Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

665 results about "Collagen fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collagenous fiber [kəlaj′ənəs] any one of the tough, white protein fibers that constitute much of the intercellular substance and the connective tissue of the body. Collagenous fibers contain collagen.

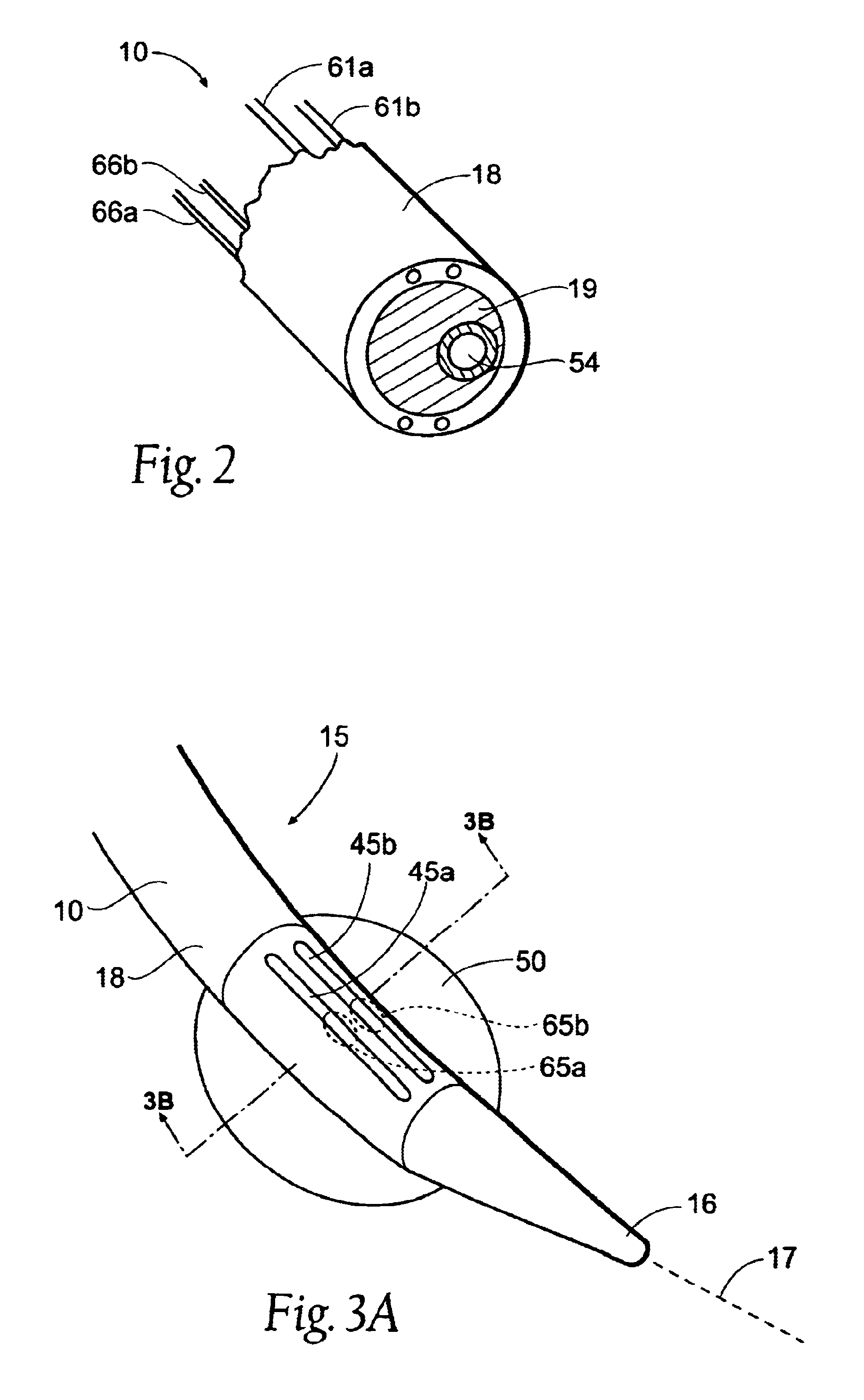

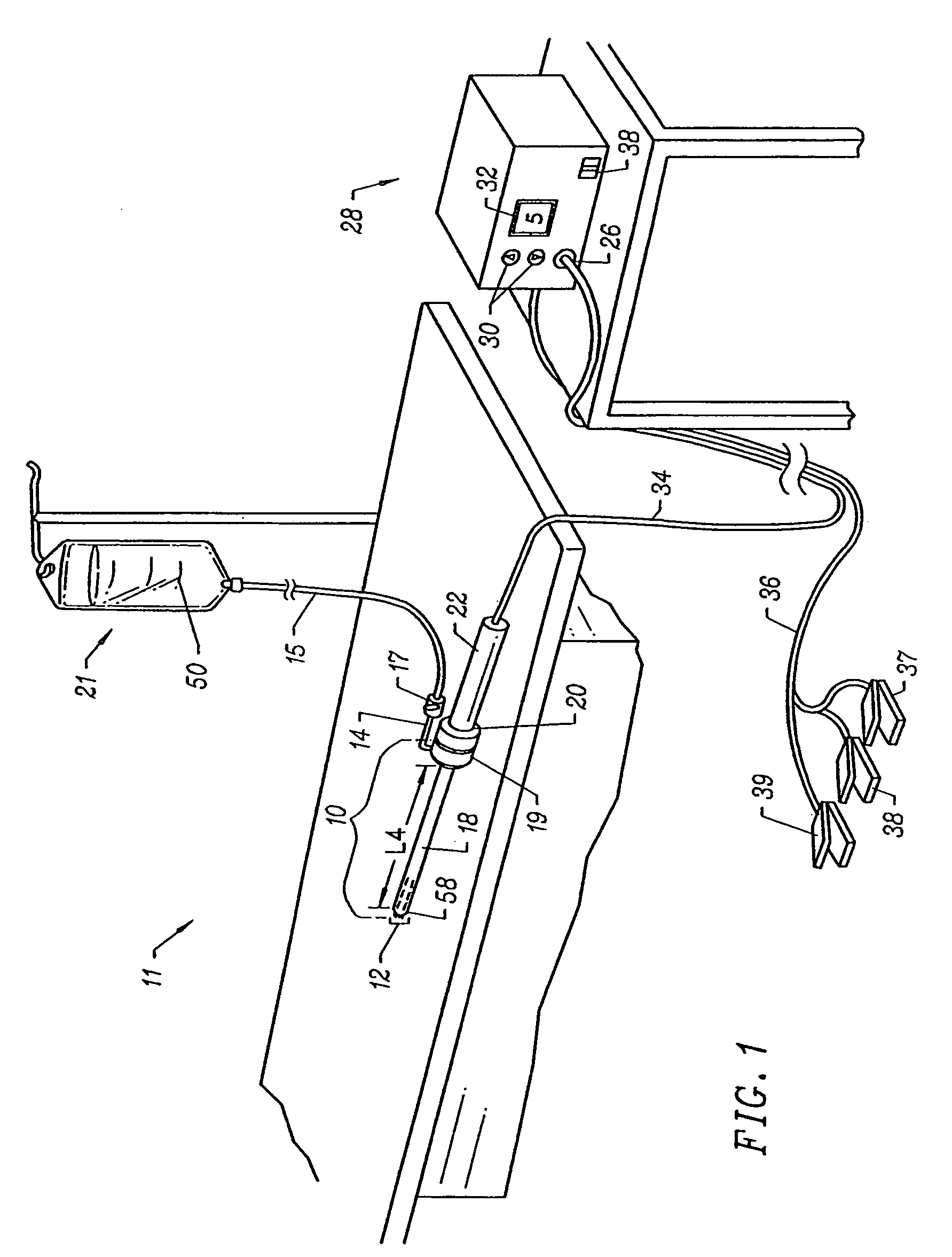

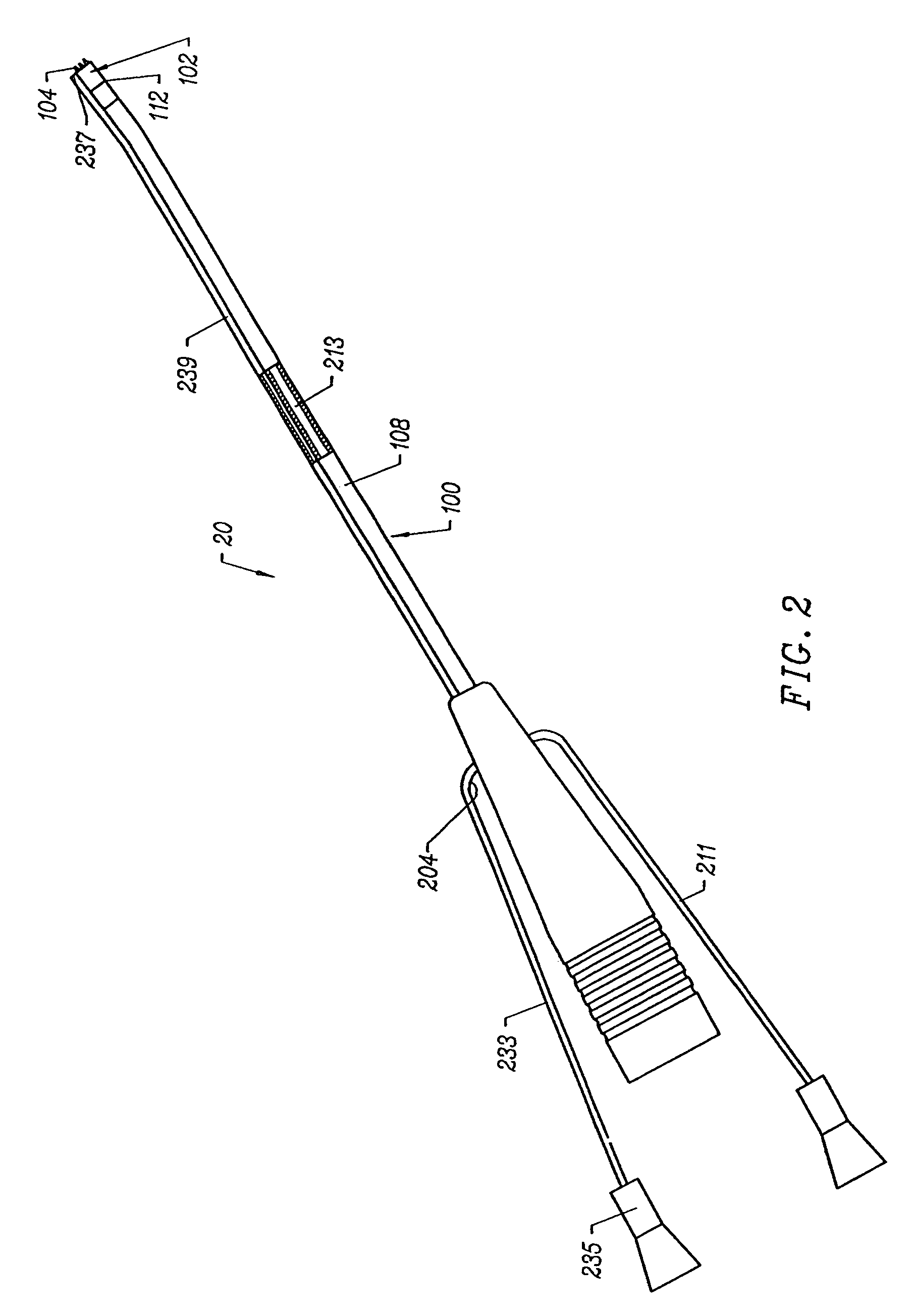

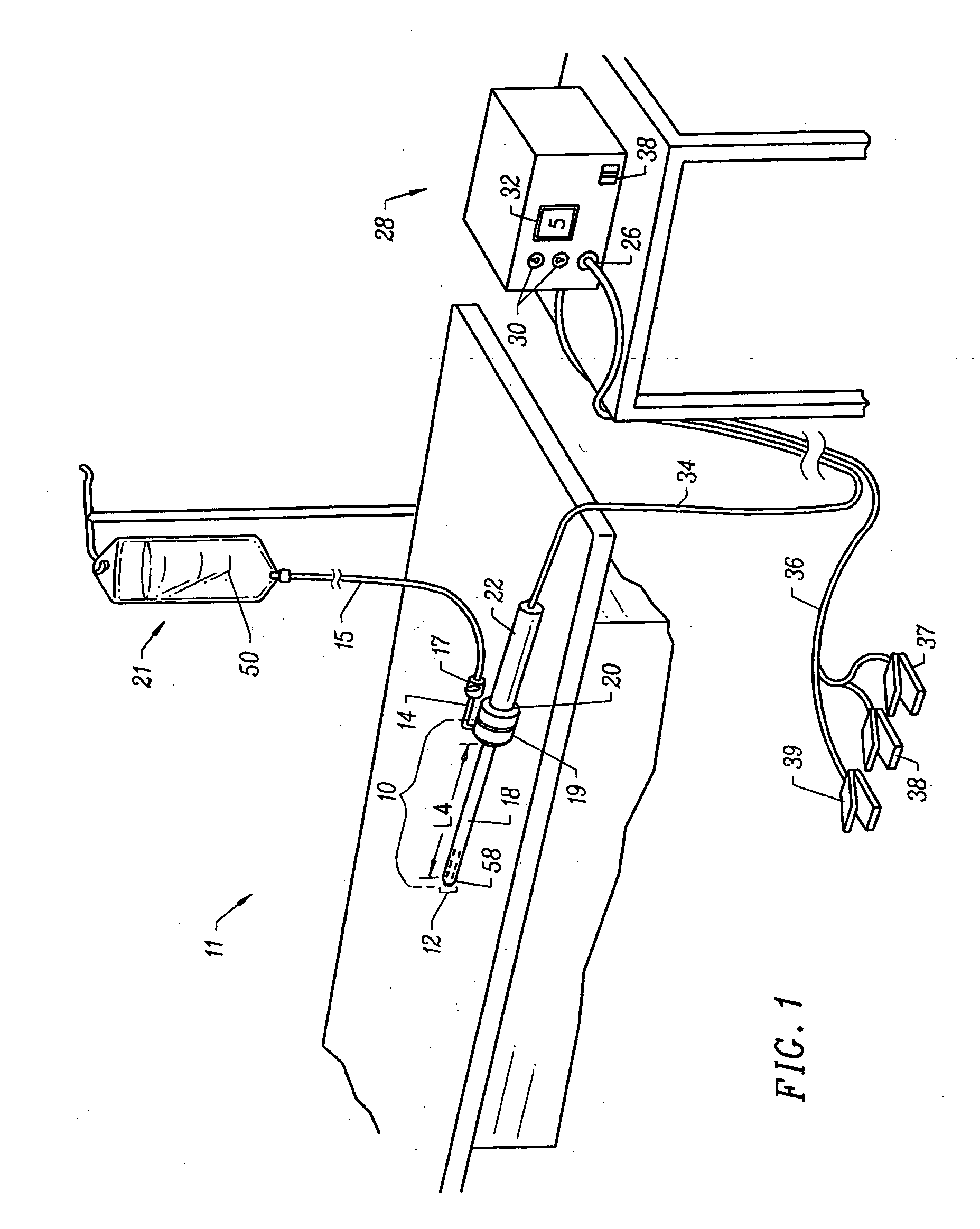

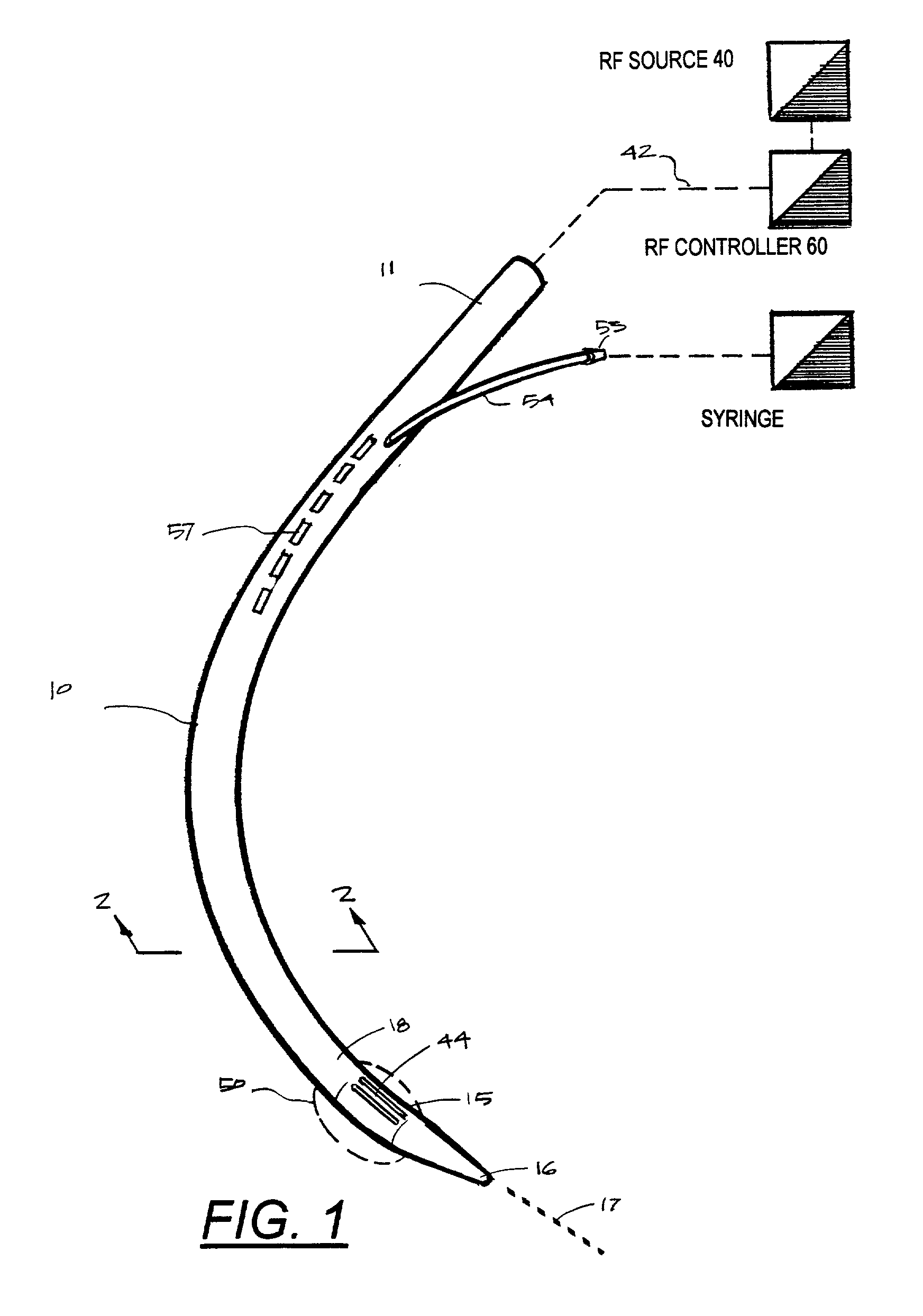

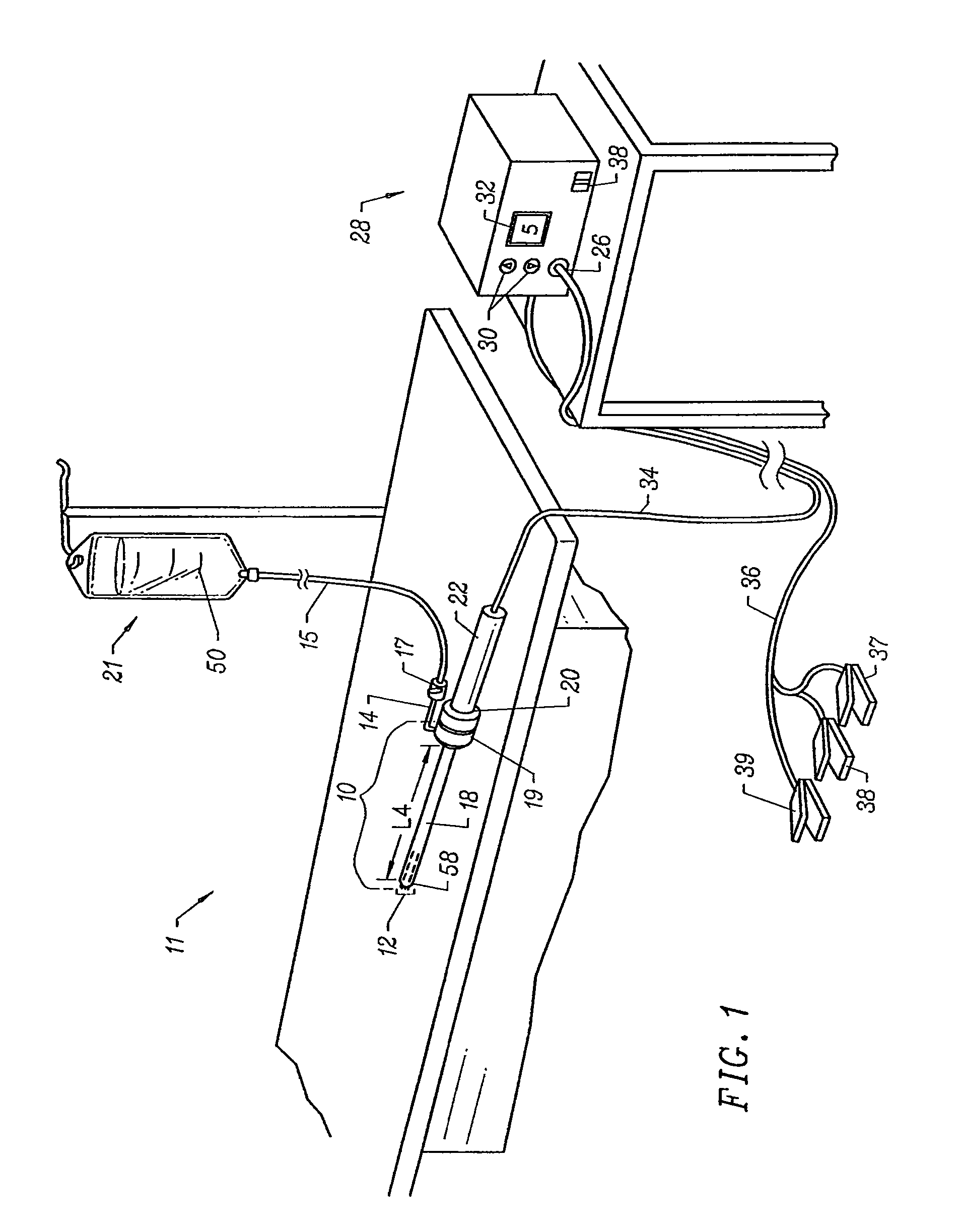

Methods for electrosurgical tissue contraction within the spine

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for treating herniated or swollen discs within a patient's spine by applying sufficient electrical energy to the disc tissue to contract or shrink the collagen fibers within the nucleus pulposis. This causes the pulposis to shrink and withdraw from its impingement on the spinal nerve.

Owner:ARTHROCARE

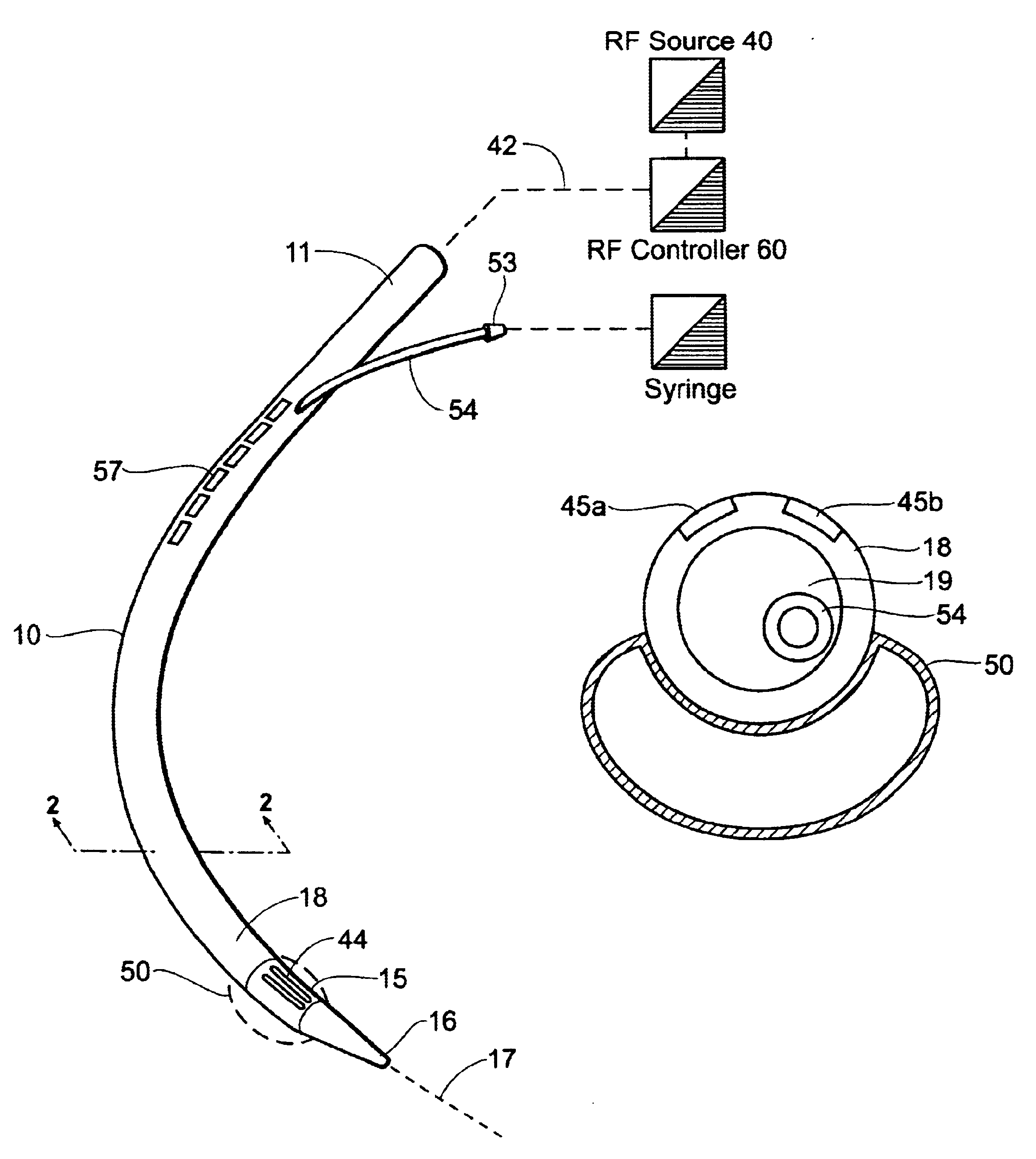

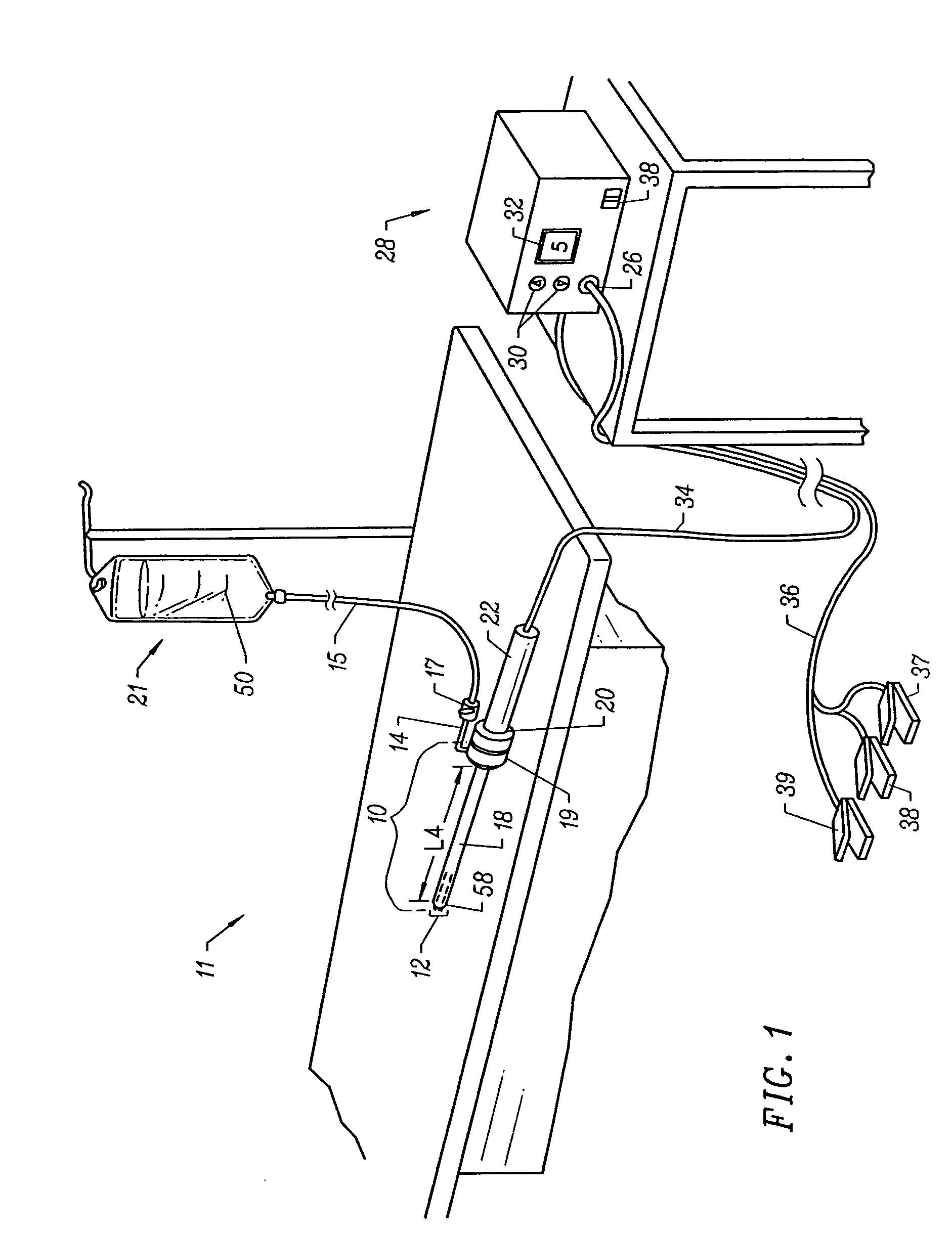

Systems and methods for electrosurigical treatment of obstructive sleep disorders

InactiveUS7004941B2Increase the apertureEffectively treating sleep apneaSurgical instruments for heatingTherapeutic coolingRadix linguaeMedicine

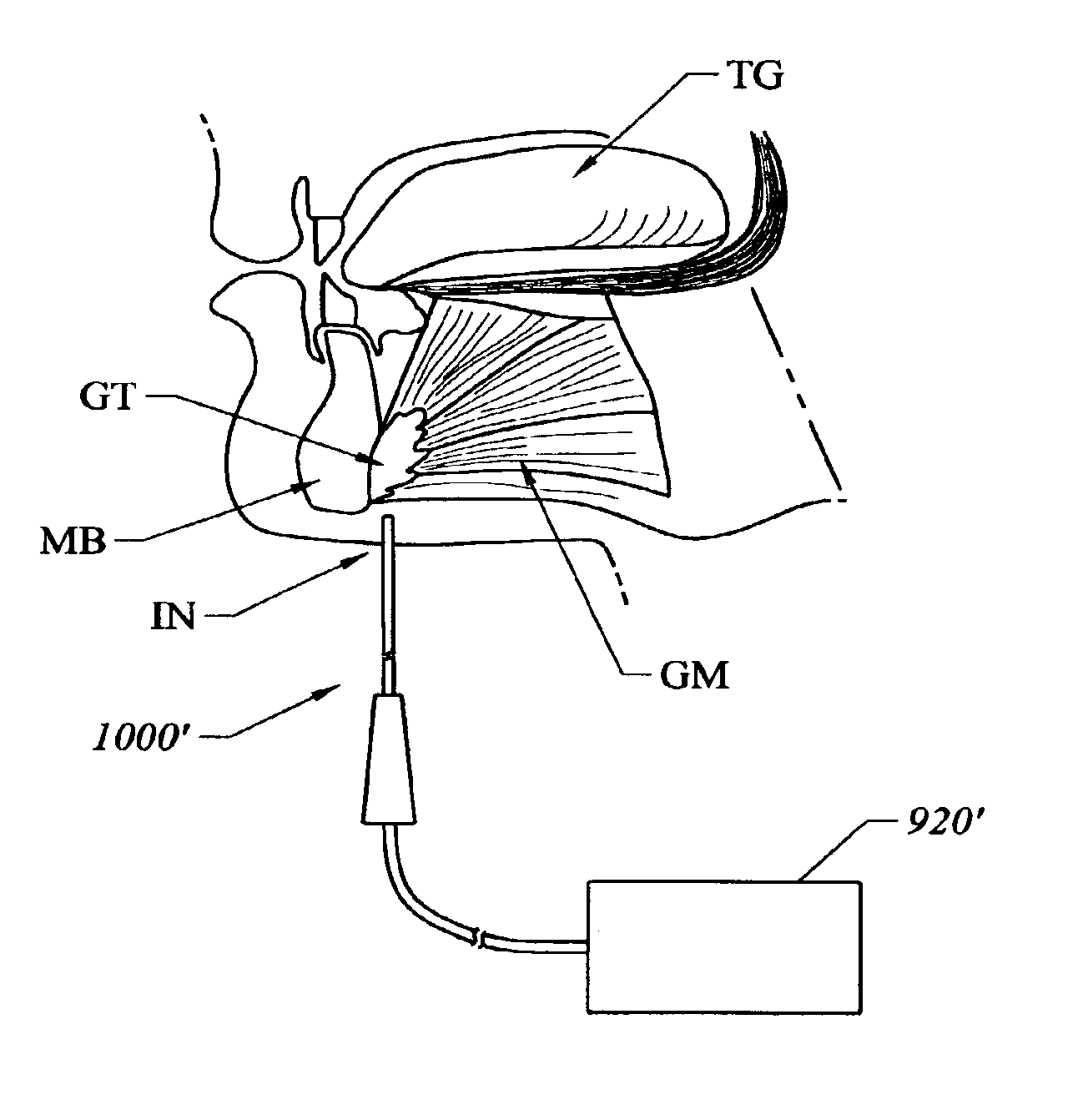

Systems, apparatus, and methods for selectively applying electrical energy to a target location within the head or neck of a patient for treating obstructive sleep disorders. A method of the present invention involves positioning an electrosurgical probe with respect to a target tissue that affects the aperture of the upper airway of the patient. For example, the position of the tongue and the radix linguae affect the upper airway. The position of the tongue is controlled by the genioglossus muscle and tendon. The tendon of the genioglossus muscle may be irreversibly shrunk by positioning an electrosurgical probe in at least close proximity to the tendon, and applying a suitable high frequency voltage to the probe in a sub-ablation mode. Controlled heating of the tendon is effected by application of the high frequency voltage to the probe, wherein the voltage is insufficient to ablate the tissue of the tendon. The controlled heating of the tendon effects contraction of collagen fibers of the tendon, whereby the tongue is advanced and / or depressed, and the aperture of the upper airway is increased.

Owner:ARTHROCARE

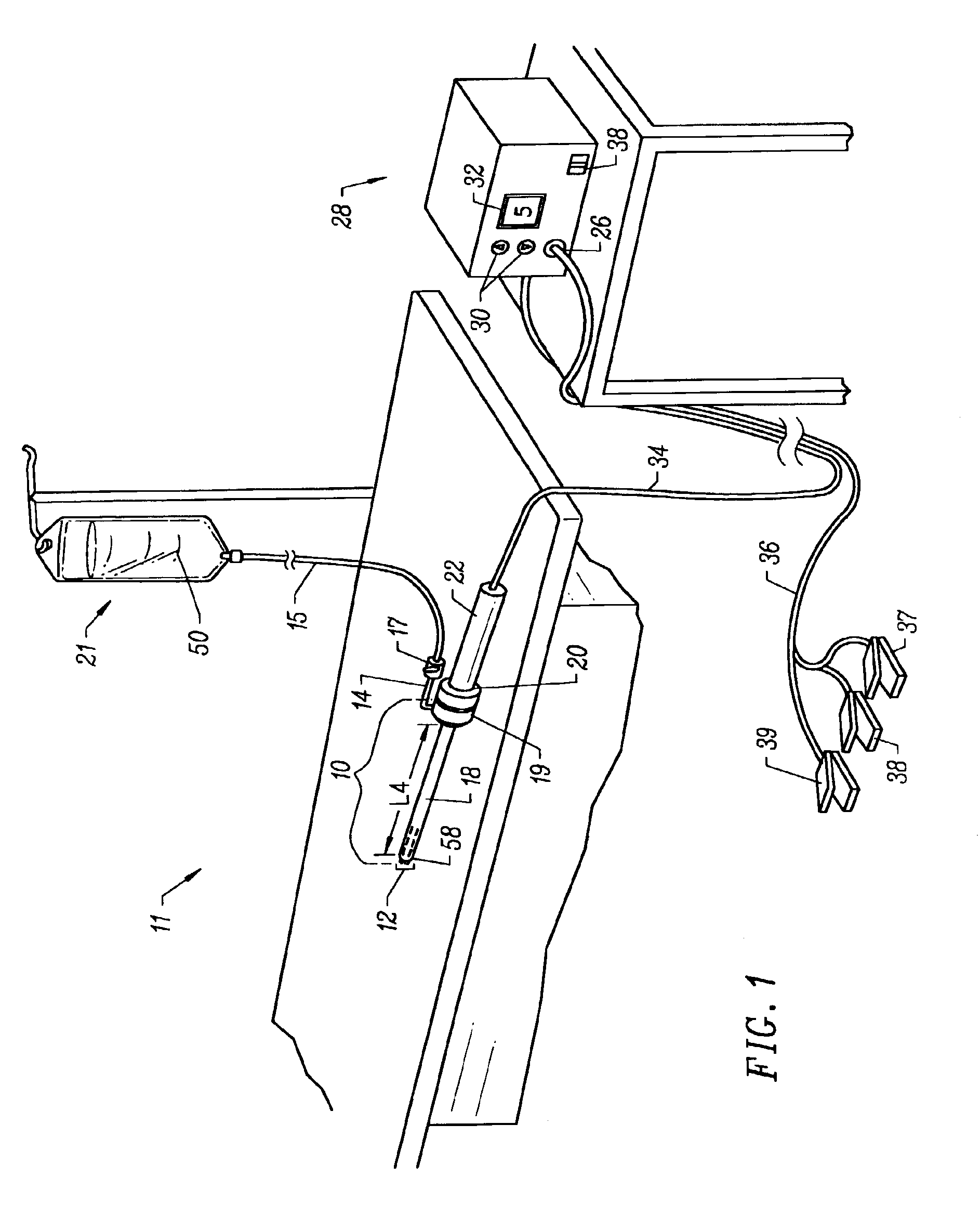

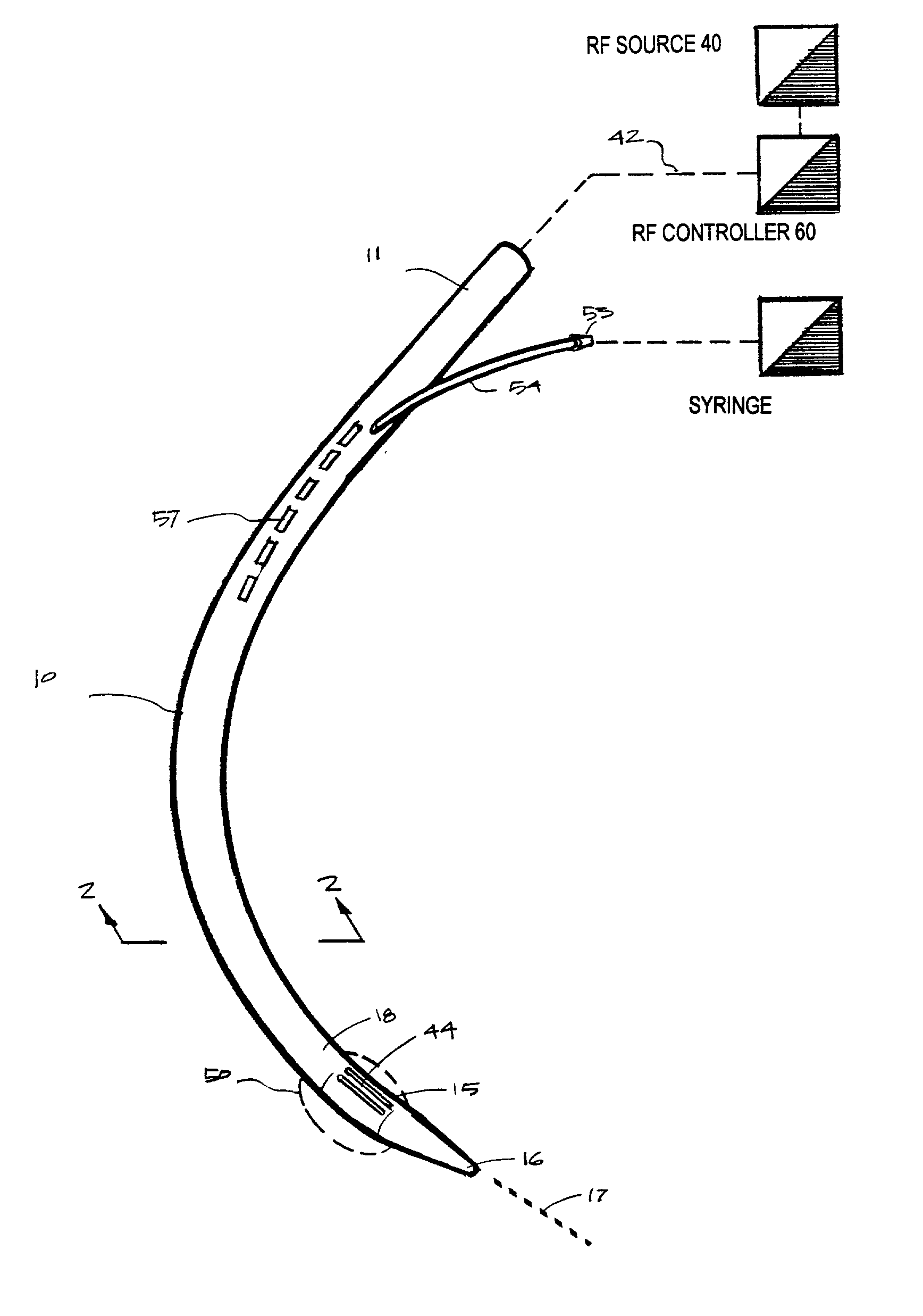

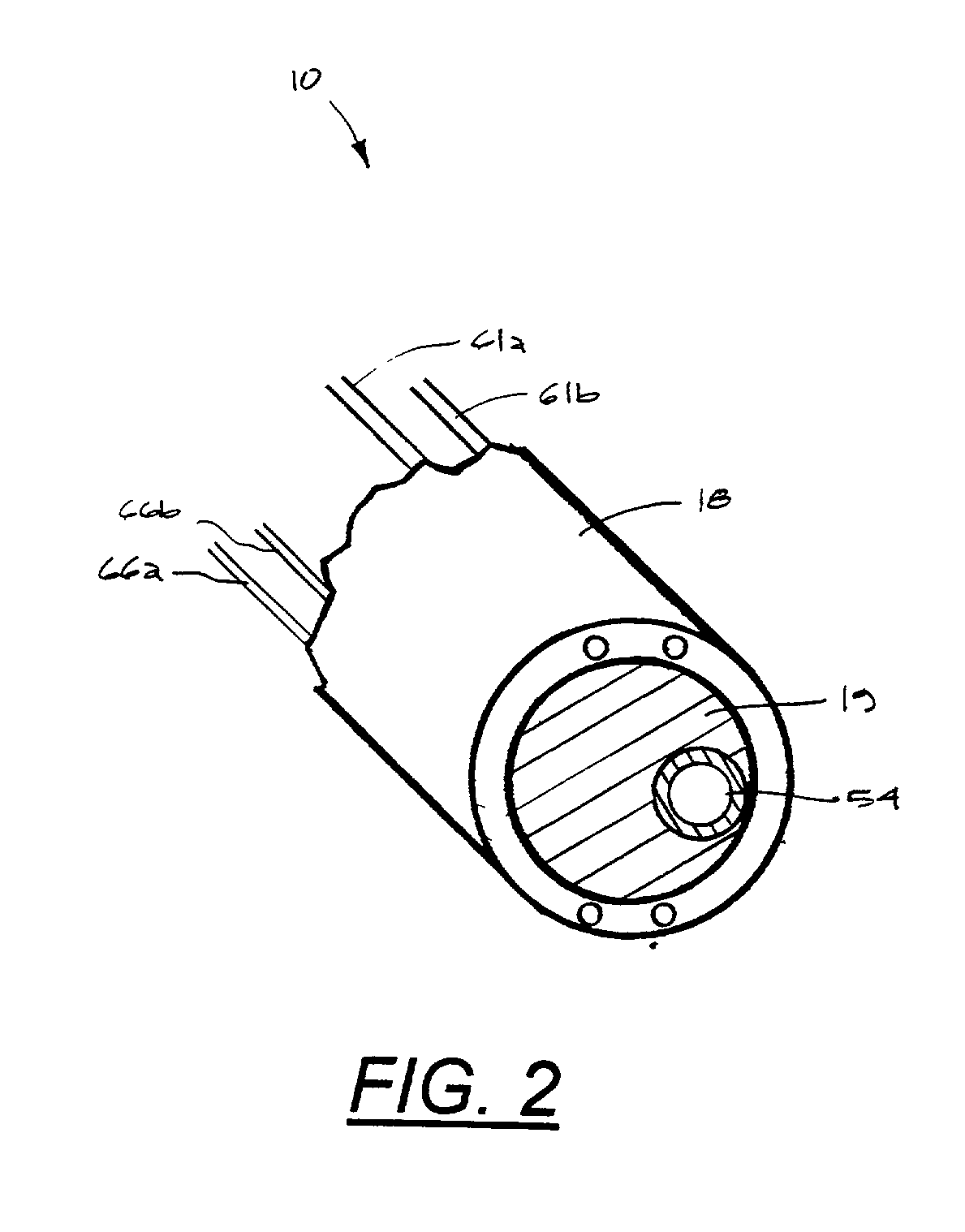

Surgical instruments for treating gastro-esophageal reflux

InactiveUS6740082B2Augment objectInexpensive and disposableElectrotherapyEndoscopesSensor arrayFiber

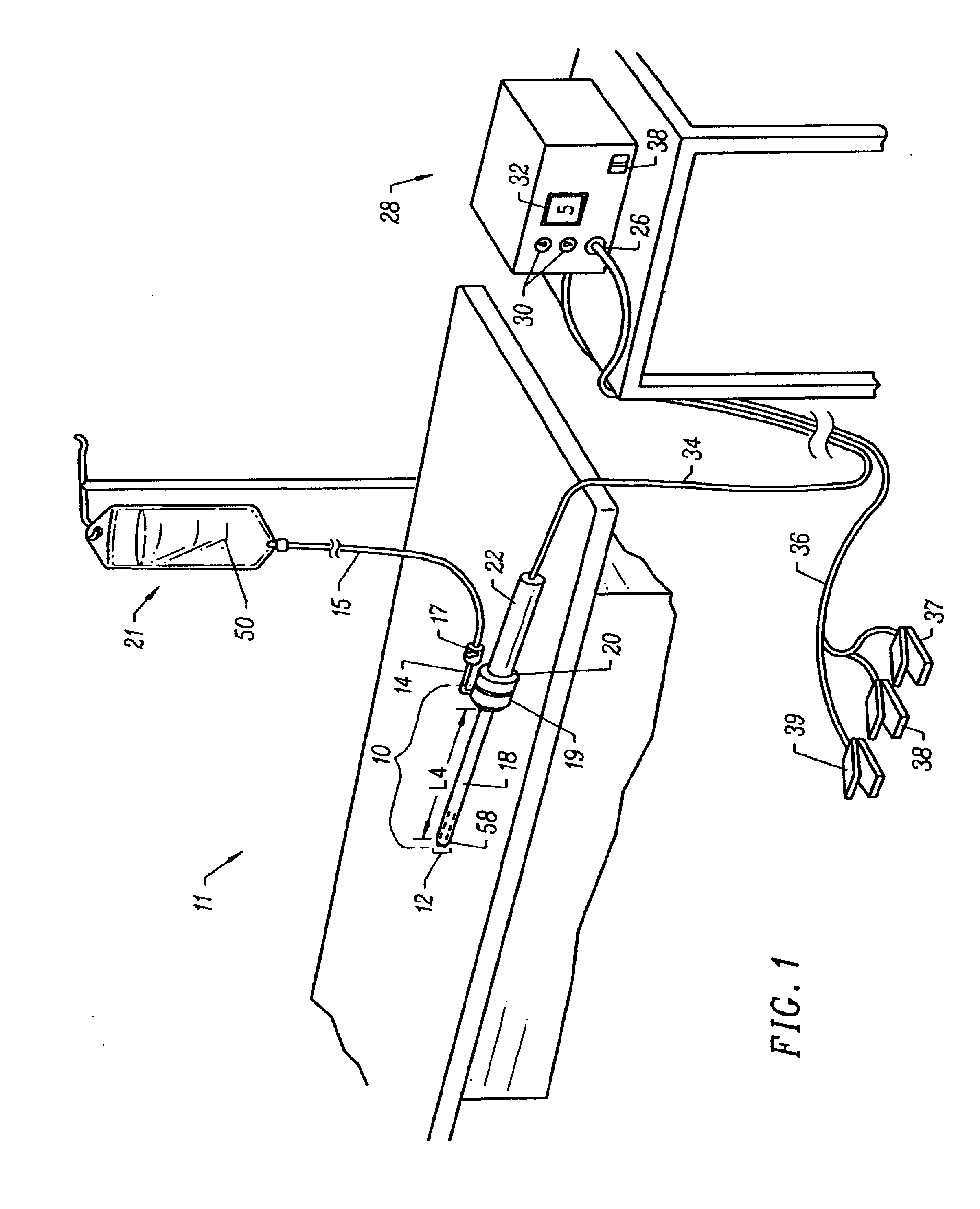

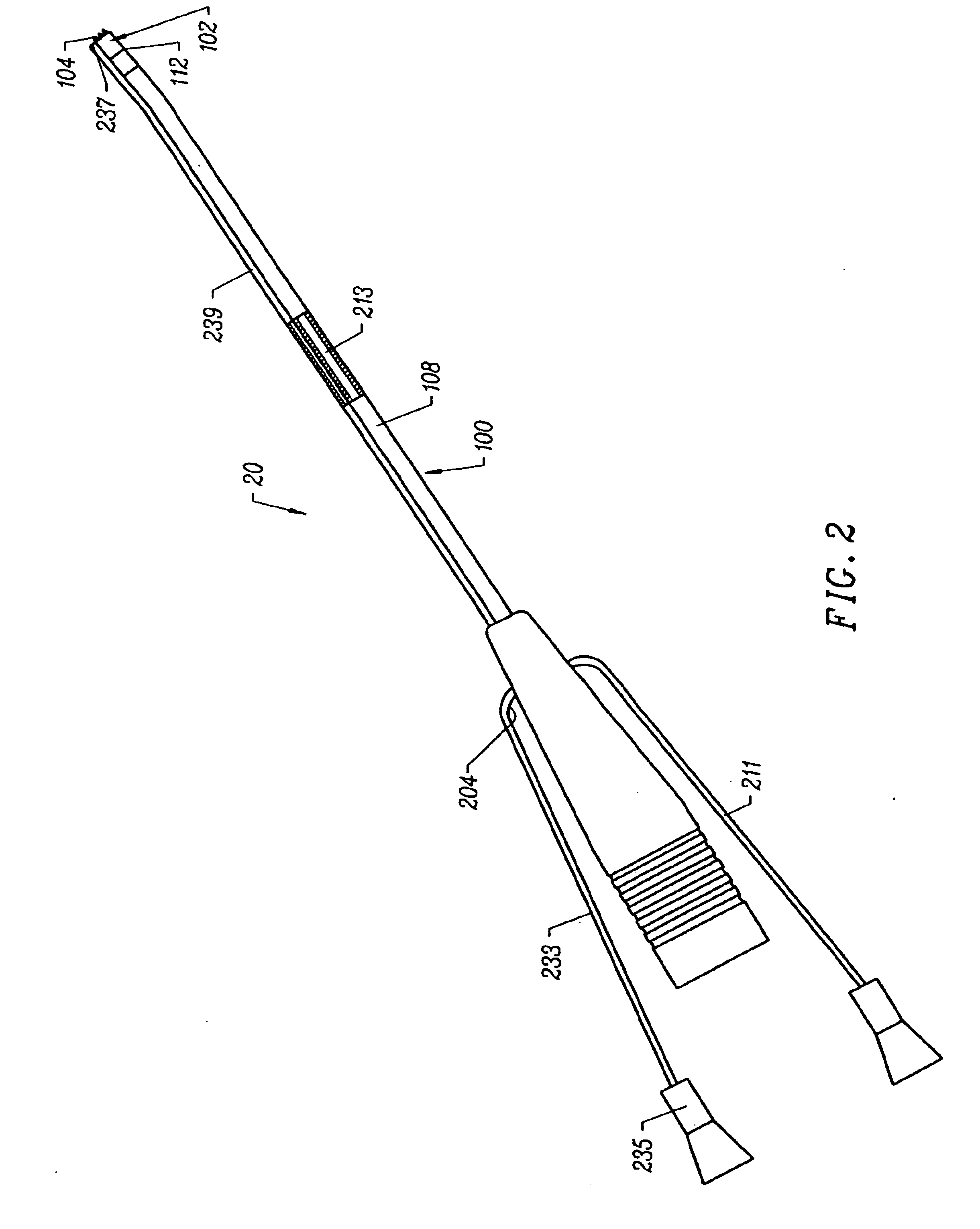

Instruments for thermally-mediated treatment of a patient's lower esophageal sphincter (LES) to induce an injury healing response to thereby populate the extracellular compartment of walls of the LES with collagen matrices to altere the biomechanics of the LES to provide an increased intra-esophageal pressure for preventing acid reflux. A preferred embodiment is a bougie-type device for trans-esophageal introduction that carries conductive electrodes for delivering Rf energy to walls of the LES (i) to induce the injury healing response or (ii) to "model" collagenous tissues of the LES by shrinking collagen fibers therein. Typically, an Rf source is connected to at least one conductive electrode that may be operated in a mono-polar or bi-polar fashion. A sensor array of individual sensors is provided in the working end. A computer controller is provided, which together with feedback circuitry, is capable of full process monitoring and control of: (i) power delivery; (ii) parameters of a selected therapeutic cycle, (iii) mono-polar or bi-polar energy delivery, and (iv) multiplexing of current flow between various paired electrodes. The controller can determine when the treatment is completed based on time, temperature, tissue impedance or any combination thereof.

Owner:MEDERI RF LLC

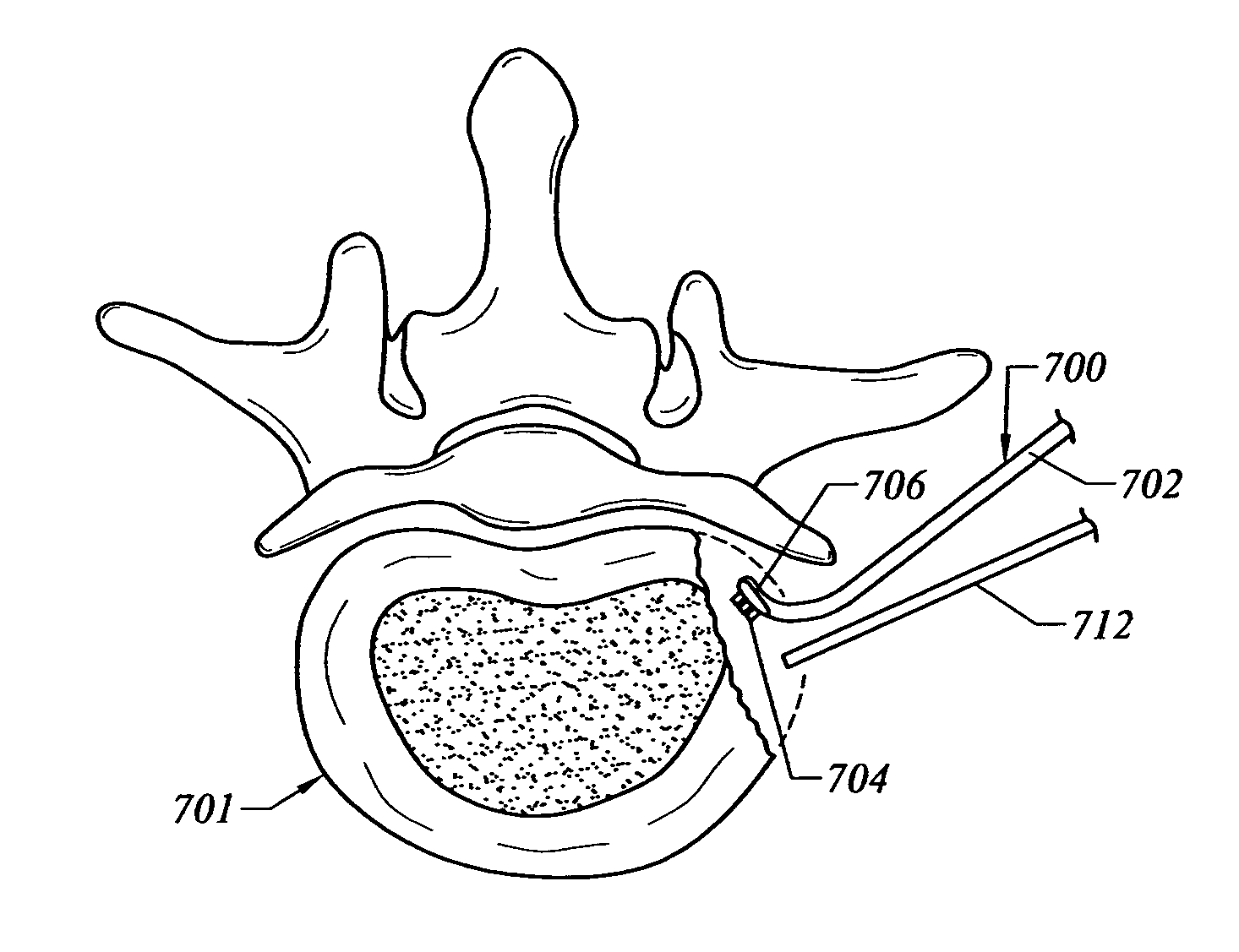

Intervertebral disc replacement method

InactiveUS7104986B2Minimize damageMinimize necrosisCannulasEnemata/irrigatorsFiberIntervertebral disc arthroplasty

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for removing a vertebral disc in preparation for implanting a prosthetic disc or removing a portion of the vertebral disc such as the nucleus pulposus in preparation for placing a prosthetic nucleus within the annulus of the disc. The present invention also teaches shrinking residual tissue in preparation for placing the implants.

Owner:ARTHROCARE

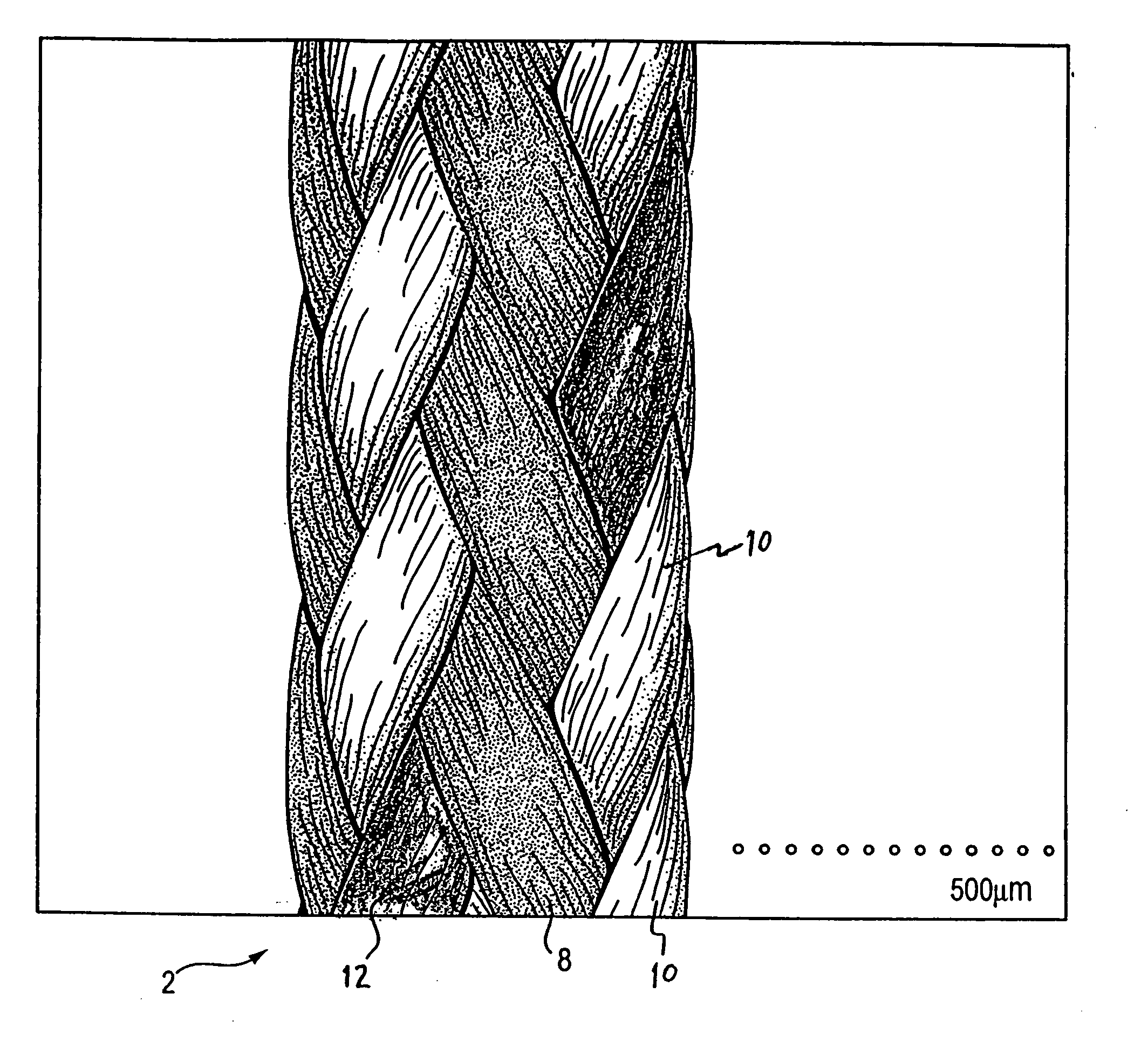

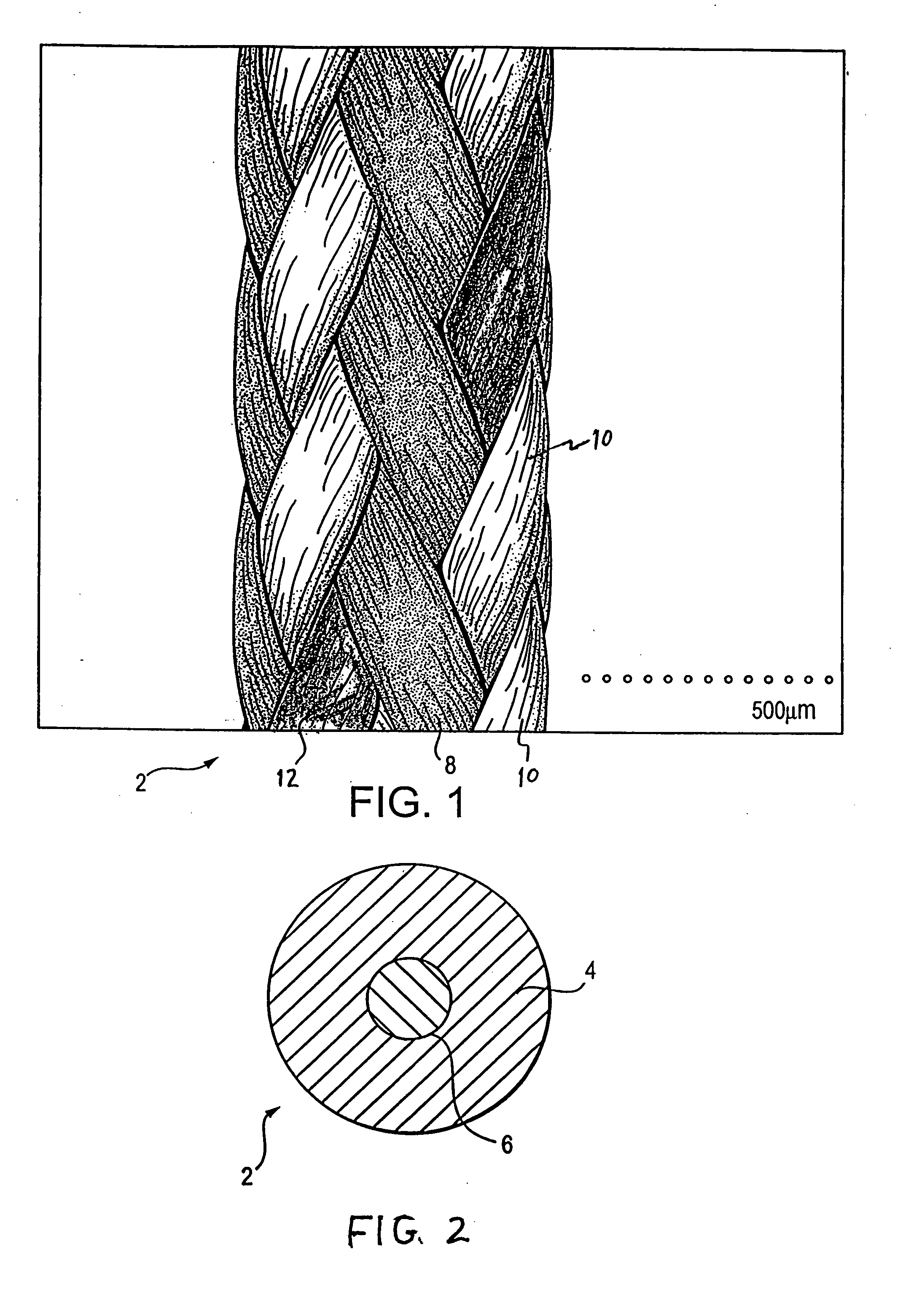

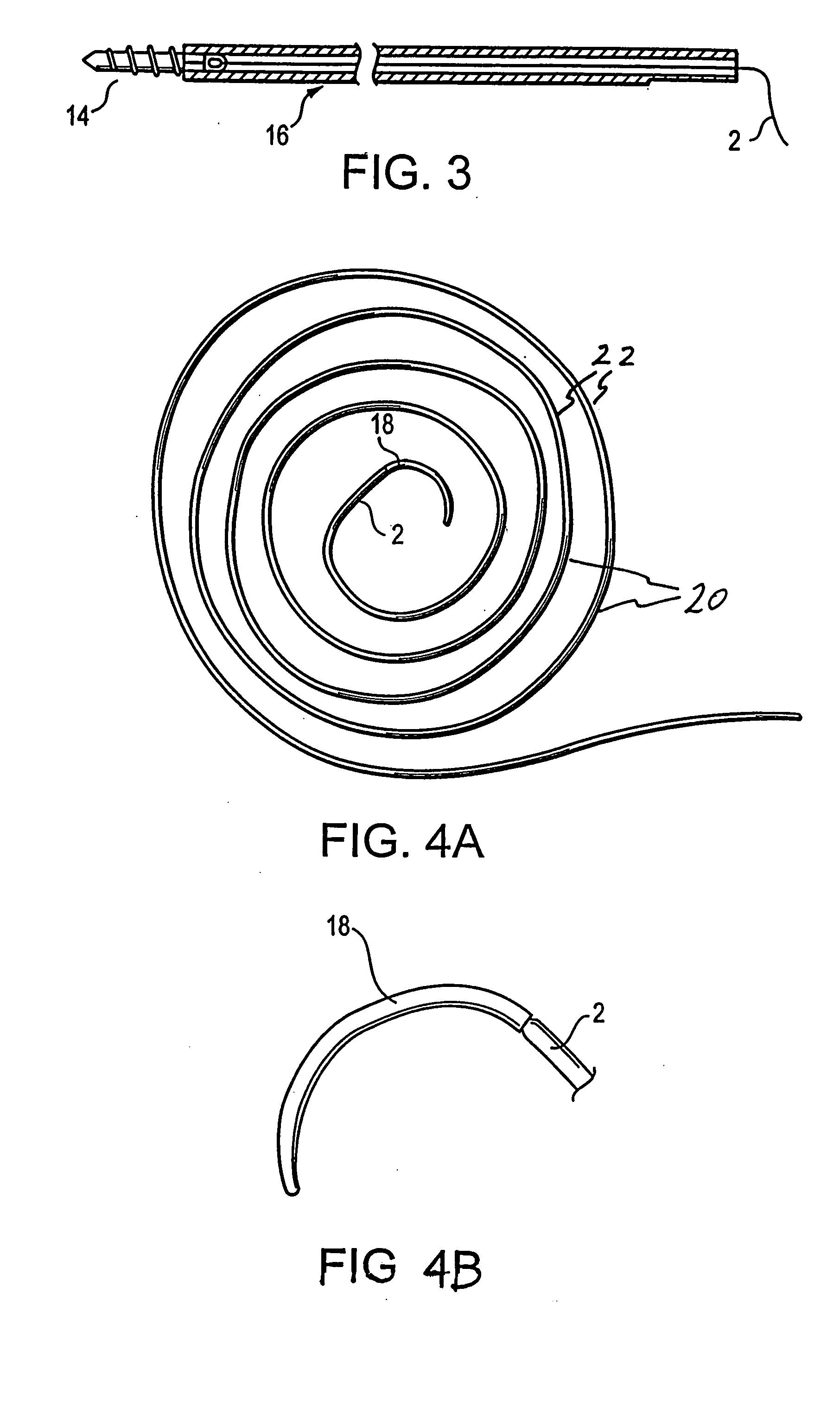

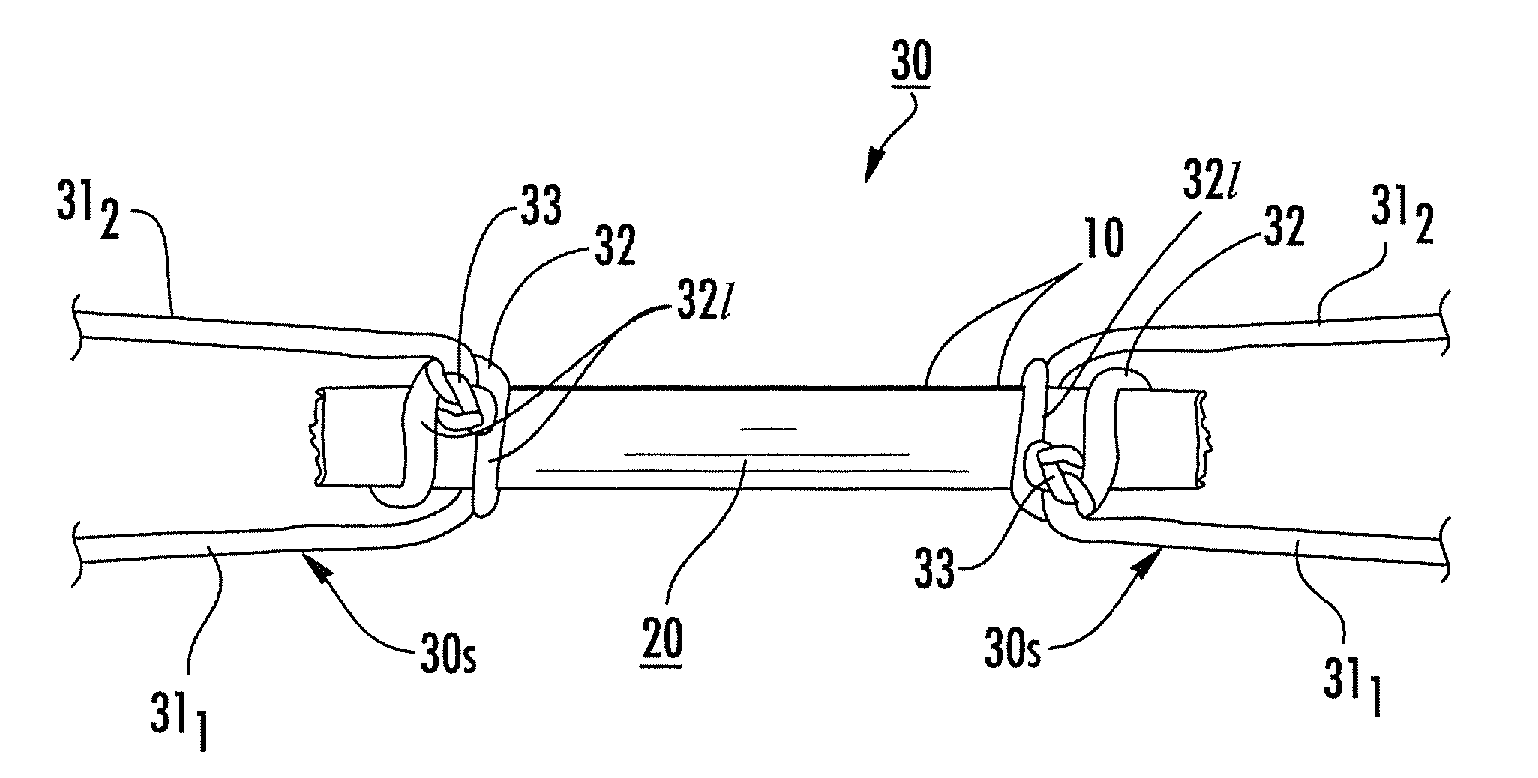

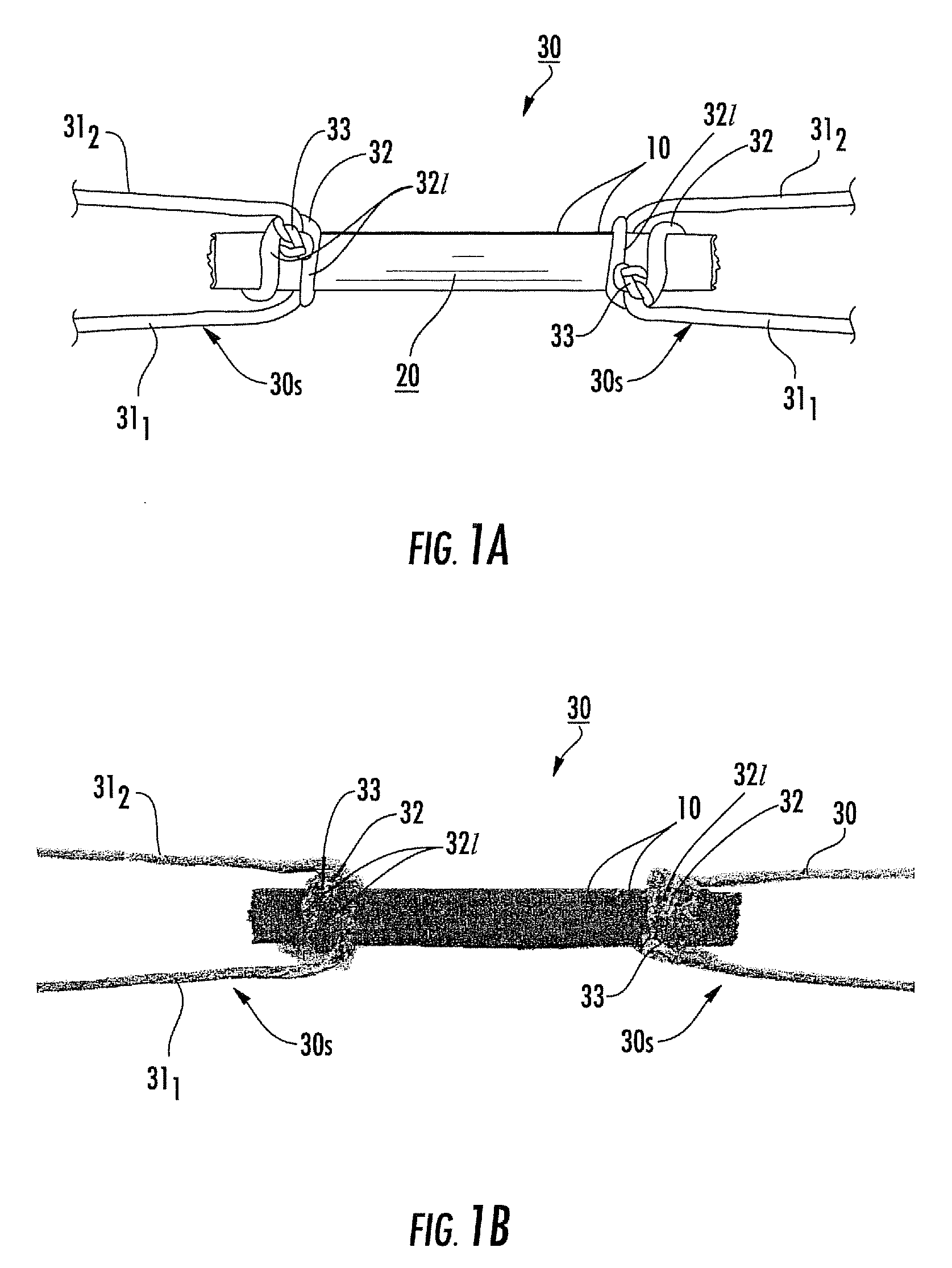

High strength suture with collagen fibers

InactiveUS20050033362A1High strengthGood tissue compatibilitySuture equipmentsSurgical needlesPolyesterTissue remodeling

Owner:ARTHREX

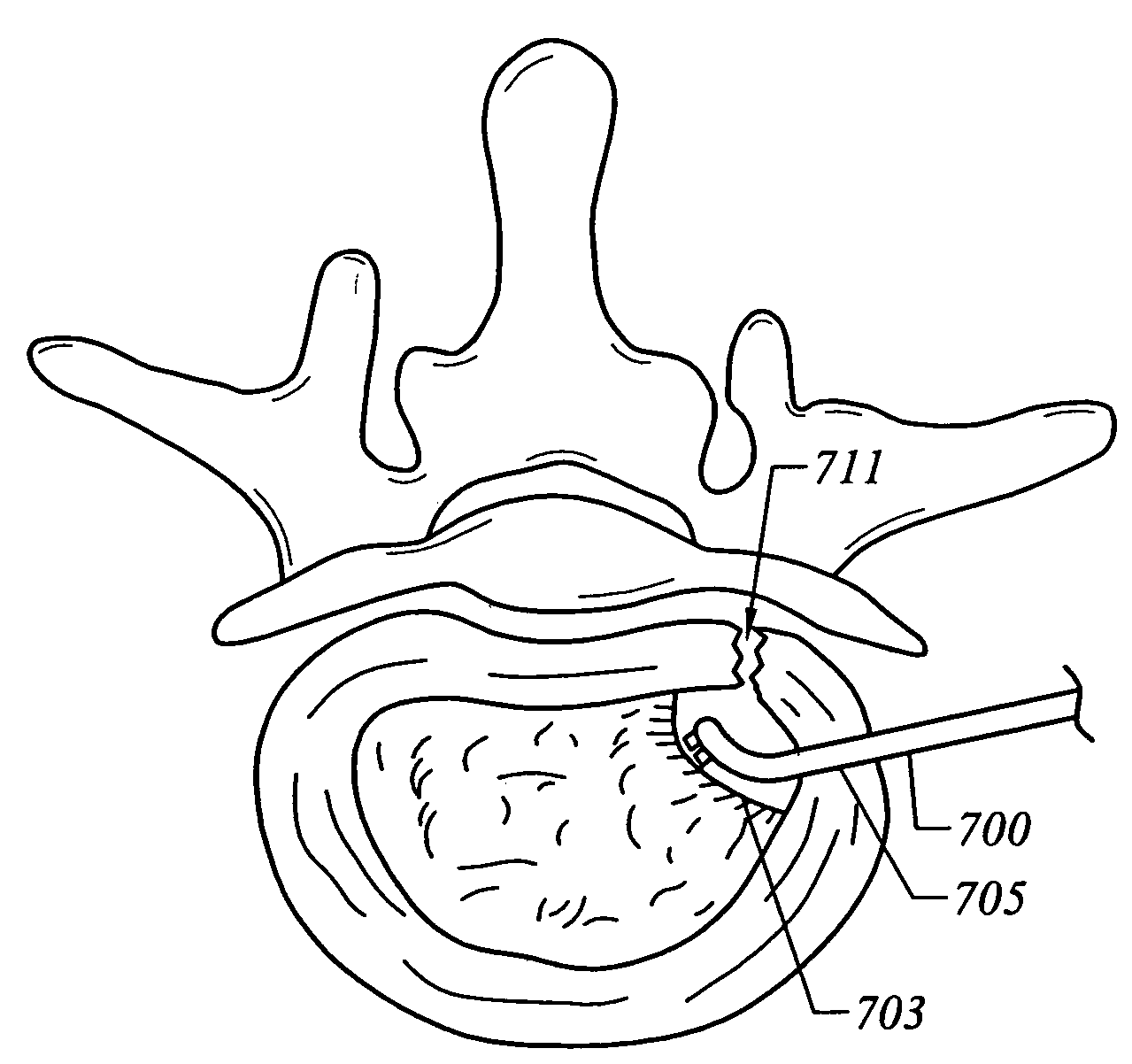

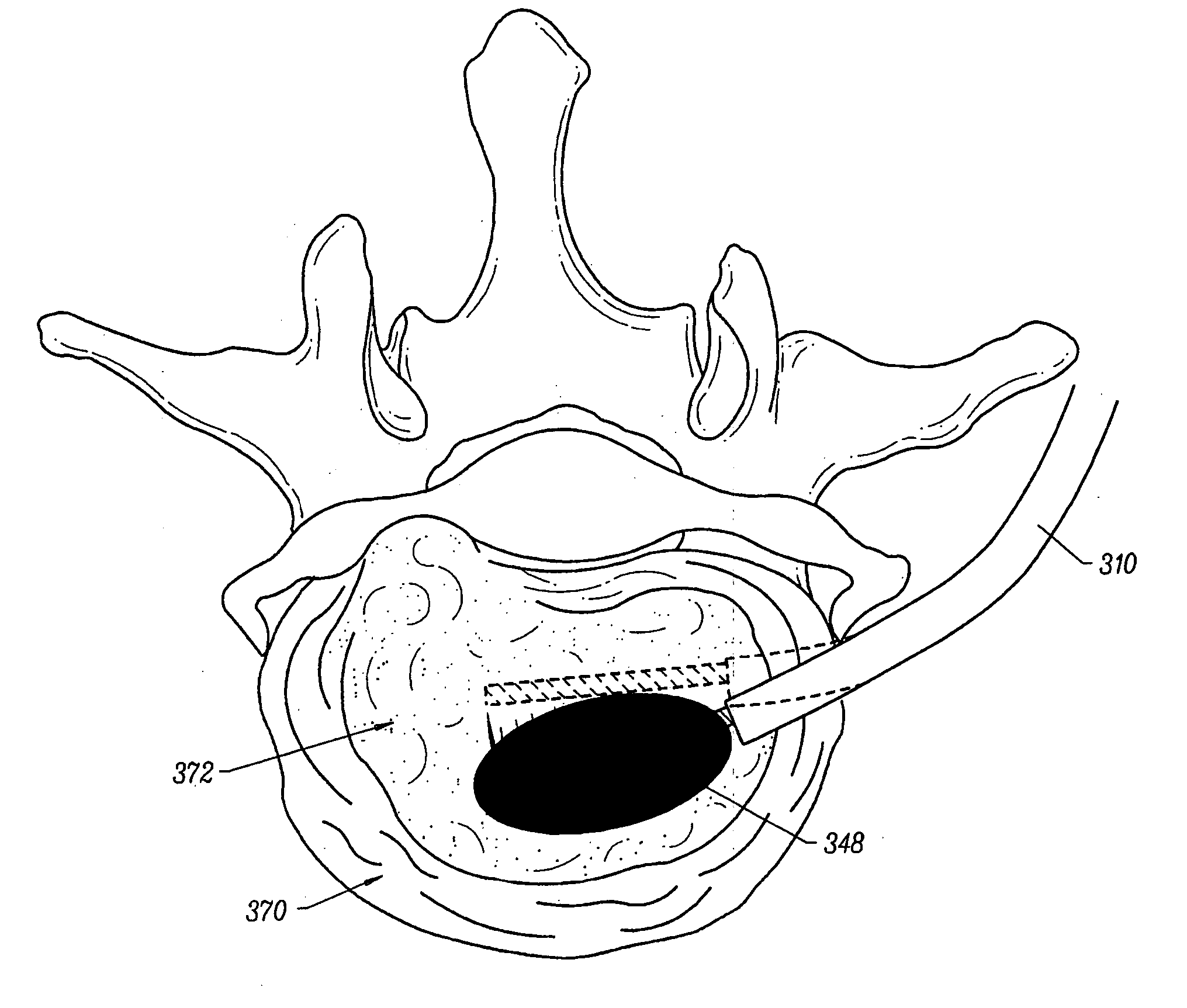

Systems and methods for electrosurgical prevention of disc herniations

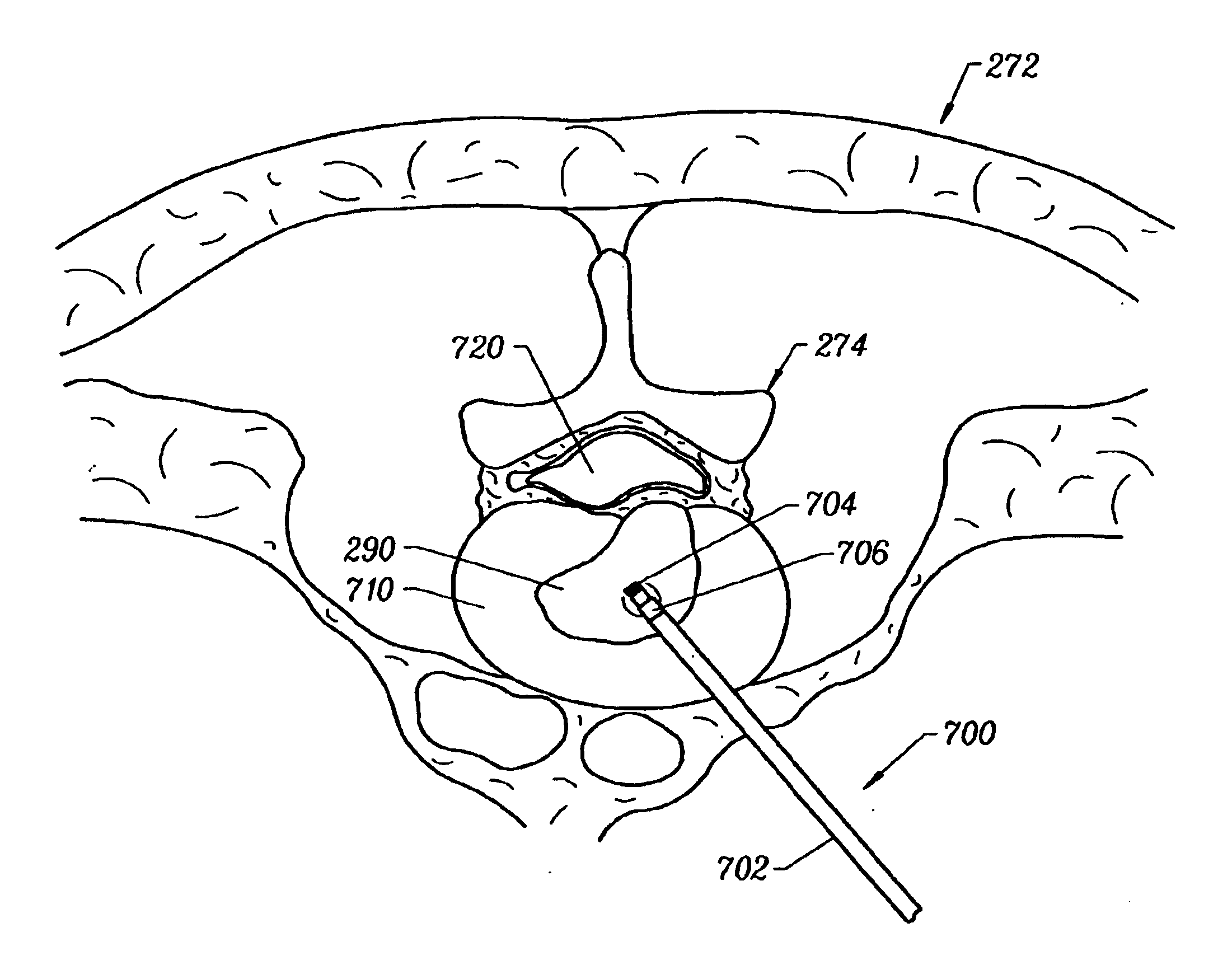

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid or saline-rich tissue to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for contracting a portion of the nucleus pulposus of a vertebral disc by applying a high frequency voltage between an active electrode and a return electrode within the portion of the nucleus pulposus, where contraction of the portion of nucleus pulposus inhibits migration of the portion nucleus pulposus through the fissure.

Owner:ARTHROCARE

Systems and methods for electrosurgical tissue contraction within the spine

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for treating herniated or swollen discs within a patient's spine by applying sufficient electrical energy to the disc tissue to contract or shrink the collagen fibers within the nucleus pulposis. This causes the pulposis to shrink and withdraw from its impingement on the spinal nerve.

Owner:ARTHROCARE

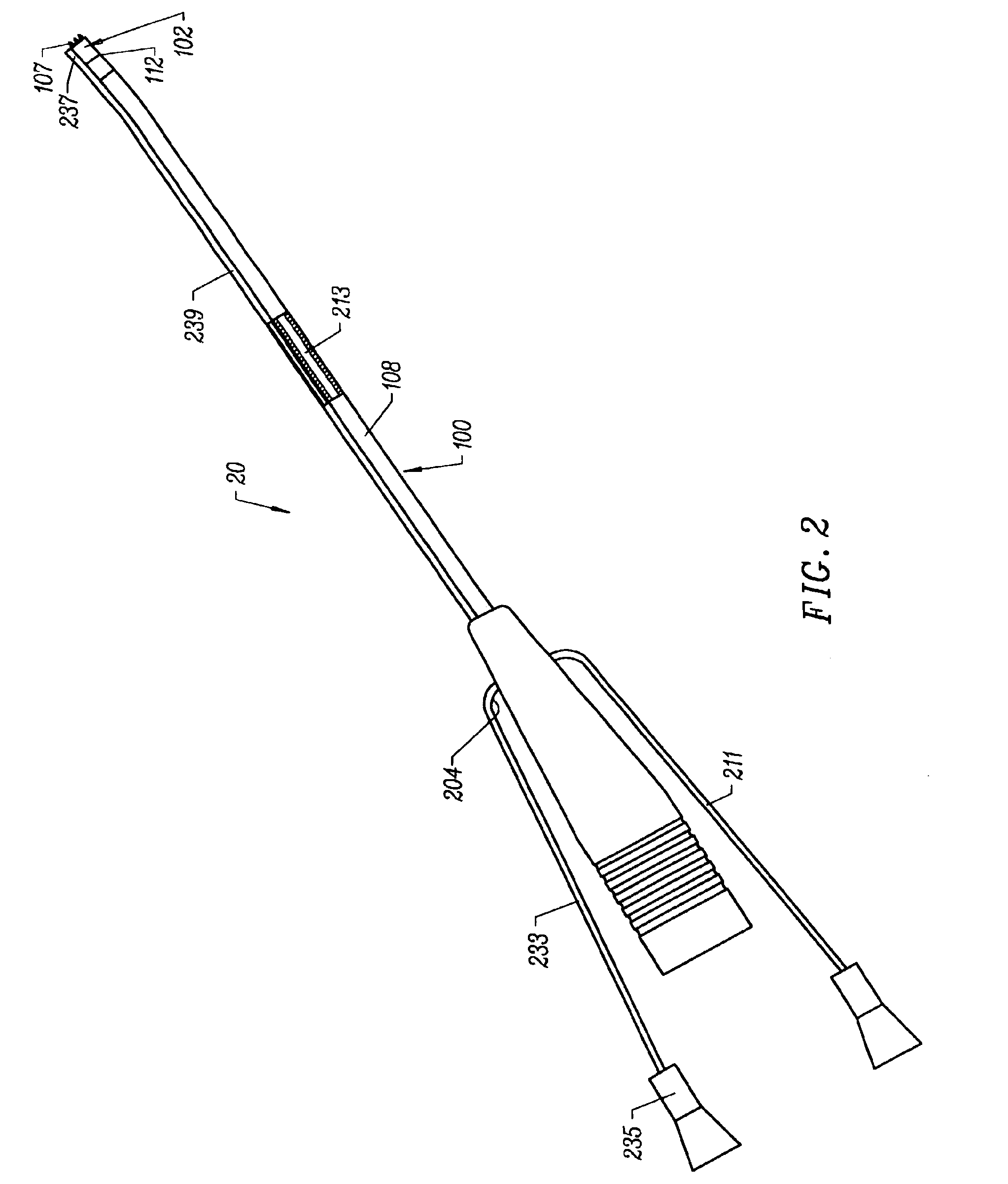

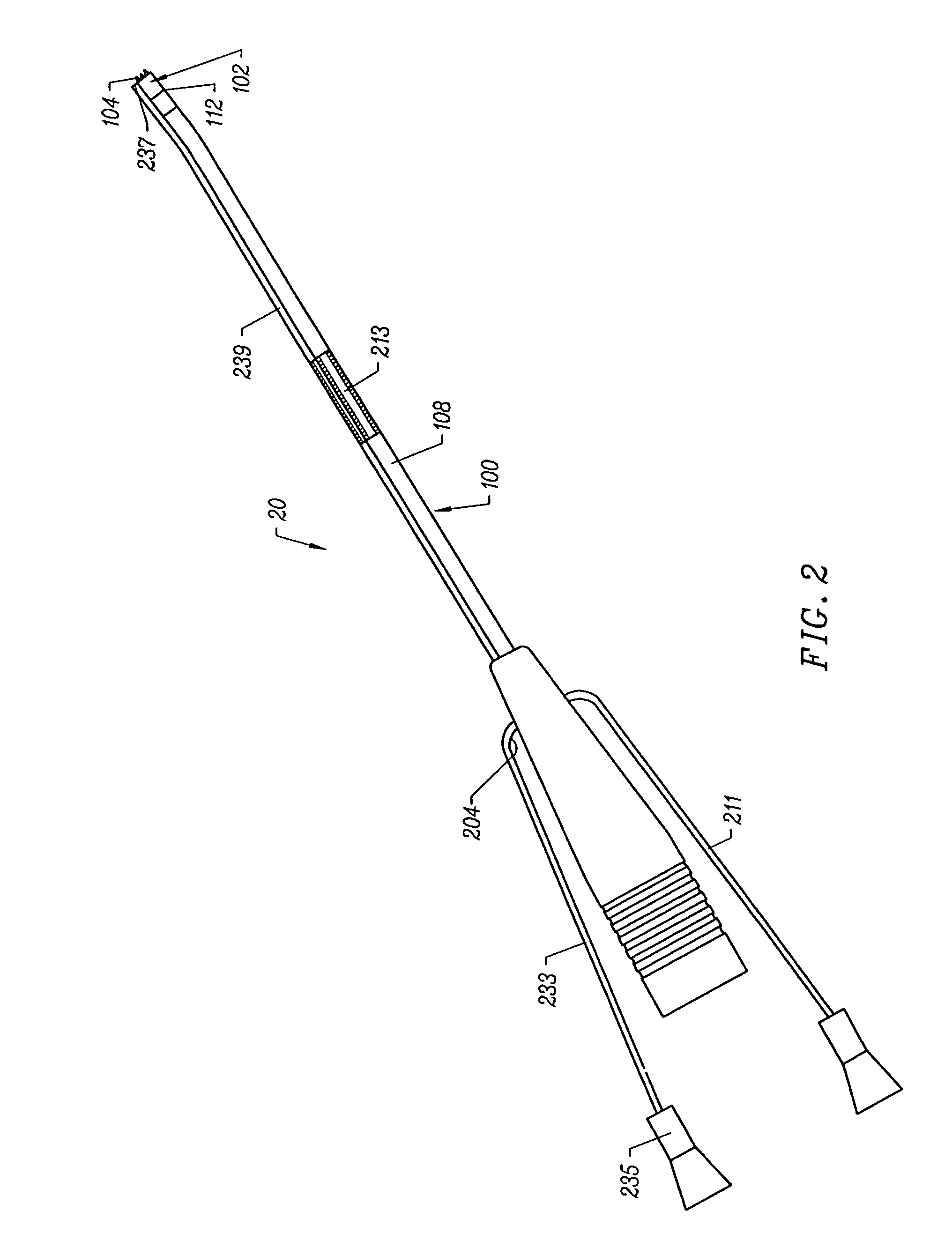

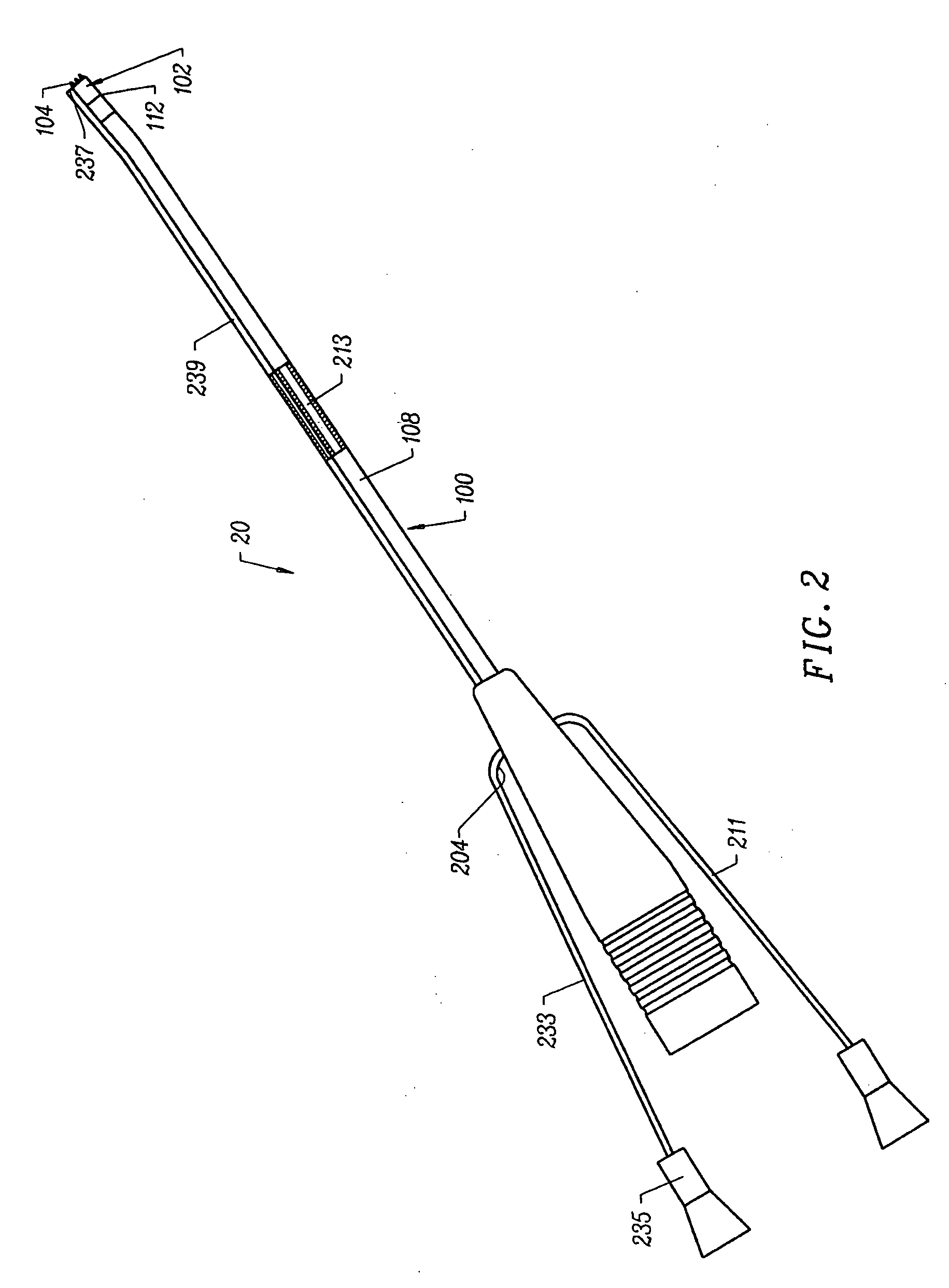

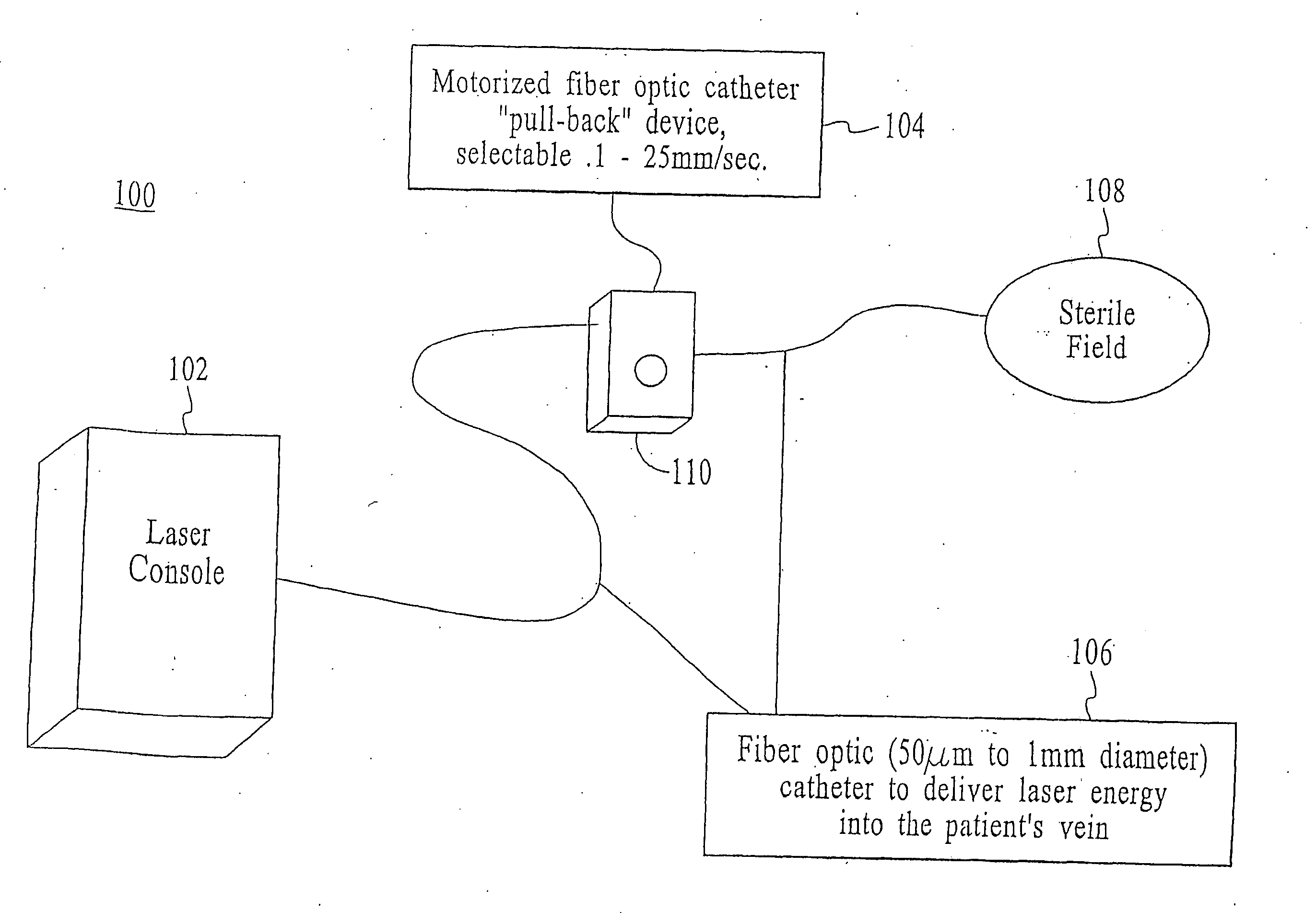

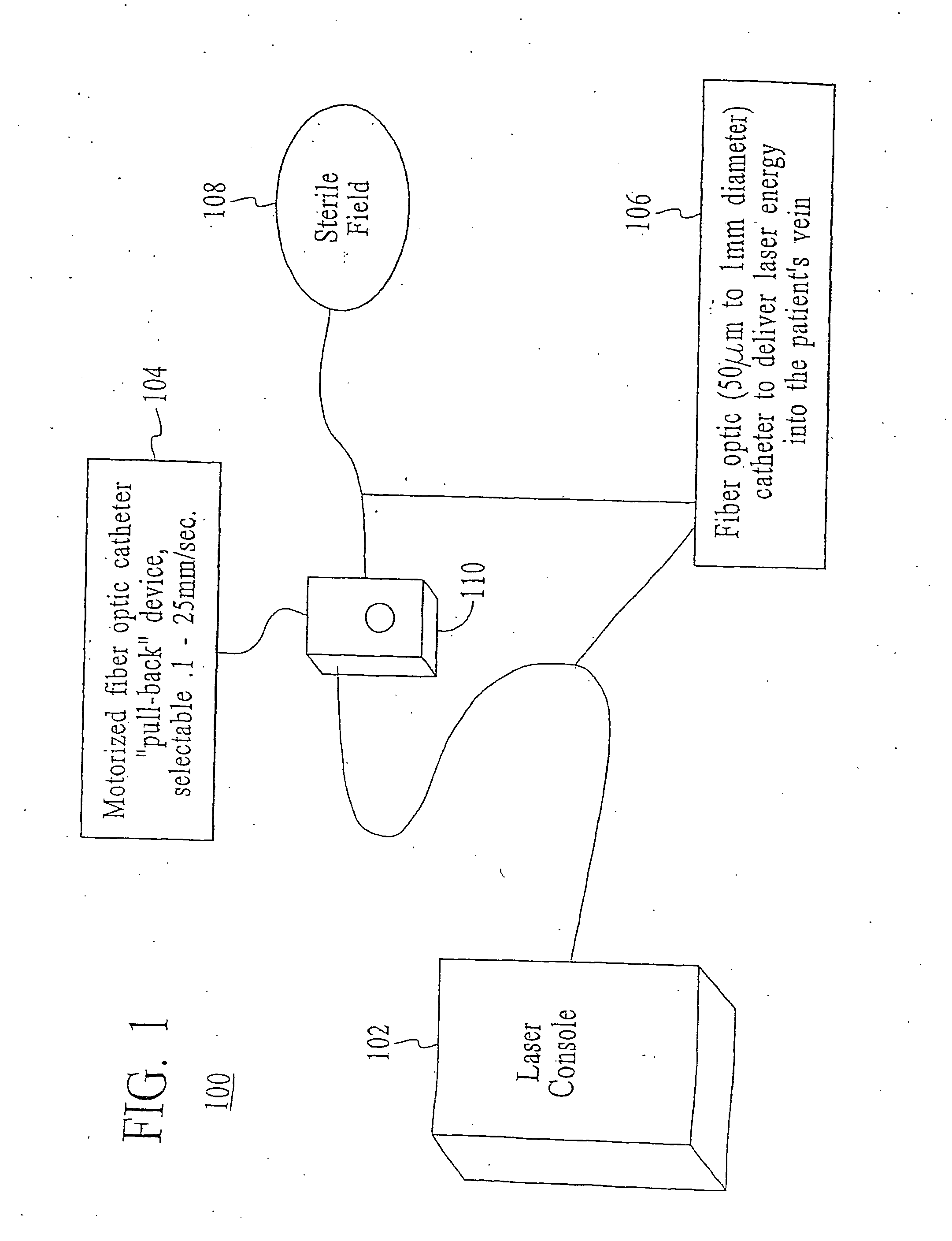

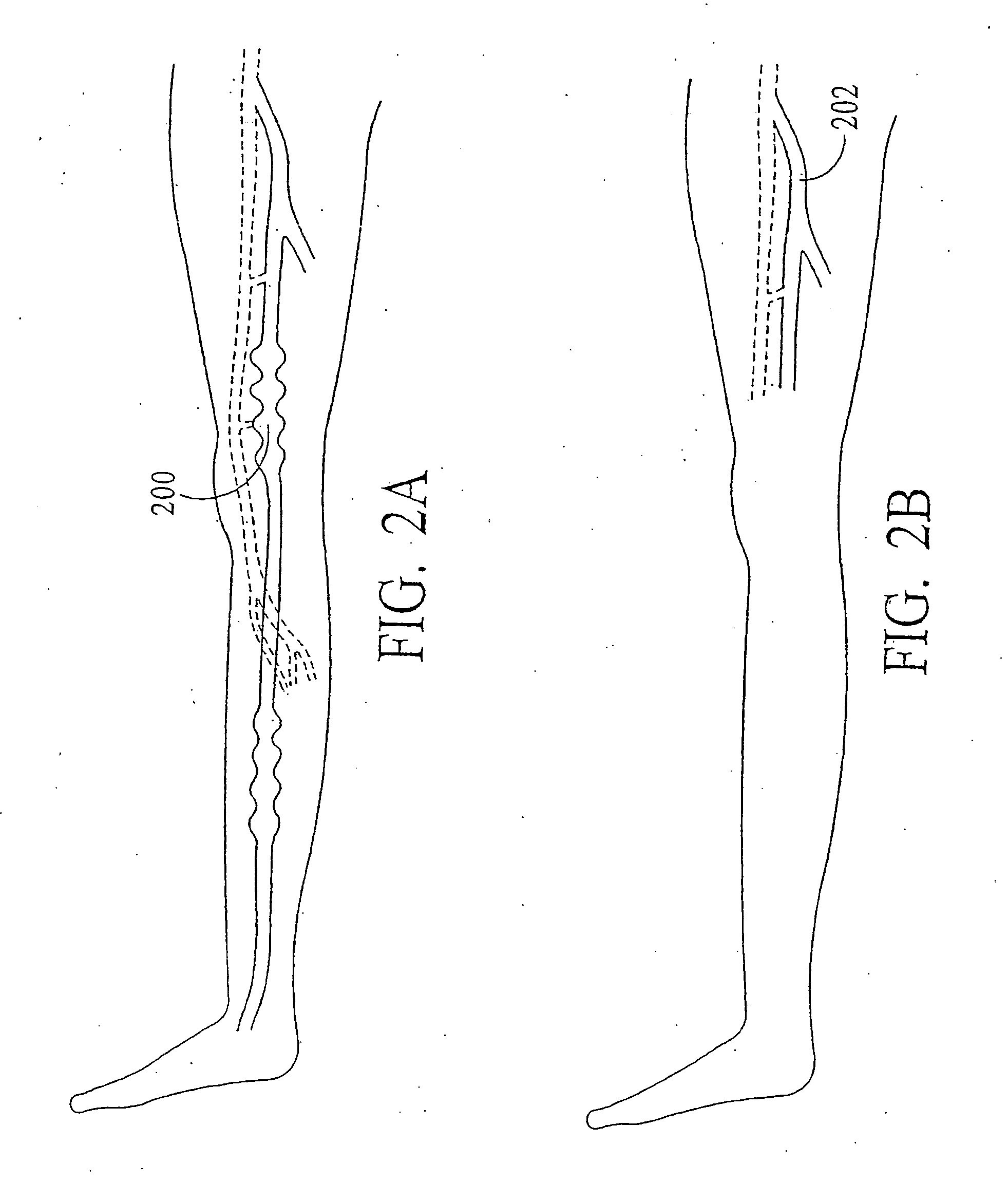

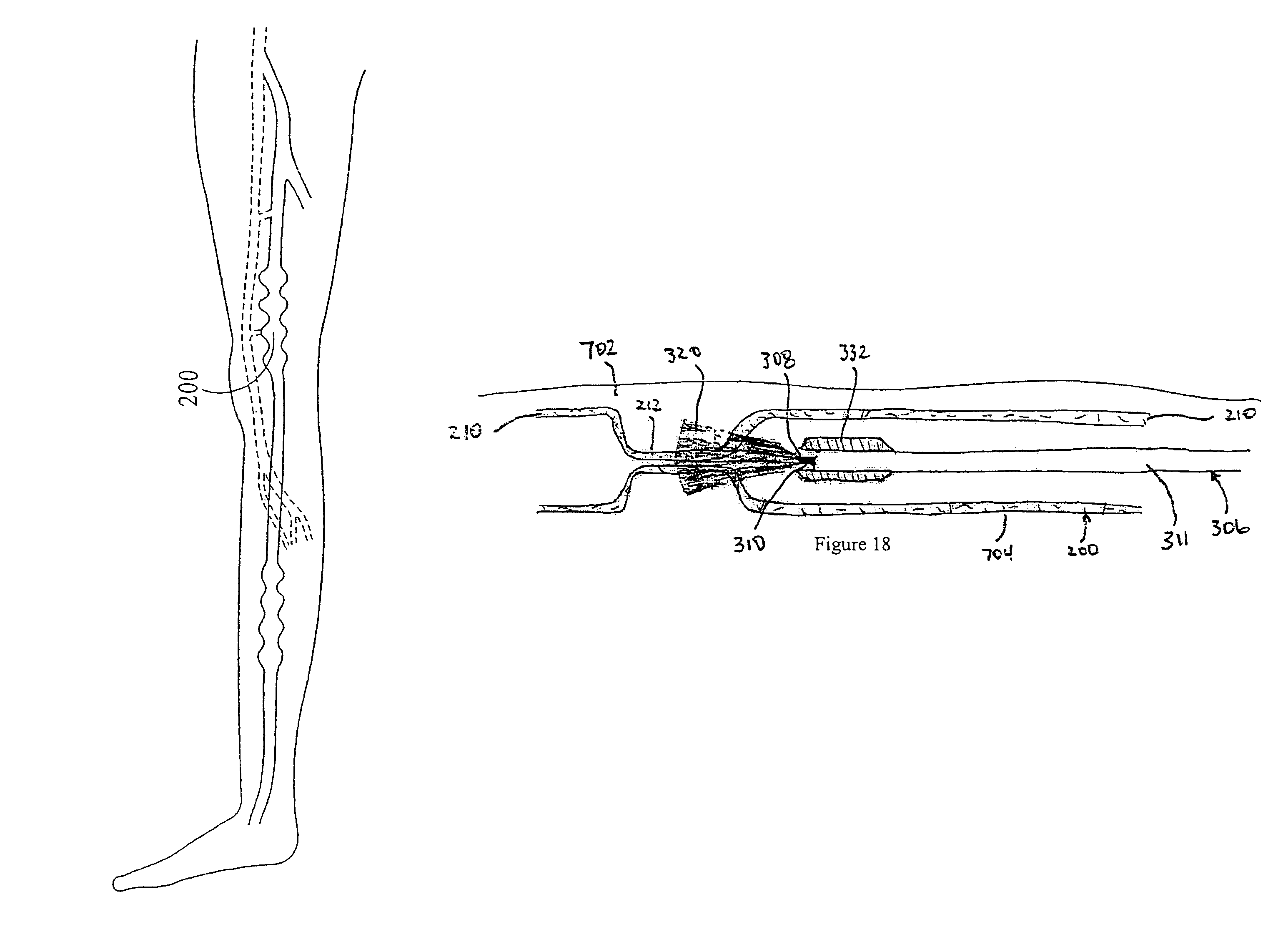

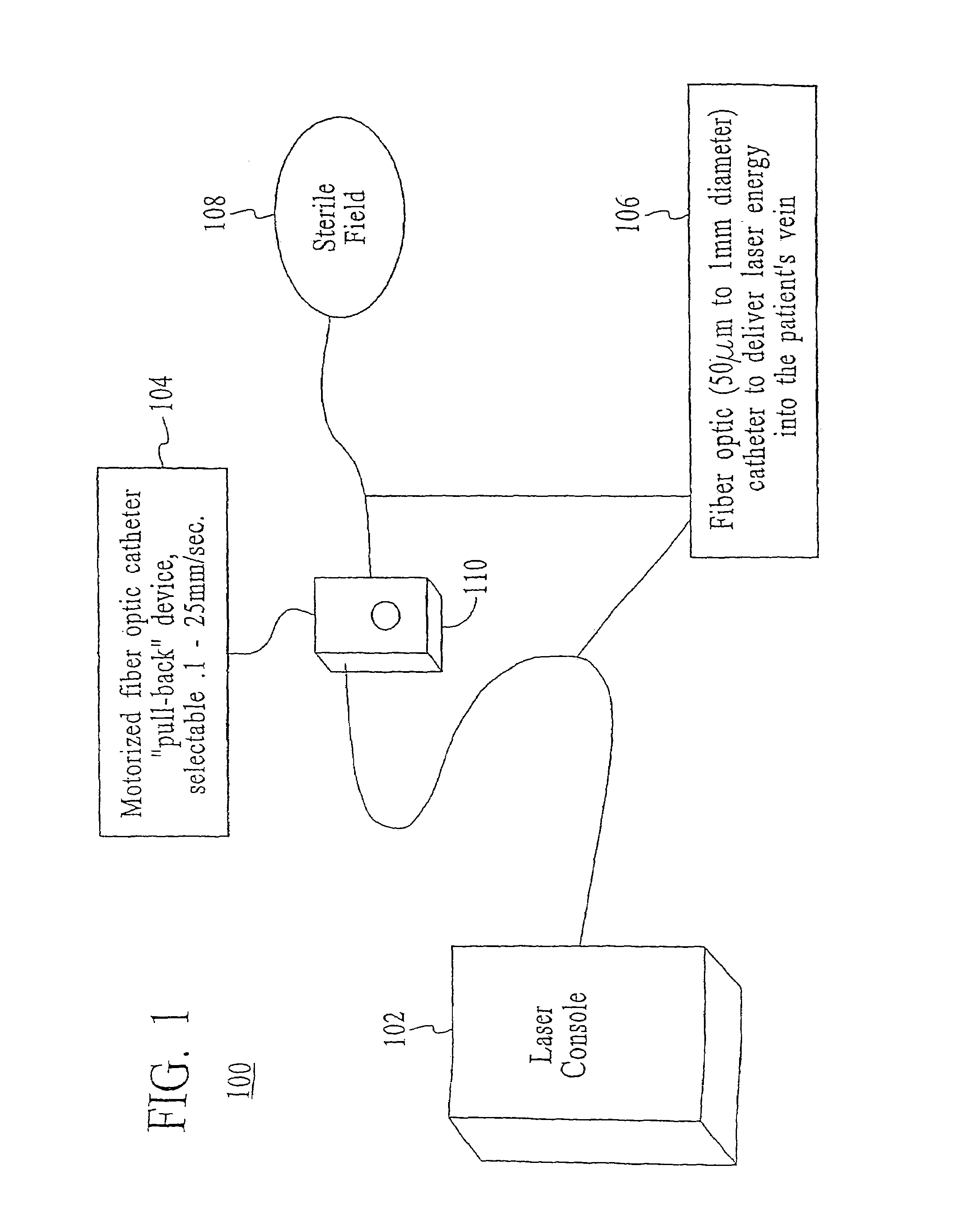

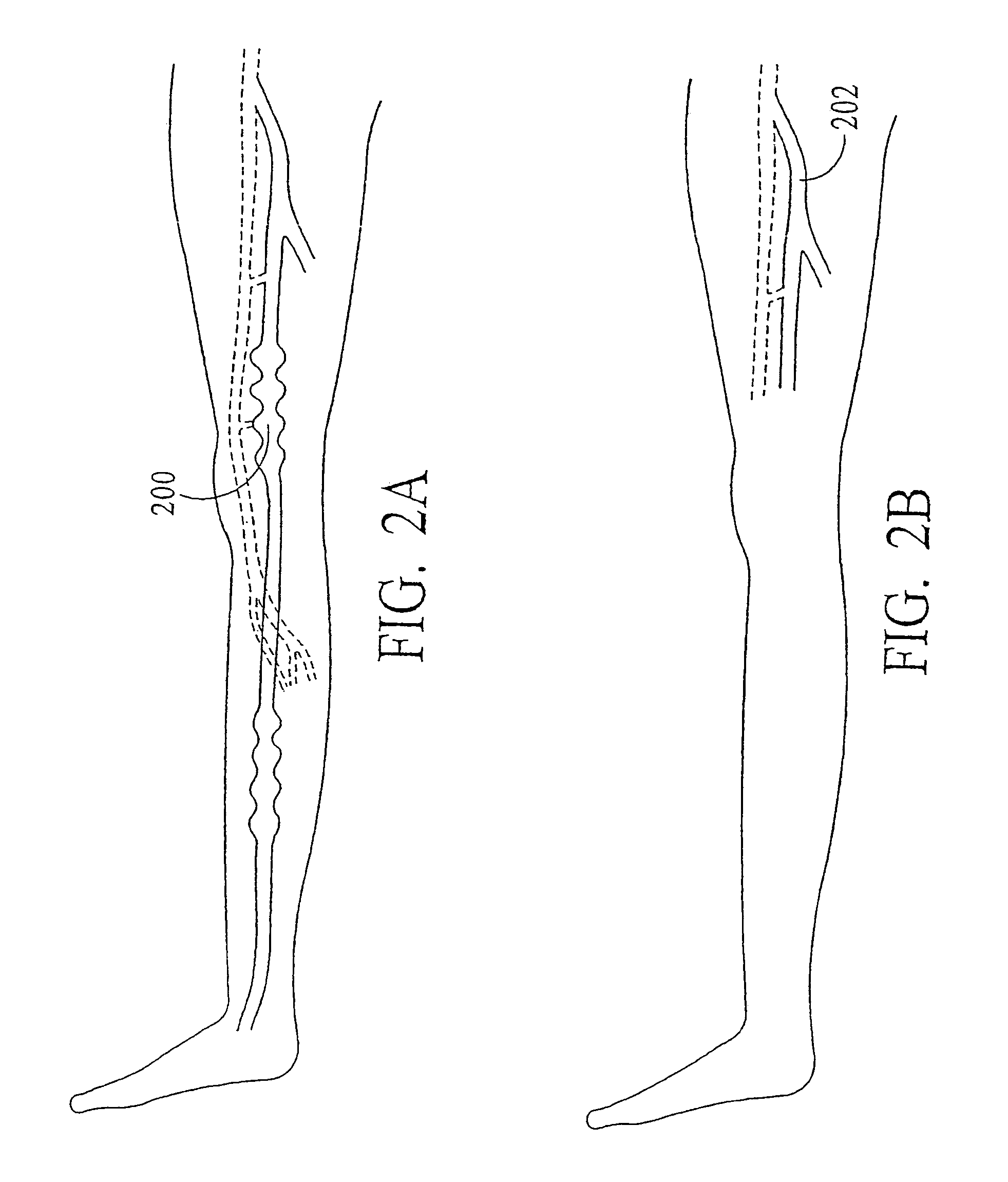

Endovenous closure of varicose veins with mid infrared laser

InactiveUS20050131400A1Less energyAvoid damageDiagnosticsSurgical instrument detailsProper treatmentMid infrared laser

This invention is an improved method and device for treating varicose veins 200 or the greater saphenous vein 202. The method comprises the use of infrared laser radiation in the region of 1.2 to 2.2 um in a manner from inside the vessel 200 or 202 such that the endothelial cells of the vessel wall 704 are damaged and collagen fibers in the vessel wall 704 are heated to the point where they permanently contract, the vessel 200 or 202 is occluded and ultimately resorbed. The device includes a laser 102 delivered via a fiber optic catheter 300 that may have frosted or diffusing fiber tips 308, or that may be provided with a protective spacer. A motorized pull back device 104 may be used, and a thermal sensor 600 may be used to help control the power required to maintain the proper treatment temperature.

Owner:COOLTOUCH

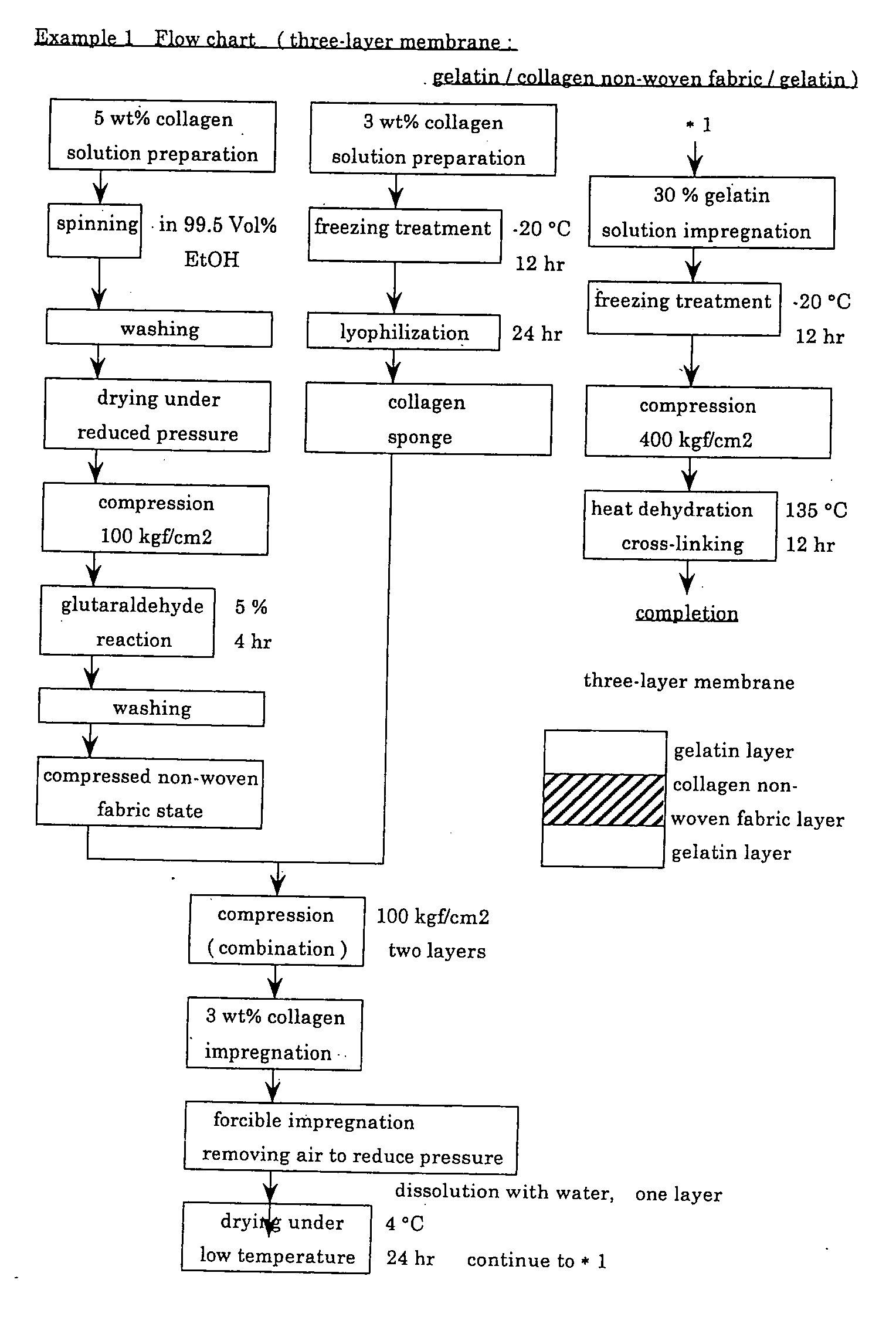

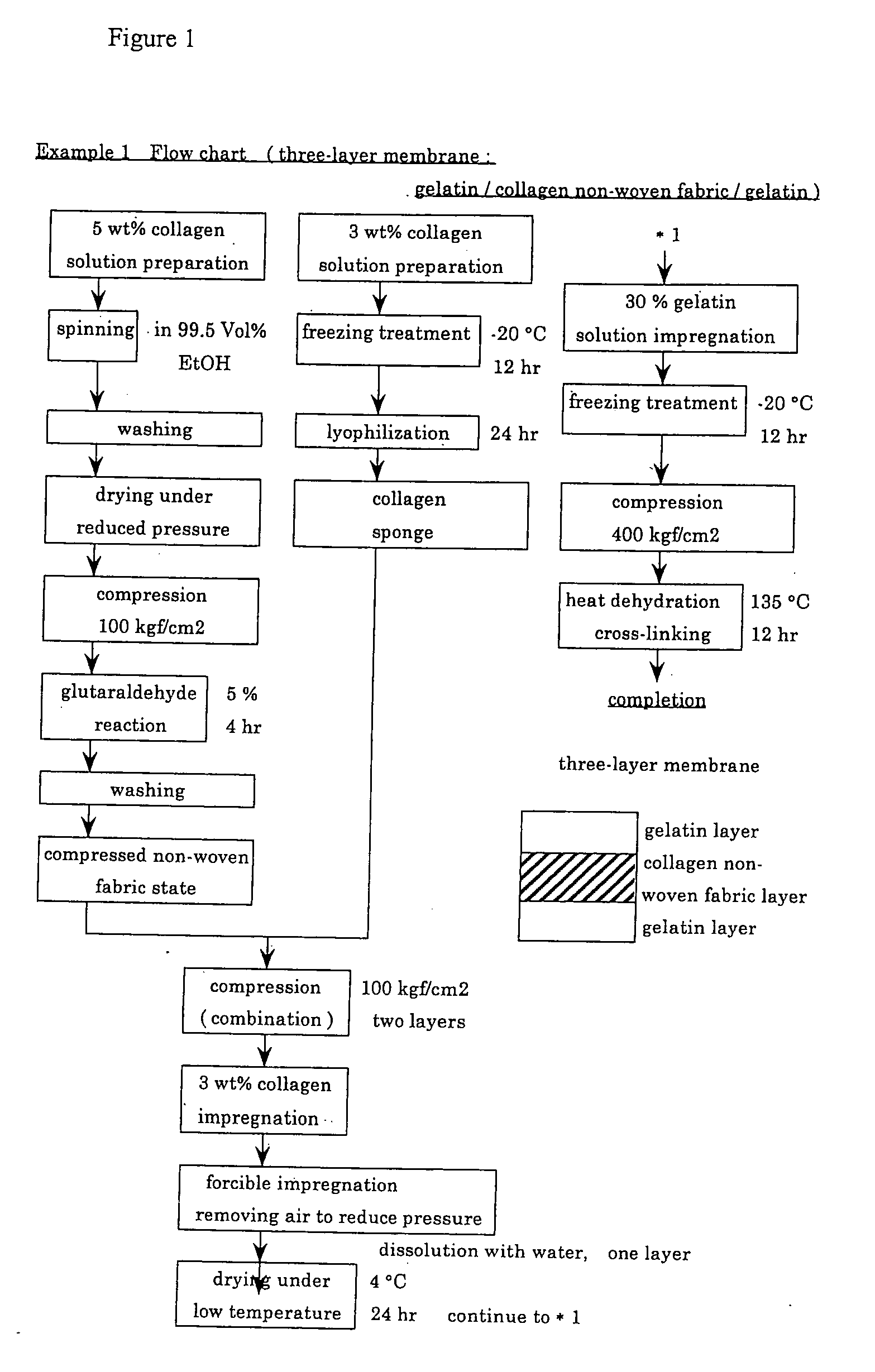

Suturable adhesion-preventing membrane

InactiveUS6977231B1High strengthGood biocompatibilitySuture equipmentsSynthetic resin layered productsCross-linkDecomposition

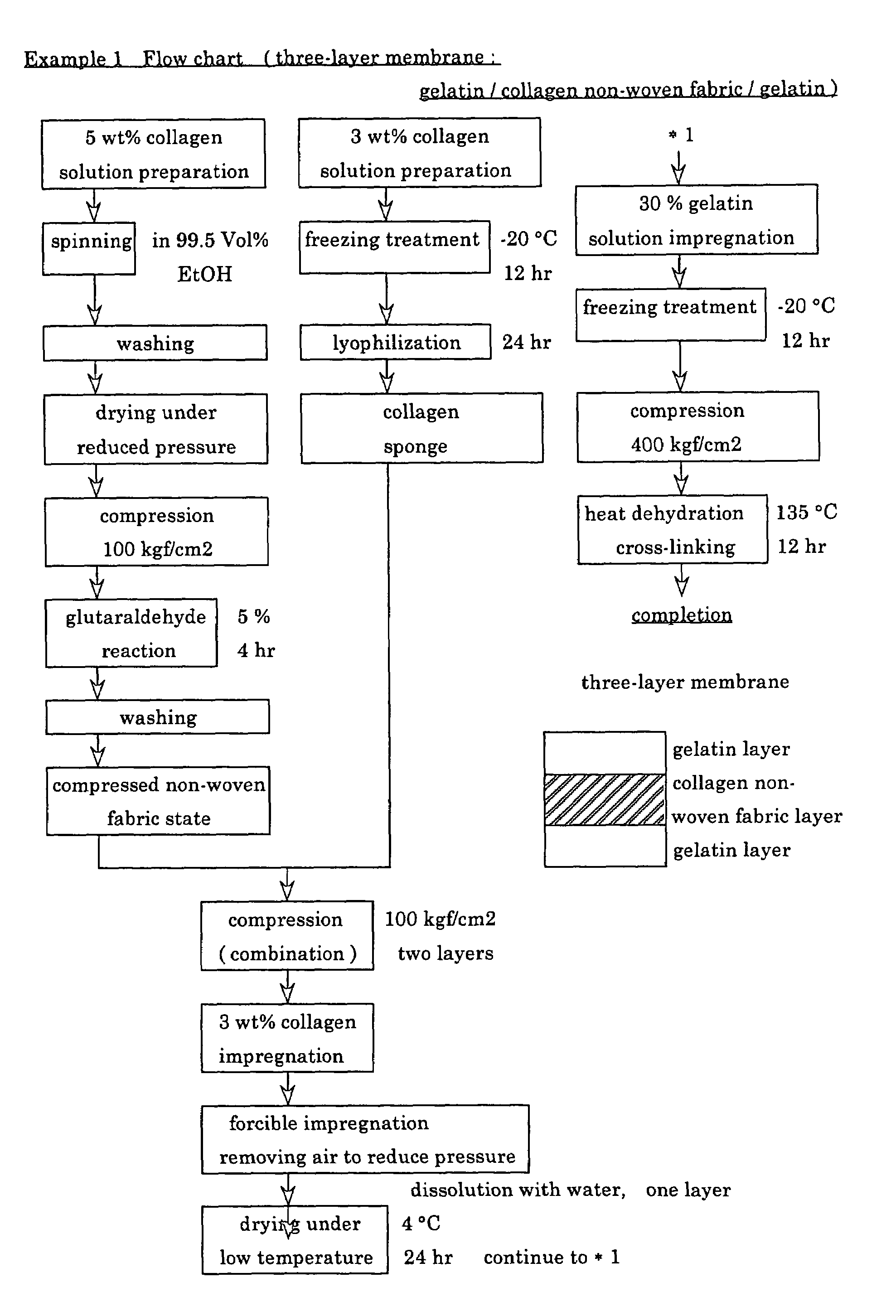

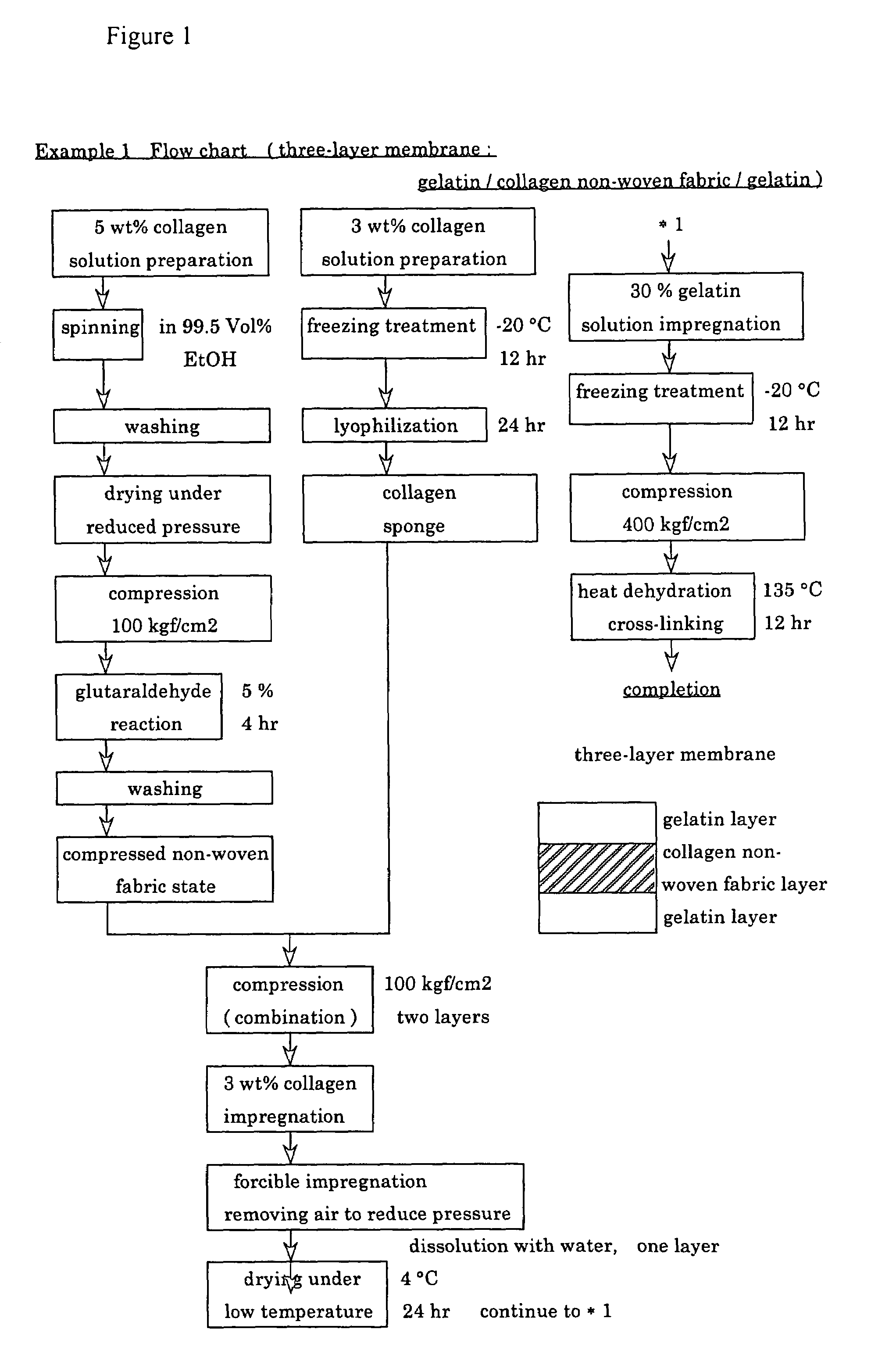

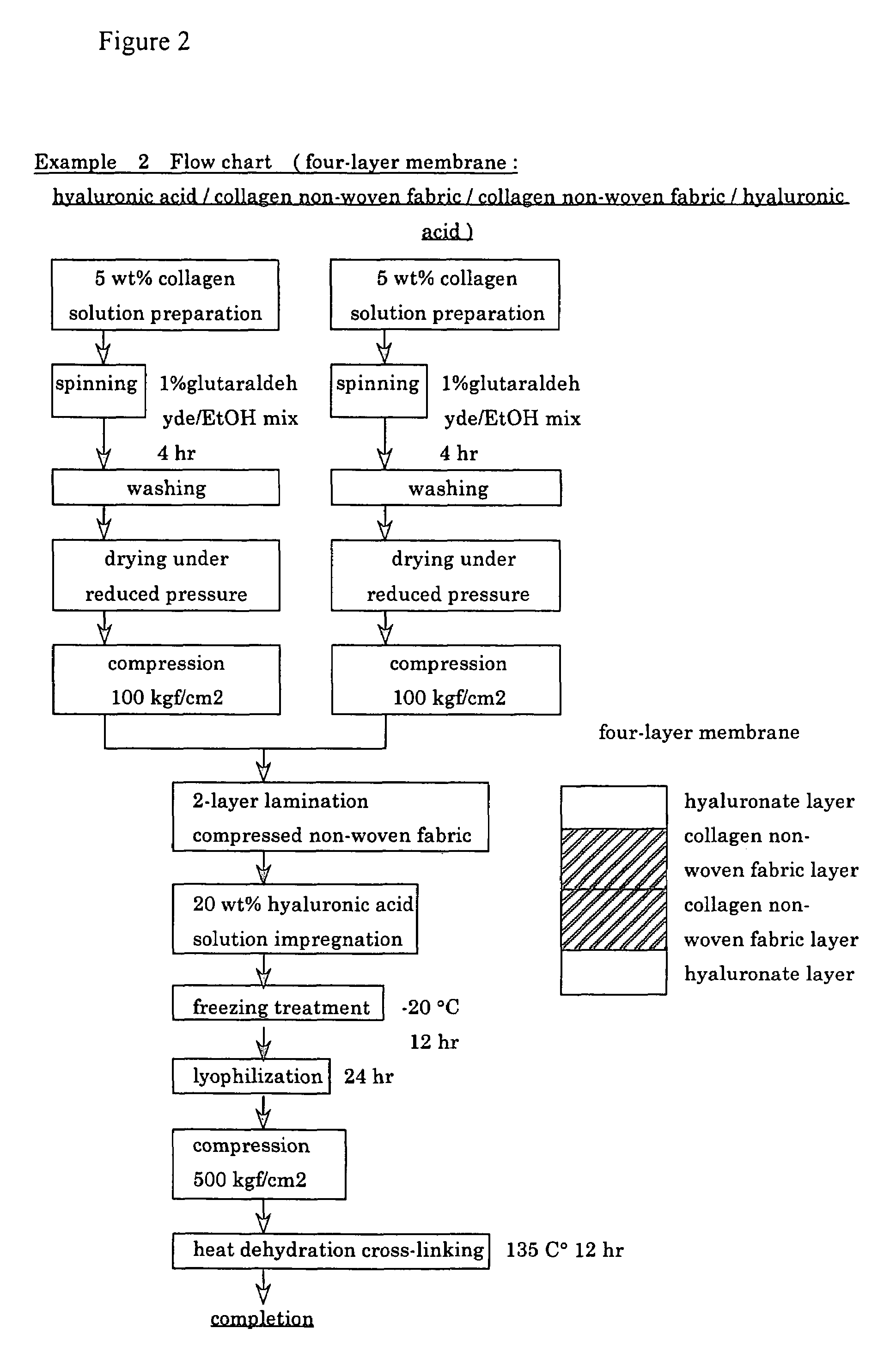

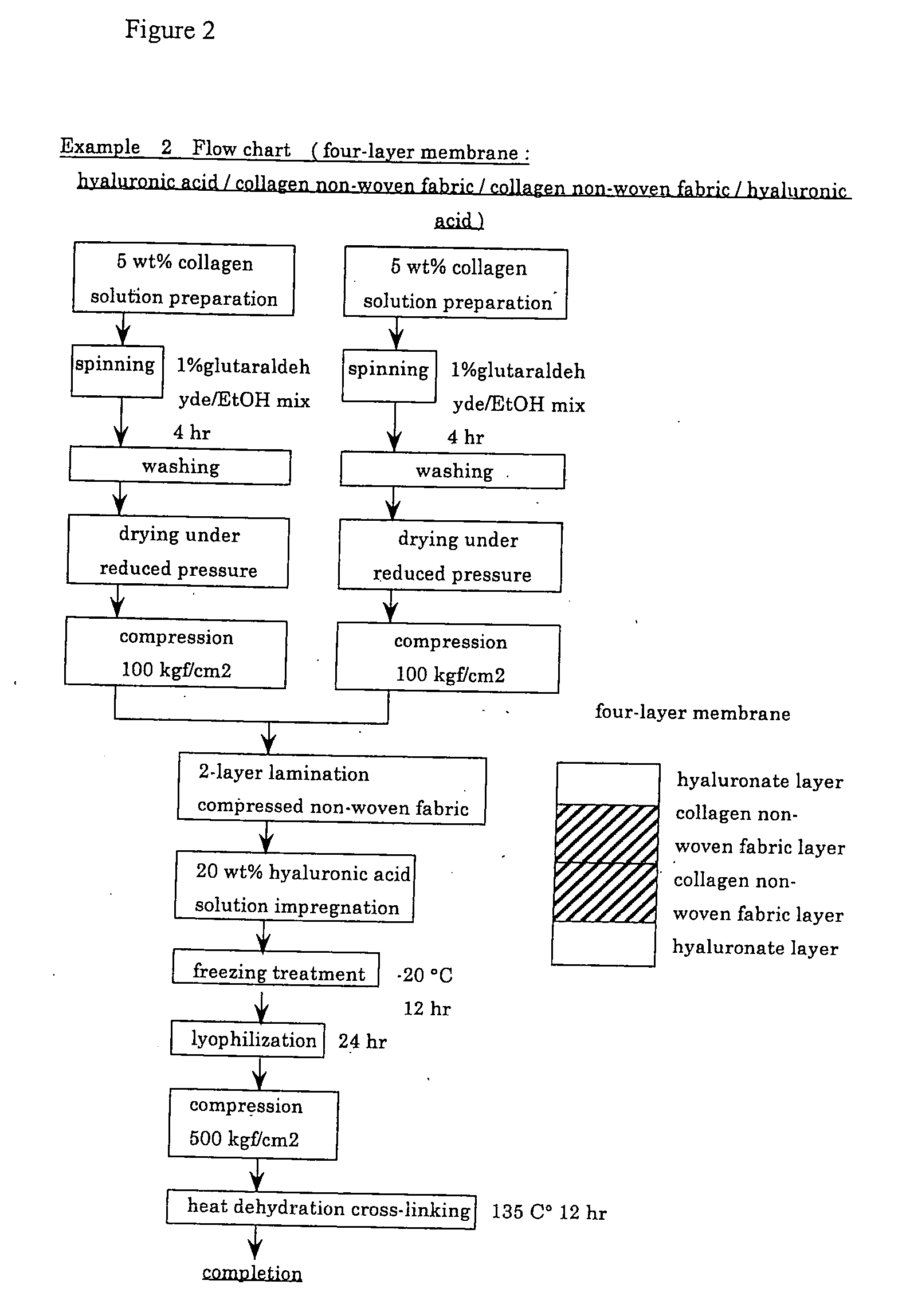

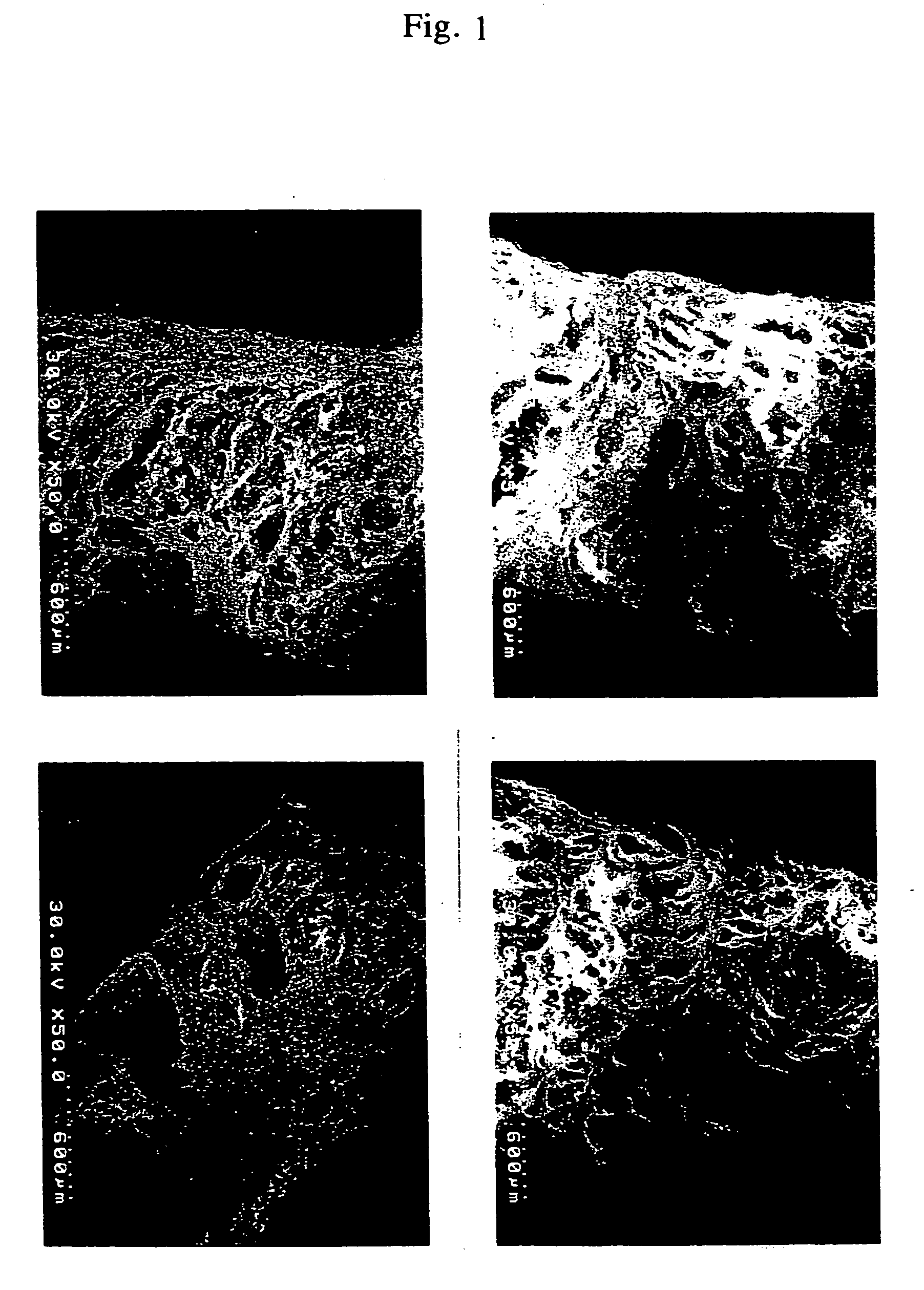

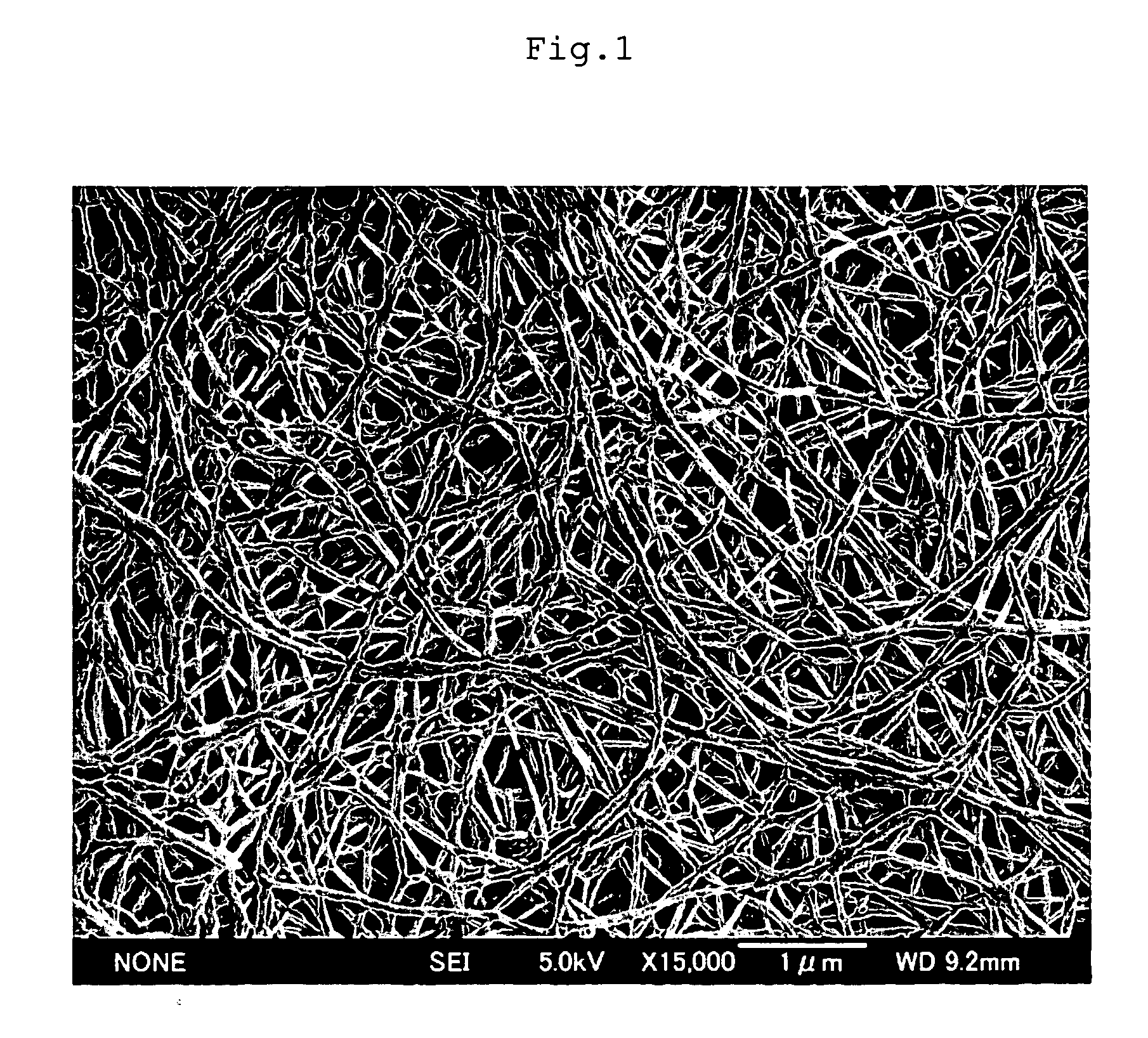

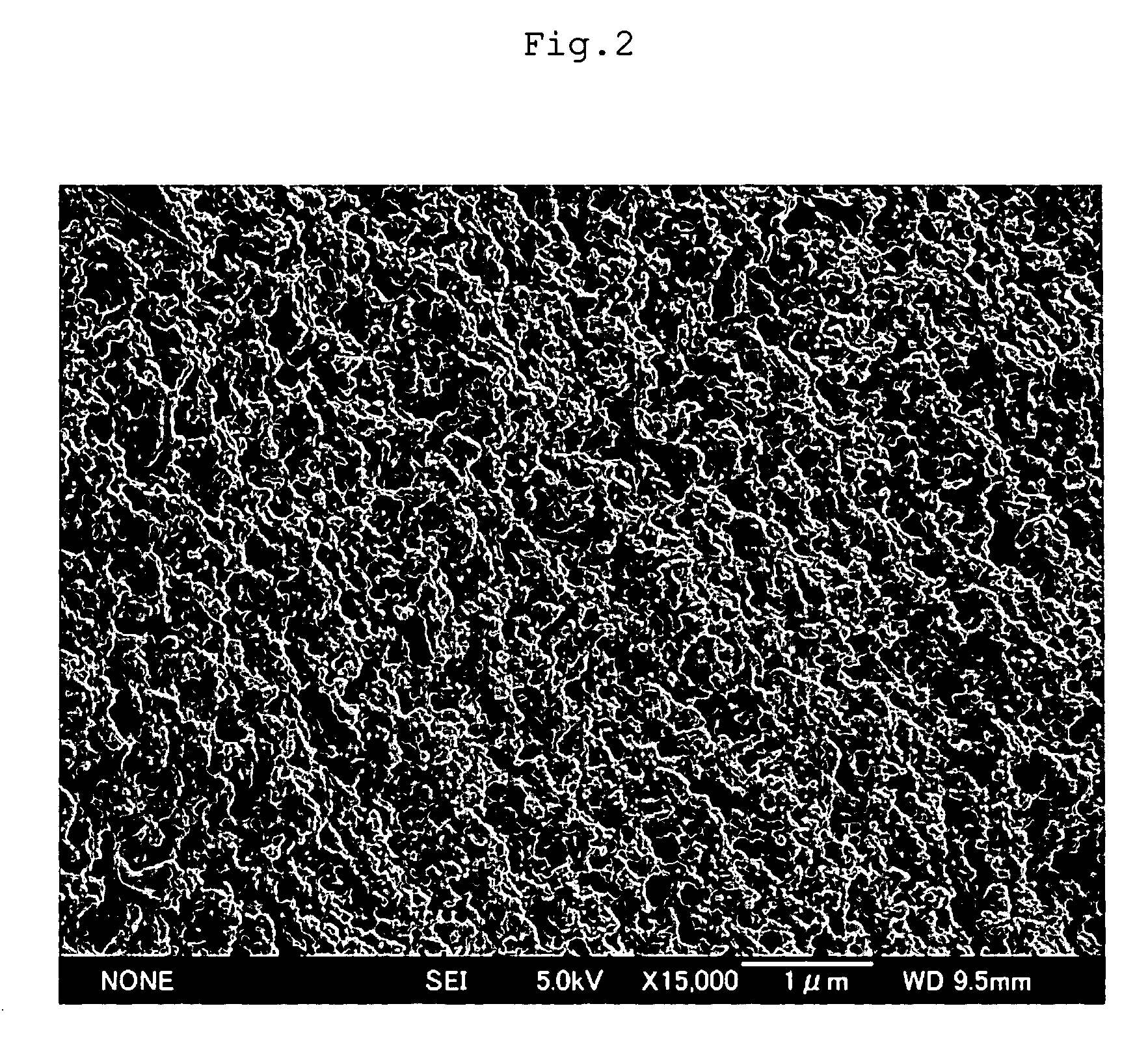

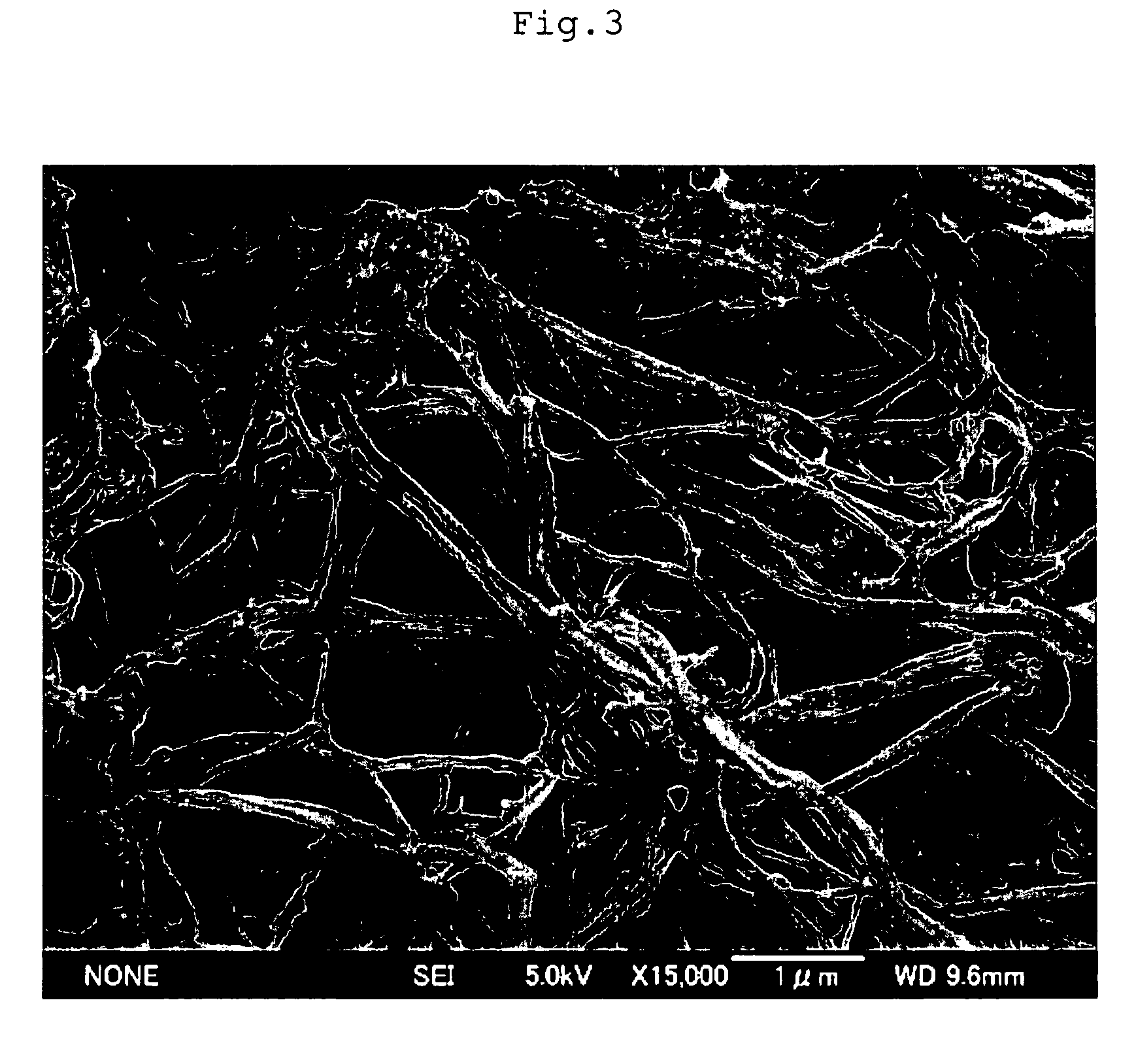

A suturable adhesion-preventing membrane has high suture strength, good biocompatibility, decomposition and absorption in a living body, sufficient adhesion-preventing effect, and desirable guided tissue regeneration. The membrane is composed of at least one non-woven fabric layer made of collagen fibers, or a laminated membranous substance consisting of at least one non-woven fabric layer made of collagen fibers and at least one sponge layer made of collagen, and a coating layer of gelatin or hyaluronic acid on the surface or surfaces of the above membrane. Preferably, the membrane comprises one to six compressed cross-linked collagen non-woven fabric layers wherein a layer has a fibers having a fiber diameter of 0.05 mm to 1.0 mm, a bulk density of 5.0×10−4 to 5 g / cm3 and a thickness of 0.1 mm to 50 mm, and a coating layer containing gelatin or hyaluronic acid and having a thickness of 0.05 mm to 20 mm, wherein the coating layer covers one or both sides or a part or whole of the surface of the membrane.

Owner:NIPRO CORP

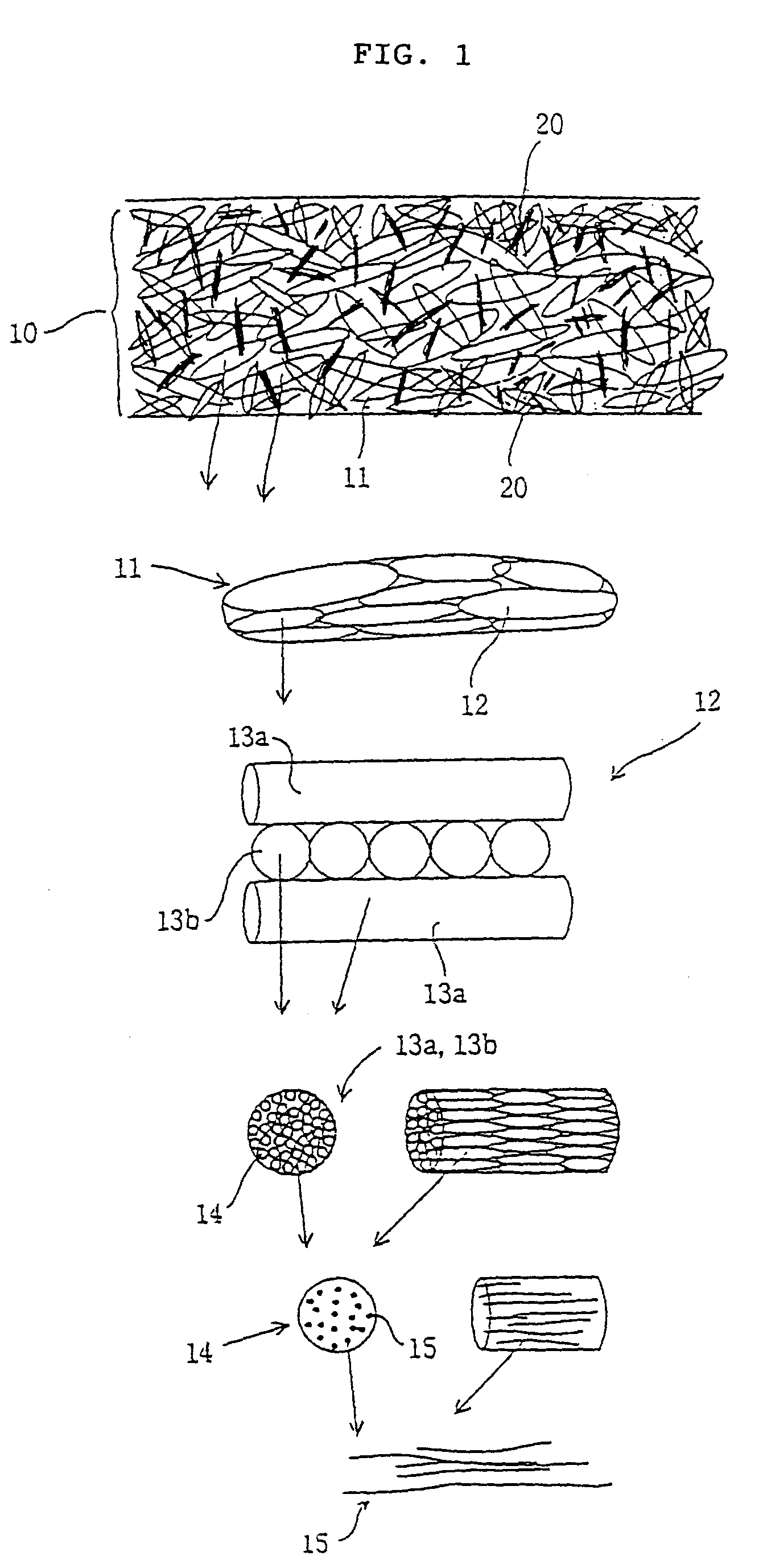

Collagen material and its production process

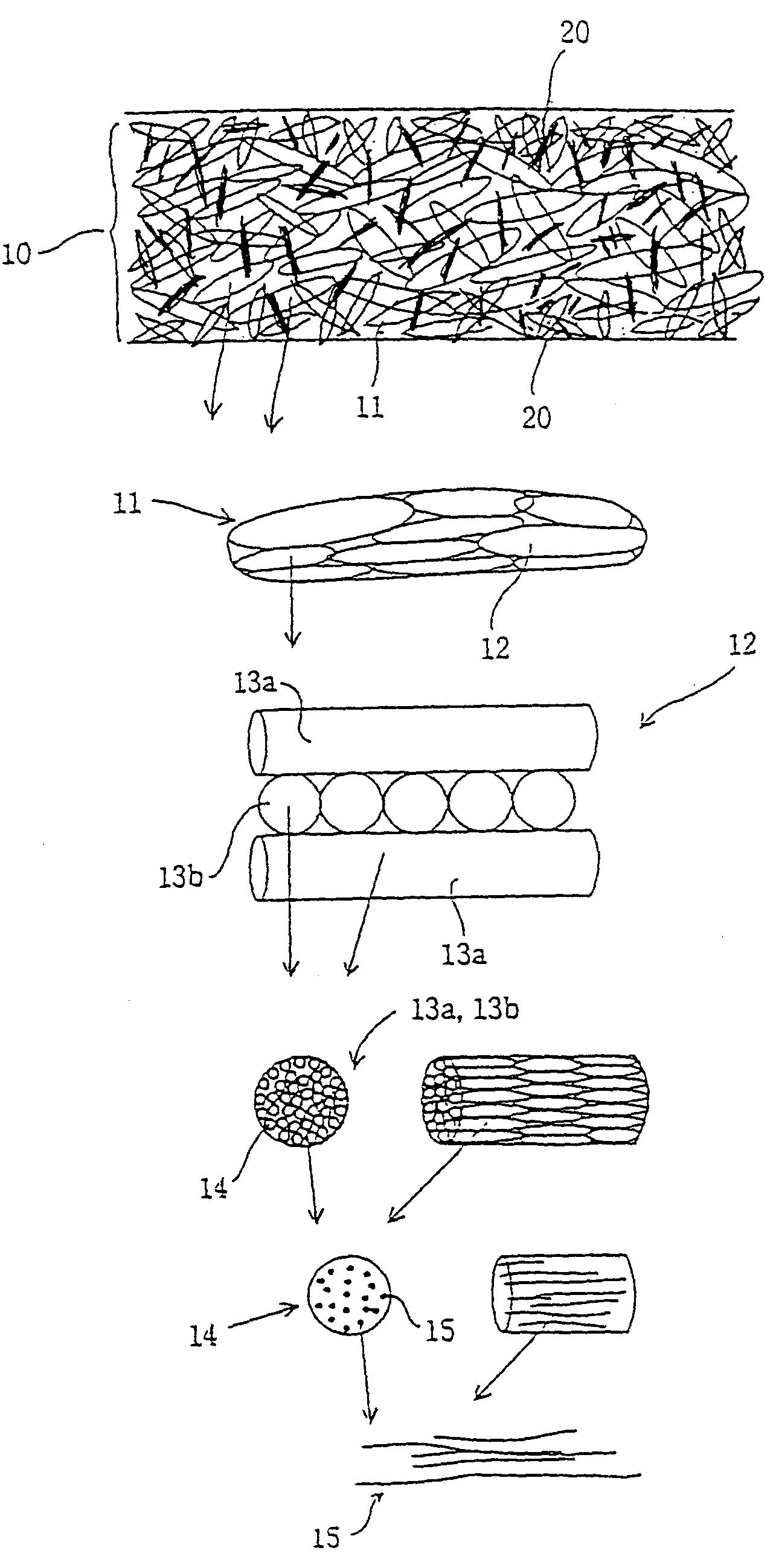

InactiveUS7084082B1Avoid stickingPromote regenerationSuture equipmentsSynthetic resin layered productsEndocraniumBiocompatibility Testing

The objective of the present invention is to provide a collagen material that possesses physical properties to an extent that allows suturing while still maintaining the biochemical properties inherently possessed by collagen, and retains its shape for a certain amount of time even after application to the body; its production process; and, a medical material on which it is based, examples of which include a artificial tube for nerve, artificial tube for spinal cord, artificial esophagus, artificial trachea, artificial blood vessel, artificial valve or alternative medical membranes such as artificial endocranium, artificial ligaments, artificial tendons, surgical sutures, surgical prostheses, surgical reinforcement, wound protecting materials, artificial skin and artificial cornea, characterized by filling or having inside a substance having biocompatibility that can be degraded and absorbed in the body into a matrix of a non-woven fabric-like multi-element structure of collagen fibers having ultra-fine fibers of collagen as its basic unit.

Owner:TAPIC INT

Malleable multi-component implants and materials therefor

ActiveUS20090246244A1High viscosityEfficiently formedPeptide/protein ingredientsSkeletal disorderFiberMedicine

Described are implantable, malleable medical materials comprising mineral particles, insoluble collagen fibers, and a gel-forming polysaccharide component and / or another added gel-former. The malleable medical materials can be used treat bone or other tissue defects in patients, including in conjunction with biologically active factors such as osteogenic proteins. Also described are methods and materials that can be used to prepare the malleable medical materials.

Owner:WARSAW ORTHOPEDIC INC

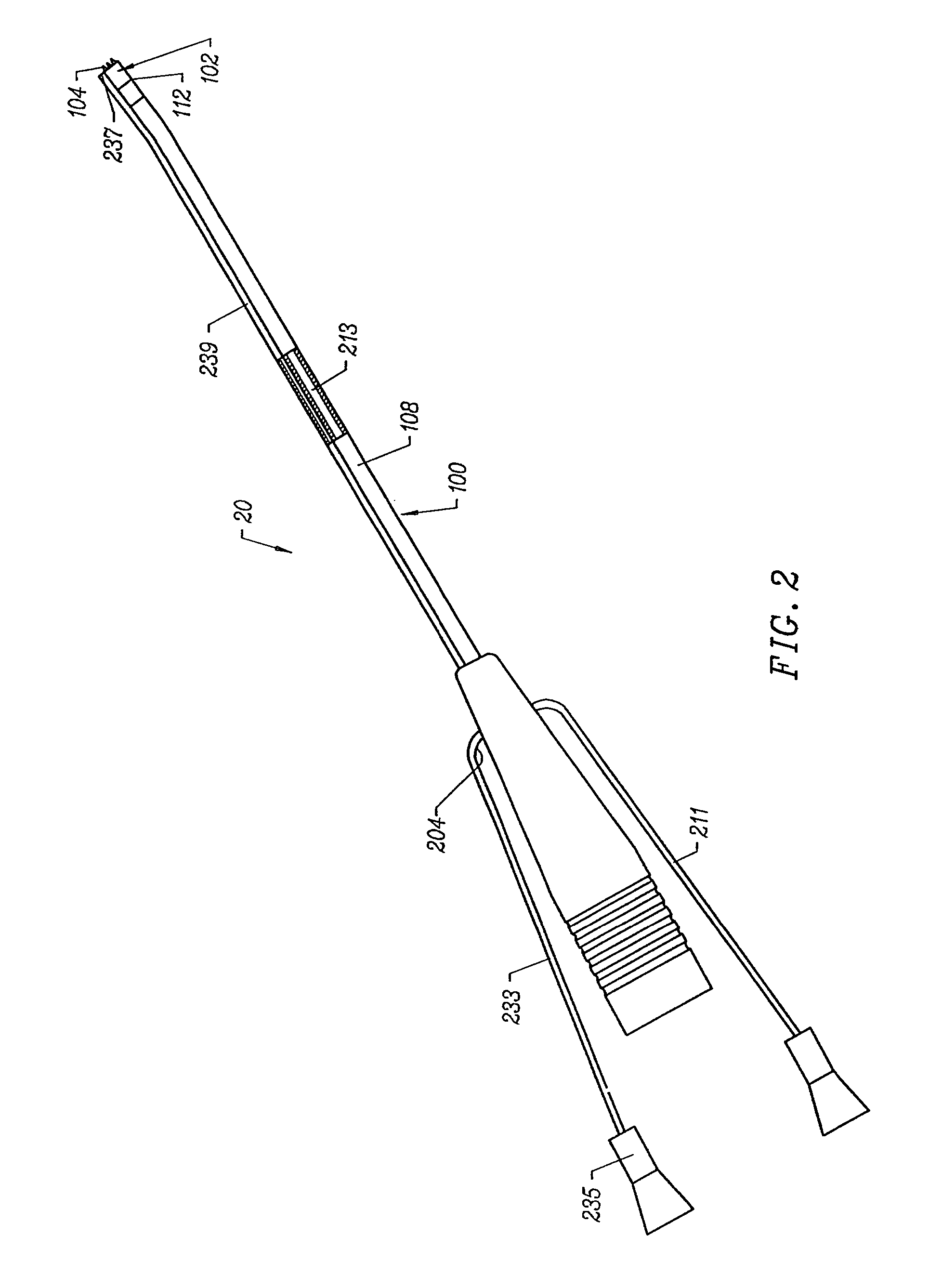

Endovenous closure of varicose veins with mid infrared laser

InactiveUS7524316B2More controllableMore predictableDiagnosticsCatheterProper treatmentMid infrared laser

This invention is an improved method and device for treating varicose veins 200 or the greater saphenous vein 202. The method comprises the use of infrared laser radiation in the region of 1.2 to 2.2 um in a manner from inside the vessel 200 or 202 such that the endothelial cells of the vessel wall 704 are damaged and collagen fibers in the vessel wall 704 are heated to the point where they permanently contract, the vessel 200 or 202 is occluded and ultimately resorbed. The device includes a laser 102 delivered via a fiber optic catheter 300 that may have frosted or diffusing fiber tips 308, or that may be provided with a protective spacer. A motorized pull back device 104 may be used, and a thermal sensor 600 may be used to help control the power required to maintain the proper treatment temperature.

Owner:COOLTOUCH

Surgical instruments for treating gastro-esphageal reflux

Instruments for thermally-mediated treatment of a patient's lower esophageal sphincter (LES) to induce an injury healing response to thereby populate the extracellular compartment of walls of the LES with collagen matrices to altere the biomechanics of the LES to provide an increased intra-esophageal pressure for preventing acid reflux. A preferred embodiment is a bougie-type device for trans-esophageal introduction that carries conductive electrodes for delivering Rf energy to walls of the LES (i) to induce the injury healing response or (ii) to "model" collagenous tissues of the LES by shrinking collagen fibers therein. Typically, an Rf source is connected to at least one conductive electrode that may be operated in a mono-polar or bi-polar fashion. A sensor array of individual sensors is provided in the working end. A computer controller is provided, which together with feedback circuitry, is capable of full process monitoring and control of: (i) power delivery; (ii) parameters of a selected therapeutic cycle, (iii) mono-polar or bi-polar energy delivery, and (iv) multiplexing of current flow between various paired electrodes. The controller can determine when the treatment is completed based on time, temperature, tissue impedance or any combination thereof.

Owner:MEDERI RF LLC

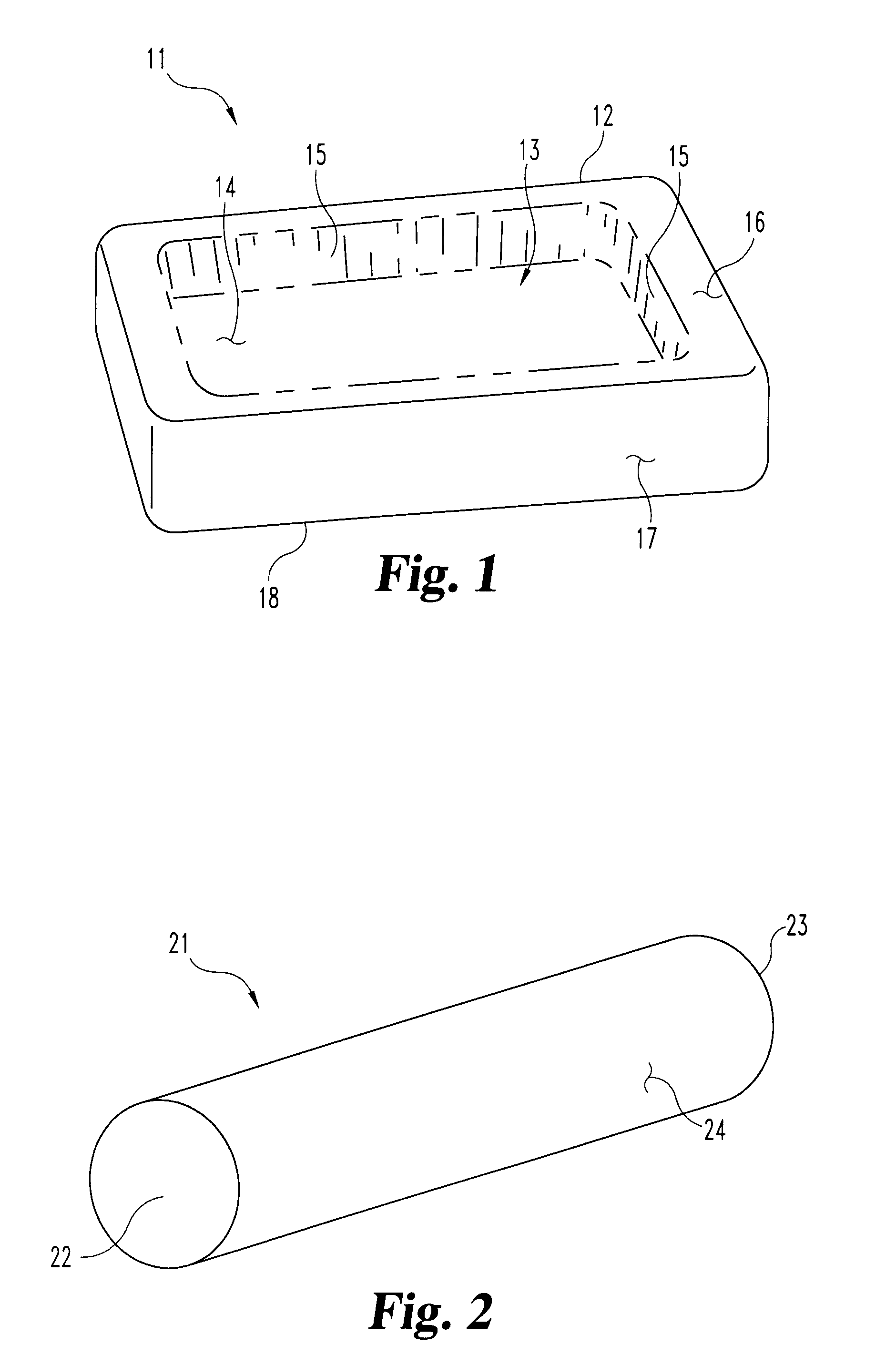

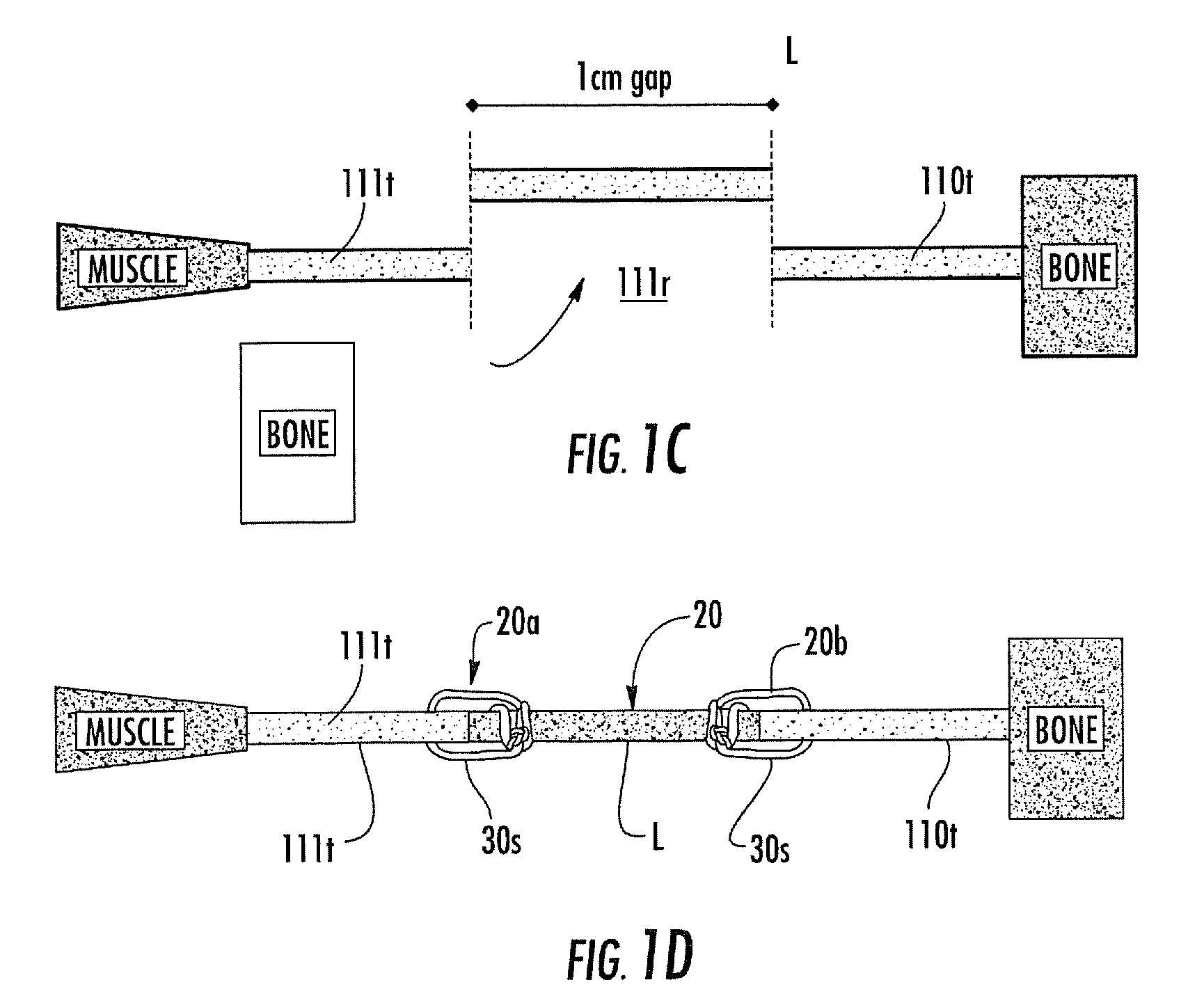

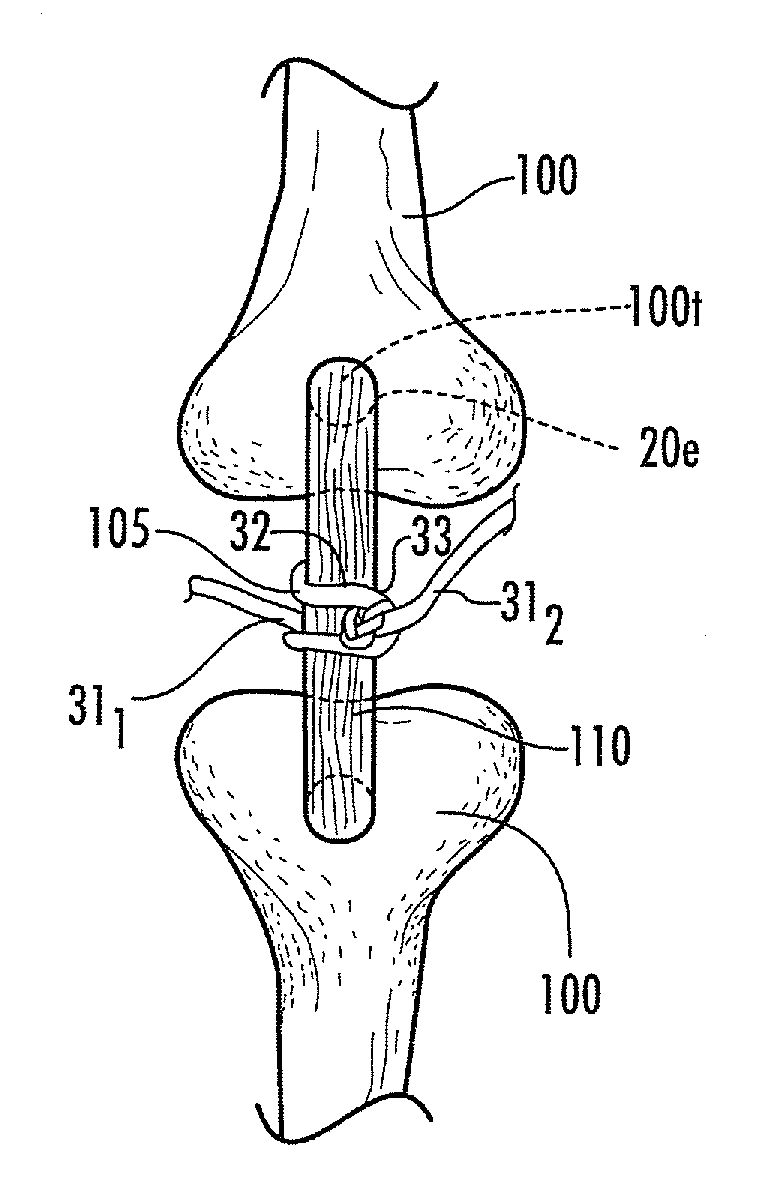

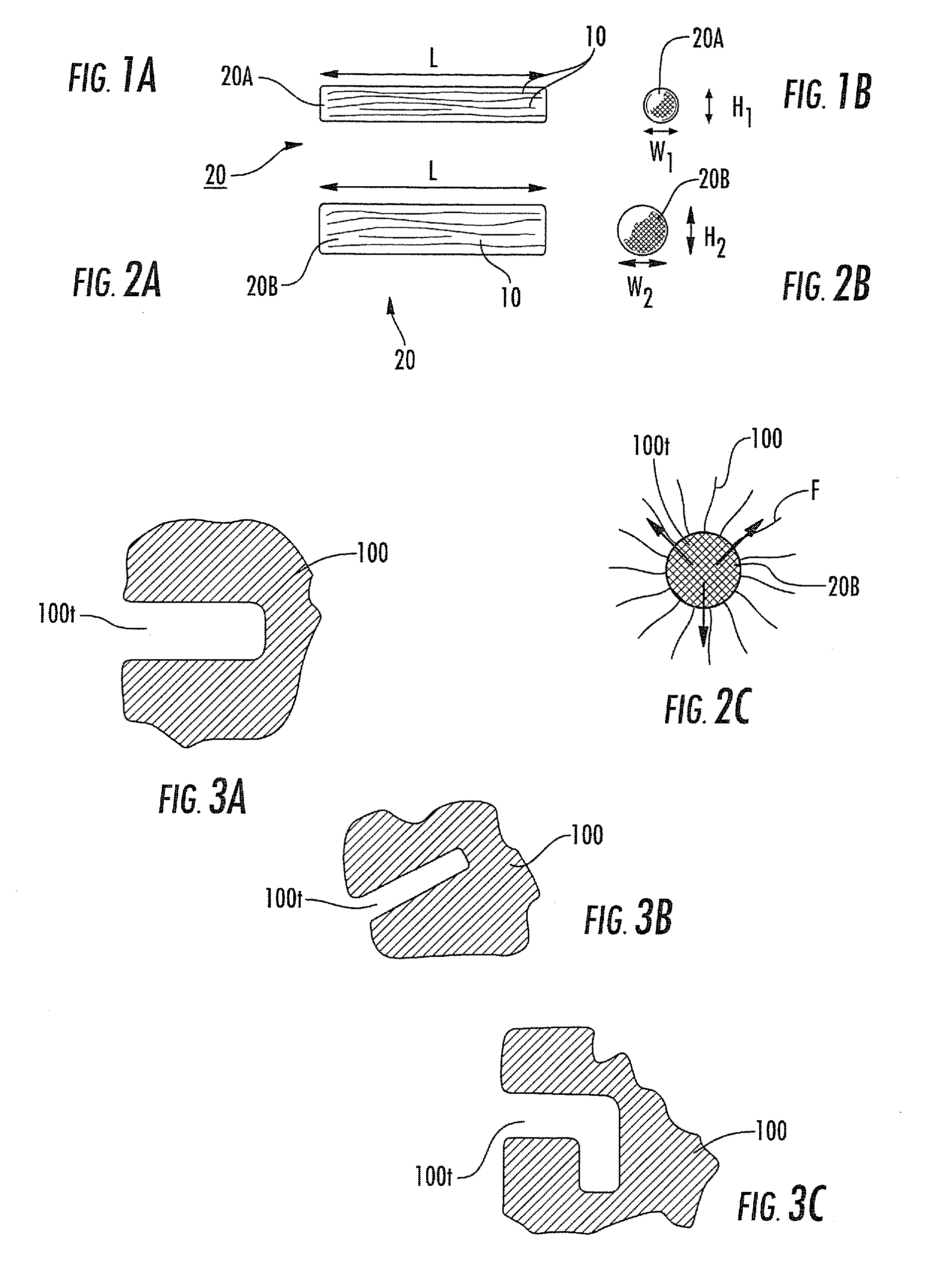

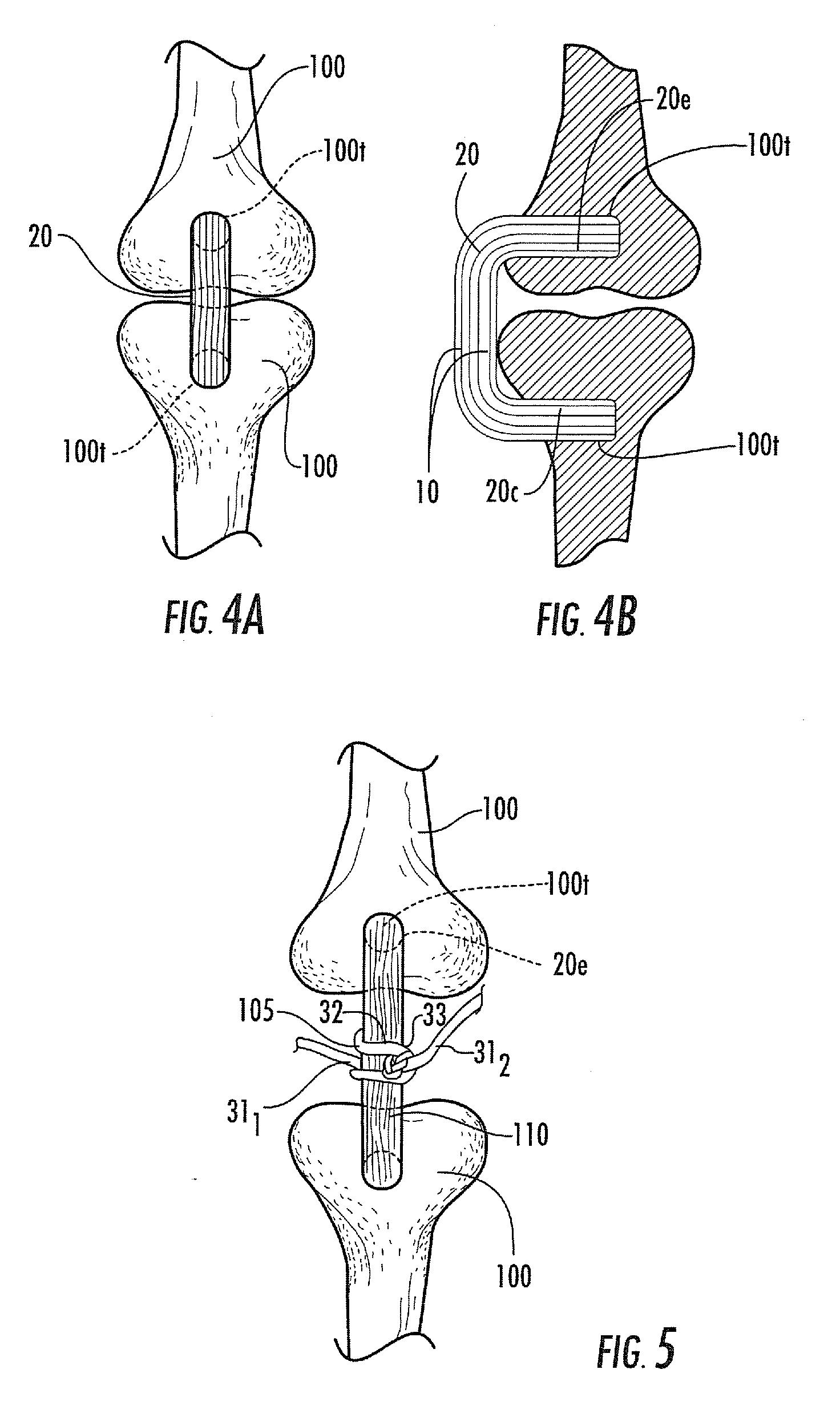

Tendon or ligament bioprostheses and methods of making same

The disclosure describes implantable bioprosthesis having an implantable construct with a multi-fiber array of collagen fibers attached together.

Owner:SHRINERS HOSPITALS FOR CRIPPLED CHILDREN

Method for organizing the assembly of collagen fibers and compositions formed therefrom

InactiveUS7354627B2Stable supportMonocomponent protein artificial filamentLiquid surface applicatorsFiberCollagen fiber

The present invention provides a protein polymer material and a method for preparing the protein polymer material involving applying an energy such as electrical energy or gravitational energy to a protein to cause the protein to assemble in a controlled arrangement. The protein used in this method may be any suitable fibrillar protein capable of self-assembling.

Owner:DEPUY PROD INC

In vivo hydraulic fixation including bio-rivets using biocompatible expandable fibers

The disclosure describes implantable medical products, that include dry or partially hydrated biocompatible constructs comprising collagen fibers configured to expand in situ after implantation to frictionally engage a bone tunnel wall to thereby affix the construct in the bone tunnel.

Owner:SHRINERS HOSPITALS FOR CRIPPLED CHILDREN

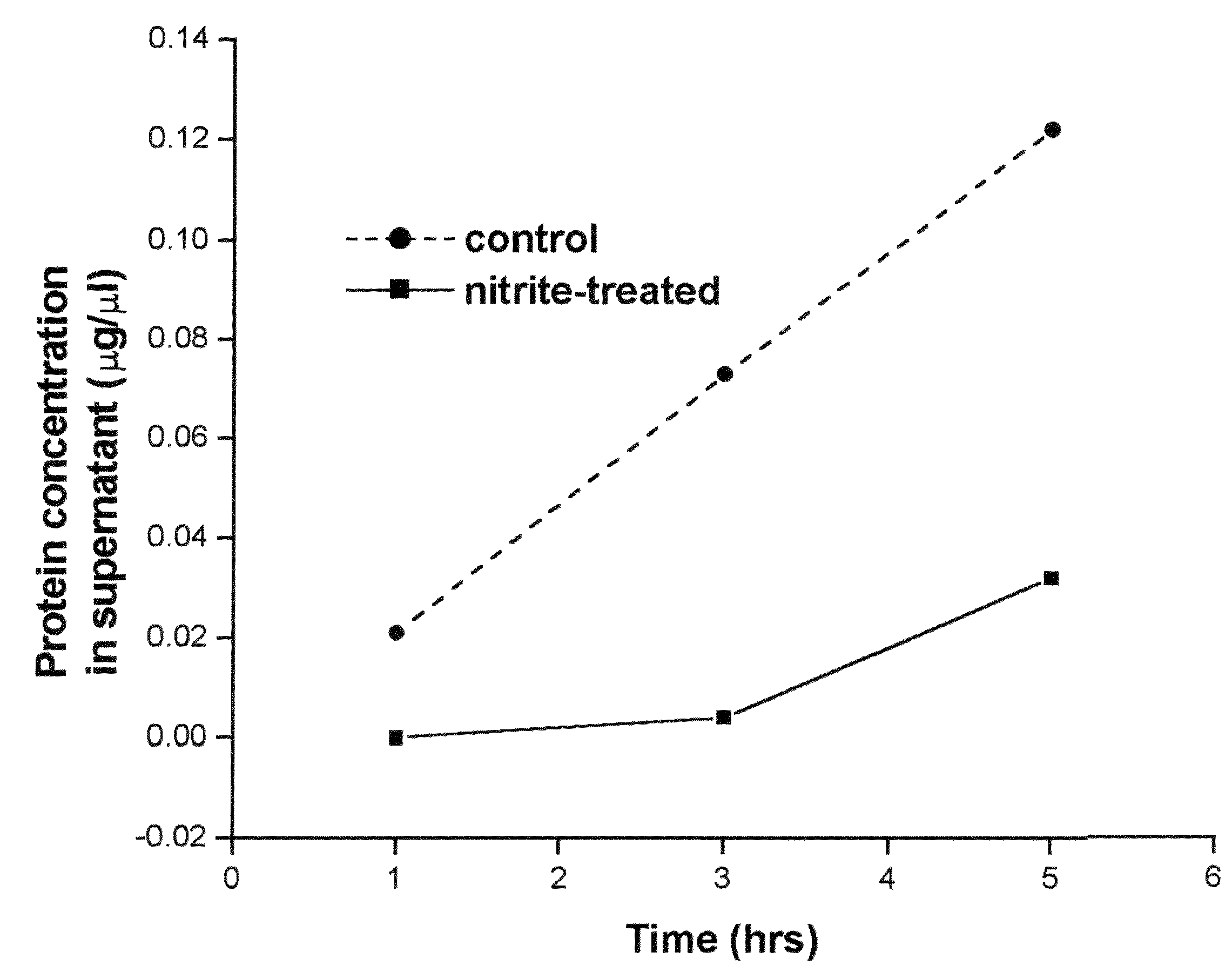

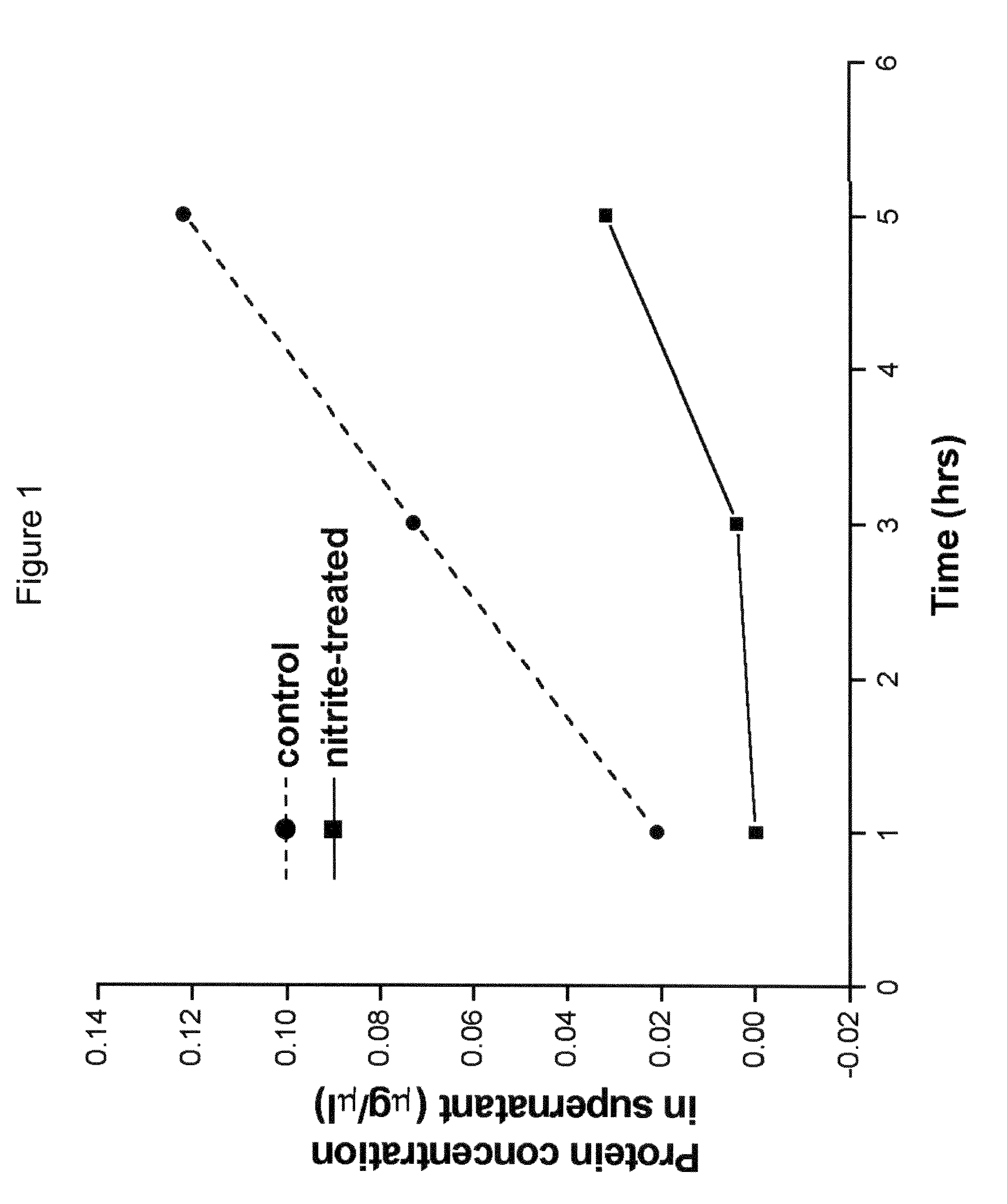

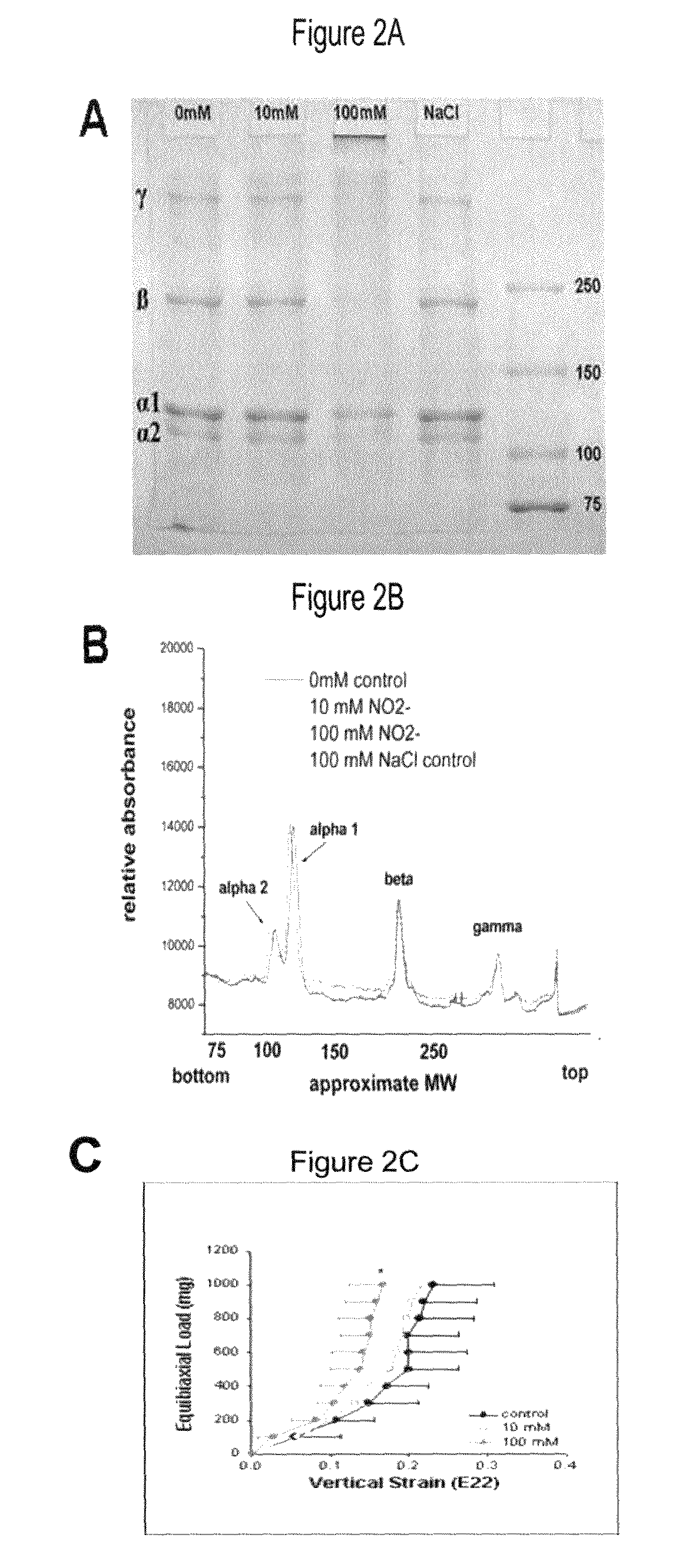

Method of stabilizing human eye tissue by reaction with nitrite and related agents such as nitro compounds

A method for stabilizing collagenous eye tissues by nitrite and nitroalcohol treatment. The topical stiffening agent contains sodium nitrite or a nitroalcohol in a buffered balanced salt solution and can be applied to the surface of the eye on a daily basis for a prolonged period. Application of the solution results in progressive stabilization of the corneal and scleral tissues through non-enzymatic cross-linking of collagen fibers. The compounds can penetrate into the corneal stroma without the need to remove the corneal epithelium. In addition, ultraviolet light is not needed to activate the cross-linking process. The resulting stabilization of corneal and scleral tissues can prevent future alterations in corneal curvature and has utility in diseases such as keratoconus, keratectasia, progressive myopia, and glaucoma.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

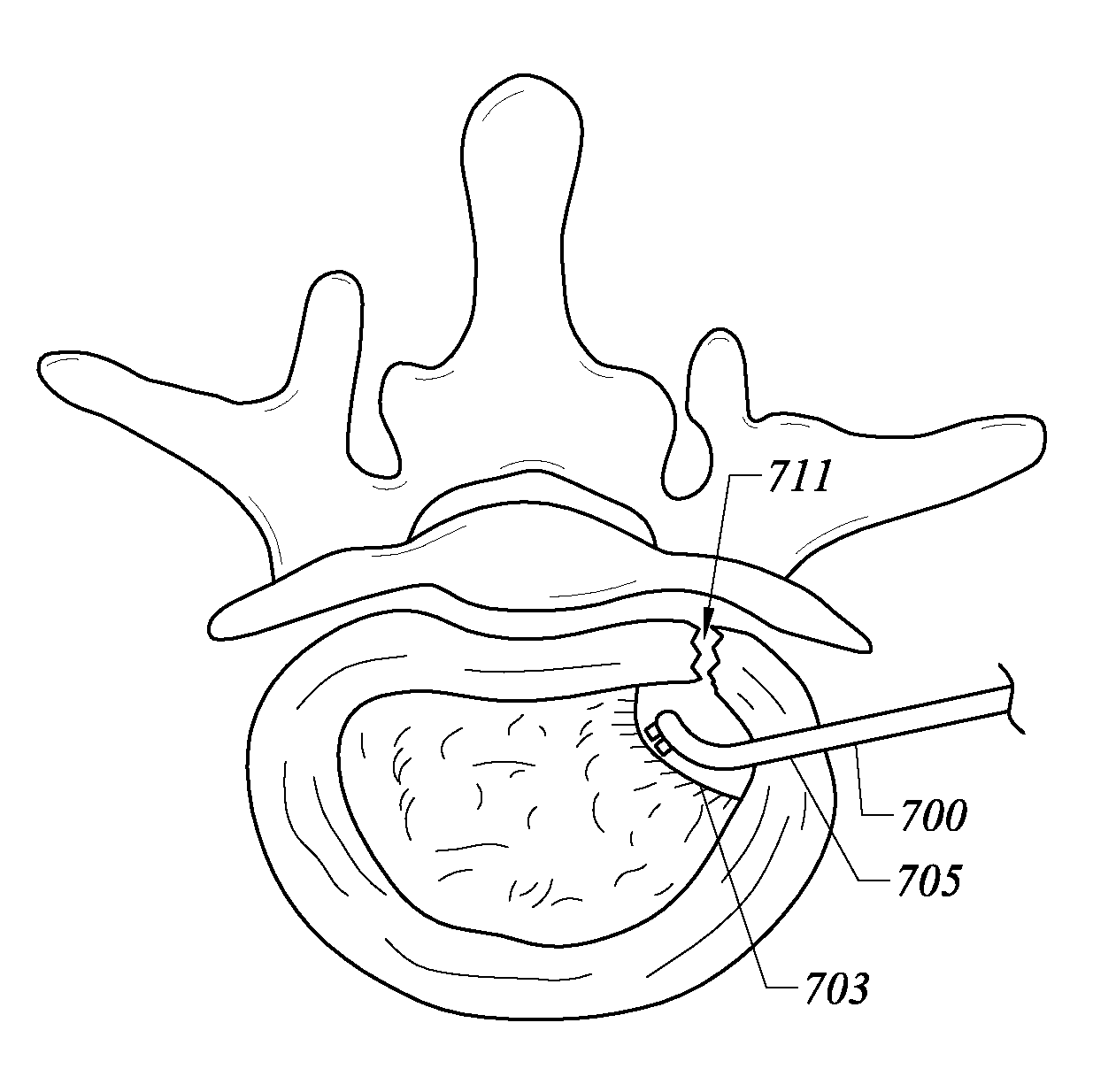

Systems and methods for electrosurgical intervertebral disc replacement

InactiveUS7794456B2Minimize damage and necrosisPrecisely and quickly removingCannulasEnemata/irrigatorsFiberIntervertebral disc

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid or saline-rich tissue to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for contracting a portion of the nucleus pulposus of a vertebral disc by applying a high frequency voltage between an active electrode and a return electrode within the portion of the nucleus pulposus, where contraction of the portion of nucleus pulposus inhibits migration of the portion nucleus pulposus through the fissure.

Owner:ARTHROCARE

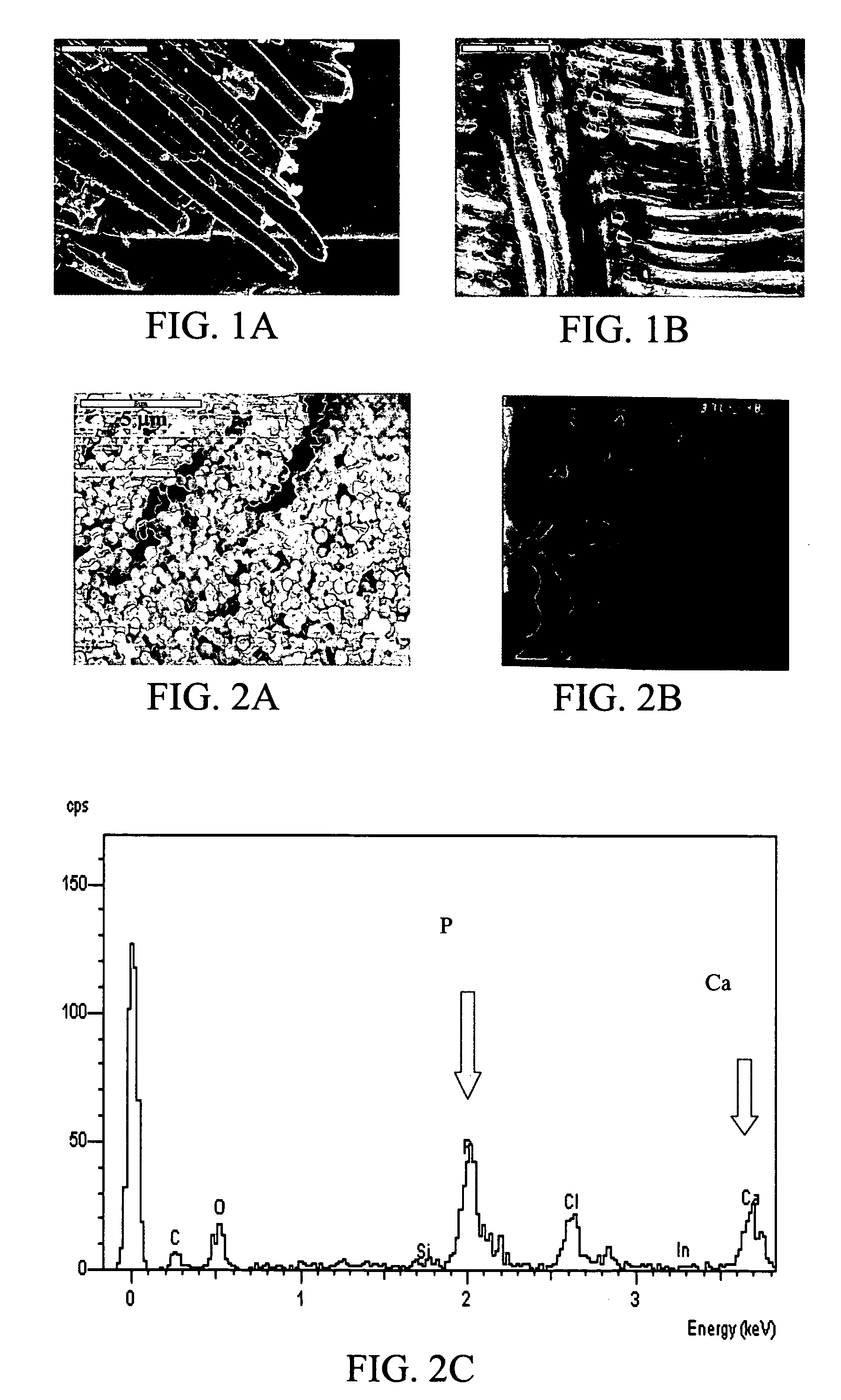

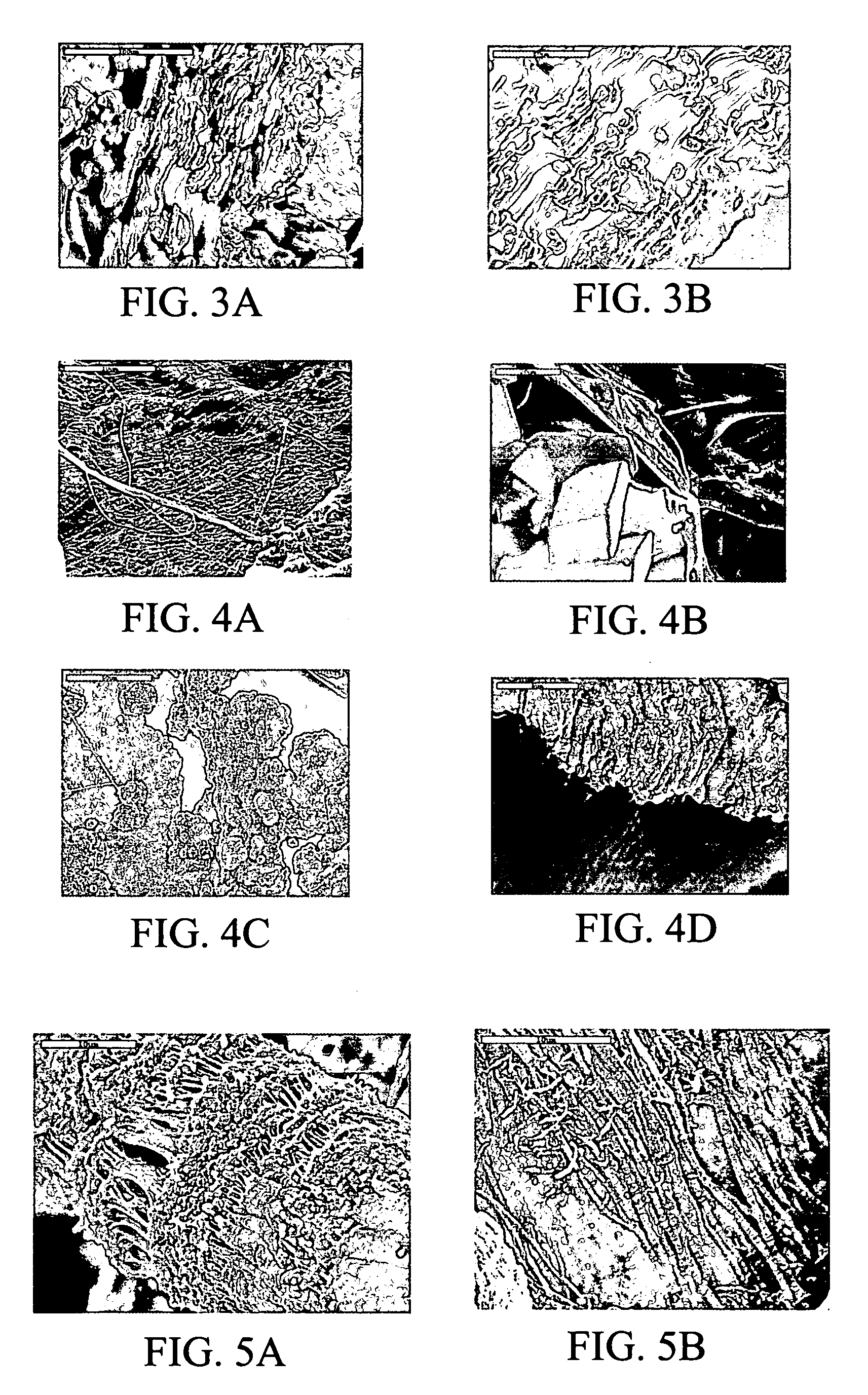

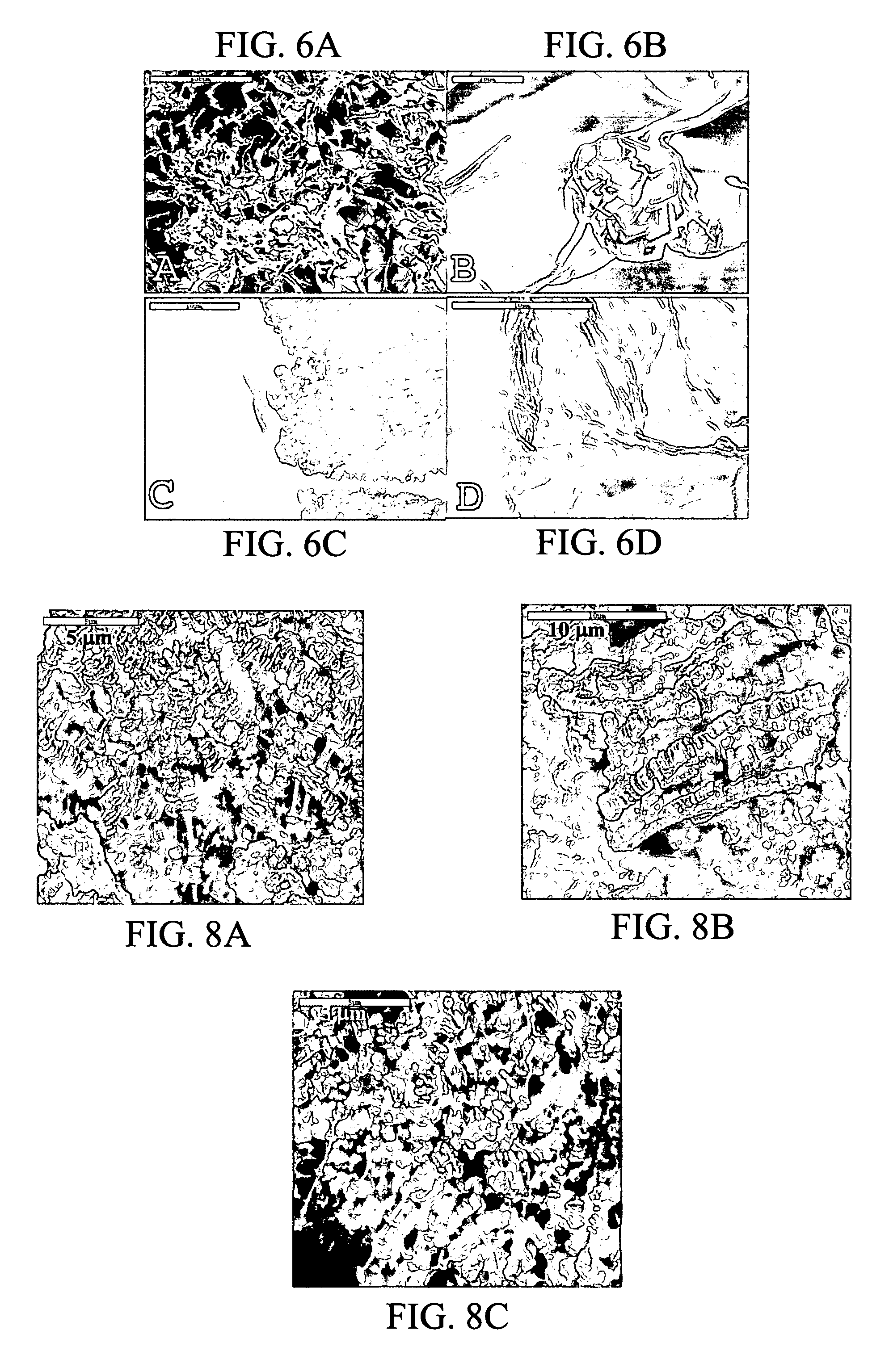

Biomimetic organic/inorganic composites, processes for their production, and methods of use

The subject invention concerns a composite comprising an organic fluid-swellable, fibrous matrix, such as collagen, and a mineral phase, such as calcium carbonate or phosphate mineral phase, for use as a biomimetic of bone. In another aspect, the subject invention concerns a process for making a composite involving the inclusion of acidic polymers to a supersaturated mineralizing solution, in order to induce an amorphous liquid-phase precursor to the inorganic mineral, which is then absorbed (pulled by capillary action) into the organic matrix. Advantageously, once solidified, a high mineral content can be achieved, with the inorganic mineral crystals embedded within the collagen fibers (intrafibrillarly) and oriented such that they are aligned along the long axes of the fibers of the organic matrix, thereby closely mimicking the natural structure of bone. The present invention further concerns a method of treating a patient suffering from a bone defect by applying a biomimetic composite to the bone defect site.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Biostaples suitable for wrist, hand and other ligament replacements or repairs

The disclosure describes implantable medical products, that include dry or partially hydrated biocompatible biostaples suitable for ligament repairs or replacements comprising collagen fibers that may be configured to expand in situ after implantation to frictionally engage a bone tunnel wall or bone sleeve to thereby affix the construct in the bone tunnel.

Owner:MIMEDX GROUP

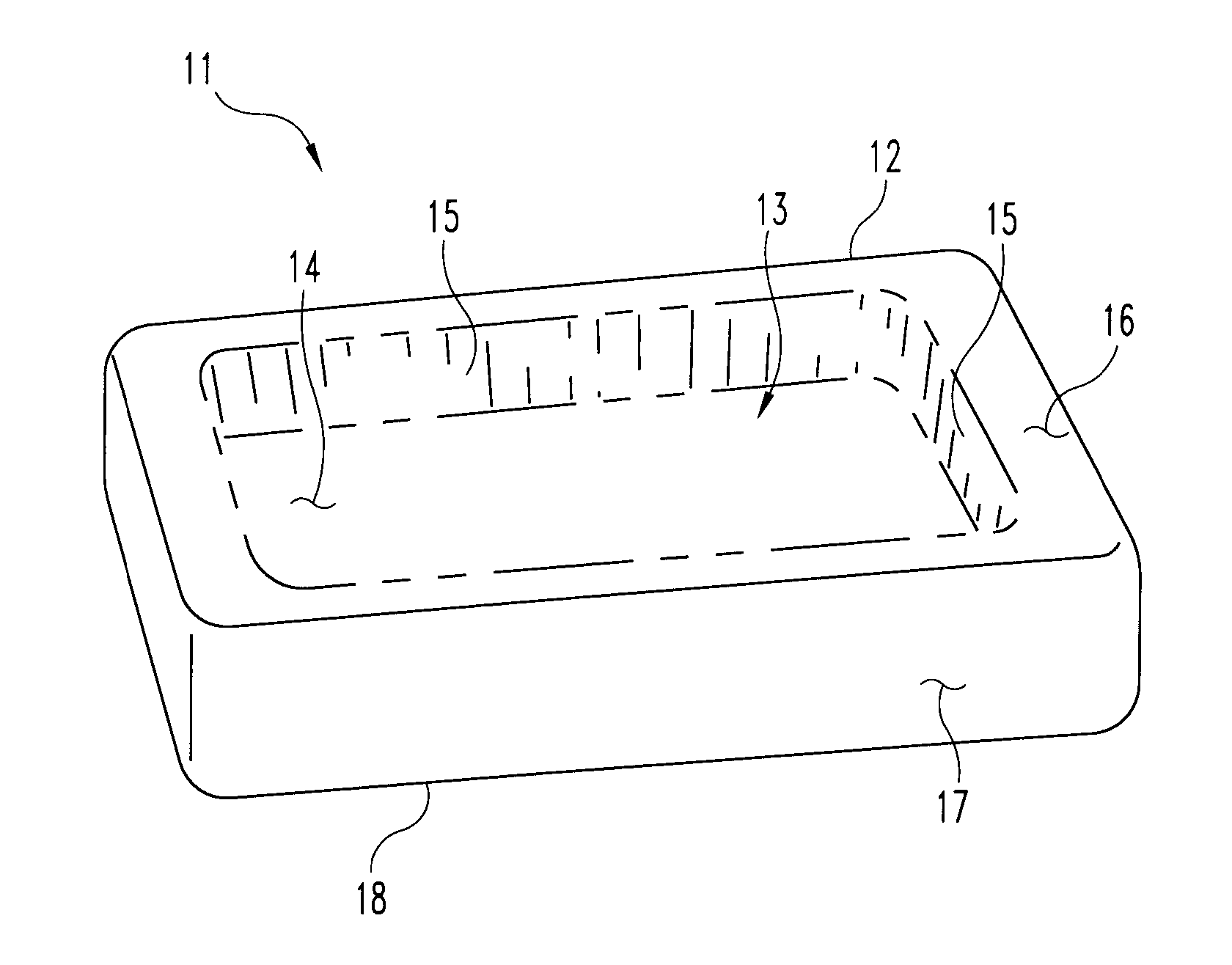

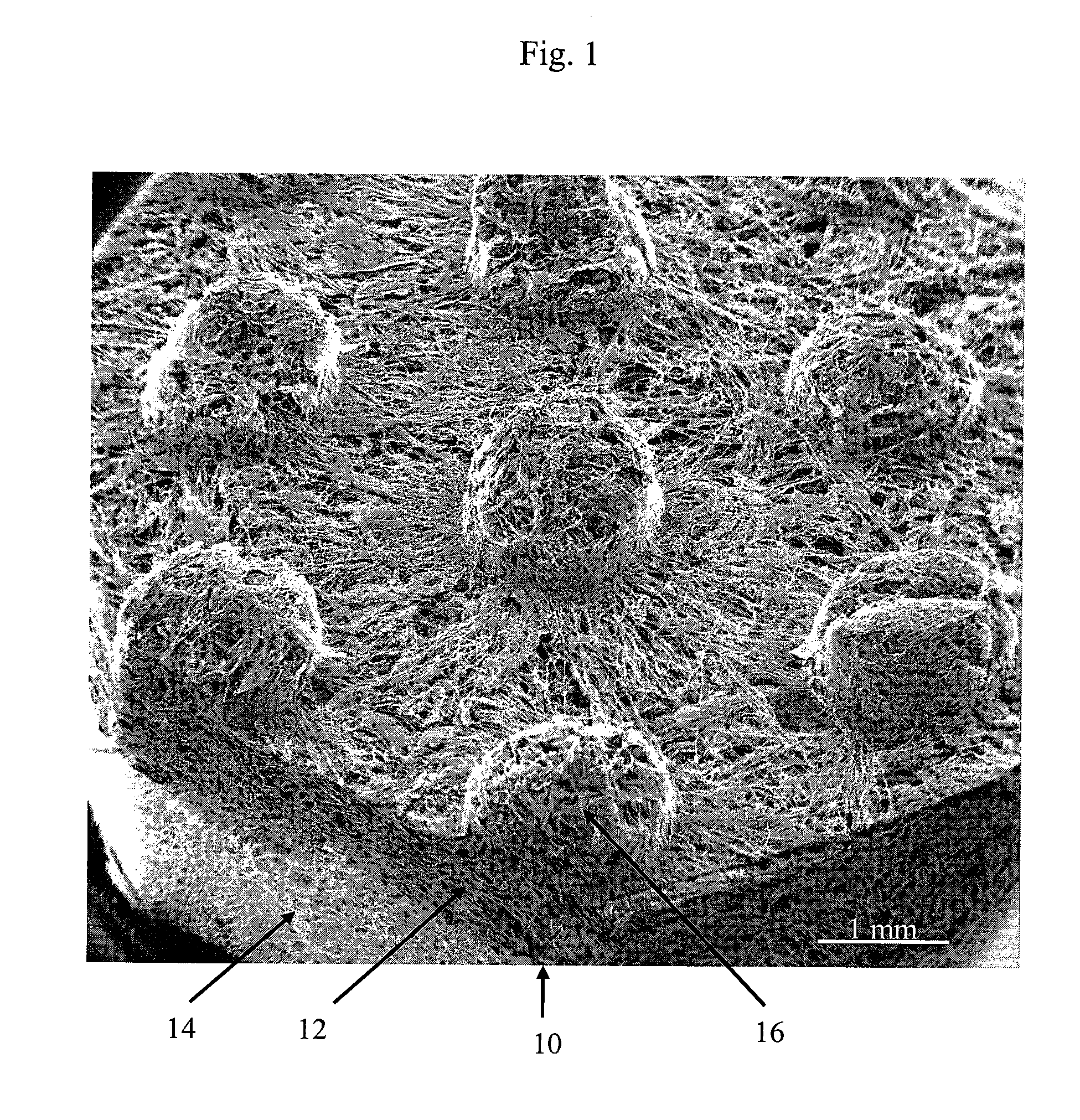

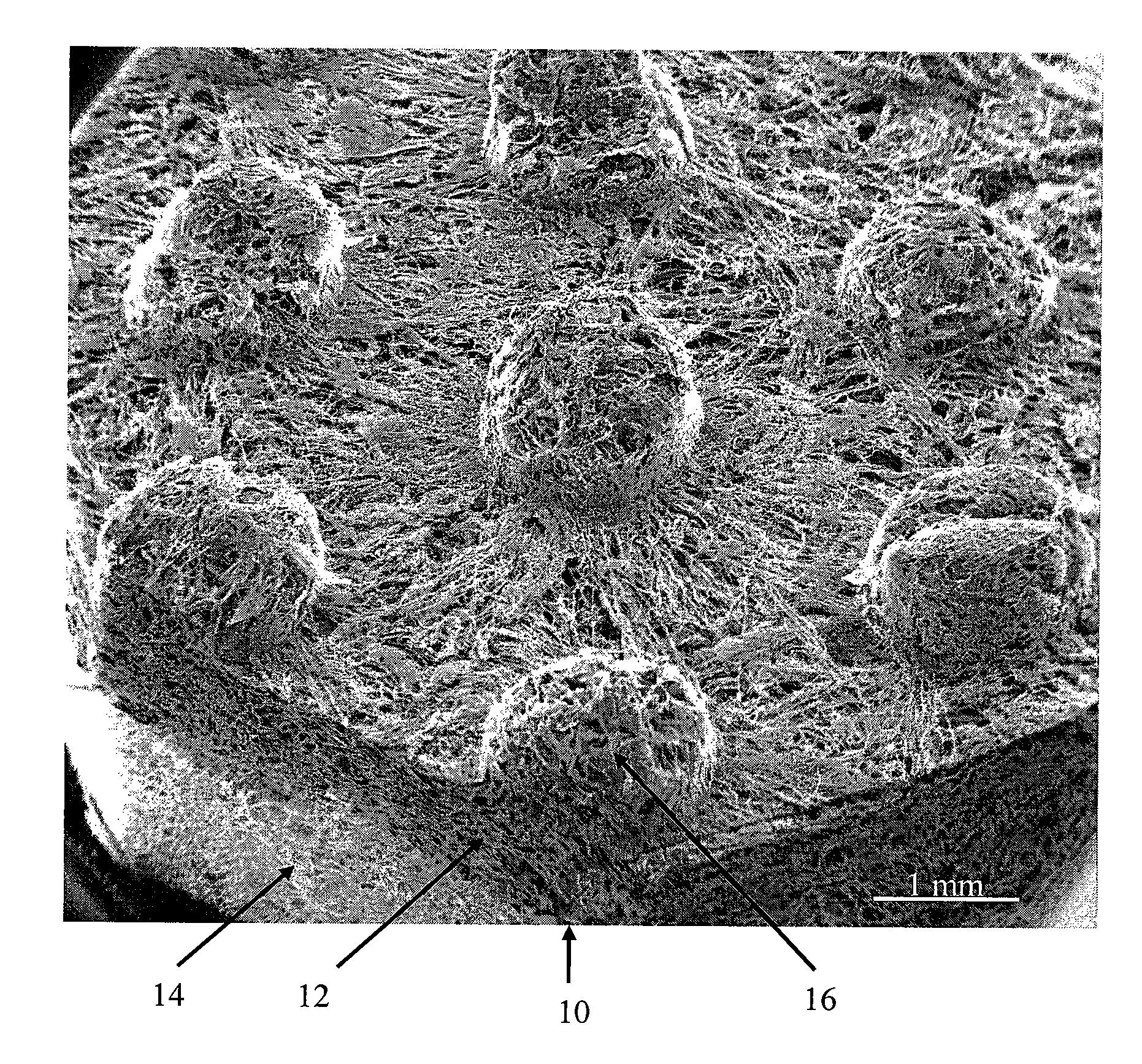

Suturable dural and meningeal repair product comprising collagen matrix

A matrix for tissue growth includes: (a) a first layer including a first assembly of collagen fibers; (b) a plurality of projections on a top surface of the first layer; and (c) a second layer bonded to a bottom portion of the first layer and including a second assembly of collagen fibers, wherein the second layer has a lower density than the first layer, and the matrix includes pores effective to support cell growth into the matrix. A method for providing the matrix is also described.

Owner:INTEGRA LIFESCI

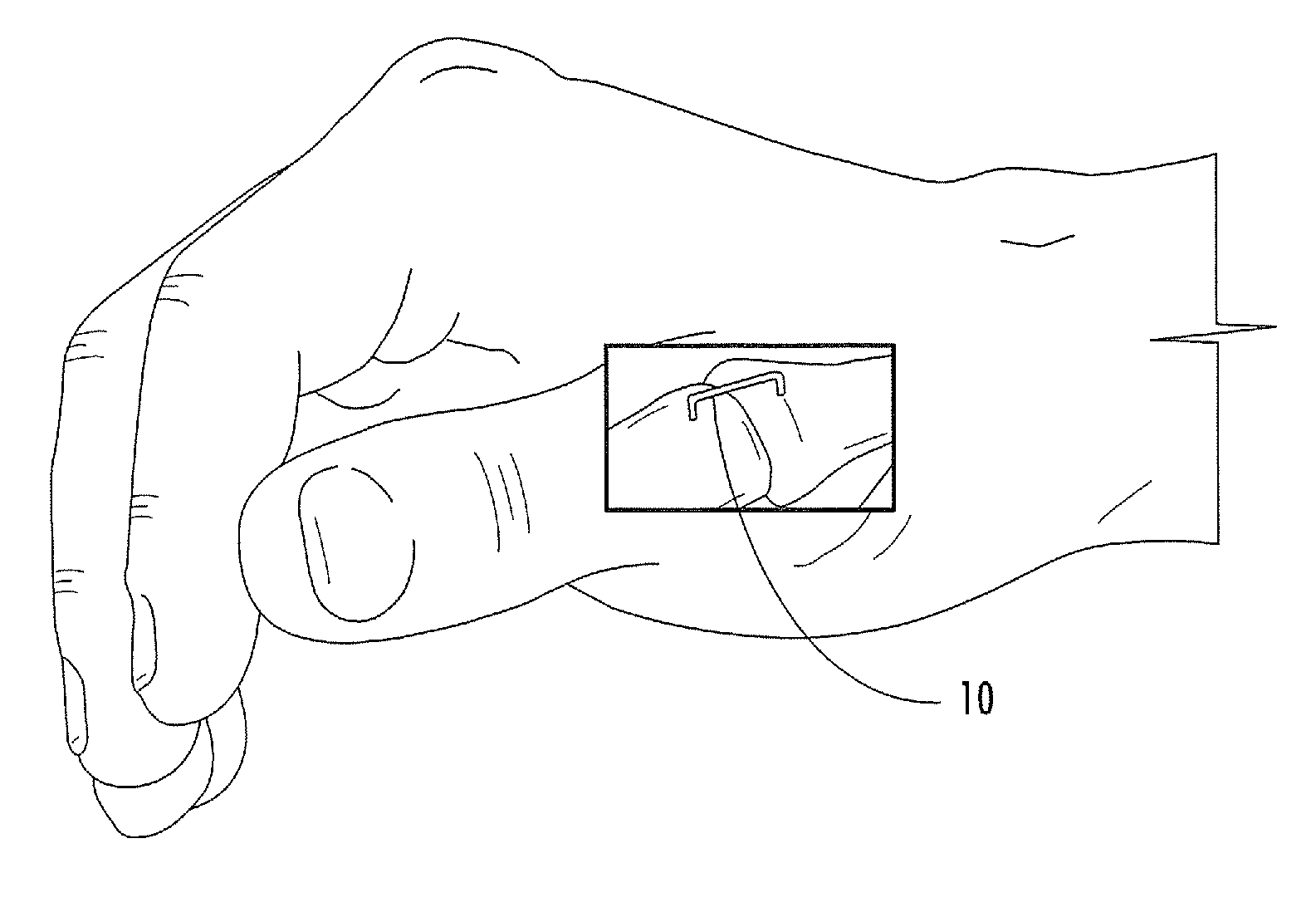

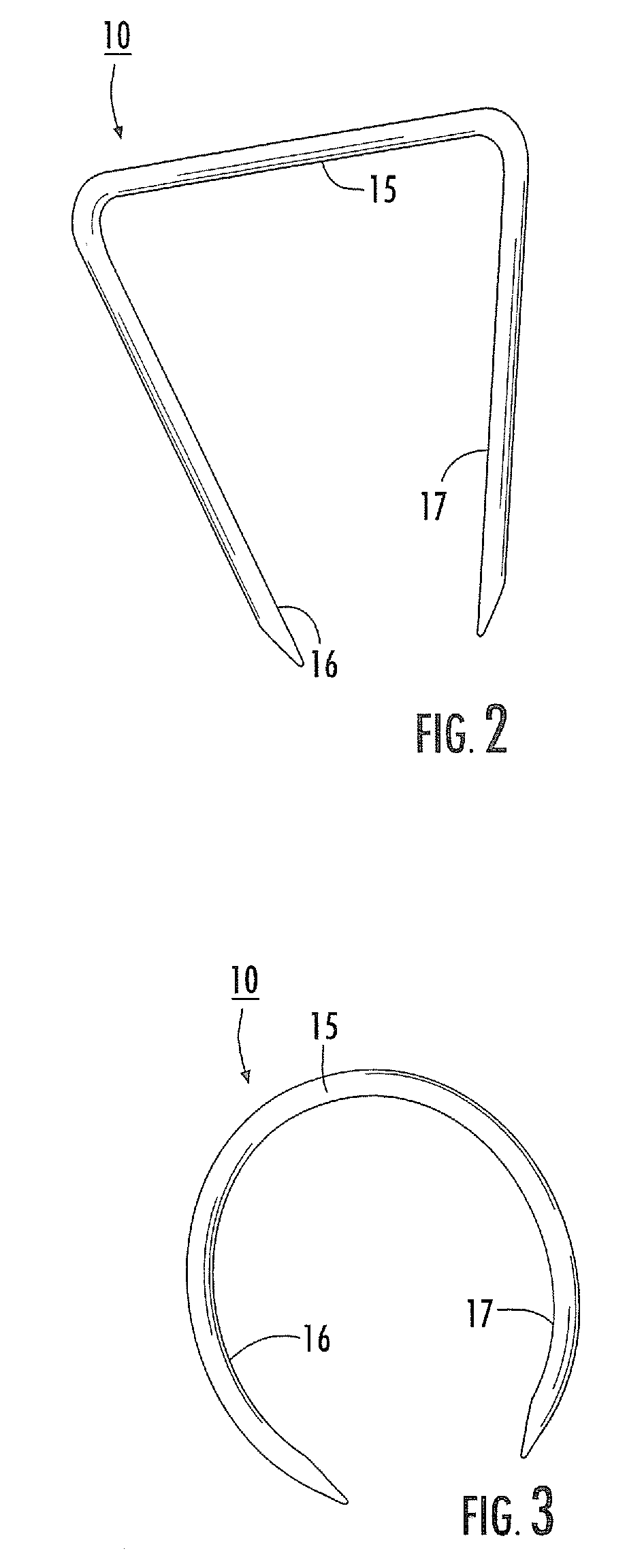

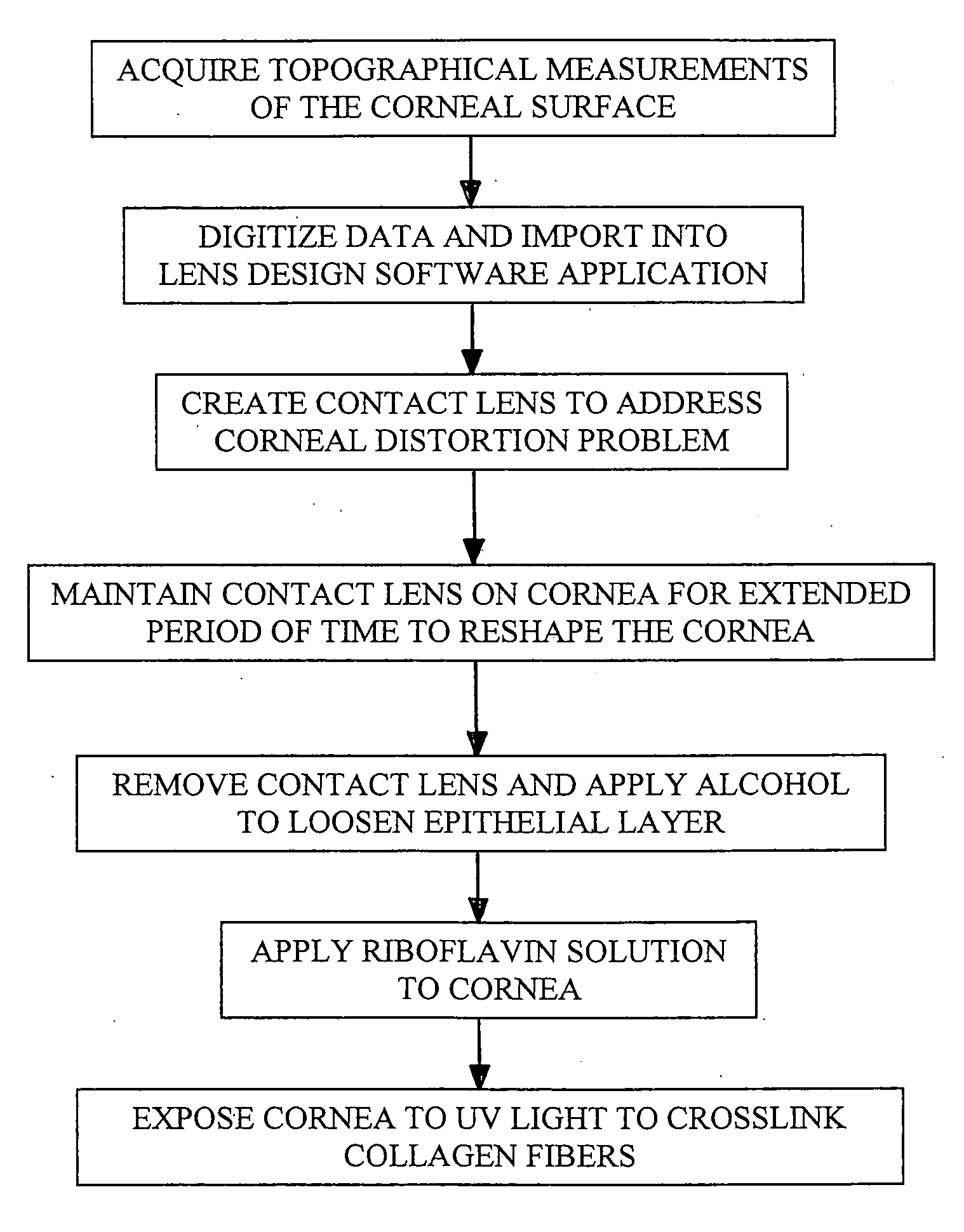

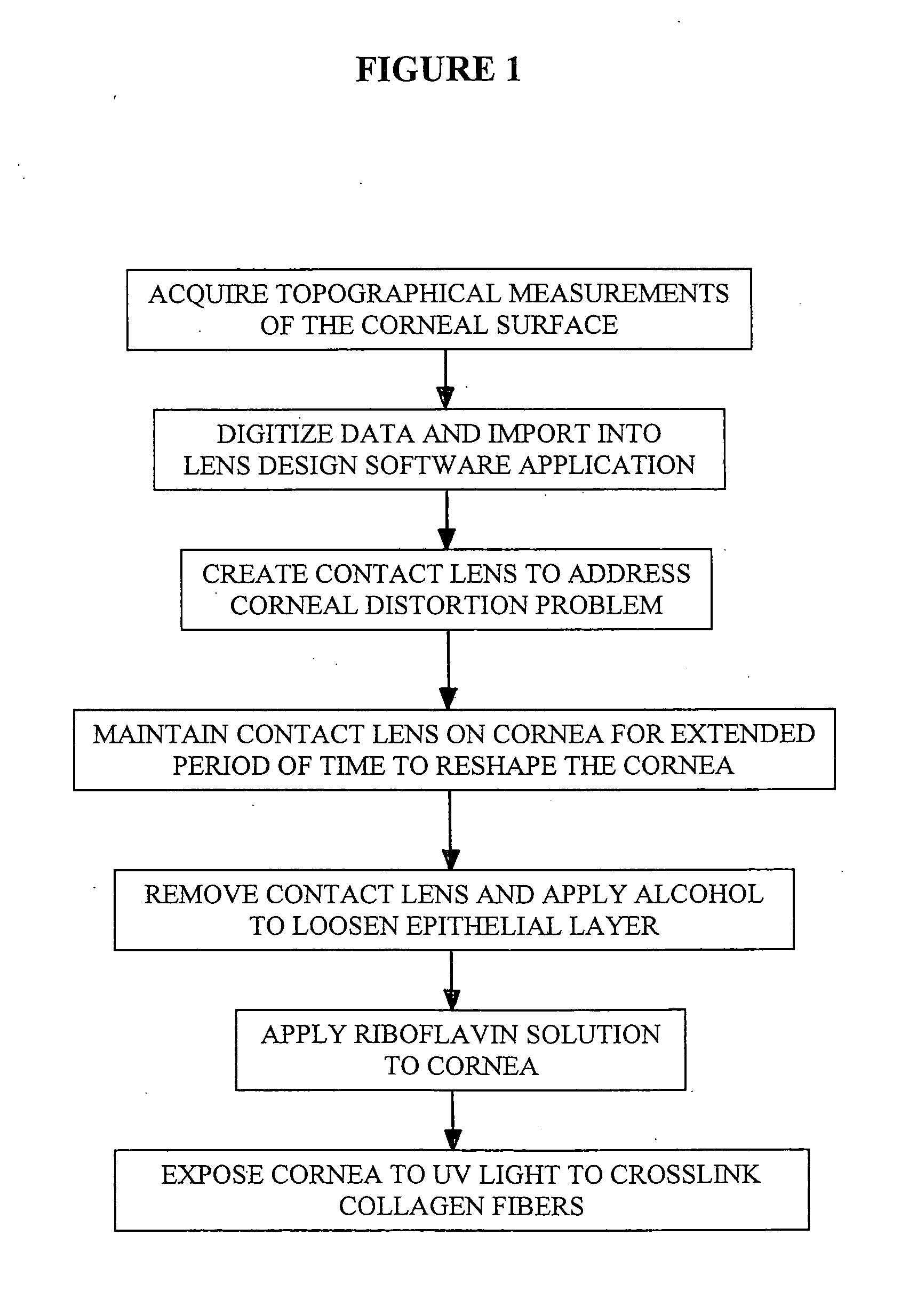

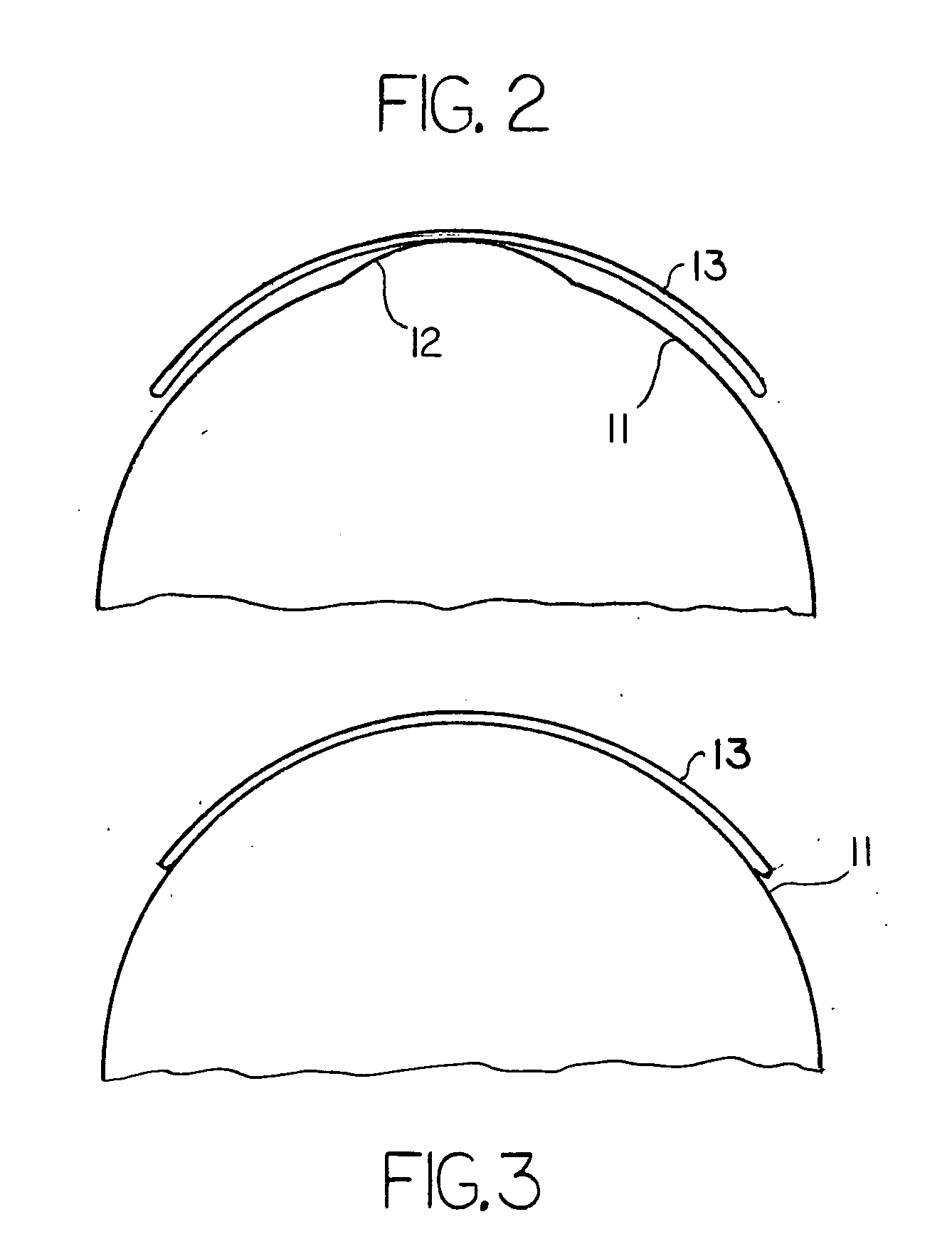

Method of improving vision using contact lenses and corneal collagen crosslinking

A method of improving vision by reshaping the cornea to correct for abnormal surface curvature by measuring the surface topography of the cornea, providing a rigid contact lens to reshape the cornea into a more desirable configuration, wearing the contact lens for sufficient time to achieve the reshaping, removing the contact lens, applying an alcohol solution to the epithelial layer, applying a riboflavin solution to the cornea, and subjecting the cornea to UV light for sufficient time to induce cross-linking of collagen fibers within the cornea, whereby the cornea is stabilized in the reshaped desirable configuration.

Owner:LEWIS SCOTT E +3

Suturable adhesion-preventing membrane

A suturable adhesion-preventing membrane has high suture strength, good biocompatibility, decomposition and absorption in a living body, sufficient adhesion-preventing effect, and desirable guided tissue regeneration. The membrane is composed of at least one non-woven fabric layer made of collagen fibers, or a laminated membranous substance consisting of at least one non-woven fabric layer made of collagen fibers and at least one sponge layer made of collagen, and a coating layer of gelatin or hyaluronic acid on the surface or surfaces of the above membrane. Preferably, the membrane comprises one to six compressed cross-linked collagen non-woven fabric layers wherein a layer has a fibers having a fiber diameter of 0.05 mm to 1.0 mm, a bulk density of 5.0×10−4 to 5 g / cm3 and a thickness of 0.1 mm to 50 mm, and a coating layer containing gelatin or hyaluronic acid and having a thickness of 0.05 mm to 20 mm, wherein the coating layer covers one or both sides or a part or whole of the surface of the membrane.

Owner:MATSUDA KAZUHISA

Suturable dural and meningeal repair product comprising collagen matrix

A matrix for tissue growth includes: (a) a first layer including a first assembly of collagen fibers; (b) a plurality of projections on a top surface of the first layer; and (c) a second layer bonded to a bottom portion of the first layer and including a second assembly of collagen fibers, wherein the second layer has a lower density than the first layer, and the matrix includes pores effective to support cell growth into the matrix. A method for providing the matrix is also described.

Owner:INTEGRA LIFESCI

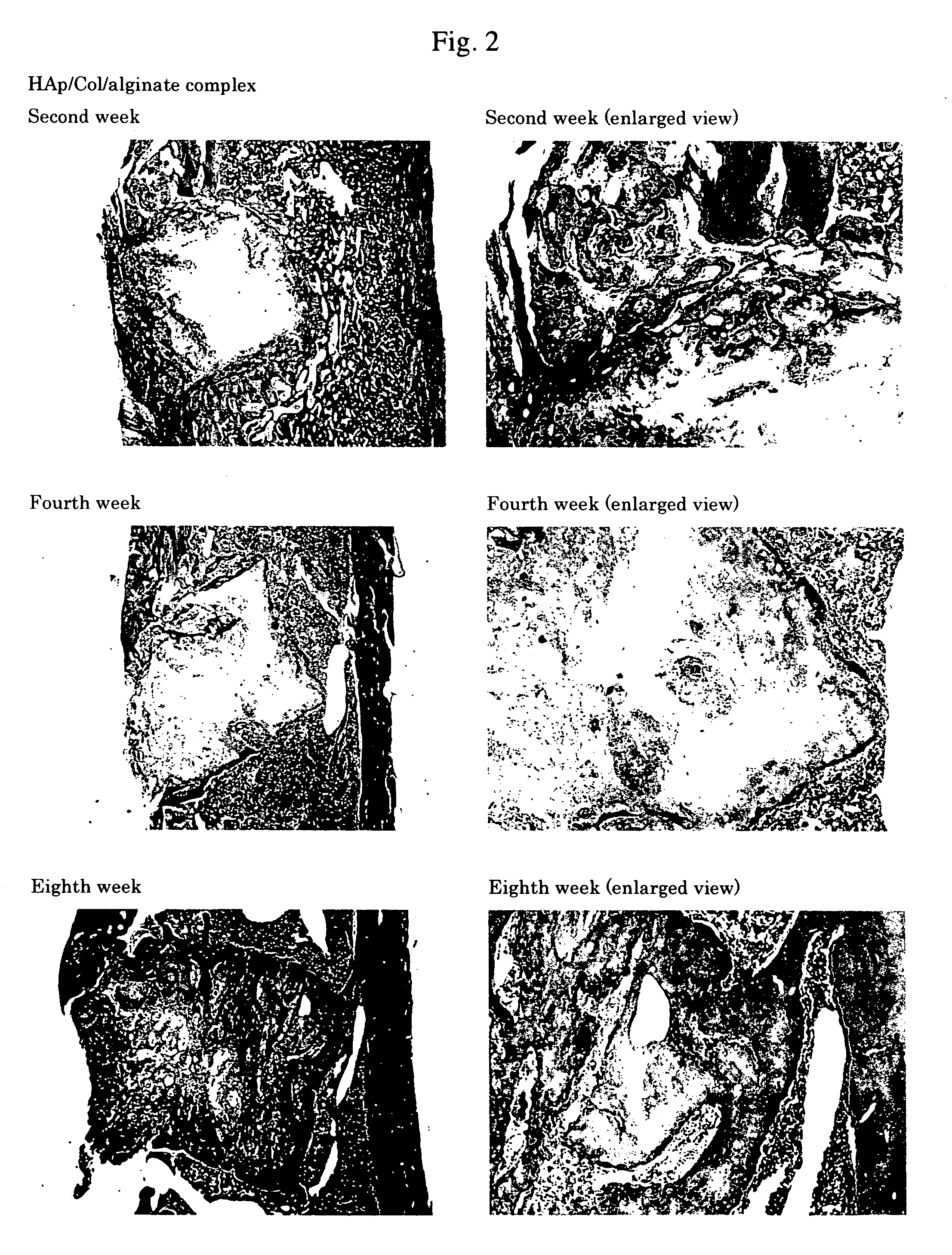

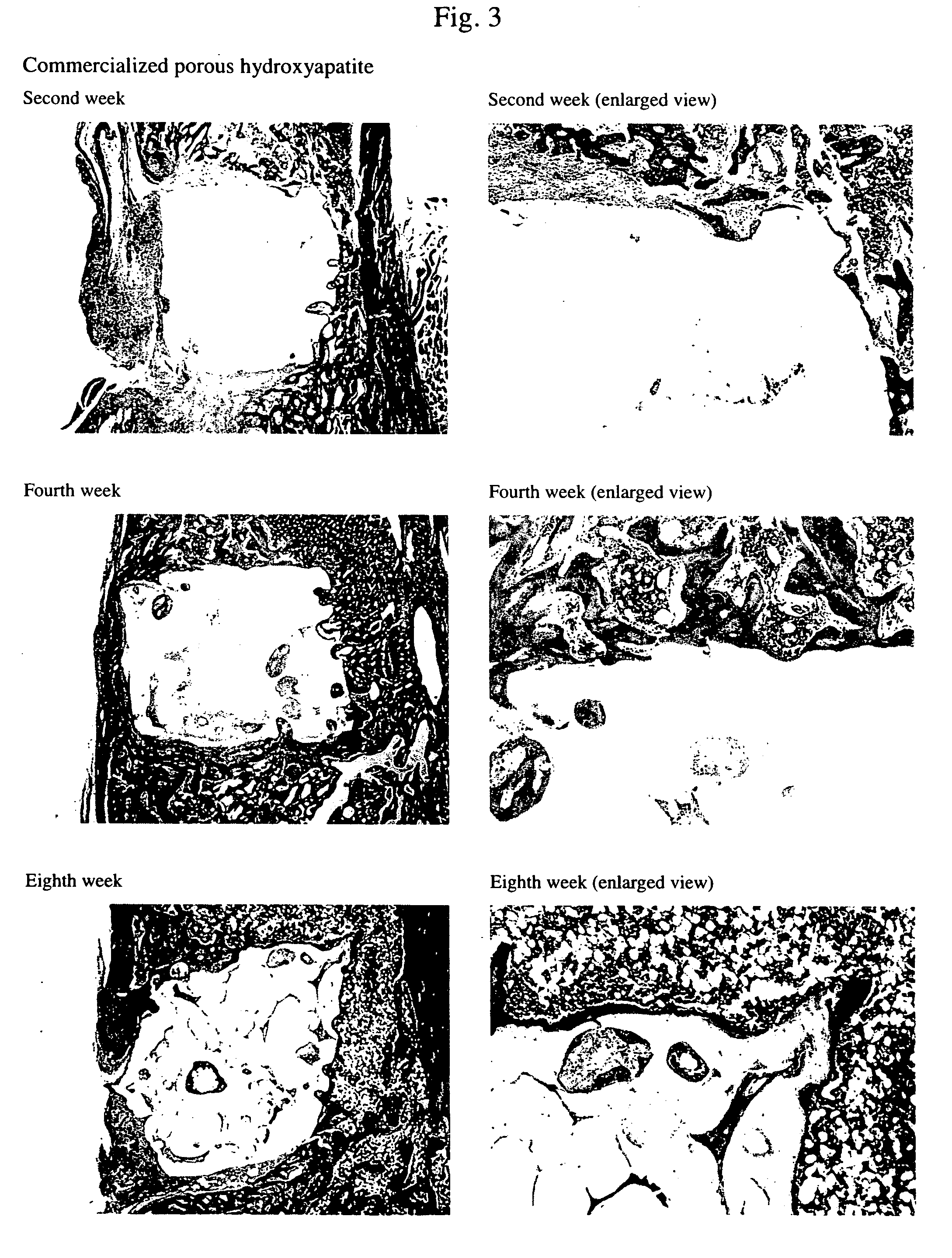

Composite biomaterials

InactiveUS20060172918A1Excellent bioadaptability and bone inductivityDecrease bone inductivity and strengthPhosphatesPeptide/protein ingredientsFiberApatite

Owner:NAT INST FOR MATERIALS SCI

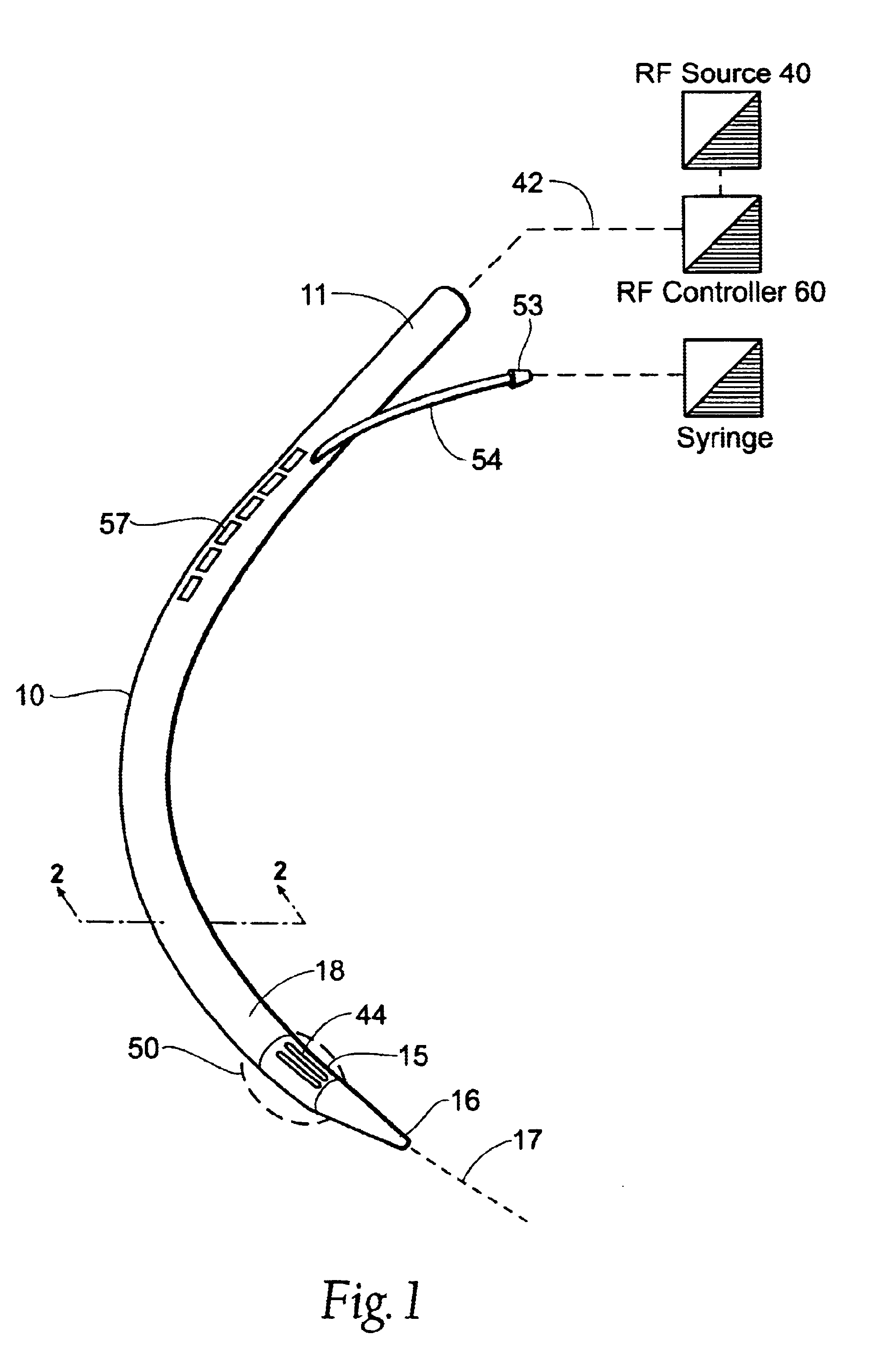

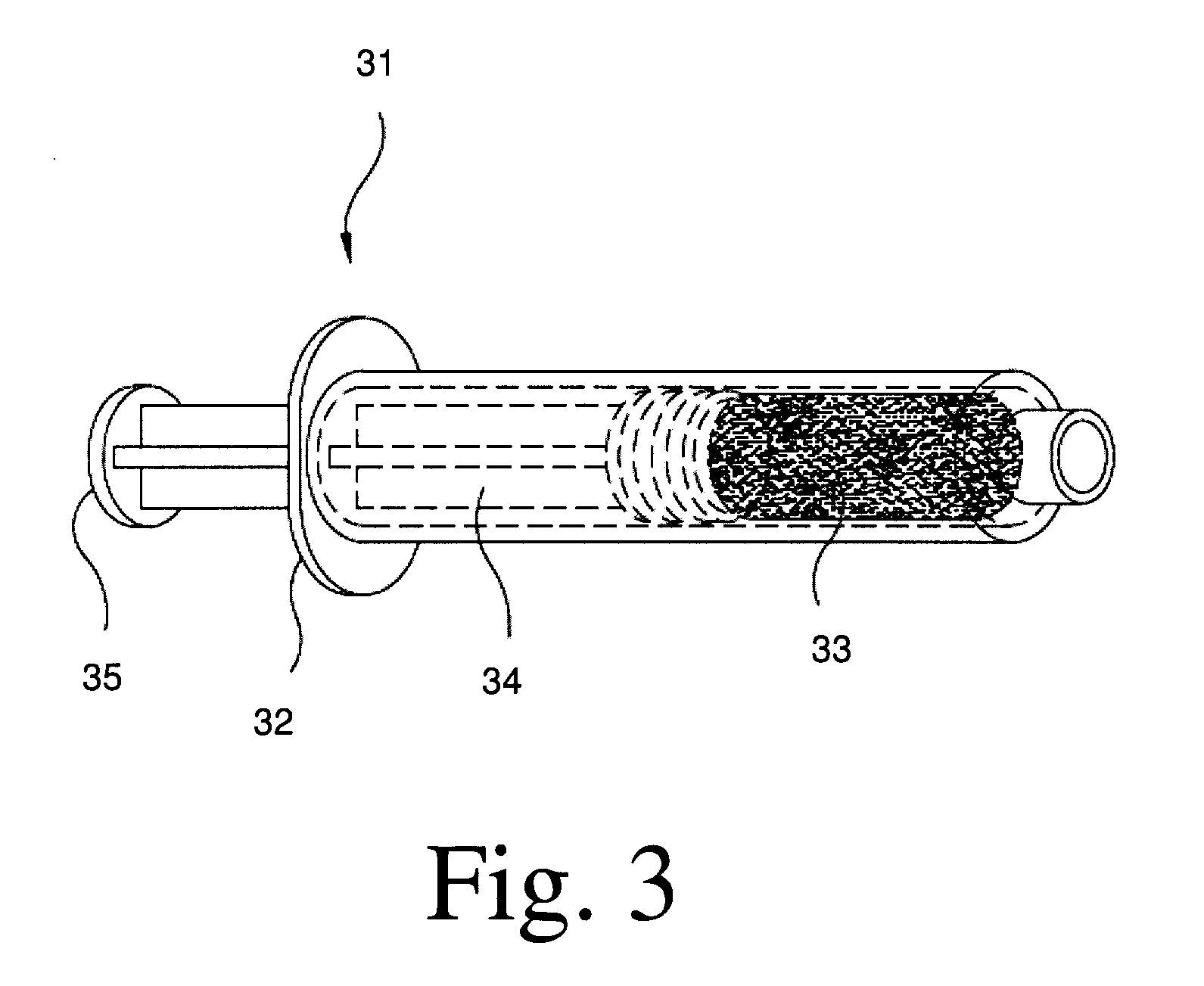

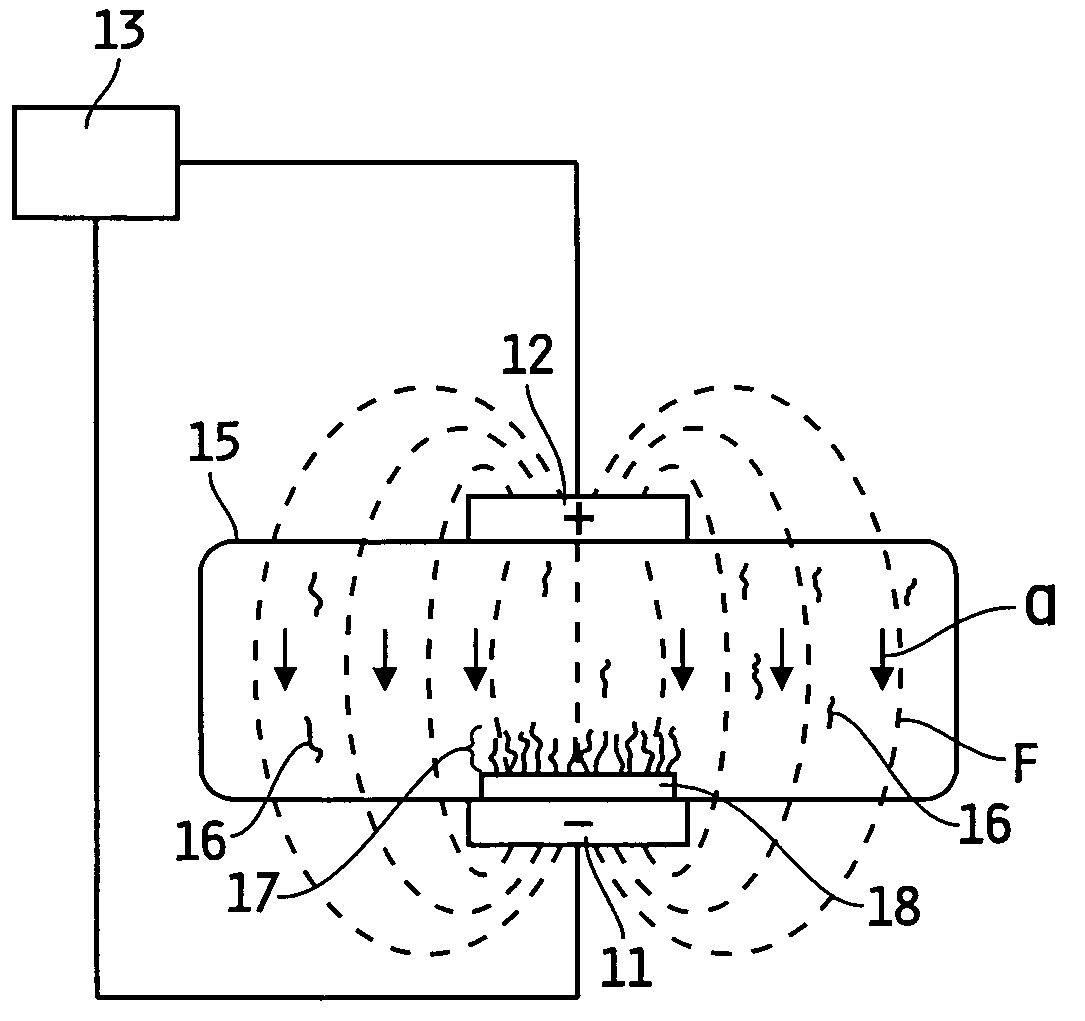

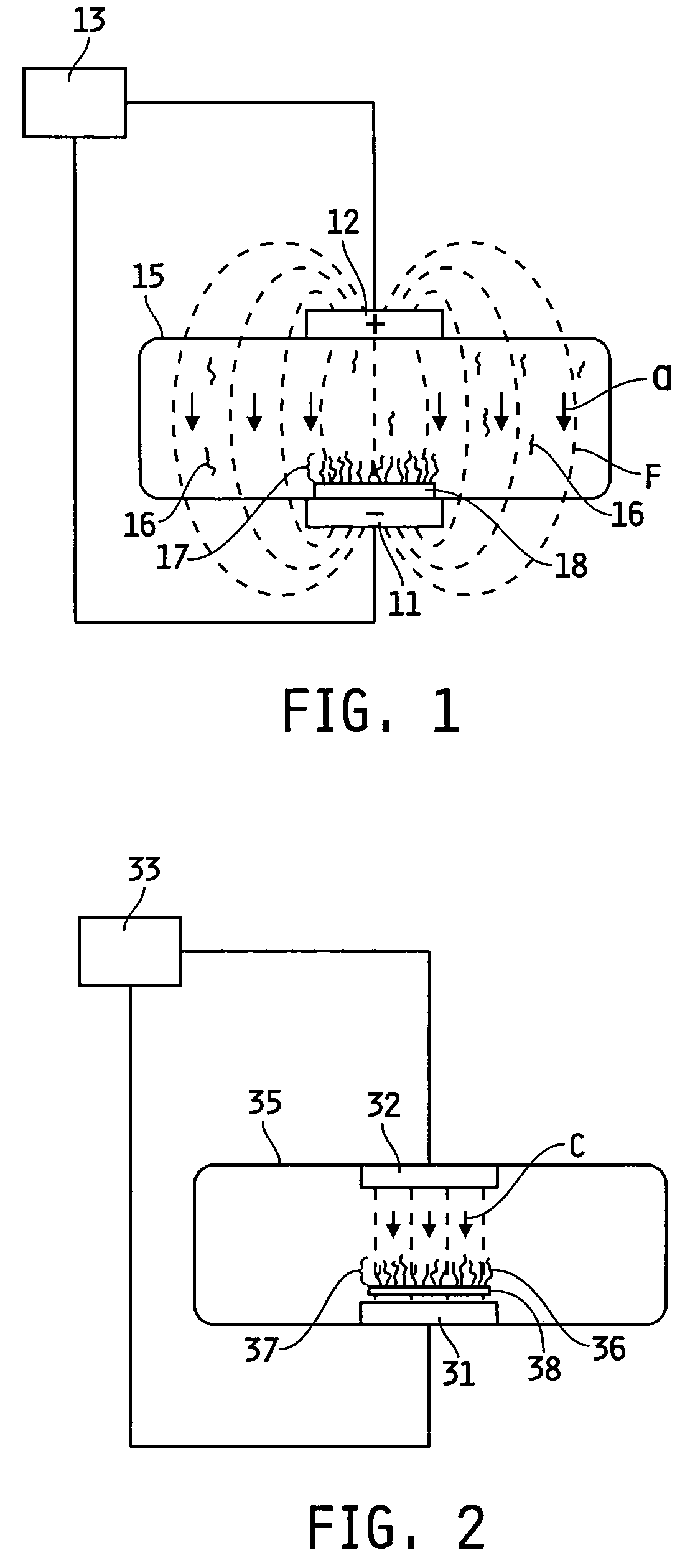

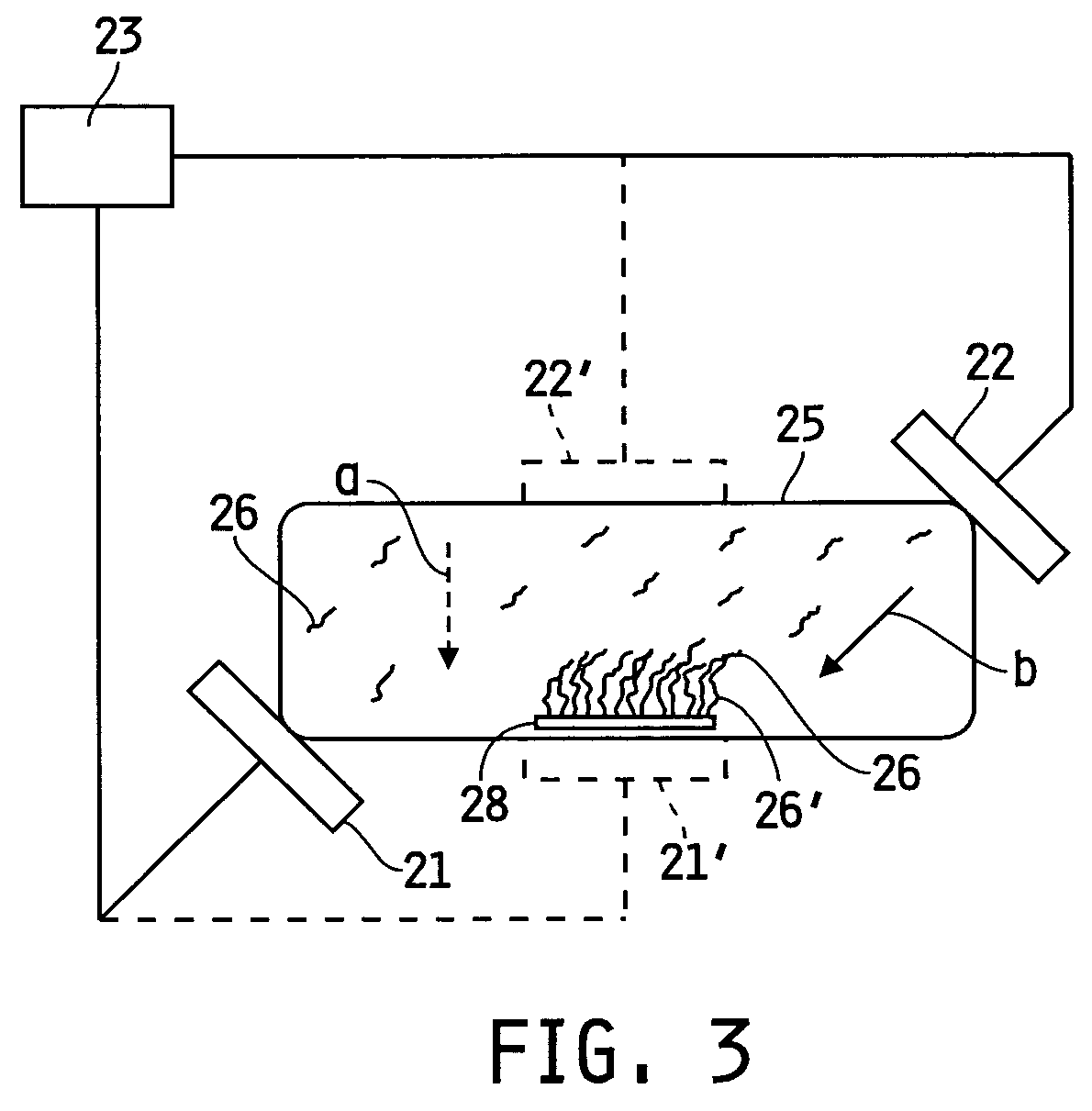

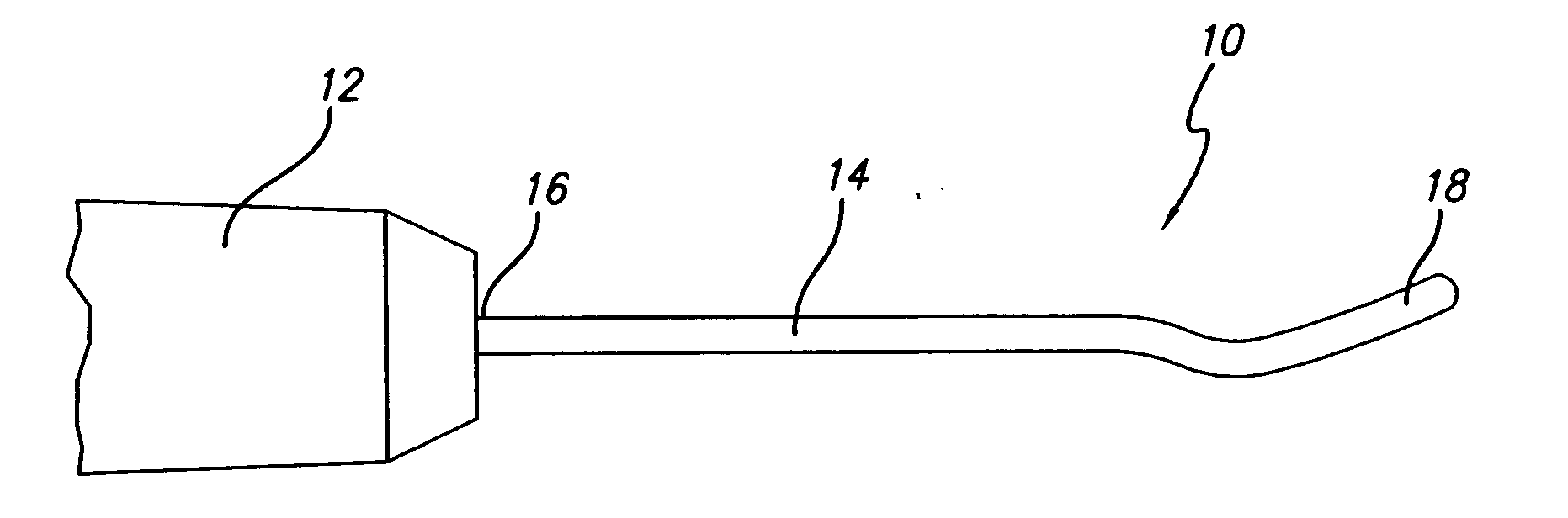

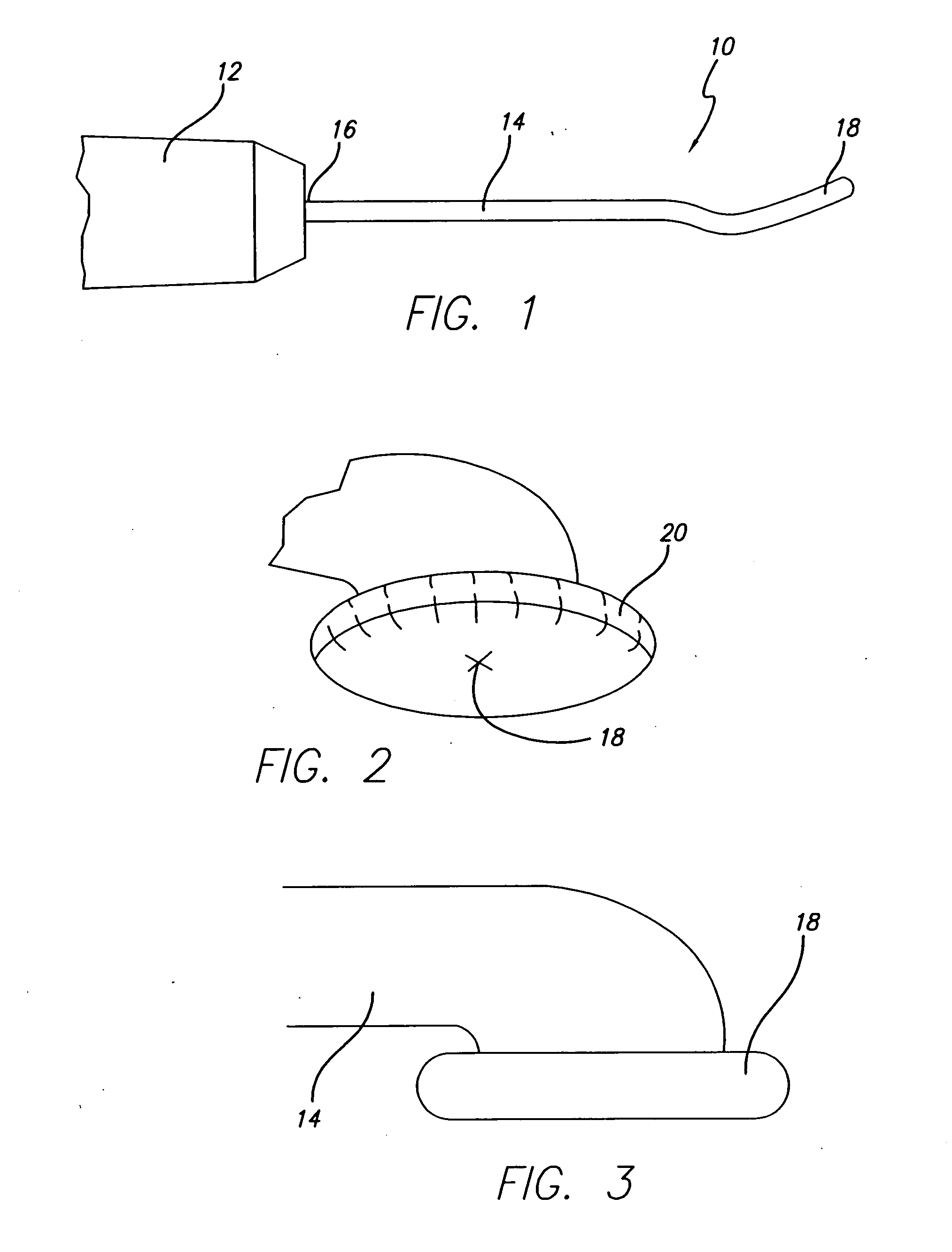

Method and apparatus for controlled contraction of soft tissue

An apparatus and method are provided for control contraction of tissue that includes collagen fibers. The apparatus includes a handpiece, and an electrode with an electrode proximal end associated with the handpiece. A distal end of the electrode has a geometry that delivers a controlled amount of energy to the tissue for a desired contraction of the collagen fibers. This is achieved while dissociation and breakdown of the collagen fibers is minimized. The handpiece, with electrode, is adapted to be introduced through an operating cannula in percutaneous applications. Additionally, an operating cannula may be included in the apparatus and be attached to the handpiece. The apparatus and method provides for a desired level of contraction of collagen soft tissue without dissociation or breakdown of collagen fibers.

Owner:LAX RONALD G +2

Paper made from collagen fiber and its processing method

InactiveCN101050602ARaise the gradeImprove flame retardant performancePaper/cardboardRaw material divisionPlant fibrePapermaking

The present invention discloses a kind of paper made of collagen fiber and its processing method. The paper made of collagen fiber includes fiber component and non-fiber component; said fiber component is formed from 10-100 wt% of collagen fiber and 0-90 wt% of other fiber for making paper. Its processing method mainly includes the following steps: screening raw materials, liquid defibrination, cleaning, rinsing, and opening by using liquor, dewatering and drying, opening and removing impurity, carding, pulping and papermaking.

Owner:张立文

Collagen gel and process of producing the same

InactiveUS20060177492A1Improve stabilityHigh strengthPowder deliveryPeptide/protein ingredientsCross-linkFiber

The present invention relates to a process of producing a collagen gel comprising collagen fibers cross-linked with each other by a cross-linking agent on the way of fibrosis of collagen, and a collagen gel comprising the cross-linked collagen fibers obtained by the process. The collagen gel comprising cross-linked collagen fibers of the present invention has high strength and thermal stability and can be widely used as cell carriers and medical materials.

Owner:IHARA

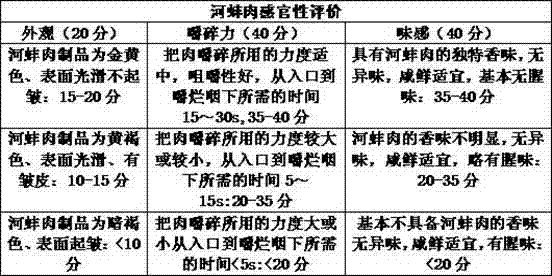

Method for preparing ready-to-eat mussel flesh products

The invention relates to a method for ready-to-eat mussel flesh products. The method is characterized in that: 1, the mussel flesh is softened by protease, so that actomyosins and elastins in collagen fibers and connective tissues can be effectively degraded, the connections among partial amino acids are broken, and proper chewing force is given to the mussel flesh products; 2, the fishy compositions of the mussel flesh are embedded by a beta-cyclodextrin embedding process, so that the original off-flavor of the mussels can be effectively reduced; 3, on a basis of effectively removing the fishy smell, flavoring agents, white granulated sugar, soy sauce and the like are added in a proper ratio to flavor the mussel flesh for a better taste; and 4, the mussel flesh is dried by a low-temperature hot air drying process, and the water content is properly controlled on a basis of ensuring the quality of the mussel flesh products. The method has the advantages of overcoming the defects of too high toughness, poor chewing property and strong fishy smell existing in the conventional process of making the mussel flesh products, along with simple process, low cost and easy operation.

Owner:BENGBU COLLEGE

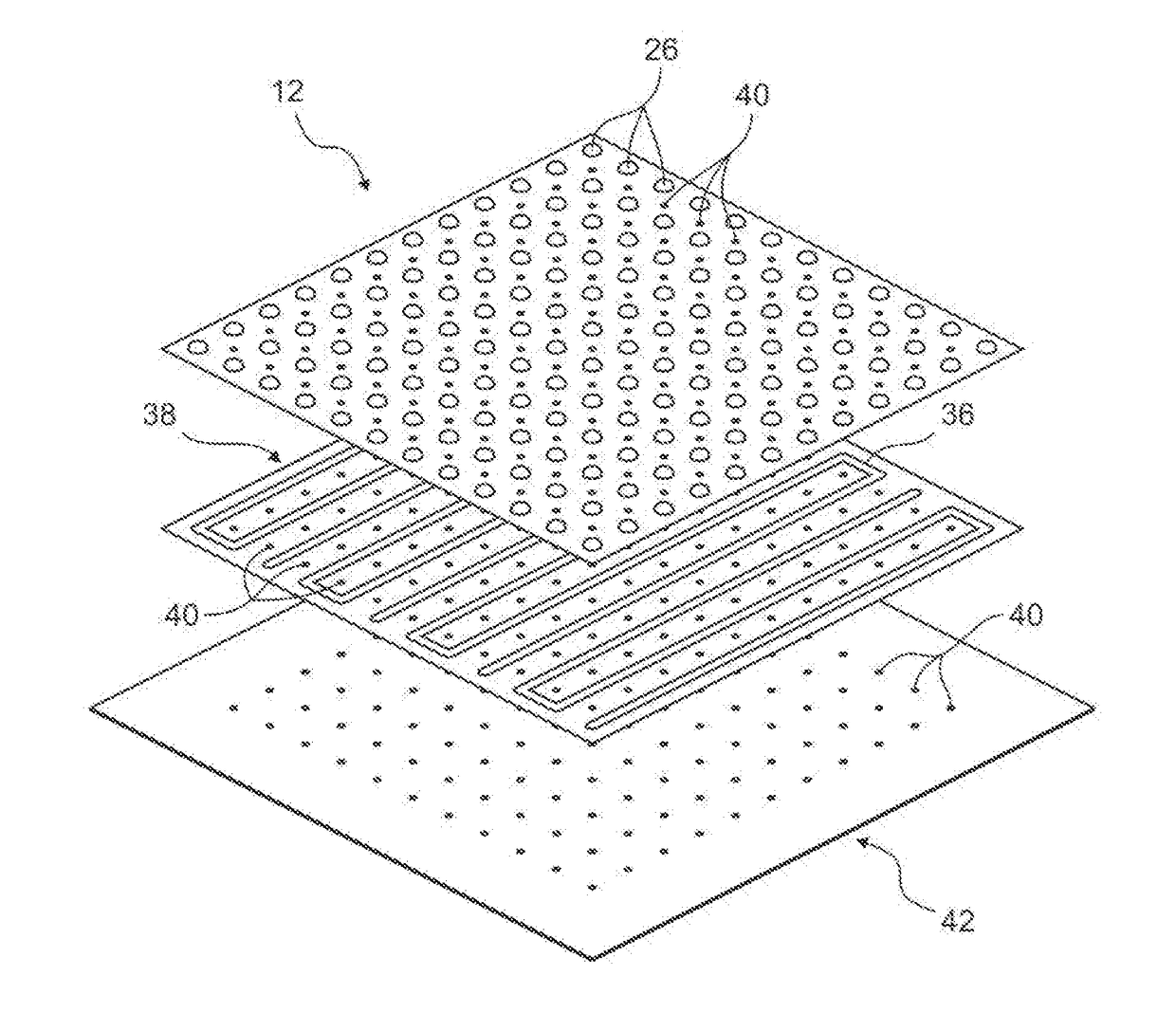

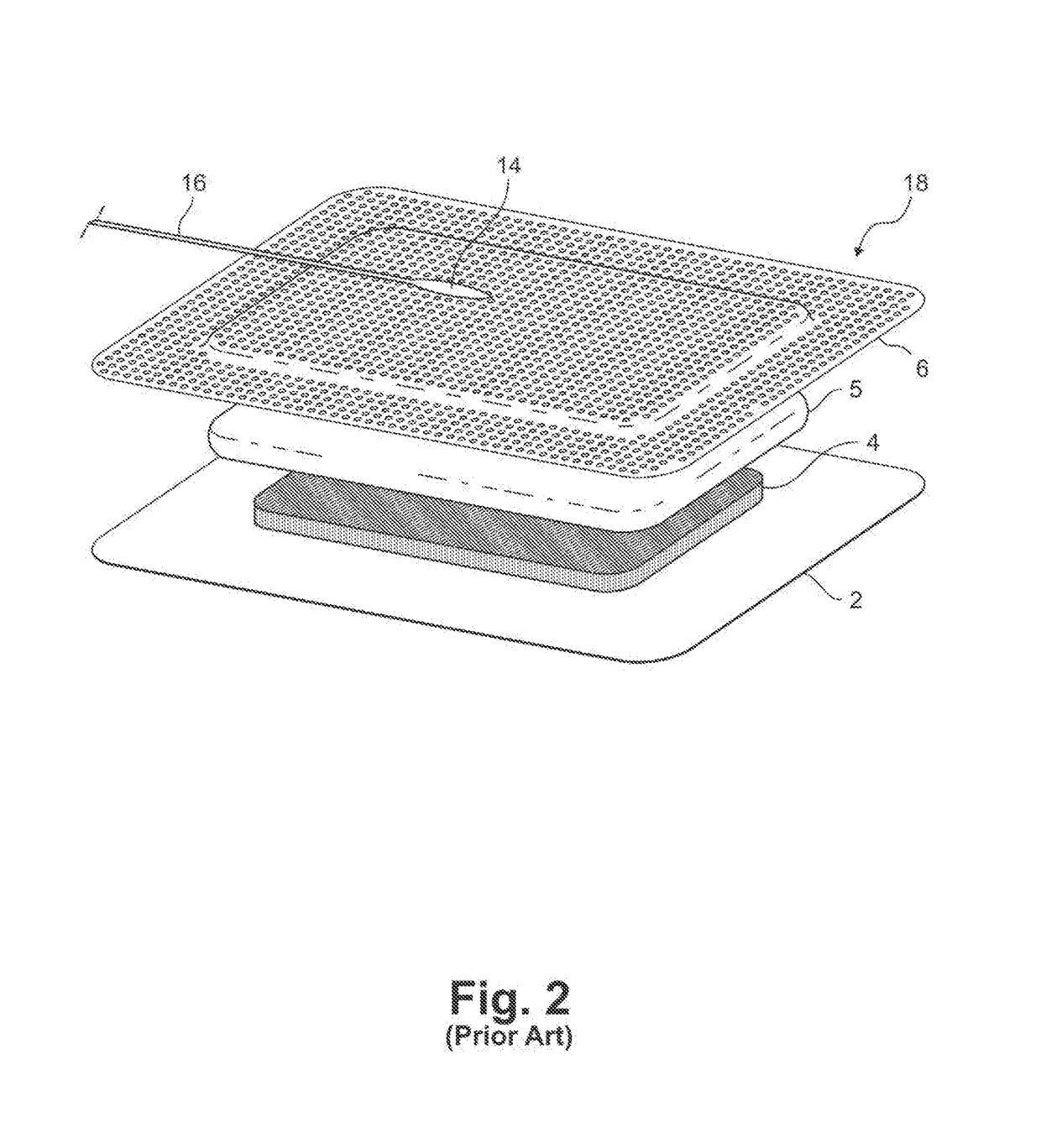

Wearable Micro-LED Healing Bandage

InactiveUS20180056087A1Aid in healing of woundRelieve painMedical devicesAdhesive dressingsFiberWound dressing

A wound dressing and method of use is provided that increases healing of tissues by targeting damaged tissue at a predetermined wavelength. The device includes the use of a negative pressure bandage, a flexible light sheet, and one or more bioactive marine extracts. Light emitted from the flexible light sheet penetrates through the bandage to target damaged tissue, which accelerates the wound healing process and works synergistically with the negative pressure bandage and bioactive marine extracts such as collagen fibers, alginate, chitosan and fucoidan, or any combination thereof to accelerate healing.

Owner:RIBEIRO ADOLFO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com