Silicone lens for LED (Light Emitting Diode) packaging and manufacturing method thereof

A technology of LED packaging and silicone lens, which is applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as broken gold wires, achieve the effects of saving mold costs, reducing the risk of broken gold wires, and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

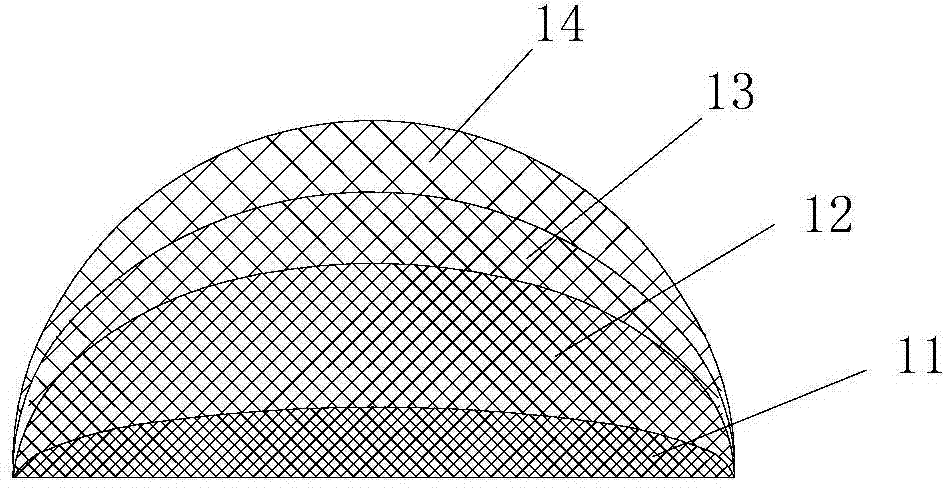

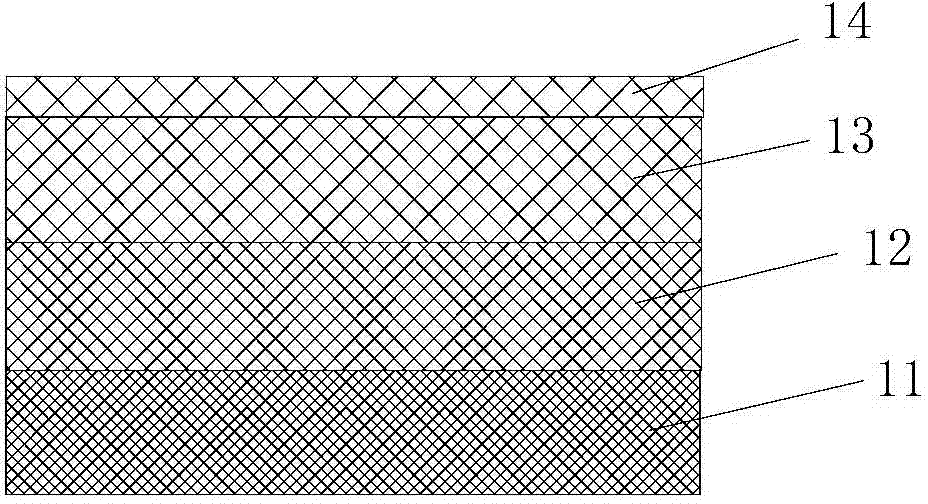

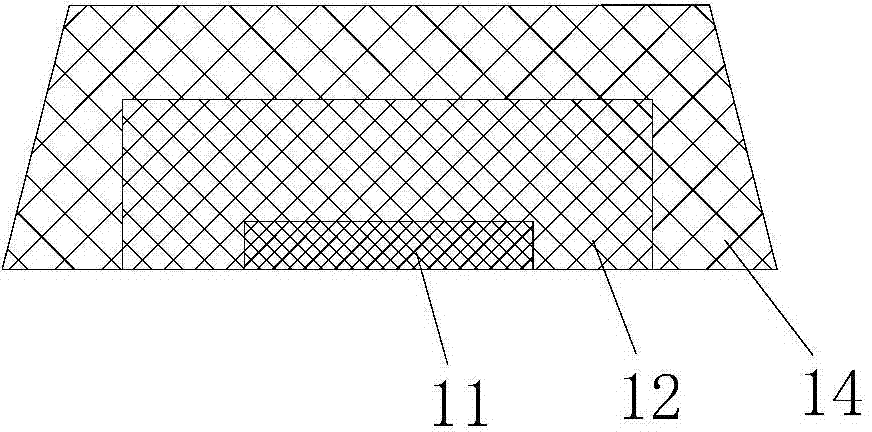

[0037] The invention relates to a multilayer silicone lens which can be used on LED devices. The shape of the lens is determined by the designer's requirements or the shape of the light source. It can be in the shape of a convex lens, flat or tubular. In particular, the silica gel lens is composed of at least two layers of silica gel with different refractive indices. The surface of the lens can be rough or finely structured, and some scattering particles can also be added. For multi-layer silicone lenses, the refractive index of the outermost layer is generally slightly lower than that of the inner layer. In addition, fluorescent materials such as fluorescent powder or quantum dots can be added to the outermost layer of the lens to adjust the colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com