Bolt hole machining device for die machining

A technology for machining and processing devices, applied in the field of bolt hole processing devices for mold machining, can solve the problems of excessively fast feed of drill bits and broken ends of drill bits, and achieve the effects of reducing the risk of fracture, improving efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

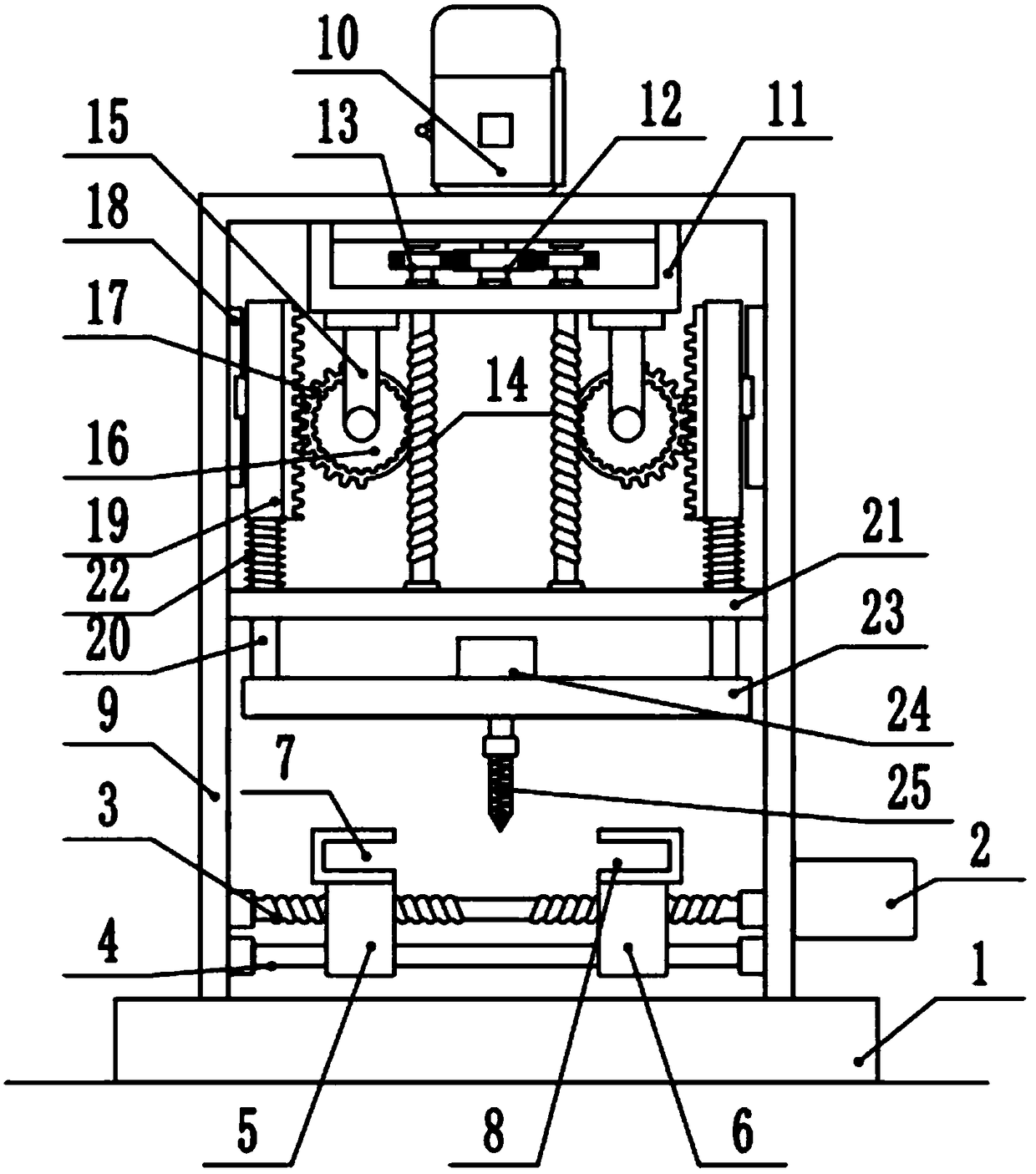

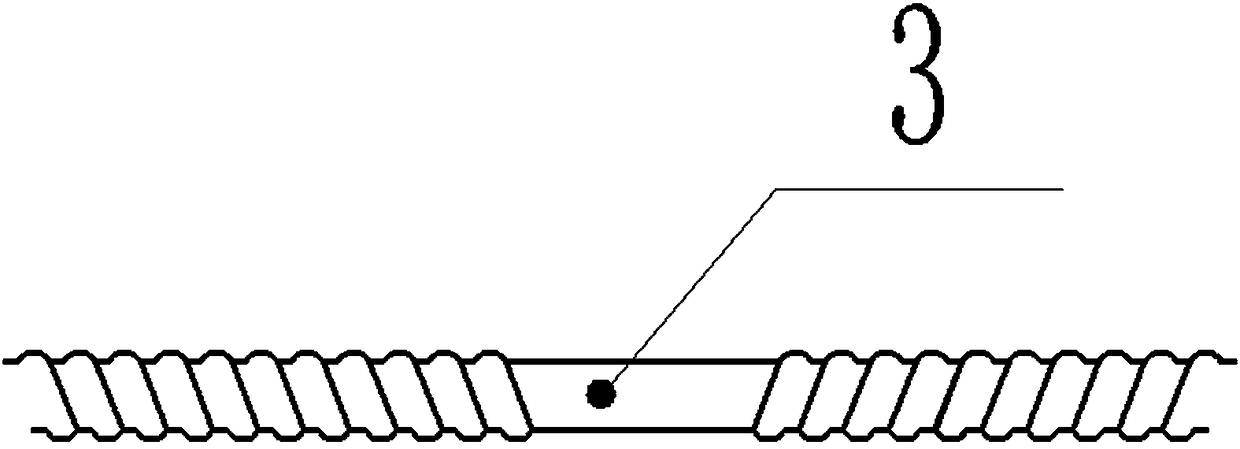

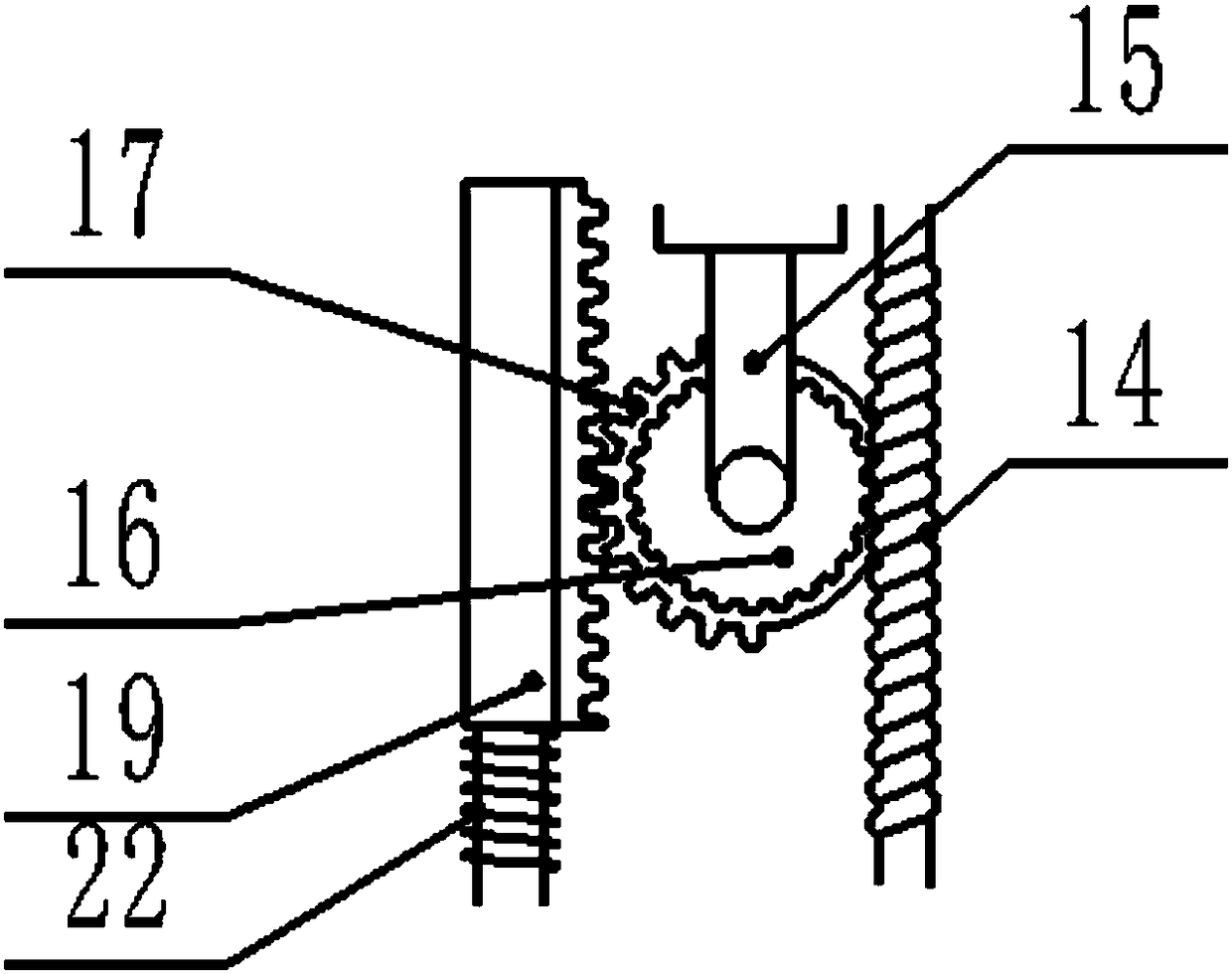

[0019] see Figure 1-3 , a bolt hole processing device for mold machining, comprising a base 1, a clamping motor 2, a left jaw 7, a right jaw 8, a main drive motor 10, a lifting frame 23 and a drilling motor 24, the platform 3 The upper surface is provided with a main bracket 9, and the main bracket 9 and the platform 3 are fixedly connected by screws. The right side of the main bracket 9 is fixed with a clamping motor 2, and the clamping motor has 2 servo motors, and the output shaft of the clamping motor 2 Horizontally to the left and penetrate the inside of the main bracket 9, the left end of the output shaft of the clamping motor 2 is fixedly installed with a ball screw 3 through a coupling, and the other end of the ball screw 3 is installed on the main bracket 9 through a bearing rotation. Both the left and right parts of the rod 3 are tapped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com