Rapid preparation process of inert dispersion fuel pellet

A technology for dispersing fuel and preparation technology, which is applied in nuclear engineering, manufacturing reactors, climate sustainability, etc. It can solve the problems of poor dispersing effect of TRISO particles, difficulty in meeting application technical requirements, and difficulty in realizing industrialization, so as to improve the tolerance Performance, shortening of preparation cycle, and the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The purpose of this embodiment is to overcome the deficiencies in the existing inert-based dispersed fuel pellet preparation methods, and to provide a method for preparing silicon carbide-enhanced uranium dioxide inert-based dispersed fuel pellets, which can be produced in a short process cycle. An inert-based dispersed fuel pellet with high TRISO particle content, good particle integrity, uniform dispersion, and high density silicon carbide matrix is obtained.

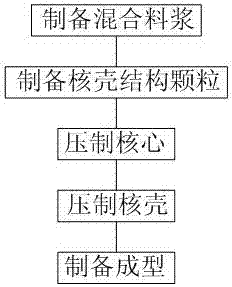

[0032] Such as figure 1 Shown, a kind of rapid preparation process of inert base dispersed fuel pellets, comprises the following steps:

[0033] (1) Preparation of mixed slurry: First, in parts by weight, wet-mix 0-15 parts of sintering aid and 85-100 parts of silicon carbide powder with a wet-mixing solvent, and then add 0.5-3 parts of dispersant, and stirred for 4~24h to obtain a uniformly dispersed silicon carbide mixed slurry;

[0034] (2) Preparation of core-shell particles: put TRISO particles into a ...

example 1

[0040] (1) Preparation of mixed slurry: by weight, 5 parts of alumina powder, 3 parts of yttrium oxide powder, 2 parts of silicon dioxide powder, 90 parts of silicon carbide powder and absolute ethanol Wet mixing was carried out as a wet mixing solvent. After mixing evenly, 2 parts of polyethyleneimine was added as a dispersant. After mixing for 12 h, a silicon carbide mixed slurry was obtained.

[0041] (2) Preparation of core-shell particles: A TRISO particle containing uranium dioxide, three-structure isotropy, and a diameter of 0.8-1.0mm is loaded into a heatable drum, and the heating temperature of the drum is controlled at 80°C. The TRISO particles are rolled in the drum, and after the temperature of the TRISO particles rises above 75°C, a part of the silicon carbide mixed slurry is continuously sprayed on the surface of the TRISO particles by spray deposition, and a silicon carbide coating layer is formed on the surface of the TRISO particles, thereby obtaining TRISO / Si...

example 2

[0046] (1) Preparation of mixed slurry: wet-mix 100% silicon carbide powder with a particle size of 20nm~50μm in the weight percentage with absolute ethanol as a wet mixing solvent. After mixing evenly, add 0.5% of the total mass of silicon carbide powder % polyethyleneimine was used as a dispersant, and the silicon carbide mixed slurry was obtained after mixing for 24 hours.

[0047] (2) Preparation of core-shell particles: put a TRISO particle containing uranium dioxide, three-structure isotropy, and a diameter of 0.8-1.0mm into a heatable drum, and the heating temperature is 60°C, so that the TRISO particles are in the drum Rolling, silicon carbide is sprayed onto the surface of TRISO particles by spray deposition to obtain SiC / TRISO core-shell structure particles, and the weight of TRISO particles increases by 170%.

[0048] (3) Press the core: put the SiC / TRISO core-shell structure particles into the powder metallurgy mold and press it under the pressure of 80MPa to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com