Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1217results about How to "Reduced risk of breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

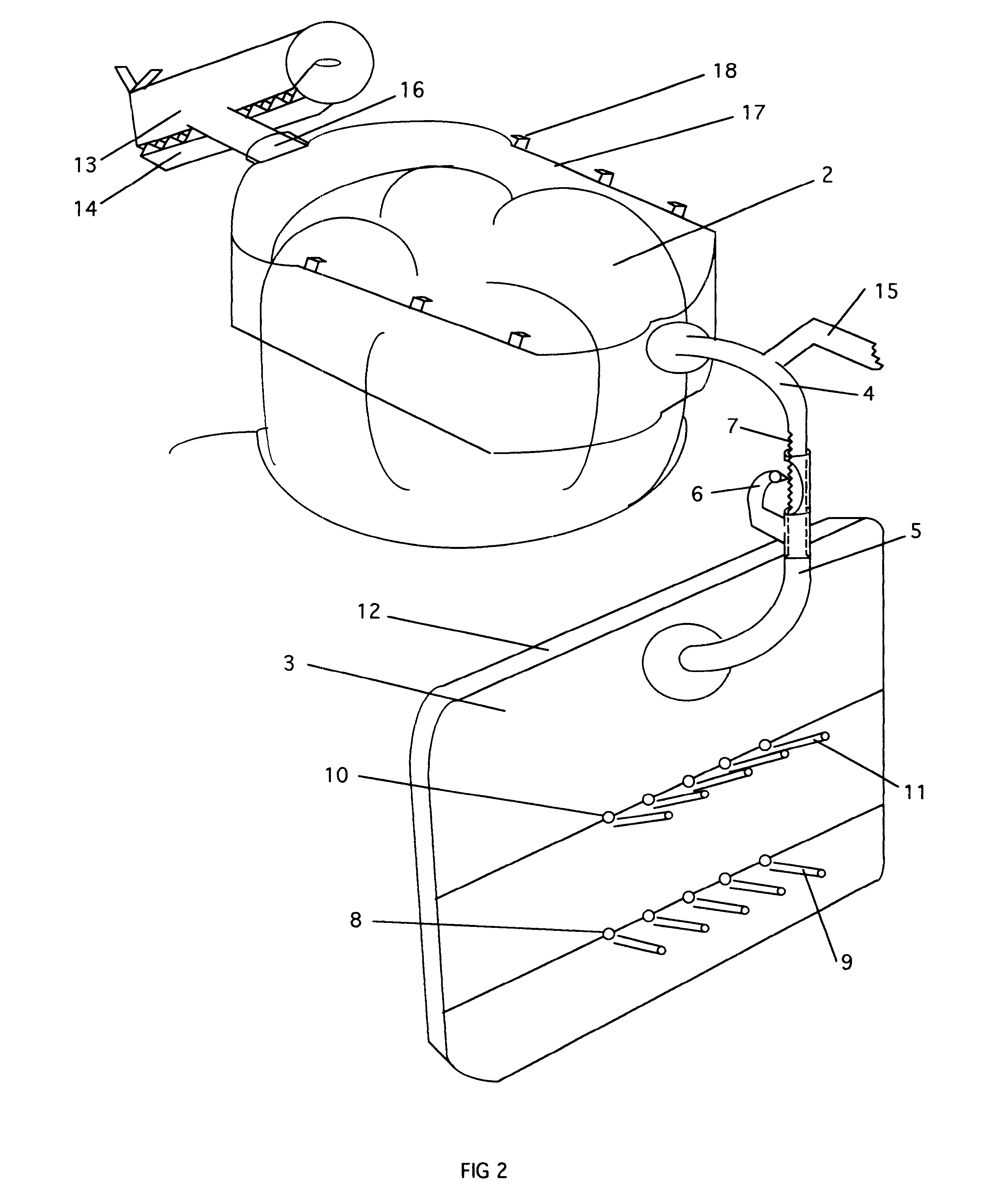

Two-part package for medical implant

ActiveUS7712606B2Low costProcedure be minimizedDispensing apparatusHeart valvesBiomedical engineeringMedical treatment

Owner:BOSTON SCI SCIMED INC

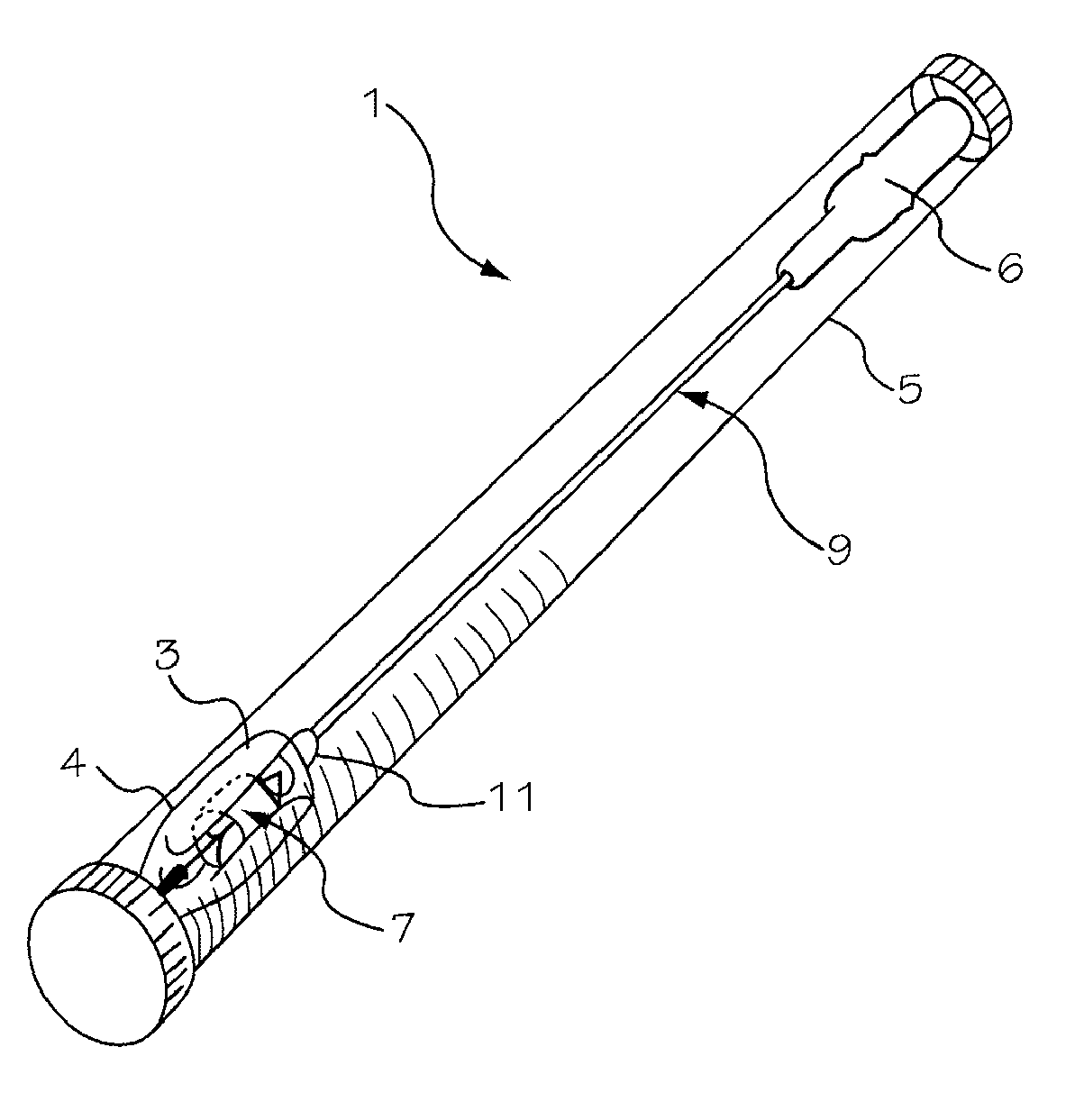

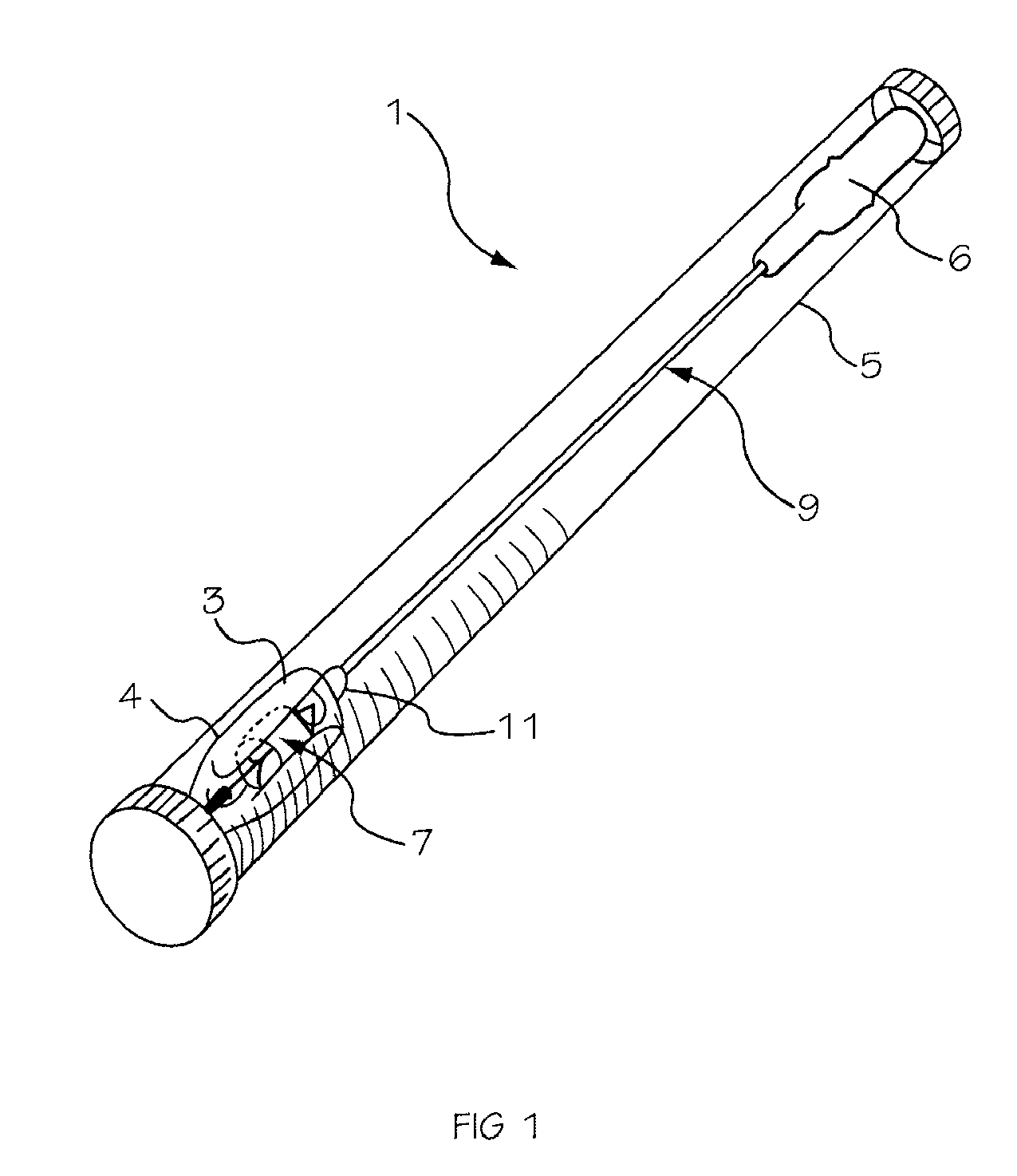

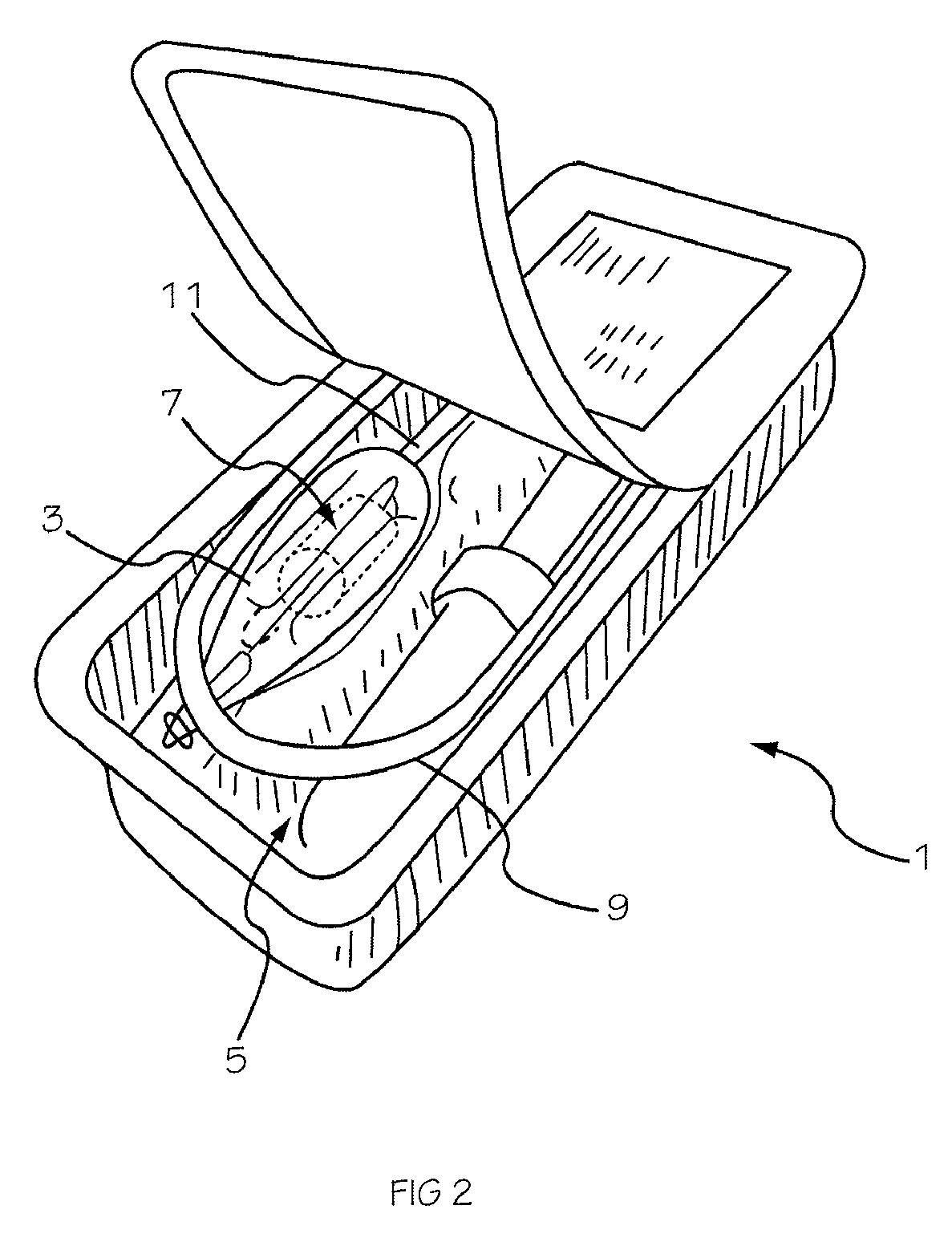

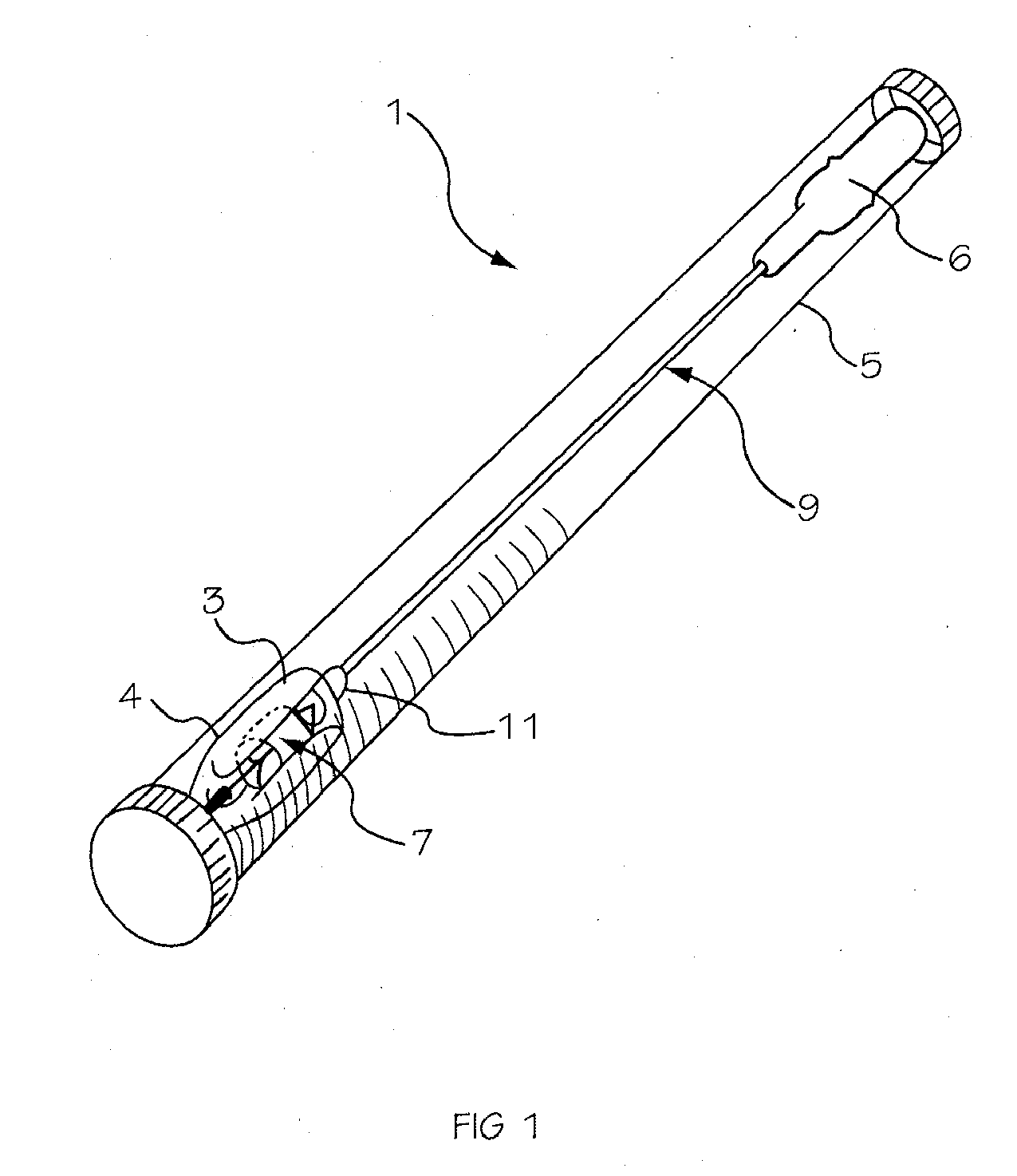

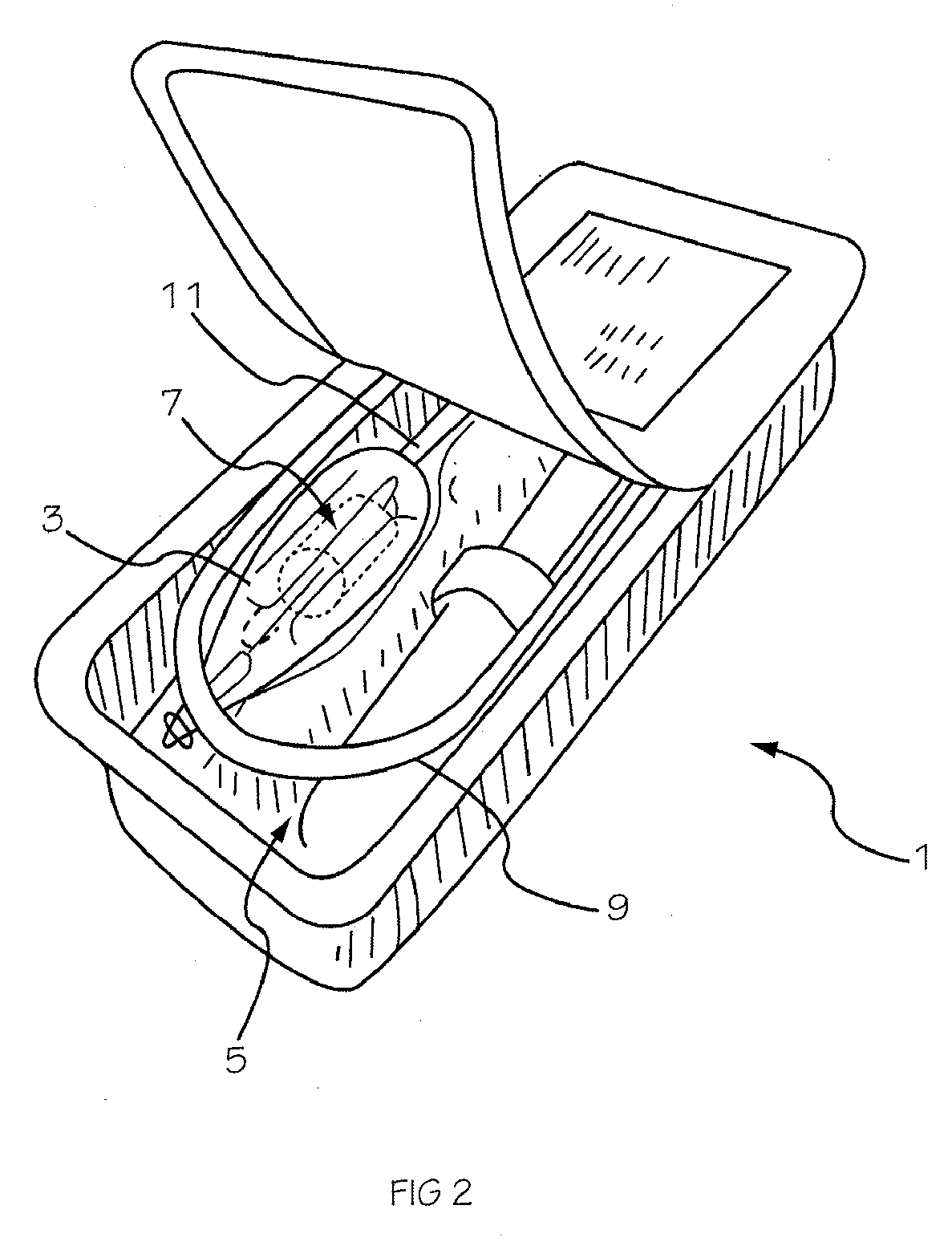

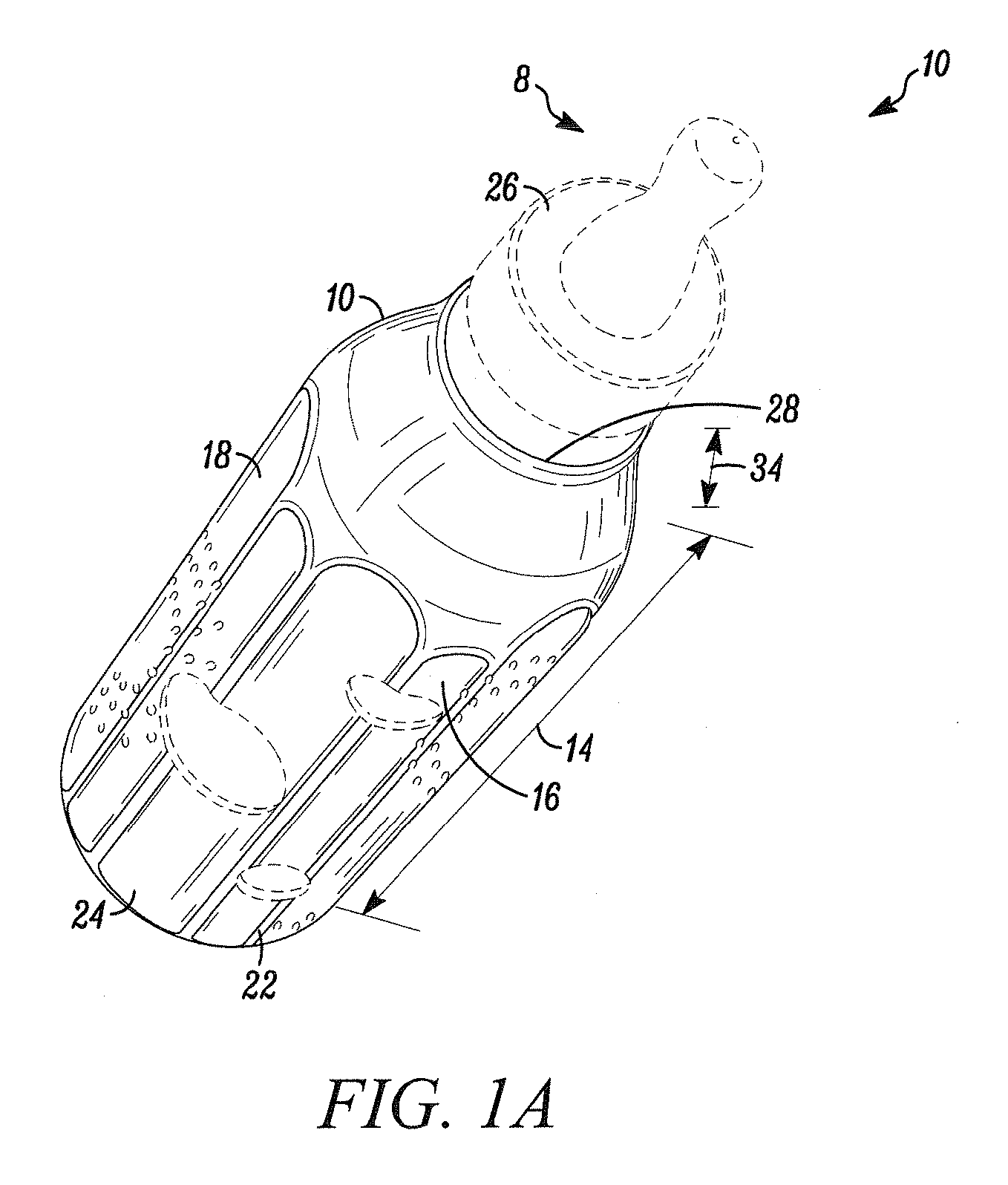

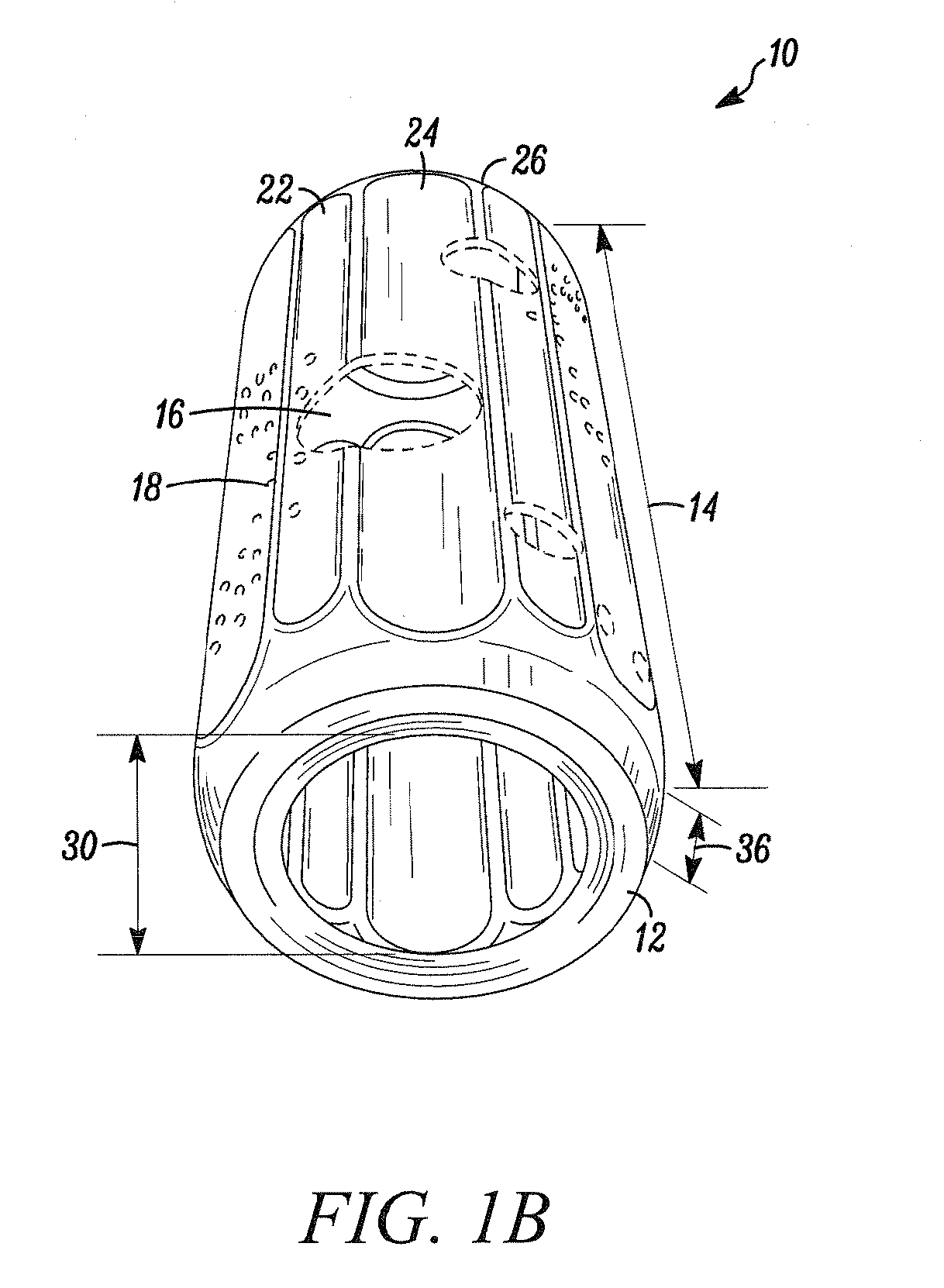

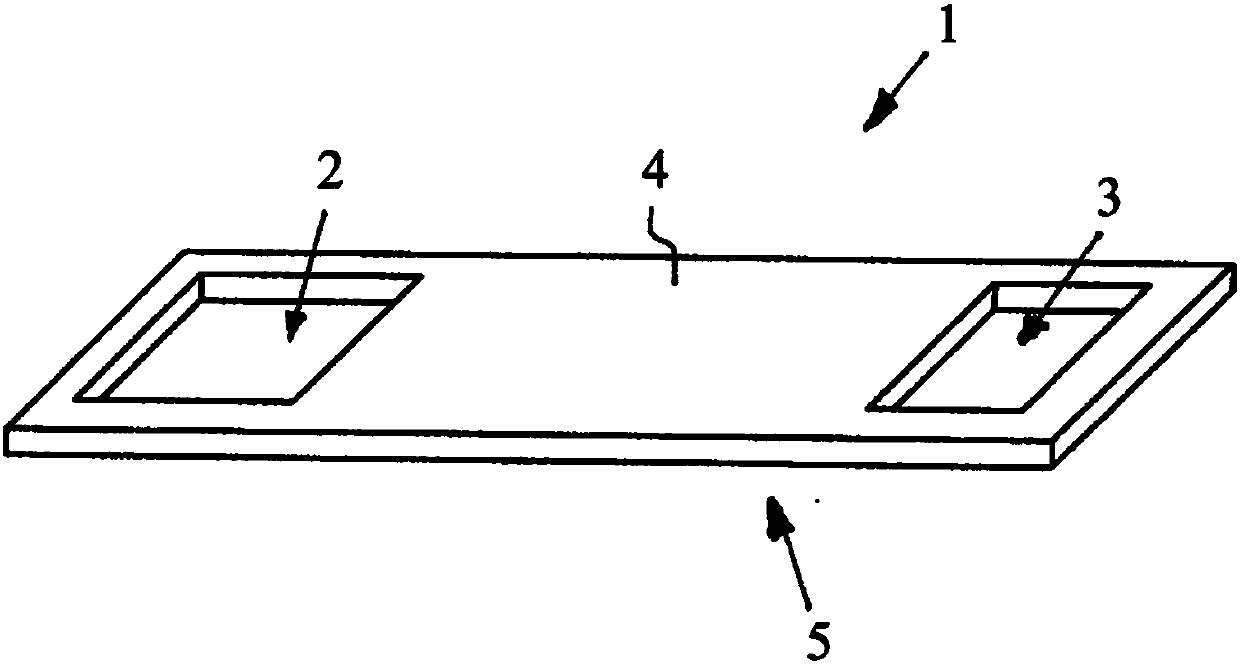

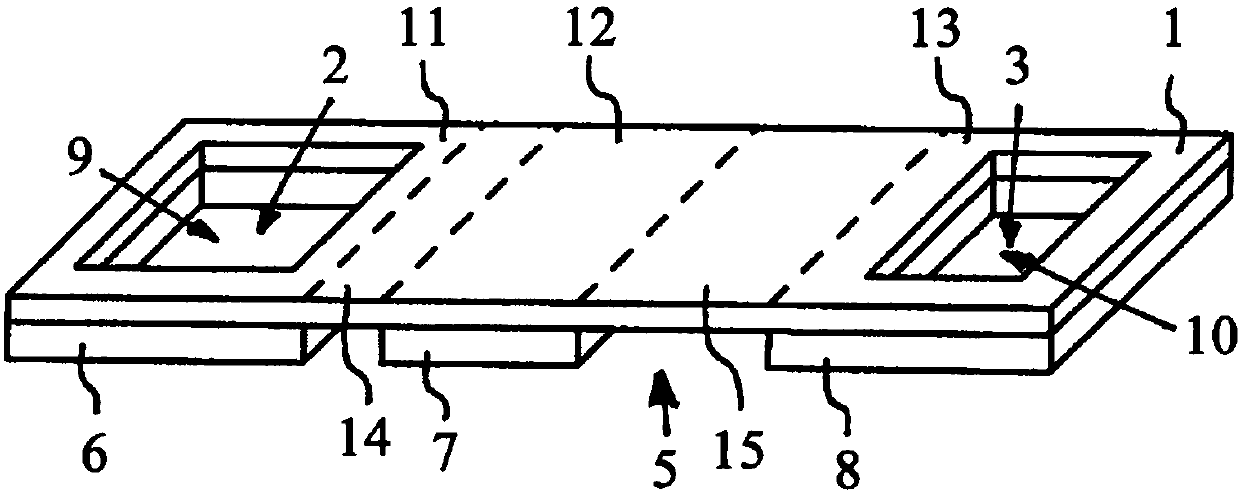

Two-Part Package For Medical Implant

ActiveUS20070061008A1Low costMinimize preparation timeDispensing apparatusHeart valvesBiomedical engineeringMedical treatment

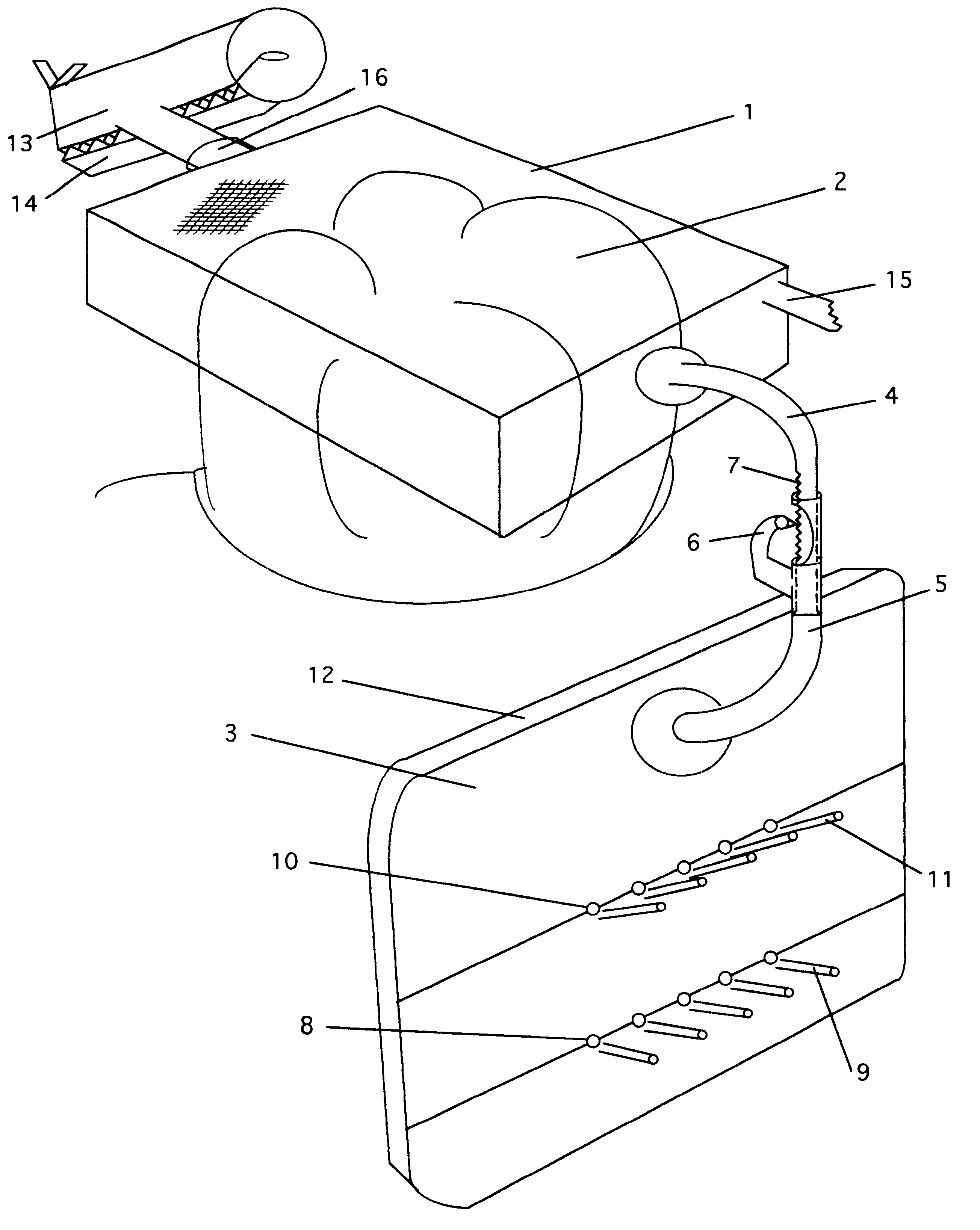

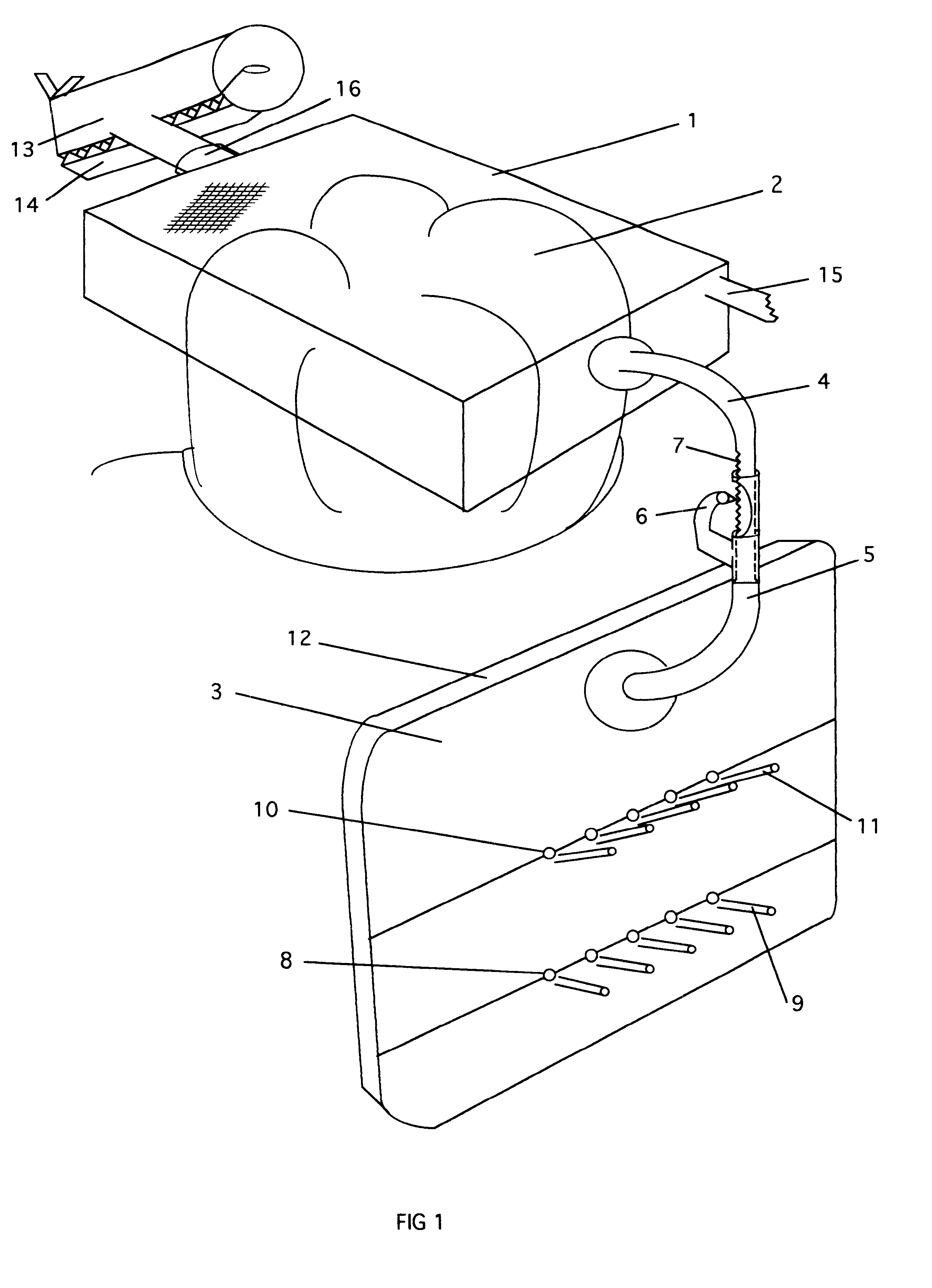

The invention provides a two-part package and method of use for a pre-attached medical implant and delivery tool system. The package includes a wet compartment and a dry compartment and allows a pre-attached implant and delivery tool system to be at least partially stored immersed in a fluid in the wet compartment and at least partially stored in the dry compartment. In one embodiment the implant comprises a replacement heart valve, and the heart valve is stored inside the wet compartment while the heart valve delivery tool remains dry in the dry compartment.

Owner:BOSTON SCI SCIMED INC

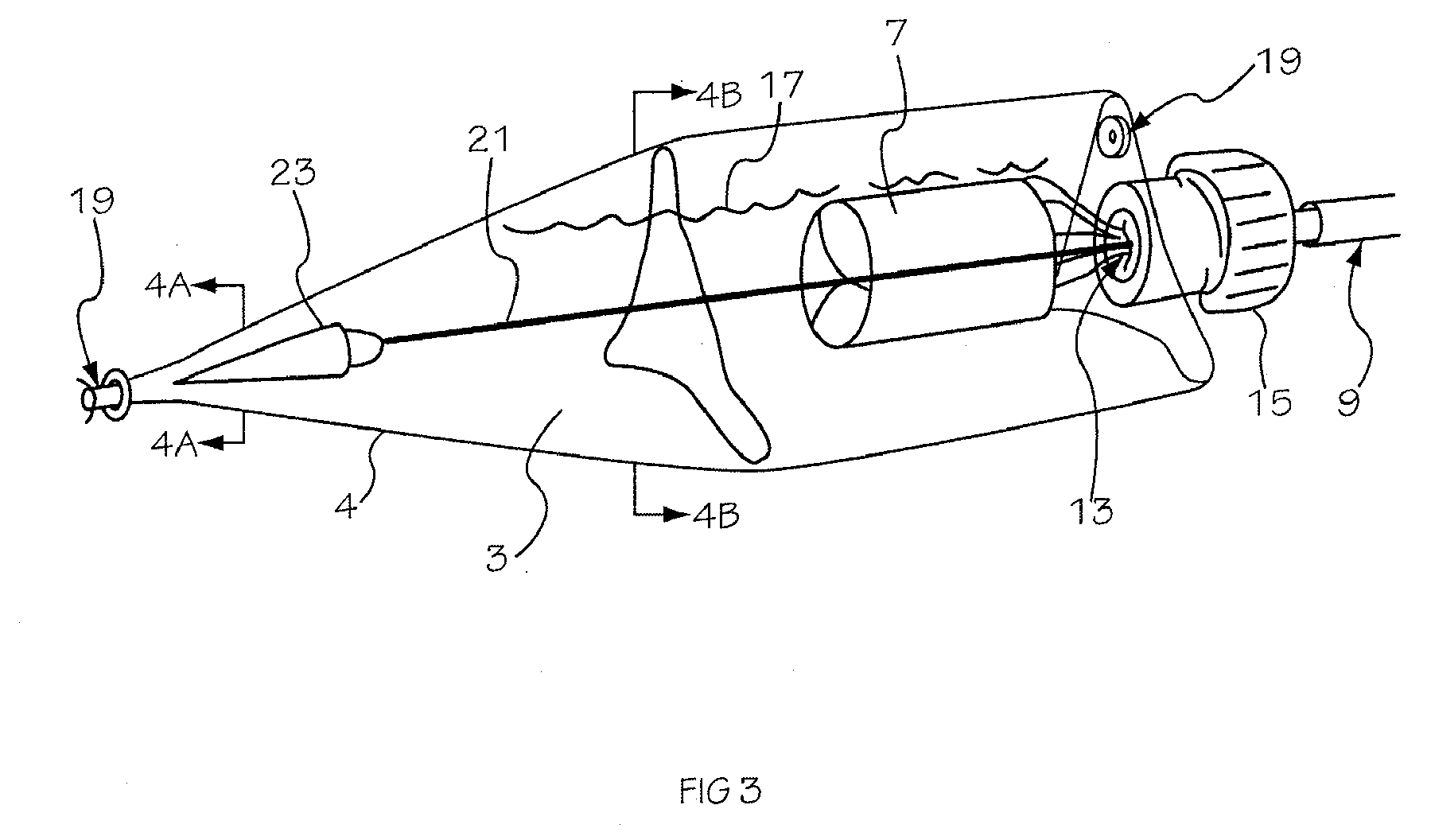

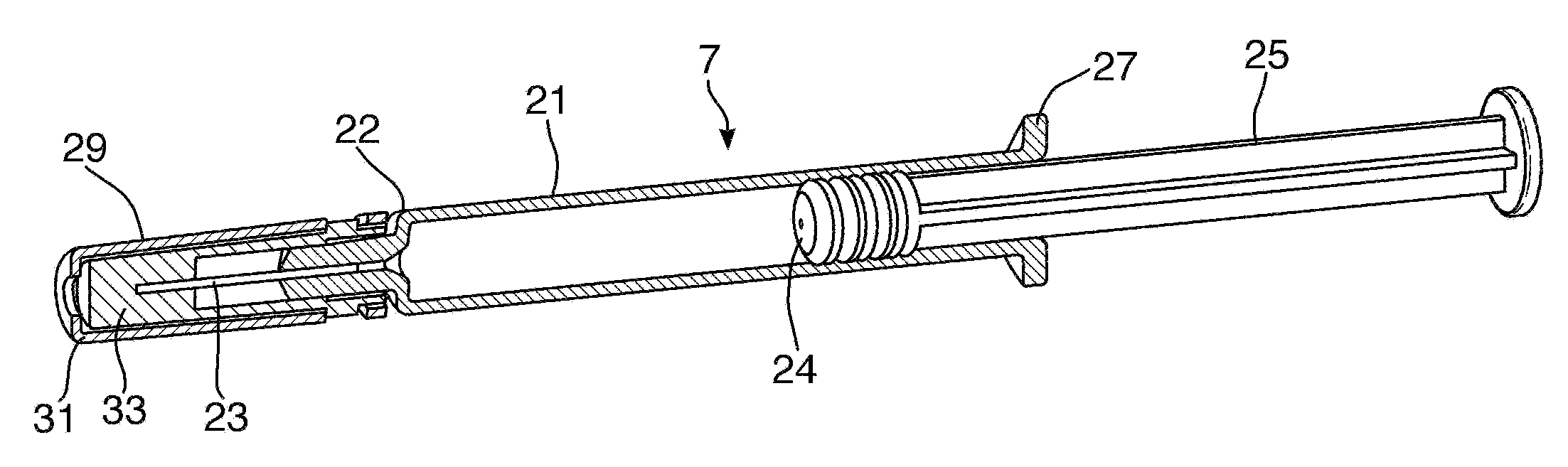

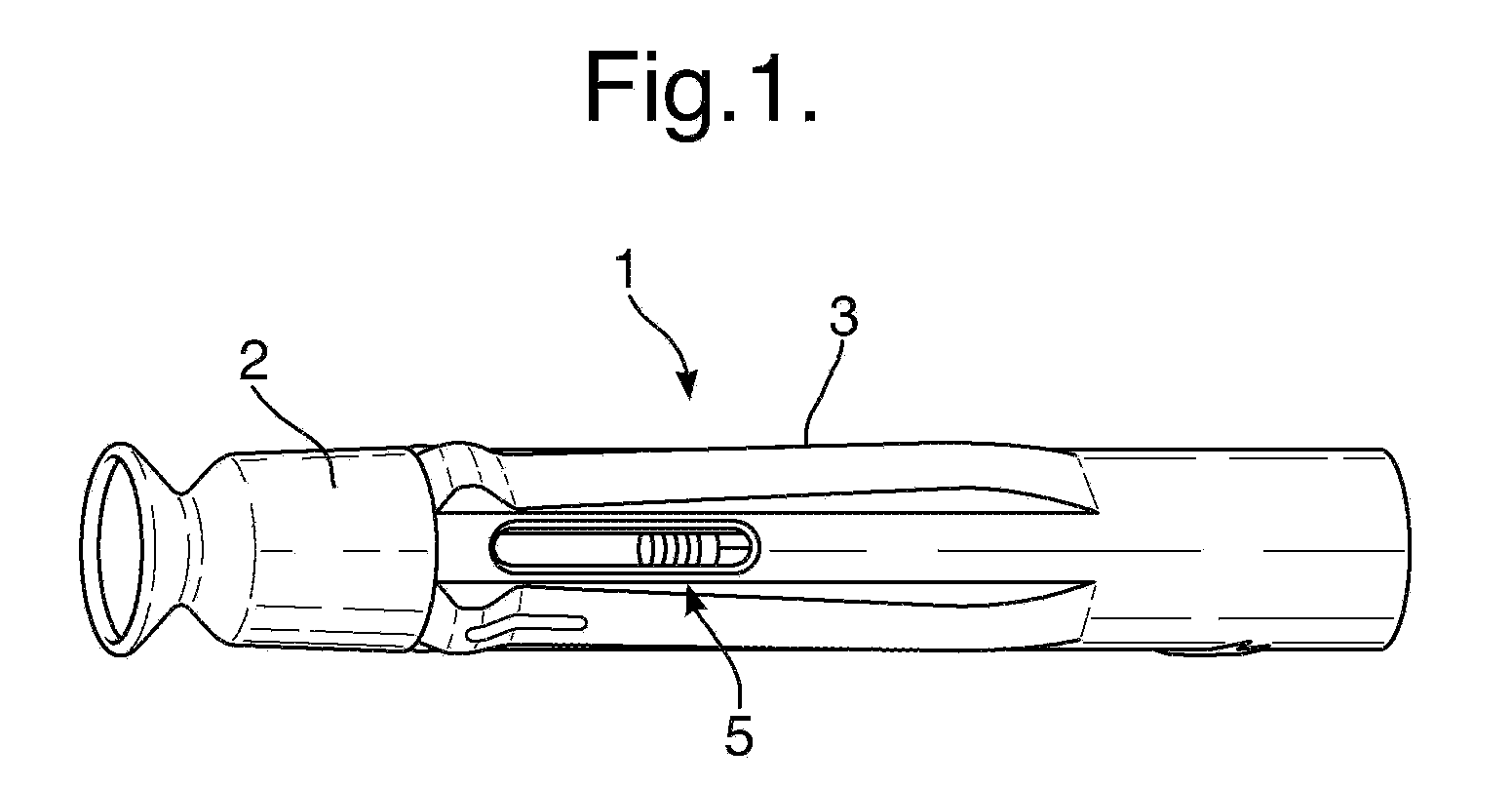

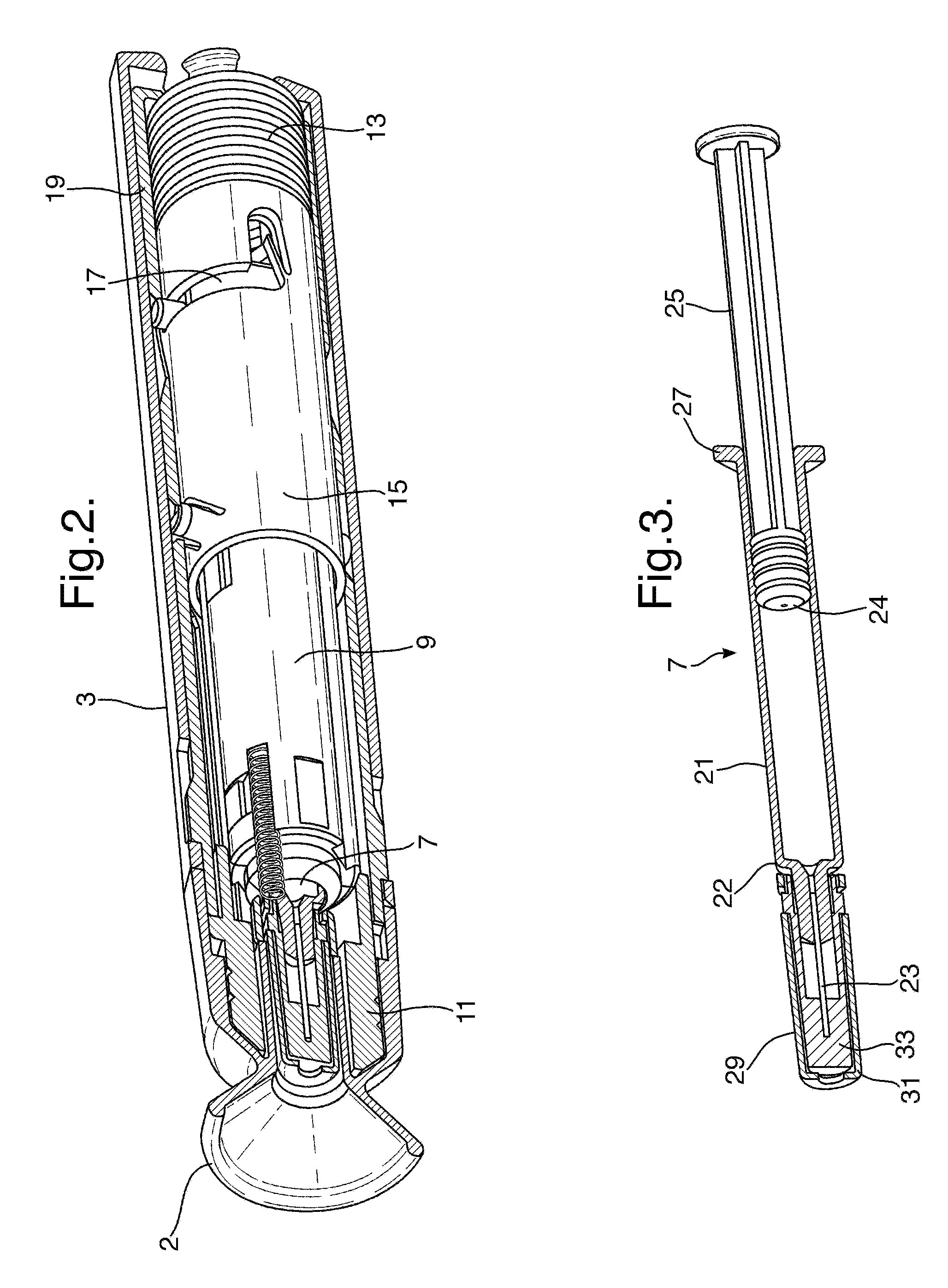

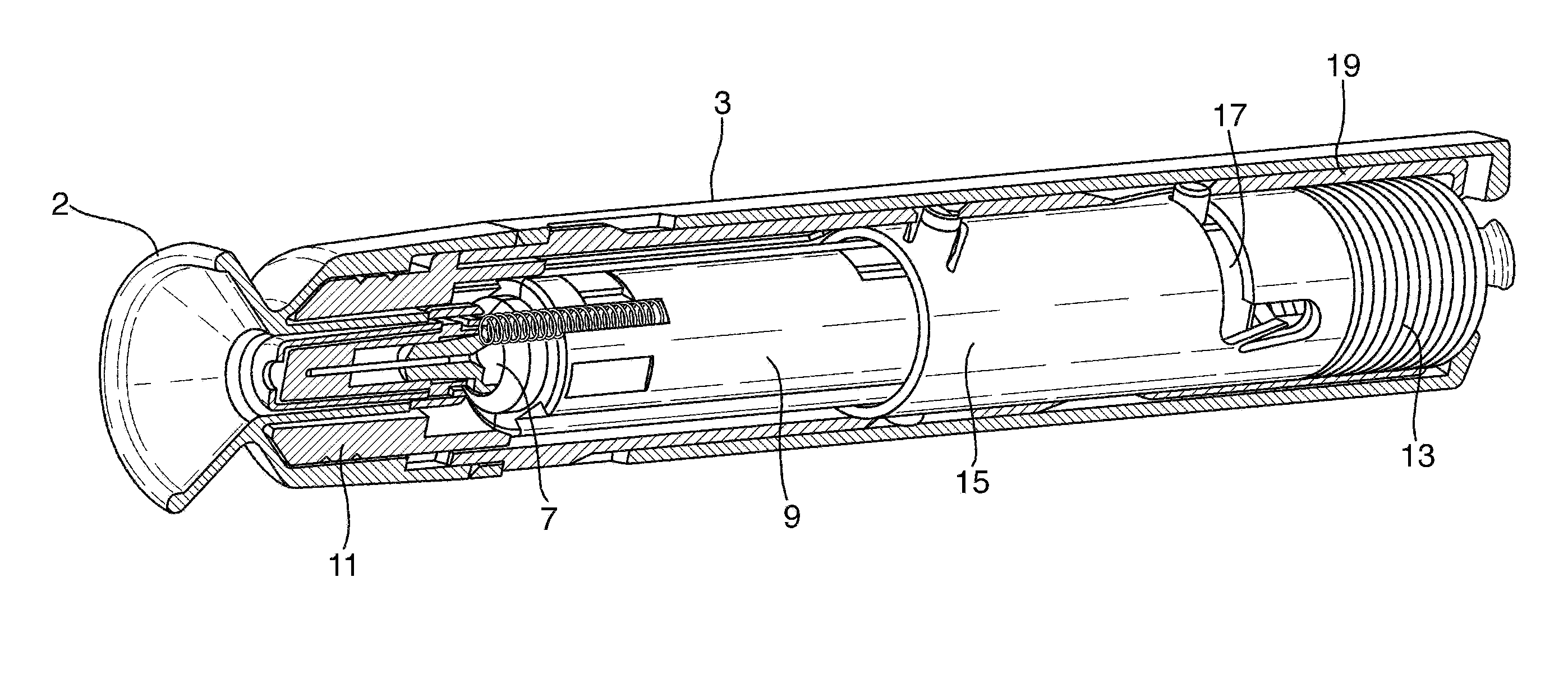

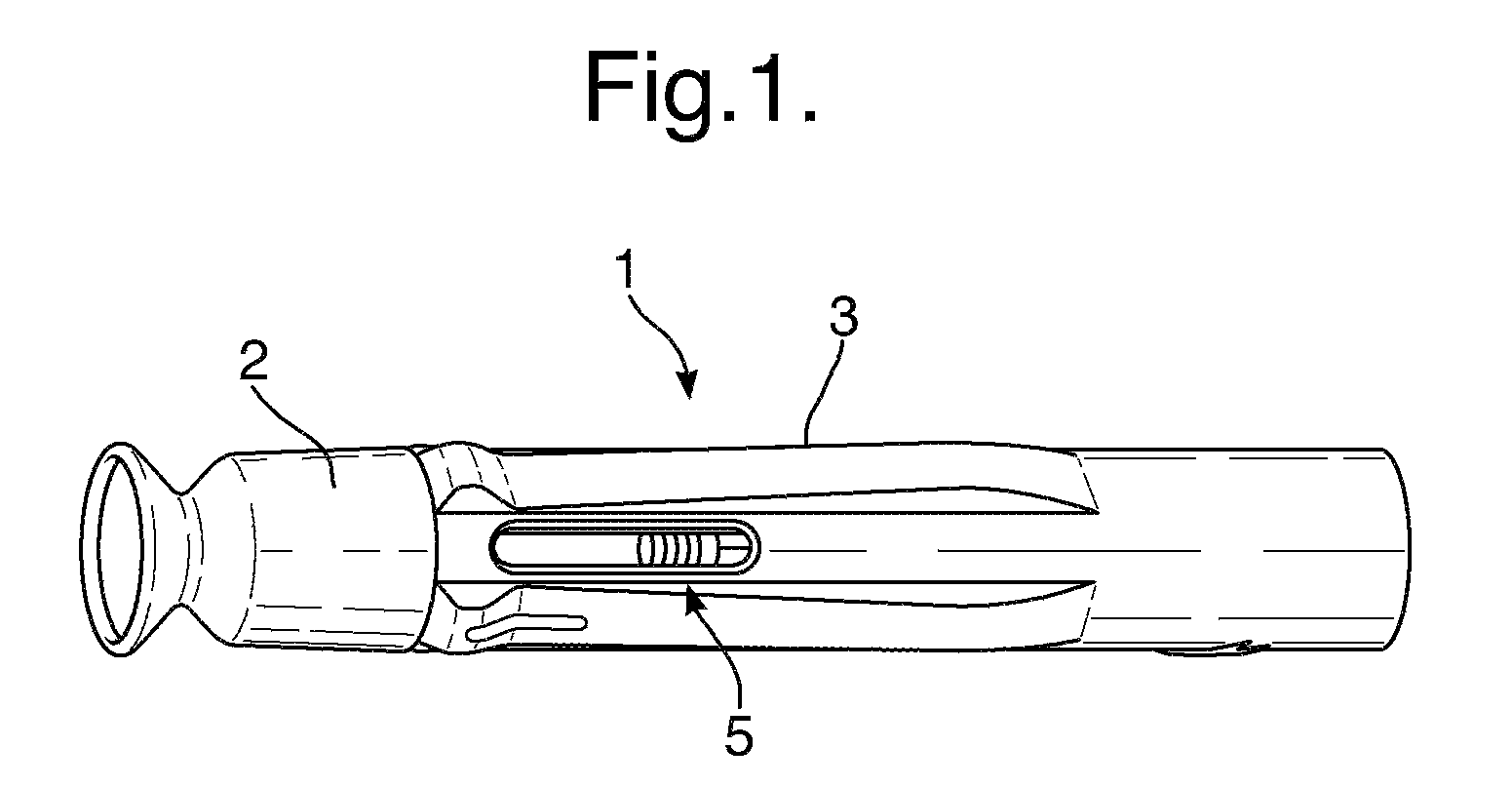

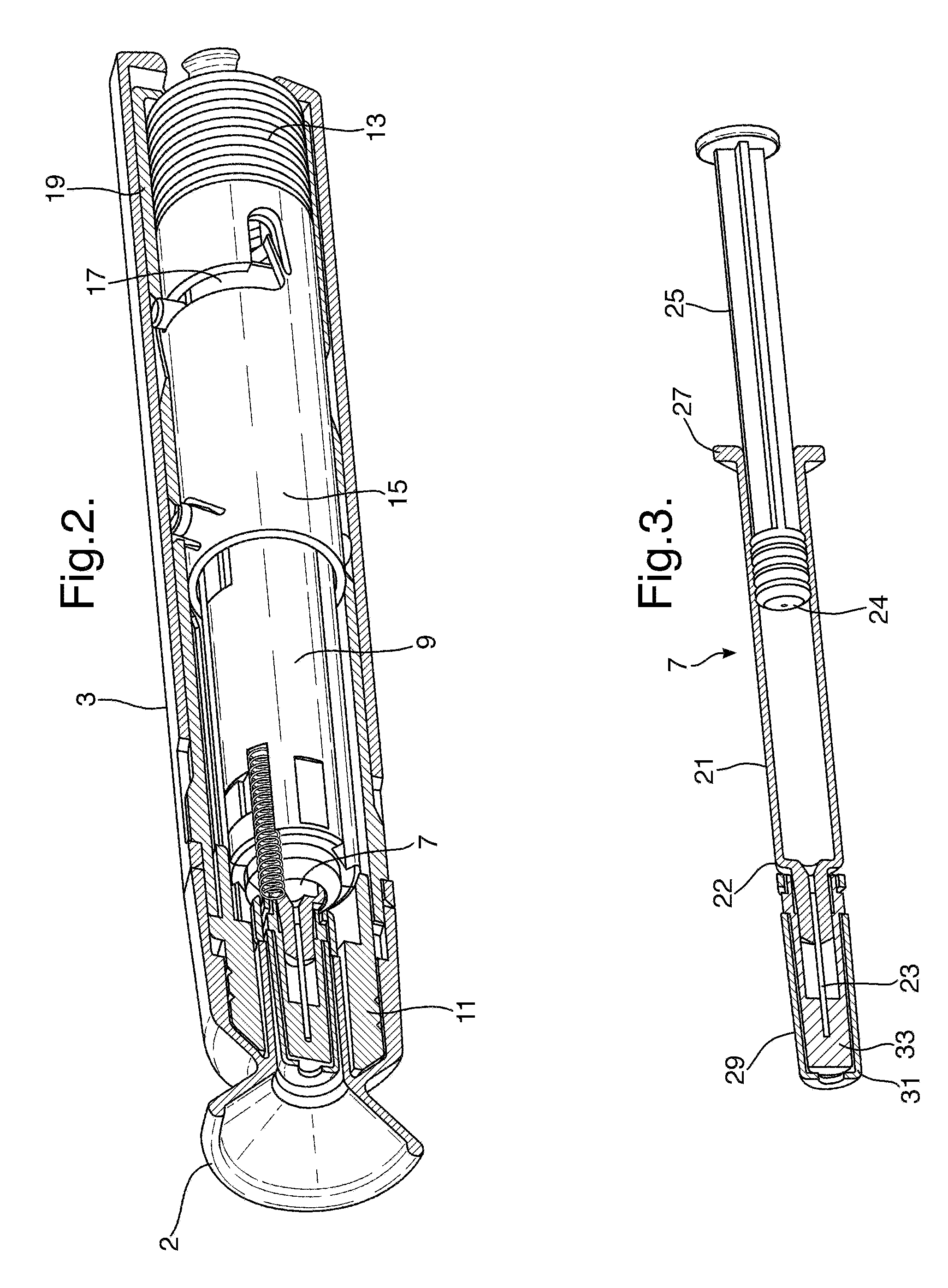

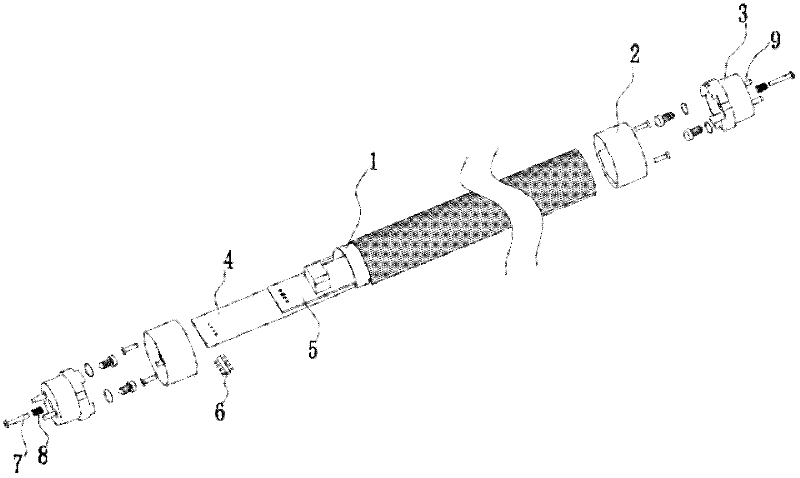

Injection device

ActiveUS20100185178A1Avoid frictional effectEqually distributedAutomatic syringesMedical devicesSyringeEngineering

An injection device including a syringe having a needle, a barrel and a plunger. The device is configured to provide an automatic injection cycle and includes a drive coupling arrangement between a driving spring and the syringe. In operation, a drive force can be selectively transmitted between the respective first and second parts of the drive coupling arrangement depending upon their relative rotational positions such that, when the first and second parts are in a first relative rotational position during the dispensing stage, a driving force is transmitted to the plunger to drive the plunger into the barrel, and, when the first and second parts are in a second relative rotational position during the retraction stage, no force is transmitted to the plunger to allow the plunger and the syringe to retract.

Owner:FUTURE INJECTION TECH

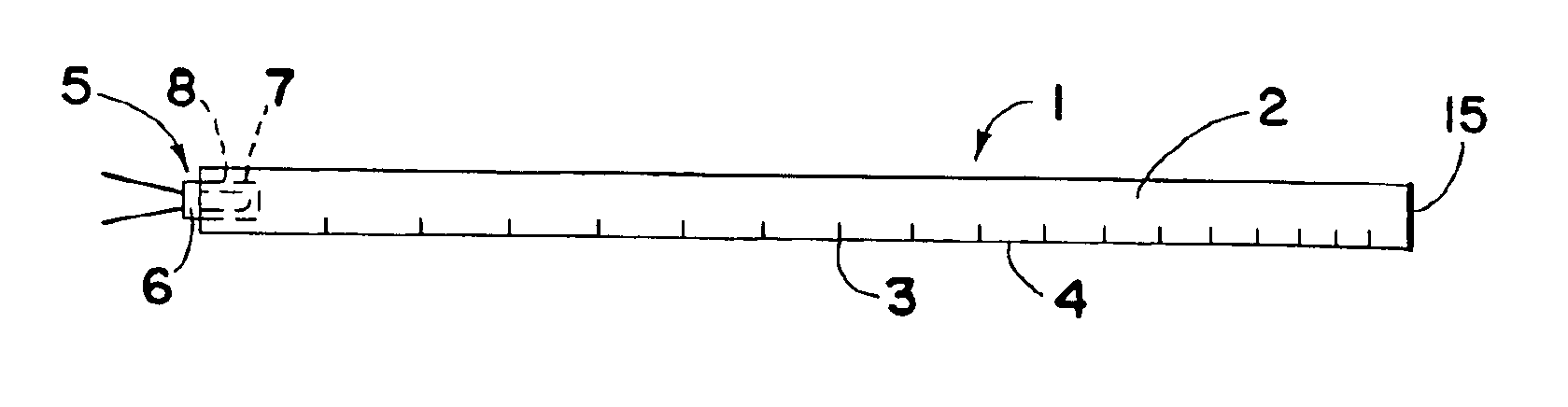

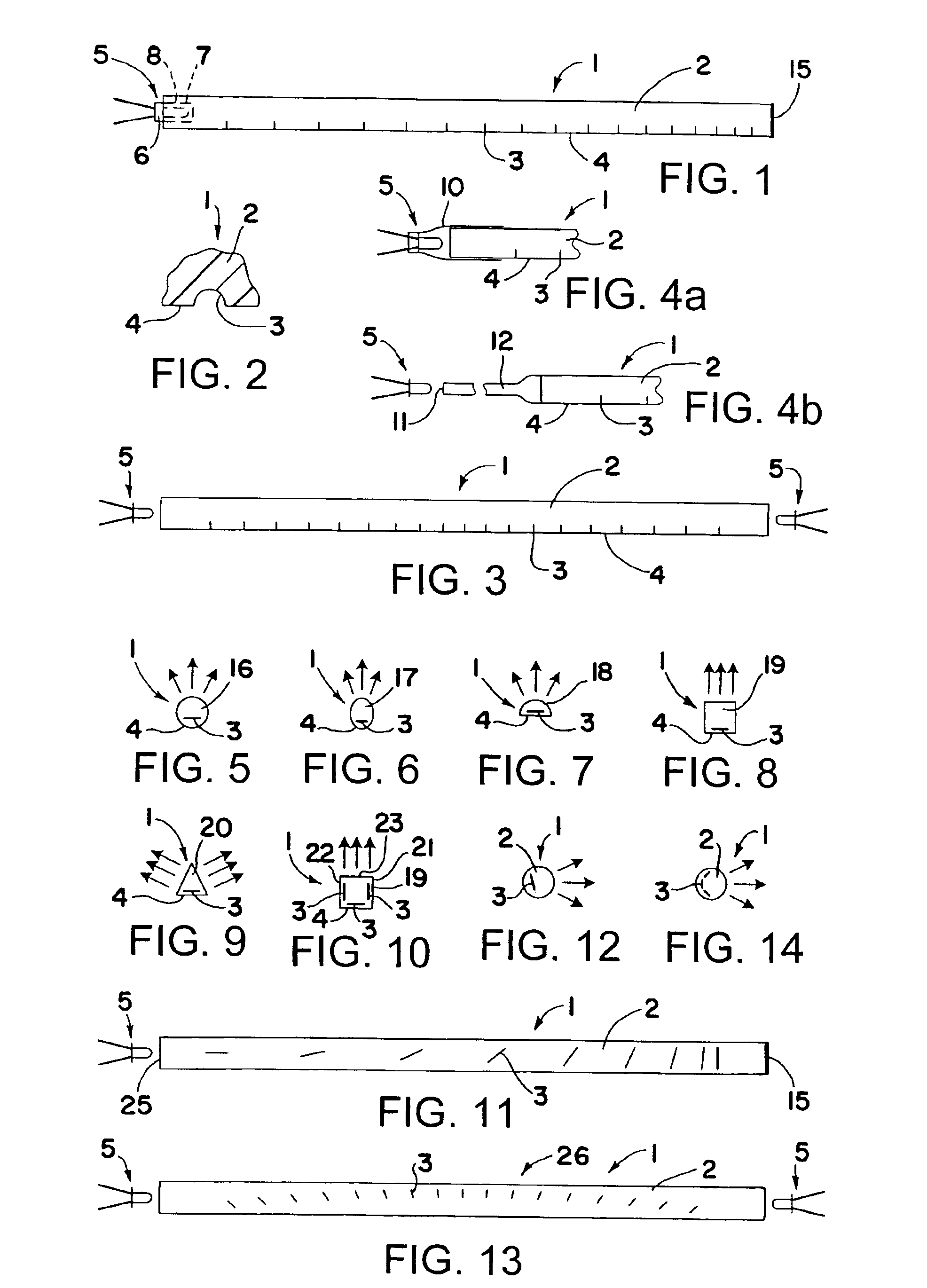

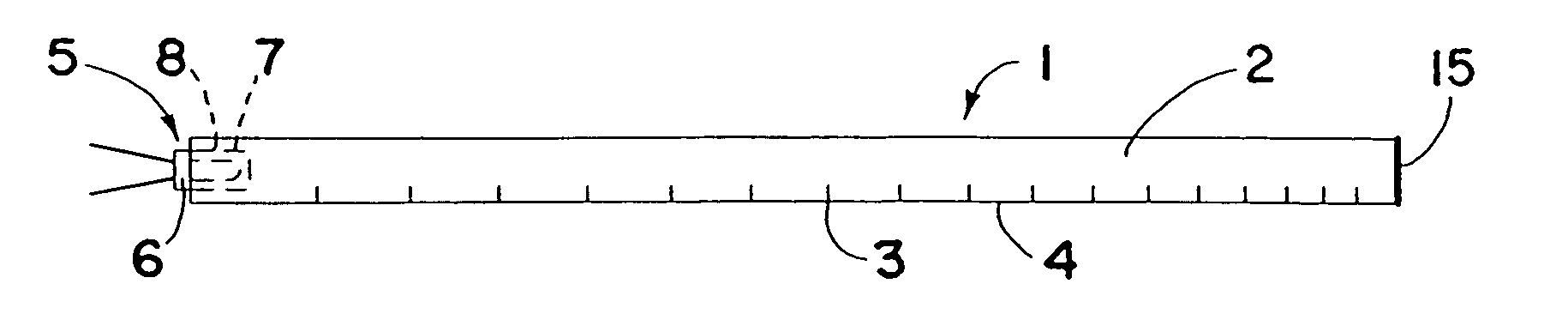

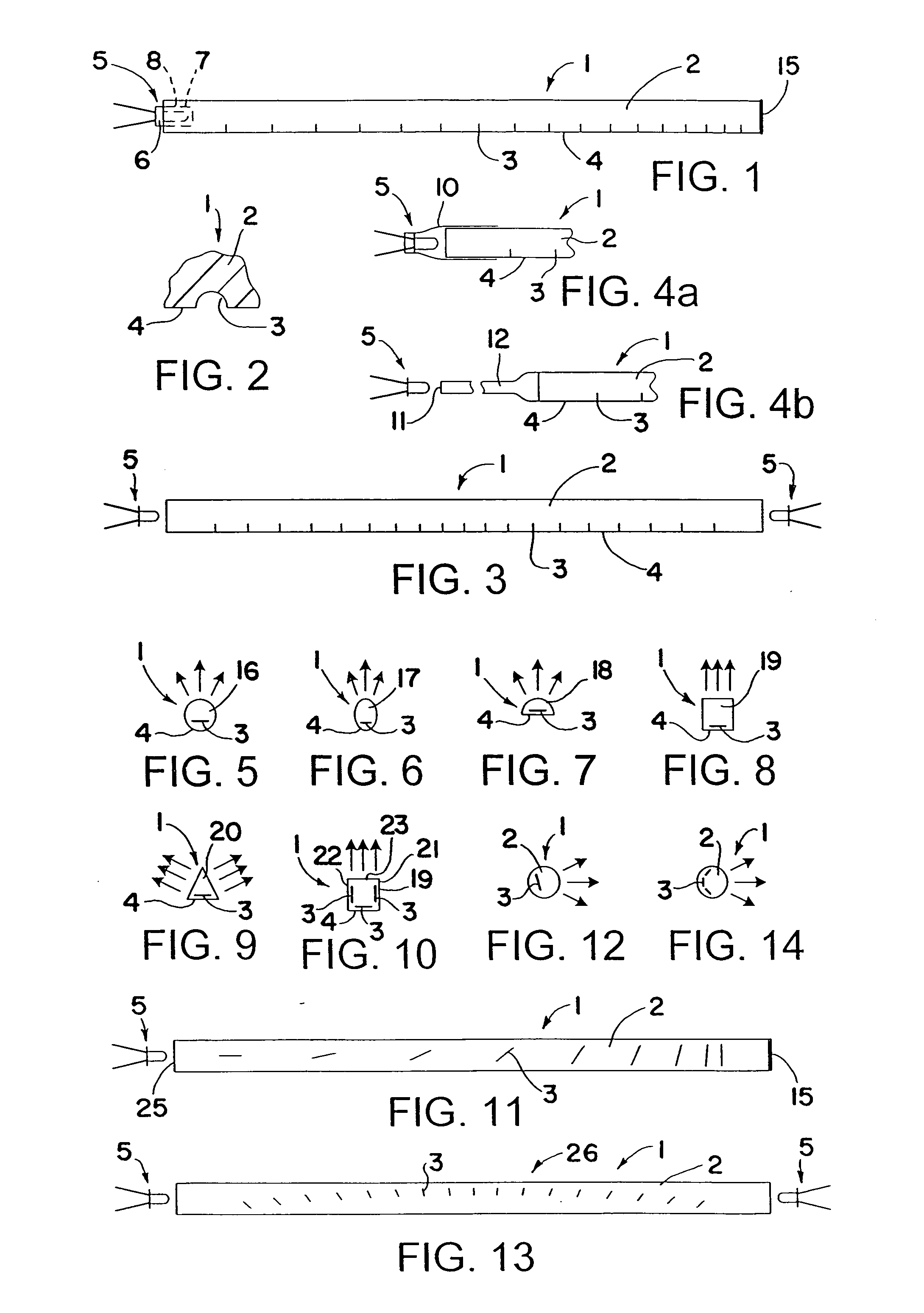

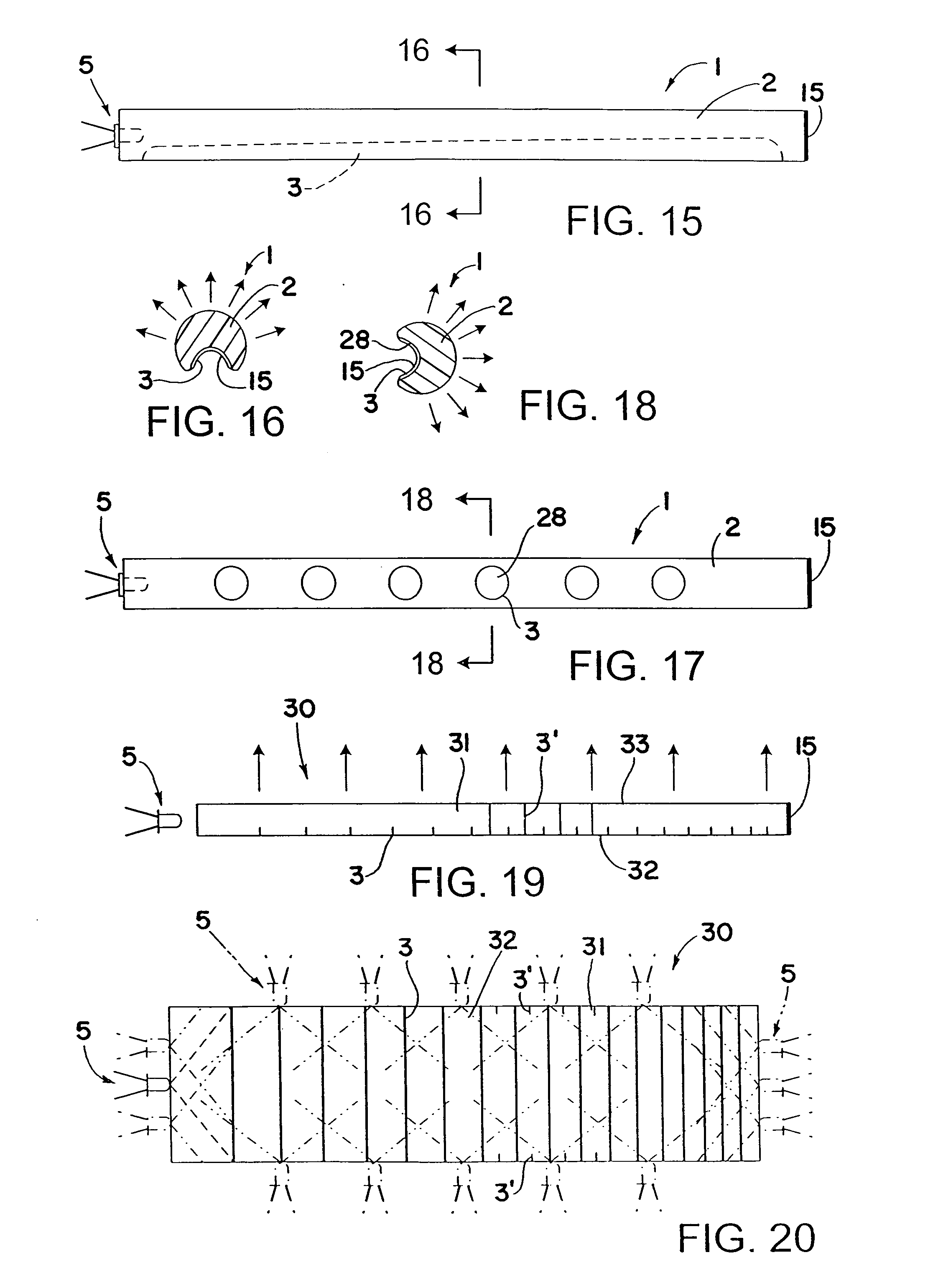

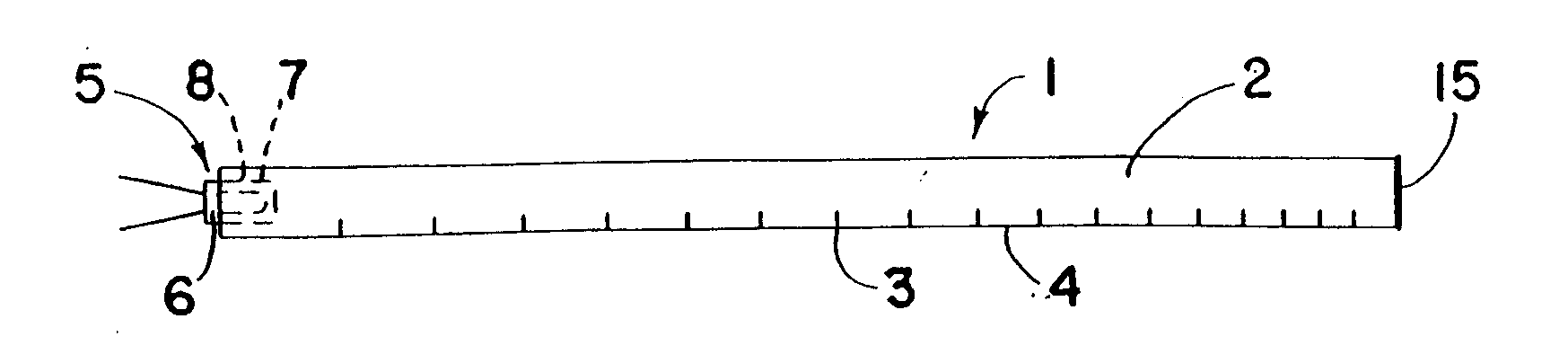

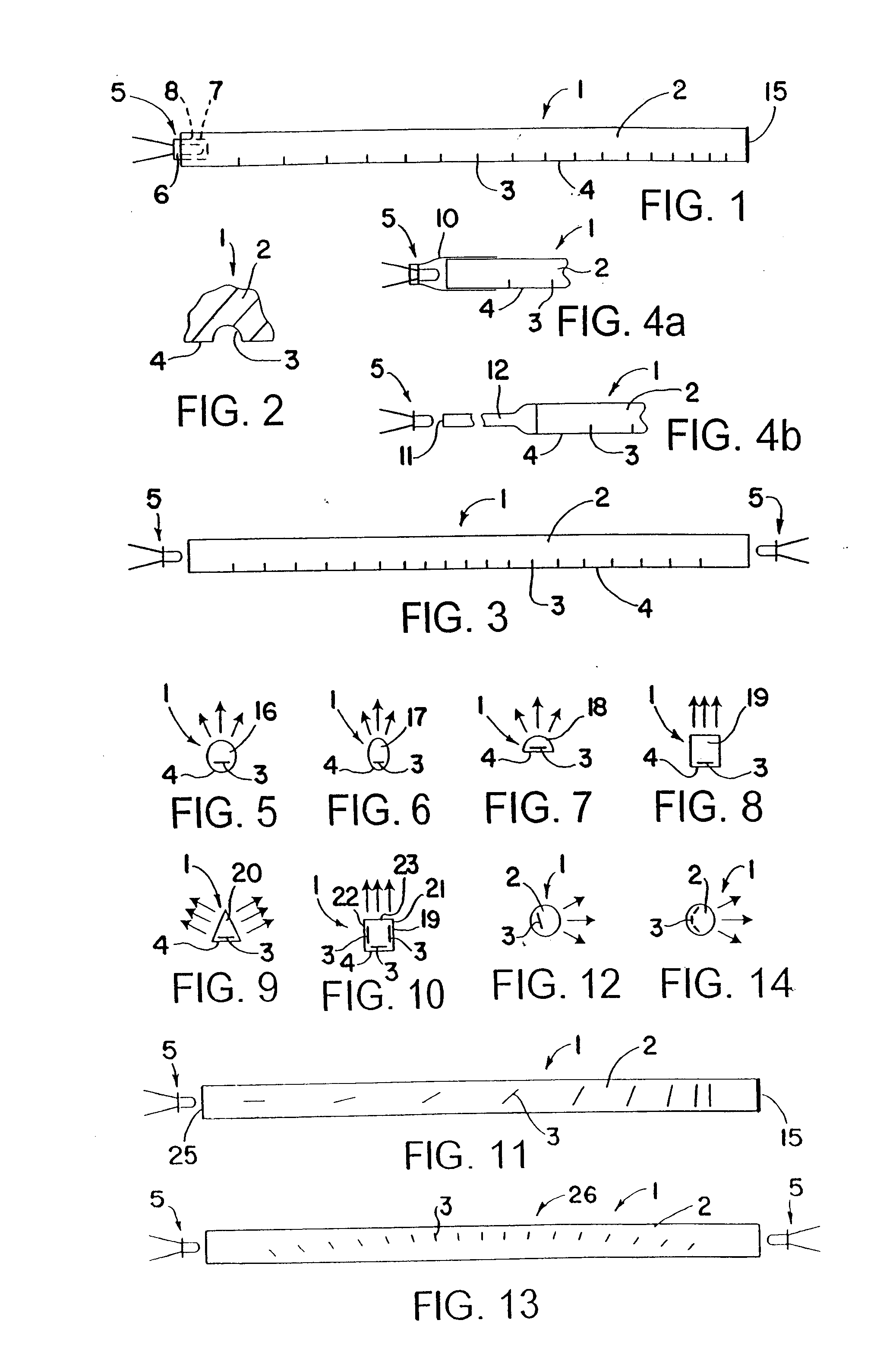

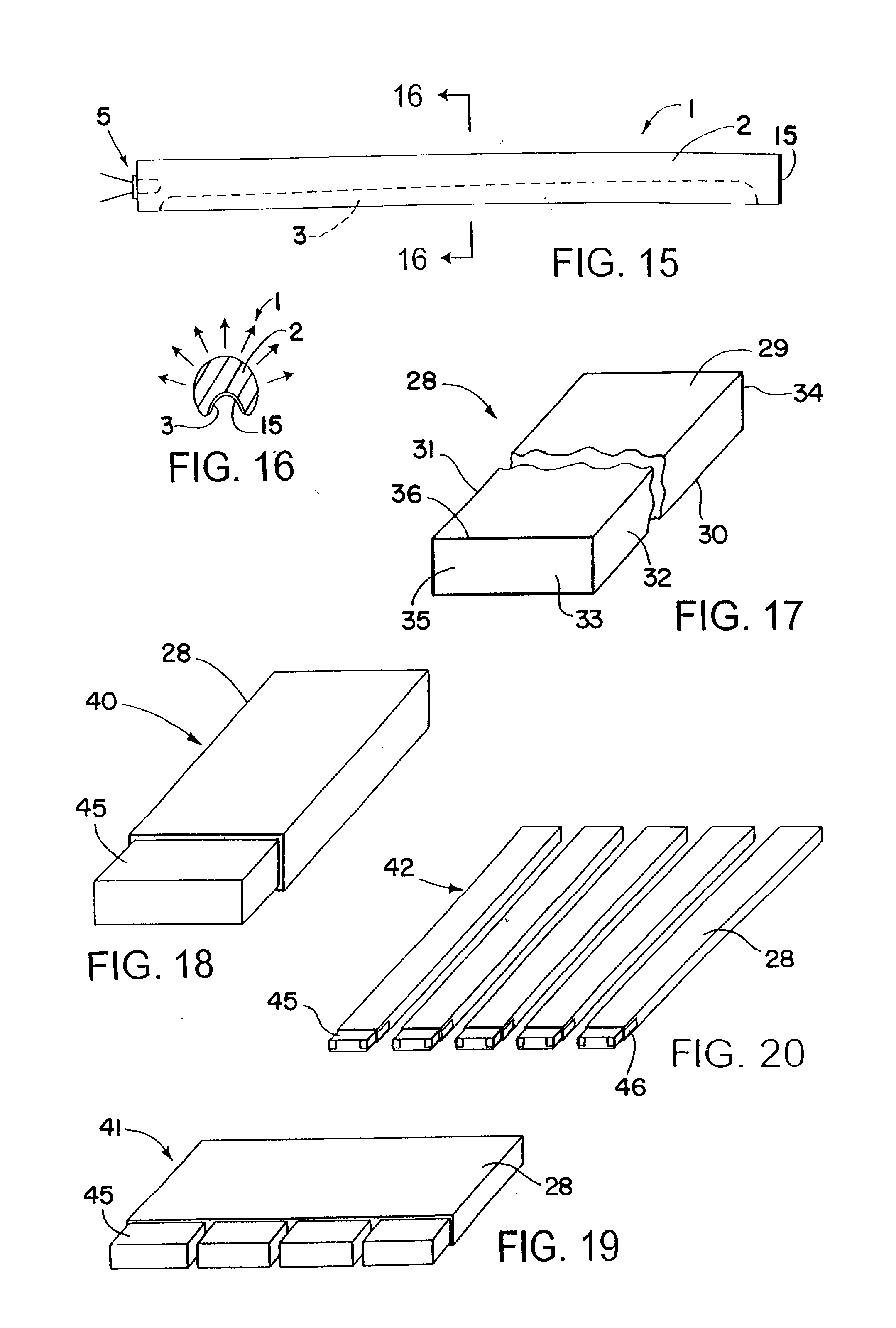

Transparent light emitting members and method of manufacture

InactiveUS6910783B2Reduced risk of breakageSimple moldingMeasurement apparatus componentsPoint-like light sourceEngineering

Illuminators include transparent light emitting members having a pattern of rounded shallow notches or grooves in one or more surfaces of the members for causing internally reflected light to be emitted from the members. The notches or grooves may be cut using a circular cutting tool. The relative speed of the cutting tool and feed rate of the cutting tool relative to the members may be controlled to produce a roughened surface on the notches or grooves.

Owner:LUMITEX

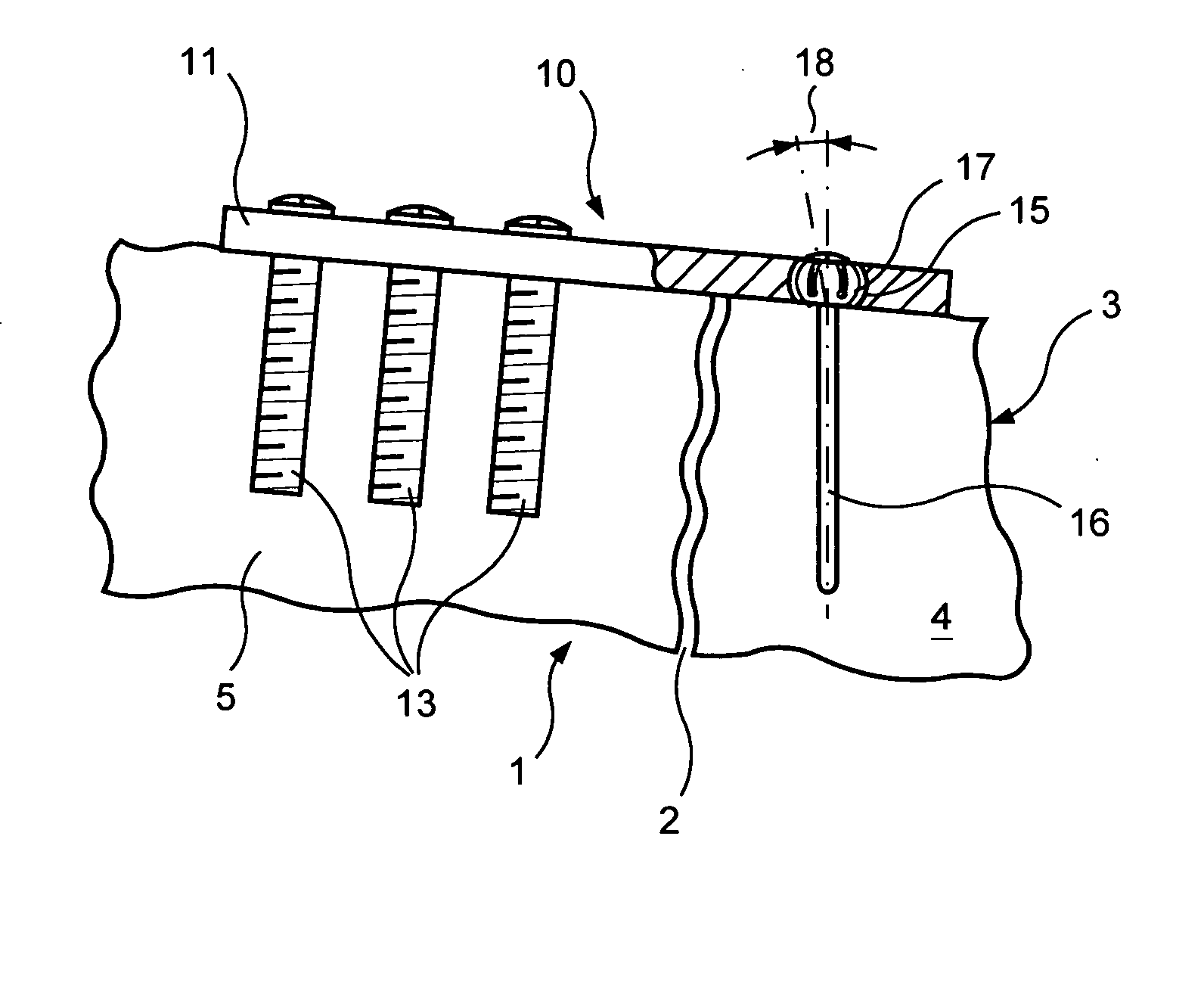

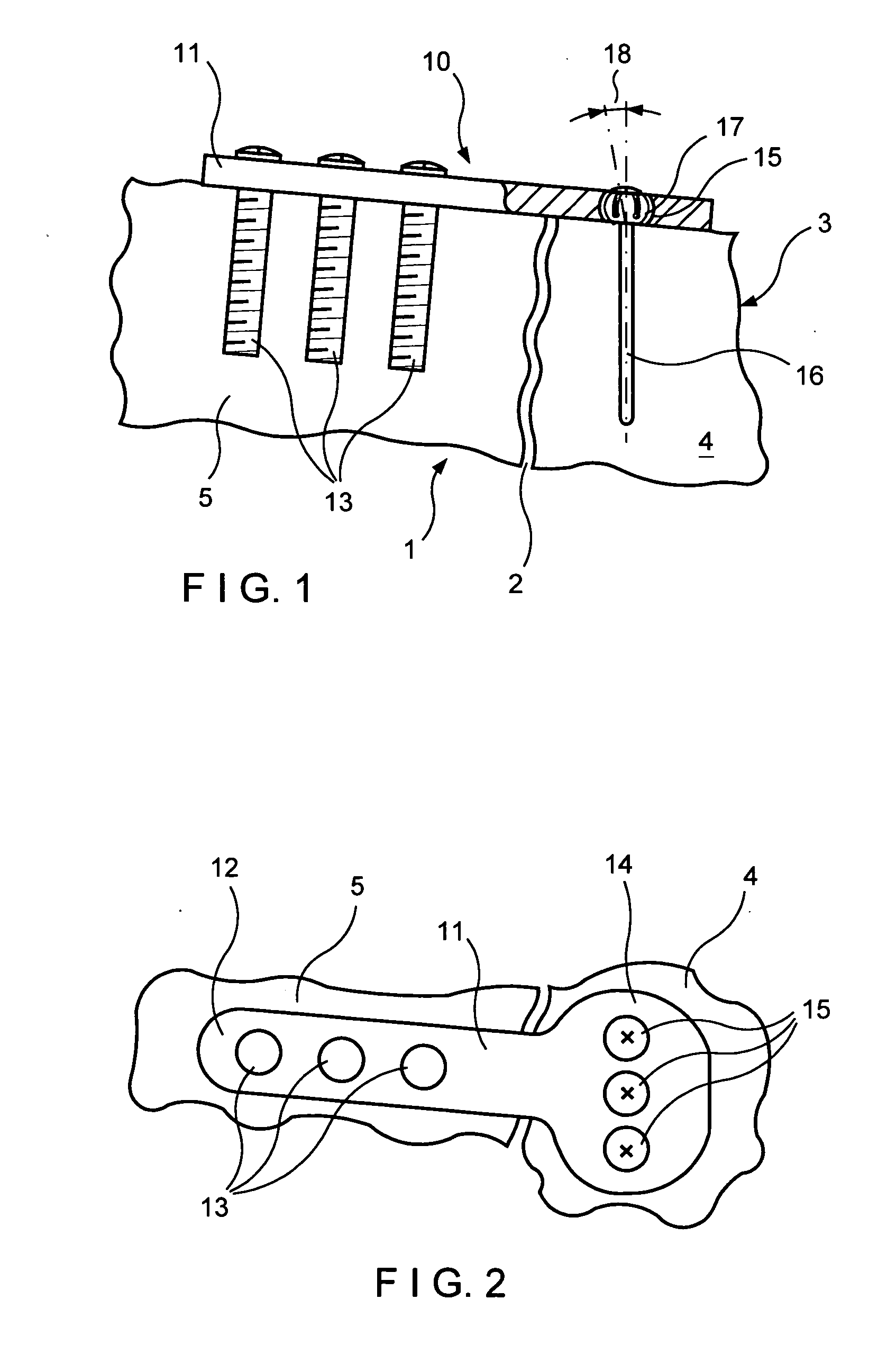

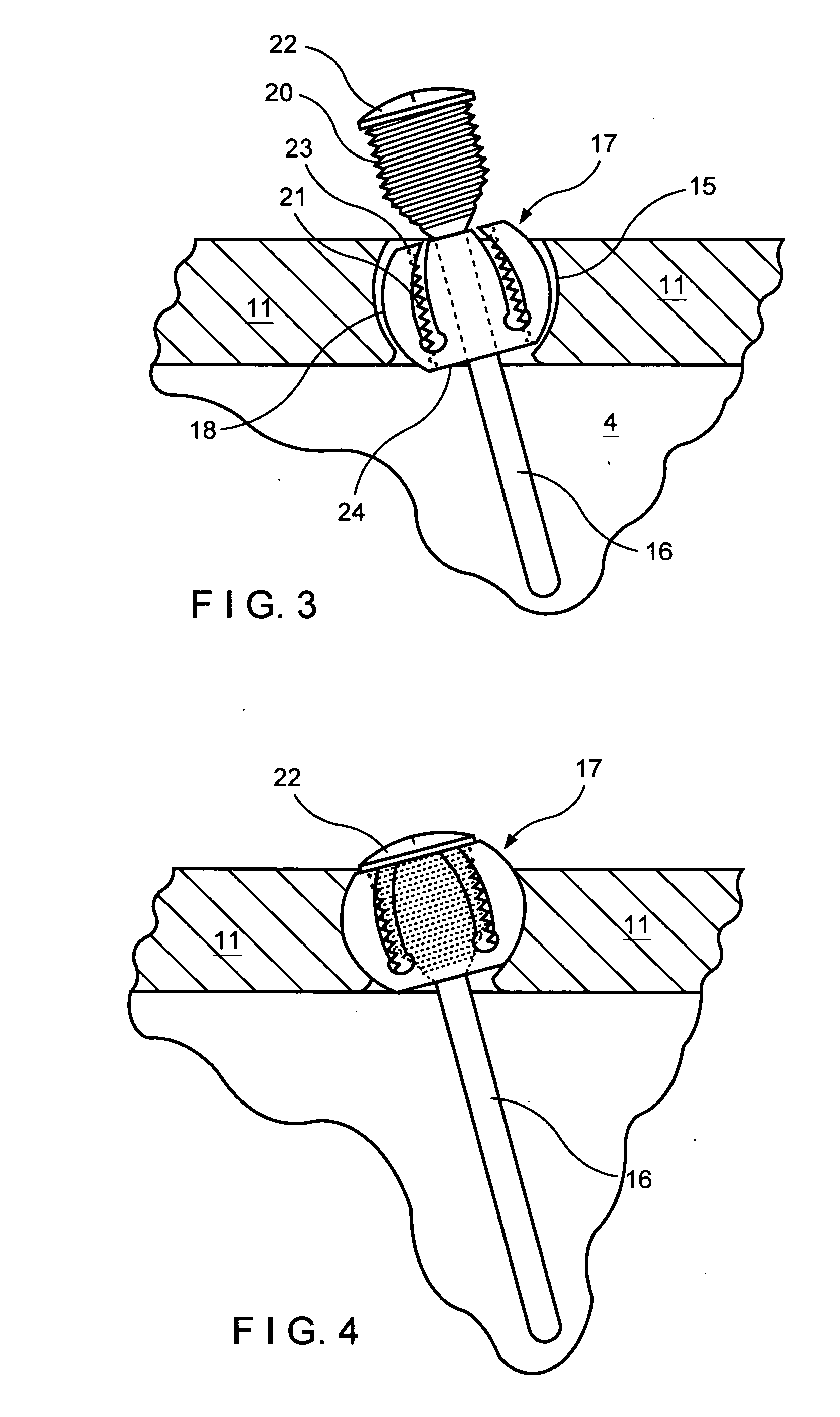

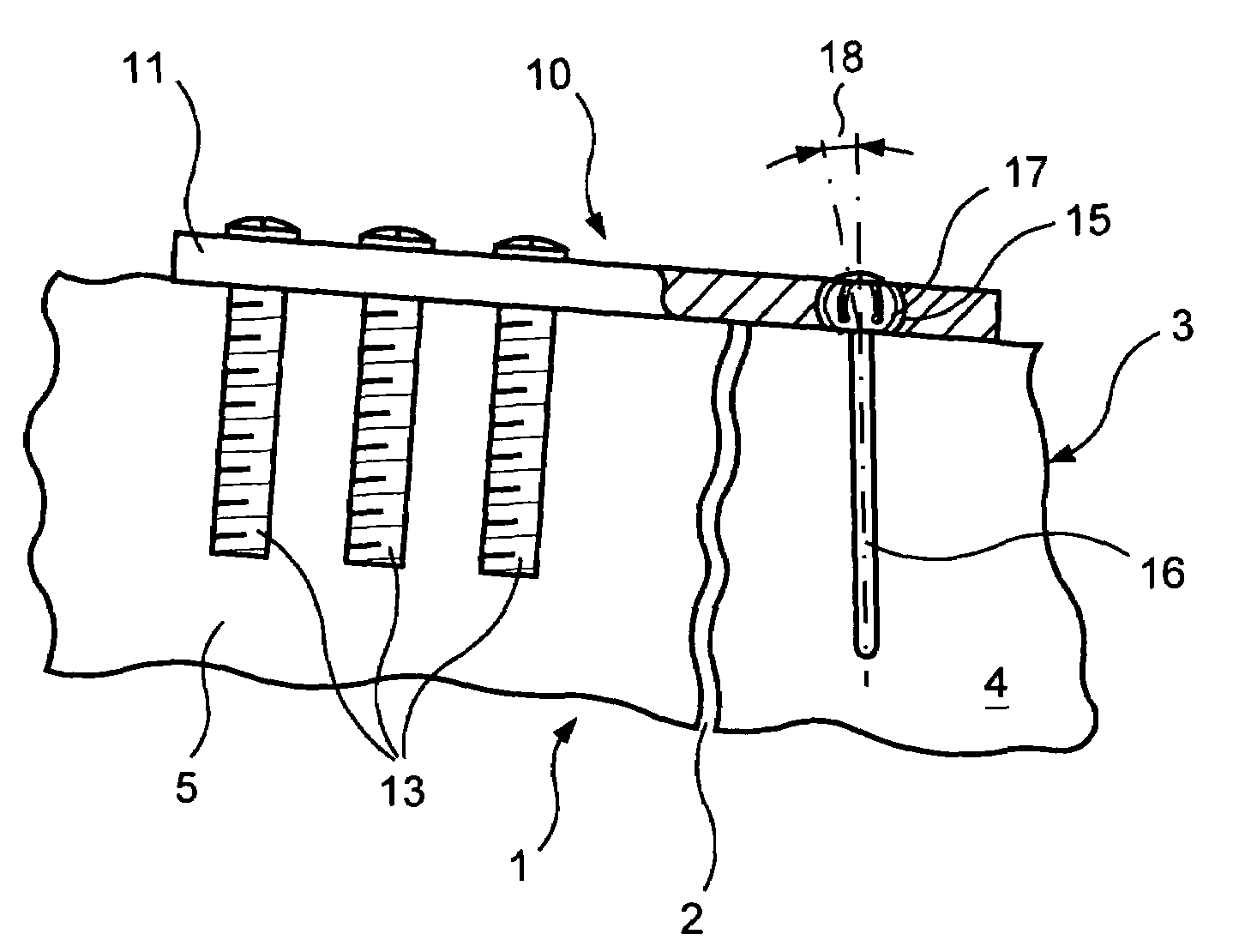

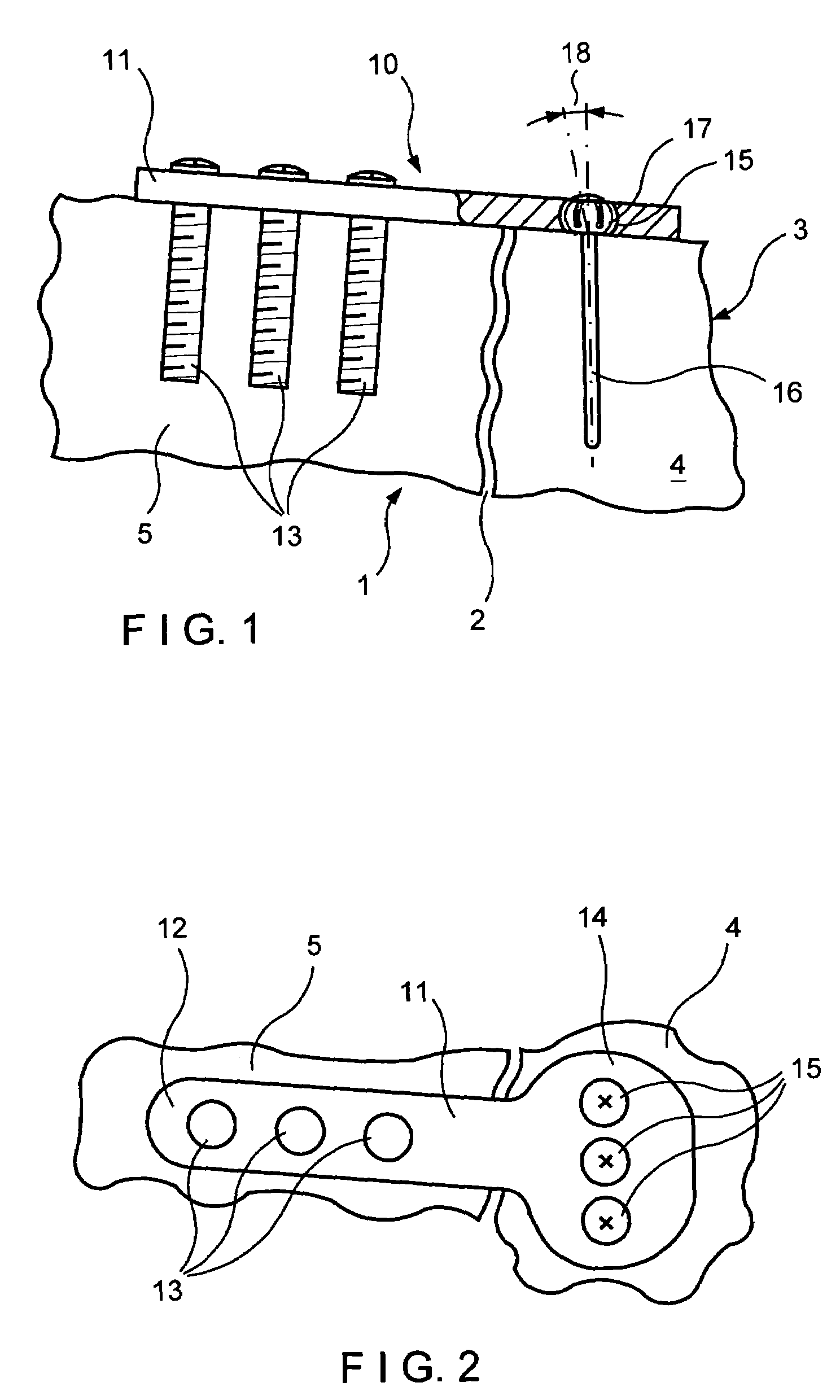

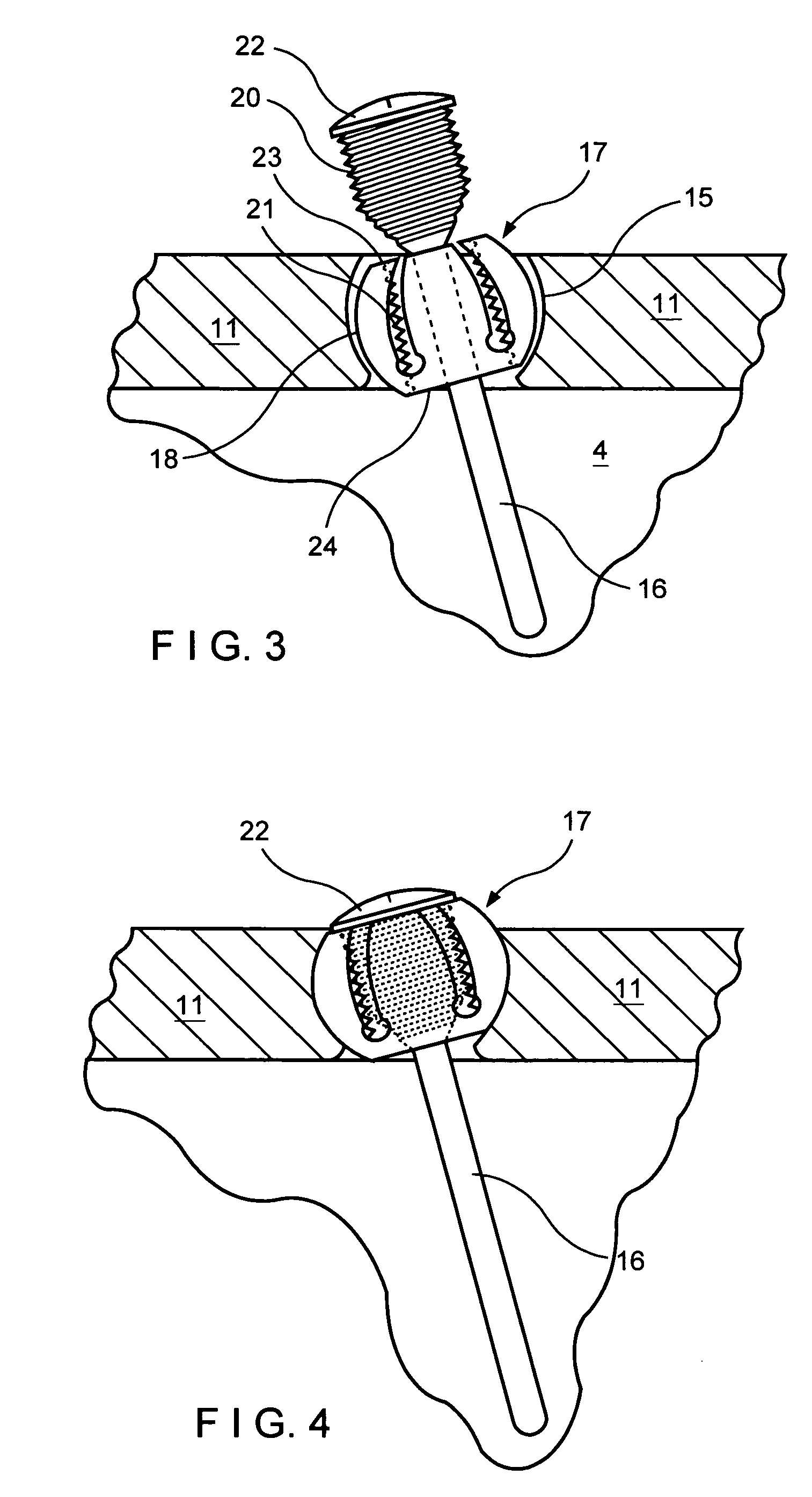

Fracture fixation system

ActiveUS20050154392A1Reliable simple securingImprove the immunitySuture equipmentsLigamentsMedicineGonial angle

A fracture fixation system in which a plate is secured to stable bone and posts are inserted at varying angles into an unstable bone fragment by engaging in rotatable bearings which are fixedly secured in the plate when the posts are fully engaged in the bone fragment. The bearings are formed as truncated spherical members having a number of longitudinal slots extending partway along the length of the bearing to form petals which are expanded outwardly when the posts are advanced in the bearing to produce non-uniform distribution of forces between the bearing and the plate which generate force couples to resist angulation of the posts and loss of fracture fixation. Various other ways of producing non-uniform force distribution are described.

Owner:MEDOFF ROBERT J +2

Fracture fixation system

ActiveUS7195633B2Reliable simple securingImprove the immunitySuture equipmentsLigamentsEngineeringBone fragment

A fracture fixation system in which a plate is secured to stable bone and posts are inserted at varying angles into an unstable bone fragment by engaging in rotatable bearings which are fixedly secured in the plate when the posts are fully engaged in the bone fragment. The bearings are formed as truncated spherical members having a number of longitudinal slots extending partway along the length of the bearing to form petals which are expanded outwardly when the posts are advanced in the bearing to produce non-uniform distribution of forces between the bearing and the plate which generate force couples to resist angulation of the posts and loss of fracture fixation. Various other ways of producing non-uniform force distribution are described.

Owner:MEDOFF ROBERT J +2

Dental cortical plate alignment platform

InactiveUS6592368B1Reduced risk of breakageReduce traumaImpression capsSurgical needlesOpaque markerCortical plate

This application relates to a dental apparatus for the initial and subsequent guidance of drills, hypodermic needles, or drug delivery devices into the cortical plate of human mandibular and maxillary bones. The invention comprises a thin platform with one or a plurality of angled or straight preformed perforations serving as entrance ports. Each port is optimally heralded by a radio-opaque marker to enable a view of the tooth root prior to drilling for a superior selection of a nerve deadening site and a whisker tubule visually displaying the drill's angle. The platform can be positioned on either the inner or outer side of the cortical plate, and is optimized for use with a dedicated indexing bite apparatus, a dedicated rubber dam style clamp, or by attachment to a RINN positioner or the like.

Owner:LVI GLOBAL

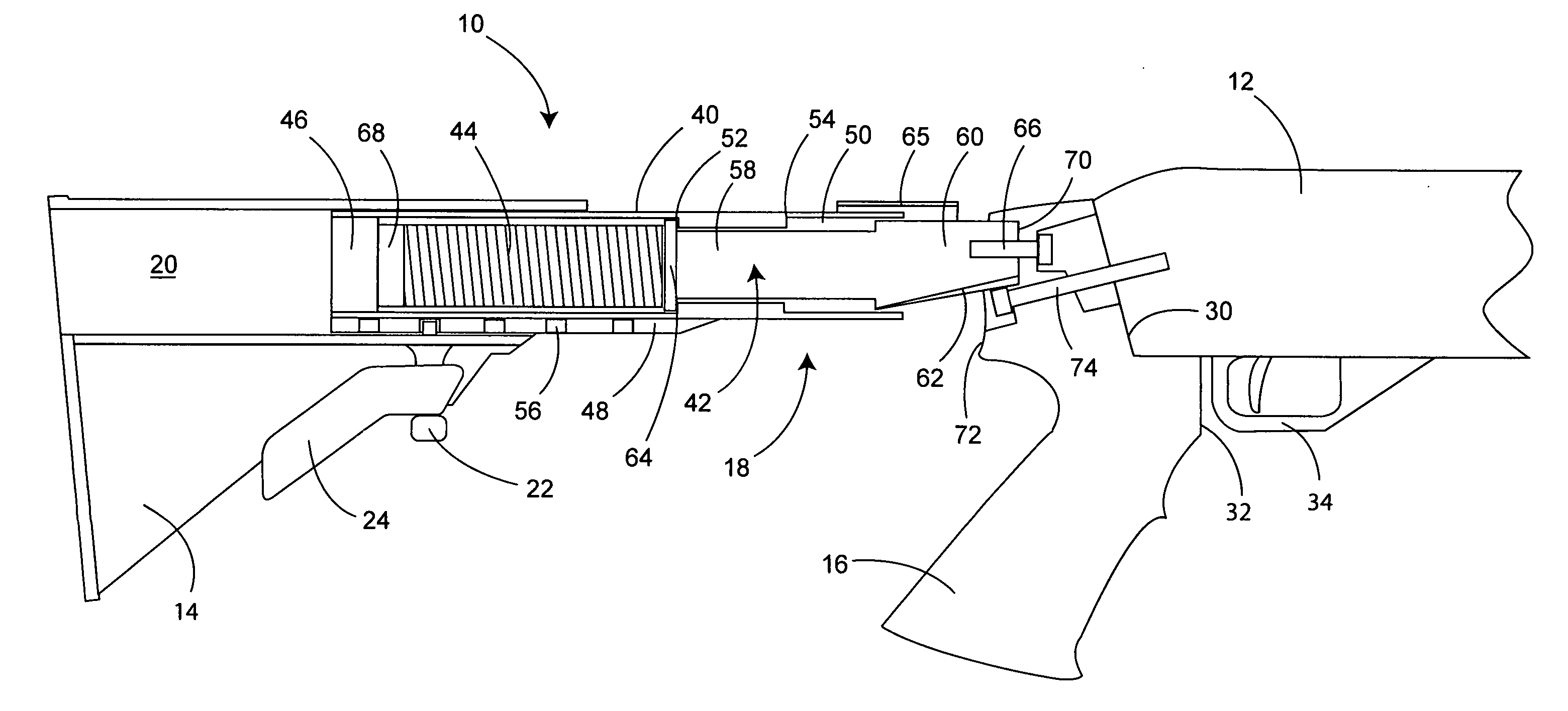

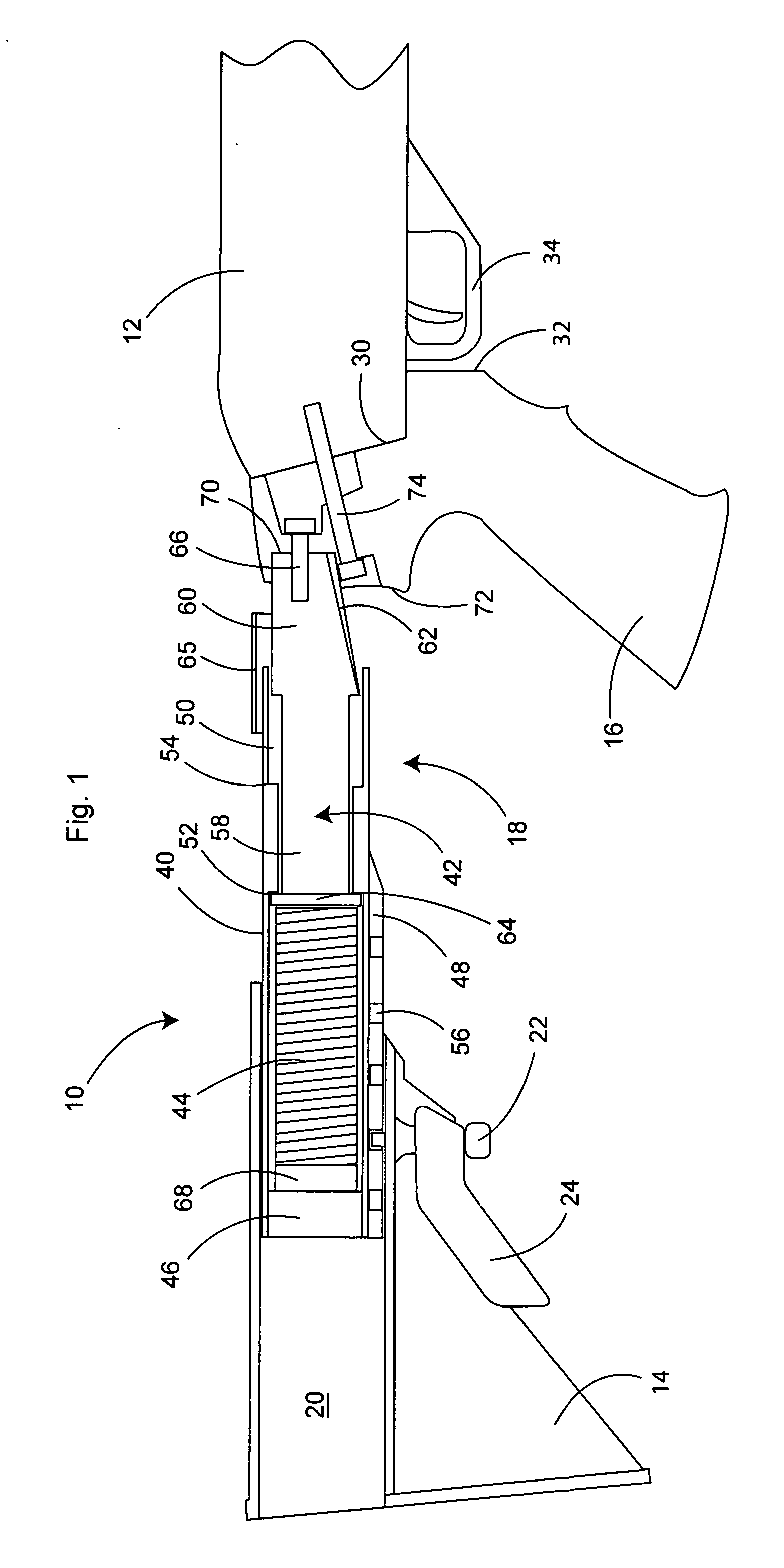

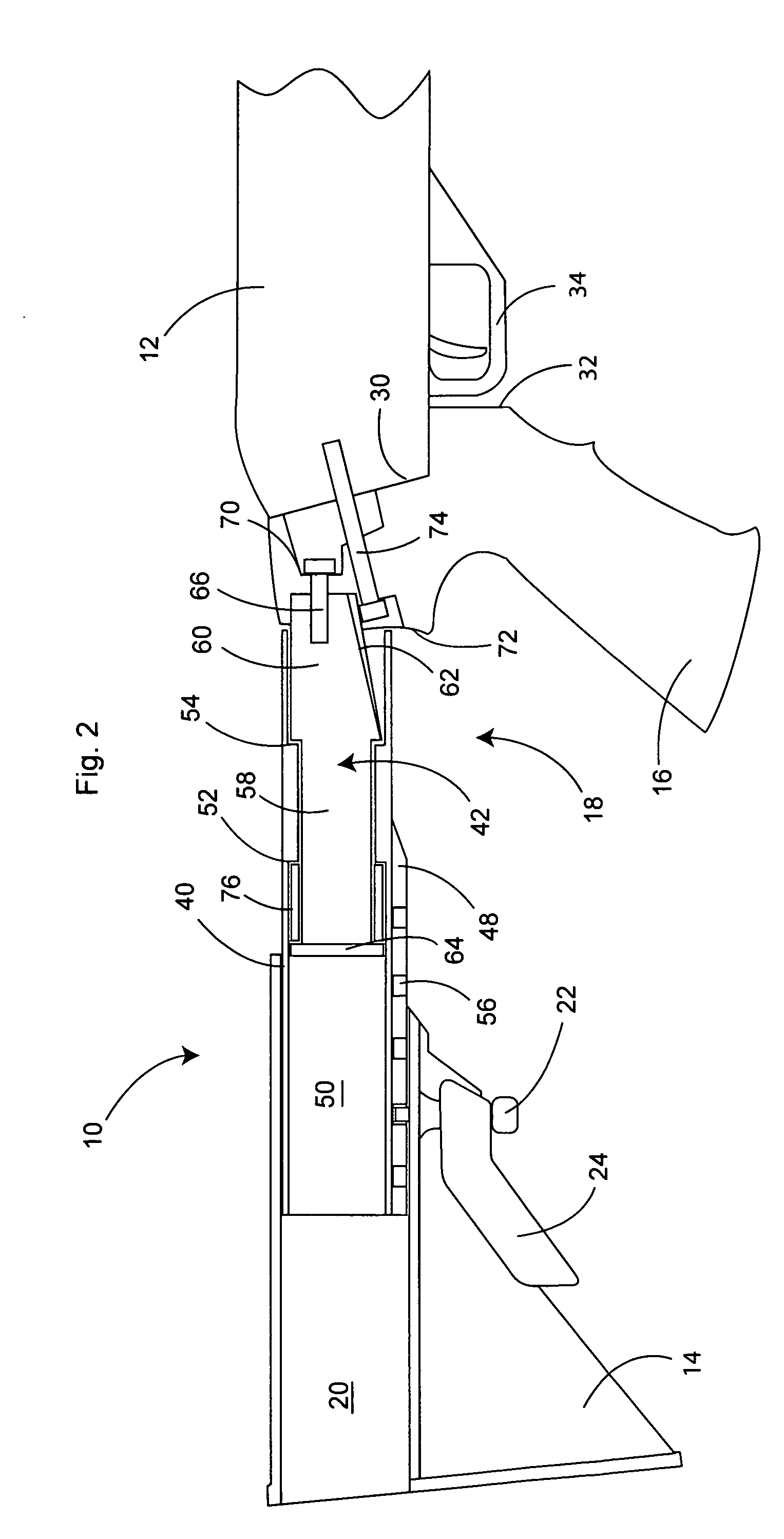

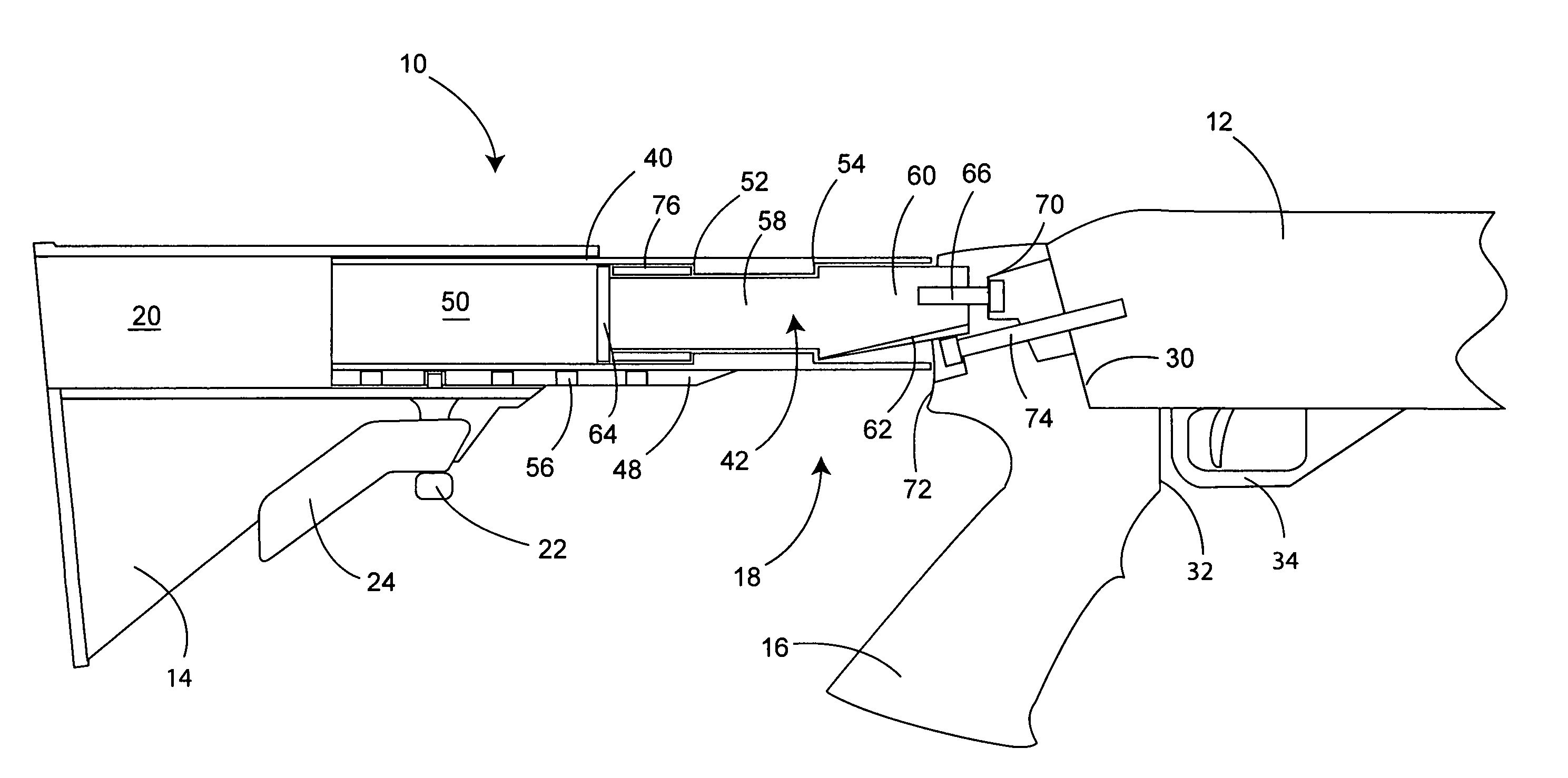

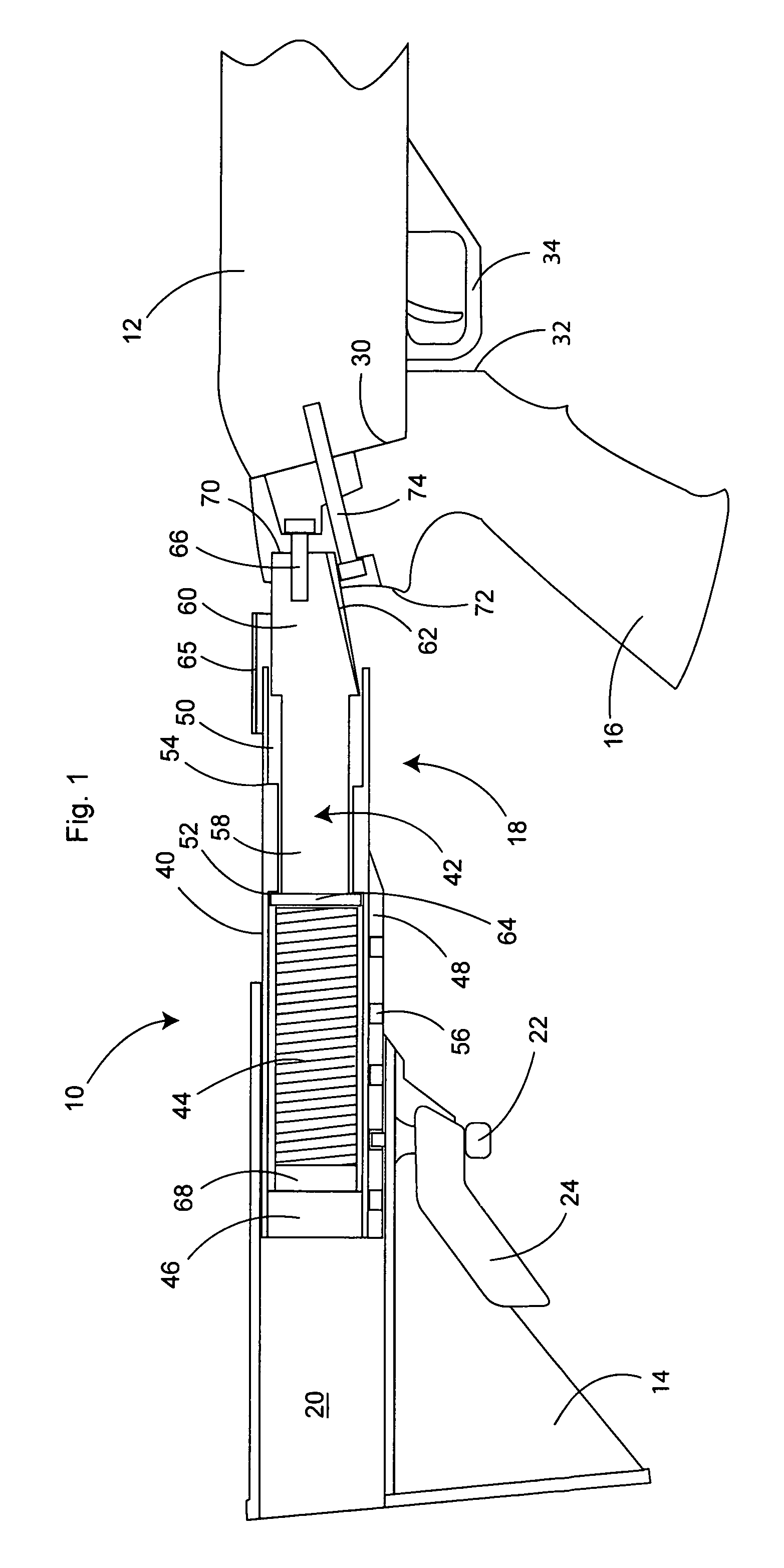

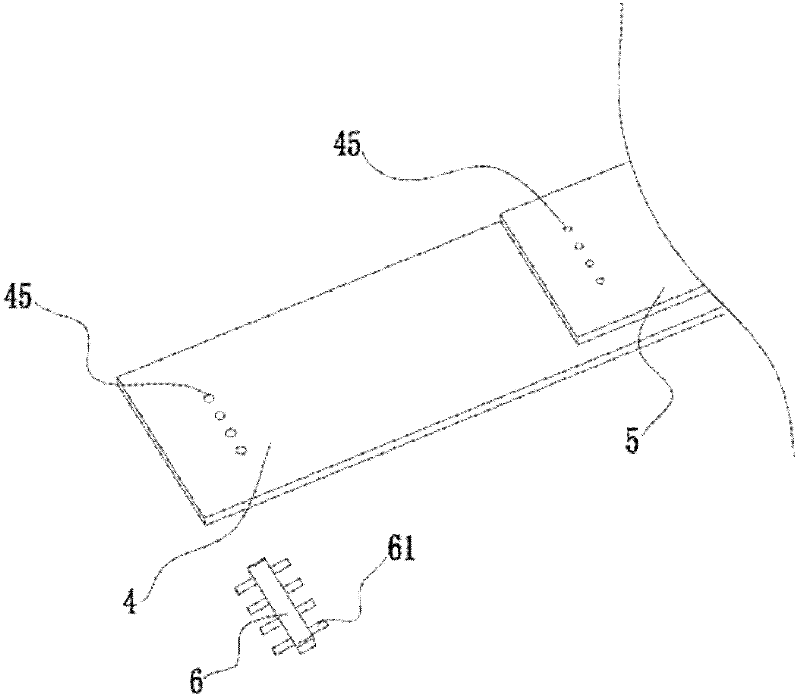

Stock assembly with recoil suppression

A stock assembly for attachment to the receiver of a shotgun is described. The assembly includes a pistol grip; a stock; a connector tube slidable within a conduit in the stock, the stock and connector being selectively lockable to each other; an attachment member slidable within the tube conduit between fully inserted and fully extended positions; a first elongated connector attached to the attachment member and extending parallel to the longitudinal axis of the tube into attachment with the pistol grip; a second elongated connector extending from the pistol grip into engagement with the receiver, the second member being at an angle to the first member; and a compression spring in the tube conduit urging the attachment member toward its fully extended position.

Owner:PHOENIX TECHNOLOGIES LTD

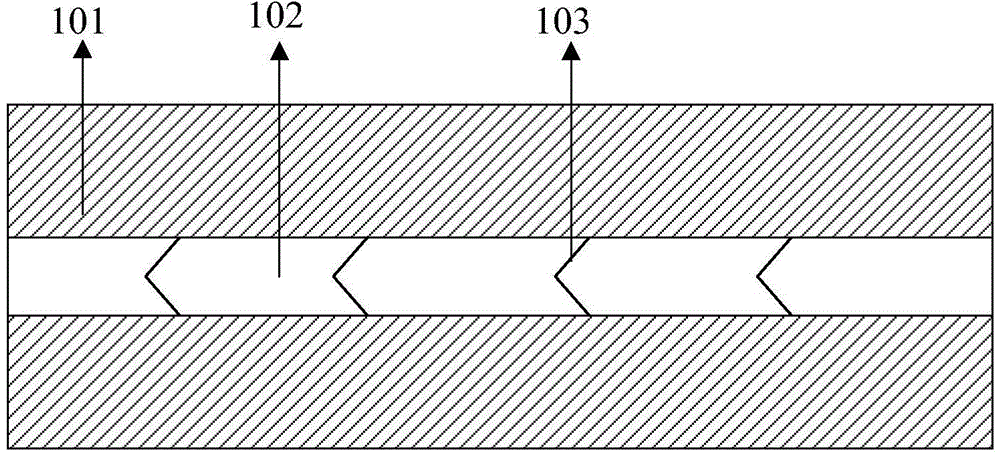

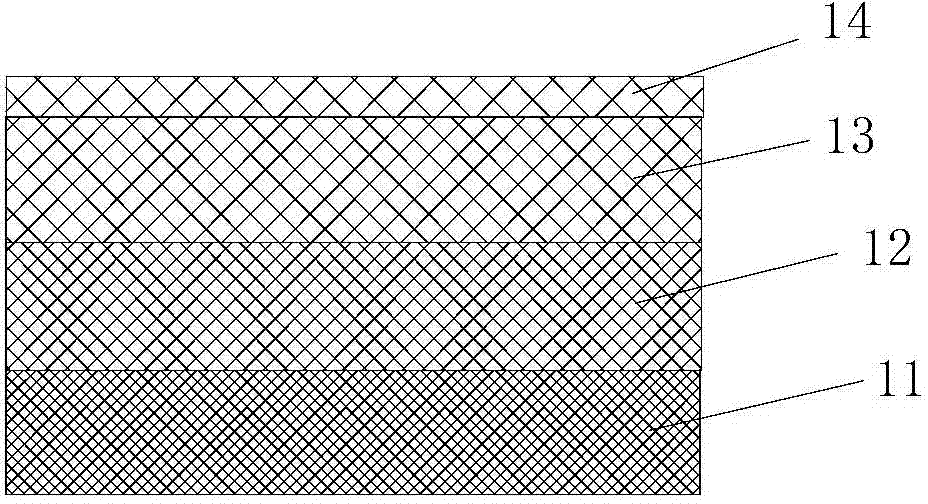

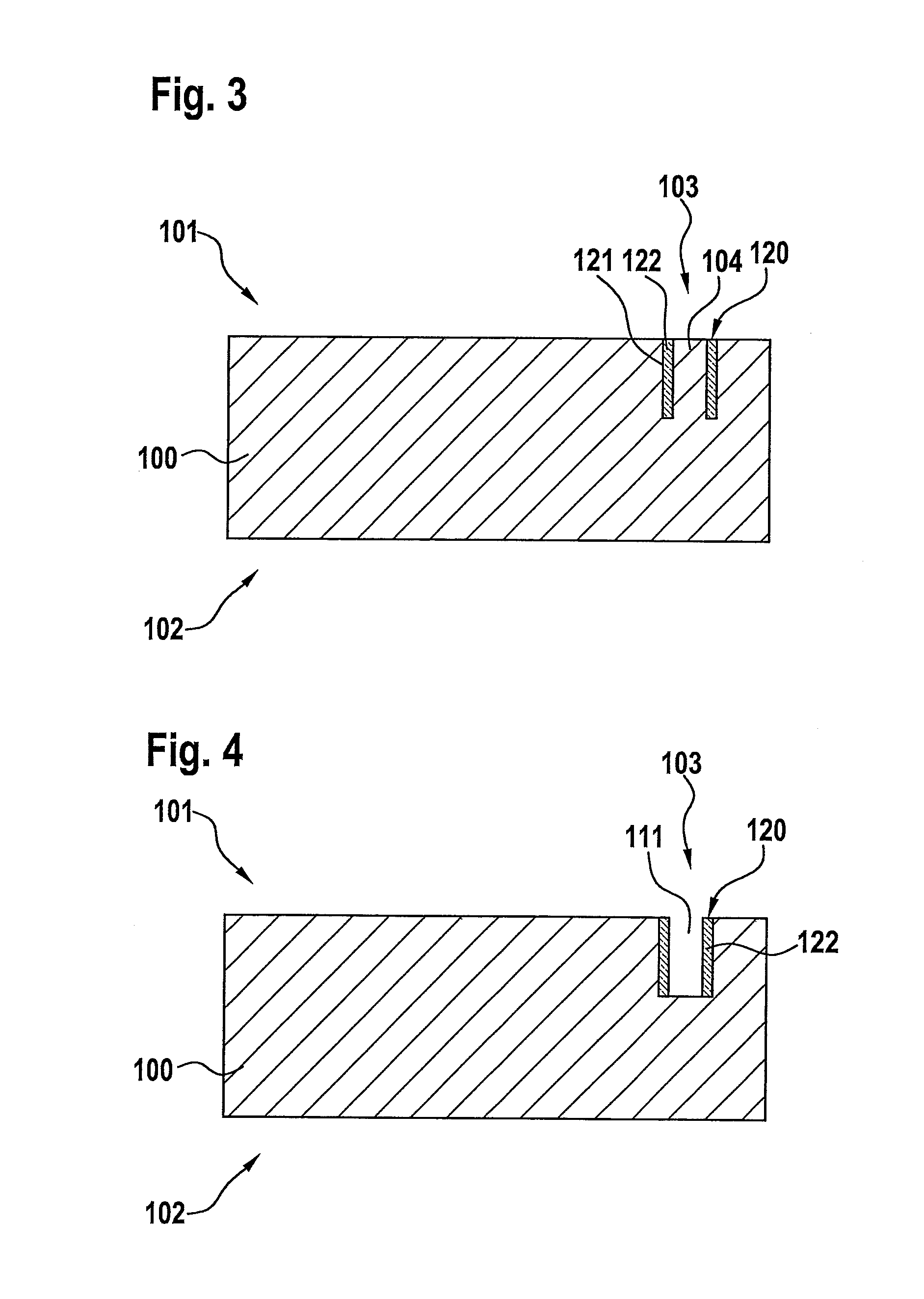

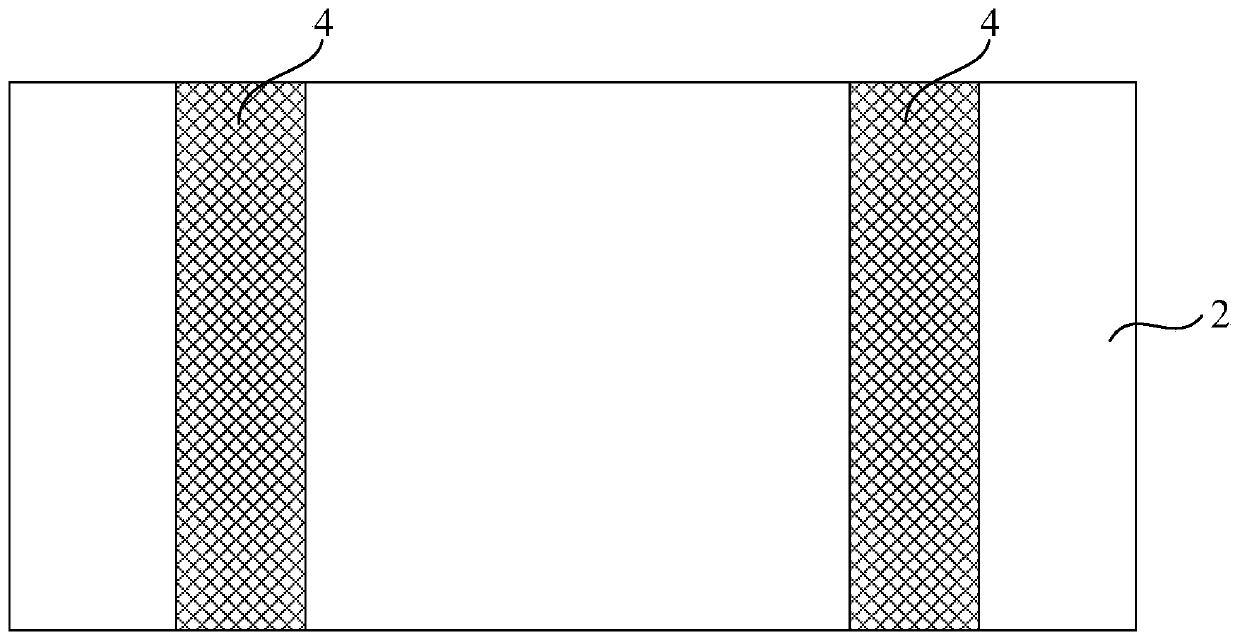

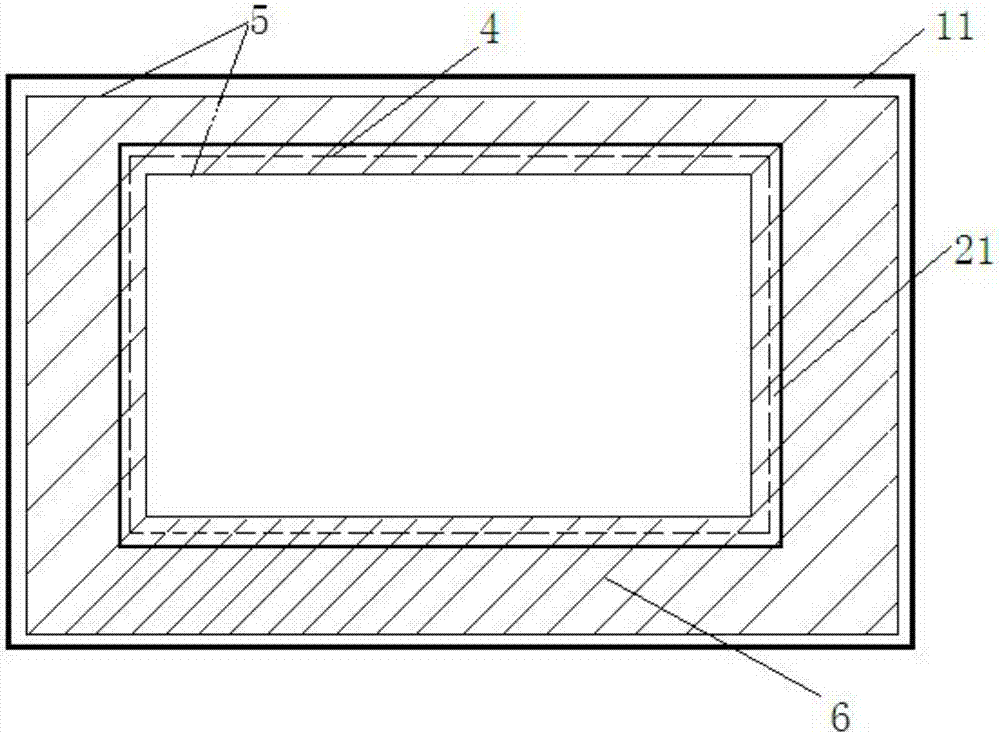

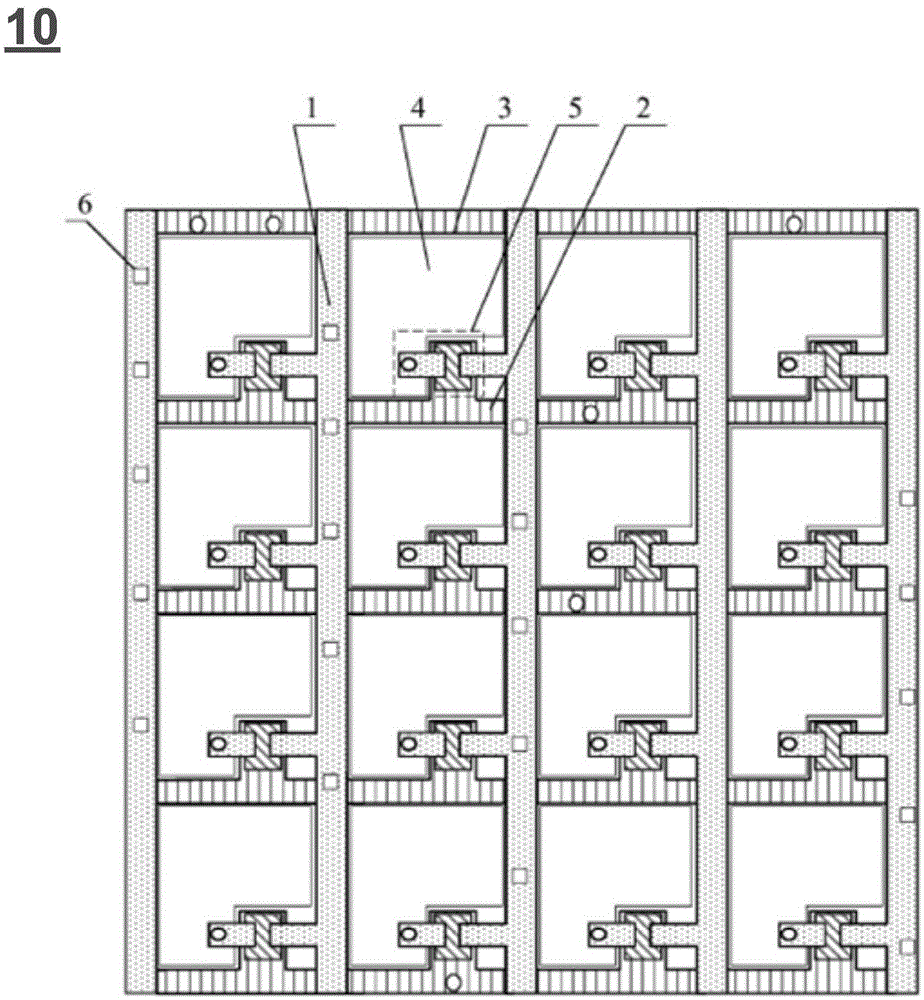

Barrier film, manufacturing method thereof and display device

ActiveCN104538425AAvoid stress concentrationReduced risk of breakageSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmStress concentration

The embodiment of the invention discloses a barrier film, a manufacturing method thereof and a display device. The barrier film comprises a first organic film layer and a second organic film layer, a first groove is formed in the first organic film layer, at least one inorganic film layer is arranged on the first organic film layer, the first groove is filled with the inorganic film layer, and the thickness of the inorganic film layer is smaller than or equal to the depth of the first groove; the second organic film layer is arranged on the inorganic film layer and is a flattened layer. Due to the fact that the thickness of the inorganic film layer is smaller than or equal to the depth of the first groove, an inorganic layer is discontinuous and does not located in the same layer, the phenomenon of stress concentration can be avoided in the bending process, and the risk that the inorganic layer is cracked is lowered.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Injection device

ActiveUS8734402B2Equally distributedEasy to controlAutomatic syringesMedical devicesEngineeringInjection device

An injection device including a syringe having a needle, a barrel and a plunger. The device is configured to provide an automatic injection cycle and includes a drive coupling arrangement between a driving spring and the syringe. In operation, a drive force can be selectively transmitted between the respective first and second parts of the drive coupling arrangement depending upon their relative rotational positions such that, when the first and second parts are in a first relative rotational position during the dispensing stage, a driving force is transmitted to the plunger to drive the plunger into the barrel, and, when the first and second parts are in a second relative rotational position during the retraction stage, no force is transmitted to the plunger to allow the plunger and the syringe to retract.

Owner:FUTURE INJECTION TECH

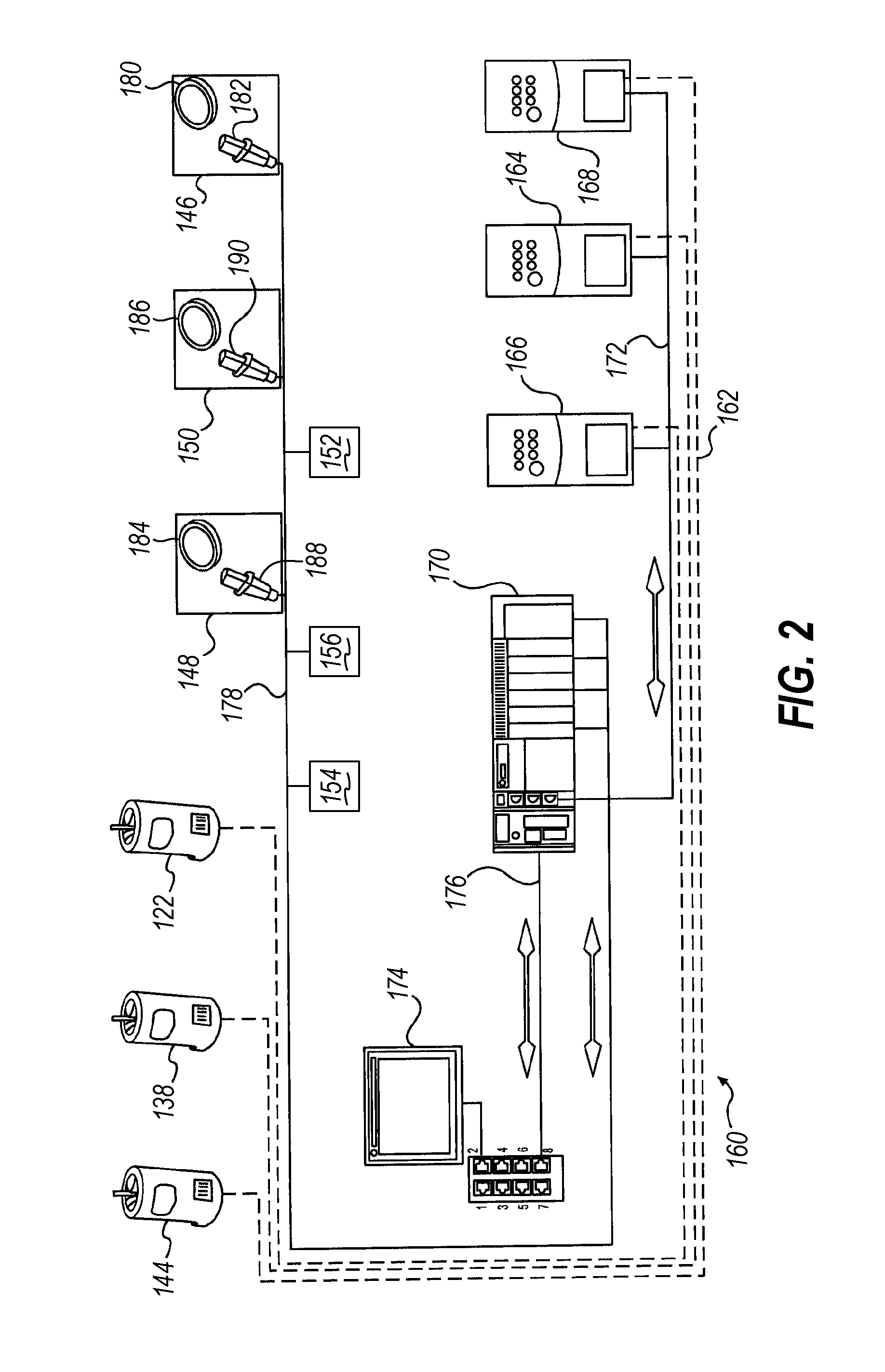

Effective circumference-based wrapping

ActiveUS20140116007A1Reduce tensionIncrease forcePackaging cigaretteWrapper folding/bending apparatusEngineeringMechanical engineering

A wrapping apparatus and method utilize an effective circumference-based wrap speed model that dynamically controls the rate at which packaging material is dispensed based on an effective circumference of a load during relative rotation established between the load and a packaging material dispenser. The effective circumference of a load may be indicative of an effective consumption rate of the load, and may refer to a dimension or size of a tangent circle that is substantially centered at the center of rotation of the load and substantially tangent to a line substantially extending between a first point proximate to where the packaging material exits the dispenser and a second point proximate to where the packaging material engages the load. The effective circumference of the load dynamically changes throughout the relative rotation of the load, and by controlling the dispense rate based at least in part on this dimension, fluctuations in tension in the packaging material may be reduced, often enabling containment force to be increased while reducing the risk of breakage in the packaging material.

Owner:LANTECH COM

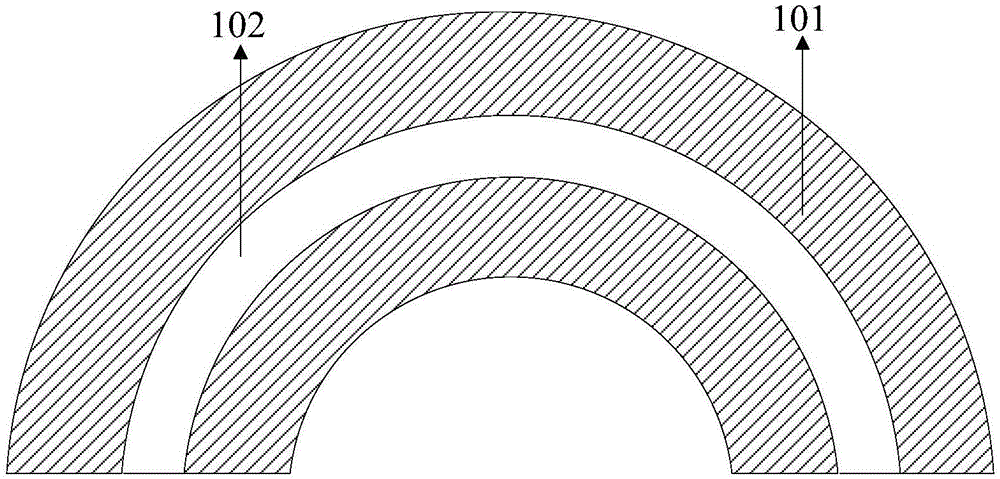

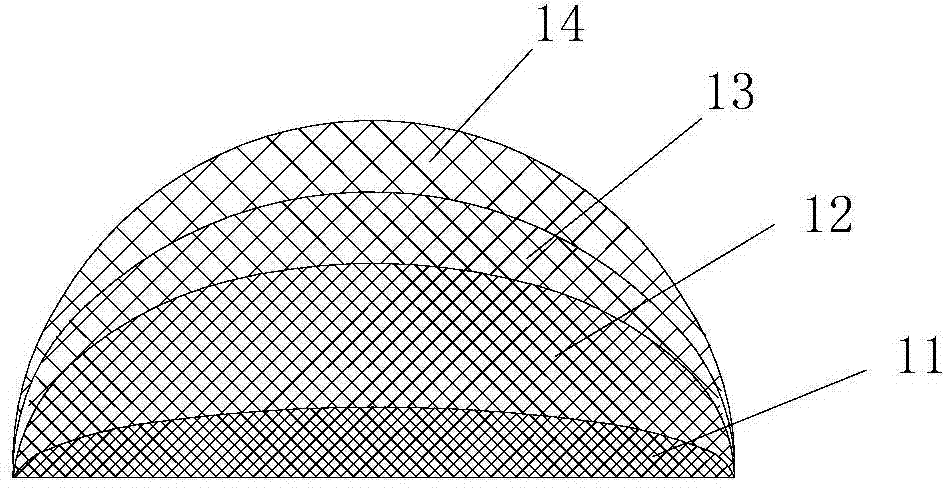

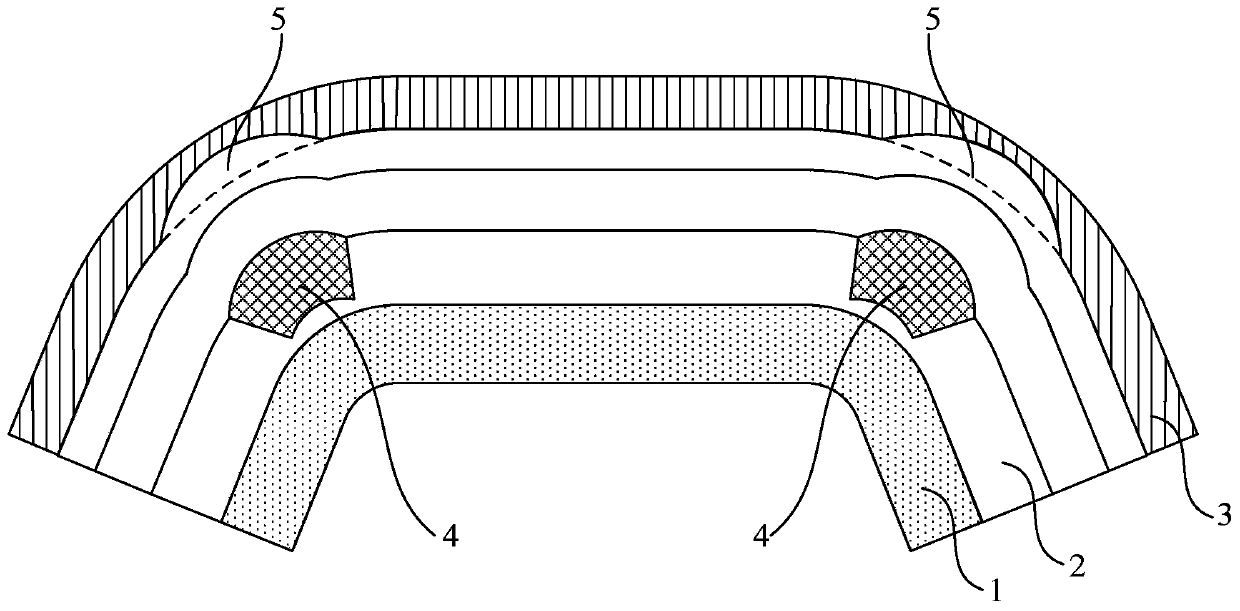

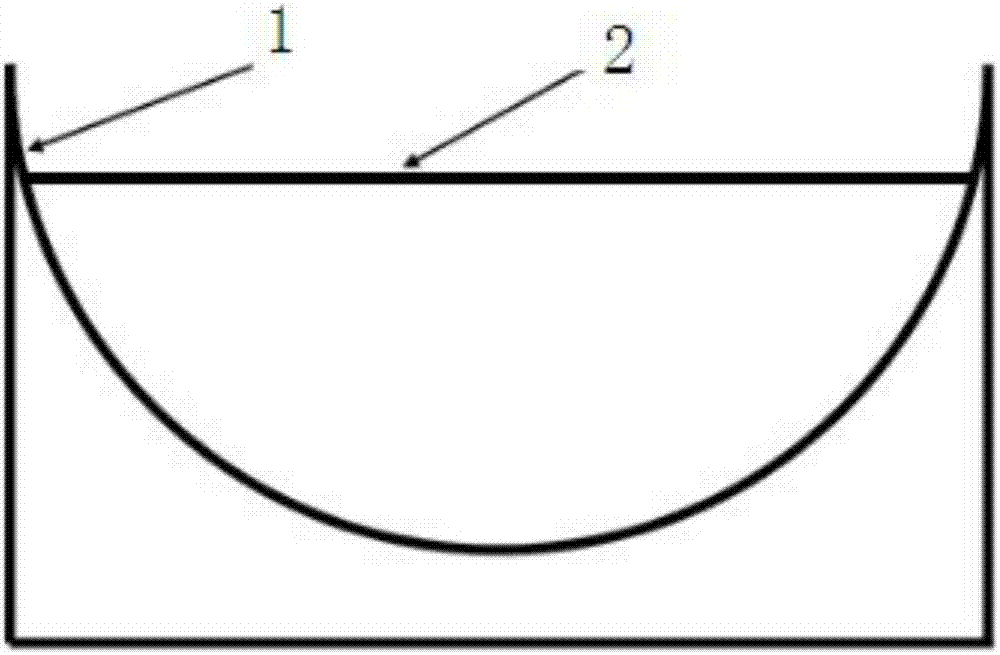

Silicone lens for LED (Light Emitting Diode) packaging and manufacturing method thereof

InactiveCN103681991AImprove light extraction efficiencyImprove stabilitySemiconductor devicesOn boardRefractive index

The invention discloses a silicone lens for LED (Light Emitting Diode) packaging, which is used for being adhered to the surface of a COB (Chip On Board) packaging body so as to improve the light extraction efficiency. The silicone lens is in a convex surface structure, and comprises at least two silicone layers arranged in sequence from inside to outside, wherein the refractive index of the silicone layer positioned on the outer layer is smaller than or equal to that of the silicone layer positioned on the inner layer. The multi-layer silicone lens disclosed by the invention can greatly improve the light extraction efficiency of an LED light source, particularly a high and medium power COB packaging body.

Owner:NANJING TECH CORP LTD

Transparent light emitting members and method of manufacture

InactiveUS20050210643A1Reduced risk of breakageSimple moldingMechanical apparatusUmbrellasRough surfaceEngineering

Illuminators include transparent light emitting members having a pattern of rounded shallow notches or grooves in one or more surfaces of the members for causing internally reflected light to be emitted from the members. The notches or grooves may be cut using a circular cutting tool. The relative speed of the cutting tool and feed rate of the cutting tool relative to the members may be controlled to produce a roughened surface on the notches or grooves.

Owner:LUMITEX INC

Stock assembly with recoil suppression

Owner:PHOENIX TECHNOLOGIES LTD

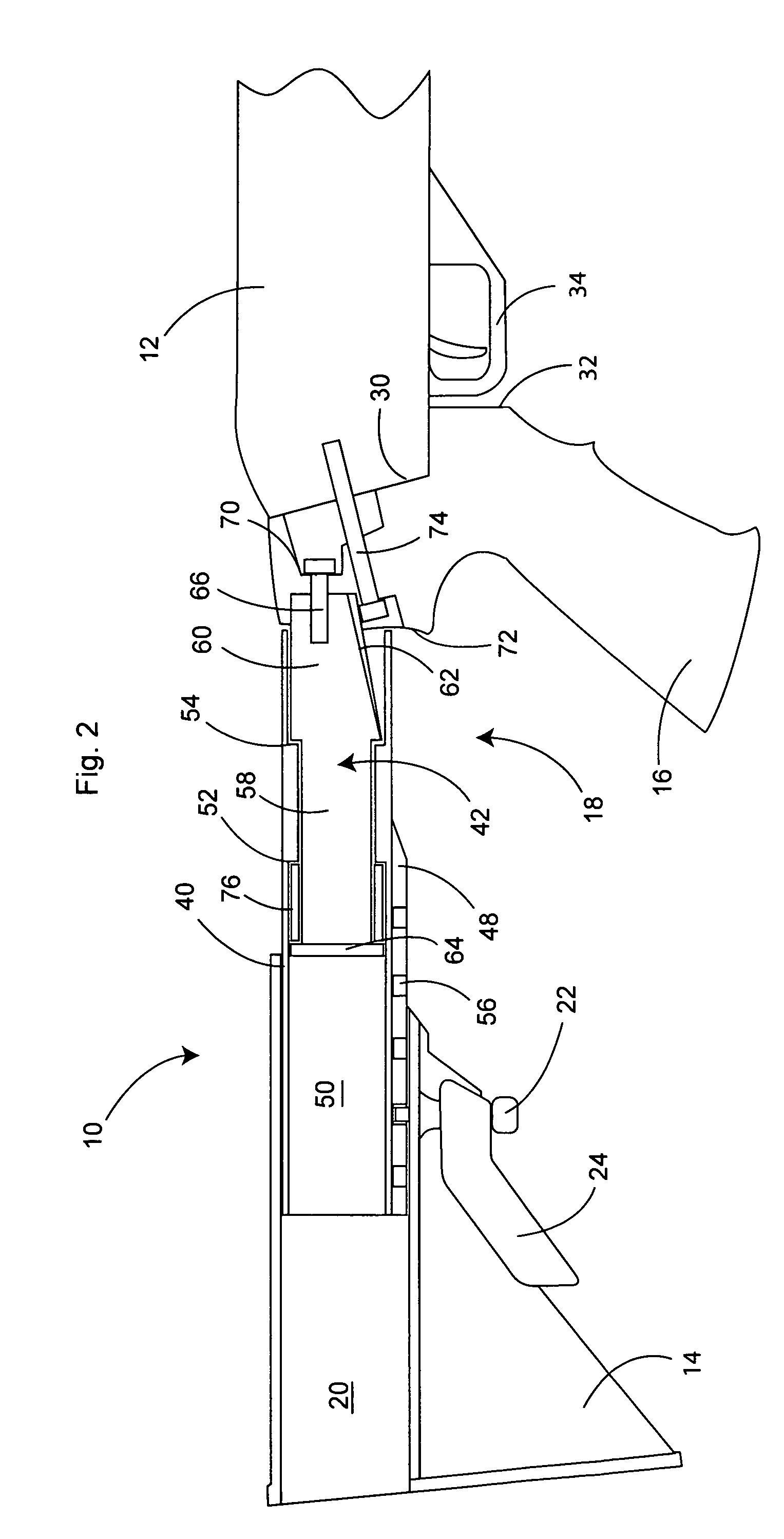

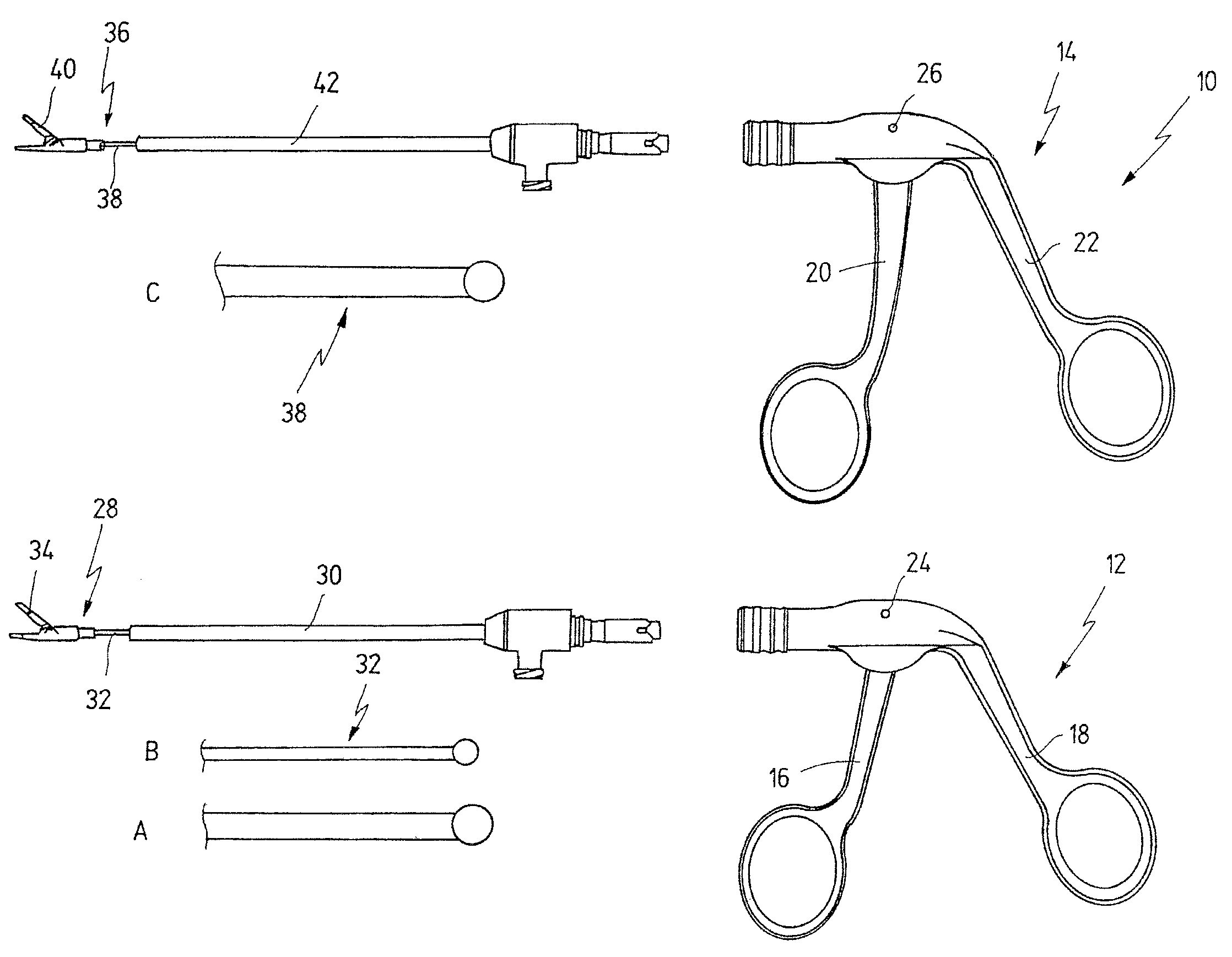

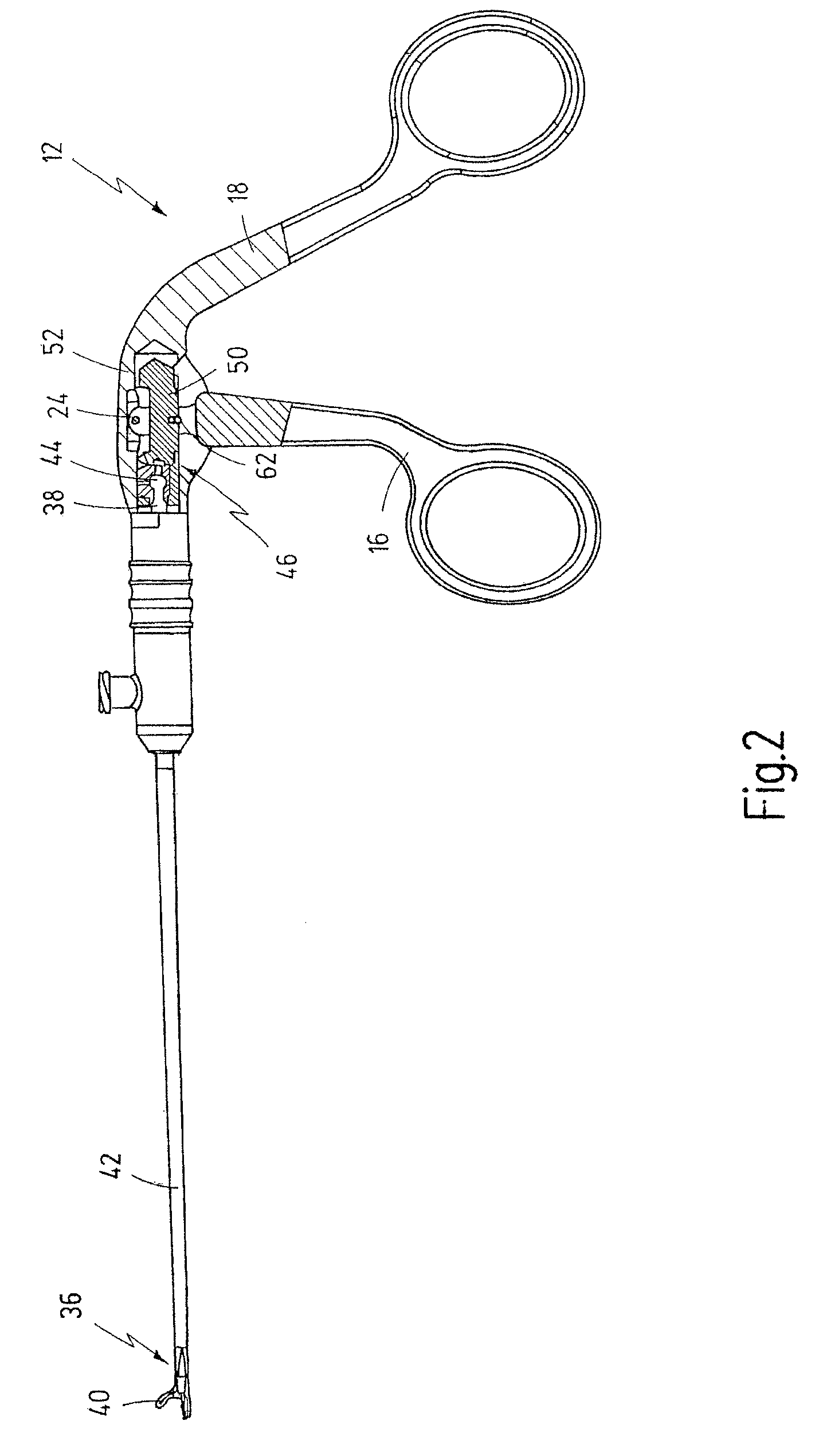

Dismantable Medical Forceps System

A dismantlable medical forceps system has a first force transmission element, which is designed to transmit a first maximum force, at least a second force transmission element, which is designed to transmit a second maximum force greater than the first maximum force, and at least a first grip, which has at least one movable grip part, the at least one first grip having a coupling device by means of which one of the force transmission elements can be connected with a force fit to the movable grip part, the first force transmission element having a first connection element and the at least second force transmission element having a second connection element for respective connection to the coupling device. The first connection element has a first cross section, which differs from a second cross section of the second connection element, and the coupling device has a first seat, which is designed for force-fit connection to the first connection element, and at least a second seat, which is designed for force-fit connection to the second connection element. According to another aspect, such a forceps system has a second grip, which has a second coupling device with a second seat for force-fit connection to the second connection element, which is designed such that the first connection element can be connected with a force lit to this seat.

Owner:KARL STORZ GMBH & CO KG

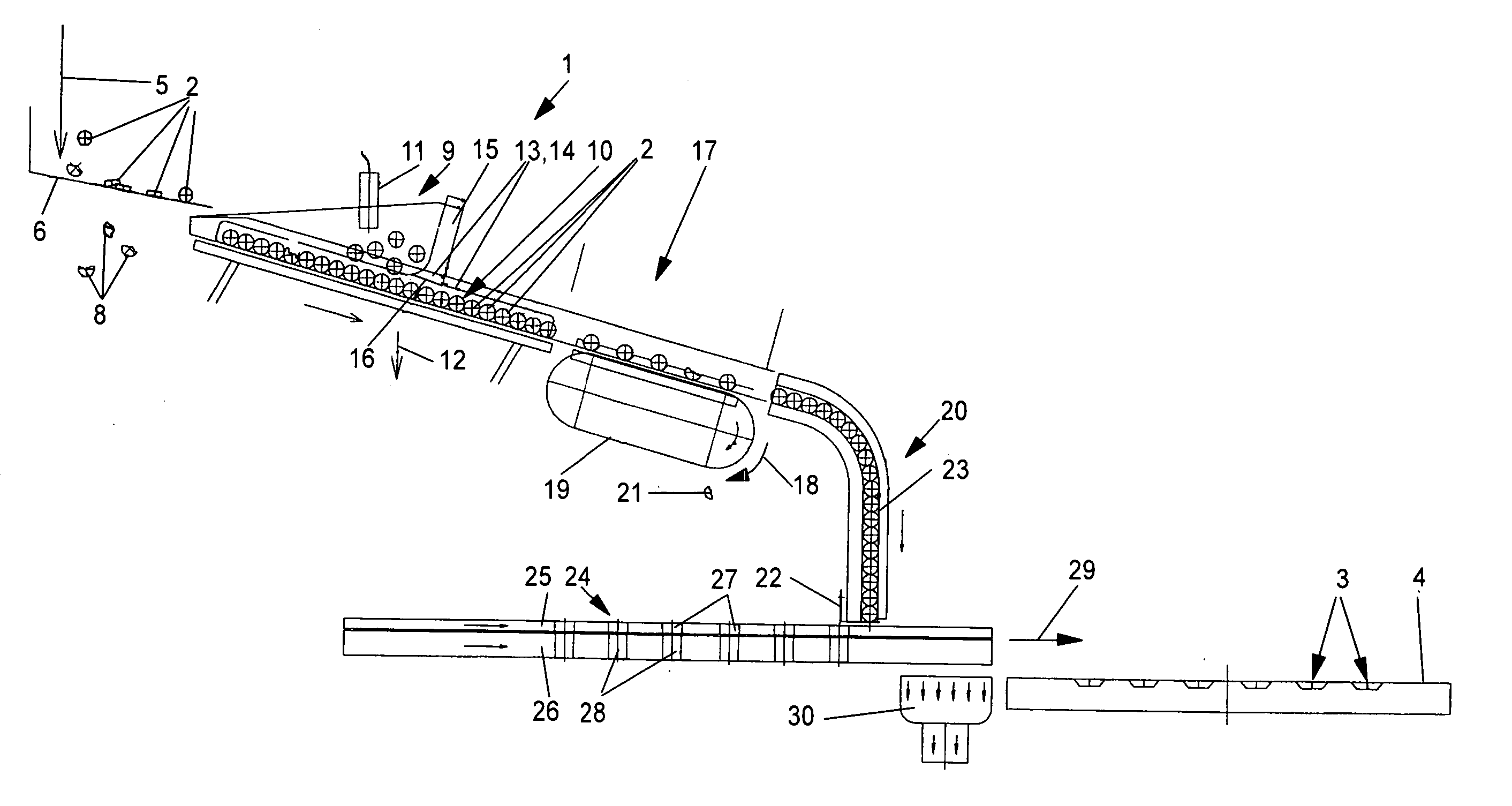

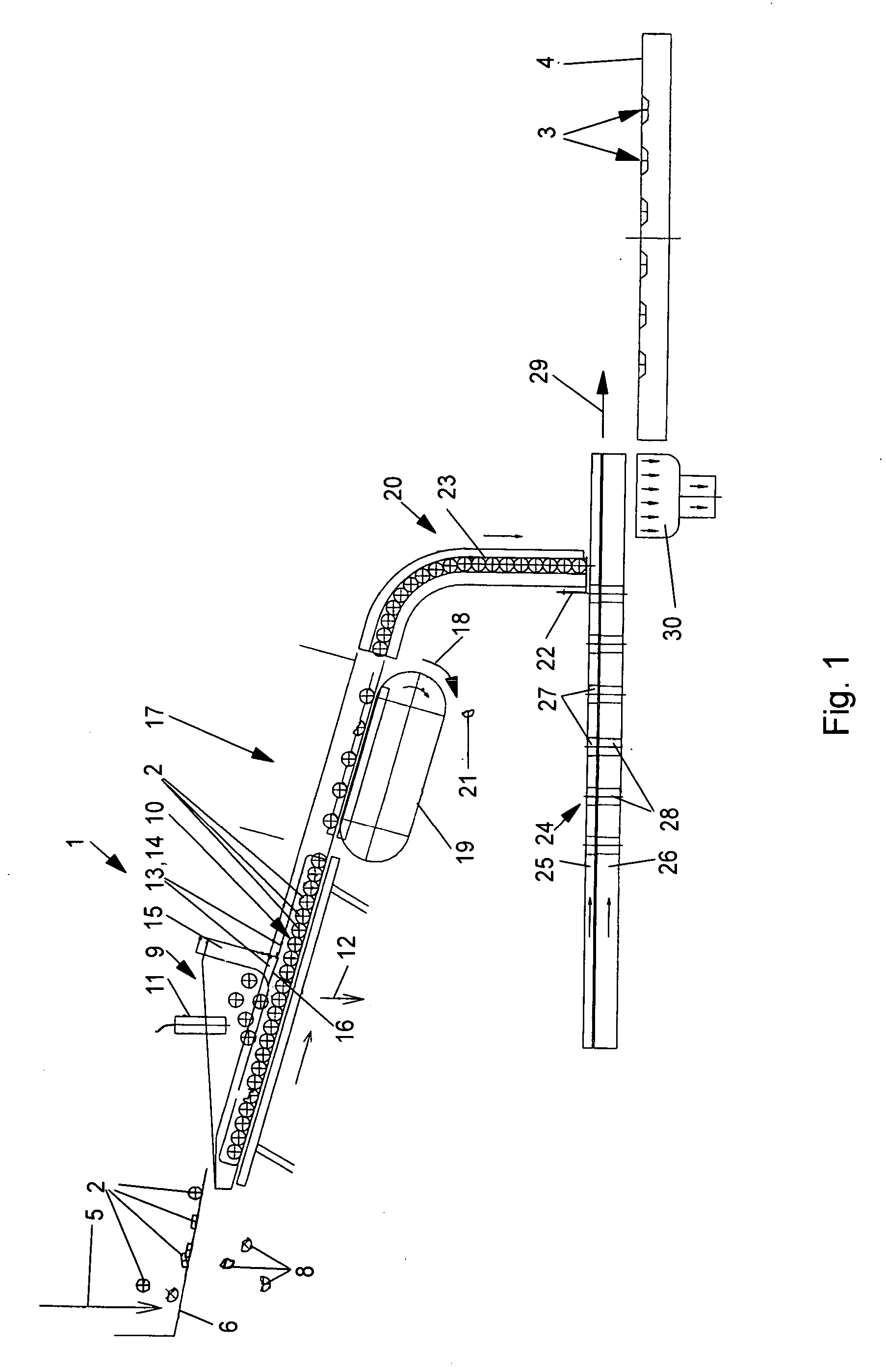

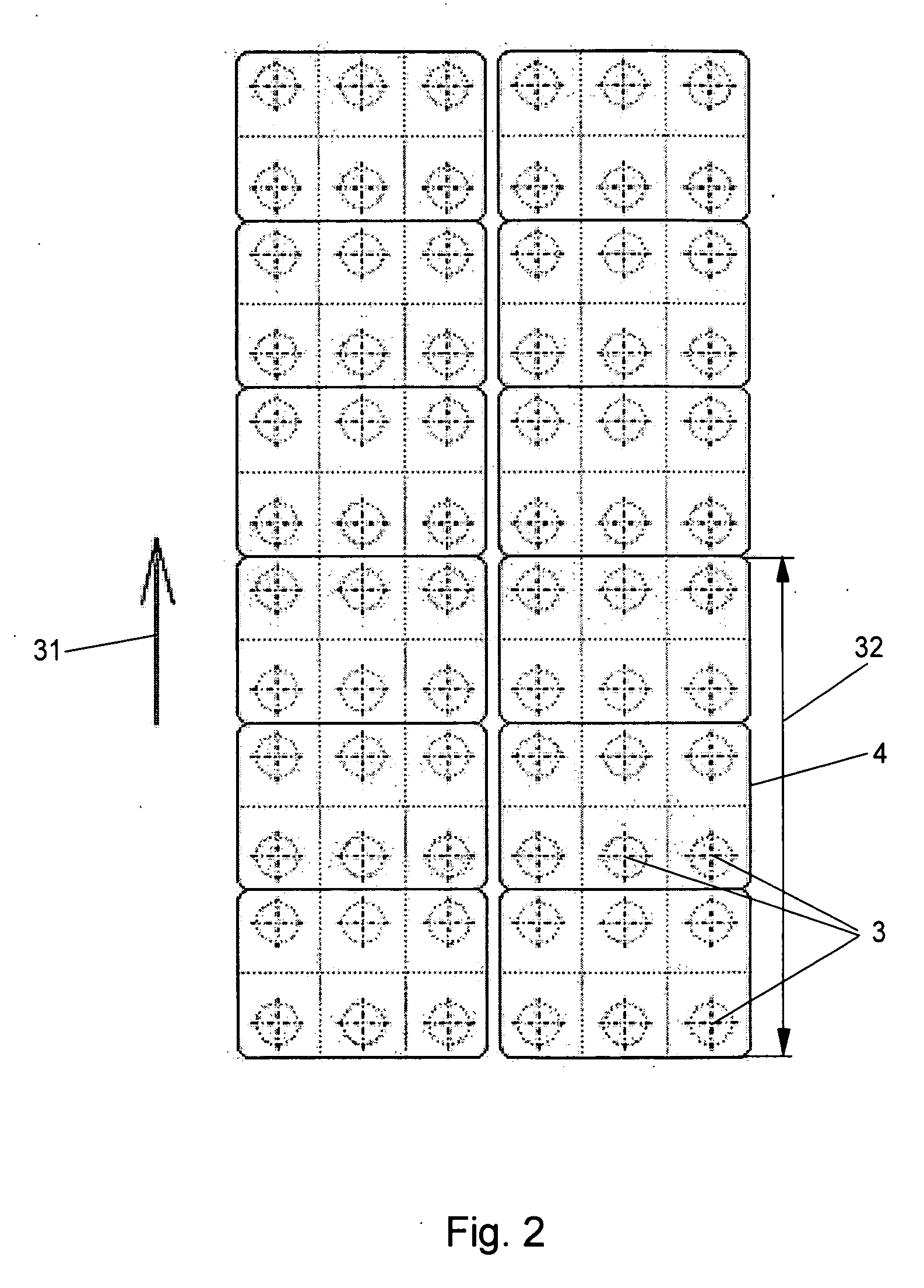

Method and apparatus for placing tablets into pockets of thermoformed bottom foil

InactiveUS20060076077A1Easy to replaceSmall heightMaterial analysis by optical meansPackaging automatic controlStructural engineeringMechanical engineering

A method and an apparatus (1) serve to place tablets (2) into pockets (3) of thermoformed bottom foil (4). The tablets (2) are accumulated as they are located in their flat position. The tablets (2) are rotated in an erecting station (9) such that they reach an approximately upright position. A plurality of lines of approximately upright tablets (2) is formed. The approximately upright tablets (2) are rotated back into their flat position by a transfer unit (24) including a plurality of channels (28). The tablets (2) are then placed into the pockets (3) of the bottom foil (4) by the transfer unit (24).

Owner:MEDISEAL GMBH

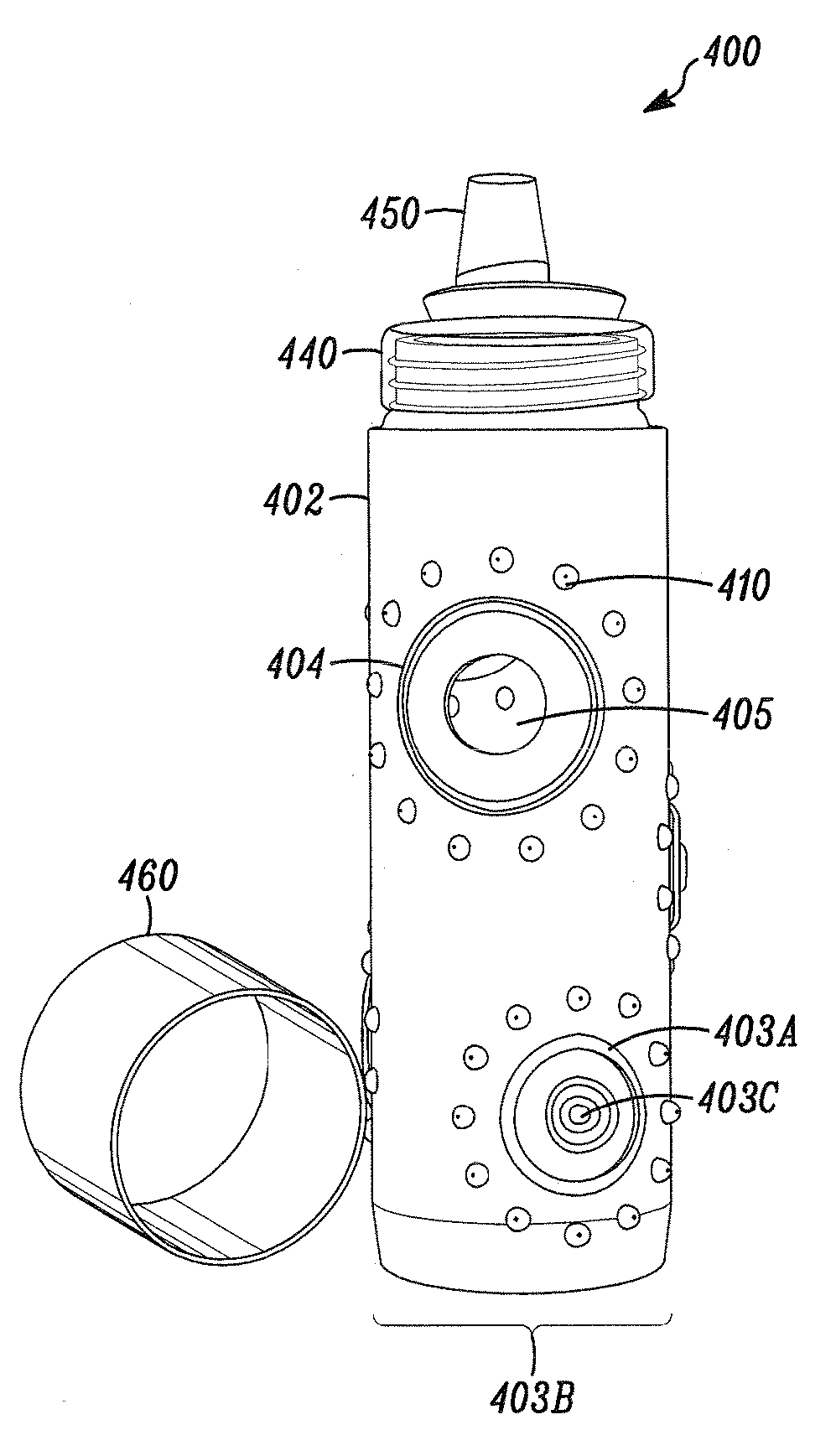

Impact-resistant casing for breakable containers

InactiveUS20100224585A1Reduce frequencyAvoid stress concentrationLarge containersFeeding-bottlesEngineeringBaby bottle

The teachings provided herein are directed to an impact-resistant casing for breakable containers, and a system comprising the impact-resistant casing and a breakable container, such as a glass container. Very useful systems incorporating these components could include, of course, a glass baby bottle, a toddler sippy-cup, or an adult drinking glass, for example. These and other embodiments will be apparent to one of skill upon a review of the teachings provided herein.

Owner:SILIKIDS

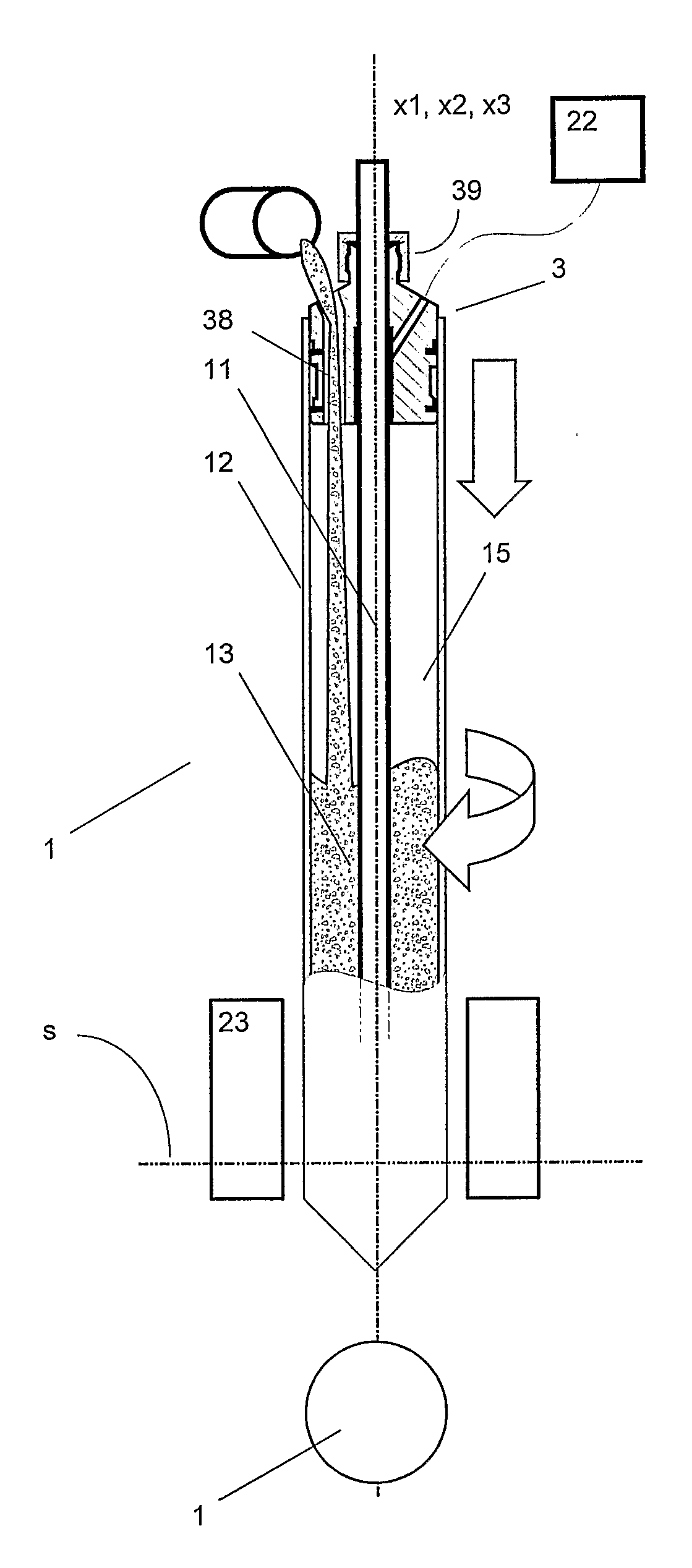

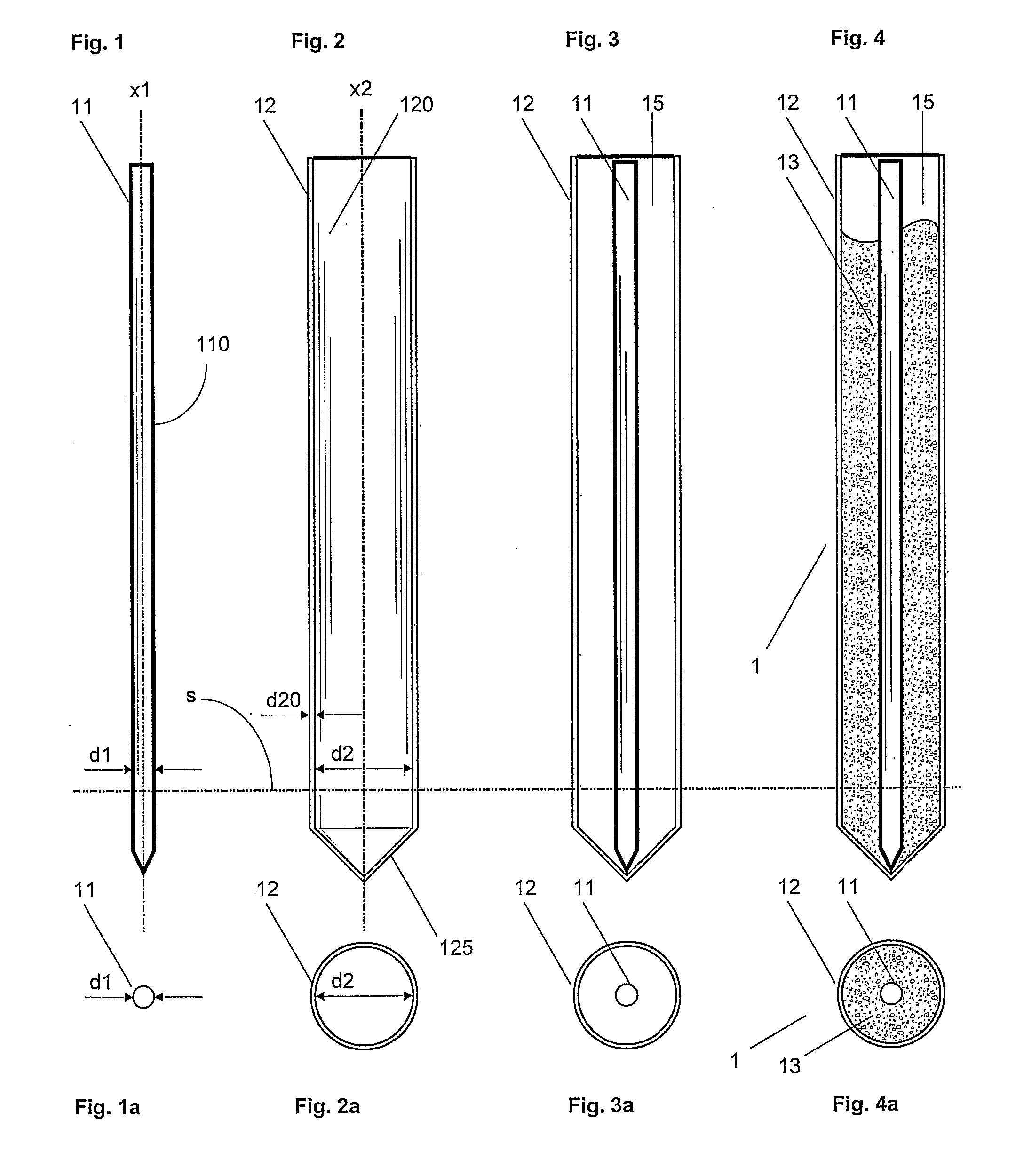

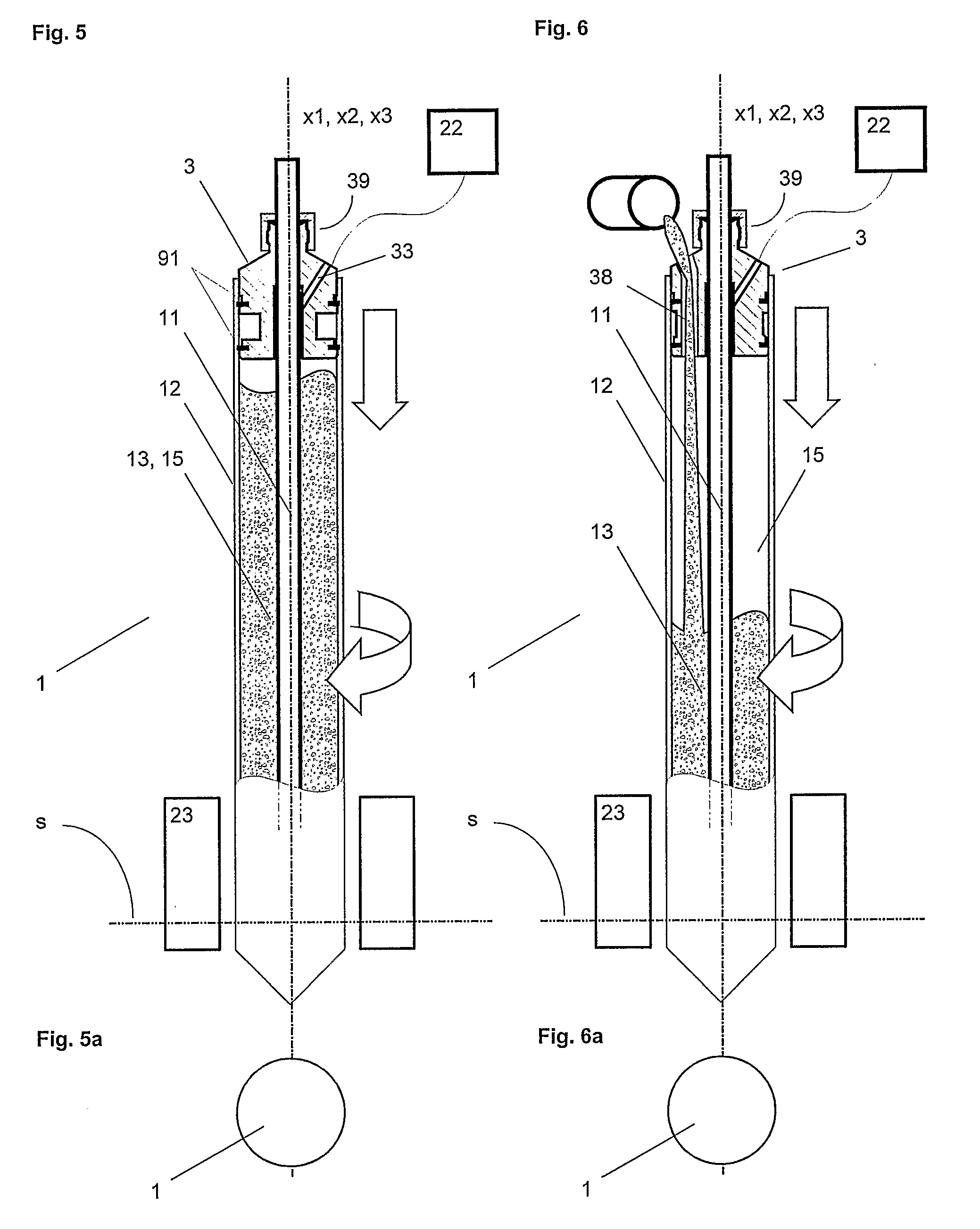

Method for Fabricating an Optical Fiber, Preform for Fabricating an Optical Fiber, Optical Fiber and Apparatus

ActiveUS20070214841A1Reduce tensionReduced risk of breakageGlass fibre drawing apparatusRigid pipesInterior spaceEngineering

The method for fabricating an optical fiber comprises the steps of inserting a primary optical fiber preform (11) having a first primary axis (x1) and an outer surface (111) into an overcladding tube (12) having a second primary axis (x2) and an inner surface (120), so that said outer surface and inner surface define an interior space (15); holding the primary preform (11) in a centrally inserted position within the overcladding tube (12) with said first and second primary axes (x1, x2) in substantial alignment with each other; supplying overcladding grain (13) into the interior space (15) that is limited at the lower end of the overcladding tube (12) by means of a closure (125); generating a condition of reduced pressure within the interior space (15) that is limited at the upper end of the overcladding tube (12) by means of an adjoiner (3), which holds the primary optical fiber preform (11) and the overcladding tube (12) in position; and heating the unprocessed secondary preform (1), that consists of the primary preform (11), the overcladding tube (12) and the overcladding grain (13), at its lower end to a softened state and simultaneously or subsequently drawing an optical fiber therefrom.

Owner:SILITEC

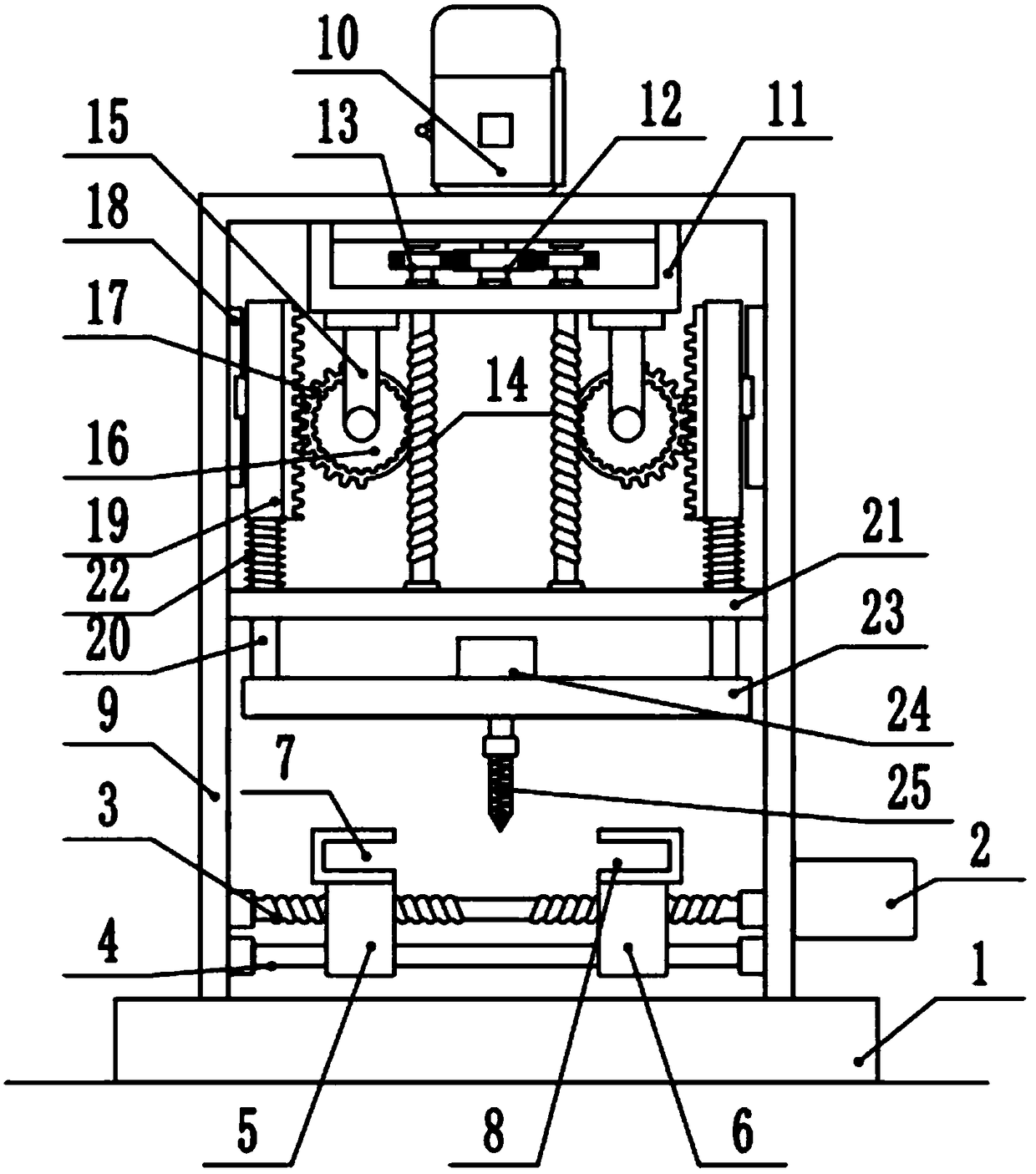

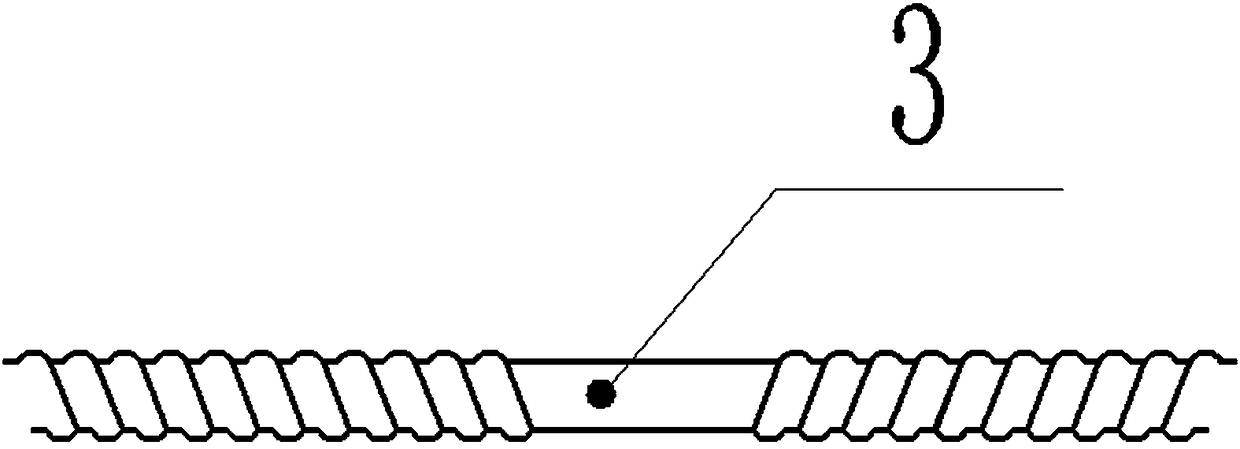

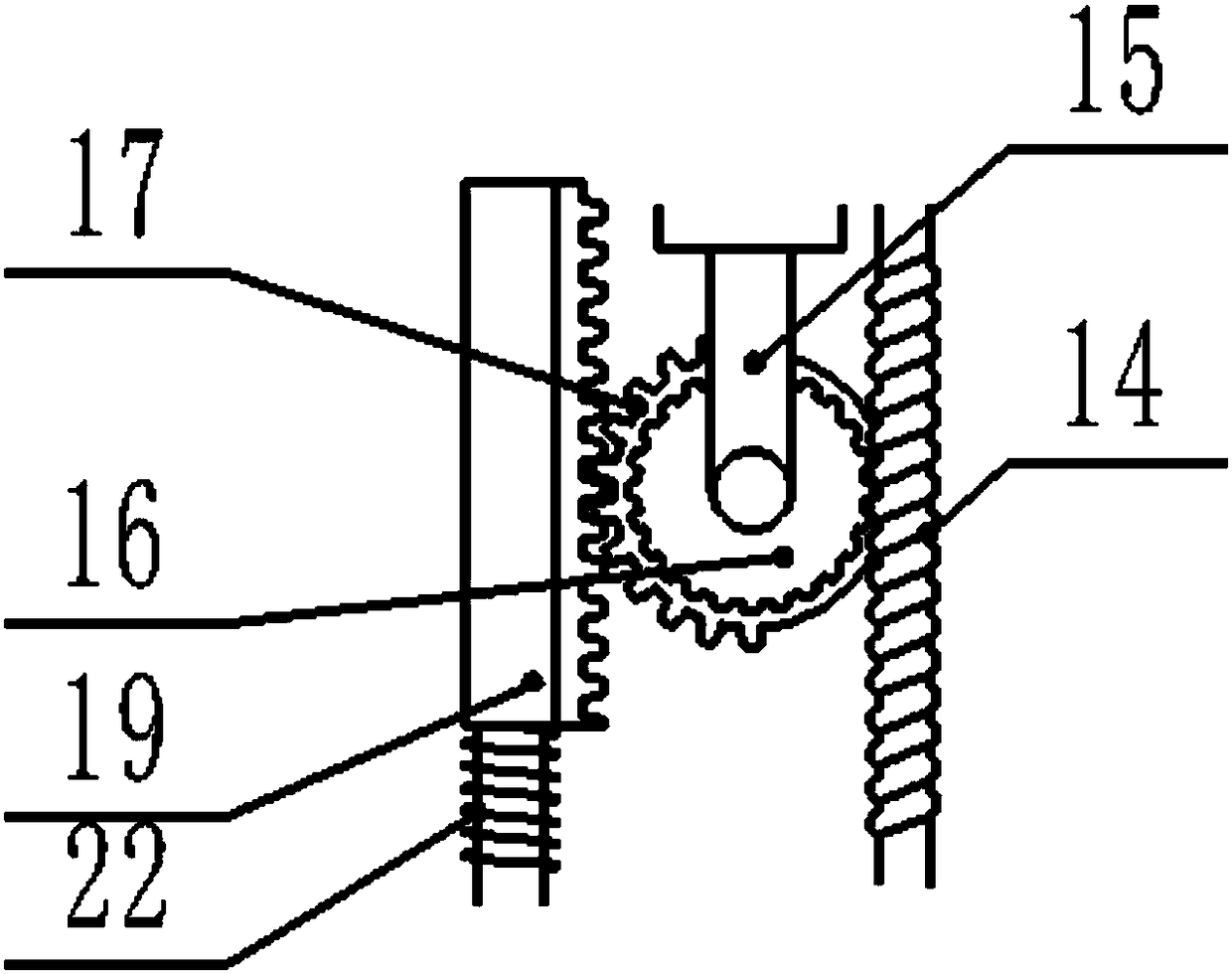

Bolt hole machining device for die machining

InactiveCN108340182AReduced risk of breakageConsistent inner diameterFeeding apparatusPositioning apparatusBall screwCoupling

The invention discloses a bolt hole machining device for die machining. The bolt hole machining device comprises a clamping motor, a left clamping jaw, a right clamping jaw, a main driving motor, a lifting frame and a drilling motor, wherein a main support is arranged on the upper surface of a platform, the clamping motor is fixedly installed on the right side of the main support, the left end ofthe output shaft of the clamping motor is fixedly provided with a ball screw through a coupler, a left sliding block and a right sliding block are installed on the left portion and the right portion of a ball screw in a threaded mode, and the left clamping jaw and the right clamping jaw are fixedly arranged on the upper side of the left sliding block and the upper side of the right sliding block through screws respectively. The right sliding block is novel in structure, the distance between the left sliding block and the right sliding block is adjusted, the clamping work of molds with different specifications can be met, the universality of the device is greatly improved, and the mold does not need to be replaced during machining; and through the cooperation of a half gear and a sliding rack, a drill bit can move up and down continuously, and compared with a one-time drilling mode, the drill bit can be effectively protected in a continuous pressurization and continuous drilling mode, and the fracture risk of the drill bit is reduced.

Owner:单义丹

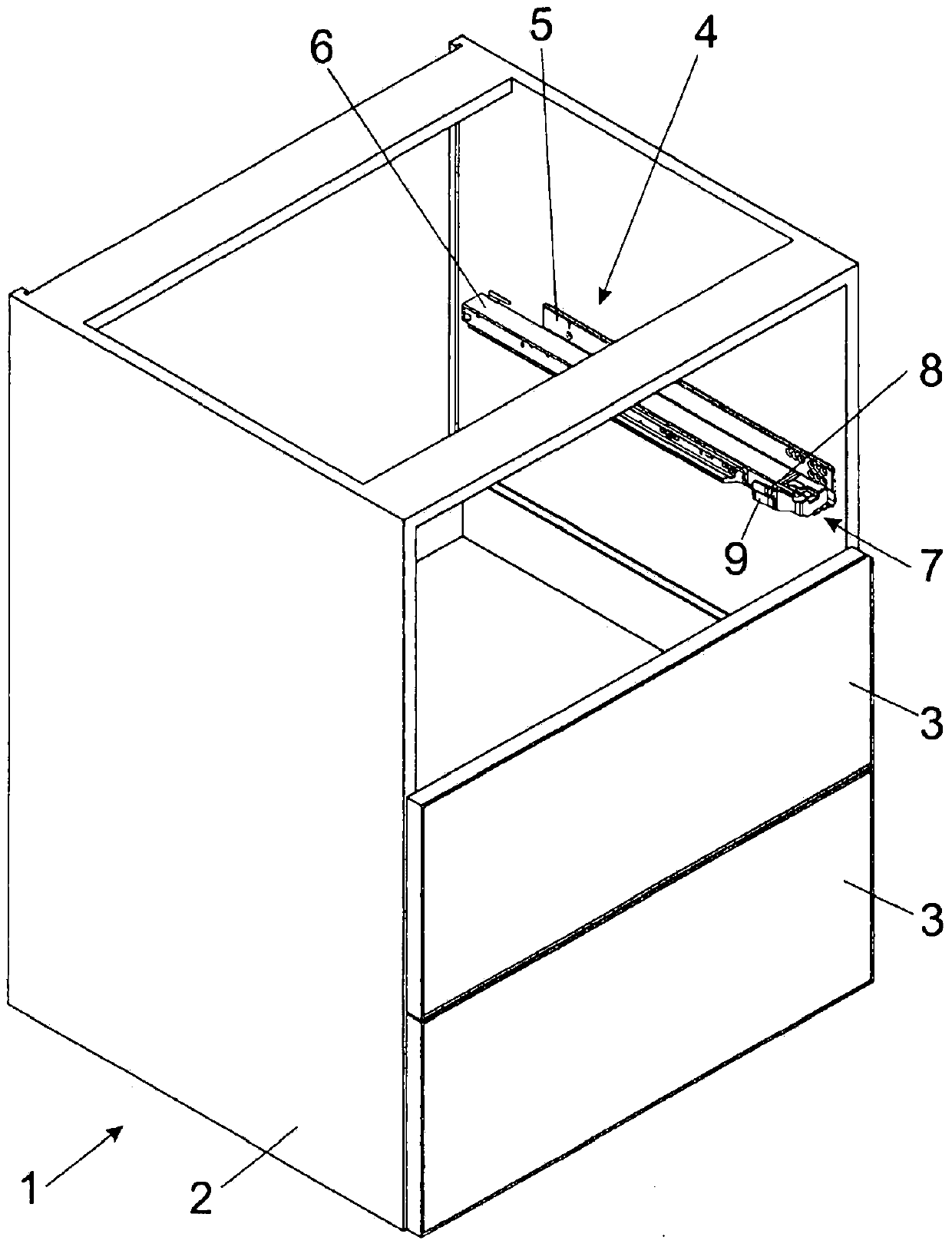

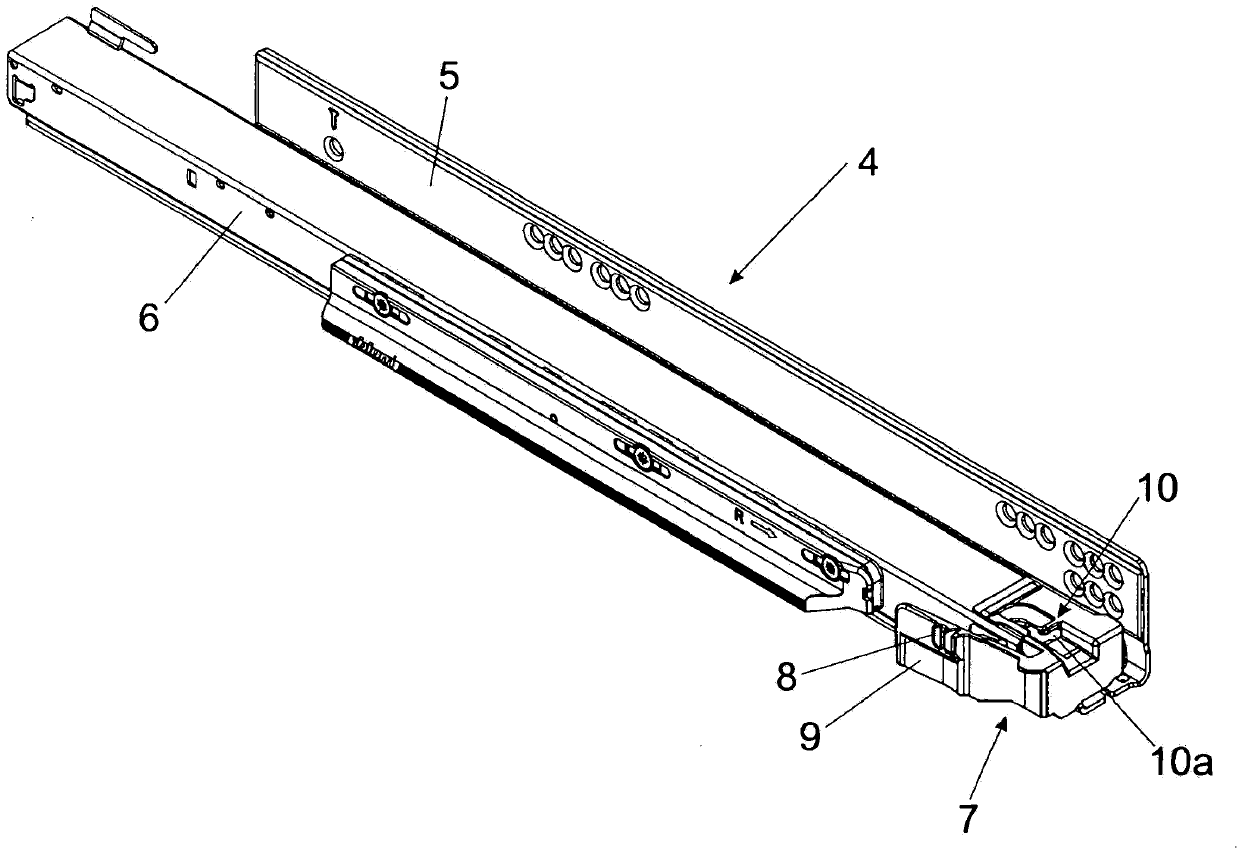

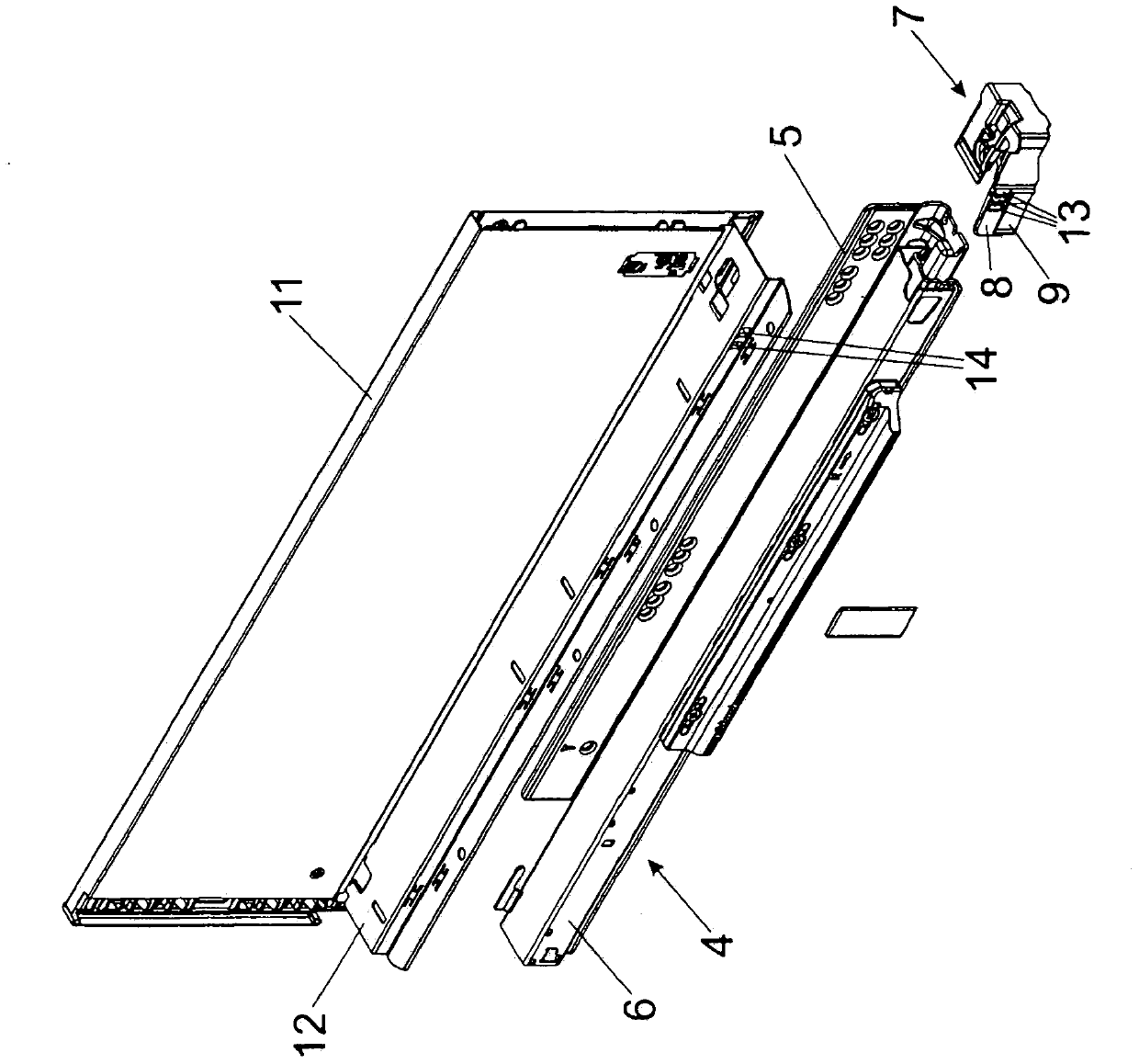

Drawer pull-out guide

Owner:JULIUS BLUM GMBH

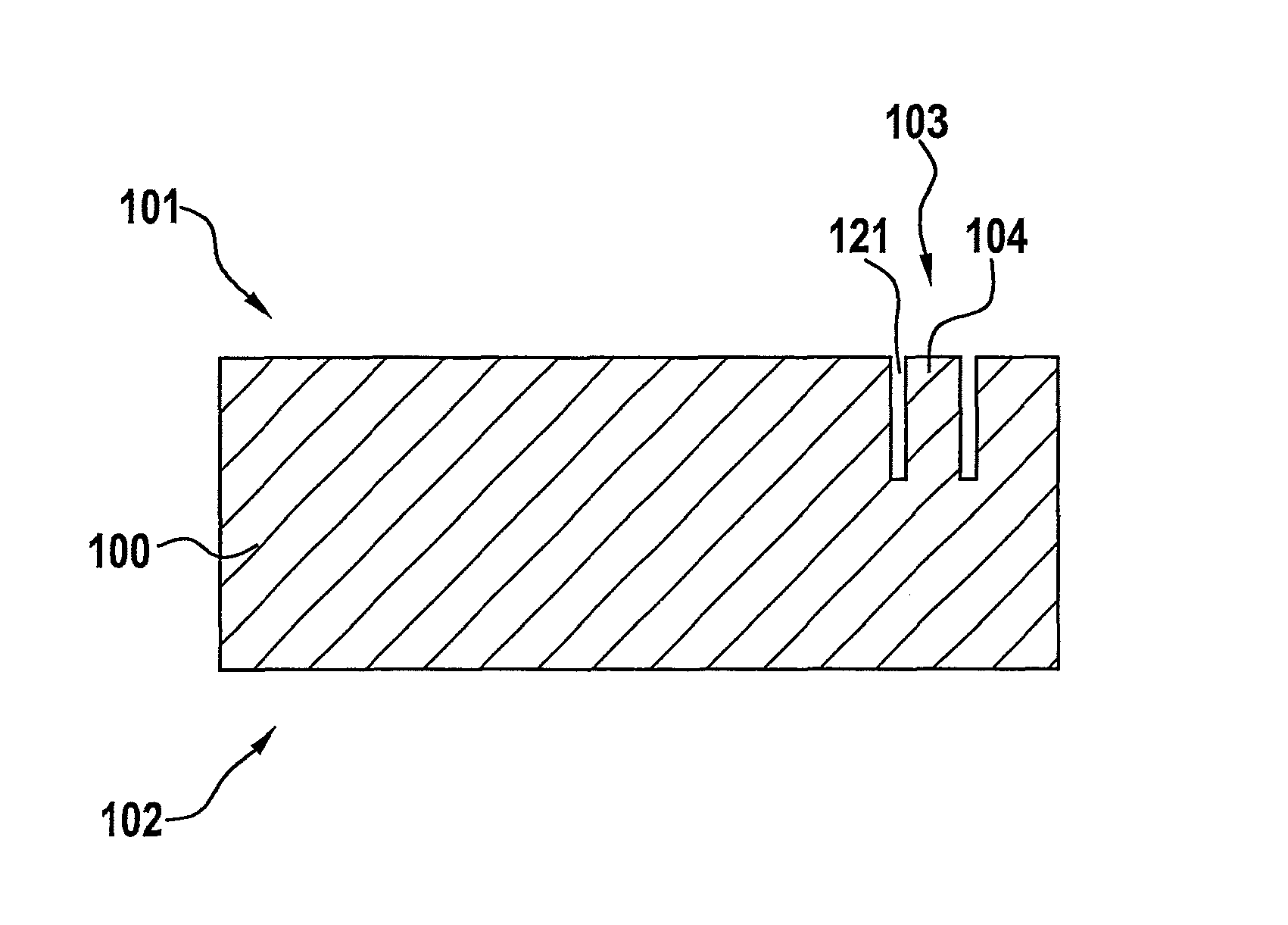

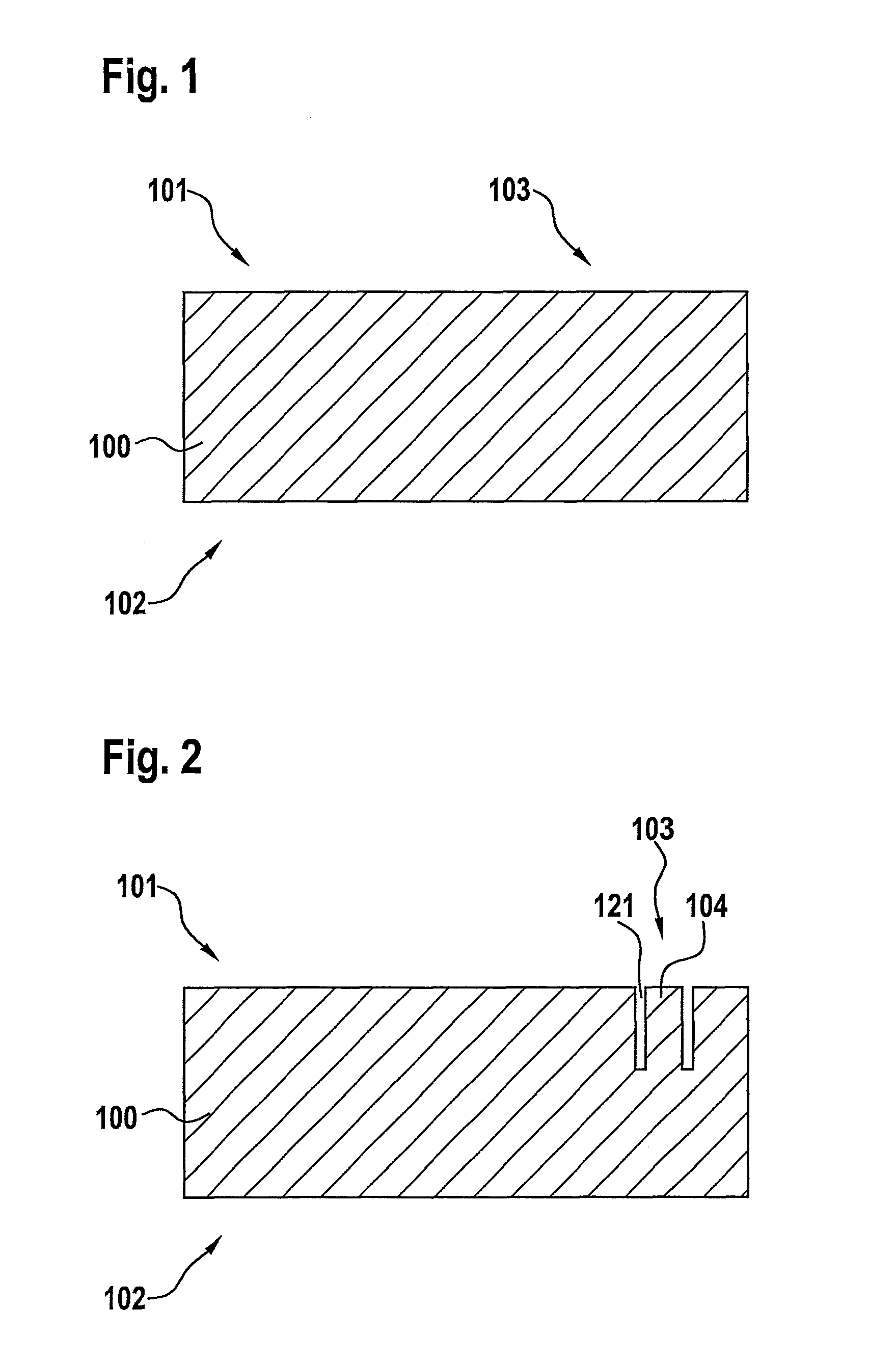

Method for manufacturing a component having an electrical through-connection

ActiveUS20130341738A1Efficient productionReduced base areaDecorative surface effectsSemiconductor/solid-state device manufacturingElectricityEngineering

A method for manufacturing a component having an electrical through-connection includes: providing a semiconductor substrate having a front side and a back side opposite from the front side; producing, on the front side of the semiconductor substrate, an insulating trench which annularly surrounds a contact area; introducing an insulating material into the insulating trench; producing a contact hole on the front side of the semiconductor substrate by removing the semiconductor material surrounded by the insulating trench in the contact area; and depositing a metallic material in the contact hole.

Owner:ROBERT BOSCH GMBH

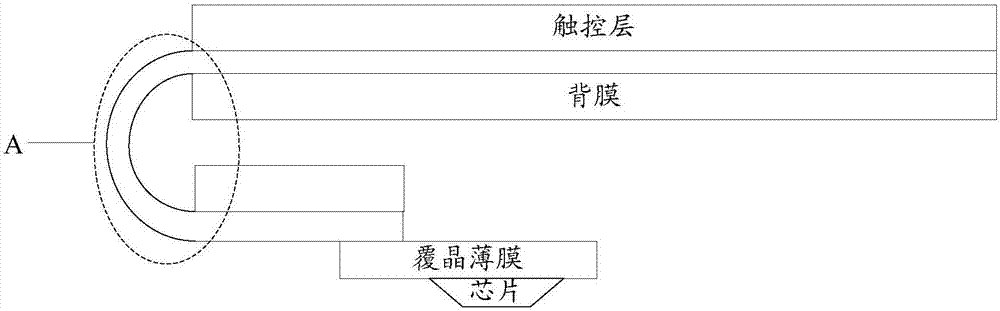

Display panel and display device

ActiveCN110148620AAvoid breakingImprove bending resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel and a display device. The display panel comprises at least one bending area, and the display device further comprises a substrate; a stress release layer, wherein at least one first groove is formed in the stress release layer, and the first groove is located in the bending area, and a first notch is formed on a first surface of one side, close to the coverplate, of the stress release layer. The first groove is filled with a flexible material, and the elastic modulus of the flexible material is less than that of the stress release layer. The display panel also comprises the cover plate which is located at one side of the substrate, wherein the stress release layer is located at one side, close to the substrate, of the cover plate, and at least one second groove is formed in the cover plate. The second groove is provided with a second notch in the second surface, close to one side of the stress release layer, of the cover plate, and the orthographic projection of the second notch and the orthographic projection of the first notch on the substrate are overlapped. According to the display device, the problems that module materials in the display device are broken and the display device is layered when the display device is bent are solved, and the display effect of the display device is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Transparent light emitting members and method of manufacture

InactiveUS20070248307A1Easy to manufactureEasy low volume manufacturabilityGlass making apparatusCladded optical fibreLight guideLaser

Light emitting members or illuminators in the form of a light guide which may comprise one or more flat optical fibers having a pattern of U shaped notches or grooves in at least one side to cause conducted light to be emitted therefrom. A laser may be used to cut any desired pattern of notches or grooves in the light guide.

Owner:LUMITEX

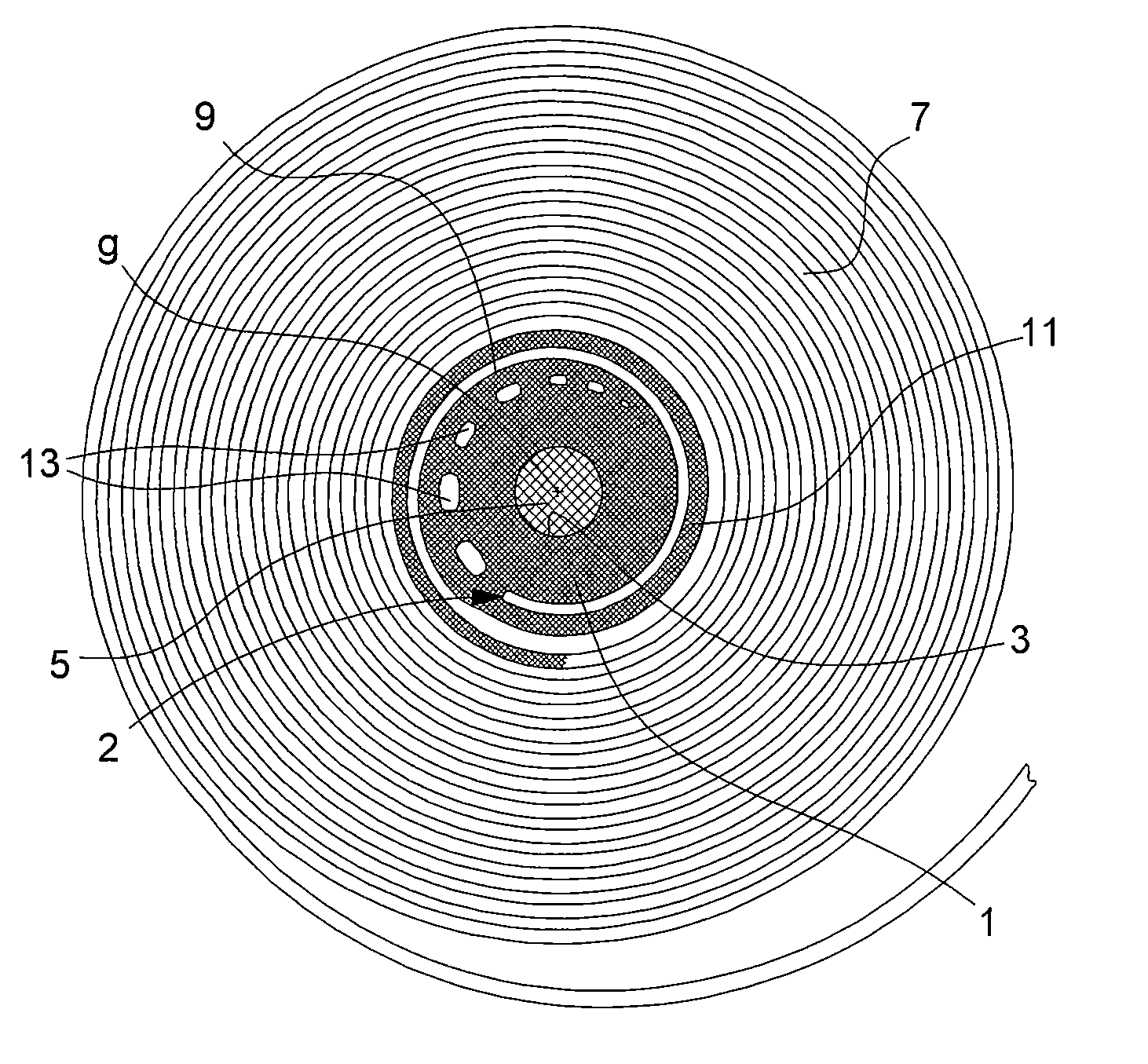

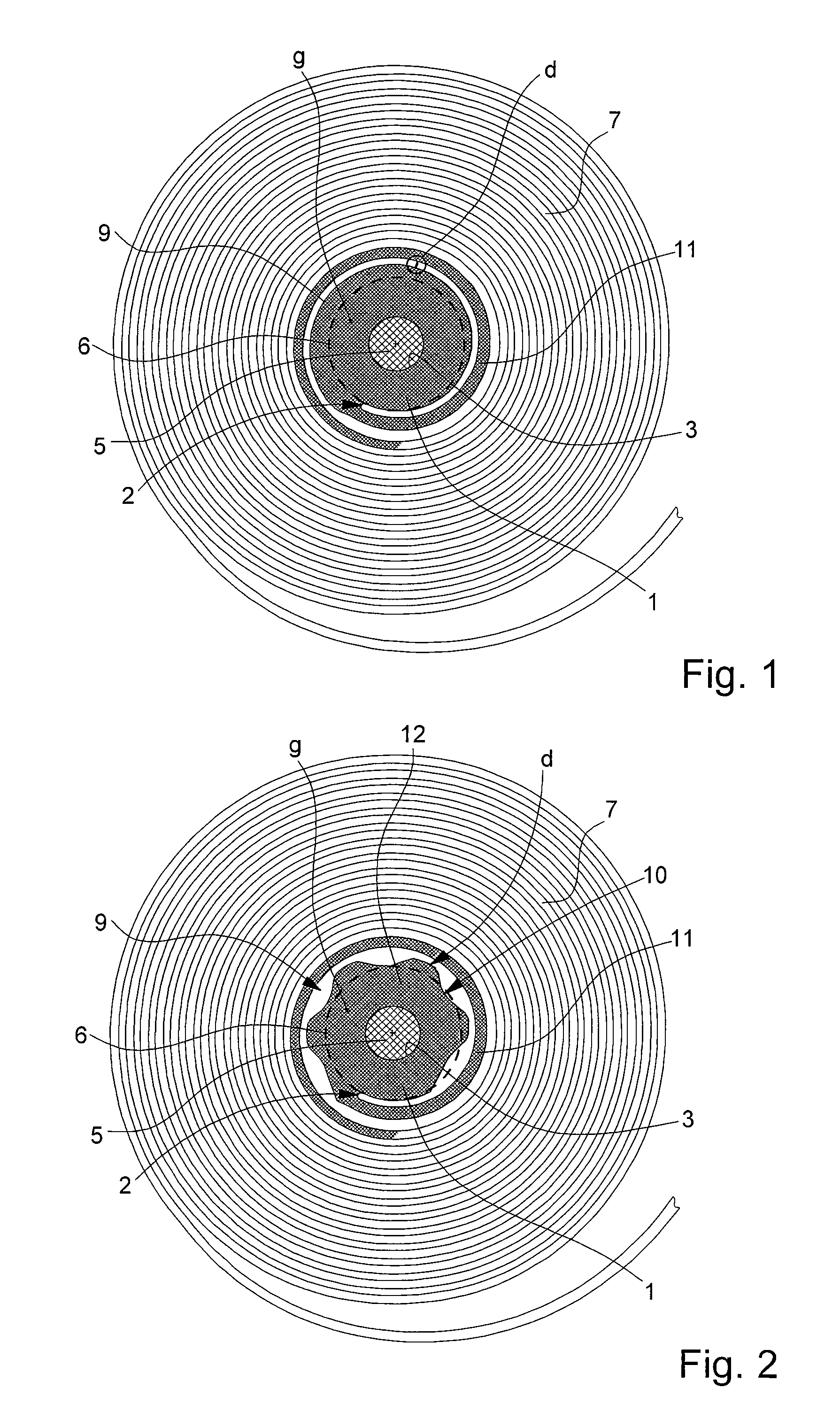

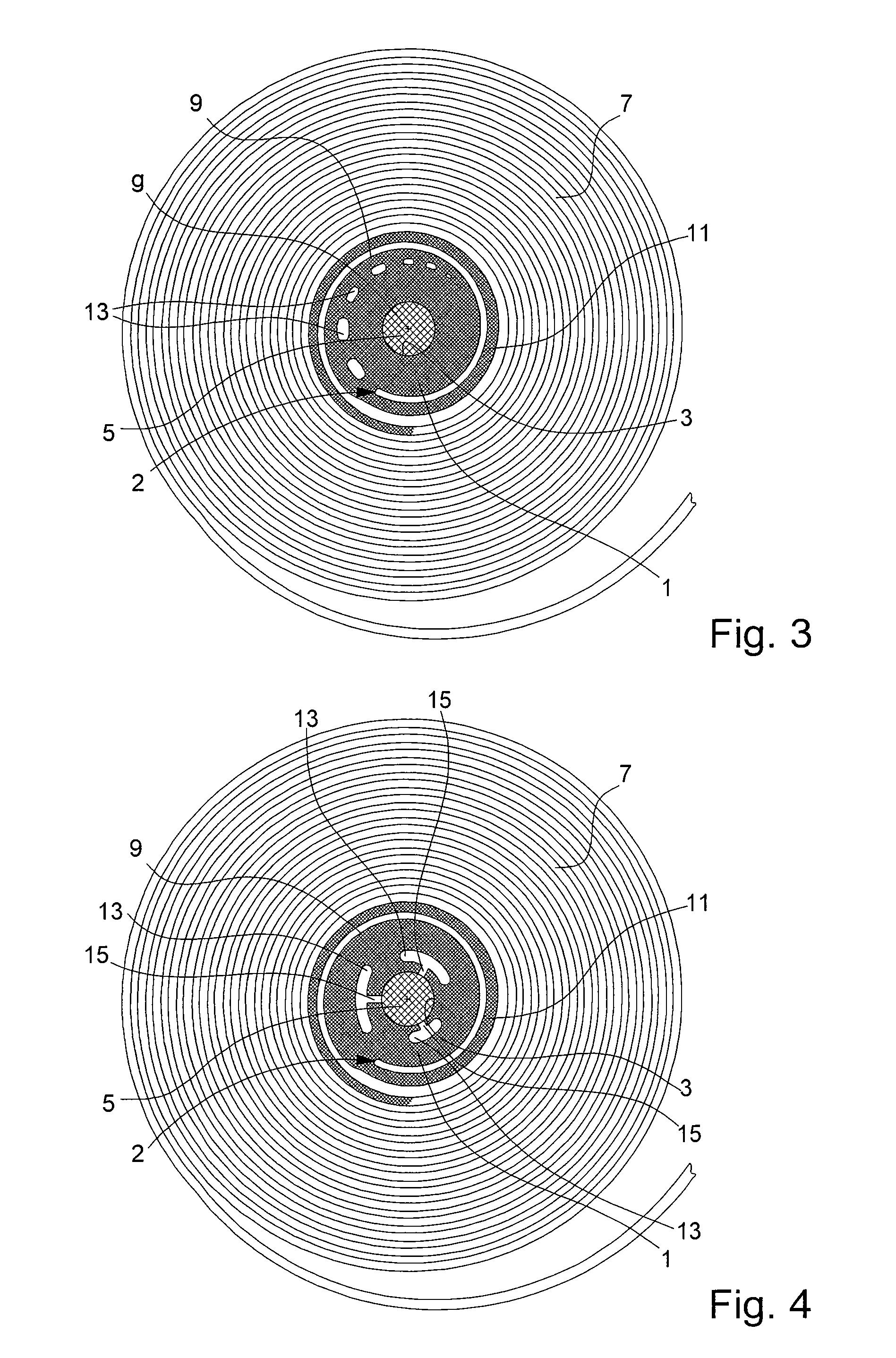

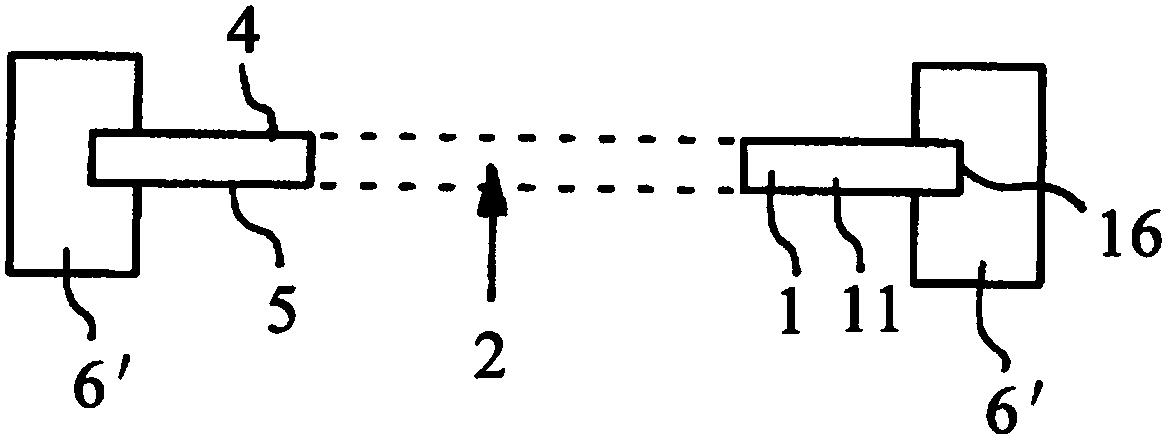

Anti-shock collet

ActiveUS20100061192A1Negative effectResilienceFrequency stabilisation mechanismEngineeringGravitation

The collet, which can be made in a single piece and at the same time as the balance-spring, is formed by a plate (1) which includes an aperture (3) for attachment to a balance staff (5) and has an asymmetrical contour (9) which follows at a substantially constant distance d the contour of the first coil (11) of the inner terminal curve. The plate can further include recesses (13) for repositioning the centre of gravity g on the balance staff (5).

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

led rotary built-in power fluorescent lamp

InactiveCN102287737AWon't shakeFirmly connectedPoint-like light sourceElongate light sourcesElectricityEngineering

Owner:NINGBO TONGTAI ELECTRIC

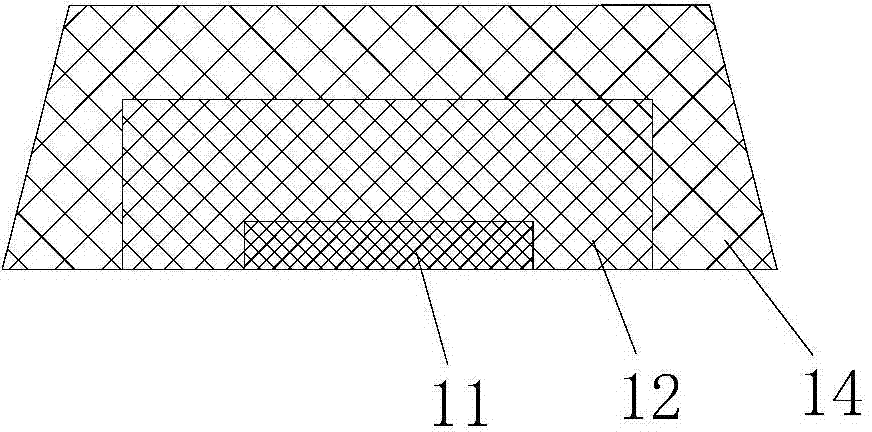

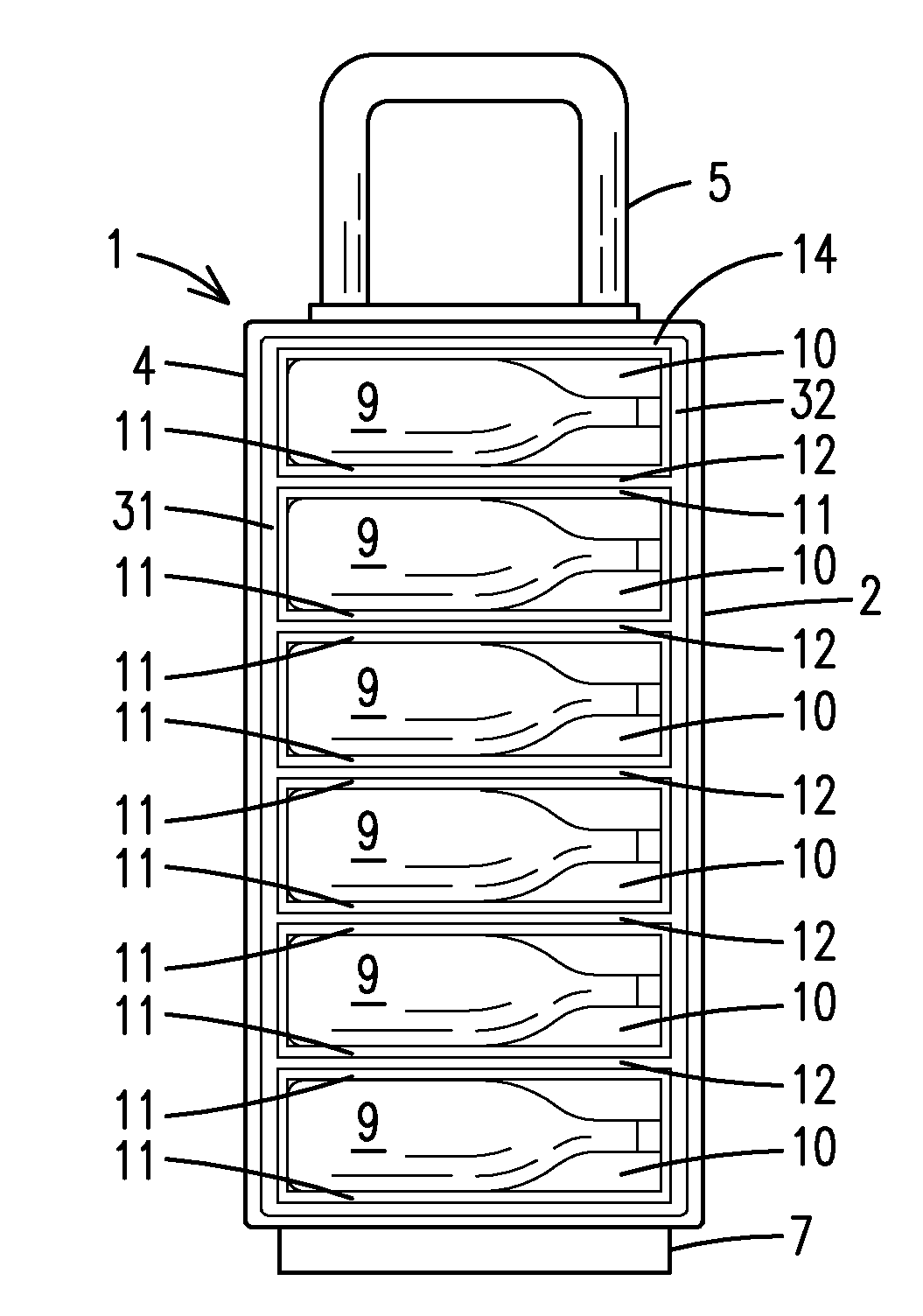

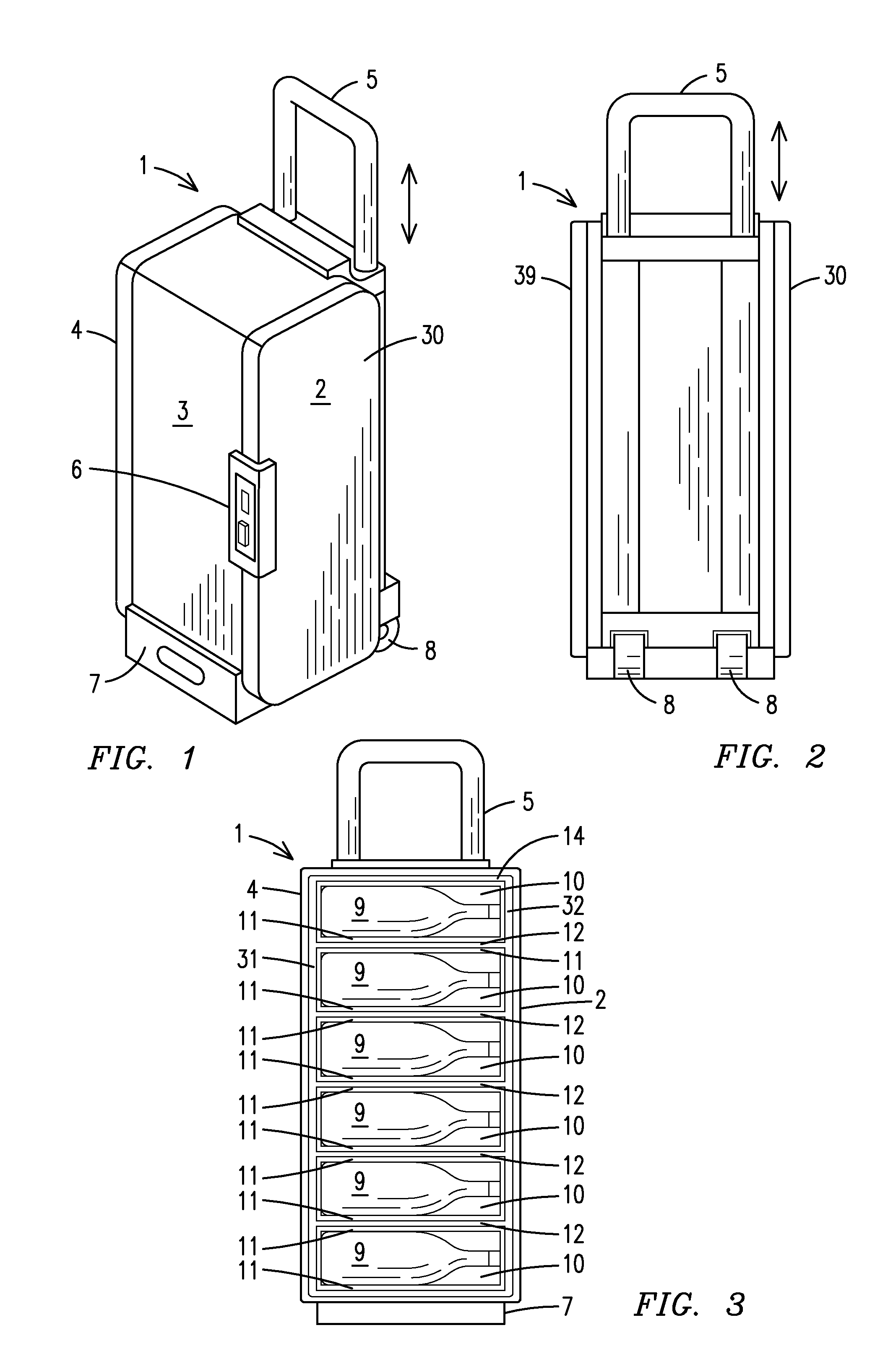

Bottled beverage holding luggage

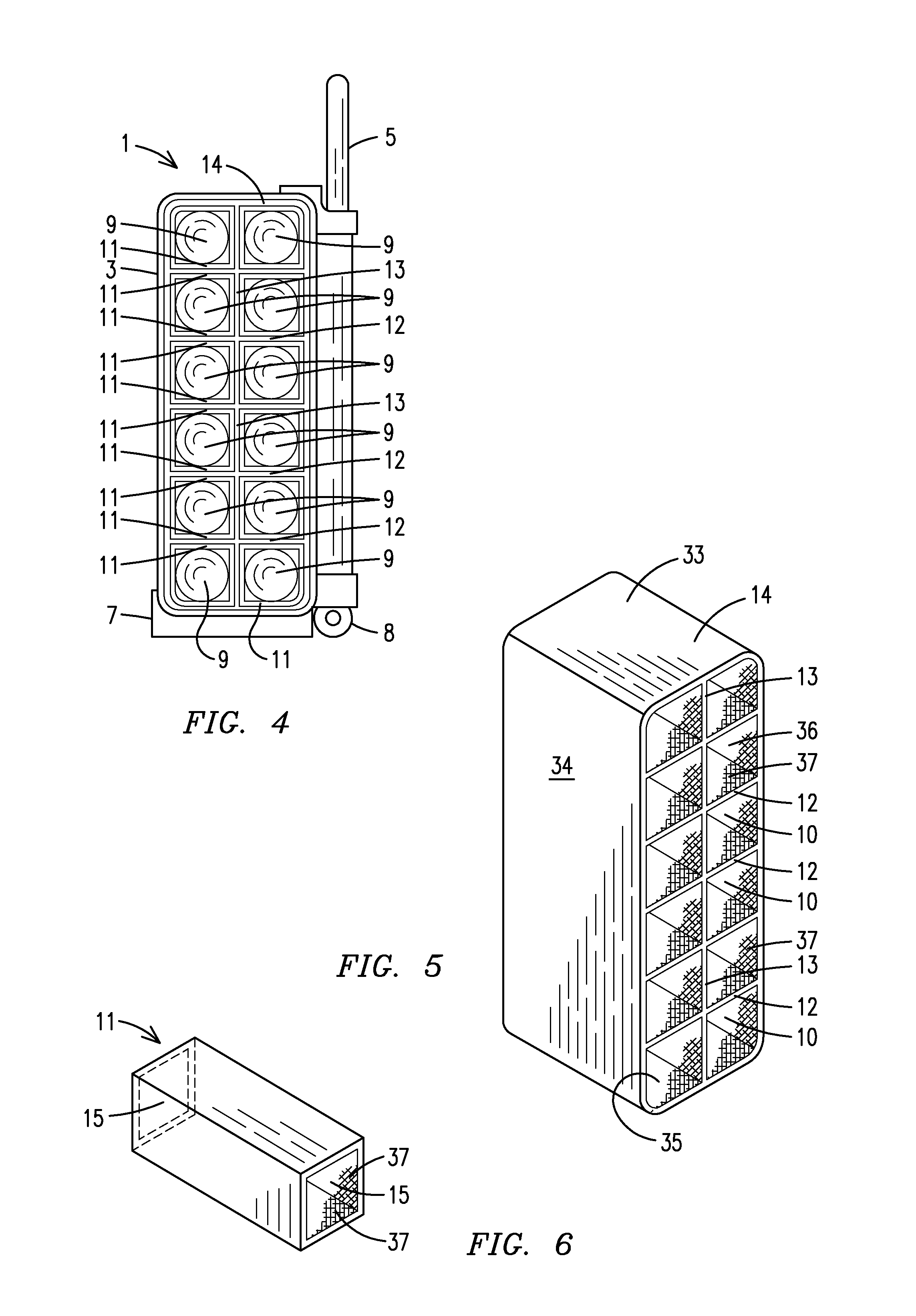

InactiveUS20090050429A1Safe and convenient transportationReduce riskFlexible coversWrappersEngineeringBottle

A bottled beverage holding luggage (1) having a core (14), a vertical wall (13) located within the core and a plurality of horizontal walls (12) located within the core (14). The horizontal walls (12) intersect with the vertical wall (13) to form a plurality of openings (10) for the acceptance of bottles (9), which may be bottled beverages. Shock-absorbent sleeves (11) having at least one aperture (15) may be inserted into the openings (10). Thus, the bottles (9) are placed within the sleeves (11) and the sleeves (11) are ultimately placed within the openings (10) in the core (14) to protect the bottles (9) from breakage during transit. Alternatively, the core (14) may include removable horizontal and vertical shelves (17 and 22) which form the openings (10) or include a plurality of foldable dividers (27) which form the openings (10) for acceptance of the bottles (9). The core (14) may be removable from a luggage case (30), built into a luggage case (30) or have wheels (8), a handle (5) and a rigid exterior shell (41) so as to be its own luggage case (30).

Owner:ADAMS JR A STANLEY

Method for fabricating a vehicle interior trim part and vehicle interior trim part

ActiveCN107757516AFirmly connectedReduced risk of breakageDashboard fitting arrangementsSynthetic resin layered productsEngineeringCold forming

The present application relates to a method for fabricating a vehicle interior trim part. The proposed method comprises the step of providing a glass panel (1) with a backside (5) and a first and a second region. In a further step, a first stiffener (6, 7, 8) is attached to the first region of the glass panel (1). Thereby, a stiffened region (11, 12, 13) of the glass panel (1) is formed. The method further comprises the step of bending the second region of the glass panel (1) by cold forming so that a bent region (14, 15) of the glass panel (1) is formed in a region adjacent to the stiffened region (11, 12, 13). The method further comprises the step of holding the glass panel (1) in shape using a means of fixation.

Owner:FAURECIA INNENRAUM SYST

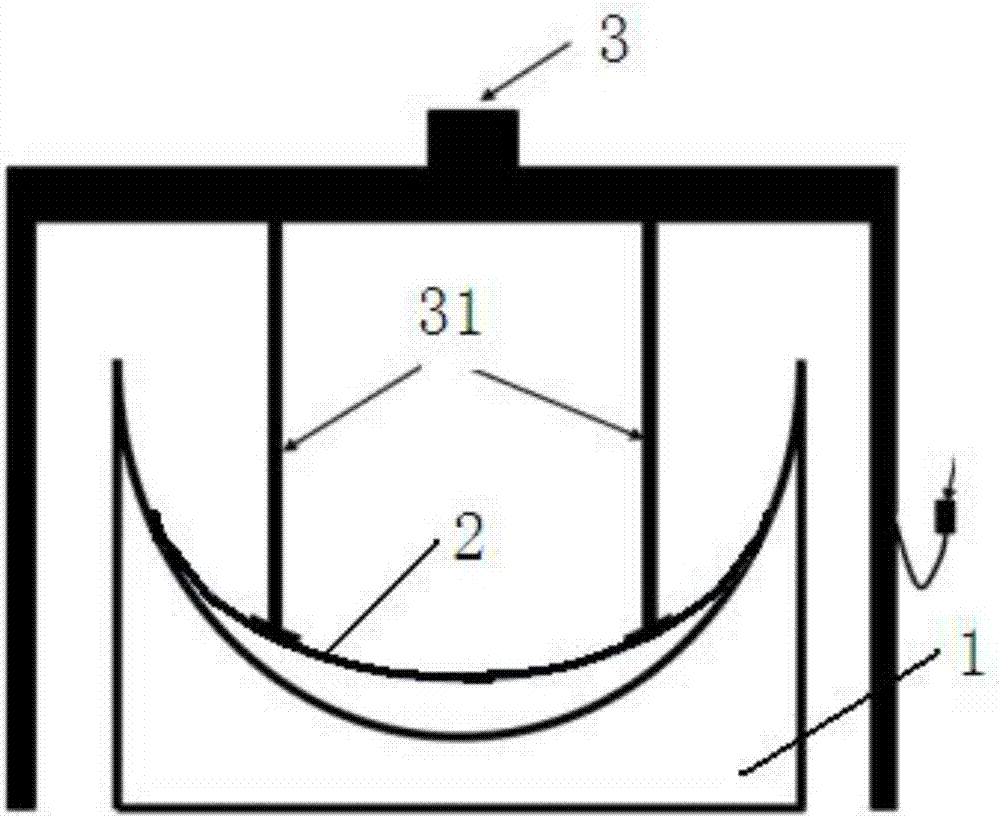

Creep age forming method for aluminium alloy plate

The invention provides a creep age forming method for an aluminium alloy plate. The method comprises the steps as follows: a to-be-formed component is arranged on the molded surface of a mold firstly, and parts (the whole lower surface and the peripheral edge of the upper surface) of the component are covered with air-permeable felt; a plate is bent downwards by a mechanical loading device, and the mechanical loading device stops moving downwards after reaching the set force value; the load is unchanged, at least one circle of a sealant is sequentially bonded to the component and the edge of the mold, a vacuum bag is laid and bonded between the sealants, a closed space is formed, vacuum pumping treatment is performed, and the component is almost attached to the molded surface of the mold as far as possible or is kept to be attached to the molded surface of the mold; and then the mechanical loading device is detached, the component and the mold are placed into an autoclave for vacuum creep age forming, and the component and the mold are separated after ageing is completed. With the method, the time required for vacuum pumping is shortened, so that the forming efficiency is improved; less test materials are used, and thus the test cost is reduced; and the mold attaching error is reduced, and accordingly, the forming precision of the component is improved.

Owner:CENT SOUTH UNIV

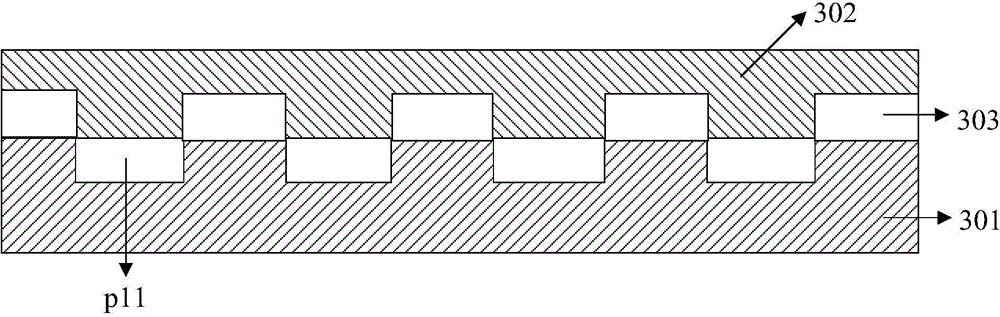

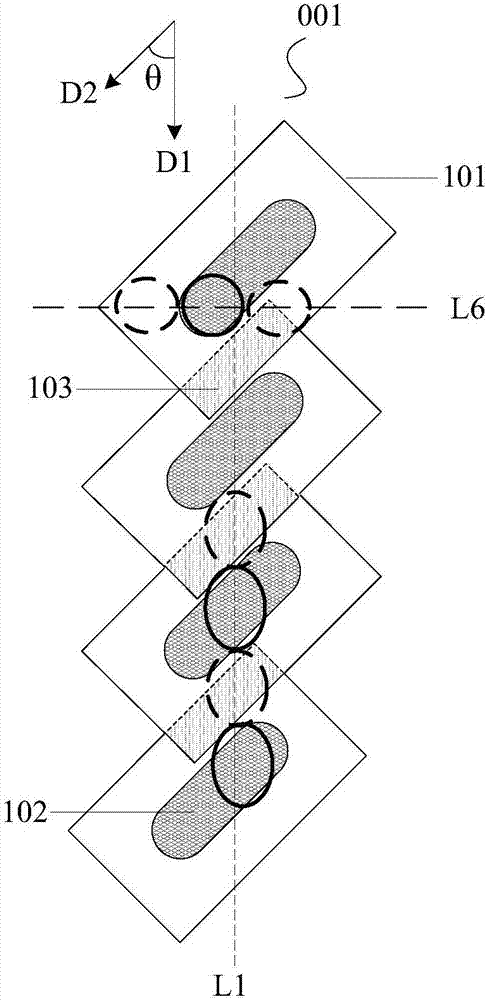

Flexible display substrate, display panel and display device

ActiveCN107025853AReduced risk of cracking or breakingReduce crackingPrinted circuit aspectsPrinted circuits stress/warp reductionLine segmentEngineering

The invention discloses a flexible display substrate, a display panel and a display device. A line in a fixed bending area is formed by sequentially connecting multiple line segments, and the line segments have preset inclination angels with the line extending direction, so that bending stress on the line can be dispersed to the line segments; further, porous structures are arranged on at least part of the line segments, the bending stress dispersed to the line segments can be diffused to edge areas of the porous structures, the bending stress on the line is dispersed to the great extent, and therefore, the risk of fracture or breakage of the line in the fixed bending area is greatly reduced. Besides, a surface contact structure is formed between every two mutually connected line segments, so that multiple contact points are reserved between every two mutually connected line segments, even though fracture or breakage occurs at any contact point, connection of two adjacent line segments can still be realized through the other contact points, and the risk of fracture or breakage of the line is further reduced.

Owner:BOE TECH GRP CO LTD

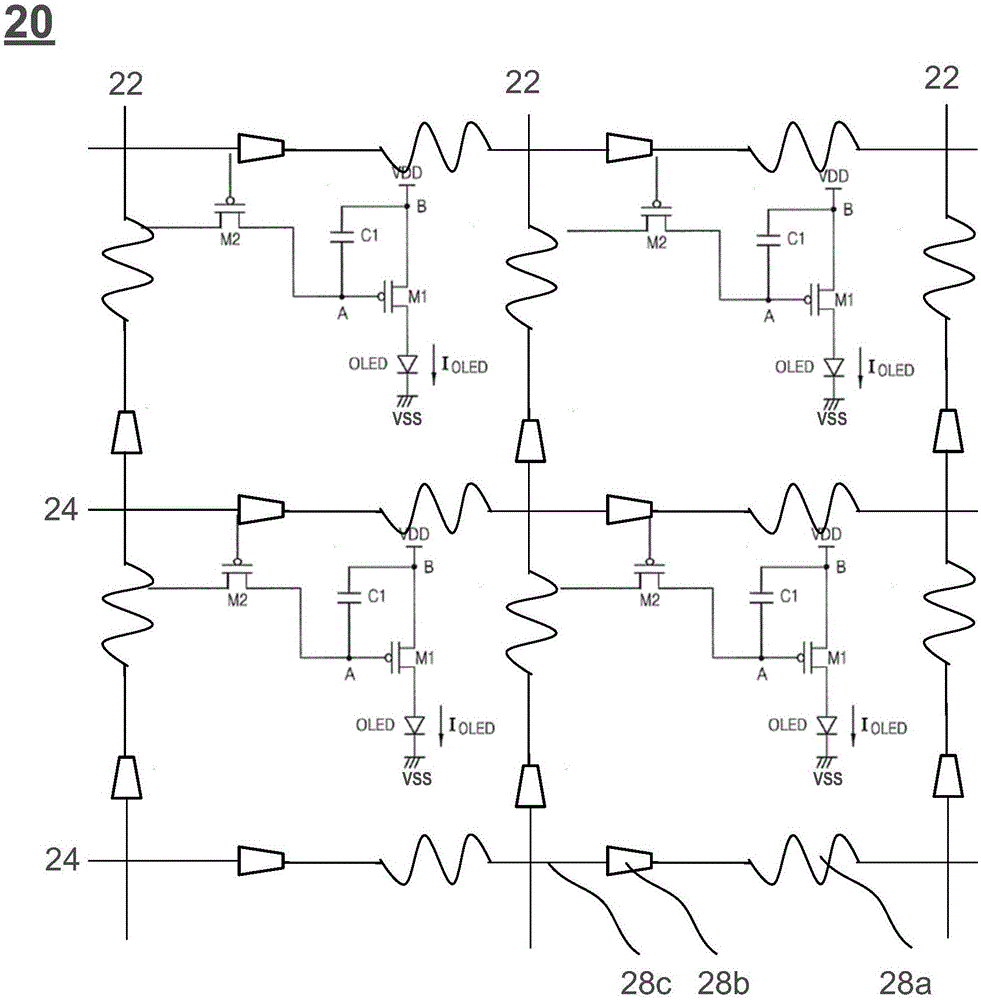

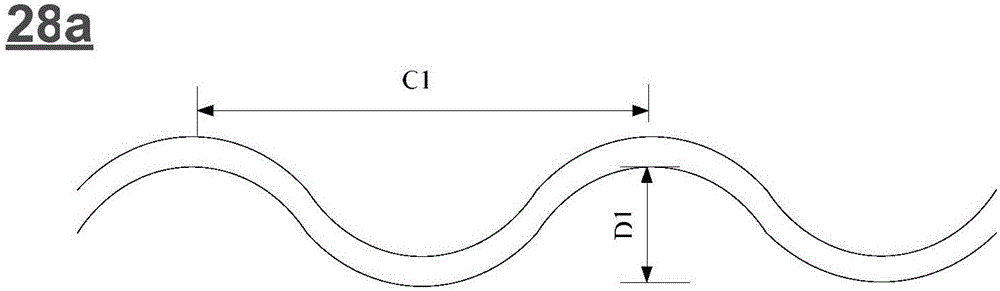

Flexible display device and manufacturing method thereof

InactiveCN106298798AImprove the ability to withstand stressIncrease usageSolid-state devicesSemiconductor devicesLine segmentEngineering

The present invention provides a flexible display device and a manufacturing method thereof, wherein the flexible display device comprises a flexible substrate and a metal line arranged on the flexible substrate, and a part of the metal line is an arc-shaped line segment. According to the flexible display device and the manufacturing method thereof provided by the present invention, by setting a part of line segment of the metal line as the arc-shaped line segment, the stress bearing capability of the metal line is improved, thereby prolonging the usage times of the metal line, and improving the service life of the flexible display device. Further, the arc-shaped line segment adopts an up-down fluctuation structure and a plane bending structure which are arranged alternatively, so that the break risk of the metal line is reduced further, and the reliability of the flexible display device is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com