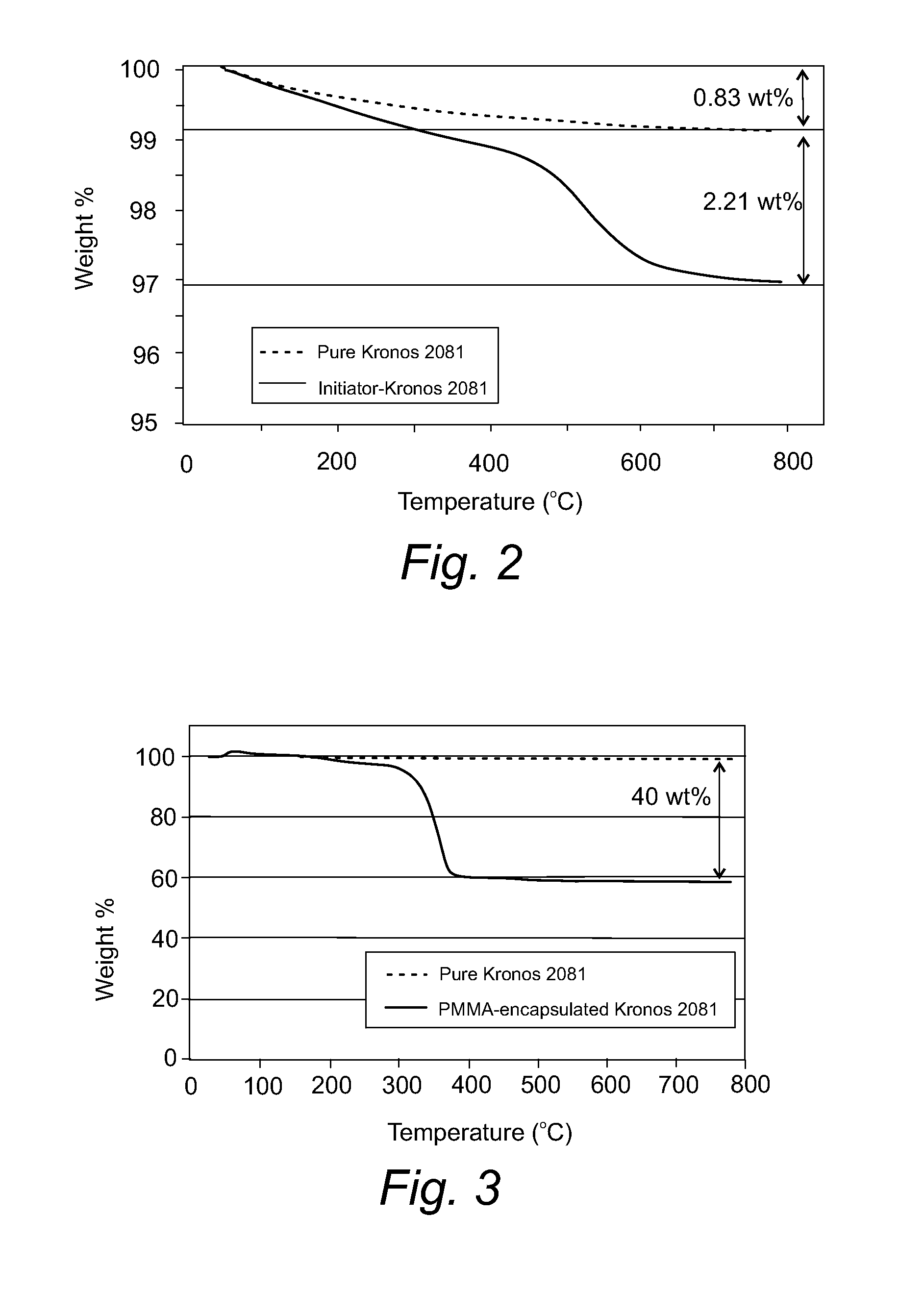

ActiveUS20120277346A1Controllable thicknessControllable functionalityMaterial nanotechnologyPigmenting treatmentPre treatmentTitanium oxide

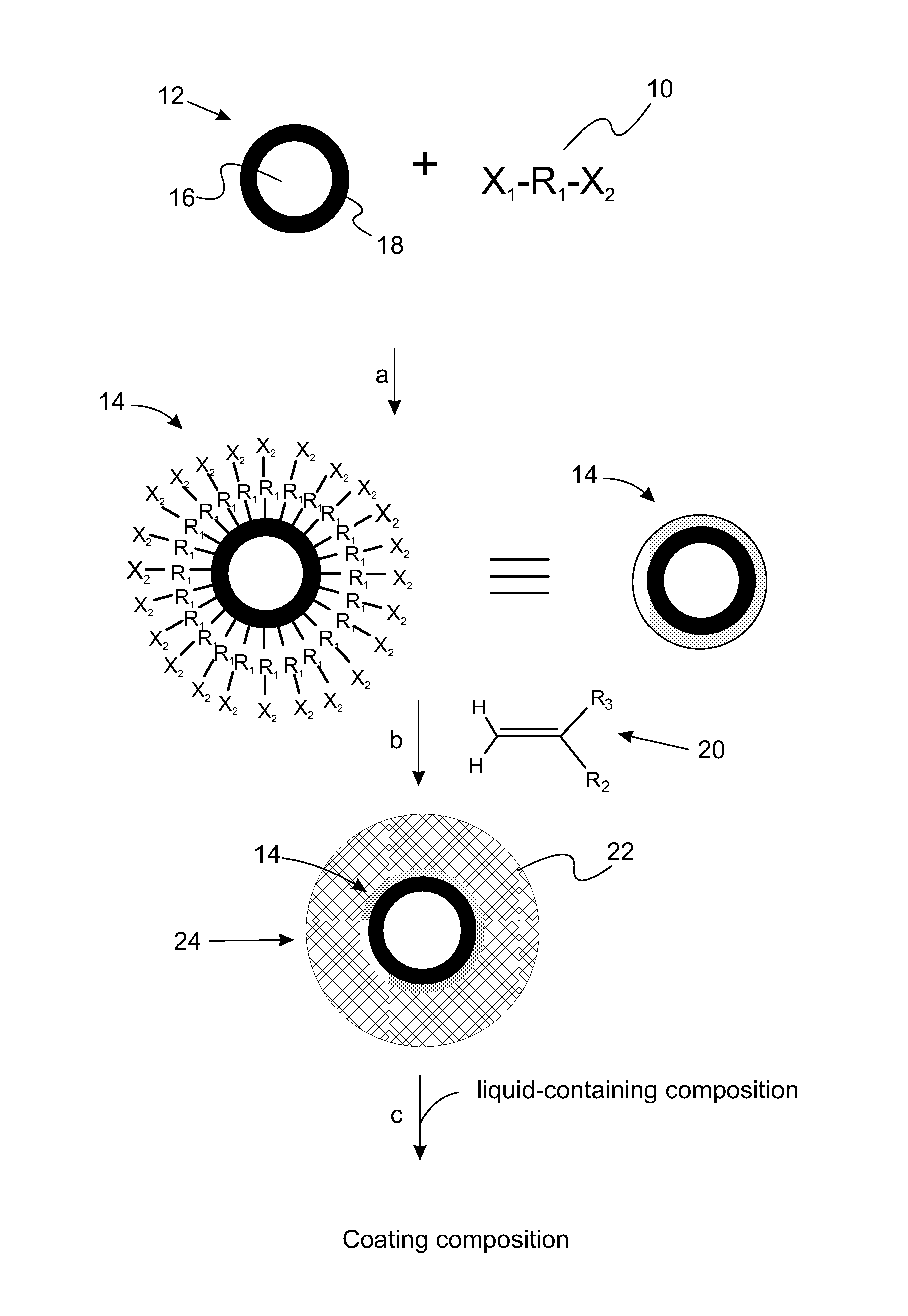

A method of making a titanium oxide-containing coating composition comprises attaching an initiator to a pretreated titanium oxide to form an initiator / pretreated titanium oxide complex. The pretreated titanium oxide includes a plurality of pretreated titanium oxide particles which are titanium oxide particles that are pretreated with at least one metal oxide. The initiator / pretreated titanium oxide complex is contacted with a polymerizable unsaturated monomer such that a polymeric encapsulate forms on the initiator / pretreated titanium oxide particles to form polymeric encapsulated titanium oxide particles.

Owner:BEHR PROCESS +1

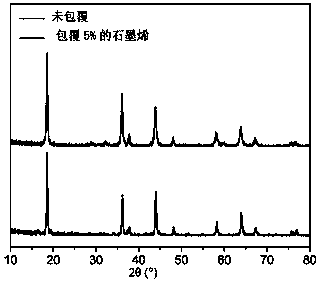

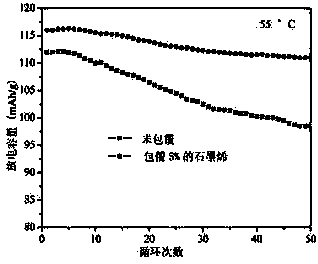

Coating method of lithium manganite cathode material for lithium battery

ActiveCN103972490AEasy to prepareControllable thicknessCell electrodesSecondary cellsMuffle furnaceSodium acid carbonate

The invention relates to a coating method of a lithium manganite cathode material for a lithium battery. The coating method comprises the steps as follows: a MnSO4 aqueous solution and a sodium carbonate aqueous solution are prepared, and a complexing agent ammonium hydroxide is added to the sodium carbonate aqueous solution; then a peristaltic pump is utilized to continuously input the mixed aqueous solution into a reaction flask; after reaction is finished, precipitation is separated centrifugally, washed repeatedly by distilled water to remove residual ions and dried; then the precipitation and Li2CO3 or LiOH are mixed and ground uniformly for calcination in a muffle furnace step by step, a calcined product is dispersed in a graphite oxide solution and subjected to ultrasonic dispersion, centrifugation and drying; and the calcined product is placed in a vacuum tube furnace and calcined in protective atmosphere at the temperature of 400 DEGC-700 DEG C. According to the coating method of the lithium manganite cathode material for the lithium battery, direct contact between the cathode material and an electrolyte solution can be effectively reduced, dissolution of Mn ions is reduced, meanwhile, the conductivity of lithium manganite is further improved, the electrical loss is reduced, and specific capacity and rate capability of the lithium manganite cathode material are greatly improved.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

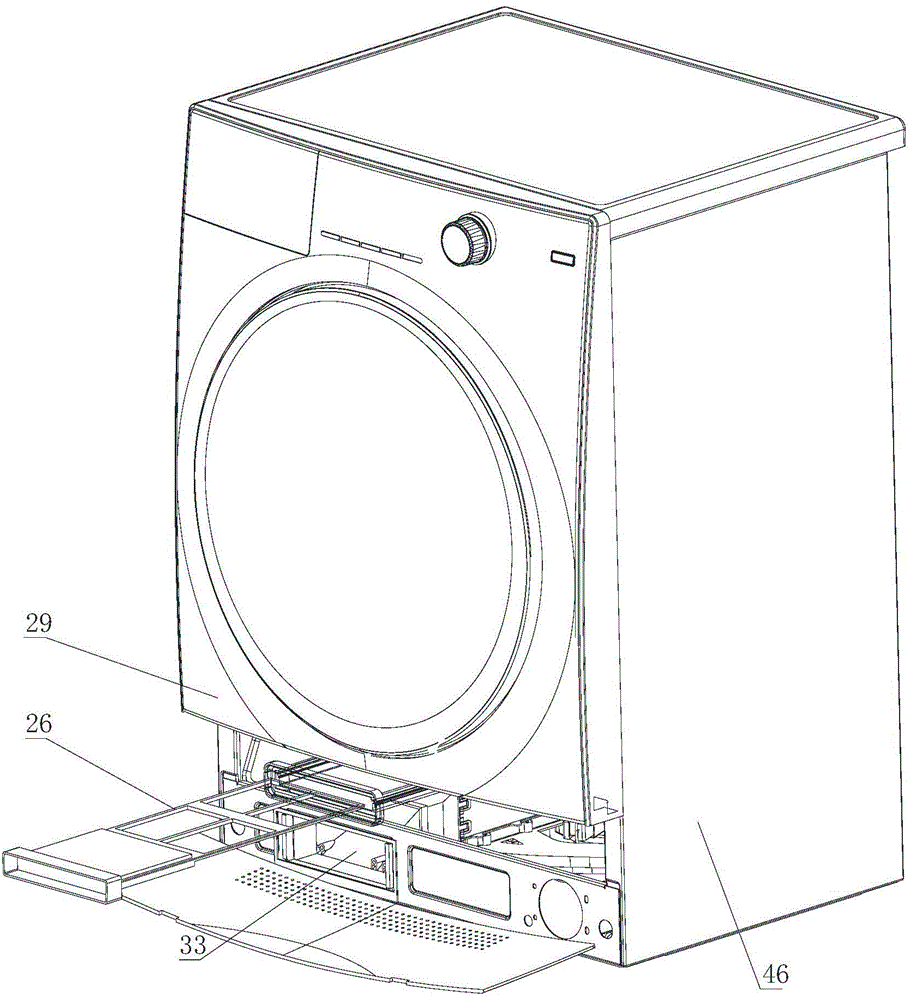

Air condensation structure

ActiveCN104911881ASimple moldingControllable thicknessTextiles and paperHeat exchanger fasteningAirflowHeating efficiency

The invention discloses an air condensation structure which is a shell body. The air condensation structure comprises an air inlet and an air outlet of hot air. The air condensation structure further comprises an air inlet and an air outlet of cold air. An overlaying type heat exchanger is arranged in the air condensation structure. The overlaying type heat exchanger is plastic fins which are placed in a criss-cross mode. A frame of an inclosure structure is arranged on the outer portion of the overlaying type heat exchanger. The air condensation structure is high in heat efficiency and is provided with a filtering structure, a flushing structure and an air uniform structure, the problem that wire chips block an air way can be avoided, air flow is smooth and even, and the structure is simple.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

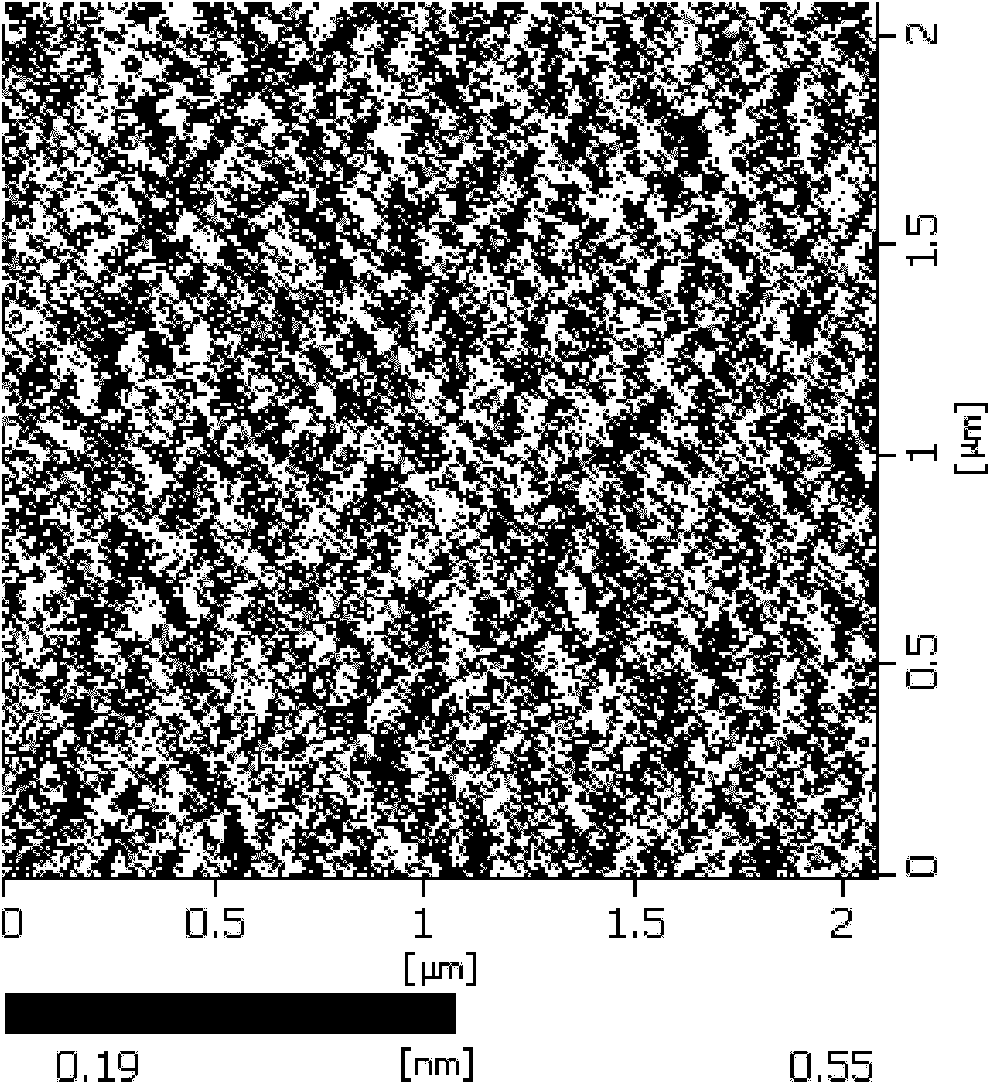

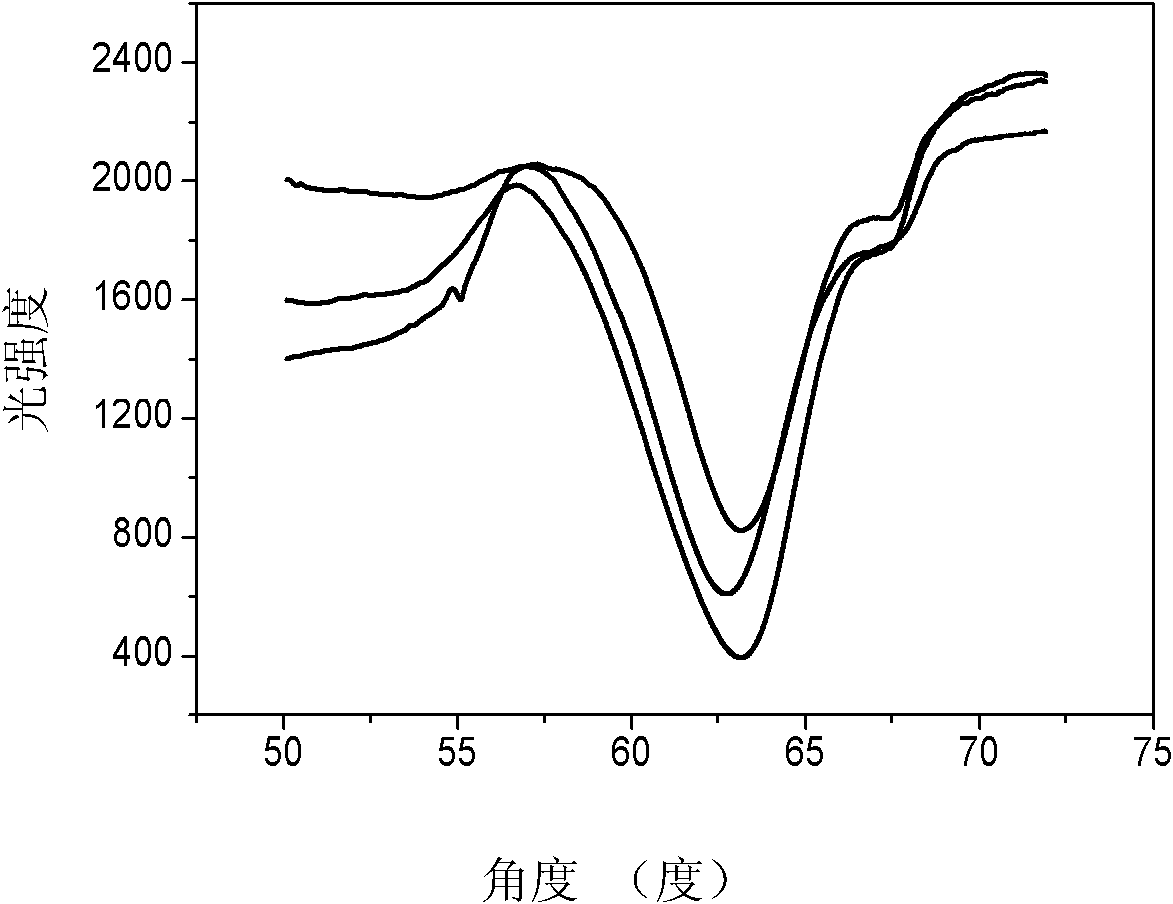

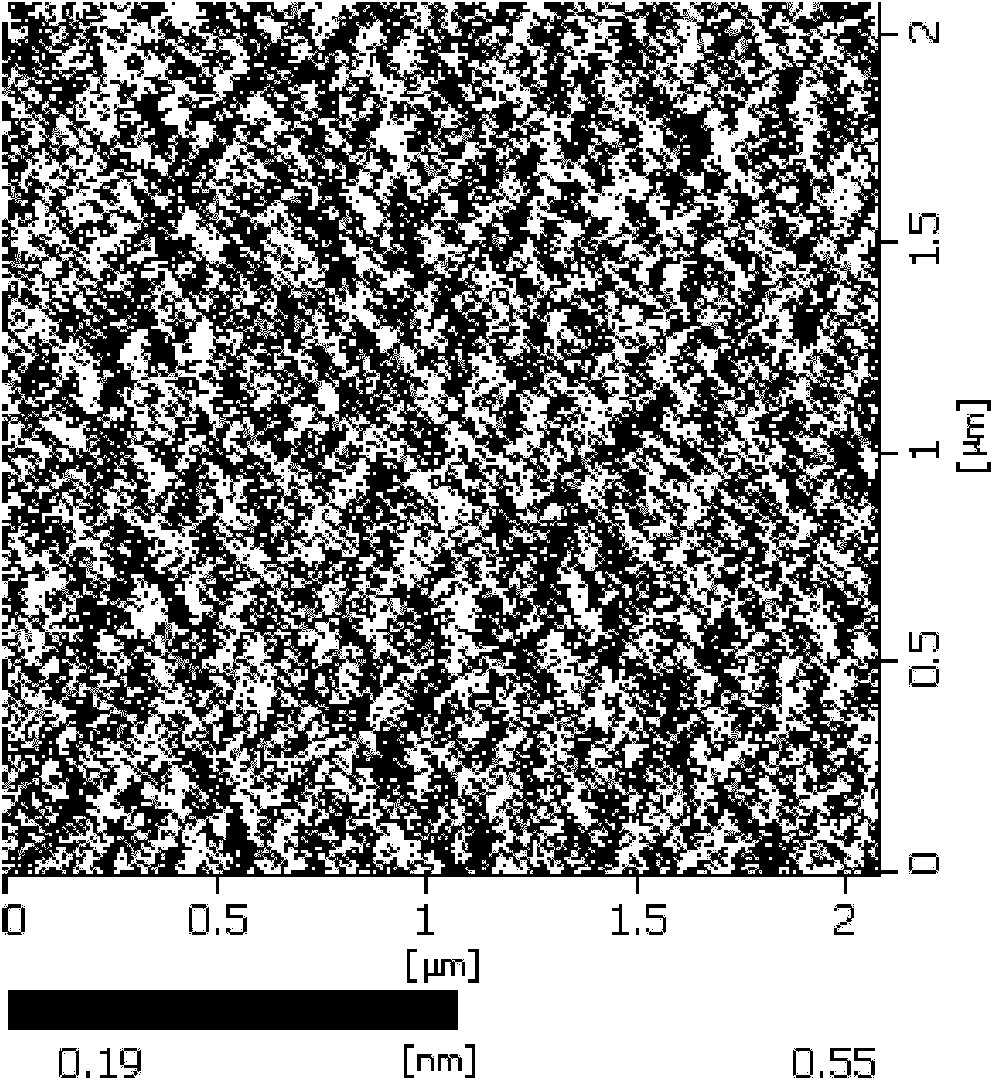

Method for preparing surface plasma resonance chip

ActiveCN102002670AFlat surfaceControllable thicknessVacuum evaporation coatingSputtering coatingChromiumPlasma resonance

The embodiment of the invention discloses a method for preparing a surface plasma resonance chip. The method comprises the following steps of: a) placing a glass substrate in a growth chamber of a vacuum sputtering instrument; b) introducing argon gas into the growth chamber, vacuuming until the vacuum degree is 10<-1> to 10<-3>mbr and sputtering a chromium thin film on the glass substrate at a substrate-to-target distance of 5 to 9cm by taking chromium as a target material; and c) sputtering a metal thin film on a product obtained in the step b) at the substrate-to-target distance of 5 to 9cm under the condition of vacuum degree of between 10<-1> and 10<-3>mbr by taking metal as the target material. By using a vacuum sputtering principle and the substrate-to-target distance of 5 to 9cm, the prepared metal thin film has a flat surface and controllable thickness and can be used for the surface plasma resonance chip. Experiment results show that the prepared metal thin film has uniform thickness which is about 50nm.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

Continuous production device and method for band-shaped black conductive foam

ActiveCN103480541ARich varietyControllable thicknessLiquid surface applicatorsCoatingsConductive coatingElectrically conductive

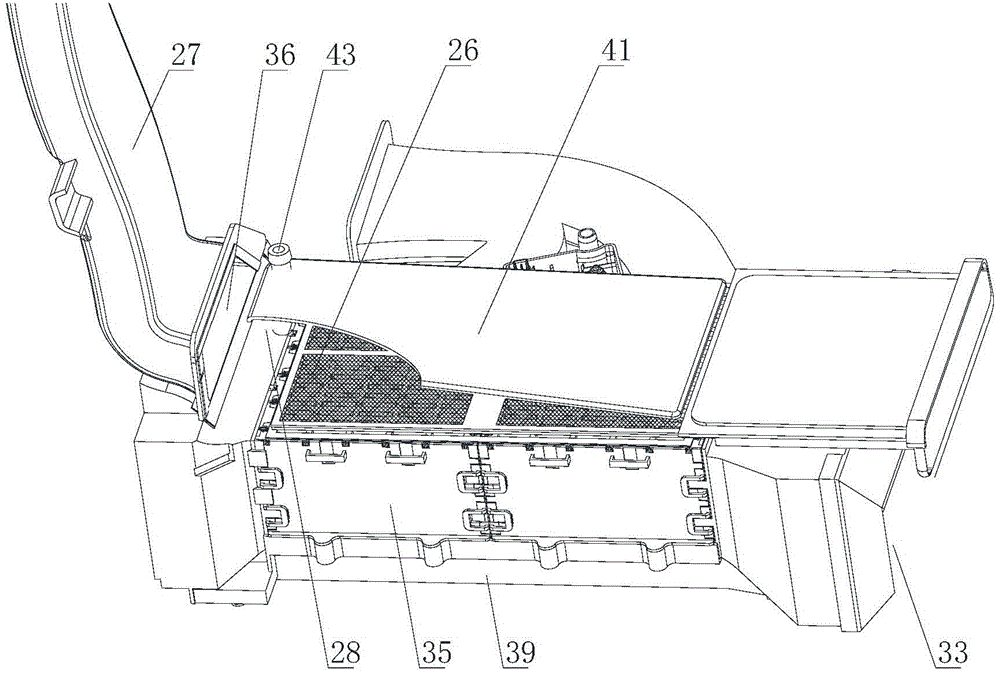

The invention discloses a continuous production device and method for band-shaped black conductive foam. A spraying chamber (4), a solidification chamber (11), a drying chamber (15) and a cooling chamber (20) are sequentially distributed between an unwinding machine (1) and a winding machine (28), a spraying driving roller (3), an atomizer (7) and a spraying pipe (8) are installed in the spraying chamber (4), a solidification driving roller (10) and infrared solidification heaters (12) are installed in the solidification chamber (11), a drying driving roller (19) and infrared drying heaters (16) are installed in the drying chamber (15), a cooling driving roller (25) and a cooling water tank (21) are installed in the cooling chamber (20), and all the components form the production device. According to the continuous production device and method for the band-shaped black conductive foam, a conductive coating is sprayed on a conductive foam base material, continuous production is achieved, the breadth and length of products are increased, and the application range of the products is extended.

Owner:HUAIAN FUYANG ELECTRONICS MATERIALS

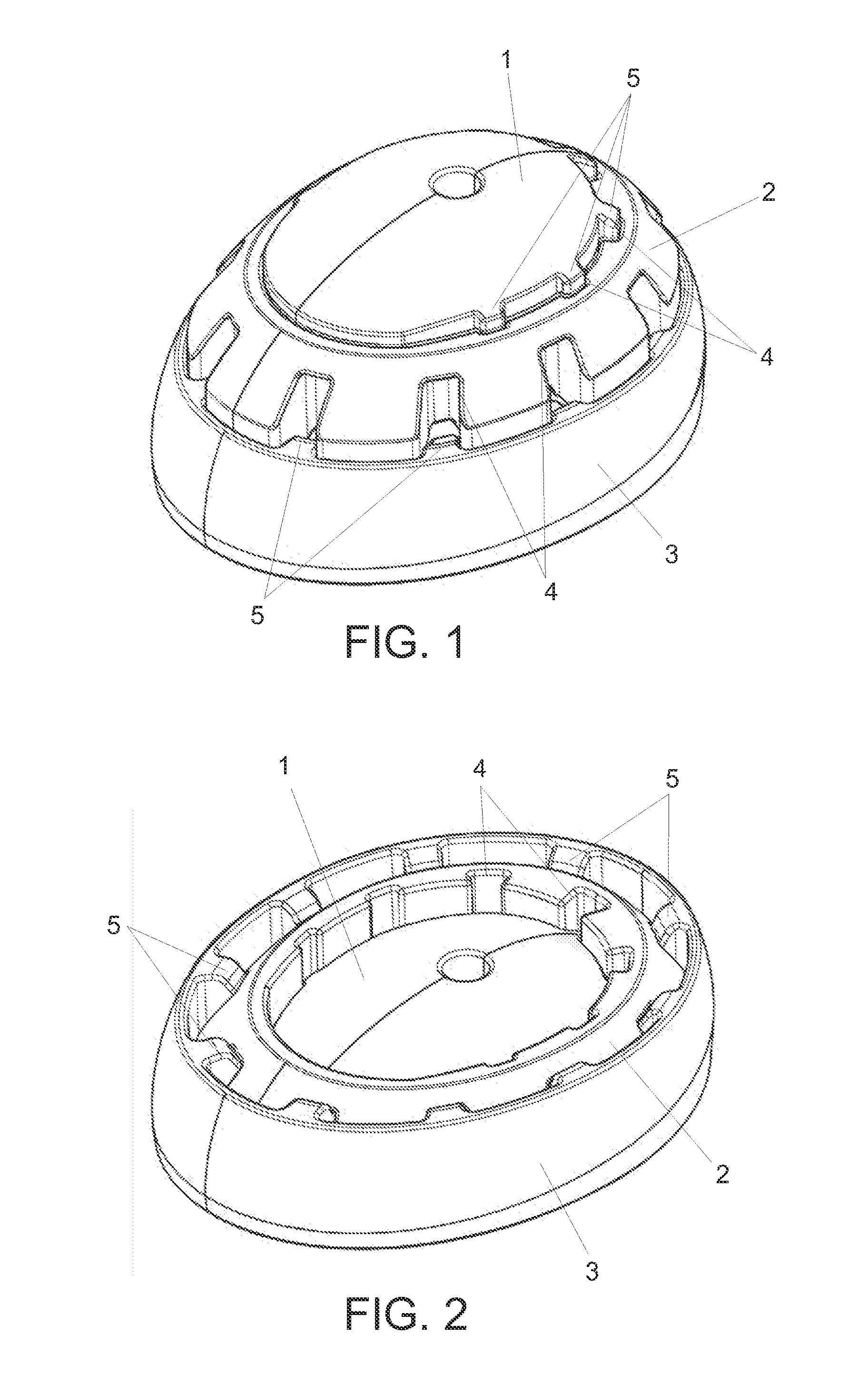

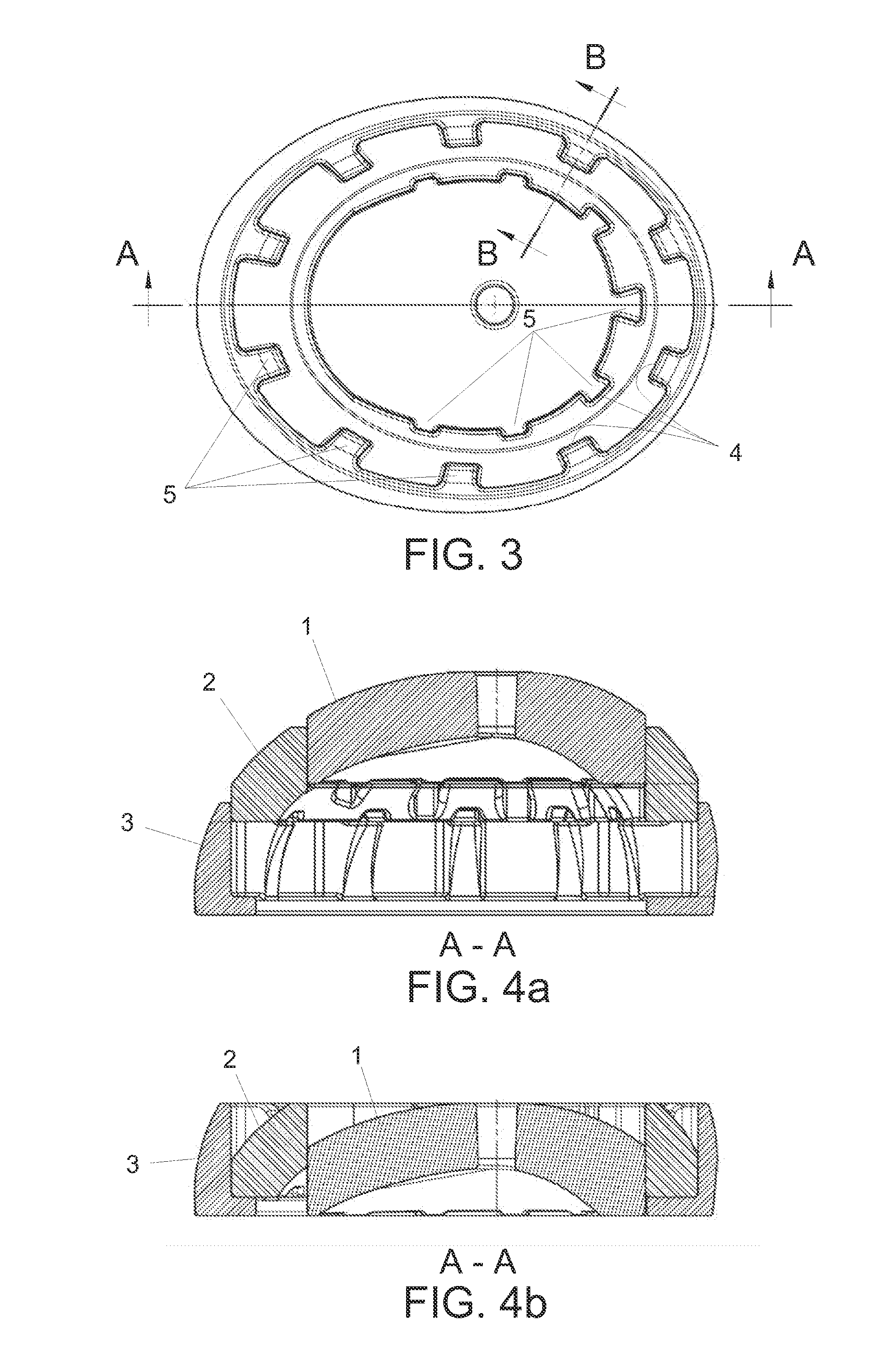

Protective helmet

Owner:FERRANDO GARCIA CARLOS +2

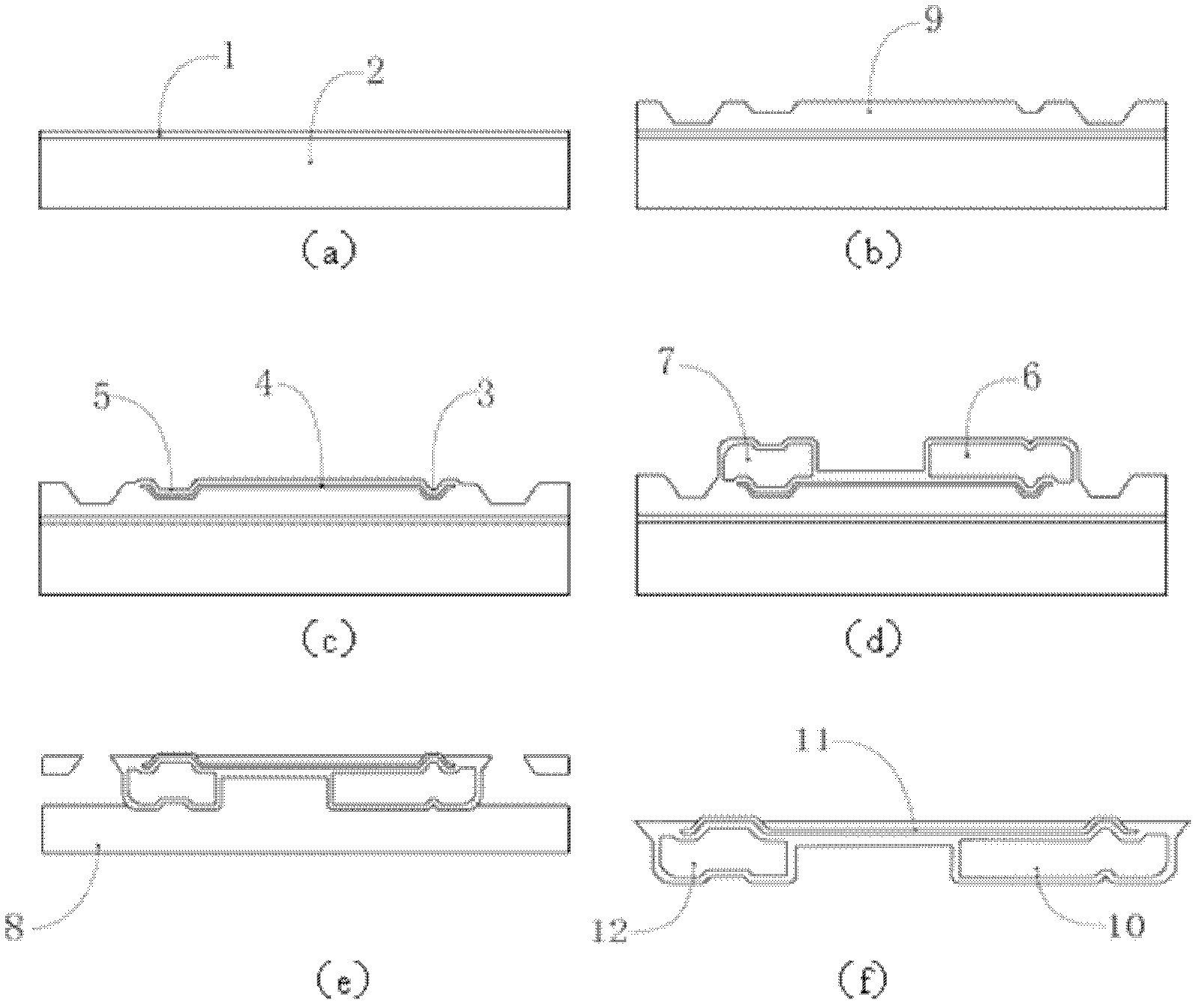

Implantable microneedle tip electrode and manufacturing method thereof

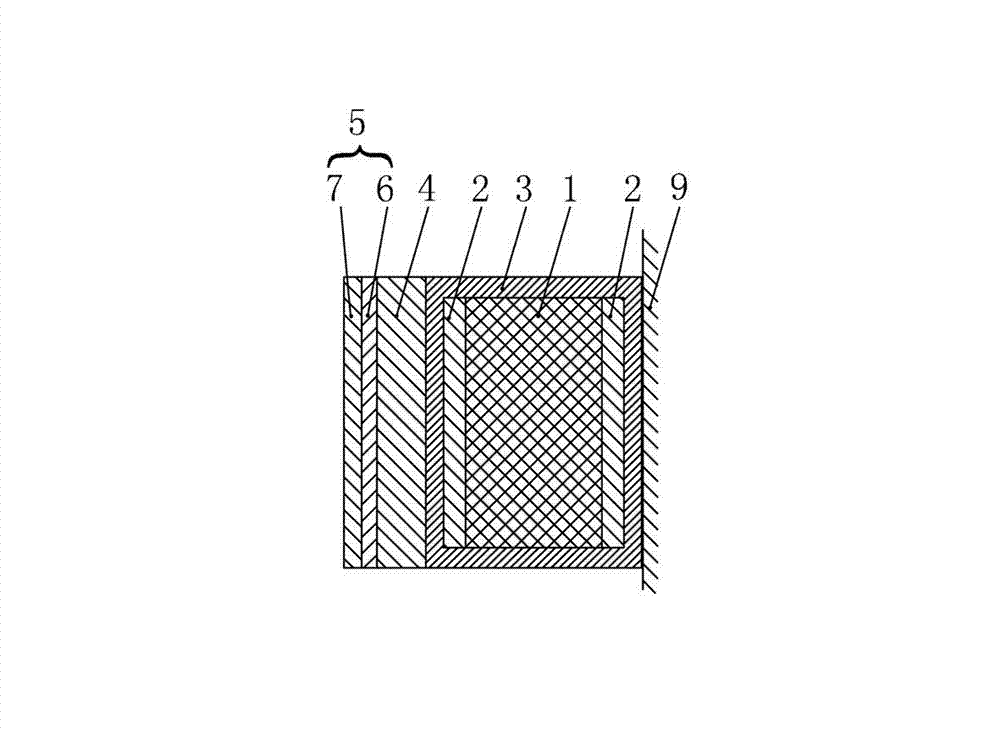

ActiveCN102289148AControllable thicknessReduce process costDecorative surface effectsInternal electrodesAluminiumMetallic Nickel

The invention discloses an embedded micro-pinpoint electrode and a manufacturing method thereof, which relates to the technical field of micro-electronic mechanical systems and embedded micro-electrodes. The method comprises the following steps: A: manufacturing a metal electrode layer of a parylene-metal alloy-parylene structure on a silicon piece (2) coated with an aluminum film (1), wherein the metal electrode layer comprises an exciting point (3), an interconnection line (4) and a lead connecting line (5); B: manufacturing a nickel metal or nickel alloy mechanical supporting layer by photoetching and plating, wherein the mechanical supporting layer comprises a nickel metal or nickel alloy micro pinpoint (6) and a base supporting body of the lead connecting point (7); C: eroding an aluminum film victimization layer by a wetting method; bonding a dry film (8) on a front surface; etching an oxygen plasma on a back surface until an exciting point and a lead connecting point are exposed; and D: eroding the dry file by the wetting method and cleaning by using deionized water to obtain the micro-pinpoint electrode. The invention has the characteristics of high mechanical performance,good biological compatibility, convenient embedding, light damage to tissue, accurate and controllable size, high sensibility and high reliability.

Owner:析芒(宁波)生物微系统有限公司

Composite humidity sensitive material used for capacitive humidity sensor and sensor preparation method

InactiveCN107607594AControllable thicknessThe operation process is simpleMaterial capacitancePolyamidePolytetrafluoroethylene

The present invention provides a composite humidity sensitive material used for a capacitive humidity sensor and a sensor preparation method, the formula of the composite humidity sensitive material is as follows: mixing titanium oxide or barium titanate with barium strontium titanate in the mass ratio of 1:1-1:3 to obtain an initial functional ceramic material, mixing polyamide or polytetrafluoroethylene with the initial functional ceramic material in the mass ratio of 0.3wt%-0.5wt% to obtain a mixture; and mixing an inert metal with the mixture in the mass ratio of 15wt%-25wt%. A composite humidity sensitive film is prepared by an aerosol deposition technology from the composite humidity sensitive material, and the capacitive humidity sensor is prepared from the film by a semiconductor processing technology. The sensor has high precision, high stability, heat resistance, pollution prevention and high reliability.

Owner:王琮

Preparation method of fullerene/metal composite film on metal surface

ActiveCN102041543AControllable thicknessUniform coatingElectrolytic coatingsNanometreMetallic materials

The invention provides a preparation method of a fullerene / metal composite film on a metal surface. The preparation method is characterized by comprising the following steps of: (1) surface pretreatment of a substrate material: cleaning, acid-cleaning and activating a metal surface; (2) preparation of an electrophoresis solution, dispersing fullerene in tetrahydrofuran, ultrasonically oscillating, filtering, reducing and regulating PH value to be 8-12; (3) preparation of a fullerene film on the metal surface with an electrophoresis method; (4) preparation of electroplating liquid: preparing the electroplating liquid containing Ni, Sn, Zn, Cu, Cr, and the like; (5) preparation of a fullerene / metal compositecoating on a metal plate, which is provided with the fullerene film and obtained from the step (3), by adopting an electroplating method; and (6) heating. The method provided by the invention can be used for modifying the metal surface; and particularly a novel surface coating film metal material can be derived and a brand-new nano composite plating metal product can be developed by utilizing the thermal diffusion characteristic of the fullerene material.

Owner:BAOSHAN IRON & STEEL CO LTD

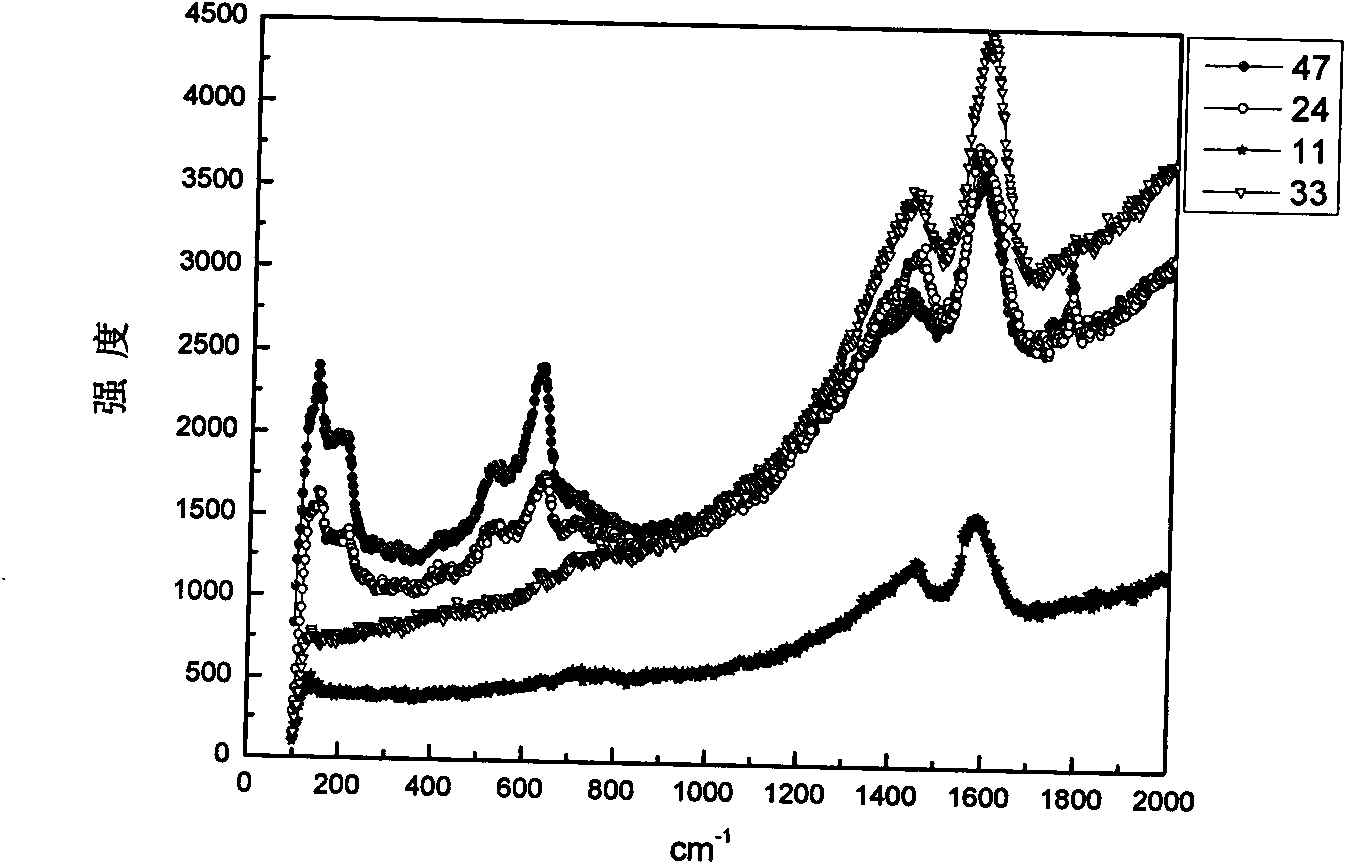

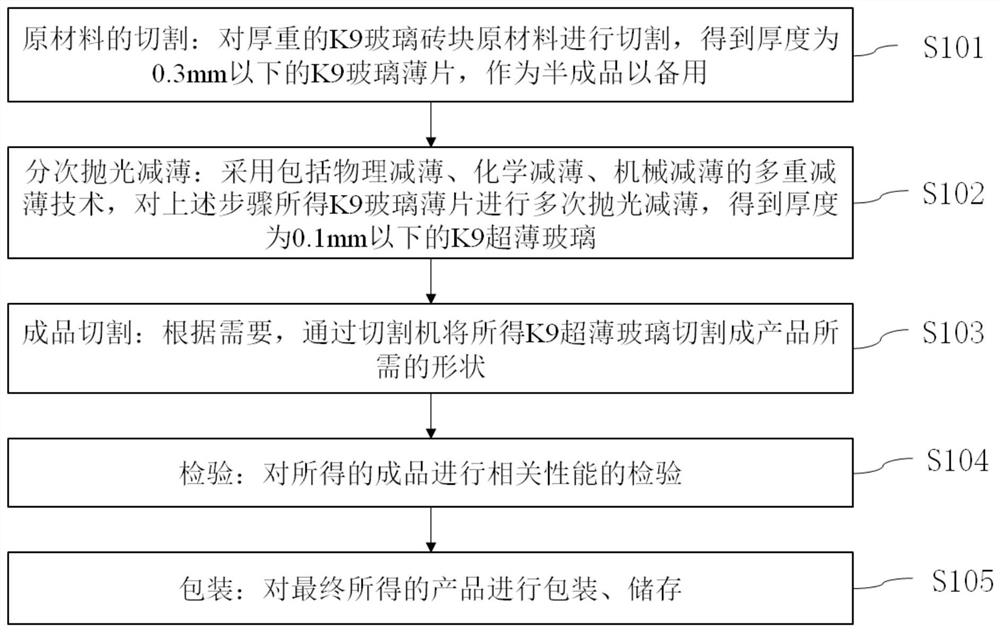

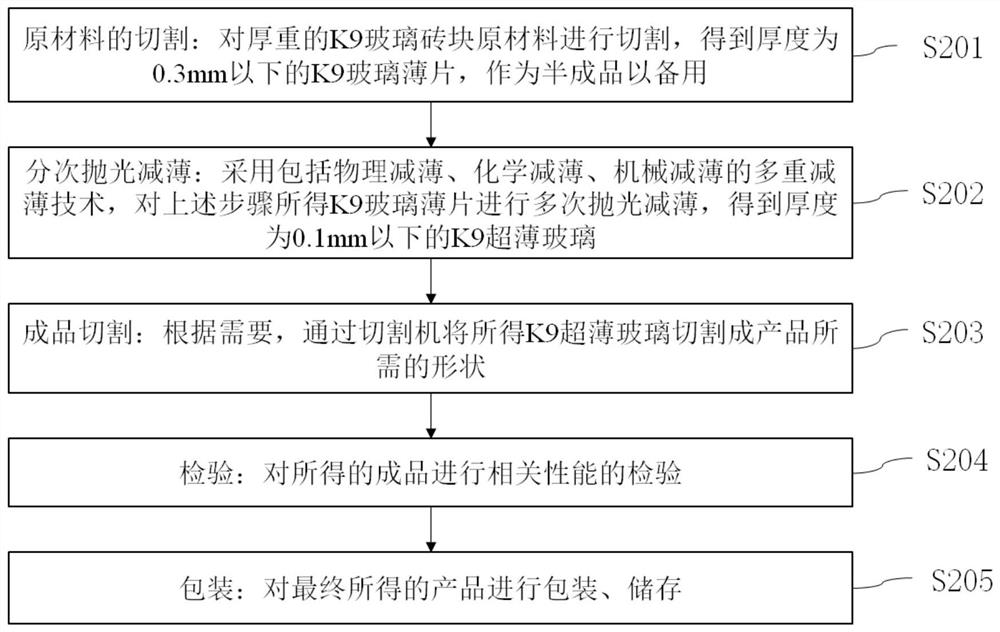

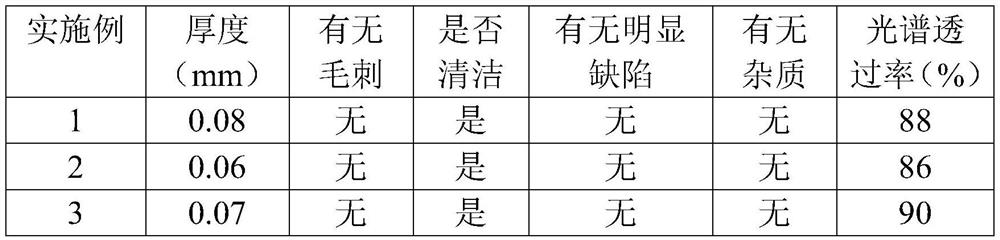

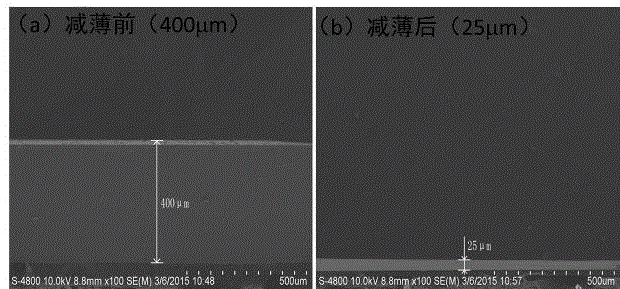

Processing method of K9 ultrathin glass

InactiveCN112408806AIncrease speedControllable thicknessGlass severing apparatusGlass tileSmooth surface

The invention relates to the technical field of optical glass processing, in particular to a processing method of K9 ultrathin glass, which comprises the following steps: cutting a thick and heavy K9glass brick raw material to obtain a K9 glass sheet as a semi-finished product for later use; then, subjecting the obtained K9 glass sheet to polishing and thinning for multiple times to obtain K9 ultrathin glass, wherein the process specifically comprises the steps of physical thinning, attaching and fixing, chemical thinning, cleaning, mechanical thinning and peptizing; cutting and inspecting afinished product; and finally, packaging and storing the finally obtained product. The advantages of physical thinning, chemical thinning and mechanical thinning are brought into full play, the thinning speed is high, the thinning thickness is controllable, and the K9 ultrathin glass with the ideal thickness and the flat and smooth surface is obtained; and by the adoption of a top-spraying waterfall flow type chemical thinning method, an etching solution can be recycled, energy and cost are saved, the automation degree of industrial production is improved, and application and popularization are facilitated.

Owner:TRIUMPH SCI & TECH GRP CO LTD +1

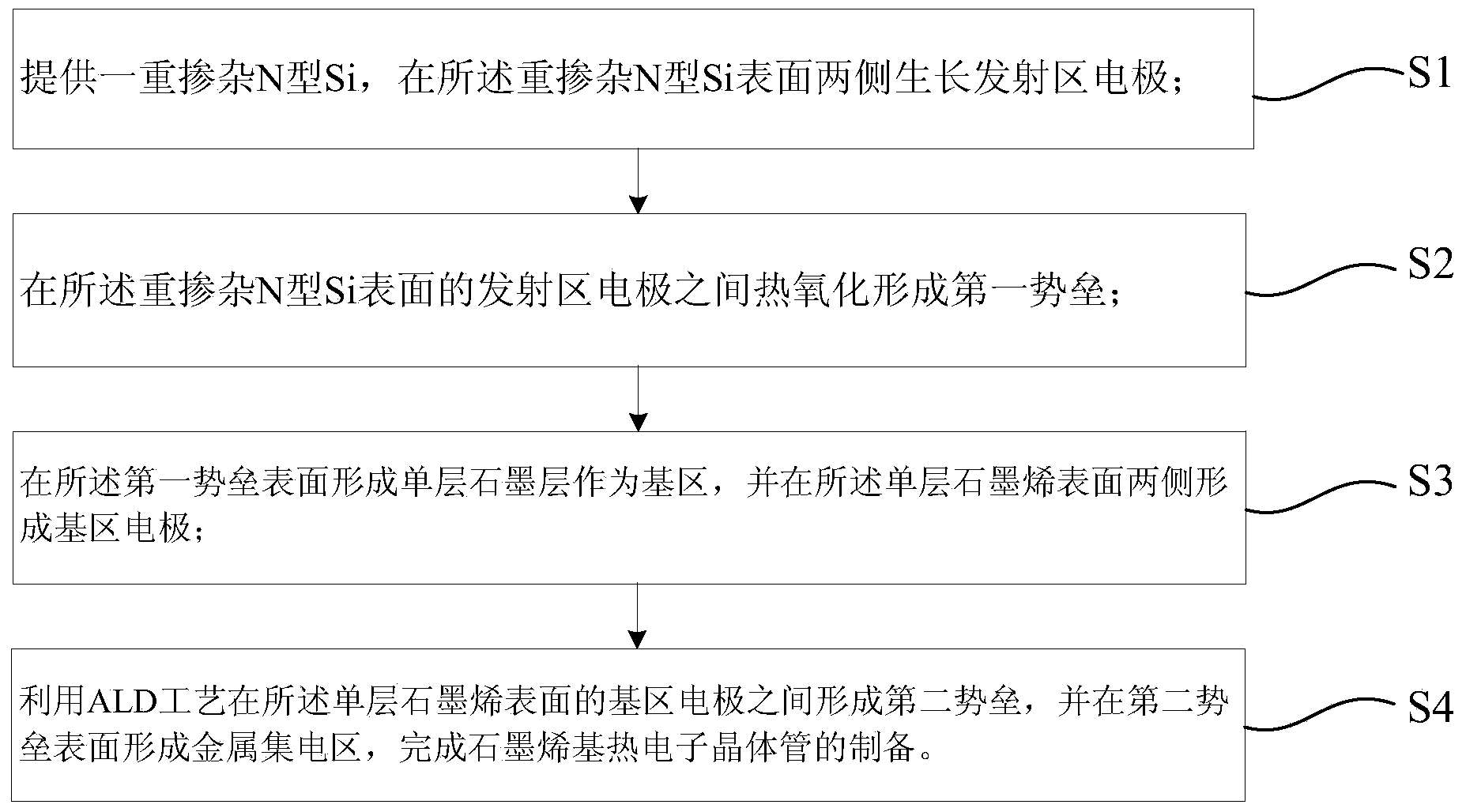

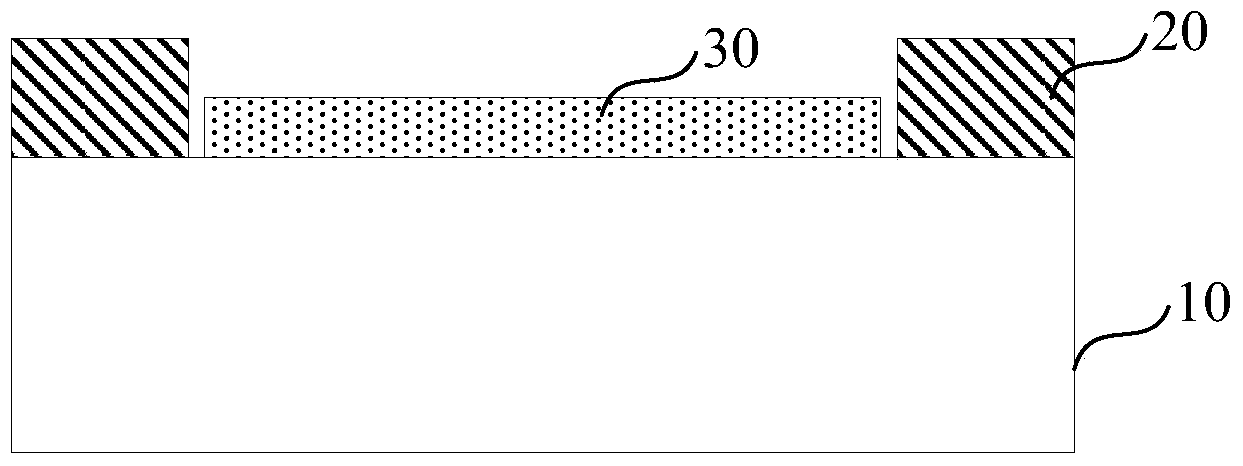

Graphene-based hot-electron transistor based on ALD (atomic layer deposition) and preparation method of graphene-based hot-electron transistor

InactiveCN103985741AGood performanceControllable thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesSingle layer grapheneCvd graphene

The invention provides a graphene-based hot-electron transistor based on ALD (atomic layer deposition) and a preparation method of the graphene-based hot-electron transistor. The preparation method comprises the following steps: (1) providing heavy doping N-type Si and growing emitter region electrodes at both sides of the surface of the Si; (2) carrying out thermal oxidation on the surface of the heavy doping N-type Si to form a first potential barrier; (3) forming a single graphitic layer on the surface of the first potential barrier as a base region and forming base region electrodes at both sides of the surface of the single graphitic layer; and (4) forming a second potential barrier between the base region electrodes on the surface of single-layer graphene by utilizing an ALD process and forming a metal collector region on the surface of the second potential barrier. By adopting the preparation method, the performance of a hot-electron device is relatively good by preparing the single graphene layer as the base region, utilizing the performance of quasi ballistic transport of the graphene and combining tunneling characters of hot-electron, and the potential barrier of high-k metallic oxide grown on the surface of the single-layer graphene by utilizing the ALD is controllable in thickness, free of pinhole and good in quality. In addition, the preparation method provided by the invention is accurate in preparation, simple and high in yield.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

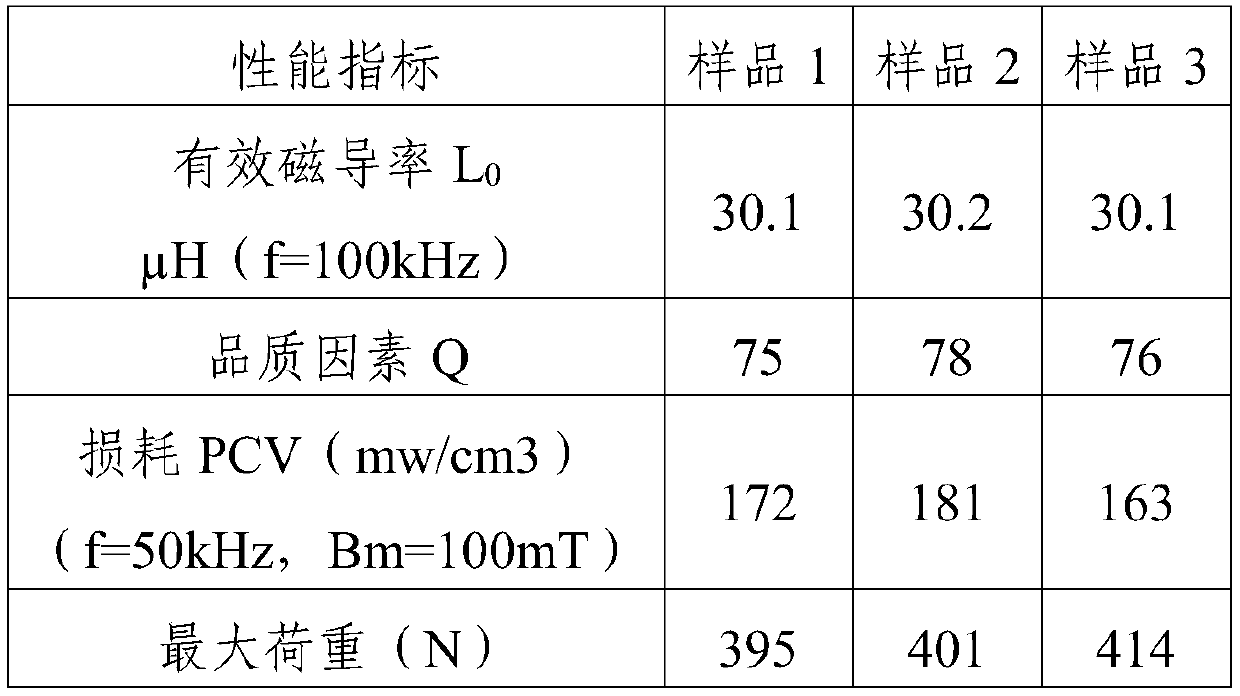

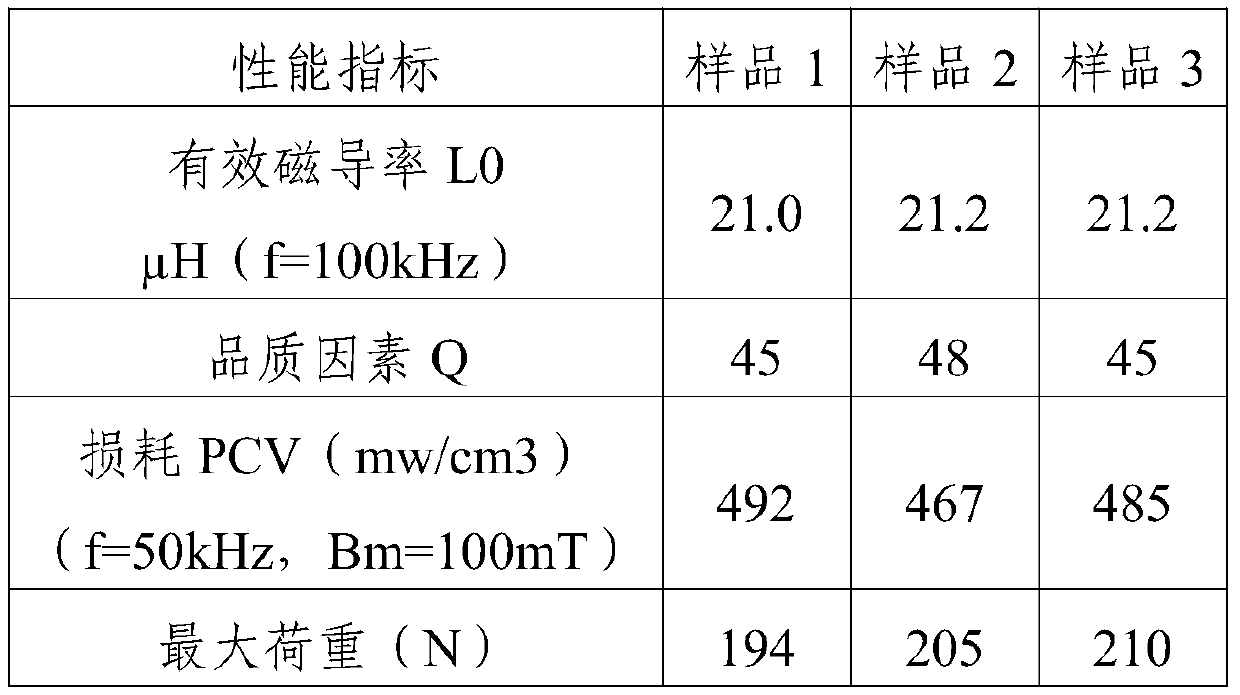

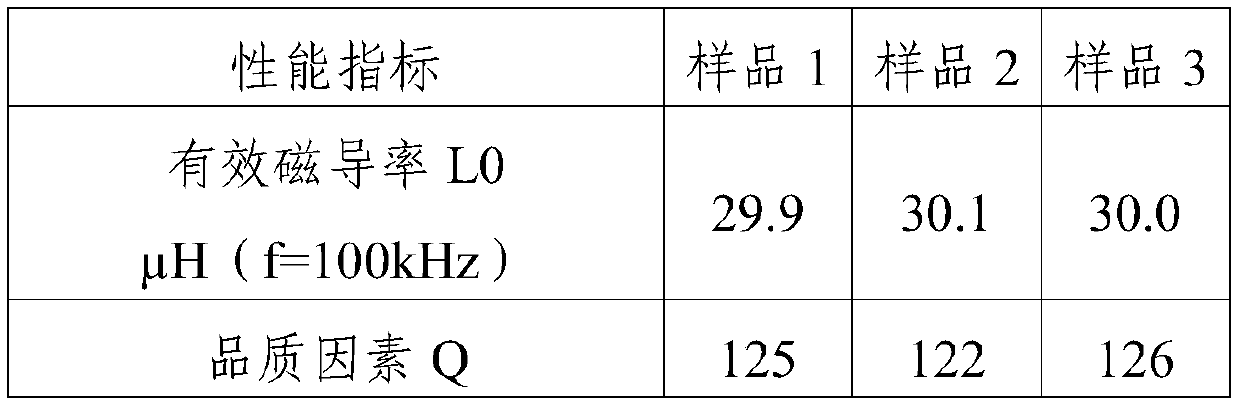

Full-inorganic high-temperature-resistant insulating bonding method for iron-based metal soft magnetic composite material

ActiveCN111029126AUniform coatingControllable thicknessInductances/transformers/magnets manufactureMagnetic powderBatch production

The invention provides a full-inorganic high-temperature-resistant insulating bonding method for an iron-based metal soft magnetic composite material, and relates to the technical field of iron-basedmetal soft magnetic composite materials. The method comprises the following steps: 1) sieving iron-based magnetic powder to carry out size grading; (2) compounding silica sol and alumina sol, carryingout insulation coating on the prepared magnetic powder and drying; and 3) mixing the dried magnetic powder with a binder and a filler and then drying; and adding demolding powder, carrying out dry pressing molding, and carrying out thermal treatment under the protection of nitrogen to obtain the magnetic powder core. The mixed sol is used for coating the magnetic powder, the coating layer is uniform, the thickness is controllable, the thermal stability is high, the resistivity is high, the loss is low, and the magnetic property and the mechanical property are excellent; and the mixed sol is adopted to insulate and coat the magnetic powder so that the operability is high and batch production is facilitated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Hole metallizing method for circuit board with high ratio of thickness to radial dimension

InactiveCN106535501AReduce pollutionControllable surfaceVacuum evaporation coatingSputtering coatingCopperElectroplating

The invention provides a hole metallizing method for a circuit board with a high ratio of thickness to radial dimension, and solves problems that there is no tin layer for protecting the hole bottom after etching, there is no copper in the hole and thereby the circuit board is caused to be discarded because a metalized back drill hole with the high ratio of thickness to radial dimension is relatively deep and a tin layer is difficult to set at the bottom of the hole in a coating manner after pattern electroplating. Therefore, the invention proposes the method for improving the no-copper condition of a metalized back drill hole of the circuit board with the high ratio of thickness to radial dimension. The invention can effectively control the thickness of hole wall copper, and the thickness can be controlled. The method can avoid the material waste caused by the normally-used thick copper technology in the prior art, can enable the surface copper layer of the hole wall to be uniform in thickness, enables the surface to be flat, and can meet the requirements of the performances of a precise circuit element circuit board. The method is simple, is advanced in technology, improves the electroplating current density, shortens the electroplating time, improves the deep electroplating capability, and effectively reduces the pollution caused by electroplating.

Owner:奥士康精密电路(惠州)有限公司

Electrostatic coating device of locomotive-mounted wheel rail friction control material

InactiveCN105728218AIncrease profitDensity controllableRail lubricationRail wetting/lubricationElectrostatic coatingEngineering

The invention discloses an electrostatic coating device of a locomotive-mounted wheel rail friction control material. The electrostatic coating device comprises a high-voltage electrostatic generator, a high-voltage electrode and a powder pump; the powder pump is provided with a secondary wind pressure pipe and a primary wind pressure pipe; a feed port of the powder pump is connected with a supply electromagnetic valve; the supply electromagnetic valve is connected with a storage tank; a discharge port of the powder pump is connected with a powder-air mixing pipe; the powder-air mixing pipe is connected with a nozzle; and the high-voltage electrode is arranged in the nozzle, and is connected with the high-voltage electrostatic generator. The electrostatic coating device has the following advantages: the electrostatic coating device saves such links as heating, stirring and insulation transportation in a solid-liquid-solid coating mode, so that the caused defects are prevented, the device is compact in structure, small in size and more convenient for installation, largely increases the material utilization rate, realizes controllability of coating thickness and density, and can adjust the coating thickness and density through a mode of adjusting primary and secondary wind pressure and voltage of the electrostatic generator according to specific conditions of different curves; and a coating method is more scientific and precise, and greatly improves the coating effect.

Owner:张峰

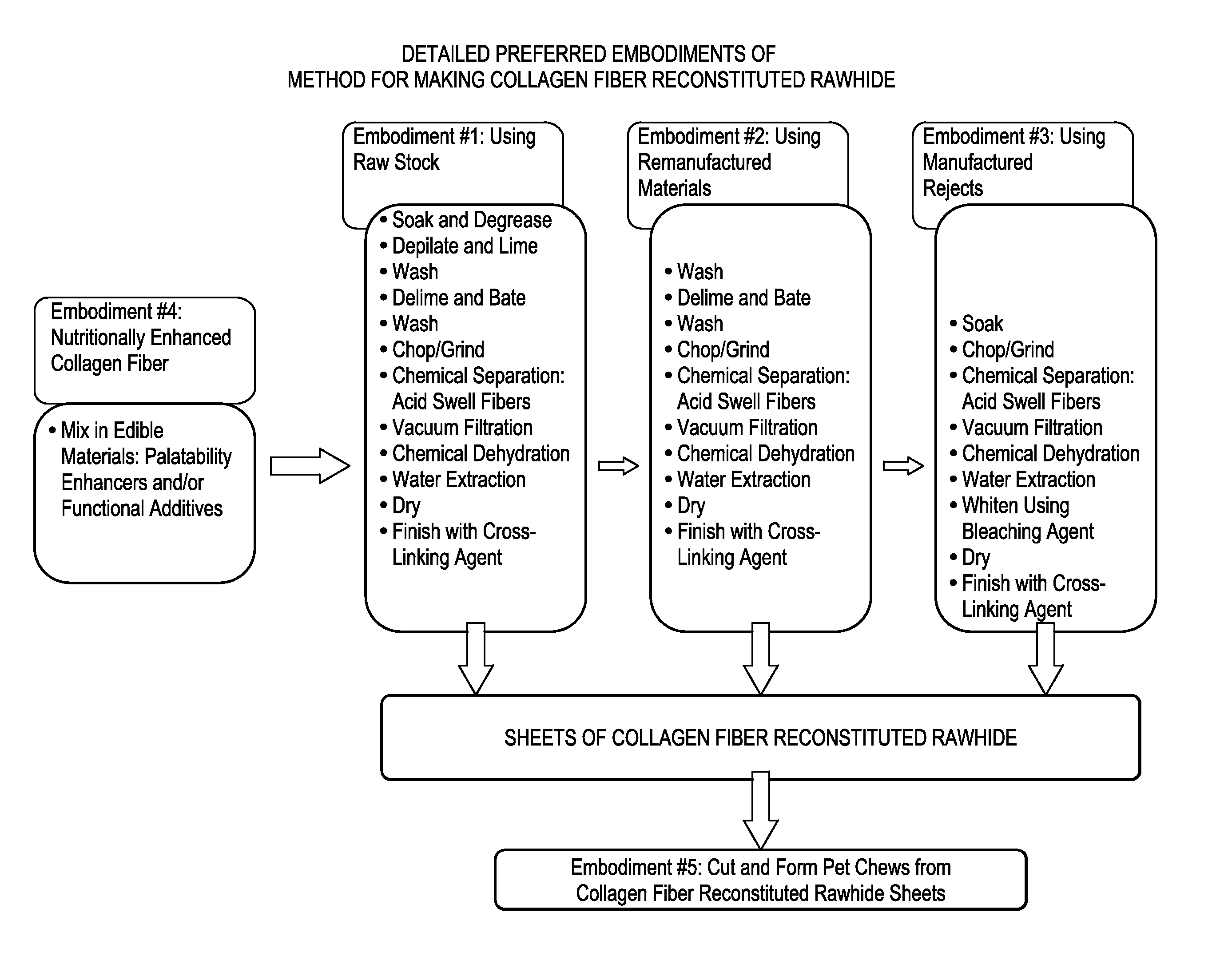

Collagen fiber reconstituted rawhide and process for making

InactiveUS9016241B2Add flavorIncrease valueMeat/fish preservationAnimal feeding stuffFiberCross-link

This invention describes a collagen fiber reconstituted rawhide useful in the production of pet chews, and a method for making the same. Beginning materials include animal skins with hair, depilated limed splits and leftovers from the manufacture of rawhide pet chews. The materials are pretreated, ground, subjected to acid treatment to swell and separate the collagen fibers that comprise the animal hide, further ground into pulp, vacuum filtered, mixed with a dehydration agent that chemically shrinks the expanded fibers, drained, formed and dried into sheet and finally exposed to a cross-linking agent to increase the adhesive strength of the end product. Edible materials, including meats, may be added to the solution prior to draining, to enhance the nutritional value and palatability of the final product, and the reconstituted rawhide sheets may be bleached for appearance.

Owner:PETPAL PET NUTRITION TECH CO LTD

Wet chemical etching method for preparing large-area and flexible ultra-thin monocrystalline silicon wafers

ActiveCN105047528AControllable thicknessSimple processSemiconductor/solid-state device manufacturingSilicon chipPotassium hydroxide

The invention discloses a wet chemical etching method for preparing large-area and flexible ultra-thin monocrystalline silicon wafers, and belongs to the field of semiconductor technology. According to the method, acetone, anhydrous ethanol, deionized water and hydrofluoric acid are adopted to treat a N(100) double-side-polished monocrystalline silicon wafer in advance, so that the surface of the silicon surface is cleaned. Potassium hydroxide, isopropanol and deionized water are uniformly mixed to prepare a reducer and the reducer is preheated in a water-bath. After that, the silicon wafer is well fixed and dipped in the reducer by a clamp. In this way, an ultra-thin wafer of a desired thickness can be obtained through controlling the reaction time and the reaction temperature, The surface of the silicon wafer is bright, flat, smooth and free of any obvious thinning defect, and appears the mirror-surface result. According to the technical scheme of the invention, the thinning process of silicon wafers is simplified by adopting the single-step method, and the characteristics of the wet etching technique in the low-temperature and normal-pressure condition are maintained. Silicon wafers with the thickness thereof smaller than 10 mm are obtained for the first time. Meanwhile, the application range of the wet silicon etching technique is expanded. Therefore, the method provides a novel idea and a novel technical means for the thinning process of silicon wafers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Multilayer hollow Nano fiber in use for cell culture, and preparation method

InactiveCN100463713CSimple methodControllable thicknessSemi-permeable membranesTissue/virus culture apparatusFiberCulture cell

A multi-layer hollow nanofiber used to culture cells is prepared through providing electrically spun fibers as template, alternatively adsorbing the polymers with positive and negative charges onto the surface of template, and using organic solvent to remove said template.

Owner:SOUTHEAST UNIV

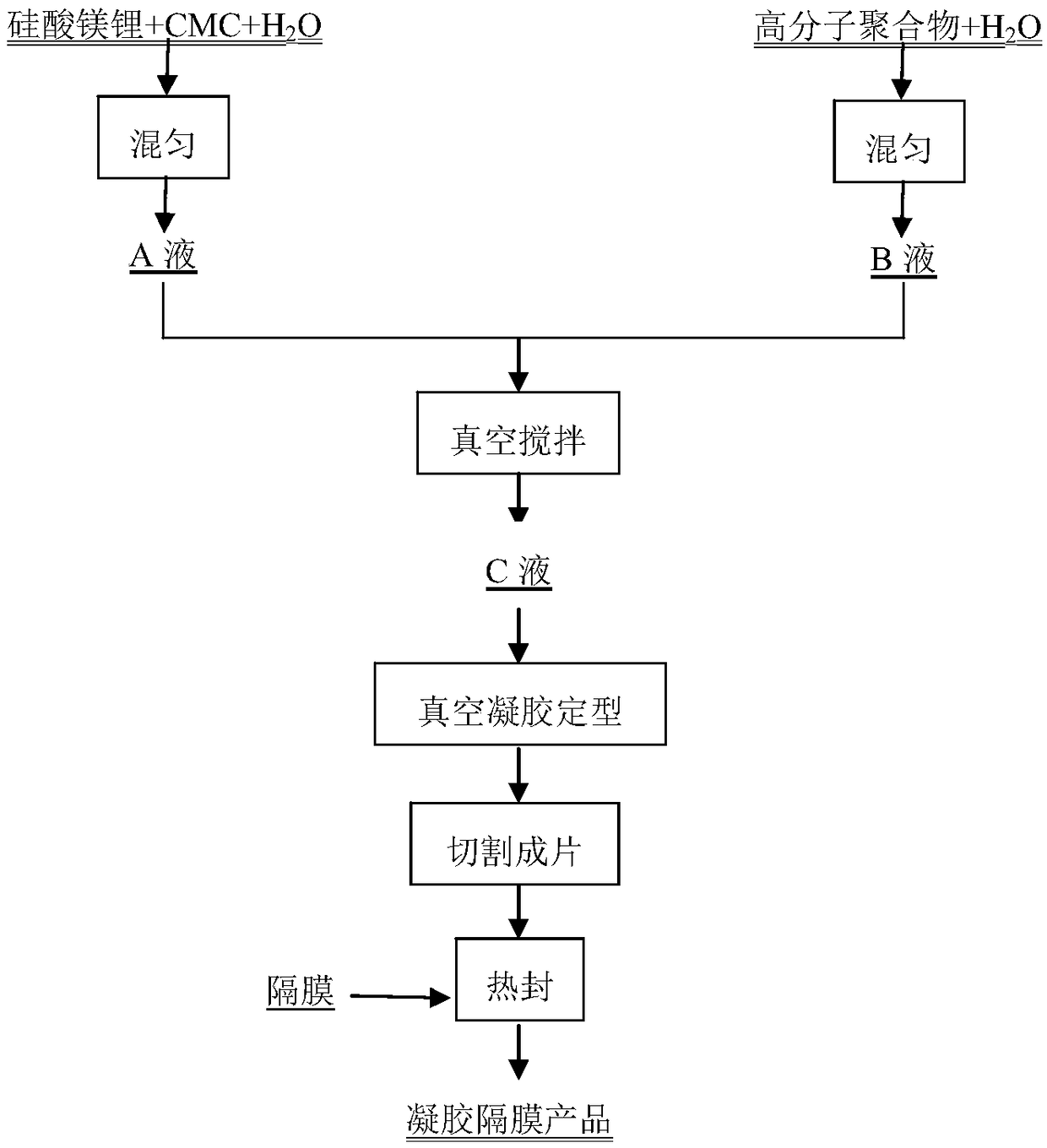

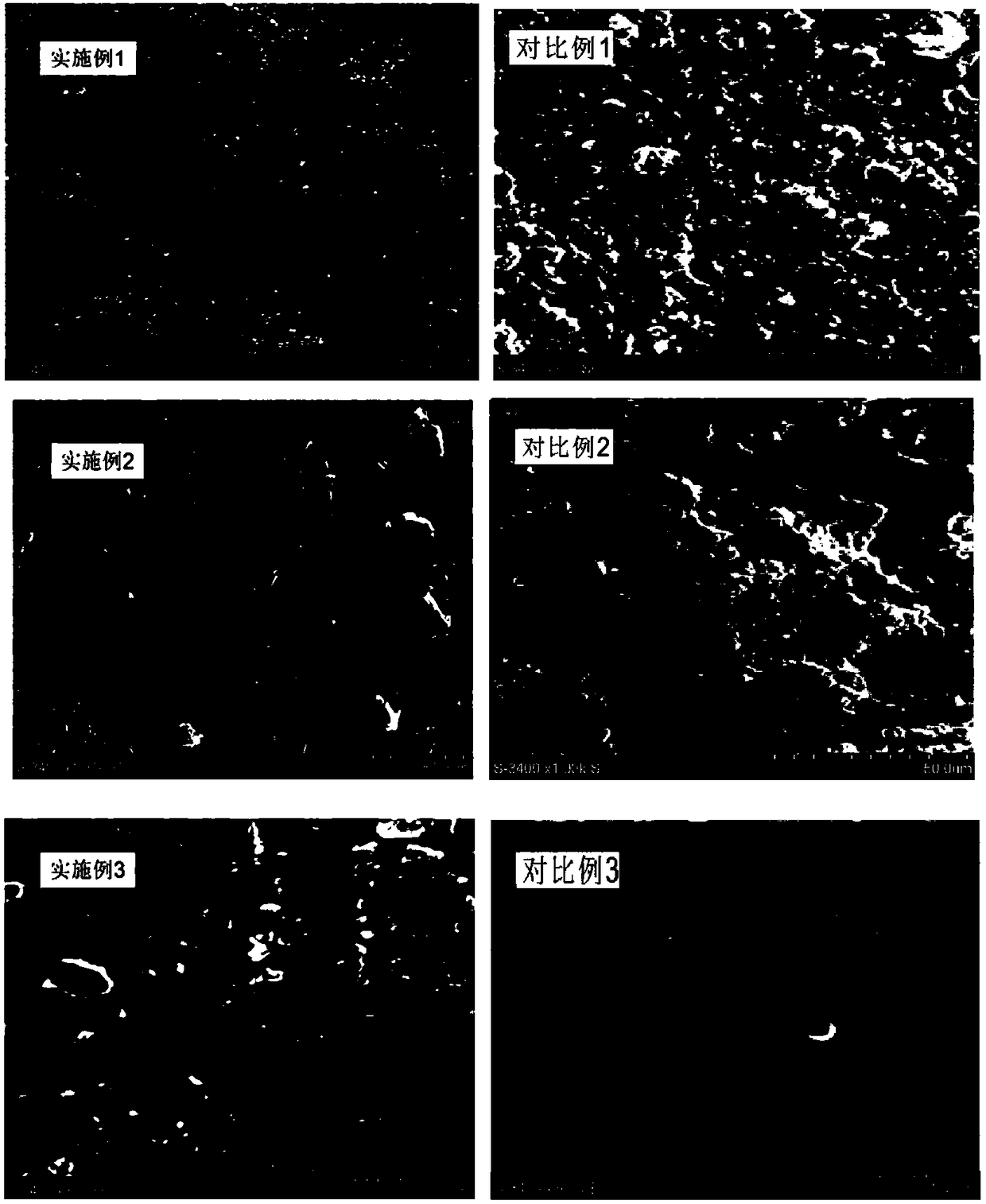

Gel diaphragm for new rare-earth power supply and preparation method thereof

ActiveCN108598347AControllable thicknessThickness resistant to carbonizationCell seperators/membranes/diaphragms/spacersNickel accumulatorsMagnesiumElectrical resistivity and conductivity

The present invention belongs to the field of polymer composites and functional materials, and relates to a gel diaphragm for a new rare-earth power supply and a preparation method thereof. After an Asolution and a B solution are mixed, a mixture is placed into a bucket for vacuum gel forming. Then, gel is cut into sheets and is heat-sealed with a diaphragm to obtain the gel diaphragm for a new rare-earth power supply, wherein the A solution is obtained by mixing magnesium lithium silicate, CMC and H2O, and the B solution is obtained by mixing a polymer and water. The gel diaphragm of the present invention is prepared under the combination of inorganic thixotropic gel and organic gel, is controllable in thickness and resistant to carbonization, and has high mechanical strength. The problem that a gel diaphragm with high mechanical strength cannot be prepared under conventional process treatment in the prior art is solved. The gel diaphragm of the present invention has the features ofhigh conductivity and low interfacial energy of a liquid electrolyte, and also has the advantage of good long-range stability of a solid electrolyte. The present invention also provides a preparationmethod of the gel diaphragm. The preparation method can realize industrialization and has good reproducibility. A production process of the preparation method is non-toxic, pollution-free and environmentally friendly.

Owner:包头昊明稀土新电源科技有限公司

Preparation method of positive electrode material of lithium ion battery and product thereof

PendingCN112614967AControllable thicknessReduce crackingElectrode collector coatingSecondary cells servicing/maintenanceElectrical batteryCyclic stability

The invention discloses a preparation method of a positive electrode material of a lithium ion battery and a product thereof, belonging to the technical field of electrochemical batteries. The method comprises the following steps: mixing a manganese-based positive electrode material of the lithium ion battery and a modification body, performing granulating, and conducting sintering to obtain the positive electrode material of the lithium ion battery. According to the invention, a high-electron conductor or a high-ion conductor is used as a modifier for uniformly modifying the surface of the positive electrode material by adopting a solid-phase fusion technology, and the thickness of a modification layer can be controlled by adjusting a mass ratio of the manganese-based positive electrode material of the lithium ion battery to the modification body; the surface of the modified positive electrode material of the lithium ion battery is more stable, dissolution of transition metal ions and generation of cracks between particles in the circulation process are slowed down, and the specific capacity and the circulation stability of the positive electrode material of the lithium ion battery are effectively improved; and the preparation method disclosed by the invention is friendly to environment, free of pollution and low in process cost.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com