Preparation method for fine metal powder and equipment achieving method

A metal powder and fine technology, which is applied in the field of preparation of fine metal powder, can solve the problems of high production cost, huge equipment, high tank body, etc., and achieve the effect of low cost, convenient operation and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

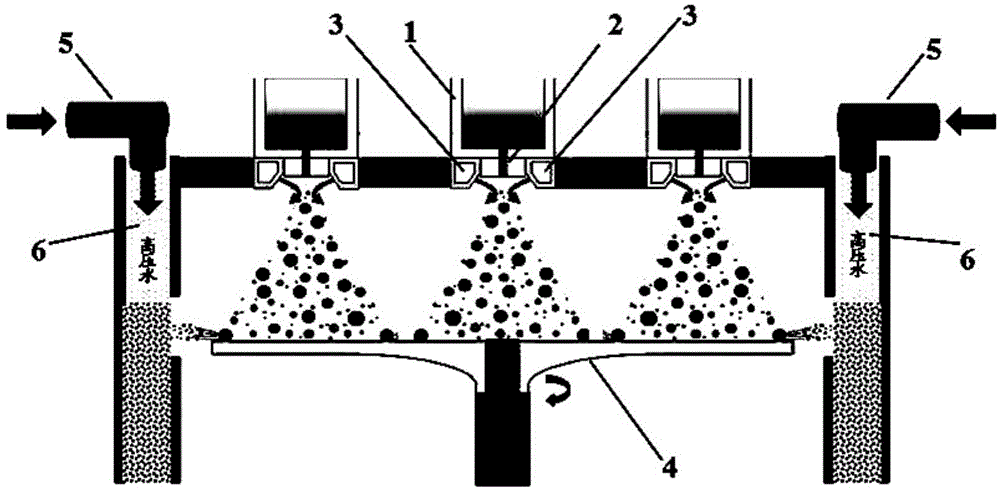

[0039] In this embodiment, the schematic diagram of the preparation equipment structure of fine metal powder is as follows figure 1 As shown, it includes a melting furnace (not shown in the figure), a crucible 1 , a gas atomization device 3 , a rotary disk 4 and a cooling device 5 .

[0040] The melting furnace communicates with the crucible 1, and the crucible 1 is provided with at least one nozzle 2. After the metal material is melted into a melt in the melting furnace, it is sprayed out by at least one nozzle 2 under a certain pressure. After the melt sprayed out of each nozzle 2 passes through the gas atomization device, the smaller droplets are due to the effect of surface tension. , Condensate and shrink into a spherical powder, relatively large unsolidified or semi-solidified droplets fall down and spray.

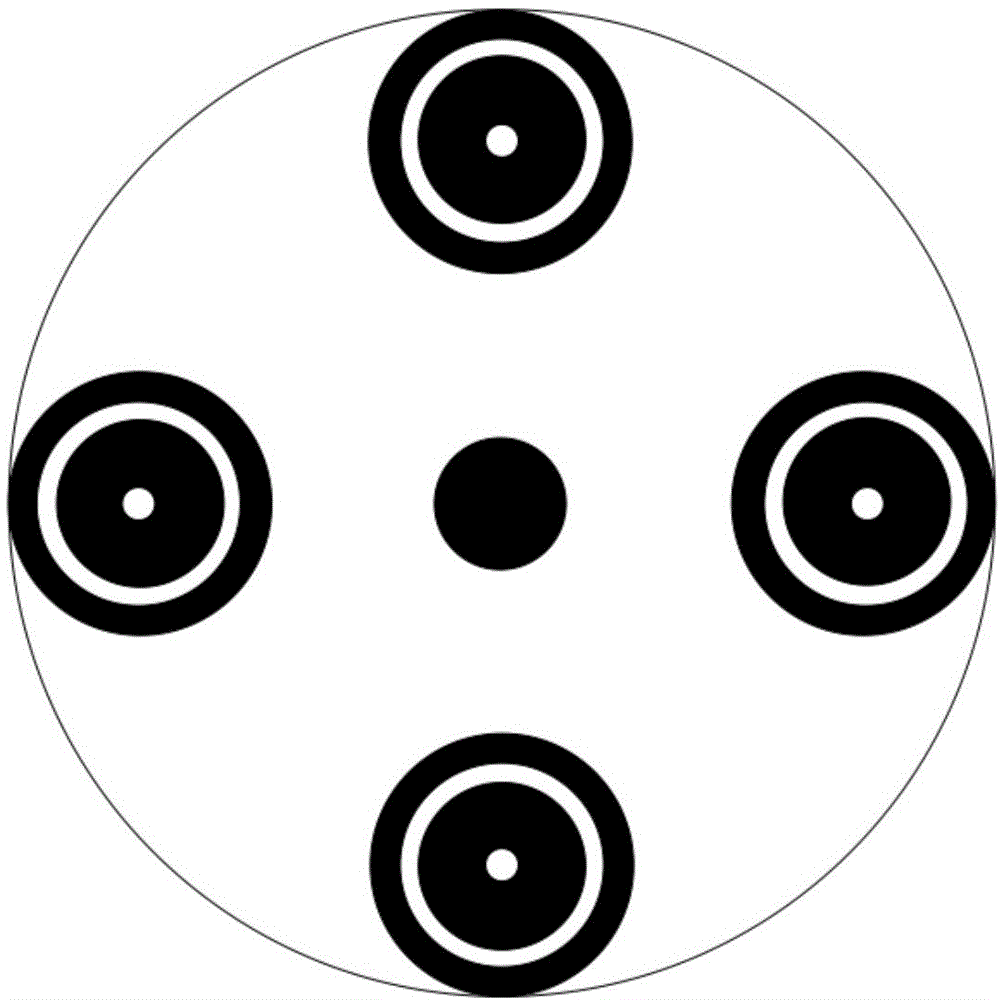

[0041] The rotary disk 4 is arranged below the metal droplet, and the surface of the rotary disk is perpendicular to the central axis of the metal droplet falling d...

Embodiment 2

[0052] In this example, the structure of the fine metal powder preparation equipment is exactly the same as the preparation equipment in Example 1, and the method of using this equipment to prepare metal powder is exactly the same as the preparation method in Example 1.

[0053] Using the above equipment to prepare fine copper powder, the main process parameters for control and adjustment are: the heating temperature in the melting furnace is 280°C above the melting point of copper, and the melting process is protected by argon; the gas atomization pressure is 2.5MPa, and the melt The flow rate is 4kg / min; the distance between the nozzle and the rotary disc is 100mm, the diameter of the rotary disc is 600mm, and the rotation speed is 10000 rpm; the cooling water pressure is 1.5MPa.

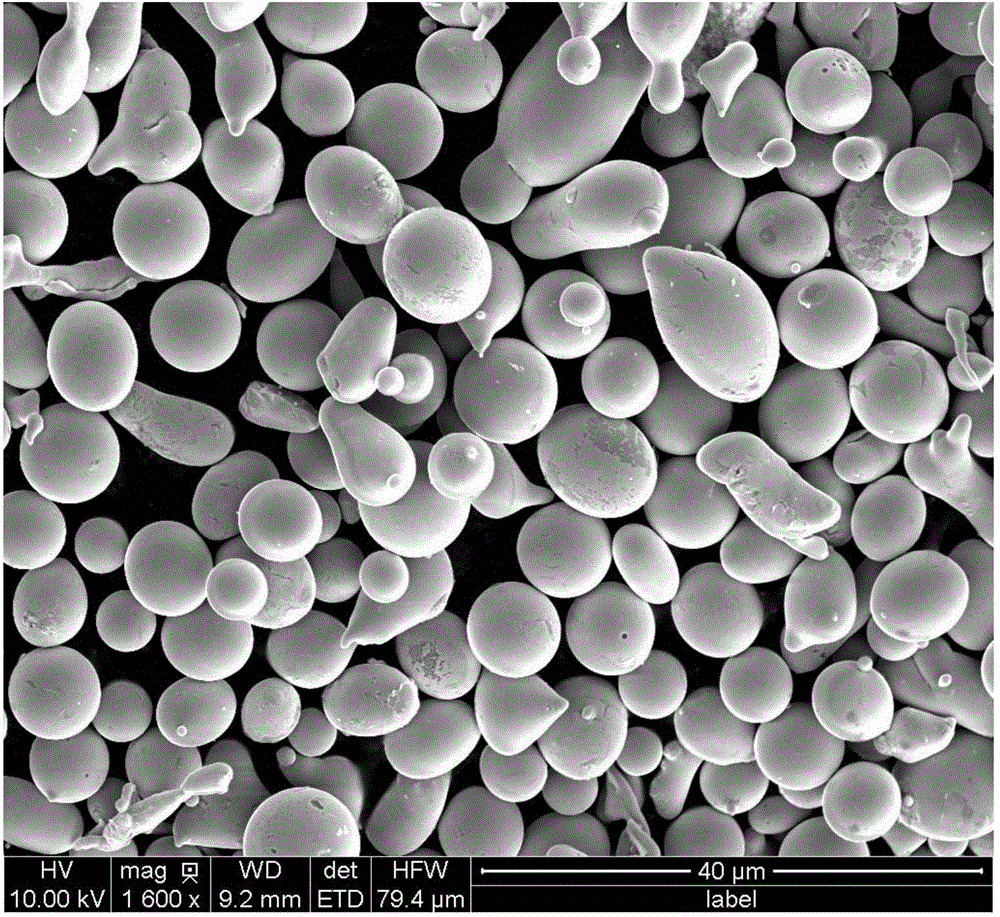

[0054] The SEM image of the Cu powder prepared according to the above parameters shows that the particle size of the powder is small, the average particle size is 9-12 μm, the sphericity is good, t...

Embodiment 3

[0056] In this example, the structure of the fine metal powder preparation equipment is exactly the same as the preparation equipment in Example 1, and the method of using this equipment to prepare metal powder is exactly the same as the preparation method in Example 1.

[0057] The quasicrystalline powder whose composition is Al-Cu-Fe-Cr-Mn is prepared by using the above-mentioned equipment. The main process parameters to be controlled and adjusted are: the heating temperature in the melting furnace is 200°C for the superheating of the melt, and the melting process is protected by argon; The atomization pressure is 0.8MPa, the melt flow rate during atomization is 3kg / min; the distance between the nozzle and the lower rotary disc is 80mm, the diameter of the rotary disc is 600mm, and the rotation speed is 10000 rpm; the cooling water pressure is 1.5 MPa.

[0058] The SEM image of the Al-Cu-Fe-Cr-Mn quasicrystalline powder prepared according to the above parameters shows that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com