Air condensation structure

An air and air inlet technology, which is applied in the field of drying clothes, can solve the problems of uneven air intake in the air condensation structure, small contact area between steam and condenser, and high production cost of aluminum alloy materials, so as to improve heat exchange efficiency and increase contact Heat dissipation area and the effect of reducing the failure maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

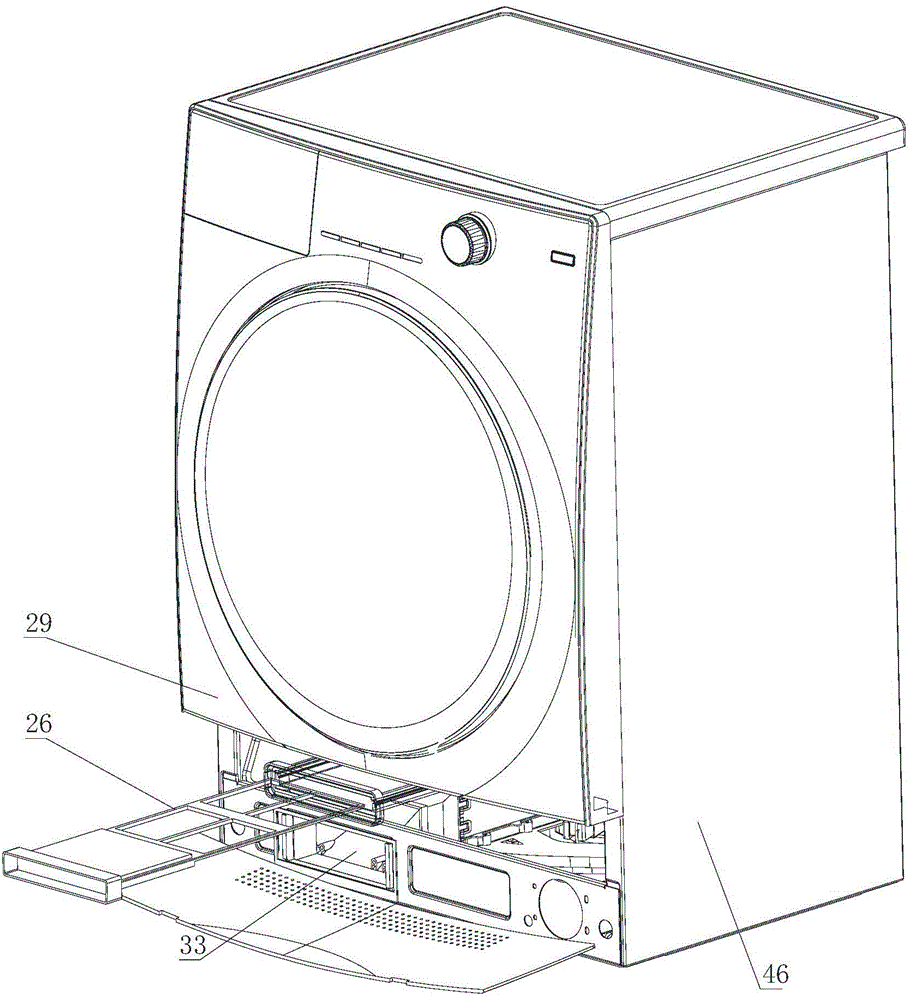

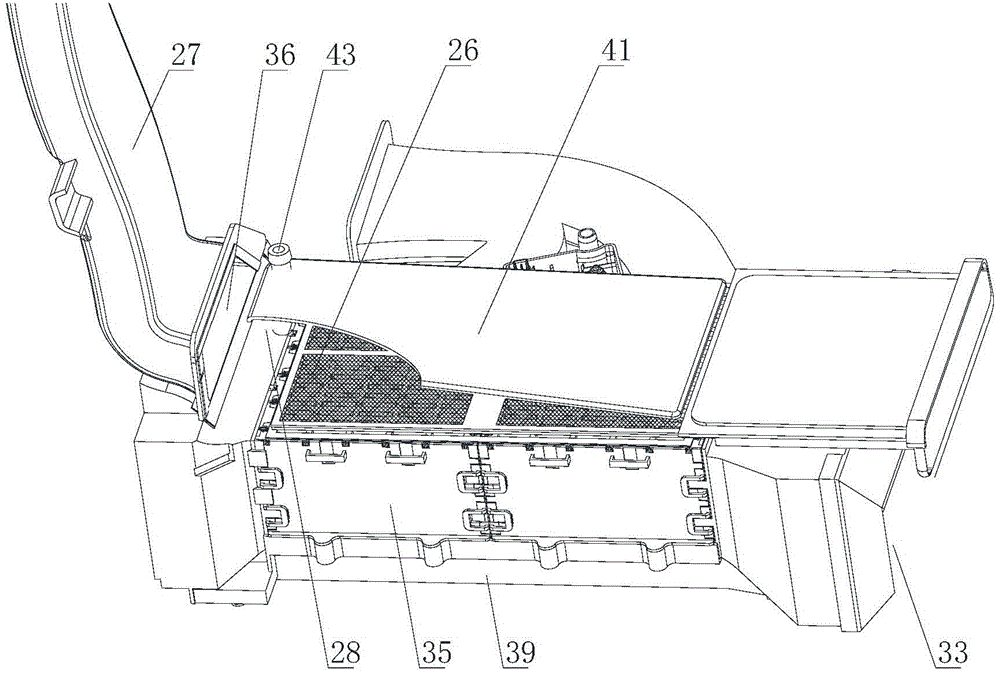

[0042] Such as image 3 As shown, a kind of air condensation structure of the present invention, described air condensation structure is a casing, comprises the air inlet 36 of hot air and the air outlet 37, also includes the air inlet 33 of cold wind and air outlet, the inside of air condensation structure A stacked heat exchanger is provided, and the heat exchanger is a plastic warp stacked in a criss-cross pattern, and a frame of a cage structure is arranged outside the heat exchanger.

[0043] Such as Figure 10 , Figure 11 , Figure 12 As shown, the stacked heat exchanger includes a plurality of stacked flaps 1, and the opposite sides of each flap 1 are bent upwards to cooperate with the upper flap 1 to form a ventilated air path. The adjacent flaps 1 are arranged vertically and horizontally alternately, forming horizontal wind passages and vertical wind passages which are mutually independent and spaced up and down. Among them, high-temperature air can be passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com